Glow-worm Energy Saver 80 - 100 User Manual

Instructions for Use

Installation and Servicing

To be left with the user

221564F.11.00

Energysaver

Combi

80 100

G.C. No. 47-047-01 G.C. No. 47-047-02

Condensing

Combination Boiler

Energysaver

Combi

This is a Cat I2H Appliance

Reference in these instructions to British Standards and Statutory

Regulations/Requirements apply only to the United Kingdom.

The instructions consist of three parts, User, Installation and Servicing Instructions, which includes the Guarantee Registration

For Ireland the rules in force must be used.

Card. The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety

(Installation and Use) Regulations, be handed to the user on completion of the installation.

6548

Guarantee Registration

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased

In the centre pages are to be found your Guarantee Registration Card, which we recommend you complete and

If this card is missing you can obtain a copy or record your registration by telephoning the Heatcall Customer

Our Guarantee gives you peace of mind plus valuable protection against breakdown by covering the cost of:

✔

All replacement parts

❏

✔

All labour charges

❏

All call-out charges

✔

❏

One Contact Local Service

to offer our customers' a Comprehensive First Year Guarantee.

return as soon as possible.

Service number 01773 828100.

REGISTER YOUR GLOW-WORM APPLIANCE

FOR 1ST YEAR GUARANTEE PROTECTION

CALL 0208 247 9857

Customer Services:

Tel: (01773) 828100

Fax: (01773) 828070

Nottingham Road, Belper, Derbyshire. DE56 1JT

Tel: (01773) 824141 Fax: (01773) 820569

Hepworth Heating Ltd.,

General/Sales enquiries:

Contents

CONTENTS DESCRIPTION SECTION PAGE No.

INSTRUCTIONS

FOR USE

INSTALLATION

INSTRUCTIONS

SERVICING

INSTRUCTIONS

Introduction 3

Operating the Boiler 3

Clock Setting 5

General Information 1 6

Boiler Position 2 8

Flue Location and Ventilation 3 9

Heating System 4 11

Domestic Hot Water System 5 13

Installation Preparation 6 13

Flue Preparation 7 15

Boiler Fixing 8 17

Gas, Water and Condensate Conns. 9 17

Electrical Connections 10 18

Commissioning 11 20

Servicing 12 25

Fault Finding 13 29

Replacement Parts 14 32

Important Information

General

Please read these instructions and follow them carefully for the

safe and economical use of your boiler.

Once the controls are set, the boiler is automatic in operation.

The Energysaver 80 and 100 Combi boilers are able to provide

room heating as part of a central heating system and domestic

hot water direct from the cold water supply, without the need for

secondary storage.

Gas Category

This boiler is for use only on G20 gas.

Gas Safety (Installation and Use) Regulations

In your own interests and that of safety, it is the Law that ALL

gas appliances are installed by a competent person in

accordance with the current issue of the above regulations.

Gas Testing and Certification

The boiler is tested and certificated for safety and performance.

It is, therefore, important that no alteration is made to the boiler

unless approved, in writing, by Hepworth Heating Ltd.

Any alteration not approved by Hepworth Heating Ltd., could

invalidate the certification, boiler warranty and may also infringe

the current issue of the Statutory requirements.

CE Mark

This boiler meets the requirements of Statutory Instrument, No.

3083 The Boiler Efficiency Regulations, and therefore is deemed

to meet the requirements of Directive 92/42/EEC on the efficiency

requirements for new hot water boilers fired with liquid or

gaseous fuels.

Type test for purposes of Regulation 5 certified by:

Notified body 0063.

Product/production certified:

Notified body 0063.

The CE Mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the Laws of

the Member States relating to appliances burning gaseous

fuels.

2. Directive 73/23/EEC on the harmonization of the Laws of the

Member States relating to electrical equipment designed for

use within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of

the Members States relating to electromagnetic compatibility.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act 1974, we

are required to provide information on substances hazardous

to health.

The adhesives and sealants used in this appliance are cured

and give no known hazard in this state.

Refractory Ceramic Fibre

This product uses insulation material containing Refractory

Ceramic Fibre (RCF), which are man-made vitreous silicate

fibres. Excessive exposure to these materials may cause

temporary irritation to eyes, skin and respiratory tract,

consequently, it makes sense to take care when handling these

articles to ensure that the release of dust is kept to a minimum.

To ensure that the release of fibres from these RCF articles is

kept to a minimum, during installation and servicing we

recommend that you use a HEPA filtered vacuum to remove

any dust accumulated in and around the boiler before and after

working on the boiler. When replacing these articles we

recommend that the replaced items are not broken up, but are

sealed within heavy duty polythene bags, clearly labelled as

RCF waste. This is not classified as “hazardous waste” and

may be disposed of at a tipping site licensed for the disposal of

industrial waste.

221564F

2

Important Information

Protective clothing is not required when handling these articles,

but we recommend you follow the normal hygiene rules of not

smoking, eating or drinking in the work area and always wash

your hands before eating or drinking.

Insulation Pads/Ceramic Fibre, Glass yarn

These can cause irritation to skin, eyes and the respiratory tract.

If you have a history of skin complaint you may be susceptible

to irritation. High dust levels are usual only if the material is

broken.

Introduction

Gas Leak or Fault

If a gas leak or fault exists or is suspected, turn the boiler mains

electrical supply off and turn off the gas supply at the meter.

Consult your local gas company or your local installation/

servicing company.

Electrical Supply Failure

The boiler will not work without an electrical supply.

Normal operation of the boiler should resume when the electrical

supply is restored. If not, the boiler safety cut-off may have

operated, please refer to the following section to reset.

Reset any external controls, to resume normal operation of the

central heating.

The digital timer, if fitted, has a lithium battery back up and will

not need resetting.

Normal handling should not cause discomfort, but follow normal

good hygiene and wash your hands before eating, drinking or

going to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the skin

seek medical attention.

