BA230

BA230 - (AS05550)

Apparecchiatura elettronica

ISTRUZIONI PER L’INSTALLAZIONE

Electronic control unit

INSTRUCTIONS FOR INSTALLATIONS

I UK F E

D P NL

GR

• Questo prodotto è stato collaudato in GI.BI.DI. verificando la perfetta corrispondenza delle

I

caratteristiche alle direttive vigenti.

• La GI.BI.DI. S.r.l. si riserva la facoltà di modificare i dati tecnici senza avviso, in funzione dell'evoluzione

del prodotto.

LEGGERE ATTENTAMENTE QUESTO MANUALE PRIMA DI PROCEDERE ALL’INSTALLAZIONE.

UK

• This product has been tested in Gi.Bi.Di. verifying the perfect correspondence of the characteristics to

the current directive.

• Gi.Bi.Di. S.r.l. reserves the right to modify the technical data without prior notice depending on the

product development.

PLEASE READ CAREFULLY THIS MANUAL BEFORE PROCEEDING WITH THE INSTALLATION.

F

• Ce produit a été essayé en Gi.Bi.Di. en vérifiant la correspondance parfaite des caractéristiques aux

règles en vigueur.

• Gi.Bi.Di. S.r.l. se réserve la faculté de modifier les données techniques sans aucun préavis suivant

l’évolution de ses produits.

S’IL VOUS PLAÎT DE LIRE AVEC ATTENTION CETTE MANUAL AVANT DE PROCÉDER AVEC L’INSTALATION.

• Este producto ha sido probado en Gi.Bi.Di. averiguando la perfecta correspondencia de las

E

características a las normas vigentes.

• La empresa Gi.Bi.Di. S.r.l. se reserva el derecho de modificar los datos técnicos sin previo aviso, en

función de la evolución del producto.

POR FAVOR LEER CON ATENCIÓN ESTE MANUAL ANTES DE PROCEDER CON LA INSTALACIÓN.

BA230

D

• Dieses Produkt wurde in Gi.Bi.Di. geprüft um die perfekte Entsprechung der merkmäle an die geltende

vorschriften zu prüfen.

• Gi.Bi.Di. S.r.l. behält sich das recht vor, die technischen daten der produktentwicklung entsprechend

ohne voranzeige abzuändern.

BITTE LESEN SIE VORSICHTIG DIESEN MANUAL BEVOR MIT DER ANGLAGE VORZUGEHEN.

P

• Este produto foi testado em Gi.Bi.Di. verificando a correspondência perfeita das características ao

normas vigentes.

• A Gi.Bi.Di. S.r.l. reserva-se o direito de modificar os dados técnicos sem pré-aviso em função de

evolução do produto.

LER COM ATENÇÃO ESTE MANUAL ANTES DE PROCEDER COM A INSTALAÇÃO.

NL

• Dit product werd gekeurd in Gi.Bi.Di. Er werd nauwlettend gecontroleerd of de kenmerken van het

product perfect overeenkomen met de geldige richtlijnen.

• Gi.Bi.Di. S.r.l. behoudt zich het recht voor de technische gegevens te wijzigen zonder waarschuwing

vooraf, als dat nodig is voor de evolutie van het product.

LEES DEZE GEBRUIKSAANWIJZING ZEER AANDACHTIG ALVORENS DE INSTALLATIE AAN TE VATTEN.

GR

• Η εταιρία GI.BI.DI. S.r.l. έχει ελέγξει αυτό το προιόν όσον αφορά την τέλεια προσαρμογή των

χαρακτηριστικών του στην ισχύουσα νομοθεσία.

• Η εταιρία Gi.Bi.Di. S.r.l διατηρεί το δικαίωμα αλλαγής των τεχνικών προδιαγραφών χωρίς

προειδοποίηση, όσον αφορά ανάπτυξη των προιόντων της.

LEES DEZE GEBRUIKSAANWIJZING ZEER AANDACHTIG ALVORENS DE INSTALLATIE AAN TE VATTEN.

