Glow-worm Flexicom cx User Manual

Installation

and Servicing

Condensing Boilers/

Flexicom cx

24cx

30cx G.C.No. 47-047-34

35cx G.C.No. 47-047-35

G.C.No. 47-047-33

Guarantee Registration

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances are manufactured to the very highest standard so we are pleased to offer

our customers a Comprehensive Guarantee.

This product is guaranteed for 24 months from the date of installation or 30 months from the date

of manufacture, whichever is the shorter, for parts and labour.

The second year of the parts guarantee, from the beginning of the 13th month onwards after

installation or manufacture, is conditional upon the boiler having been serviced by a competent

person approved at the time by the Health and Safety Executive in accordance with the

manufacturer’s recommendations. We strongly recommend regular servicing of your gas

appliance, but where the condition is not met, any chargeable spare parts or components issued

within the applicable guarantee period still benet from a 12 month warranty from the date of issue

by the manufacturer.

We recommend you complete and return as soon as possible your guarantee registration card.

If your guarantee registration card is missing you can obtain a copy or record your registration by

telephoning the Glow-worm Customer Service number 01773 828100.

Customer Service:

01773 828100

Technical Helpline:

01773 828300

General and Sales enquiries:

Tel. 01773 824639

Fax: 01773 820569

To register your Glow-worm appliance call:

0800 0732142

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided

with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future

reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of

Practice which is available from the Heating and Hotwater Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

TABLE OF CONTENTS

These instructions consist of, Installation, Servicing, Fault Finding, Replacement of Parts

and Spares. The instructions are an integral part of the appliance and must, to comply

with the current issue of the Gas Safety (Installation and Use) Regulations, be handed to

the user on completion of the installation.

CONTENTS DESCRIPTION SECTION PAGE

Warnings 4

Important Information 4

INTRODUCTION

INSTALLATION

Statutory Requirements 5

Boiler Design 6

Safety Devices 6

Servicing, Maintenance and Spare Parts 6

Boiler Specication 1 7

Boiler Dimensions and

Hydraulic Schematic 2 8

Boiler Location, Clearances

and Ventilation 3 9

Evacuation of Combustion Gas 4 10

Water Systems 5 14

Installation Preparation 6 18

Gas/Water Connections 7 20

Boiler Fixing 8 21

Safety Discharge Valve and

Condensate Connections 9 22

Electrical Connection 10 24

Commissioning 11 25

MAINTENANCE

APPENDIX

Servicing 12 29

Fault Finding 13 34

Replacement of Parts 14 40

Spare Parts 15 48

Manual Handling 16 49

Benchmark Logbook 50

Commissioning Flow Chart 53

- 3 -

INTRODUCTION

WARNINGS

Gas Leak or Fault

Turn off the gas emergency control valve immediately. Eliminate all sources of ignition, i.e.smoking, blowlamps,

hot air guns etc. Do not operate electrical lights or switches either on or off. Open all doors and windows,

ventilate the area.

Metal Parts

This boiler contains metal parts (components) and care should be taken when handling and cleaning,

with particular regard to edges.

Sealed Components

Under no circumstances must the user interfere with or adjust sealed parts.

Important Information

Gas Category

This boiler is for use only on G20 natural gas.

Gas Safety (Installation and Use)

Regulations

In your own interests and that of safety, it is the Law that ALL

gas appliances are installed by a competent person approved

at the time by the Health and Safety Executive in accordance

with the current issue of these regulations.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act 1974, we

are required to provide information on substances hazardous to

health.

The adhesives and sealants used in this appliance are cured

and give no known hazard in this state.

Manual Handling

With regards to the “Manual Handling Operations, 1992

Regulations”, the appliance exceeds the recommended weight

for a one man lift, refer to section 16 for more information.

The handling of the boiler may involve lifting, pushing and

pulling, the use of a sack truck may be required.

The following handling techniques and precautions should be

considered:

- Grip the boiler at its base

- Be physically capable

- Use safety clothing where appropriate, e.g. gloves, safety

footwear.

Ensure safe lifting techniques are used

- Keep back straight.

- Avoid twisting at the waist.

- Avoid upper body/top heavy bending.

- Always grip using the palm of the hand.

- Use designated hand holds.

- Keep load as close to body as possible.

- Always use assistance if required.

Electrical Supply

The boiler MUST be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

External wiring must be correctly earthed, polarised and in

accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The boiler MUST be connected to a permanent 230V ac, 50Hz

supply.

Connection of the whole electrical system of the boiler, including

any heating controls, to the electrical supply MUST be through

one common isolator and must be fused 3 Amp maximum.

Isolation should be by a double pole switched fused spur box,

with a minimum gap of 3mm for both poles. The fused spur

box should be readily accessible and preferably adjacent to the

appliance. It should be identied as to its use.

Alternatively connection can be made through an unswitched

shuttered socket and 3A fused 3-pin plug both to the current

issue of BS 1363, provided they are not used in a room

containing a bath or shower.

Wiring to the boiler must be PVC 85°C insulated cable, not less

than 0.75mm2 (24/0.20mm).

Testing and Certication

This boiler is tested and certicated for safety and performance.

It is, therefore, important that no alteration is made to the boiler,

without permission, in writing, by Glow-worm.

Any alteration not approved by Glow-worm, could invalidate the

certication, boiler warranty and may also infringe the current

issue of the statutory requirements.

- 4 -

0020107232_03 - 12/14 - Glow-worm

INTRODUCTION

CE Mark

This boiler meets the requirements of Statutory Instrument,

No. 3083 The Boiler (Efciency) Regulations, and therefore is

deemed to meet the requirements of Directive 92/42/EEC on

the efciency requirements for new hot water boilers red with

liquid or gaseous fuels.

Type test for purposes of Regulation 5 certied by: Notied

body 0087.

Product/production certied by: Notied body 0086.

The CE mark on this appliance shows compliance with:

1. Directive 2009/142/EC on the approximation of the laws

of the Member States relating to appliances burning gaseous

fuels.

2. Directive 73/23/EEC on the harmonisation of the Laws of

the Member States relating to electrical equipment designed for

use within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of

the Member States relating to electromagnetic compatibility.

IMPORTANT

Where no British Standards exists, materials and equipment

should be t for their purpose and of suitable quality and

workmanship.

The installation of this boiler must be carried out by a

competent person approved at the time by the Health and

Safety Executive in accordance the rules in force in the

countries of destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

Statutory Requirements

In GB, the installation of the boiler must comply with the

requirements of the current issue of BS6798 and be carried out

by a competent person, approved at the time by the Health

and Safety Executive, as described in the following regulations:

The manufacturer’s instructions supplied.

The Gas Safety (Installation and Use) Regulations.

