Goodman GMNT100-4B, GMNT080-4B Owner’s Manual

EFFICIENCY

RATING

CERTIFIE D

ama

INSTALLATION & OPERATING

INSTRUCTIONS

for GMNT

CONDENSING GAS FURNACE

(CATEGORY IV)

®

C

US

WARNING

THIS FURNACE IS DESIGN CERTIFIED FOR

INSTALLATION IN BUILDINGS CONSTRUCTED ON

SITE ONLY.

CARBON MONOXIDE (REFERRED TO AS CO) CAN

CAUSE SERIOUS PERSONAL INJURY OR DEATH.

WARNING

WARNING

WARNING

DO NOT USE THIS FURNACE IF ANY PART HAS

BEEN UNDER WATER. IMMEDIATELY CALL A

QUALIFIED SERVICE TECHNICIAN TO INSPECT

THE FURNACE AND TO REPLACE ANY PART OF

THE CONTROL SYSTEM AND ANY GAS CONTROL

THAT HAS BEEN UNDER WATER.

All information contained herein is subject to change without notice.

Goodman Manufacturing Company, L.P.

I0-213D 2550 North Loop West, Suite 400, Houston, TX 77092 2/04

www.goodmanmfg.com

© 2003-2004 Goodman Manufacturing Company, L.P.

IF THIS FURNACE IS INSTALLED IN AN ENCLOSED

AREA, SUCH AS A GARAGE OR UTILITY ROOM,

EITHER ALONE OR WITH ANY OTHER CARBON

MONOXIDE PRODUCING DEVICE (E.G.

AUTOMOBILE, SPACE HEATER, WATER HEATER,

ETC.), ENSURE THAT THE ENCLOSED AREA IS

PROPERLY VENTILATED.

INDEX

REPLACEMENT PARTS................................................ 2

WARNINGS ................................................................... 2

GENERAL INFORMATION ............................................. 3

LOCATION, CLEARANCES ........................................... 4

COMBUSTION AIR ........................................................ 4

VENTING ....................................................................... 5

CONDENSATE DRAINS ................................................ 8

GAS PIPING ................................................................ 11

CIRCULATING AIR ....................................................... 11

ELECTRICAL SUPPLY CONNECTIONS ...................... 12

CONTROL VOLTAGE CONNECTIONS ........................ 12

FEATURES .................................................................. 12

RATING THE FURNACE .............................................. 13

TIMING THE GAS METER ........................................... 13

SPECIAL INSTRUCTIONS FOR WHITE ....................... 14

RODGERS 36G22 GAS VALVE ADJUSTMENT

SAFETY CONTROL ..................................................... 15

CIRCULATING AIR FILTERS ........................................ 16

TEMPERATURE RISE ................................................. 16

MOTOR LUBRICATION AND MAINTENANCE .............. 16

SERVICE INSTRUCTIONS ........................................... 16

SEQUENCE OF OPERATION...................................... 16

REMOVING AN EXISTING APPLIANCE ....................... 17

INSPECTING AND CLEANING ..................................... 17

THE HEAT EXCHANGER

LIGHTING INSTRUCTIONS .......................................... 18

WIRING DIAGRAM ...................................................... 19

THIS FURNACE CONTAINS ELECTRONIC COMPONENTS,

WHICH REQUIRE A DEFINITE GROUND. PROVISIONS ARE

MADE FOR CONNECTION OF THE GROUND. A DEDICATED

GROUND FROM THE MAIN POWER SUPPLY OR AN EARTH

GROUND MUST BE PROVIDED.

REPLACEMENT PARTS

Replacement parts for this appliance are available through

your contractor or local distributor. For the location of your

nearest distributor consult the white business pages, the

yellow page section of the local telephone book or contact:

SERVICE PARTS DEPARTMENT

GOODMAN MANUFACTURING CO., L.P.

2550 NORTH LOOP WEST, SUITE 400

HOUSTON, TEXAS 77092

(713) 861 – 2500

The major parts groups are as follows:

BLOWER ASSEMBLY

Motor

Blower Housing

Blower wheel

Misc. sheetmetal items

Capacitor

HEAT EXCHANGER

Heat exchanger sections

Secondary coil

Collector Box

ELECTRICAL CONTROLS

Control board

Auxiliary / main limit switch

Roll-out switch

Transformer

Door interlock switch

Air pressure switch

Induced draft blower

BURNER ASSEMBLY

Burners

Manifold

Orifices

Gas Valve

Igniter

Flame sensor

MISCELLANEOUS

Wrapper

Access doors

Chimney

Gaskets and seals

Wiring assemblies

In order to effectively process the parts requirement the

distributor / contractor will need the entire model number

and serial number found on the series and rating plate

located inside the blower compartment.