BA230

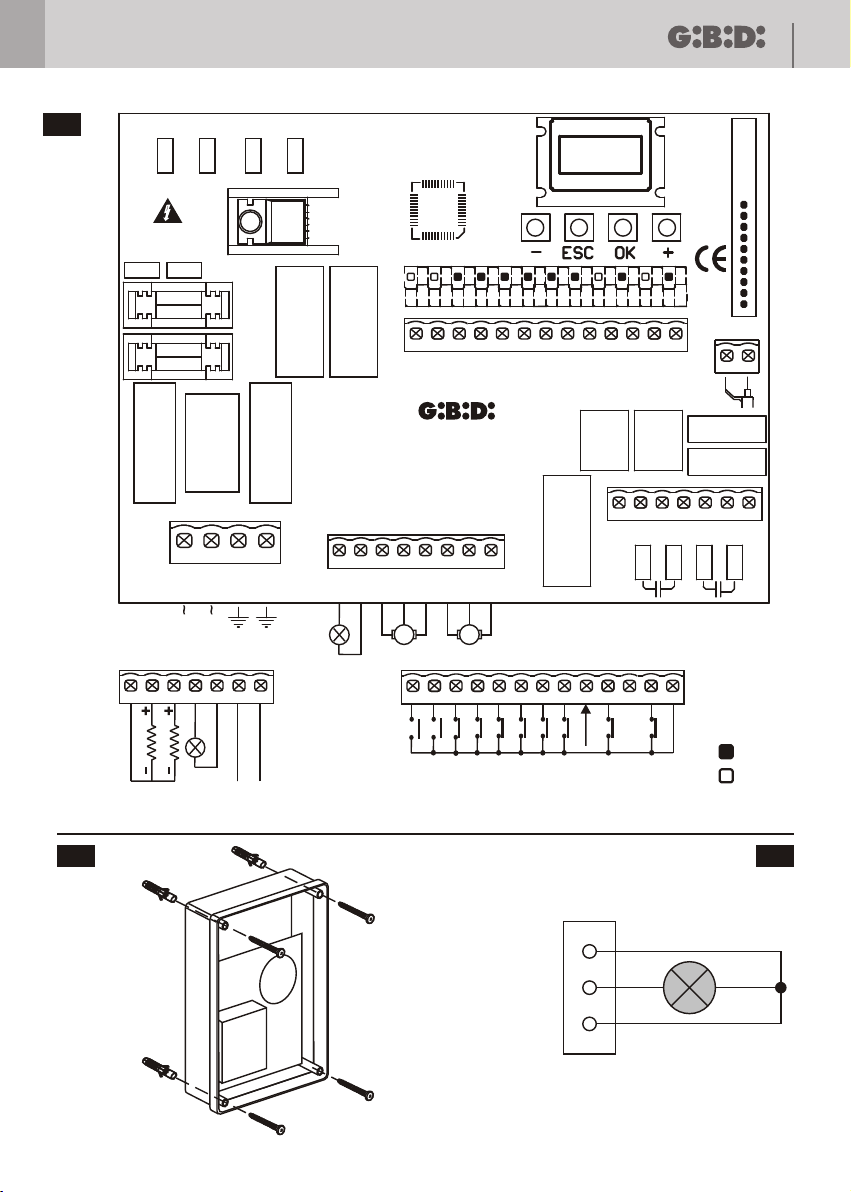

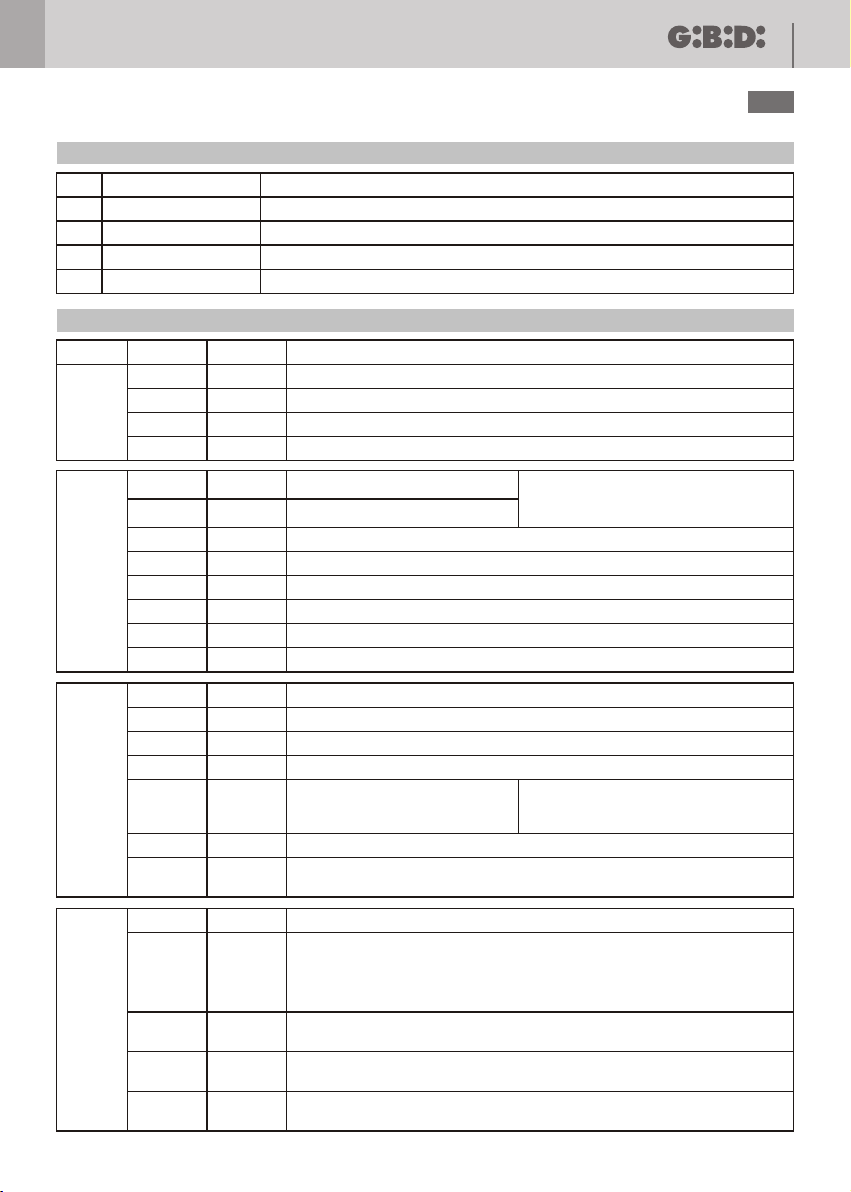

91

CF4 CF2 CF6 CF5

CF1 CF3

F2

F1

L1

C2

U2

RL1 RL2

C8

LCD1

U5

JP4

DL1

DL2

DL3

20 21 22 23 24 25 26 27 28 29 30 31 32

PED

STOP

START

SW1 SW2 SW3 SW4

DL4

DL5

DL6

DL7

FCA M1

FCC M1

FCA M2

FCC M2

PHOTO 2

DL8

DL9

DL10

DL11

COSTA

CCOSTA

RISERVA

BA230

G:B:D:021G1

RL4

RL5

RX

DL12

JP7

JP6

COM

PHOTO 1

33 34

GND

ANT

RL6

RL7

JP5

JP5

131415

JP1

1 2 3 4

PHASE

NEUTRAL

230 Vac

230 Vac

16 17

24Vdc 3W MAX

JP2

56789 10 11 12

MOTOR

LAMP

LAMP

MOTOR

EARTH

EARTH

CLOSE

CLOSE

MOTOR

OPEN

MOTOR

COM

MOTOR

OPEN

MOTOR

COM

M1

M2

JP4

19

18

20

21 222324

25 26

230Vac 40W MAX

PED (NO)

STOP (NC)

+24Vcc

+24Vcc

START (NO)

FCA M1 (NC)

FCA M2 (NC)

FCC M2 (NC)

FCC M1 (NC)

131415 16 17 18 19

RL3

27

PHOTO 2 (NC)

28 29

RISERVA

COM EL

COSTA (NC)

EL1

EL2

CF7

CF8

CM2 CM1

30 31 32

COM

CCOSTA (NO)

PHOTO 1 (NC)