The appropriate Buildings Regulations either The Building

Regulations, The Building Regulations (Scotland),The Building

Regulations (Northern Ireland).

The Water Supply (water ttings) Regulations 1999 and water

byelaws 2000, Scotland.

The Health and Safety at Work Act, Control of Substances

Hazardous to Health (COSHH).

The Current I.E.E. Wiring Regulations.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a competent

person approved at the time by the Health and Safety

Executive and installed in accordance with the current edition

of I.S.813 “Domestic Gas Installations”, the current Building

Regulations and reference should be made to the current ETCI

rules for Electrical Installation.

GB: the following Codes of Practice apply:

BS4814, BS6798, BS5440 Part 1 and 2, BS5546 Part 1,

BS5449, BS6891, BS6700, BS7074 Part 1 and 2, BS7593,

BS7671.

IE: I.S.813, BS5546, BS 5449, BS 7074, BS 7593.

NOTE: For further information, see the current issue of the

Building Regulations, approved document L1 ( in the UK) and

the following current issues of:

1) Central heating system specication (CheSS)

and

2) Controls for domestic central heating system and hot water.

BRECSU.

Gas Supply

The gas installation must be in accordance with the relevant

standards.

In GB, this is BS6891.

In IE, this is the current edition of I.S.813 “Domestic Gas

Installations”.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion, test the gas installation for tightness using the

pressure drop method and suitable leak detection uid, purge in

accordance with the above standard.

Domestic Hot Water

All domestic hot water circuits, connections, ttings must be

in accordance with the relevant standards and water supply

regulations.

GB: Guidance G17 to G24 and recommendation R17 to R24 of

the Water Regulations Guide.

IE: The current edition of I.S.813 “Domestic Gas Installations”.

Heating System

In GB, it is necessary to comply with the Water Supply (Water

Fittings) Regulations 1999 (for Scotland, the Water Byelaws

2000, Scotland).

To comply with the Water regulations your attention is drawn

to: The Water Regulations guide published by the Water

Regulations Advisory Service (WRAS) gives full details of the

requirements.

In IE, the requirements given in the current edition of I.S.813

“Domestic Gas Installations” and the current Building

Regulations must be followed.

0020107232_03 - 12/14 - Glow-worm

- 5 -

INTRODUCTION

Boiler Design

Boiler Design

These boilers are designed for use as part of a sealed water

central heating system with fully pumped circulation. The

pump, expansion vessel and associated safety devices are all

tted within the boiler. The hot water PRE HEAT temperature

facility will improve the boilers hot water delivery response.

The daily pump and 3 way valve exercise programme combined

with the built-in frost protection will help to maintain and protect

the boiler.

Range Rating

The boilers are fully modulating for central heating, it is

therefore not necessary to range rate the boiler. However, if

desired, it is possible to range rate the max. CH output in 1kW

increments, refer to section 11.

Safety Devices

Electrical Supply Failure

The boiler will not work without an electrical supply.

Normal operation of the boiler should resume when the

electrical supply is restored. Reset any external controls, to

resume normal operation of the central heating. If the boiler

does not resume normal operation press the reset button. If

the boiler does not resume normal operation after this call your

Installation/Servicing company or Glow-worm service.

Overheating Safety

The boiler software is designed to recognise the potential for

an overheat lockout and will shutdown before this happens. To

restart the boiler, press the reset button on the controls fascia.

If the boiler fails to resume normal operation and all external

controls are calling for heat, then call your Installation/Servicing

company or Glow-worm service.

Safety Discharge Valve

A safety discharge valve and discharge pipe are tted to the

boiler. This valve must not be interferred with, should there be

any discharge from the pipe, isolate the boiler electrical supply

and call your installer or Glow-worm’s own service organisation

using the telephone number on the inside front cover of this

booklet.

Condensate Drain

A plastic drain pipe must be tted to allow discharge of

condensate to a drain. Condensate should, if possible, be

discharged into the internal household draining system. If

this is not practical, discharge can be made externally into the

household drainage system or a purpose designed soak away,

see section 8 for more details.

Pluming from ue terminal

Like all condensing boilers this appliance will produce a plume

of condensation from the ue terminal in cool weather. This is

due to the high efciency and hence low ue gas temperature of

the boiler. This is normal and not an indication of a fault.

Frost protection

The appliance has a built in frost protection device that protects

the boiler from freezing. With the gas and electric supplies

ON and irrespective of any room thermostat setting, the frost

protection device will operate the pump when the temperature

of the boiler water falls below 8°C.

A timer is used so that the temperature can be checked

periodically. After 10 minutes the pump will be stopped if the

temperature is higher than 10°C or has already reached 35°C.

The burner will activate if the boiler temperature does not reach

10°C after 30 minutes or at any time if the temperature drops to

5°C.

The burner will switch off when the temperature reaches 35°C.

Condensate Drain Blockage

As a safety feature the boiler will stop working if the condensate

drain becomes blocked. During freezing conditions an ice

blockage in the condense drain, external to the house would

also activate the safety feature. Use warm cloths on the pipe to

release an ice blockage.

Once the blockage is removed the boiler should then restart.

Servicing, Maintenance and Spare Parts

Servicing and Maintenance

To ensure the continued efcient and safe operation of the

boiler it is recommended that it is checked and serviced as

necessary at regular intervals. The frequency of servicing will

depend upon the particular installation conditions and usage.

If this applaince is installed in a rented property there is a duty

of care imposed on the owner of the property by the current

issue of the Gas Safety (Installation and Use) Regulations,

Section 35.

Servicing/maintenance should be carried out by a competent

person approved at the time by the Health and Safety

Executive in accordance with the rules in force in the countries

of destination.

To obtain service, please call your installer or Glow-worm’s own

service organisation using the telephone number on the inside

front cover of this literature.

After servicing, complete the relevant Service Interval Record

- 6 -

section of the Benchmark Checklist located on the inside back

pages of these instructions.

Spare Parts

Remember, when replacing a part on this appliance, use

only spare parts that you can be assured conform to the

safety and performance specication that we require. Do not

use reconditioned or copy parts that have not been clearly

authorised by Glow-worm.

If a part is required contact Glow-worm’s own service

organisation using the telephone number on the inside front

cover of this booklet.

Please quote the name of the appliance, this infomation will be

on the name badge on the front of the appliance.

If in doubt seek advice from the local gas company or Glowworm’s own service organisation using the telephone number

on the inside front cover of this booklet.