Reset Button

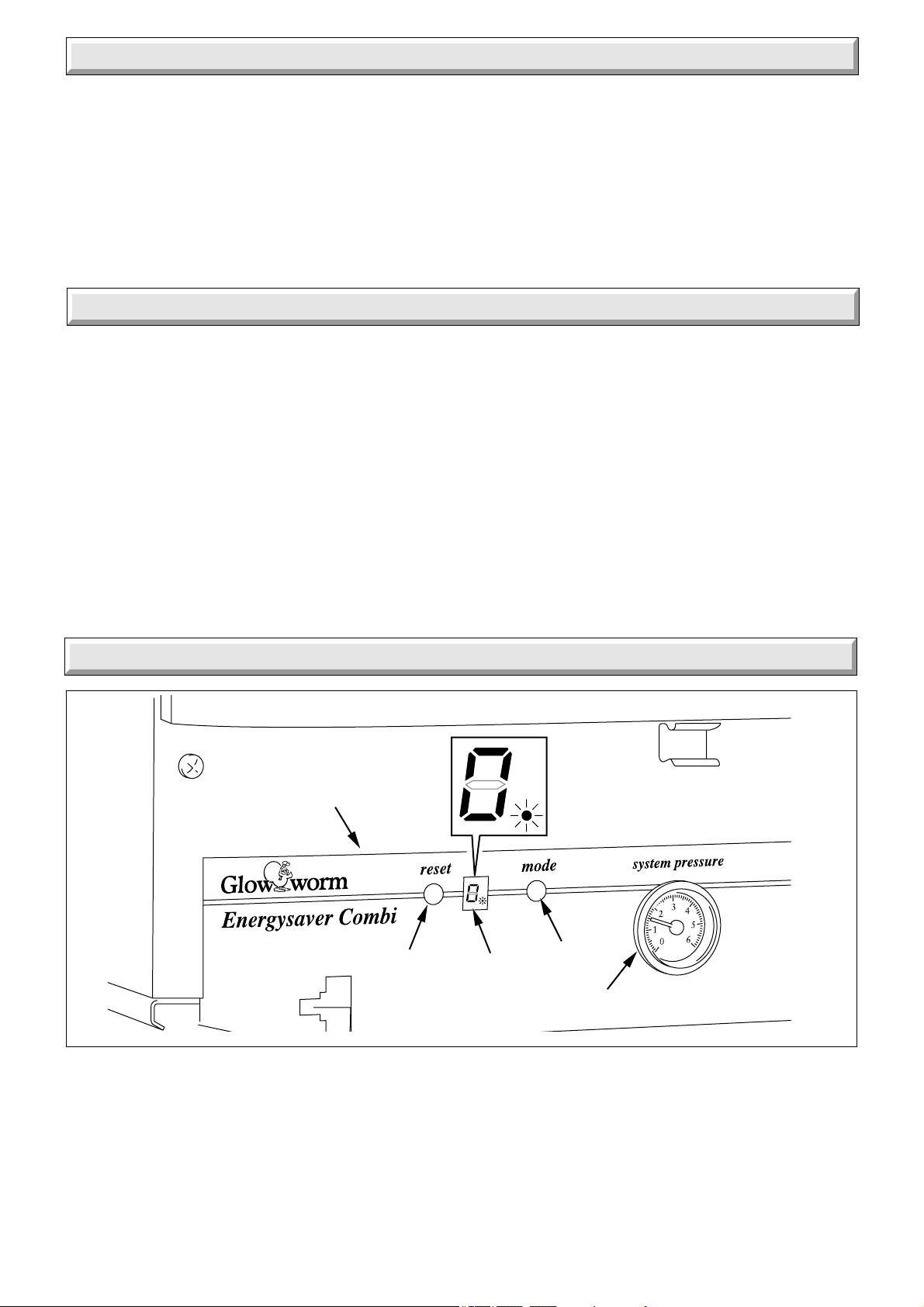

Refer to diagram 1 which shows the fascia behind the drop

down panel.

If the burner goes out check the digital display. Flashing digits

on the display indicate a fault. Allow the boiler to cool down for

at least four minutes then press the ‘Reset’ button. This should

restart the boiler.

To obtain service call your installer or Heatcall (Glow-worm’s

own service organisation) using the telephone number given on

the front page of these instructions.

Operating the Boiler

FASCIA

RESET

BUTTON

To Operate the Boiler

1. Check that all five isolating valves are open with their slots

in line with the length of the valve, see diagram 8.1 in Installation

instructions.

2. CAUTION: A sealed pressurised system must be filled and

pressurised by a competent person.

Only operate the boiler when you are sure that the system has

been filled and pressurised. Check this by looking at the

DIGITAL

MODE

BUTTON

DISPLAY

PRESSURE

GAUGE

Diagram 1

pressure gauge which should read a minimum of 1.0bar, see

diagram 1.

3. Open a hot water tap, check that water flows, then close it.

4. If you are in any doubt about the boiler being filled with water

contact your installation/servicing company or the local gas

company.

5. Check that the electrical supply to the boiler is ON at the

external isolator.

6561

3 221564F

Operating the Boiler

6. Set clock/timer (if fitted) and any remote controls as required.

7. If the display is flashing, press the 'reset' button, shown on

diagram 1.

8. The boiler should now operate. It is factory preset to supply

domestic hot water up to 65oC and central heating up to 70oC.

User Controls

The operation of the boiler can be altered by using the ‘Mode’

button. Temperature Selection and Control Options are detailed

in sections 11.8 to 11.11.

Additional Options

Other modes are available by repeatedly pressing the ‘Mode’

button. These cover fault indication and servicing and should

only be accessed by the service engineer. Repeated pressing

of the ‘Mode’ button will eventually return the display to show

boiler temperature, see diagram 11.4.

To Turn the Boiler Off

It is preferable to leave the electrical supply on whenever

possible to permit operation of the built-in frost protection (see

‘Protection Against Freezing’) and daily pump and valve exercise.

To turn off the central heating use the room thermostat or clock/

timer.

To turn off the domestic hot water select

and diagram 11.4).

For holiday mode, refer to section 11.8.

To turn off the boiler for servicing, isolate it from the electrical

supply. To turn it on again follow the instructions given in ‘To

Operate the Boiler’.

(see section 11.8

Maintenance and Servicing

If this appliance is installed in a rented property there is a duty

of care imposed on the owner of the property by the current

issue of the Gas Safety (Installation and Use) Regulations,

Section 35.

Servicing/maintenance should be carried out by a competent

person in accordance with the rules in force in the countries of

destination.

To obtain service, please call your installer or Heatcall (Glowworm’s own service organisation) using the telephone number

on the back cover of this booklet.

Please be advised that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning and servicing.

All CORGI Registered Installers carry a CORGI ID card, and

have a registration number. Both should be recorded in your

boiler Logbook. You can check your installer is CORGI registered

by calling CORGI direct on :- 01256 372300.

Clearances

If the boiler is fitted into a compartment or cupboard do not use

the compartment or cupboard for storage.

If the mains electricity and gas are to be turned off for any long

periods during severe weather, it is recommended that the

whole system, including the combination boiler, should be

drained to avoid the risk of freezing.

If in doubt, contact you installation/servicing company for advice.

As a safety feature the boiler will stop working if the condensate

drain becomes blocked. The display will repeatedly flash ‘

‘8*’. During freezing conditions this may be due to the

then

forming of ice in the condense drain external to the house.

Release an ice blockage by the use of warm cloths on the pipe.

Press the reset button to restart the boiler. Contact your

installation / servicing company if the fault persists.

0’

Draining and Filling

CAUTION: This boiler works in a pressurised system which

must only be drained, refilled and pressurised by a competent

person.

NOTE: If the pressure gauge indicates a loss of system

pressure, i.e. less than 0.7bar, the appliance will shut down

showing flashing:

CONTACT YOUR INSTALLER.

‘1’ then ‘2*’ on the display. YOU MUST

Pressure Relief Safety Valve

CAUTION: A pressure relief safety valve and discharge pipe is

fitted to the boiler. This valve must not be touched. Should there

be any discharge from the pipe, isolate the boiler electrical

supply and contact your installation/servicing company.

Cleaning

WARNING: This appliance contains metal parts and care

should be taken when handling and cleaning with particular

regard to edges.

The boiler casing can be cleaned using a mild liquid detergent

with a damp cloth, then a dry cloth to polish.

Do not use any form of abrasive or solvent cleaner as you may

damage the paint work.

Boiler Casing

CAUTION. Do not remove or adjust the casing in any way, as

incorrect fitting may result in incorrect operation or failure to

operate at all. If in doubt seek advice from the local gas

company or your installation/servicing company.

Replacement Parts

If replacement parts are required apply to your local supplier or

British Gas.

Please quote the name of the appliance.

Condensation Pluming

Like all condensing boilers this appliance will produce a plume

of condensation from the flue terminal in cool weather. This is

due to the high effiency and hence low flue gas temperature of

the boiler.

Protection Against Freezing

The boiler has a built in frost protection programme as long as

the electricity and gas are left switched on.

This device only protects the boiler. Any other exposed areas

of the system should be protected.