GND

SPIA

CF9

SEC

24Vcc

CF10

LED STATUS

ON

OFF

992 993

12

11

10

BA230

23

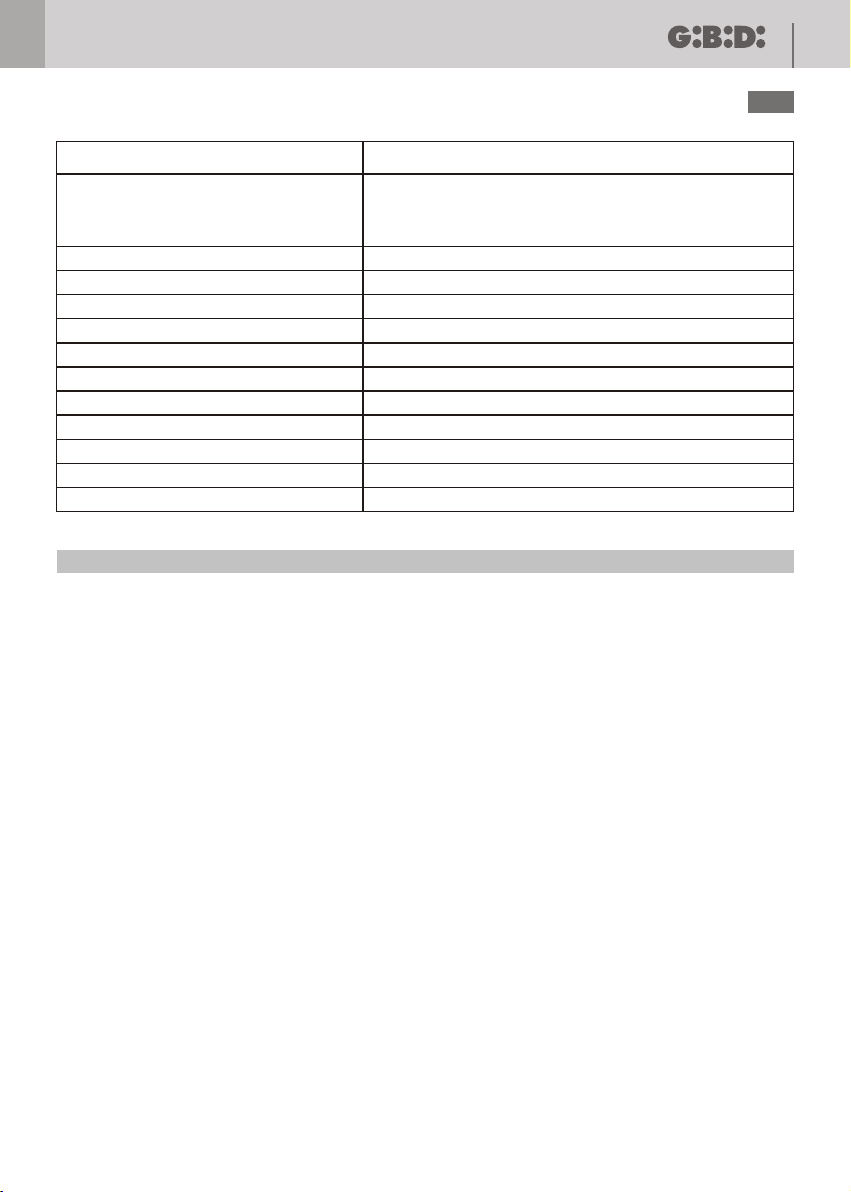

UK

Control unit

Type

Power supply

N° motors

Motor power supply

Flashing light

Warning light

Electric lock

Accessory power supply

Safety device power supply

Radio receiver

Operating temperature

Operating time

Electronic control unit for the automation

of one or two 230V motors for swinging and sliding gates,

24Vdc 8W max including safety devices power supply

24Vdc 8W max including accessories power supply

BA230 / AS05550

overhead doors and barriers

230Vac monophase 50/60 Hz

1 or 2

230Vac

230Vac 40W max

24Vdc 3W max

12Vdc 15W max

Plug-in

-20°C +60°C

300s max

TECHNICAL SPECIFICATIONS / FUNCTIONS

• Times self-learning.

• Red warning leds of n.c. contacts. There is not the safety devices led (ex. edge), the possible anomaly is

indicated by the writing SAF on the LCD.

• Green warning leds of n.o. contacts.

• Two independent 12Vdc electrical locks management.

• Management of courtesy light with 12 Vdc or 230 Vac output.

• Safety test run before the opening and closing movement.

• Photocell 1 test run before the opening and closing movement.

• Stop and motion inversion for 2 s after the intervention of the safety devices. At the next start pulse, the motion

restarts in the obstacle freeing direction.

• SEPARATE SAFETY DEVICES POWER SUPPLY. The connection to this power supply will allow the TEST of

the devices before the motion. Connect to this clamp the safety devices that will be supplied only during the o

perating cycle.

• Digital programming of all functions.

• Working time adjustable independently in opening and closing for each single motor.

• Deceleration time adjustable independently in opening and closing for each single motor in the motion final

phase (soft-stop).

• Gate phase shift time adjustable independently in opening and closing.

• Adjustable pedestrian working time.

• Adjustable and differentiated pause time for complete or pedestrian opening.

• Adjustable thrust force with 3 modalities on 10 levels for each motor.

• Selectable and independently adjustable decelerations with 3 modalities on 10 levels for each motor.

• Decelerations enabling with single or double limit switch.

• 4 possible working functions (step-by-step, step-by-step with stop, condominium or automatic, dead man).

• Possibility of choosing the system configuration from swing gate, overhead/barrier and sliding gate, single our

double.

• SAFETY DEVICE choice with N.C. contact or 8K2 resistive.

• Specific menu for the exclusion of the accessories not used (photocell 1, photocell 2 and safety devices).

24

BA230

UK

• Management of courtesy light with 12 Vdc or 230 Vac output.

• Possibility to program: automatic closing, fast closing, pre-flashing, hammer stroke, final closing and opening

stroke, courtesy light, ending movement additional time, flashing light (both flashing and fixed), external clock

management with three different modes, number of cycles for scheduled maintenance, installer code and

number of performed cycles.

INSTALLATION

Use glands adequate to ensure proper mechanical connection of cable and maintain the box protection degree IP55. (2)

INSTALLATION WARNINGS

• Before proceeding with the installation, fit a magnetothermal or differential switch with a maximum capacity of

10A upstream of the system. The switch must guarantee omnipolar separation of the contacts, with an opening

distance of at least 3 mm.

• To prevent possible interference, differentiate and always keep the power cables (minimum cross-section

1,5mm²) separate from the signal cables (minimum cross-section 0,5mm²).

• Make the connections referring to the following tables and to the attached screen-print. Be extremely careful to

connect in series all the devices that must be connected to the same N.C. (normally closed) input, and in

parallel all the devices that share the same N.O. (normally open) input. Incorrect installation or improper use of

the product may compromise system safety.

• Keep all the materials contained in the packaging away from children, since they pose a potential risk.

• The manufacturer declines all responsibility for improper functioning of the automated device if the original

components and accessories suitable for the specific automation are not used.

• At the end of the installation, always check carefully the proper functioning of the system and the devices used.

• This instruction manual addresses people qualified for the installation of “live equipment”. Therefore, good

technical knowledge and professional practice in compliance with the regulations in force are required.

• Maintenance must be carried out by qualified personnel.

• Before carrying out any cleaning or maintenance operation, disconnect the control unit from the mains.

• This control unit may only be used for the purpose for which it was designed.

• Use of the product for purposes different from the intended use has not been tested by the manufacturer,

therefore any work is carried out on full responsibility of the installer.

• Mark the automated gate with visible warning plates.

• Warn the user that children and animals may not play or stand around near the gate.

• Appropriately protect the dangerous points (for example, use a sensitive frame).

WARNINGS FOR THE USER

In the event of an operating fault or failure, cut the power upstream of the control unit and call the Technical

Service.

Periodically check the functioning of the safety devices. Any repairs must be carried out by specialised personnel

using original and certified materials.

The appliance is not to be used by children or people with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or instruction.

Do not touch the card for adjustments and/or maintenance.

WARNING: IMPORTANT SAFETY INSTRUCTIONS.