CARBON MONOXIDE POISONING HAZARD

Special Warning for Installation of Furnace or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unventilated garages, utility rooms or parking areas because of

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parking area and a carbon monoxide producing

device is operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device continues to operate in

the enclosed area. Carbon monoxide emissions can be (re)circulated

throughout the structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain damage or death.

B10259-216

-

IO-213D 2/04

2

WARNING

WHILE CARBON MONOXIDE DETECTORS DO PROVIDE

ADDITIONAL PROTECTION, LIMITATIONS TO THEIR

EFFECTIVENESS REQUIRE THAT YOU OTHERWISE

CONTINUE TO FOLLOW APPROPRIATE INSTRUCTIONS

LOCATED IN THE “INSTALLATION & OPERATING

INSTRUCTIONS” AND “USER’S INFORMATION MANUAL”

RELATING TO PROTECTING PERSONS FROM THE RISKS

OF CARBON MONOXIDE. REVIEW EACH CO DETECTOR’S

MANUFACTURERS’ EXPLANATION OF THEIR UNIT’S

CAPABILITIES AND FOLLOW THE INSTALLATION AND

OPERATING MANUAL WHEN INSTALLING AND

OPERATING SUCH UNITS.

WARNING

THE CIRCULATING AIR DUCTS MUST BE COMPLETELY

AND POSITIVELY SEALED TO PREVENT THE

COMBUSTION PRODUCTS, INCLUDING CARBON

MONOXIDE, FROM ENTERING THE LIVING SPACE.

WARNING

TO ENSURE PROPER INSTALLATION AND OPERATION OF

THIS PRODUCT, COMPLETELY READ AND UNDERSTAND

THESE INSTRUCTIONS PRIOR TO ATTEMPTING TO

ASSEMBLE, INSTALL, MAINTAIN, OR REPAIR. IF THESE

INSTRUCTIONS ARE NOT FOLLOWED PRECISELY THERE

IS A POTENTIAL OF CARBON MONOXIDE POISONING,

WHICH CAN RESULT IN SERIOUS ILLNESS OR DEATH.

WARNING

UNLESS ALLOWED BY LOCAL CODE, DO NOT INSTALL A

LIQUID PETROLEUM GAS BURNING APPLIANCE IN A PIT,

BASEMENT, OR SIMILAR LOCATION. L.P., A HEAVIER THAN

AIR GAS, CAN COLLECT IN LOW AREAS AND MAY NOT

DISPERSE NATURALLY. APPLIANCES SO FUELED SHALL

NOT BE INSTALLED IN AN ABOVE GRADE UNDER FLOOR

SPACE OR BASEMENT UNLESS SUCH LOCATION IS

PROVIDED WITH APPROVED MEANS FOR REMOVAL OF

UNBURNED GAS.

WARNING

THIS FURNACE WAS EQUIPPED AT THE FACTORY FOR

USE WITH NATURAL GAS ONLY. LIQUID PETROLEUM (L.P.)

CONVERSION, IF REQUIRED, MUST BE PERFORMED BY

A QUALIFIED TECHNICIAN FAMILIAR WITH PERFORMING

THIS TYPE OF CONVERSION. IF L.P. CONVERSION IS

REQUIRED, ALL INSTRUCTIONS INCLUDED WITH THE

FACTORY AUTHORIZED KIT MUST BE FOLLOWED. THE

ONLY KIT THAT MUST BE USED FOR THIS CONVERSION

IS THE FACTORY AUTHORIZED LPT-01. FAILURE TO

FOLLOW THOSE INSTRUCTIONS EXPLICITLY MAY CAUSE

FIRE, EXPLOSION, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

WARNING

NEVER LAY THIS FURNACE ON ITS FRONT OR REAR.