0020107232_03 - 12/14 - Glow-worm

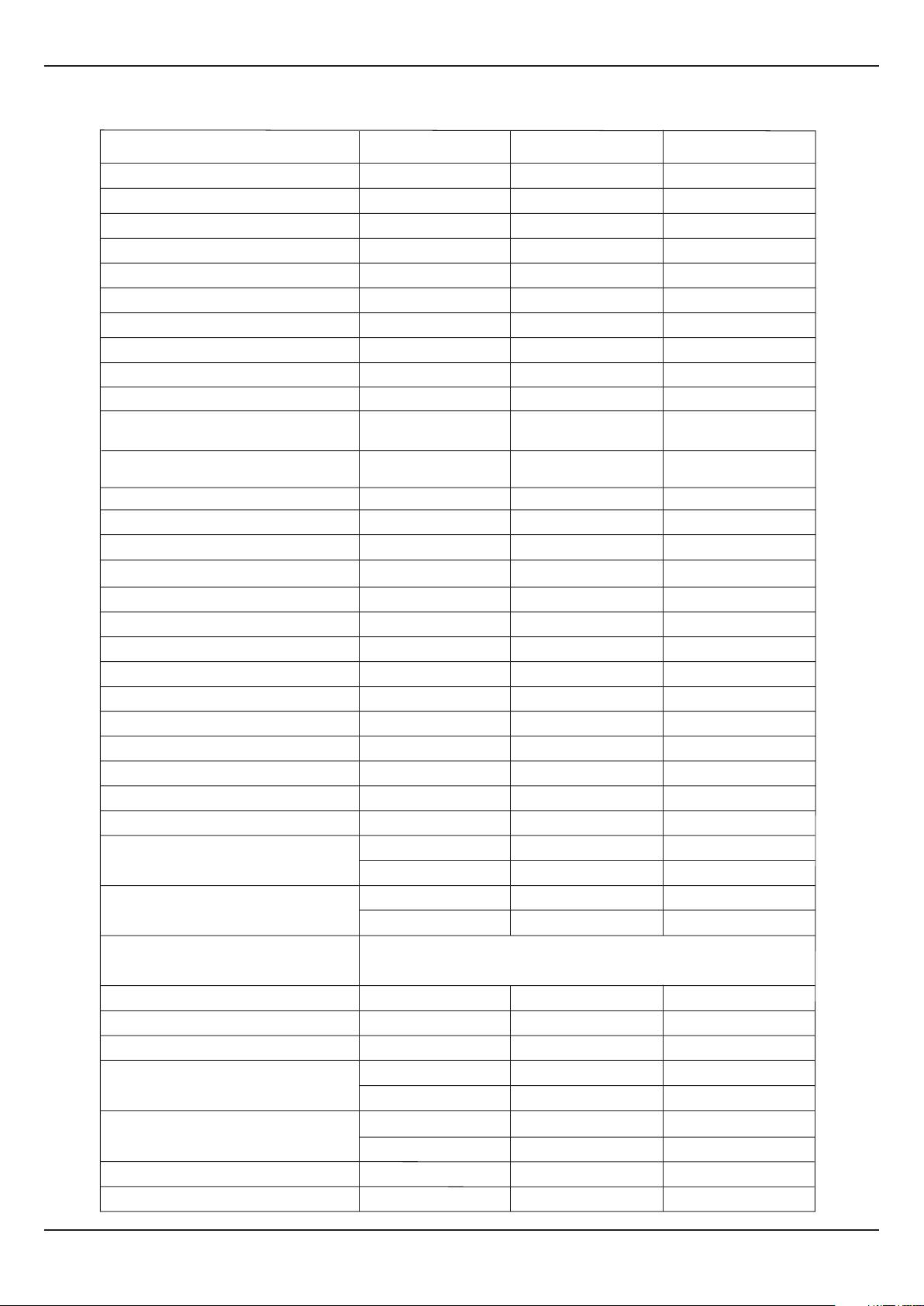

BOILER SPECIFICATION 24cx 30cx 35cx

Lift weight 36kg (79Ib) 36kg (79Ib) 36kg (79lb)

Total weight (installed) 41kg (90Ib) 41kg (90Ib) 41kg (90lb)

Gas connection Ø O.D. 15mm. copper 15mm. copper 15mm. copper

Heating and return connection Ø O.D. 22mm. copper 22mm. copper 22mm. copper

Domestic hot water connection Ø O.D. 15mm. copper 15mm. copper 15mm. copper

Condensate connection Ø I.D. 21.5mm. plastic 21.5mm. plastic 21.5mm. plastic

Safety valve discharge connection ØO.D. 15mm. copper 15mm. copper 15mm. copper

Heating circuit safety valve (preset) 3 bar (43.5Ibf/in

2

) 3 bar (43.5Ibf/in2) 3 bar (43.5Ibf/in2)

Heating system minimum pressure 0.7bar (10.1Ibf/in

2

) 0.7bar (10.1Ibf/in2) 0.7bar (10.1Ibf/in2)

Maximum domestic hot water circuit 10bar (145Ibf/in

2

) 10bar (145Ibf/in2) 10bar (145Ibf/in2)

1.0bar (14.5lbf/in

2

) 1.0bar (14.5lbf/in2) 1.0bar (14.5lbf/in2)

0.2bar (2.9Ibf/in

2

) 0.2bar (2.9Ibf/in2) 0.2bar (2.9Ibf/in2)

Specific water rate at 35° rise 9.85L/min. 12.3L/min. 14.4L/min

Min. flow rate around C.H. at 20° rise 776L/hr. 1032L/hr. 1204L/hr

Maximum domestic hot water temperature 63° 63° 63°

Expansion vessel capacity 8 litres (1.76 gallons) 8 litres (1.76 gallons) 8 litres (1.76 gallons)

Expansion vessel charge pressure 0.5bar (7.3Ibf/in

2

) 0.5bar (7.3Ibf/in2) 0.5bar (7.3Ibf/in2)

Electrical supply 230V~50Hz fused 3A 230V~50Hz fused 3A 230V~50Hz fused 3A

Electrical rating 180W fused 3A 180W fused 3A 180W fused 3A

EN437 IP clasification IPX4D IPX4D IPX4D

Internal fuse rating on main PCB 2A 2A 2A

Gas supply (governed meter only) and Cat G20 natural gas G20 natural gas G20 natural gas

Gas Category I

2H

I

2H

I

2H

Inlet gas working pressure 20mbar 20mbar 20mbar

Burner % CO

2

case on 9.3 nominal 9.3 nominal 9.3 nominal

Burner % CO

2

case off 9.3 nominal 9.3 nominal 9.3 nominal

1.93 m

3

/h 2.59 m3/h 3.26 m3/h

68.1 ft

3

/h 91.5 ft3/h 115 ft3/h

0.99 m

3

/h 0.99 m3/h 0.99 m3/h

35.1 ft

3

/h 35.1 ft3/h 35.1 ft3/h

Flue type C

13, C33, C43 C13, C33, C43 C13, C33, C43

NOx Class 5 Class 5 Class 5

Heat output condensing mode 18.8kW 24.9kW 31.0kW

Heat input Nett Q = kW DHW max. 25.5 min. 9.4 DHW max. 30.8 min. 9.4 DHW max. 35.8 min. 9.4