It is very important to follow the present instructions for your own safety.

Please keep this manual.

BA230

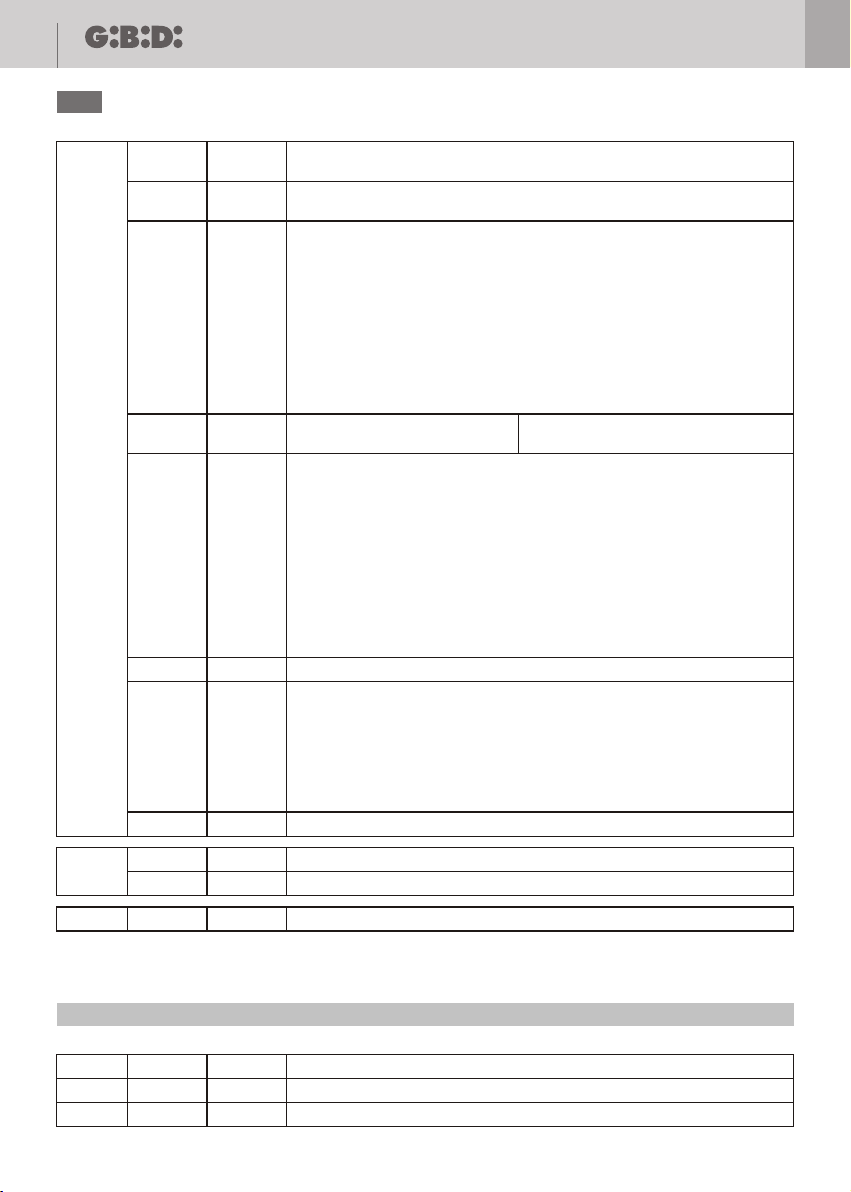

ELECTRICAL CONNECTIONS: FASTON

1

2

3

4

5

CF1 - CF3

CF2 - CF4

CF5 - CF6

CF7 - CF8

CF9 - CF10

ELECTRICAL CONNECTIONS: TERMINAL BOARDS

Morsetto

Posizione Segnale

JP1

JP2

JP5

1

2

3

4

5

6

7

8

9

10

11

12

13

15 EL2

16

17

18

19

Primary connection of 230Vac transformer (black cables)

Secondary connection of 14Vac transformer (red cables)

Secondary connection of 22Vac transformer (blue cables)

Motor 2 capacitor connection

Motor 1 capacitor connection

Descrizione

PHASE

NEUTR

LAMP

LAMP

OPEN

COM

CLOSE

OPEN

COM

CLOSE

COM

GND

SPIA

+ ACC

+ SAF

Power supply 230Vac

Power supply 230Vac

Ground wire connection

GND

Ground wire connection

GND

Flashing light output 230Vac 40W

Flashing light output 230 Vac 40W

Motor 1 connection 1 (opening)

Common motor 1

Motor 1 connection 1 (closing)

Motor 2 connection (opening)

Common motor 2

Motor 2 connection (closing)

Negative electrical lock

Positive +12 Vdc motor 1 electrical lock14

EL1

Positive +12 Vdc motor 2 electrical lock

Negative external accessories power supply

Warning light output +24 Vdc 3W max

External accessories (photocells, radio…) +24Vdc power supply

External safety devices +24Vdc power supply.

CAUTION: output present only during the operating cycle

UK

Operation:

Fast flashing during opening, off during pause,

slow flashing during closing

Operation:

Slow flashing during opening, fixed light during

pause, fast flashing during closing.

25

JP4

20

21

22

23

24

START

STOP

FCAM1

FCCM1

START (N.O.) input

PEDESTRIAN input (N.O.) (It opens for the time set in menu H10).

WARNING

PED

After an emergency intervention with motion intervention of the second leaf, the

pedestrian command will start both motors.

STOP input (N.C.).

If not used, jump with terminal n° 32

Limit switch input opens motor 1 (N.C.).

If not used, disable during the programming phase.

Limit switch input closes motor 1 (N.C.).

If not used, disable during the programming phase.

26

BA230

UK

JP4

JP6

JP7

25

26

27 PH2

28

29

30

31

32

33

34

FCAM2

FCCM2

RISERVA

COSTA

PH1

COM

GND

ANT

Limit switch input opens motor 2 (N.C.).

If not used, disable during the programming phase.

Limit switch input closes motor 2 (N.C.).

If not used, disable during the programming phase.

PHOTOCELL 2 input (N.C.).

If not used, disable during the programming phase.

Operation:

Input enabled during both opening and closing.

If intercepted, it stops the motion immediately and holds it stopped until the photocell is

freed. Upon release, motion always starts in opening.

If intercepted when the gate is closed, following a Start command it does not allow the

opening of the gate: this will be signalled with 5 fast flashes, then the warning light turns

on to indicate that the door is not in stand-by. Upon release, the gate will start opening

without further commands.

If intercepted during pause, it reloads the pause time.

Multitasking input

SAFETY DEVICES input (see menu C9)

If not used, disable during the programming phase.

Operation:

Input enabled during both opening and closing.

It stops and inverts the motion for 2 s. The gate will remain locked until the next Start

pulse, which will make it start in the obstacle-freeing direction.