221564F

4

Clock Setting

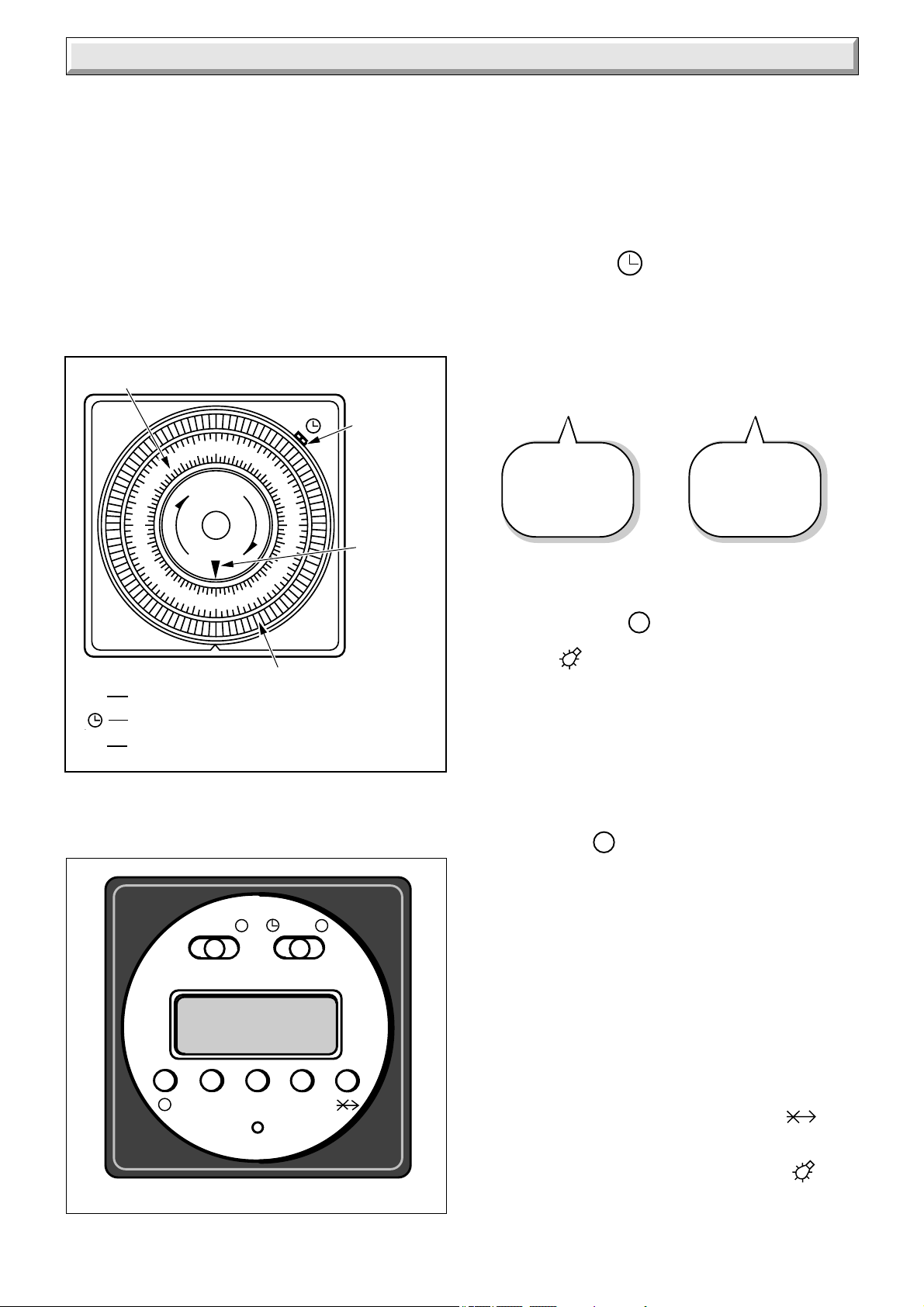

Setting Instructions for Electro/mechanical

Clock - if fitted

Refer to diagram 2.

This clock has a twenty four hour dial, i.e. 1pm is '13'.

To set the time, turn the whole face clockwise until the pointer

is against the time of day.

To set any “Off” time, push the tappets outwards.

To set any “On” time, push the tappets inwards.

Time can be set either “On” or “Off” in fifteen minute segments.

Note. The clock supplied is fitted with an override device, which

switches the clock programme “On” or “Off” permanently.The

switch will need to be repositioned to resume programmed

working.

CLOCK FACE

0

12

11

13

14

15

16

17

18

19

20

21

22

10

9

8

7

6

5

4

3

2

1

23

24

OVERRIDE

SWITCH

I

POINTER

TAPPETS

0

CONSTANT OFF

PROGRAMMED

I

CONSTANT ON

Diagram 2

Setting Instructions for the 7 Day Digital

Clock/Timer - if fitted

Refer to diagram 3.

5673

P

AUTO

I

MT

WTh

P

DAY HR MIN

RUN

FS

R

Su

This is a 24 hour clock/timer, that is 1pm is '13:00', and has 8

“ON” and 8 “OFF” daily switching actions.

It is fitted with a lithium battery back up which protects the

programme in the event of an electrical failure. The battery

should have a life of several years.

Setting the Clock

1. With both AUTO and RUN switches set to the central

position, press R reset button, the display will flash.

2. Set RUN switch to .

3. Set day of week by pressing button DAY.

4. Set time of day by pressing buttons HR and MIN.

5. Set RUN switch to the central position, colon will flash, this

indicates the clock is set.

With the clock set, the factory preset programme shown below

will operate.

4956

MON/FRI

ON - 06:30

OFF - 08:30

ON - 16:30

OFF - 22:30

SAT/SUN

ON - 07:00

OFF - 09:00

ON - 16:00

OFF - 23:00

Setting Timed Programmes

With the clock set to the correct time, see SETTING THE

CLOCK paragraphs 1-4, and then continue as follows:

1. Set RUN switch to P , the display will

indicate the 1st (ON) preset programme and the

symbol

2. Set day of week to be programmed by pressing the

DAY button.

Note. The days can be selected individually or

as groups:

Mon-Fri., Mon-Sat., Mon-Sun., Sat/Sun.

An arrow will be displayed under the day or

days selected.

3. Set time of day by pressing the buttons

HR and MIN.

4. Press button P to confirm programmes, the

display will indicate the 2nd (OFF) preset

programme and subsequently, 3rd, 4th, 5th, 6th.

7th, 8th to 16th.

5. Repeat procedures 2, 3 and 4 until desired

programmes are set.

Note. It is not a requirement to use all of the 8 on

and 8 off programmes.

6. Set the RUN switch the central position, your

appliance will now operate at the programmed times.

General Notes.

With the AUTO switch in the I position the central heating will

operated constantly ON.

With the AUTO switch in the O position the central heating will

not operate.

Soft Override button indicated by the symbol

function will override the current central heating programme for

the next available.

ON time programmes are indicated by the symbol

.

, this

.

Diagram 3

5 221564F

145

1 General Information

373

208

520

6513

101

CONDENSATE

DRAIN

Condensate Drain

Connection

INSIDE WALL

FIXING FACE

145

SPIGOT

145

1.1 Installation

Where no British Standards exists, materials and equipment

should be fit for their purpose and of suitable quality and

workmanship.

WARNING: When installing the appliance, care should be taken

to avoid any possibility of personal injury when handling sheet

metal parts.

The installation of this boiler must be carried out by a competent

person in accordance the rules in force in the countries of

destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

1.2 Gas Supply

This boiler is for use only on G20 gas.