WARNING

HEATING UNIT SHOULD NOT BE UTILIZED WITHOUT

REASONABLE, ROUTINE, INSPECTION, MAINTENANCE

AND SUPERVISION. IF THE BUILDING IN WHICH ANY

SUCH DEVICE IS LOCATED WILL BE VACANT, CARE

SHOULD BE TAKEN THAT SUCH DEVICE IS ROUTINELY

INSPECTED, MAINTAINED AND MONITORED. IN THE

EVENT THAT THE BUILDING MAY BE EXPOSED TO

FREEZING TEMPERATURES AND WILL BE VACANT, ALL

WATER-BEARING PIPES SHOULD BE DRAINED, THE

BUILDING SHOULD BE PROPERLY WINTERIZED, AND

THE WATER SOURCE CLOSED. IN THE EVENT THAT THE

BUILDING MAY BE EXPOSED TO FREEZING

TEMPERATURES AND WILL BE VACANT, ANY HYDRONIC

COIL UNITS SHOULD BE DRAINED AS WELL AND, IN SUCH

CASE, ALTERNATIVE HEAT SOURCES SHOULD BE

UTILIZED.

GENERAL INFORMATION

The GMNT series furnace can be installed as an upflow,

downflow or horizontal furnace. It can also be installed as a

direct vent or a non-direct vent furnace.

These Installation and Operating Instructions are intended

for use by fully qualified installation technicians. Some

localities require the installer/sevicer to be licensed. If in

doubt, check with local authorities.

INSTALLATION: In the USA, this furnace MUST be installed

in accordance with the latest edition of the ANSI Z223.1

booklet entitled “National Fuel Gas Code” (NFPA 54), and

the requirements or codes of the local utility or other authority

having jurisdiction. In Canada, this furnace must be installed

in accordance with the current CAN/CGA-B149.1 & 2 Gas

Installation Codes, local plumbing or waste water codes and

other applicable codes.

Additional helpful publications available from the NFPA are,

NFPA 90A - Installation of Air Conditioning and Ventilating

System and NFPA 90B - Warm Air Heating and Air

Conditioning System.

All venting shall be in accordance with PART 7, Venting of

Equipment, of the National Fuel Gas Code, ANSI Z223.1, or

applicable local building and/or air conditioning codes.

These publications are available from:

National Fire Protection Association, Inc.

Batterymarch Park

Quincy, MA 02269

The GMNT series of furnaces meet the California NOx

emission standards and California seasonal efficiency

standards. ANNUAL inspections of the furnace and its vent

system is strongly recommended. It is the installer’s

responsibility to inform the user of this importance. Any

installation, alteration or repair of this equipment must not

be in violation of local code or the information contained in

this manual. This furnace shall be securely fastened in place

when installed in the vertical position. This furnace must be

installed in such a manner as to allow for service, inspection,

repair or replacement without removing permanent

construction. A platform is recommended to allow for service.

IO-213D 2/04

3

LOCATION

• DO NOT install this furnace in a mobile home. This furnace

is designed only for installation in buildings constructed

on site and connected to ductwork. When installed in a

utility room or closet, the door should be wide enough to

allow the largest part of the furnace to enter, or to permit

the replacement of another appliance, such as a water

heater. This furnace is designed to be installed indoors

only.

• DO NOT install outdoors. This furnace should be installed

in such a manner so that it is protected from water. If any

components should become wetted or submerged under

water, replace those parts before returning the furnace to

operation.

• DO NOT use as a construction heater.

• DO NOT use in an area where freezing may occur without

properly protecting the vent and drain system. The drain

may crack and leak if subjected to freezing temperatures.

• DO NOT install in a room used or designed to be used as

a bedroom, bathroom or storage closet, or in any enclosed

space with access only through such a room or space.

A return air filter grille or means of inserting a filter into the

return air duct is recommended. The opening in the duct

used for filter access must be capable of being sealed air

tight if located in the same pressure zone as the furnace.

The furnace and it’s individual shut-off must be disconnected

from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2

psig (3.5kPa)

The furnace must be isolated from the gas supply piping

system by closing it’s individual manual shut-off valve during

any pressure testing of the gas supply piping system at

pressures equal to or less than 1/2 psig (3.5 kPa).

CLEARANCES

MIN. CLEARANCES TO COMBUSTIBLE SURFACES

Unobstructed front clearance of 24" for servicing is

recommended.

RIGHT SIDE - 1" VENT - 0"

REAR - 0" LEFT SIDE - 1"

TOP OF PLENUM - 1" FRONT - 3"

Line contact is permitted in the horizontal position.