CH max. 18.3 min. 9.4 CH max. 24.5 min. 9.4 CH max. 30.8 min. 9.4

Heat output P = kW DHW max. 25.1 min. 9.3 DHW max. 30.0 min. 9.3 DHW max. 35.0 min. 9.3

CH max. 18.0 min. 9.3 CH max. 24.0 min. 9.3 CH max. 30.0 min. 9.3

SEDBUK rating % 2005 90.3 90.0 90.2

SEDBUK rating % 2009 88.4 88.3

89.1

Approximate max. gas rate

after 10 mins. from cold

Approximate min. gas rate

after 10 mins. from cold

Minimum working pressure to obtain

domestic hot water

Minimum working pressure to obtain

maximum domestic flow

PLEASE REFER TO THE COMMISSIONING SECTION

Approximate gas rate

at part load.

1 Boiler Specication

TECHNICAL DATA

14732

0020107232_03 - 12/14 - Glow-worm

- 7 -

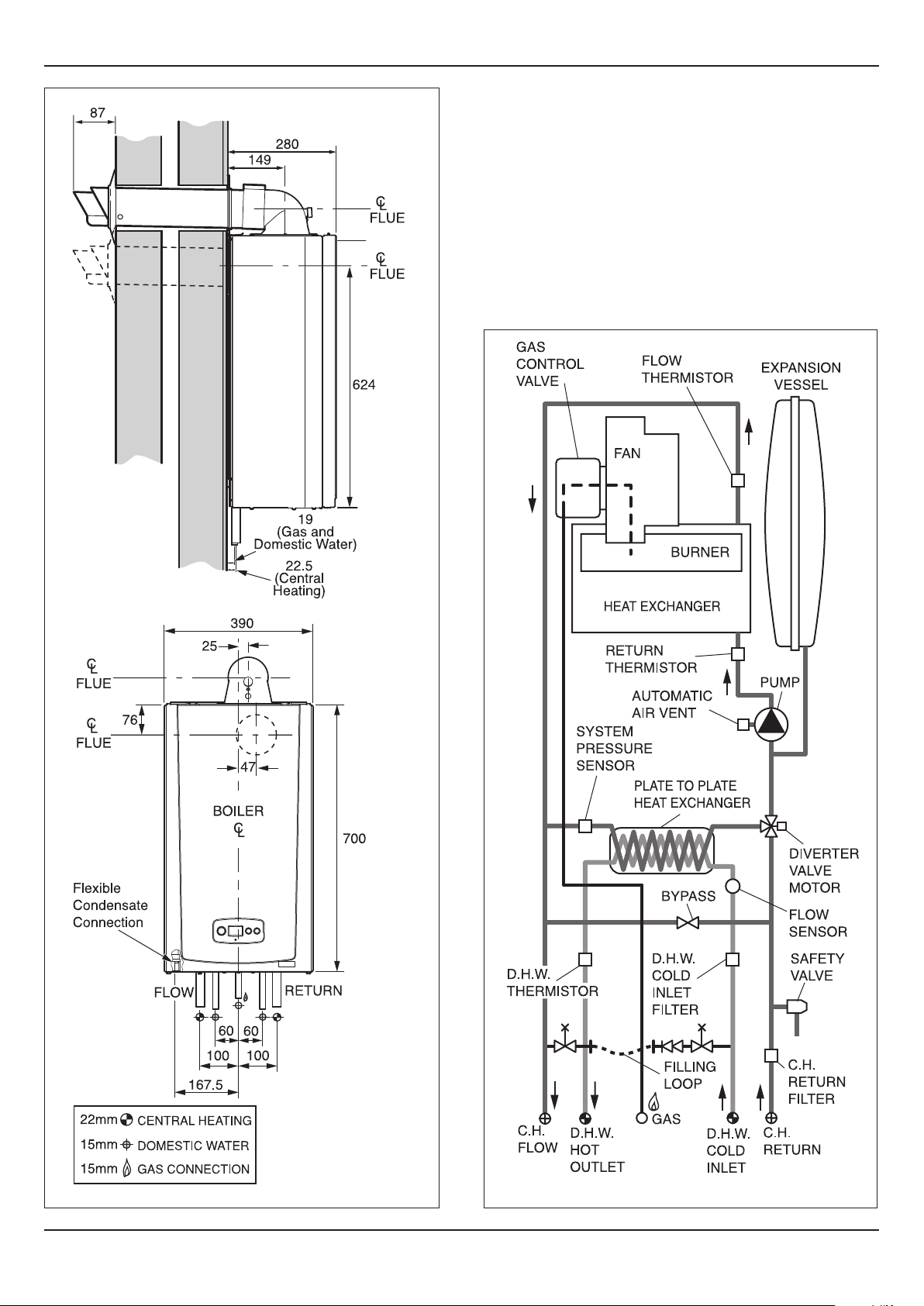

INSTALLATION

13893

2 Boiler Dimensions and Hydraulic

Schematic

All dimensions are given in millimetres (except as noted).

The general arrangment of the boiler is shown in diagram 2.1

and the hydraulic and gas schematic, diagram 2.2.

The data label is positioned on the front of the inner casing

panel.

13089

- 8 -

Diagram 2.2Diagram 2.1

0020107232_03 - 12/14 - Glow-worm

INSTALLATION

3 Boiler Location, Clearances and

Ventilation

3.1 Location

This boiler is not suitable for outdoor installation.

This boiler may be installed in any room, although particular

attention is drawn to the installation of a boiler in a room

containing a bath or shower where reference must be made to

the relevant requirements.

This boiler is suitable for installation in bathroom zones 2 and 3.

In GB this is the current I.E.E. WIRING REGULATIONS and

BUILDING REGULATIONS.

In IE reference should be made to the current edition of I.S.813

“Domestic Gas Installations” and the current ETCI rules.

3.2 Clearances

The boiler should be positioned so that at least the minimum

operational and servicing clearances are provided, see diagram

3.1.

Additional clearances may be benecial around the boiler for

installation and servicing.

For ue installations where external access is not practicable,

consideration should be given for the space required to insert

the ue internally, which may necessitate clearance larger than

those specied in diagram 3.1.

13127

3.3 Timber Frame Buildings

If the boiler is to be installed in a timber frame building it should

be tted in accordance with the Institute of Gas Engineers

document IGE/UP/7/1998. If in doubt seek advice from local

gas undertaking or Glow-worm.