The gas installation must be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion, test the gas installation for soundness using the

pressure drop method and suitable leak detection fluid, purge in

accordance with the above standard.

1.3 Data Label

The data label is on the base panel inside the appliance.

1.4 Electrical Supply

WARNING: The boiler must be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

The boiler must be connected to a permanent 230V ac, 50Hz

supply.

Connection of the whole electrical system of the boiler, including

any heating controls, to the electrical supply must be through

one common isolator.

118

33

(ES80)890

(ES100)985

C

L

BOILER

REFER TO THE WALL TEMPLATE

FOR PIPE DIMENSIONS

Diagram 1.1

Isolation should be by a double pole switched fused spur box,

with a minimum gap of 3mm for both poles. The fused spur box

should be readily accessible and preferably adjacent to the

appliance. It should be identified as to its use.

Alternatively connection can be made through an unswitched

shuttered socket and 3A fused 3 pin plug.

The mains supply cable and other cables connected to the

boiler must be the PVC flexible type of at least 0.75mm

0.20mm).

The colours of three core flexible cable are, blue - neutral,

brown - live, green and yellow - earth.

The wire coloured blue must be connected to the terminal

marked “N” or “Black”.

The wire coloured brown must be connected to the terminal

marked “L” or “Red”.

The wire coloured green and yellow must be connected to the

terminal marked “E” or “Green” or the earth symbol

2

.

1.5 Condensate

Being a condensing boiler, a condense drain MUST be fitted.

Condensate should, if possible, be discharged into the internal

household draining system, i.e. sink or washing machine drain.

If this is not practical, discharge can be made externally into the

household drainage system or a purpose designed soak away.

It is recommended that any external condensate drain pipe is

insulated and preferably of larger diameter to prevent it freezing

up in adverse weather conditions.

The condensate drain pipe should be checked during servicing

and any debris removed.

Refer to the British Gas Publication “Guidance Note For The

Installation of Domestic Condensing Boilers” for further

information.

(24/

221564F

6

1 General Information

TABLE 1 C.H. Max D.H.W.Max MIN

6499

NOMINAL kW 80 27.5 27.5 8.0

HEAT Btu/h 93,830 93,830 27,266

INPUT kW

GROSS Btu/h 110,890 110,890 34,802

NOMINAL kW 80 24.5 24.5 6.8

HEAT Btu/h 83,600 83,600 23,200

OUTPUT kW

Btu/h 98,266 98,266 30,367

COND. kW 80 25.5 25.5 7.7

HEAT Btu/h 87,000 87,000 26,170

OUTPUT kW

Btu/h 104,066 104,066 33,438

100

32.5 32.5 10.2

100

28.8 28.8 8.9

100

30.5 30.5 9.8

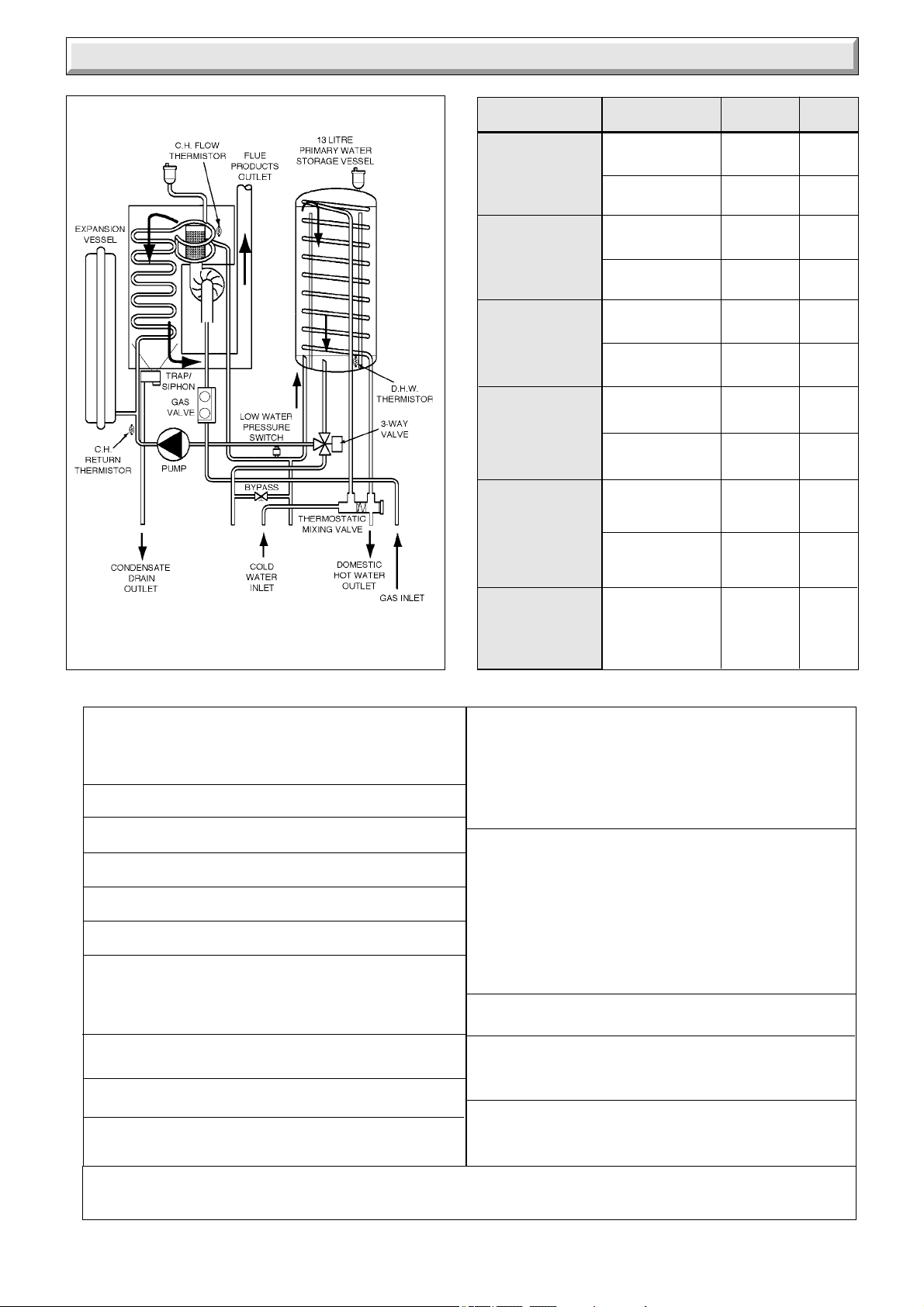

SCHEMATIC LAYOUT OF BOILER

Diagram 1.2

TABLE 2

80 100

Lift Weight 72kg (158.7lb) 77kg (169.7lb)

Total Weight (packed) 76kg (167.5lb) 81kg (178.6lb)

Total Weight (installed) 94kg (207.2lb) 99kg (218.3lb)

● Gas connection Rc1/2 (1/2in BSPT)

● Heating and return 22mm compression

● Domestic hot water 15mm compression

Safety valve Preset 3bar (43.5lbf/in

Safety valve discharge 15mm copper

80 100

Water content (heat exch) 2.7 ltr (0.59 gall) 4 ltr (0.88 gall)

Water content (primary store) 13 ltr (2.86 gall) 12.4 ltr (2.7 gall)

Water content (domestic) 1.3 ltr (0.29 gall) 2 ltr (0.44 gall)

2

)

BURNER

MANIFOLD

SUCTION

PRESSURE

HOT(APPROX)

BURNER

%CO

mbar

wg

80

mbar

-4.5 -4.5 -0.5

-1.8 -1.8 -0.2

100

-4.8 -4.8 -0.5

wg -1.92 -1.92 -0.2

CASING

DOOR ON

CASING

DOOR OFF

CASING

2

DOOR ON

CASING

DOOR OFF

80

9.2-9.6 9.2-9.6 9.2-9.6

9.0-9.4 9.0-9.4 9.0-9.4

100

9.2-9.6 9.2-9.6 9.2-9.6

9.0-9.4 9.0-9.4 9.0-9.4

m3/h 80 2.6 2.6 0.7

ft3/h 91.8 91.8 24.7

APPROX.