ACCESSIBILITY CLEARANCE, WHERE GREATER,

SHOULD TAKE PRECEDENCE OVER MINIMUM FIRE

PROTECTION CLEARANCE.

A gas-fired furnace for installation in a residential garage

must be installed so that the ignition source and burners

are located not less than eighteen inches (18") above the

floor and is protected or located to prevent physical damage

by vehicles.

A gas furnace must not be installed directly on carpeting,

tile, or other combustible materials other than wood flooring.

WARNING

A SOLID METAL BASEPLATE IS SUPPLIED WITH THIS

FURNACE. THIS BASEPLATE MUST BE IN PLACE AND

SEALED AIR TIGHT WHEN THE FURNACE IS INSTALLED

WITH SIDE RETURN AIR DUCTS. FAILURE TO DO SO

MAY PERMIT COMBUSTION PRODUCTS, INCLUDING

CABON MONOXIDE, TO ENTER THE LIVING SPACE AND

CREATE POTENTIALLY HAZARDOUS CONDITIONS SUCH

AS CARBON MONOXIDE POISONING OR DEATH. FULL

SIZE RETURN AIR DUCT OPENINGS MUST BE UTILIZED.

EMBOSSES ARE PROVIDED FOR THIS PURPOSE.

Before proceeding with this installation check the following:

• Correct clearance from combustible materials

• Adequate accessibility for servicing

• Flooring is not carpet or any other combustible material,

except wood

• Adequate combustion / ventilation air is supplied

• Metal base plate is in place when using side(s) for return

air

• In a garage, the furnace has been adequately elevated

and protected from vehicle damage

• Furnace area is free of flammable materials and vapors

such as gasoline

COMBUSTION AIR

The GMNT furnace can be installed either as a Direct Vent

(2 pipe) or a Non-Direct Vent (1 pipe) appliance. If installed

as direct vent appliance, the combustion air is to be taken

from the outdoors via a 2" or 3" schedule 40 PVC pipe and

terminate at the furnace burner box. As a non-direct vent

furnace, the combustion air is taken from the area which

the furnace is installed. Avoid combustion air sources that

contain flammable fumes and vapors, and gasses such as

carbon monoxide, hydrogen sulfide, ammonia, chlorine, and

halogenated hydrocarbons.