If the input is enabled when the door is in stand-by, after a Start or a Pedestrian command

the door will not move and 3 long flashes (2 sec.) will signal the fault.

If the input is enabled when the door is in pause, the door does not close automatically (if

automatic closing is enabled) and 3 long flashes (2 sec.) will signal the fault.

THE EDGE ENABLING IS SIGNALLED BY THE WRITING “SAF” ON THE LCD.

Not used

PHOTOCELL 1 input (N.C.).

If not used, disable during the programming phase.

Operation:

Input enabled only during closing. It stops and inverts the motion, opening the gate

completely. If the gate is closed, it does not affect its functioning.

If intercepted during pause, it reloads pause time (if C2 disabled).

It can be enabled to manage FAST CLOSING.

COMMON INPUTS - OUTPUTS

ANTENNA BRAID input

ANTENNA SIGNAL input

Connector for plug-in radio receiver

External watch:

SEE PROGRAMMING C16-C17-C18

PROTECTION FUSES

Position Value Type

F1

F2

6 A

315 mA

FAST

FAST

Description

Motors and primary transformer protection

Low tension and accessories protection

BA230

UK

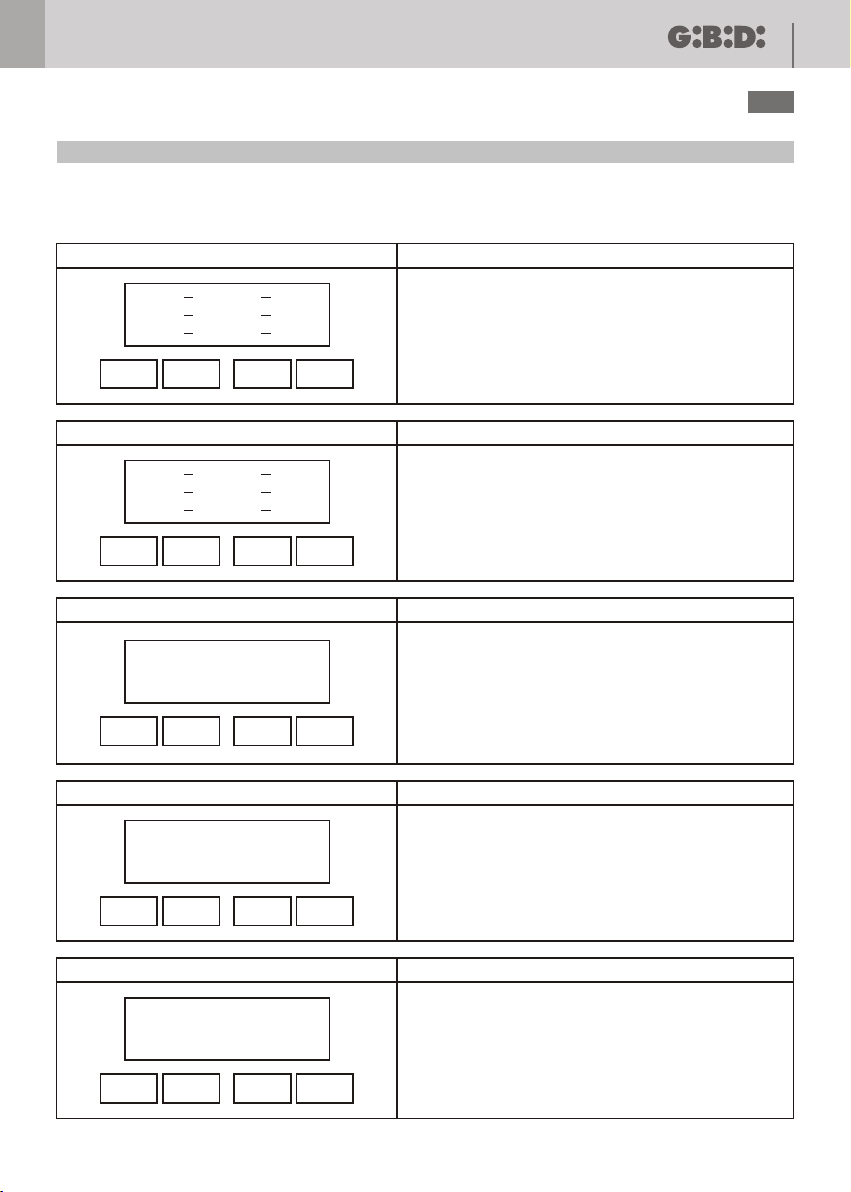

PROGRAMMING PROCEDURE AND SYSTEM CONFIGURATION

The system adjustments can be accessed via the display. There are 5 different menus marked with the letters A,

C, F , H and E.

1

To enter the programming procedure, start from the display as

Gbd

shown in the picture and press simultaneously the keys ESC and

OK for 3 s (The writing Gbd will turn off)

27

-

ESC

OK

PASS

-

ESC

OK

0 0 0 0

-

ESC

OK

4 0 0 0

-

ESC

OK

+

Go to step 2.

2

The writing P A S S appears on the display.

Press the OK key to go to step 3.

Pressing simultaneously the keys + and - for 3 s, all default settings

will be loaded (only the performed cycles settings remain stored).

Press the ESC key to go back to step 1.

+

33

4 figures appear on the display ( 0 0 0 0 ), the first one is flashing.

With the + or – keys, the user selects the first digit of the installer

code.

+

+

When the required digit is selected, presso OK to confirm and go to

step 4.

4

The second figure is flashing.

With the + or – keys, the user selects the second digit of the installer

code.

When the required digit is selected, press OK to confirm and go to

step 5.

5

The third digit is flashing.

4 6 0 0

-

ESC

OK

+

With the + or – keys, the user selects the third digit of the installer

code.

When the required digit is selected, press OK to confirm and go to

step 6.

28

UK

BA230

6

The last figure is flashing.

4 6 8 0

-

ESC

OK

+

4 6 8 3

With the + or – keys, the user selects the fourth digit of the installer

code.

When the required digit is selected, press OK to confirm and go to

step.

7

Now the installer code is complete: if it is correct, go to step 8.

If the installer code is incorrect, go back to step 2.

-

ESC

OK

PROGRAMMING EXAMPLE

MENU A

A C F H E

-

ESC

OK

A 5

-

ESC

OK

A 5

-

ESC

OK

+

8

The 5 main menus appear on the display (letters A C F H E), the A is

flashing.

Use the + or – keys to select the other menus (the relative letter will

blink).

+

Press OK to enter the selected menu (in the example, menu A).

9

Use the + or – keys to enter the submenus (A1, A2, A3, A4,…)

Y

Press OK to confirm the selected menu; a “Y” will appear next to the

menu to indicate that it is enabled.

+

10

With the + and – keys the other submenus are displayed; follow the

same procedure as above.

Press ESC to go back to the higher level (menu A, C, F, H E).