GAS RATE

m3/h

100

2.9 2.9 0.9

ft3/h 102.4 102.4 31.8

Domestic hot water flow rate

80 100

temp rise 300C 11.4l/min (2.5gall/min) 13.3l/min (2.9gall/min)

350C 9.8l/min (2.2gall/min) 11.4l/min (2.5gall/min)

Maximum flow temperature 650C

Minimum working pressure 0.1bar

■ Maximum heating 130 litres

system water (28.6 gallons)

0

content using at 75

C

fitted expansion average system

vessel, pressurised temperature

at 1bar.

Electrical supply 230V~50Hz

■ Expansion vessel capacity 7 litres (1.54 gallons)

Charge pressure 0.5bar (7.3lbf/in

Heating system 0.7bar (10.1lbf/in

2

)

2

)

minimum pressure

D.H.W Max. 8bar

working pressure (150lbf/in2)

Electrical rating 115W fused 3A

IP classification IP40

Internal Fuse rating 1) Type 2AF

2) Type 2AF

3) Type 3AT

● Ball valves are fitted in water and gas connections, plus a drain point on all water connections.

■ For larger systems use an additional expansion vessel.

7 221564F

2 Boiler Position

2.1 Location

The boiler is not suitable for fitting outdoors.

Any electrical switch or boiler control using mains electricity

must be positioned so that it cannot be touched by a person

using a bath or shower.

The boiler must be mounted on a flat wall which is sufficiently

robust to take its weight, refer to Table 2.

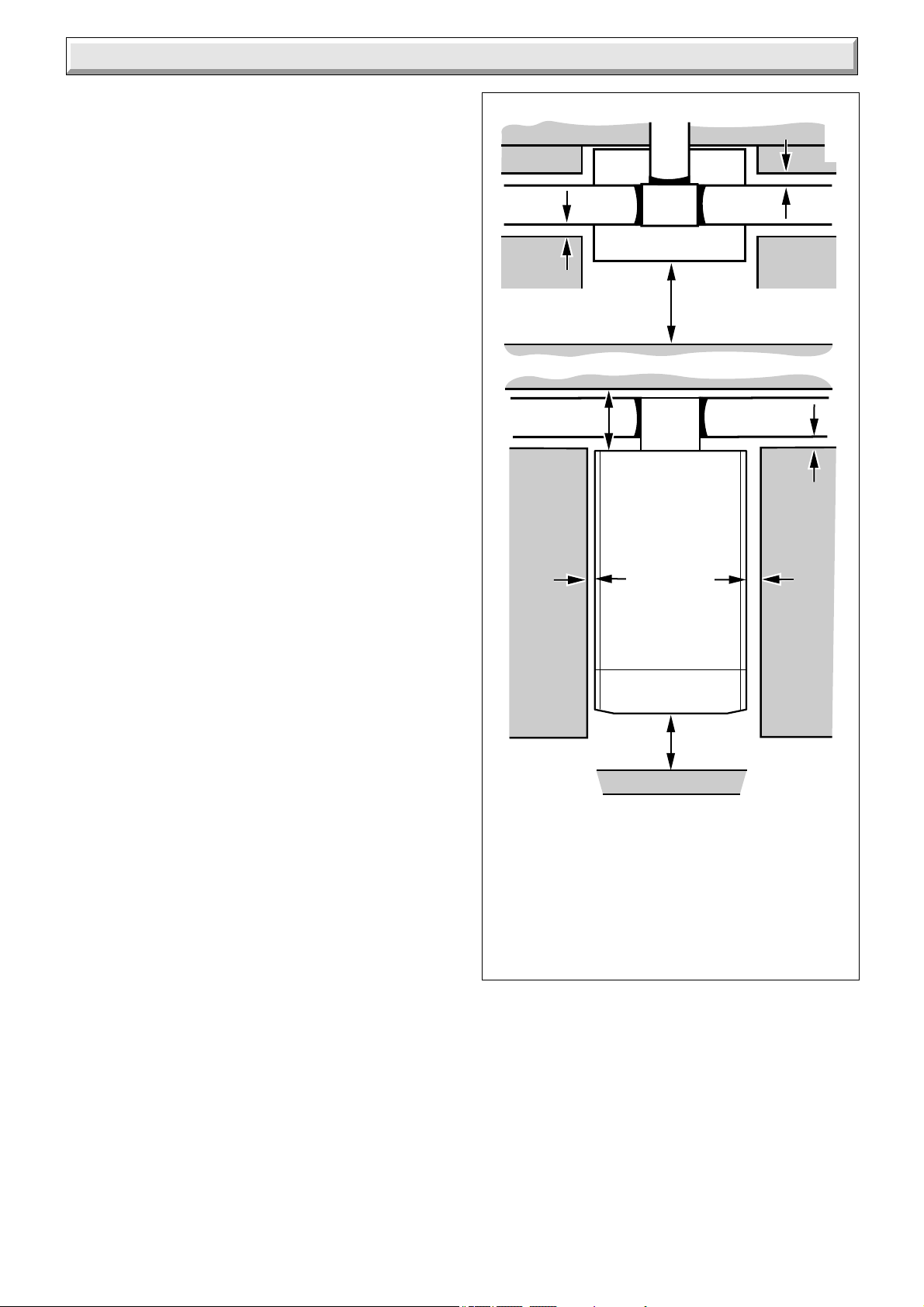

2.2 Clearances

The boiler should be positioned so that at least the minimum

operational and servicing clearances are provided, see diagram

2.1.

Additional clearances may be beneficial around the boiler for

installation.

For flue installations where external access is not practicable,

consideration should be given for the space required to insert

the flue internally which may necessitate clearance larger than

those specified in diagram 2.1.

6498

5

5

*

† 600

200

*

5

*

5

Increase to 25mm clearance from

combustible material.

*

† A removable compartment door can be

placed at least 5mm in front of the appliance.