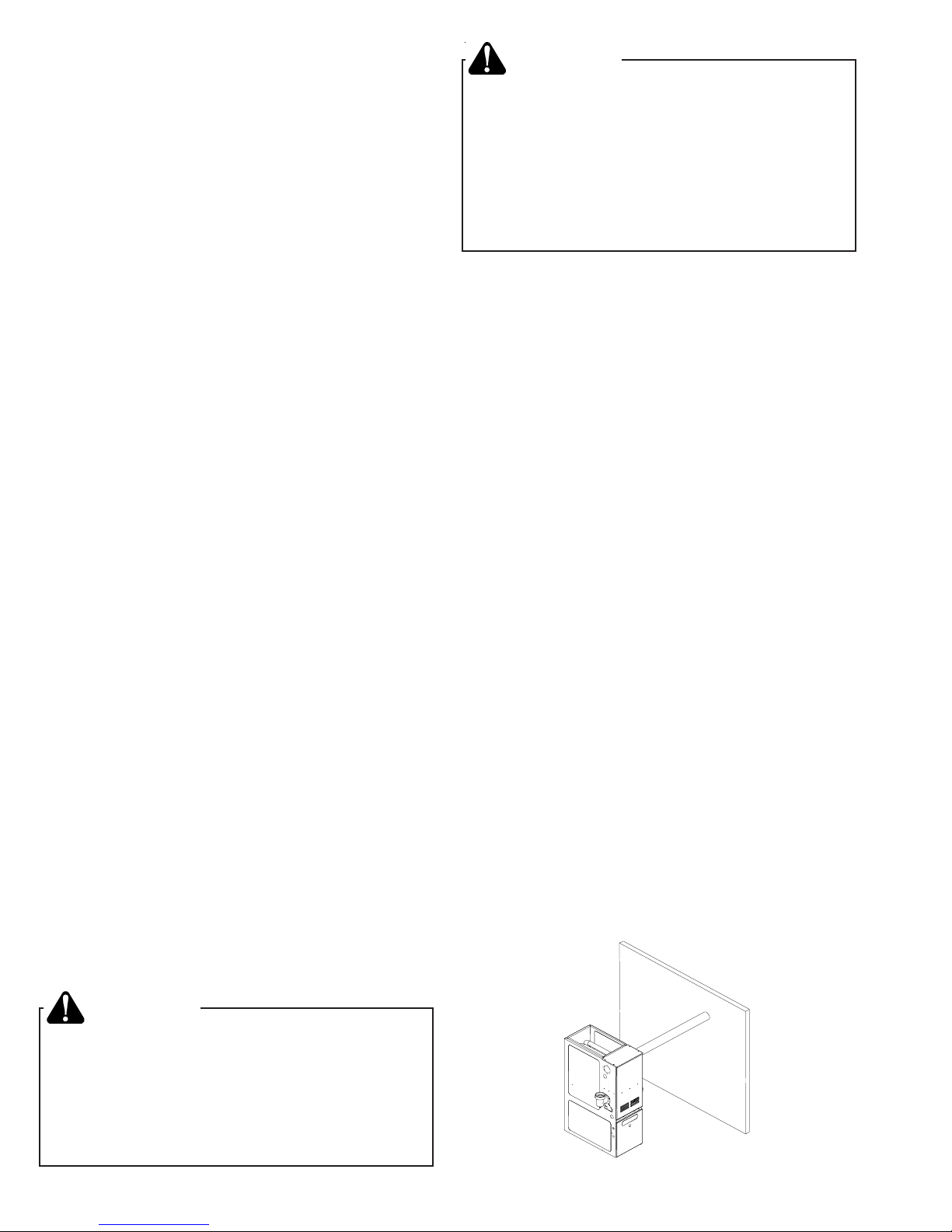

Direct Vent Combustion Air. As shown in the following

illustration, the combustion air pipe is to originate at the

furnace’s cabinet and terminate outside of the building. The

diameter of the PVC combustion air pipe depends upon

the furnace size, the length of pipe, and the quantity of

fittings employed. The table found in the “Combustion/Vent

Pipe Size” section of this manual outlines these sizing

requirements. As a direct vent installation, the “Air for

Combustion and Ventilation Air” requirements found in ANSI

Z223.1, section 5.3 is not required for the furnace to operate

correctly. However, other fuel burning appliances located

in the same space as the furnace may still require that the

area be serviced with Combustion and Ventilation Air

consistent with ANSI Z223.1, section 5.3.

WARNING

COMBUSTIBLE MATERIAL MUST NOT BE PLACED ON OR

AGAINST THE FURNACE CABINET. THE AREA AROUND

THE FURNACE MUST BE KEPT CLEAR AND FREE OF ALL

COMBUSTIBLE MATERIAL INCLUDING GASOLINE AND

OTHER FLAMMABLE VAPORS AND LIQUIDS. THE USER

MUST BE CAUTIONED THAT THE FURNACE AREA MUST

NOT BE USED AS A BROOM CLOSET OR FOR ANY OTHER

STORAGE PURPOSE.

IO-213D 2/04

4

Attaching Combustion Air Intake Fitting. A coupling for

attaching the combustion air fitting to the furnace cabinet

is included in a plastic bag packaged with the furnace. The

fitting is sized to accept a 3" diameter PVC pipe. In certain

situation, a 2" diameter pipe can be used for this application.

Refer to the combustion/ vent table for sizing requirements.

Attach the fitting to the cabinet using (4) #10 x 1/2" sheet

metal screws (field supplied). If a right hand entrance is

preferred, the plug installed on this side is to be removed

and reinstalled in the left side opening.

Non-Direct Vent Combustion Air. If the furnace is to be

installed as a non-direct vent appliance, the combustion air

pipe outlined previously is not used.

As a non-direct vent furnace, this must be installed in

accordance with the combustion and ventilation air

requirements found in ANSI Z221.3, section 5.3. When

installed as a non-direct vent furnace in an area, which is

deemed as a confined area, see (ANSI Z223.1, section 1.7,

“Space, Confined”) the requirements are as follows:

All Combustion Air Taken From The Inside Of The

Building. When installed as a non-direct vent furnace and

indoor air is used as the combustion air source, the space

is to be provided with (2) permanent openings communicating

directly with an additional room(s) of sufficient volume so

that the combined volume of all spaces meets the criteria of

an unconfined area. The total input of all gas burning

equipment shall be used to determine the minimum size of

each opening. Each opening shall be sized to be a minimum

of 1 square inch of free area per 1,000 Btu/hr of combined

input of gas utilization equipment in the area. The minimum

area for each opening shall not be less than 100 square

inches, and the minimum dimension of these openings shall

not be less than 3 inches. One opening shall commence

within 12 inches of the top of the area, while the other opening

shall commence within 12 inches of the bottom of the area.