+

BA230

A C F H E

29

UK

11MENU C

When the 5 main menus are shown on the display (letters A C F H

E) and the letter C is blinking.

Press OK to enter the selected menu (in the example, menu C).

MENU H

-

ESC

OK

C 1

-

ESC

OK

A C F H E

-

ESC

OK

H 1

-

ESC

OK

0 1 0 0

+

12

Y

+

Use the + or – keys to select the various submenus.

Press OK in sequence to:

Enable the input (the Y will appear next to C1)

Disable the input (the N will appear next to C1)

13

Enter the H1 submenu to see the setting of a numeric value.

Use the + and – to select the menu H; it will blink.

Press OK to enter the menu.

+

14

Use the + or – keys to select the submenus.

Press key to enter the selected submenu.

+

15

The stored value appears, with the first digit blinking.

Use the + and – keys to modify the value of this digit.

Press OK to confirm and go to step 16.

-

ESC

OK

0 1 0 0

-

ESC

OK

+

16

The second digit blinks.

Use the + and – keys to modify the value of this digit.

Press OK to confirm and go to step 17.

+

30

UK

0 1 0 0

BA230

17

The third digit blinks.

Use the + and – keys to modify the value of this digit.

Press OK to confirm and go to step 18.

-

ESC

OK

0 1 5 0

-

ESC

OK

H 1

-

ESC

OK

A C F H E

-

ESC

OK

E 1 Y

-

ESC

OK

E 2 Y

-

ESC

OK

+

18

The fourth digit blinks.

Use the + and – keys to modify the value of this digit.

Press OK to confirm and go to step 19.

+

19

The H1 menu indication reappears.

Now press ESC to go back to the higher level.

+

20MENU E

Enter the submenu E to see the ENABLING/DISABLING setting.

Press OK to enter the menu.

+

21

E1 = PHOTOCELL 1

Press OK in sequence to:

Enable input (the Y will appear next to E1)

Disable the input (The N will appear next to E1)

+

+

Use the + and – keys to enter the following or the previous menu.

Press ESC to leave the menu; “ACFHE” is now shown on the display.

22

E2 = PHOTOCELL 2

Press OK in sequence to:

Enable the input (the Y will appear next to E2)

Disable the input (the N will appear next to E2)

Use the + and – keys to enter the following or the previous submenu.

Press ESC to leave the menu; “ACFHE” is now shown on the display.

BA230

-

E 3 Y

ESC

A C F H E

OK

31

UK

23

E3 = SAFETY DEVICE (EDGE)

Press OK in sequence to:

Enable the input (the Y will appear next to E3)

Disable the input (the N will appear next to E3)

+

Use the + and – keys to enter the following or the previous menu.

Press ESC to leave the menu; “ACFHE” is now shown on the display.

24

Press ESC to store the settings and leave the programming phase,

accessing normal operation.

-

ESC

OK

Gbd

-

ESC

OK

+

25

The starting symbols reappear on the LCD.

At this point, the +, - and OK keys mean:

+

+

OK

START

PEDONALE

STOP

MENU A: SYSTEM CONFIGURATION AND OPERATING LOGIC SELECTION

KEY + enters the following menu A1-A2-A3-…

KEY – enters the previous menu A3-A2-A1…

KEY ESC leaves the menu

KEY OK enables Y (yes). It enables the function and automatically disables the complementary function

(example; the activation of A4 = 1 motor automatically disables A5 = 2 motors)

DescriptionMenu Function

Status

A2

OVERHEAD DOOR / BARRIER

A3

A4

SLIDING GATE

1 MOTOR CONFIGURATION

SWING /

It configures the system for swing gate, overhead door or barrier.

Y

The activation of this menu automatically disables A3.

It configures the system for a sliding gate.

This configuration automatically excludes:

gate phase shifts in opening and closing

hammer stroke

2 s opening and closing final stroke

Y

T3 additional time

NOTE: the limit switches are NOT activated automatically, choose the

required configuration with menu C5

The activation of this menu automatically disables A2.

It configures the system for 1 motor.

In the menu C11 it will be possible to set the courtesy light output:

N = courtesy light disabled

Y1 = courtesy light on MOTOR 2 output (diagram output 230 Vac) (3)

Y

Y2 = courtesy light on ELECTRIC LOCK 2 output (see diagram 12 Vdc

output)

The courtesy light output is 3-minutes timed.

The activation of this menu automatically disables A5.

32

UK

A5

2 MOTORS CONFIGURATION

A6

A8

A9

STEP BY STEP

WITH STOP LOGIC

STEP BY STEP LOGICA7 Y

AUTOMATIC / CONDOMINIUM

DEAD MAN LOGIC

LOGIC

BA230

It configures the system for 2 motors.

In the menu C11 it will be possible to set the courtesy light

output: surrendering the electric lock 2

N = courtesy light disabled

Y1 = courtesy light disabled

Y

Y2 = courtesy light on ELECTRIC LOCK 2 output (see

diagram 12 Vdc output)

The courtesy light output is 3-minutes timed.

The activation of this menu automatically disables A4.

It enables the STEP BY STEP WITH STOP Logic

Operation:

Start

Next Start

Next Start

Next Start

Y

If automatic closing has been activated (menu C1) and the opening

phase is at the end of the cycle, when the pause time has elapsed

(menu H9), the control unit automatically closes the gate. During pause,

a Start command closes the gate.

Pedestrian command is uninfluential in opening and in pause. In closing

it opens both leaves.

The activation of this menu automatically disables A7-A8-A9.

It enables the STEP BY STEP Logic

Operation:

Start

Next Start

Next Start

If automatic closing has been activated (menu C1) and the opening

phase is at the end of the cycle, when the pause time has elapsed

(menu H9), the control unit automatically closes the gate. During the

pause, a Start command closes the gate.

Pedestrian command is uninfluential in opening and in pause. In closing

it opens both leaves.

The activation of this menu automatically disables A6-A8-A9.

It enables the AUTOMATIC/CONDOMINIUM Logic

Operation:

Start

Next Start(s) uninfluential if the system is opening or it

When the pause time has elapsed, if the automatic closing is enabled

Y

(menu C1), the system closes automatically. If the automatic closing is

disabled, Start closes the gate.

If the opening is pedestrian, a pedestrian command closes the gate.

Pedestrian is uninfluential in opening and in pause In closing it opens

both leaves.

The activation of this menu automatically disables A6-A7-A9.

It enables the DEAD MAN Logic

WARNING: 2 motors always operate

Operation:

Start

Y

Pedestrian

In Dead Man's mode the keys on the control unit mean:

Start (Key +)

Pedonale (Key -)

apre

open

stop

close

open

open

close

open

reloads the pause time (if the gate is in pause)

and the automatic closing is enabled.

closes only if the Pedestrian key is held down.

opens only if the Start key is held down.

open

close

BA230

The opening and closing movement in the dead man's mode stops

always on the first limit switch.