Dimensions in millimetres

MINIMUM CLEARANCE FROM

PERMANENT SURFACES

25

200

Diagram 2.1

221564F

8

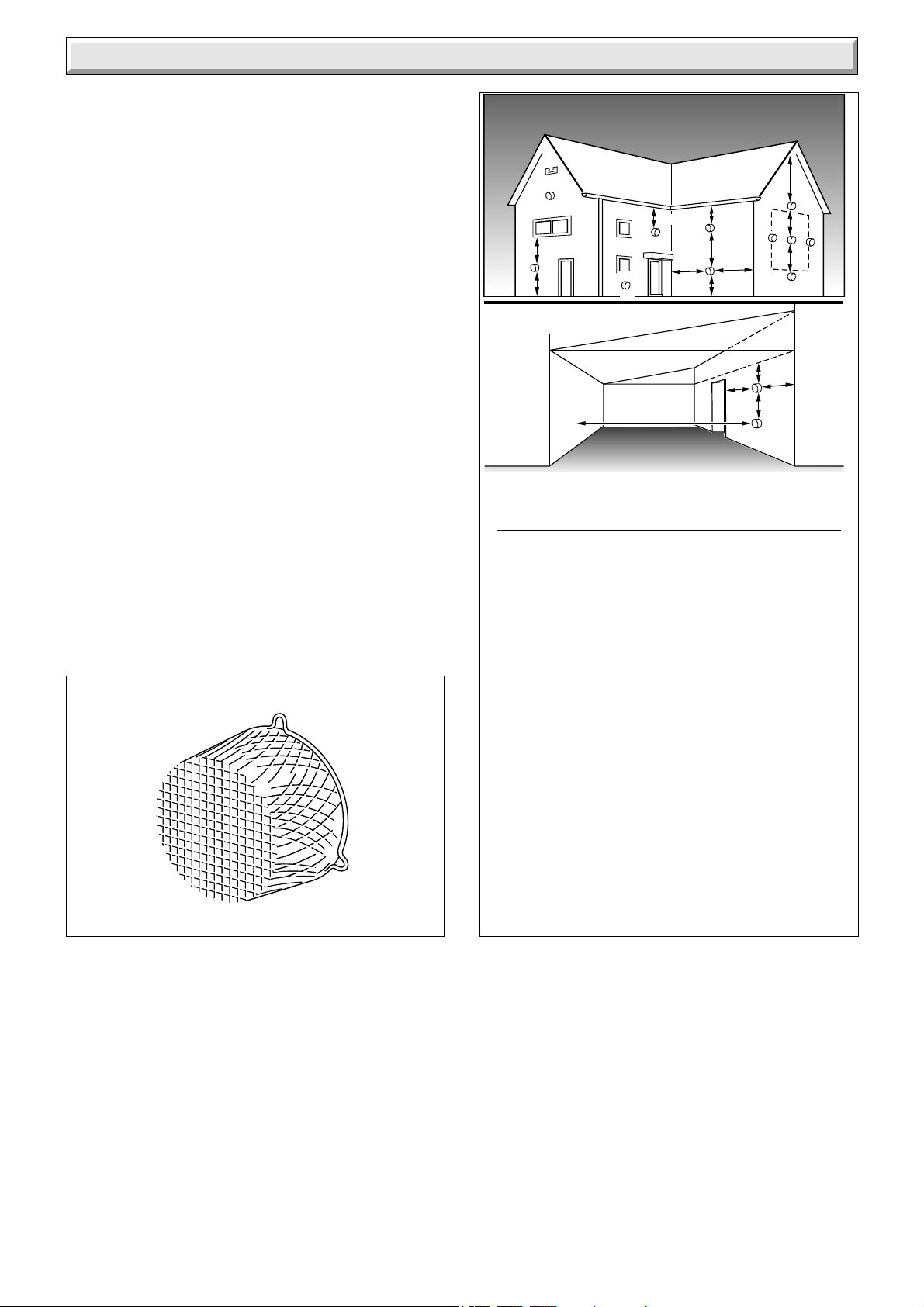

3 Flue Location and Ventilation

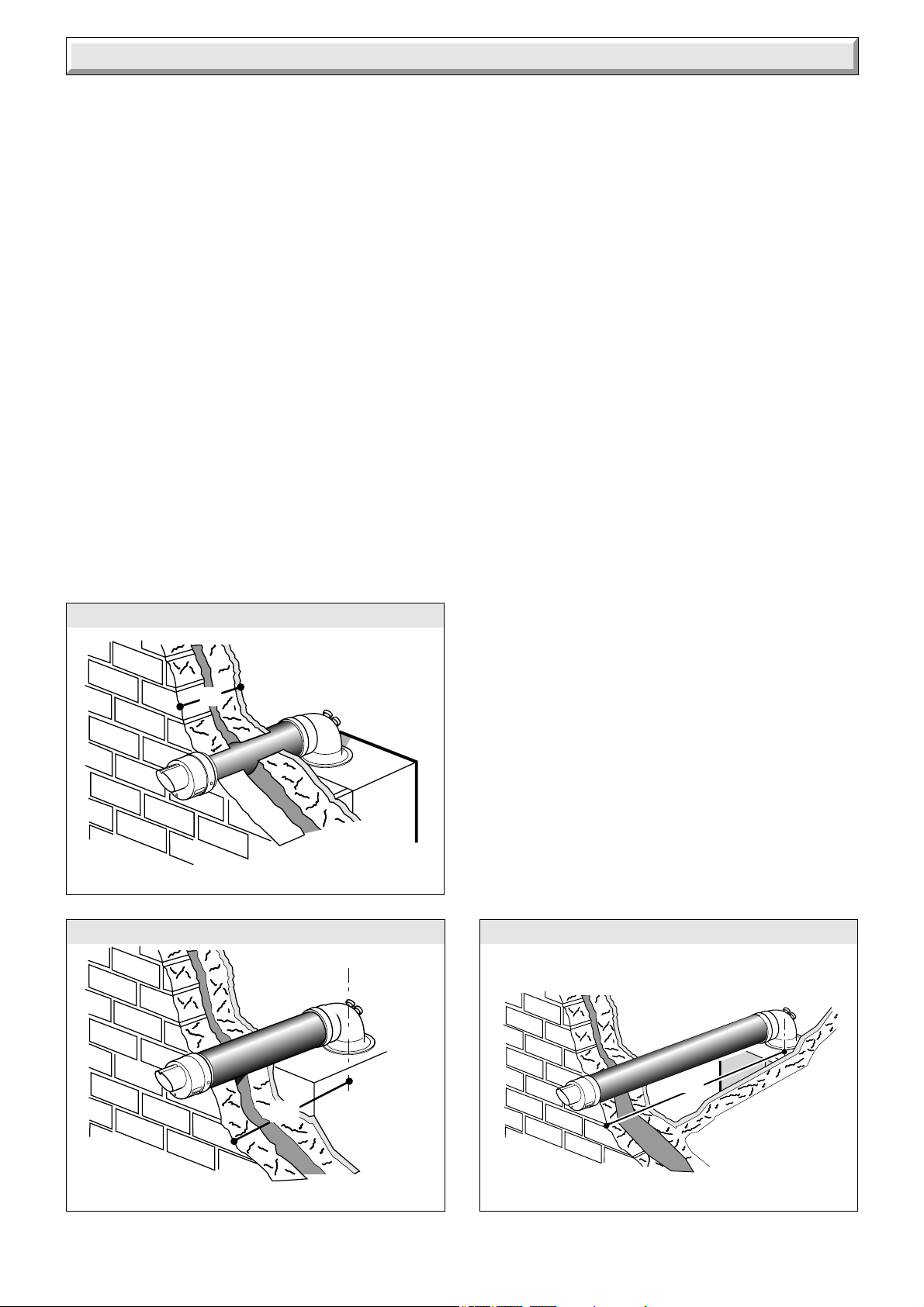

3.1 Flue Position and Length

There are several flueing options available for the Energysaver

Combi, e.g. horizontal, vertical and twin flue.

The standard horizontal flue is fitted onto the top of the boiler

using the flue elbow.

See diagrams 3.1 to 3.3 to determine whether a standard flue

can be used.

The standard flue can be extended using 1m long extension kits

and 90° elbows. A maximum of 3500mm of extension pipes plus

3x90° bends can be added to the standard horizontal flue

length.

NOTE: When extension pipes are used the flue system must be

designed to have a continuous fall to the boiler of at least 2.5°

to facilitate the removal of condensate.

3.2 Internal Flue Installation

The flue can be installed from inside the building, when access

to the outside wall face is not practicable.

3.3 Terminal Position

The minimum acceptable siting dimensions for the terminal

from obstructions, other terminals and ventilation openings are

shown in diagram 3.4.