3.4 Combustible Material

The boiler and ue are suitable for installation onto and through

combustible materials provided that:-

1) Minimum 5mm clearance is maintained around the

circumference of the ue (air intake).

2) The combustible surface and xings are suitable for

supporting the load.

3) The minimum clearances from the boiler case are

maintained.

3.5 Room Ventilation

The boiler is room sealed so a permanent air vent is not

required.

3.6 Cupboard or Compartment Ventilation

Due to the high efciency and low casing temperature of this

boiler, cupboard or compartment ventilation is not necessary.

• Existing ventilation should be investigated for its purpose

before removing.

Diagram 3.1

3.7 Airing Cupboard Installation

If the boiler is to be installed in an airing cupboard it is not

required to separate the boiler with a non-combustible partition.

However, installation and servicing clearances must be

maintained, and the boiler kept clear of any clothing. Details of

essential features of cupboard/compartment design including

airing cupboard installations are given in BS 6891. In IE the

current edition of IS 813.

3.8 Roof Restricting Installation

It is not necessary to ensure sufcient clearance between

the boiler and combustible materials or components. This is

because the temperature of the boiler will always be less than

o

C due to its nominal heat output.

85

0020107232_03 - 12/14 - Glow-worm

- 9 -

INSTALLATION

4 Evacuation of Combustion Gas

4.1 Regulation

Only ue accessories supplied by Glow-worm

must be used.

Different ue outlet congurations can be carried out.

• Consult your supplier for more information about the other

possibilities and associated accessories.

44 mm/m

• Standard ue terminal kits have an in-built fall back to the

boiler to drain the condensate. These can be tted level

between the appliance and the termination position. All other

extended ues must have a fall of at least 44mm/m

If the ue terminal is positioned near a light

source insects may enter the ue system.

Where safe and practical to do so advise the

homeowner to check the ue outlet and clear

visible insects from the terminal end.

H* and J* See diagram 4.2. These dimensions comply with

the building regulations, but they may need to be increased to

avoid wall staining and nuisance from pluming depending on

site conditions.

Terminal Guard

A terminal guard is required if persons could come into contact

with the terminal or the terminal could be subject to damage.

If a terminal guard is required, it must be positioned to provide

minimum of 50mm clearance from any part of the terminal and

be central over the terminal.

The guard should be similar to that shown in diagram 4.1.

A suitable guard is manufactured by: Tower Flue Components

Morley Rd.

Tonbridge

Kent TN9 1RA.

Size: 280mm x 165mm. Part No: CGDK3

15583

The maximum length of the ue outlet is dened according to its

type (for example C13).

• Whatever the kind of ue system chosen, observe the

minimum distances indicated in the chart below to position

the ue terminals.

• To install the ue, refer to the separate ue instruction

supplied with your appliance.

• Explain these requirements to the user of the appliance.

If necessary, you must install terminal

a

In GB the minimum acceptable siting dimensions for the

terminal from obstructions, other terminals and ventilation

openings are shown in diagram overleaf.

In IE the minimum distances for ue terminal positioning must

be those detailed in I.S.813 “Domestic Gas Installations”.

The terminal must be exposed to the external air, allowing free

passage of air across it at all times.

protection.

Caution! The connection between the ue

elbow and the ue outlet must be sealed.

Diagram 4.1

Being a condensing boiler some pluming may occur from

the ue outlet. This should be taken into consideration when

selecting the position for the terminal.

Carports or similar extensions of a roof only, or a roof and one

wall, require special consideration with respect to any openings,

doors, vents or windows under the roof. Care is required

to protect the roof if made of plastic sheeting. If the carport

comprises of a roof and two or more walls, seek advice from the

local gas supply company before installing the boiler.

- 10 -

0020107232_03 - 12/14 - Glow-worm

INSTALLATION

J

J

U

E

F

A 300mm adjacent to a boundary.

B The dimension below eaves, balconies and car ports

can be reduced to 25mm, as long as the flue terminal

is extended to clear any overhang. External flue

joints must be sealed with a suitable silicon sealant.

C 1500mm between a vertical ue terminal and a

window or dormer window.

D 1200mm between terminals facing each other.

E Vertical ue clearance, 300mm adjacent to a

boundary line.

F 600mm distance to a boundary line, unless it will

cause a nuisance. BS 5440:Part 1 recommends

that care is taken when siting terminal in relation to

boundary lines.

G 300mm minimum clearance from a skylight to a

vertical ue or to another vertical ue.

H Vertical ue clearance, 500mm to non-combustible

building material, and 1500mm clearance to

combustible building material.

J 300mm above, below and either side of an opening

door, air vent or opening window.

K 600mm diagonally to an opening door, air vent or

opening window.

L 300mm to an internal or external corner.

M 2000mm below a Velux window, 600mm above or to

either side of the Velux window.

N 400mm from a pitched roof or 500mm in regions with

heavy snowfall.

P 25mm from vertical drain pipes and soil pipes.

A

G

J

J

H

K

J

Q

G

B

S

D,T

M

V

C

N

R

L

L

P

L

S

S

Q 200mm below eaves and 75mm below gutters, pipe

and drains.

R The dimension below eaves, balconies and car ports

can be reduced to 25mm, as long as the ue terminal

is extended to clear any overhang. External ue

joints must be sealed with suitable silicon sealant.

S 300mm above adjacent ground, balcony or storm

porch.

T 600mm distance to a surface facing a terminal,

unless it will cause a nuisance. BS 5440: Part 1

recommends that care is taken when siting terminals

in relation to surfaces facing a terminal.

U 300mm clearance alongside another terminal.

V 300mm above roof level.

ll measurements are the minimum clearances required.

A

Terminals must be positioned so to avoid combustion products

entering the building.

Support the ue at approximately one metre intervals and at a change

of direction, use suitable brackets and xings.

Installations in car ports are not recommended.

A ue outlet should be protected with a guard if persons could come

into contact with it or if it could be damaged.

The ue cannot be lower than 1 metre from the top of a light well due to

the build up of combustion products.

Dimensions from a ue terminal to a fanned air inlet to be determined

by the ventilation equipment manufacturer.