A9

DEAD MAN LOGIC

MENU C: FUNCTIONS SELECTIONS

KEY + enters the following menu C1-C2-C3-…

KEY – enters the previous menu C3-C2-C1…

KEY ESC leaves the menu

KEY OK enables Y (yes). It enables or selects the function

KEY OK enables N (no). It disables the function

AUTOMATIC CLOSINGC1

C2

C3

C4

FAST CLOSING

PRE-FLASHING

SAFETY DEVICES TEST

See also menu C20

The possible regulations are: PHASE SHIFT IN OPENING - PHASE

Y

SHIFT IN CLOSING.

The enabling of this menu automatically disables A6-A7-A8.

DescriptionMenu Function

Status

Enables automatic closing after both complete opening and pedestrian

YT

opening.

Enables only automatic closing after a complete opening.

If pedestrian opening is enabled, the pedestrian key will close the gate.

YS

Enables only automatic closing after a pedestrian opening.

YP

Disables automatic closing

If the pedestrian opening is enabled, the pedestrian key will close the

gate.

N

If complete opening is enabled, a Start command will close the gate and

the pedestrian key will be uninfluemtial.

Enables fast closing function

Operation:

Y

Enabled only on photocell 1.

Reduces pause time to 3 s following interception and subsequent

freeing of the photocells.

Disables fast closing function

N

Enables 3-second pre-flashing before motors start

Y

Disables pre-flashing. The flashing light and the motors start at the

N

same time.

Enables the safety devices test

When the device is enabled (edge intercepted), the writing SAF

appears on the LCD

Operation:

PHASE 1: when the Start or the Pedestrian command is given, the

electronic circuit is tested: relay, triac, etc.

If an anomaly is detected, it will be indicated by 4 long flashes (2 sec.) of

the flashing light. The test must be performed when the motors are

Y

connected.

If the control unit is set for one motor, the test will be performed only for

motor 1 circuit.

WARNING: During the test, the motors will be activated in opening and

closing for about 300 msec.

DUE TO THE MOTION, THE DOOR MAY CRASH AGAINST THE

MECHANICAL STOPS. CHECK THE SYSTEM SAFETY/INTEGRITY

AFTER THIS PHASE.

33

UK

34

UK

C4

C5

C6

C7

C8

SAFETY DEVICES TEST

See also menu C20

LIMIT SWITCHES

DECELERATIONS

WATER HAMMER

FINAL STROKE IN OPENING

AND CLOSING

The exclusion of SAFETY DEVICE by mean of the menu E3 excludes

the safety edge test.

PHASE 2: if the edge with N.C. contact is enabled, when the Start or

Pedestrian command is given, the power to the safety devices is cut off

for 0,5 s and then restored: : if the inputs of the safety devices open and

immediately return NC, the motors start, otherwise a fault is signalled

with 3 long flashes (2 sec.) of the flashing light.

Y

PHASE 3: if the 8K2 edge is enabled, when the Start or the Pedestrian

command is given the SAFETY DEV input is tested (value 8K2). If the

value is not correct, the fault is signalled with 2 long flashes (2 sec.) of

the flashing light.

The indication of the fault detected will be only one (the first one to be

detected), even if there is more than one fault.

Disables the safety devices test.

N

Enables the single limit switch reading.

E1

See the paragraph “USE OF THE LIMIT SWITCHES”

Enables the double limit switch reading.

E2

See the paragraph “USE OF THE LIMIT SWITCHES”

Disables the limit switch reading.

N

Enables the type 1 deceleration function.

Y1

Enables the type 2 deceleration function.

Y2

Enables the type 3 deceleration function.

Y3

Disables the deceleration function.

N

Enables the water hammer function to help the release of the electric

lock/s in OPENING

Operation:

After the Start command, the sequence is:

- Electrical locks enabling

Y1

- 1 s pulse in closing

- opening

- After 2 s, electrical locks release

Disabled with sliding configuration

Enables the water hammer function to help the electrical lock/s release

in OPENING and CLOSING

Operation:

After the Start command, the sequence is:

- Electrical locks enabling

Y2

- Motor pulse in the electrical lock freeing direction

- Motion direction in the required direction

- After 2 s, electrical locks release

Disabled with sliding configuration

Disables the water hammer function.

N

Enables the final stroke in opening and closing

Operation:

Y

At the end of the opening and closing time without decelerations, a 2 s

pulse with full power is given.

BA230

BA230

FINAL STROKE IN OPENING

C8

C9

C10

C11

C13

C14

C15

AND CLOSING

SAFETY DEVICE

DISABLED

COURTESY LIGHT

T3 ADDITIONAL TIME

INVERSION FROM PEDESTRIAN

FLASHING LIGHT

If decelerations are enabled, the pulse is given at the end of the

deceleration time.

Y

The final stroke is not managed by the safety devices.

Disabled with sliding configuration and with dead man logic

Disables the closing final stroke function.

N

Enables the edge with 8K2 in series resistance.

Runs the safety test on the 8K2 edge (check the correct resistive value)

8K2

if enabled with menu C4 – E3.

Enables the edge provided with n.c. contact (normally closed).

NC

Runs the safety test on the n.c. edge if enabled with menu C4 - E3.

Enables the courtesy light working on motor 2 output .

If the installation has 2 motors the courtesy light will not be active

Y1

COURTESY LIGHT 230 Vac (see diagram).

Timed 3 min after the motors motion end.

Enables the courtesy light working on electrical lock 2 output

COURTESY LIGHT 12 Vdc.

Y2

Timed 3 min after the motors motion end.

Disables the courtesy light.

N

T3 excluded.

N

Sets T3 as the time set for the deceleration with the same setting of

YF

menus F1 and F5.

Sets T3 as the time set for the deceleration with the same setting of

YS

menus F2 and F6.

During the PEDESTRIAN closing, the PHOTO1-PHOTO2-

Y

PEDESTRIAN command will determine only the pedestrian opening.

The START will cause complete opening.

During the PEDESTRIAN closing, the PHOTO1-PHOTO2-

N

PEDESTRIAN-START command will cause the complete opening.

Blinking flashing light output (slow blinking in opening, fast in closing).

Y

Flashing light fixed output.

N

Enables the RESERVE input for the connection of an external watch.

35

UK

C16

EXTERNAL WATCH,

CLOSING ALLOWED

Operation:

If the contact on the RESERVE input is closed, following a START

command the door opens but does not close automatically. When the

Y

contact closes, after the pause time the door will close automatically.

When the door is open, closing can be started with a START command if

the menu enabled is STEP-BY-STEP or STEP-BY-STEP WITH STOP.

CAUTION: remember to set automatic closing.

Disables the RESERVE input.