The terminal must be exposed to the external air, allowing free

passage of air across it at all times.

Being a condensing boiler some pluming may occur from the

flue outlet. This should be taken into consideration when

selecting the position for the terminal.

Car ports or similar extensions of a roof only, or a roof and one

wall, require special consideration with respect to any openings,

doors, vents or windows under the roof. Care is required to

protect the roof if made of plastic sheeting. If the car port

comprises of a roof and two or more walls, seek advice from the

local gas supply company before installing the boiler.

If the terminal is fitted less than 600mm below plastic guttering

or less than 450mm below painted eaves or a painted gutter, an

aluminium shield 750mm long should be fitted immediately

beneath the guttering or eaves.

WALL THICKNESS 'X' = 75 TO 554mm

"X"

REAR FLUE - STANDARD

DISTANCE 'Y' = 307 TO 755mm

Diagram 3.1

6501

6502

DISTANCE 'Y' = 393 TO 755mm

6503

"Y"

SIDE FLUE - STANDARD Left

Diagram 3.2

"Y"

SIDE FLUE - STANDARD Right

9 221564F

Diagram 3.3

3 Flue Location and Ventilation

A

A

F

G

E

A

G

G

G

B,C

B,C

F

F

K

K

K

C

G

L

L

UNDER CAR PORT etc.

H,I

J

D

F

K

3.4 Terminal Guard

A terminal guard is required if persons could come into contact

with the terminal or the terminal could be subject to damage.

If a terminal guard is required, it must be positioned to provide

minimum of 50mm clearance from any part of the terminal and

be central over the terminal.

The guard should be similar to that shown in diagram 3.5.

A suitable guard can be obtained from.

Tower Flue Components

Morley Rd.

Tonbridge

Kent

TN9 1RA.

Their Reference CGD K3 BL.

3.5 Timber Frame Buildings

If the boiler is to be installed in a timber frame building it should

be fitted in accordance with the Institute of Gas Engineers

document IGE/UP/7/1998. If in doubt seek advice from the local

gas undertaking or Hepworth Heating Ltd.

3.6 Room Ventilation

The boiler is room sealed, so when it is installed in a room or

space, a permanent air vent is not required.

3.7 Cupboard or Compartment Ventilation

Due to the high efficiency and hence low casing temperature of

this boiler, cupboard or compartment ventilation is not necessary.

TERMINAL GUARD

Diagram 3.5

M

2816

MINIMUM SITING DIMENSIONS FOR

FANNED FLUE TERMINALS

POSITION

MM

A DIRECTLY BELOW AN OPENABLE

WINDOW, AIR VENT, OR ANY

OTHER VENTILATION OPENING 300

B BELOW GUTTER, DRAIN/SOIL PIPE 75

C BELOW EAVES 200

D BELOW A BALCONY OR CAR PORT 200

E FROM VERTICAL DRAIN PIPES AND

SOIL PIPES 75

F FROM INTERNAL CORNERS 300*

G ABOVE ADJACENT GROUND OR

BALCONY LEVEL 300

H FROM SURFACE FACING THE

TERMINAL 600*

I FACING TERMINALS 1200

J FROM OPENING (DOOR/WINDOW)

IN CAR PORT INTO DWELLING 1200

K VERTICAL FROM A TERMINAL 1500

L HORIZONTALLY FROM A TERMINAL 300

M FROM EXTERNAL CORNERS 300

Diagram 3.4

221564F

* It may be necessary to increase this dimension to prevent

staining of adjacent walls depending on weather conditions.

10

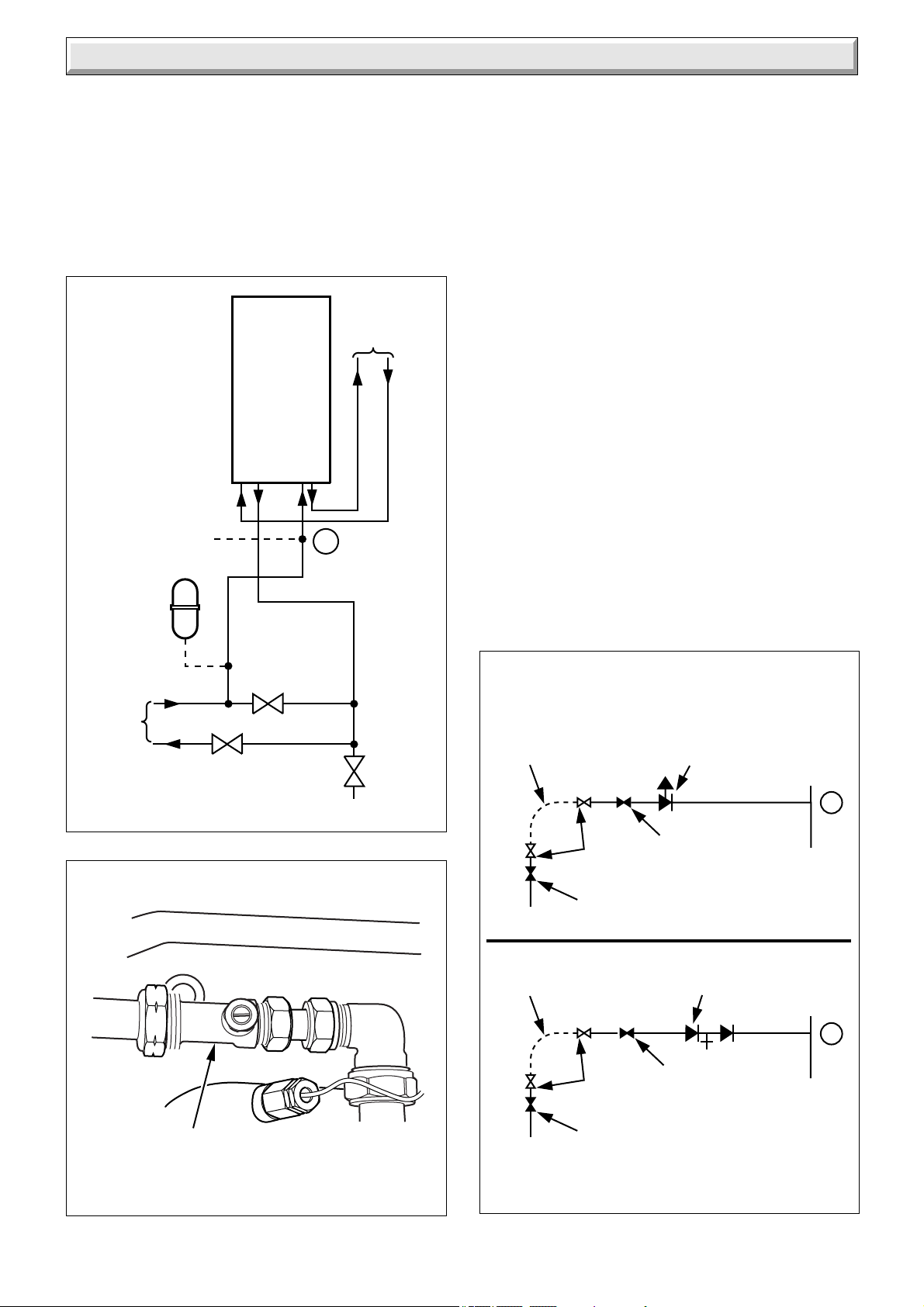

4 Heating System

4.1 General

The boiler is for use in sealed water systems only.

The safety valve is an integral part of the boiler and it cannot be

adjusted.