S

0020107232_03 - 12/14 - Glow-worm

- 11 -

INSTALLATION

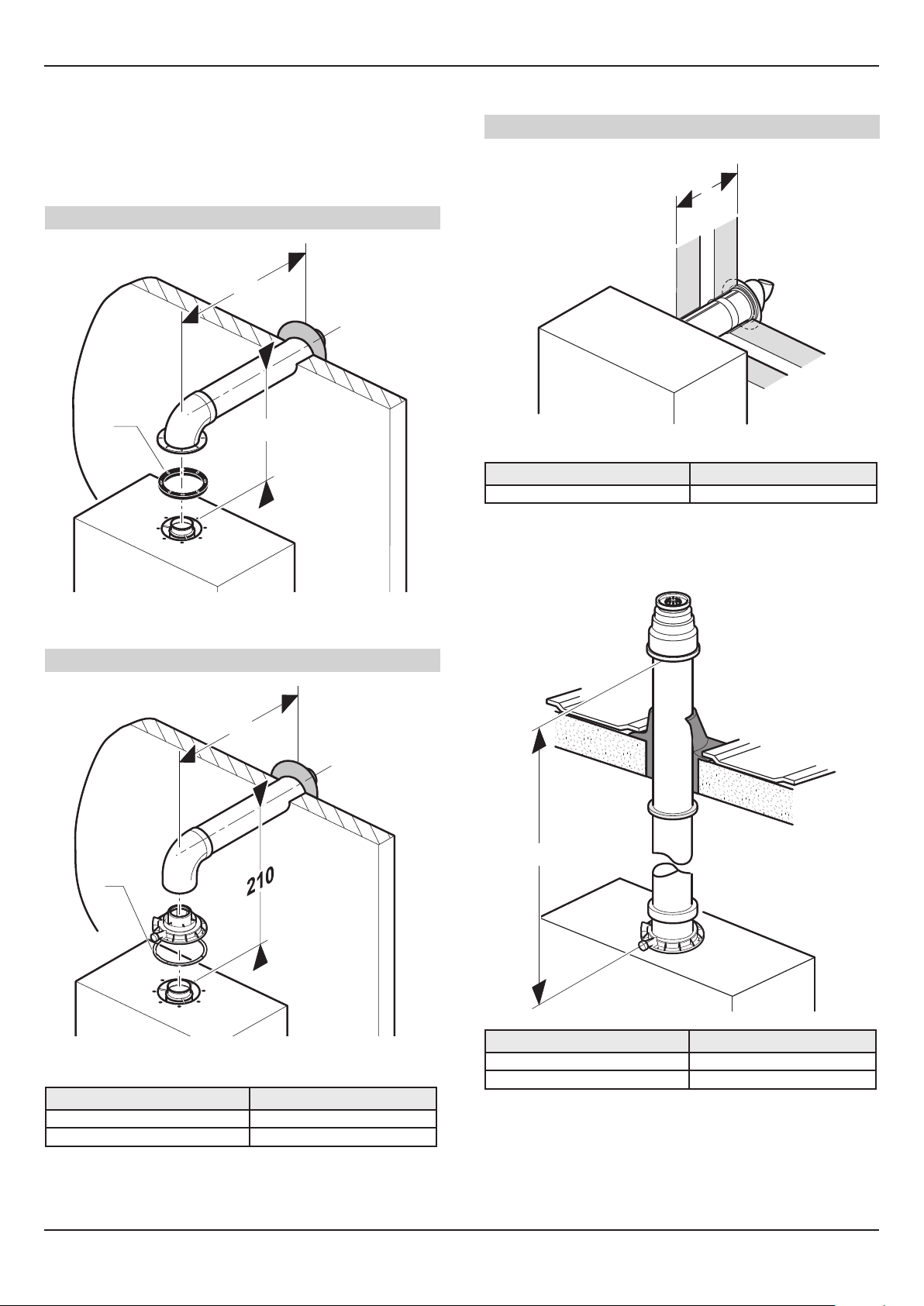

4.2 Flue conguration description

4.2.1 Horizontal concentric ue Ø 60/100 mm

or Ø 80/125 mm (C13 type installation)

Ø 60/100 mm

L

1

63

4.2.2 Telescopic direct rear ue Ø 60/100 mm

Ø 60/100 mm

L

Type Max length

Ø 60/100 512 mm

4.2.3 Vertical concentric ue Ø 60/100 mm

or Ø 80/125 mm (C33 type installation)

Key

1 Gasket (tted)

1

Key

1 Gasket (tted)

Ø 60/100 8 m

Ø 80/125 20 m

Ø 80/125 mm

L

Type Max length

L

Type Max length (L)

Ø 60/100 8 m

Ø 80/125 20 m

Each time an additional 90° bend is necessary (or 2 at 45°), the

length (L) must be reduced by 1 m.

Each time an additional 90° bend is necessary (or 2 at 45°), the

length (L) must be reduced by 1 m.

- 12 -

0020107232_03 - 12/14 - Glow-worm

4.2.4 Multiple boiler chimney ue

L

B

A

1

2

3

4

5

Ø 60/100 mm (C43 type installation)

The ue connecting from the appliance to

the ue system must be supplied from the

manufacturer of the boiler.

C43 ue systems must not be a 'pressurised

system' but act under natural draught principles

C43 type ue systems must have their

own condensate drain tted and not allow

condensate to mix into other appliances

INSTALLATION

Multiple Boiler Chimney Flue Length

The ue length must be calculated and installed according to

the relevant standards EN 13384-1 and 2 (C43 ue systems

only) with reference to the table below and the manufacturers

instructions supplied.

The appliance maximum ue length must be included when

calculating the overall design of the ue system.

NOTE: The horizontal ue terminal must be removed.

Flexicom

24cx

Exhaust mass rate (g/s)

At Min Thermal

Load (40C°/30°C)

At Max Thermal

Load (80C°/60°C)

Exhaust temperature (ºC)

At Min Thermal

Load (40C°/30°C)

At Max Thermal

Load (80C°/60°C)

11.67 14.10 16.39

Key

1 Pressure balancing system

2 Air-inlet pipe

3 Collector pipe

4 Boiler

5 Inspection hatch

A Final storey

B Ground oor

Type Max length (L)

Ø 60/100 8 m

Each time an additional 90° bend is necessary (or 2 at 45°), the

length (L) must be reduced by 1 m.

30cx

Flexicom

Flexicom

35cx

4.30 4.30 4.30

33.2 33.2 36.0

73.3 87.4 86.0

0020107232_03 - 12/14 - Glow-worm

- 13 -

INSTALLATION

5 Water Systems - General

5.1 General

This boiler is designed for use as part of a sealed water central

heating system with fully pumped circulation. The pump,

expansion vessel and associated safety devices are all tted

within the boiler.