All Combustion Air Taken From Outdoors. If installed

as a non-direct furnace and outdoor air is selected as the

combustion air source, then area shall be serviced with an

opening(s) communicating directly with the outdoors by either

of the following two methods. When calculating the minimum

area for each opening, the combined input of all gas utilization

equipment is to be considered. Also, the minimum

dimension for any opening shall not be less than 3 inches.

Method 1..... Two permanent openings communicating

directly with the outdoors via. horizontal ducts shall be

sized to be a minimum of 1 square inch per 4,000 Btu/hr

or, two permanent openings communicating directly with

the outdoors via. vertical ducts shall be sized to be a

minimum of 1 square inch per 2,000 Btu /hr.

Method 2..... One permanent opening communicating

directly with the outdoors via a horizontal duct. This

opening/duct shall be sized to be equal to 1 square inch

per 3,000 Btu / hr, but not less than the sum of the areas

all of the vent connectors in the confined space.

When installed as a direct vent furnace and NOT using the

concentric vent kit CVK-00 option, the combustion air is to

be terminated in the following manner;

OPTIONAL

INLET

SCREEN

COMBUSTION

AIR INTAKE

If the optional concentric vent kit (CVK-00) is used, follow

the instructions provided with this accessory.

SOURCE OF COMBUSTION AIR

The recommended source of combustion air is to use the

outdoor air supply. However, the use of indoor air in most

applications is acceptable except as follows;

1. If the furnace is installed in a confined space, the

necessary combustion must come from outdoors by

way of the attic, crawl space, or direct opening to the

outside.

2. If indoor combustion is used, there must be no exposure

to the substances listed in #3 below.

3. The following installations may require OUTDOOR AIR

for combustion, due to chemical exposures;

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces installed in hobby or craft rooms

• Furnaces installed near chemical storage areas

Exposures to the following substances in the combustion

air supply may also require OUTDOOR AIR for combustion;

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

VENTING

ANNUAL inspections of the furnace and it’s vent / combustion

air supply is strongly recommended. It is the contractor’s

responsibility to inform the user of this importance. All venting

shall be in accordance with Part 7; Venting of Equipment,

of the National Fuel Gas Code, ANSI Z223.1, or applicable

local building and/ or air conditioning codes.

PROPER INSTALLATION OF THE VENT / COMBUSTION AIR

SYSTEMS IS CRITICAL TO SAFE OPERATION OF THIS

APPLIANCE. CAREFULLY READ AND UNDERSTAND THE

INSTRUCTIONS IN THIS SECTION. EACH VENT AND

COMBUSTION AIR SUPPLY PIPE MUST SERVE ONLY ONE

IO-213D 2/04

5

APPLIANCE. DO NOT CONNECT TO AN EXISTING VENT OR

CHIMNEY UNLESS IT CONFORMS TO ALL PROVISIONS IN

THIS INSTRUCTION BOOKLET. THE VENT MUST TERMINATE

OUTDOORS.

VENT/COMBUSTION AIR SUPPLY PIPE LENGTHS

Elbows must be long radius types. (Quarter bends or DWV).

The maximum length of the vent pipe and the combustion

air supply pipe is 100 feet each.

Model Vent @ Vent @ more Comb. Air @ Comb. Air @

GMNT 45 ft. than 45 ft. More than 45

040-3 2 in. 3 in. 2” 3”

060-3 2 in. 3 in. 2” 3”

080-4 3 in. 3 in. 3” 3”

100-4 3 in. 3 in. 3” 3”

120-5 3 in. 3 in. 3” 3”

or less 45 ft. or less

45 ft.

Chart assumes a maximum of 4 - 90° elbows. For excess

of 4 elbows decrease length by 7.5 ft. per elbow. A

maximum of 6 elbows is acceptable. The use of two 45°

over one 90° is preferred. Do not count the termination as

an elbow.

Minimum vent length is 6 ft. for vertical and horizontal runs.

There is no minimum combustion air supply pipe length.