A pressure gauge is incorporated into the boiler to indicate the

system pressure.

The circulation pump is integral with the boiler, see diagram 4.1.

4.2 Expansion Vessel

The boiler has an integral expansion vessel with a capacity of

7 litres (1.54 gallons), with a charge pressure of 0.5bar.

The maximum heating system water content using the fitted

expansion vessel is 130 litres at an average temperature of

O

C, and charge pressure of 1.0bar.

75

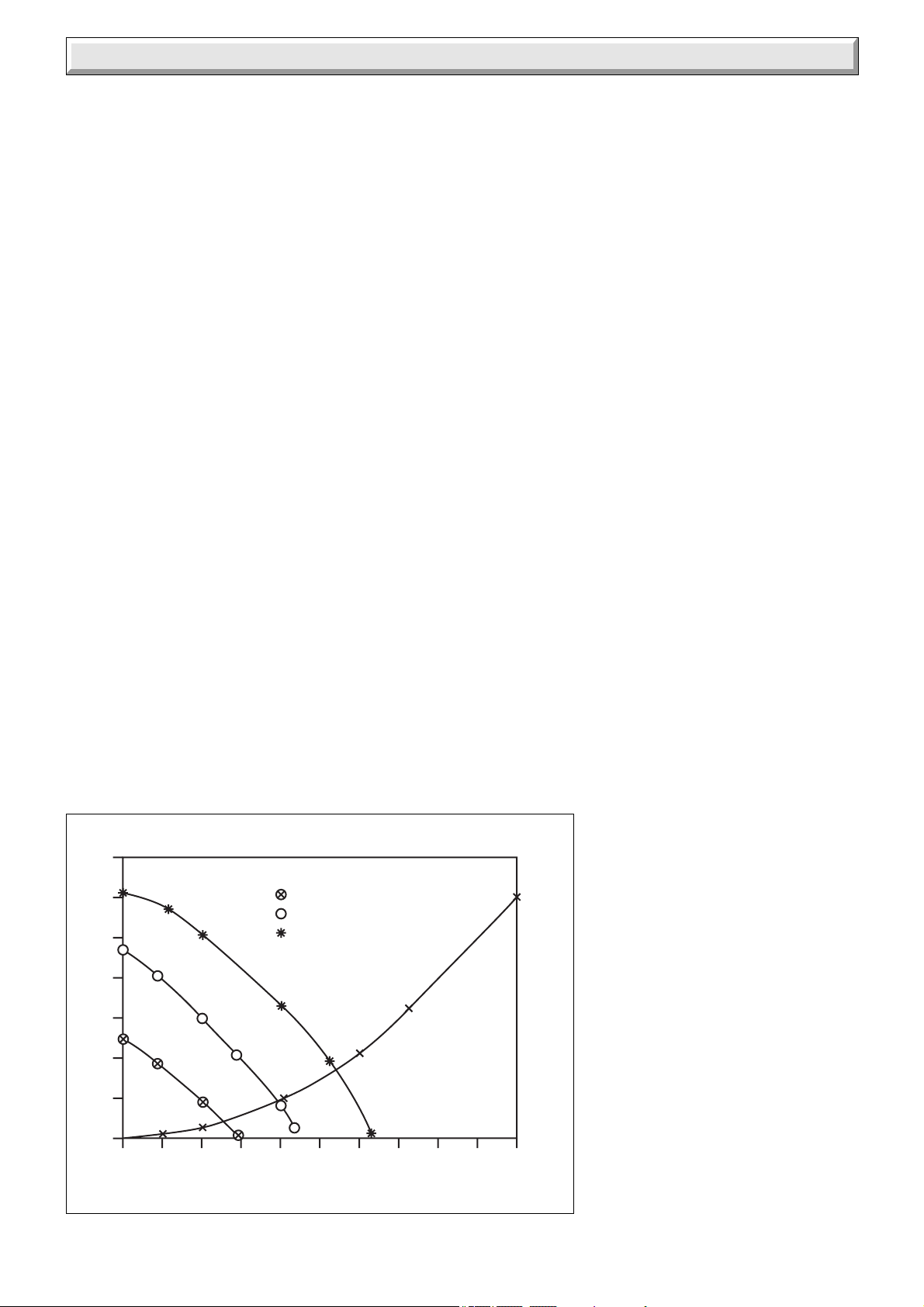

4.3 Flow Rate

The minimum flow rate through the boiler is 400 litres/hr for

ES80 and 470 litres/hr for ES100. This is equal to 20OC

differential at maximum heat input.

The system can be fitted with a lockable balancing valve if

necessary in the main flow or return pipes shown as valve "A"

in diagram 4.2.

4.4 Bypass

The boiler is fitted with a manual bypass, see diagram 4.3. This

valve may be adjusted by the installer if necessary to ensure at

least 400 litres/hr for ES80 and 470 litres/hr for ES100 flow

through the boiler. The boiler is supplied with the bypass open

by approximately half a turn and is closed by turning the white

screw clockwise. However for systems completely fitted with

thermostatic radiator valves or systems of high pressure loss an

additional bypass valve must be fitted to the heating circuit to

ensure that under no circumstances does the flow rate drop

below this level.

An additional bypass valve “B” is shown in diagram 4.2.

4.5 Filling Sealed Systems

Provision for filling the system at a low level must be made. Two

methods of filling are shown in diagram 4.4. There must be no

permanent connection to the mains water supply, even through

a non-return valve.

UPS 15-60 PUMP

7

AVAILABLE PUMP HEAD

6

5

= SETTING 1

= SETTING 2

= SETTING 3

4

3

METRES WG

2

BOILER PRESSURE LOSS CURVE

1

0

0 0.25 0.5 0.75 1.0 1.25 1.5 1.75 2.0 2.25 2.5

HEATING SYSTEM FLOW RATE X 1000 l/hr

11 221564F

6558

Diagram 4.1

4 Heating System

METHOD 1

METHOD 2

SUPPLY STOP

VALVE

SUPPLY

PIPE

HOSE

UNIONS

SERVICING

VALVE

TEMPORARY

HOSE

HEATING

SYSTEM

HEATING

SYSTEM

TEMPORARY

HOSE

HOSE

UNIONS

SERVICING

VALVE

SUPPLY

PIPE

SUPPLY STOP

VALVE

DOUBLE CHECK

VALVE ASSEMBLY

COMBINED

CHECK VALVE

AND VACUUM

BREAKER

C

C

4.6 Water Treatment

For optimum performance after installation, the boiler and its

associated central heating system should be flushed in

accordance with BS7593:1992 using a cleanser such as Sentinel

X300 or X400, or Fernox Superfloc.

For long term corrosion protection, after flushing, an inhibitor

suitable for aluminium heat exchangers should be used.

Examples are Sentinel X100 and Fernox Copal.

DOMESTIC

WATER

BOILER

HOT

COLD SUPPLY

OPTIONAL FILLING

ARRANGEMENTS,

SEE DIAGRAM 4.4

C

4.7 Draining Tap

A draining tap must be provided at the lowest points of the

system, which will allow the entire system to be drained.

The flow and return isolation valves are provided with drain

points for boiler heat exchanger drainage, see diagram 8.1.

7265

ADDITIONAL

EXPANSION

VESSEL

(if required)

HEATING

CIRCUIT

MANUAL

BYPASS

VALVE

OPTIONAL

BY-PASS

VALVE

RETURN

'A'

FLOW CONTROL

VALVE

'B'

DRAIN

POINT

Diagram 4.2

Diagram 4.3

7266

6597

Diagram 4.4

221564F

12

Loading...

Loading...