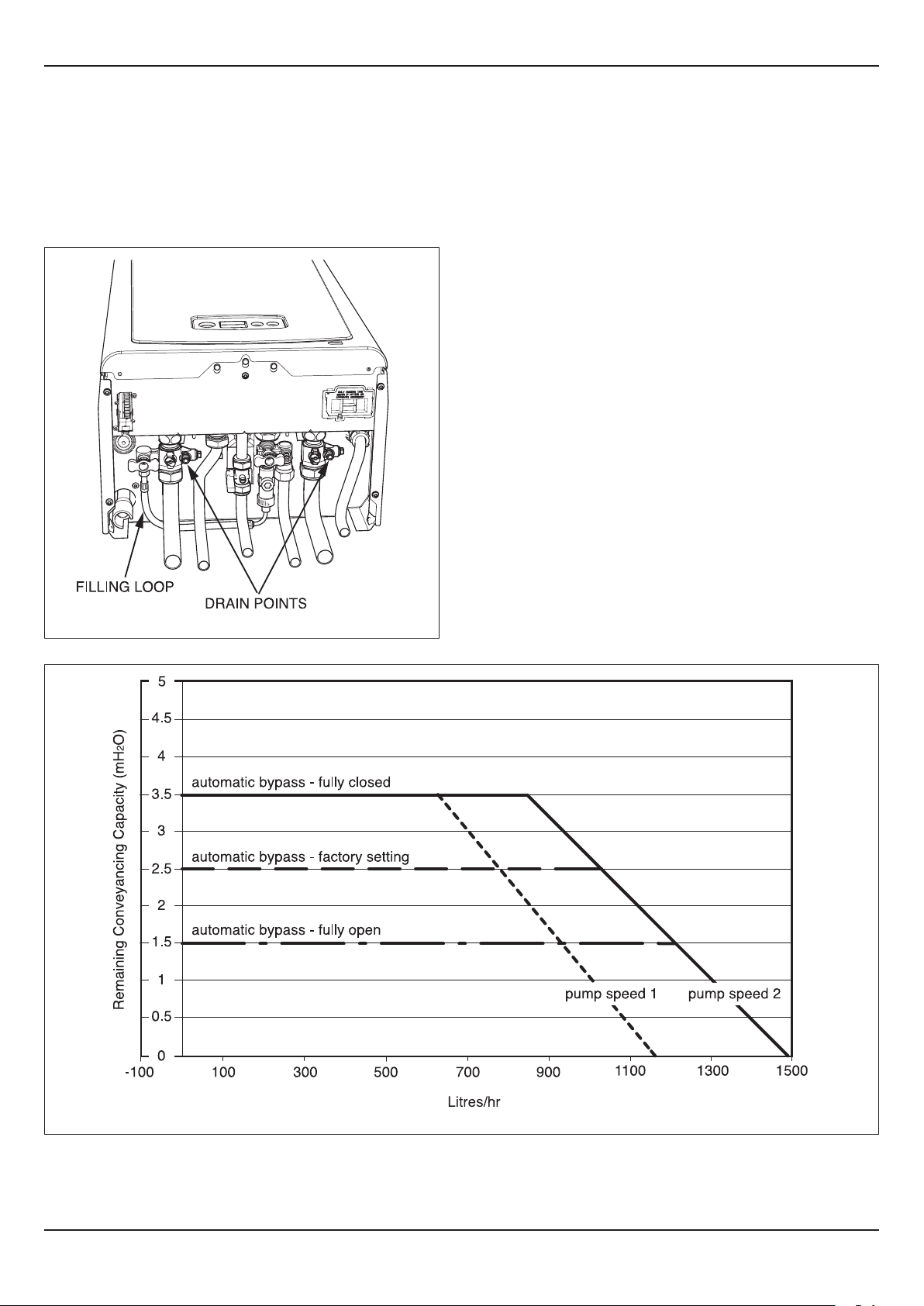

5.2 Draining Points

Draining taps must be provided at all low points of the system,

which will allow the entire system to be drained.

Draining taps shall be to the current issue of BS2879.

Drain points for the appliance are provided at the positions

shown in diagram 5.1.

13925

Diagram 5.1

13102

- 14 -

Diagram 5.2

0020107232_03 - 12/14 - Glow-worm

INSTALLATION

5.3 Water treatment

5.3.1 General

The Glow-worm Flexicom range of boilers have an

Aluminium alloy heat exchanger. Water treatment products

used in the system should be suitable for use with

Aluminium.

Existing system- It is ESSENTIAL that prior to installing

the new boiler the system is thoroughly ushed.

New system- For optimum performance after installation, the

boiler and its associated central heating system should also be

ushed.

For long-term corrosion protection, after ushing, an inhibitor

should be used, refer to the current issue of BS 5449 and BS

7593 on the use of inhibitors in central heating systems.

Debris left in the system can damage the boiler,

reduce efciency and also lead to system

corrosion and generation of ammable gas.

Failure to comply with the guidelines for the

use of water treatment with the appliance will

invalidate the appliance warranty.

The pH value of the system water must be

between 6.5 and 8.5 or the appliance guarantee

will be invalidated.

5.3.3 Inhibiting the system

Add a suitable inhibitor or combined inhibitor/anti-freeze, if the

system is exposed to freezing conditions, to the heating system

in accordance with the DWTA code of practice and inhibitor

manufacturer’s guidelines.

Examples of suitable inhibitors are:

Sentinel X100

Fernox protector F1

Articially softened water must not be used to

ll the central heating system.

Sealing agents - The addition of sealing agents

to the system water is not permitted as this can

cause problems with deposits left in the heat

exchanger.

Ensure that the pH of the treated system water is

i

i

conrmed as between 6.5 and 8.5 and free of any

residual deposits from the ushing process.

Ensure the Benchmark Logbook is completed with

information on water treatment products before

handing over to the user.

Before ushing the system

• Ensure that the system and pipe work is in good working

order.

• Where possible keep the existing boiler/circulating pump in

place when ushing the system.

5.3.2 Flushing the system

• Fill the system with cold water and check for leaks.

• Open all drain cocks and drain the system.

• Close drain cocks and add a suitable ushing agent (cleaner)

compatible with Aluminium at the correct strength for the

system conditions in accordance with the manufacturer’s

instructions.

Examples of suitable ushing agents/cleansers are:

Sentinel X300, X400

Fernox F3

• Circulate the ushing agent before the boiler is red up.

• Run the boiler/system at normal operating temperature as

directed by the manufacturer of the ushing agent.

• It is essential to drain and thoroughly ush the whole system

to remove the ushing agent and debris.

• It may be necessary to use a power ushing machine to aid

the cleansing procedure in some circumstances.

• Close the drain cocks and rell with fresh water and a

suitable inhibitor

• Vent any air from the boiler and system.

0020107232_03 - 12/14 - Glow-worm

- 15 -

INSTALLATION

5 Water systems - Domestic Hot Water

5.4 General

All domestic hot water circuits, connections, ttings must be

in accordance with the relevant standards and water supply

regulations.

For GB: Guidance G17 to G24 and recommendation R17 to

R24 of the Water Regulations Guide (for Scotland, the Water

Byelaws 2000, Scotland).

For IE: The current edition of I.S.813 “Domestic Gas

Installations”.