These furnaces are a condensing type appliance. The

products of combustion are recirculated through a secondary

coil. During this process the flue products are brought to a

point below dew point. Thus the moisture present in the

flue products condenses leaving a liquid by-product. This

by-product must be removed from the furnace and it’s

collection system.

In addition, the vent temperatures are also considerably lower

than conventional furnaces. This allows the use of low

temperature plastic as the vent system. The recommended

plastic is schedule 40 PVC, ABS, DWV (or equivalent if

allowed by local code). See the previous chart for proper

sizing. The use of two 45° elbows is suggested over the use

of a single 90° elbow. The vent pipe must slope toward the

furnace to properly drain the condensate. The drain trap and

related parts must be installed as shown in the illustrations.

Failure to follow these instructions can cause products of

combustion including CARBON MONOXIDE entering the

dwelling.

IF THIS FURNACE IS INSTALLED IN AN ATTIC OR SIMILAR

AREA WHERE CONDENSATE OVERFLOW MAY BE A PROBLEM,

AN AUXILIARY DRAIN PAN MUST BE INSTALLED UNDER THE

FURNACE WITH THE AUXILIARY DRAIN LINES ROUTED TO

THE OUTDOORS TO PREVENT WATER DAMAGE CAUSED

BY LEAKS.

THE COMBUSTION PRODUCTS AND MOISTURE IN THE

FLUE GASES WILL CONDENSE. THE CONDENSATE MAY

FREEZE ON THE EXTERIOR WALL AND SURROUNDING

SURFACES. SOME DISCOLORATION OR ETCHING IS TO BE

EXPECTED.

THE VENT AND COMBUSTION AIR SUPPLY PIPES MUST

BE INSPECTED ANNUALLY.

Visually check the vent terminal and combustion air supply

pipe screens, clean if necessary. Visually check for

blockage of the condensate disposal system. Hoses may

be disconnected to determine that proper flow is maintained.

Should an obstruction be observed, it can be dislodged by

forcing a stream of water through it using a device such as

a garden hose.

Materials and procedures must conform to:

The ASTM Standards.

Pipe and Fittings ASTM 1785, D2465 and D2266

PVC Primer and Solvent Cement ASTM D2564

Procedure for Cementing Joints ASTM D2855 (ref.) This

appliance may be vertically or horizontally vented.

HORIZONTAL THROUGH THE WALL VENTING

This appliance may be horizontally vented through an exterior

wall following the applicable instructions in the “VENTING”

section in conjunction with these additional requirements.

A wall sleeve must be used.

ALL HORIZONTAL VENT INSTALLATIONS MUST BE MADE

IN ACCORDANCE WITH THESE INSTRUCTIONS.

When selecting which exterior wall to penetrate, the following

items should be taken into consideration:

1. Layout the combustion air and vent system to avoid the

possibility of interference with beams, poles, posts,

electrical wiring, plumbing, etc.

2. When possible, the combustion air and vent termination

should not be subjected to prevailing winds.

3. The combustion air intake and vent termination must

be located at least twelve (12) inches above expected

snowfall. Consideration should be made to past unusual

snowfalls.

• DO NOT locate the terminal less than seven (7) feet above

public walkways. This applies to steps and stairwells.

• DO NOT locate the termination areas where condensate

may present a problem such as flowerbeds, patios, etc.

• DO NOT locate within four (4) feet of a gas meter, electric

meter, or gas regulator; (3) feet in Canada

• DO NOT locate the vent terminal within four (4) feet of an

adjacent building.

• DIRECT VENT INSTALLATION - DO NOT locate the vent

terminal within twelve (12) inches of an operable window

or door.

• NON-DIRECT VENT INSTALLATION - DO NOT locate the

vent terminal less than (12) inches above a door or

operable window.

• NON-DIRECT VENT INSTALLATION - DO NOT locate the

vent terminal less than (4) feet below or (4) feet horizontally

from any door, window or gravity air inlet into any building.

• DO NOT locate the vent terminal less than three (3) feet

above, or (10) feet horizontally from, a forced air inlet into

any building, other than the combustion air supply pipe.

• DO NOT locate the vent terminal within three (3) feet of an

inside corner of a building or structure. Minor corners

created by fireplace chimneys are excluded from this

requirement.

To protect the exterior surface from staining due to the

condensate, an aluminum plate or similar material may be

installed surrounding the termination. This plate should

extend approximately two (2) feet from the termination.

IO-213D 2/04

6

Loading...

Loading...