5.5 Water Pressure

The minimum working pressure to obtain the maximum

domestic ow is:-

24cx 1.0bar

30cx 1.0bar

35cx 1.0bar

The maximum working pressure of the domestic hot water

circuit is 10 bar. If the cold water supply pressure exceeds this,

then a pressure-reducing valve must be tted in the supply to

the boiler.

5.6 ‘Hard’ Water Areas

The temperatures within the heat exchanger are limited by the

boiler control system to minimise scale formation within the hot

water pipework. However, in areas where the water is ‘hard’ (i.e.

more than 200mg/litre), it is recommended that the hot water

setting is reduced and that a scale reducer is tted, refer to the

manufacturer’s instructions or consult the local water company

for additional advice.

5 Water Systems - Sealed Central Heating

system

5.8 Flow Rate

If it is necessary to alter the ow rate, the system can be tted

with a lockable balancing valve in the main ow or return pipes

shown as valve “A” in diagram 5.3. The ow rate through the

boiler must not be allowed to fall below that given in section 1 -

Specication Table.

5.9 Bypass

The boiler is tted with an automatic bypass.

Diagram 5.2 shows the pump head remaining for the heating

system depending on the bypass setting and the speed setting

of the pump, see section 11 Commisioning.

Ensure that under no circumstances does the ow rate drop

below the gure specied, refer to section 1 - Specication

Table and section 11.9.

5.10 Safety Valve

The safety valve is an integral part of the boiler and it cannot

be adjusted. The pipe from the safety discharge valve must

not discharge above an entrance, window or any type of public

access area.

15725

5.7 Domestic Water Flow Rate

The water ow rate is restricted to a maximum 9.4 l/min for

24cx, 11.7 l/min for 30cx and 13.0l/min for 35cx by a restrictor

factory tted within the boiler.

- 16 -

Diagram 5.3

0020107232_03 - 12/14 - Glow-worm

INSTALLATION

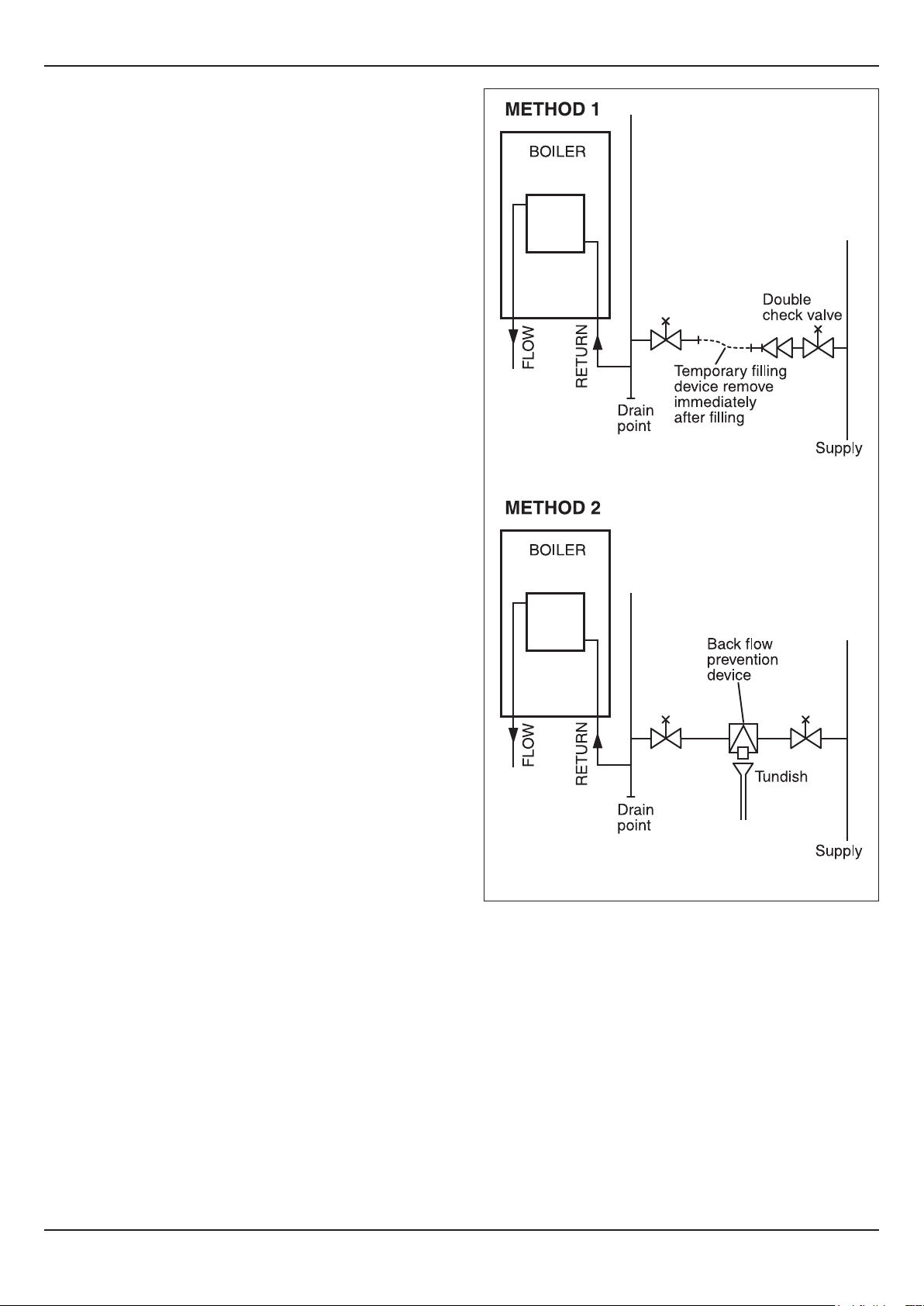

5.11 Filling the Sealed System

The boiler is supplied with a lling device, see diagram 5.1.

This lling device is designed to enable the lling and

pressurisation of the system in the event of loss of pressure.

NOTE: The water pressure at the boiler must be at least

1.2bar to enable lling the boiler to a minimum pressure. If not

pressurisation must be carried out by an alternative lling loop.

Suitable external lling systems are shown diagramatically,

see diagram 5.4. The system should be pressurised to 1bar,

indicated on the digital display with no heating demand.

5.12 Expansion Vessel

The boiler has an integral expansion vessel with a capacity of 8

litres (1.76 gallons), with a charge pressure of 0.5bar.

NOTE: The expansion vessel volume depends on the total

water system volume and the initial system design pressure.

In GB, Guidance on vessel sizing is also given in the current

issue of BS5449 and BS7074 Part 1.

In IE, current edition of I.S.813 “Domestic Gas Installations”.

12253

0020107232_03 - 12/14 - Glow-worm

Diagram 5.4

- 17 -

Loading...

Loading...