N

36

UK

C17

C18

C19

EXTERNAL WATCH,

CLOSING NOT ALLOWED

EXTERNAL WATCH

AUTOMATIC OPENING

AND CLOSING COMMAND

OLEODYNAMIC

BLOCK MAINTENANCE

BA230

Enables the RESERVE input for the connection of an external watch

Operation:

If the contact on the RESERVE input is closed, following a START

Y

command the door opens but does not close automatically. When the

contact closes, after the pause time the door will close automatically.

Closing cannot be started with a START command.

CAUTION: remember to set automatic closing.

Disables the RESERVE input.

N

Enables the RESERVE input for the connection of an external watch

Operation:

When the contact on the RESERVE input is closet, an automatic

opening command will be enabled (a START command is not required).

The door will open but will not close automatically. When the contact is

closed, tthe door will close automatically after the pause time.

Y

Closing cannot be enabled with START.

CAUTION: remember to set automatic closing.

Disabilita I'ingresso RISERVA.

N

Enables the oleodynamic block maintenance function ONLY FOR

OLEODYNAMIC OPERATORS

Operation:

If in the last 5 hours the gate has not performed a manoeuvre, a 2 s

pulse in closing is given.

Y

The enabling of the STOP key in any moment disables the function.

The function is automatically disabled with SLIDING - DEAD MAN

configuration

Disables the oleodynamic block maintenance

N

Enables photocell 1 test.

The photocell 1 transmitter must be connected to the clamps 16 and 19.

Operation:

When the “Start” or the “Pedestrian” command is given, the power to

Y

C20

C21

PHOTOCELL 1 TEST

AUTOMATIC PROGRAMMING

safety devices is cut off for 0,5 and then restored: if the photocell 1 input

opens and immediately returns NC the motors start, otherwise a fault will

be signalled by 4 blinks (1 sec.) of the flashing light.

Disables photocell 1 test 1.

N

Enables times programming in self-learning.

Operation:

Y

See “Times self-learning procedure”.

MENU F: FORCE AND SPEED ADJUSTMENTS

Menu Function

F1

MOTOR 1 FORCE

Description

Adjusts motor 1 thrust.

0001 = minimum force.

0010 =maximum force.

BA230

37

UK

F2

F5

F6

MOTOR 1 DECELERATION

SPEED 1

MOTOR 2 FORCE

MOTOR 2 DECELERATION

SPEED 2

Adjusts motor 1 thrust during deceleration phase.

0001 = minimum force.

0010 =maximum force.

Adjusts motor 2 thrust.

0001 = minimum force.

0010 =maximum force.

Adjusts motor 2 thrust during deceleration phase.

0001 = minimum force.

0010 =maximum force.

MENU H: TIMES ADJUSTMENTS AND SETTINGS

All times can be set in steps of 1 s.

Menu Function

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H11

H12

H13

H14

H15

MOTOR 1 OPENING TIME

MOTOR 1 CLOSING TIME

MOTOR 1

DECELERATION TIME

MOTOR 2 OPENING TIME

MOTOR 2 CLOSING TIME

MOTOR 2

DECELERATION TIME

LEAF 2 PHASE SHIFT TIME

IN OPENING

LEAF 1 PHASE SHIFT TIME

IN CLOSING

AUTOMATIC CLOSING

PAUSE TIME

PEDESTRIAN OPENING TIME

AUTOMATIC PEDESTRIAN

CLOSING PAUSE TIME

CYCLES NUMBER

INSTALLER CODE

SOFTWARE VERSION

NUMBER OF PERFORMED CYCLES

(*) time must be sufficient to reach the limit switches

Description

Leaf 1 opening time. (*) Tmax 300 s.

Leaf 1 closing time. (*) Tmax 300 s.

Leaf 1 operating time in deceleration mode. (*) Tmax 100 s.

Leaf 2 opening time. (*) Tmax 300 s.

Leaf 2 closing time. (*) Tmax 300 s.

Leaf 2 operating time in deceleration mode. (*) Tmax 100 s.

Delays the start in opening of leaf 2 with respect to leaf 1.

In the case of double sliding gate, the time H7 will not be considered.

Tmax 100 s.

Delays the start in closing of leaf 1 with respect to leaf 2. In the case of double sliding

gate, the time H8 will not be considered.

Tmax 100 s.

Determines the pause time in opening before the automatic closing.

Tmax 300 s.

Determines the pedestrian opening time. Tmax 300 s.

Determines the pause time in pedestrian opening before automatic closing.

Tmax 300 s.

Allows the setting of a number of cycles (opening + closing) before the maintenance

request.

The value set will always be multiplied for 10.

If 0000 is set, the numbering is excluded.

When the set number of cycles is reached, the maintenance request is signalled by a

slow blink of 60 sec. at the end of the movement.

WARNING: Every time you enter the menu H12, the cycles numbering is reset and

starts again.

Allows the input of the installer code to customize the settings in the programming

phase.

The INSTALLER CODE is the only way to enter the programming menu.

WARNING: in case of loss of the installer code, it will be possible to delete the old one

by pressing simultaneously the keys + and - for 3 s when the writing PASS appears.

In this way, all the existing settings are erased and the default ones are automatically

set. Only the settings of the performed cycles are still stored in memory.

Shows the firmware version installed on the equipment. (R__XX)

Number of performed cycles. The value displayed on the LCD is increased every 10

movements.

38

BA230

UK

MENU E: EXTERNAL DEVICES ENABLING-DISABLING

KEY + enters the following menu E1-E2-E3

KEY – enters the previous menu E3-E2-E1

KEY OK enables Y (yes). Enables the function.

KEY OK enables N (no). Disables the function.

KEY ESC leaves the menu.

WARNING: The STOP key cannot be excluded in menu E. If it is not used, jumper the clamps 22-32.

DescriptionMenu Function

Status

Photocell 1 enabled.

Y

Photocell 1 disabled.

N

Photocell 2 enabled.

Y

Photocell 2 disabled.

N

Edge enabled.

Y

Edge disabled.

N

E2

E2

E1

PHOTOCELL 1

PHOTOCELL 2

EDGE (SEFETY DEVICE)

TIMES MANAGEMENT

T3 ADDITIONAL TIME

Additional time at the end of the working time (with full force or during deceleration phase according to the

settings) that allows to continue the closing movement even if there is wind.

The T3 function is disabled with the sliding configuration.

During the T3 time, the anti-crushing is not active, so the T3 time must start as near as possible to the door

stroke.

The limit switch that determines T3 must not be exceeded to maintain the control of the limit switches in case of

motion inversion.

TIMES LEARNING PROCEDURE

CAUTION: start with the gate completely closed.

Times are programmed by means of sequences of START pulses.

Select the menu C21 to enter this procedure. (menu C21 blinking).

The times learning procedure starts by pressing OK (menu C21 Y fixed) then:

1 motor configuration

• START

• When the leaf arrives at the desired opening position

• Counting of the pause time in opening starts.

• When the desired pause time has elapsed

• When the leaf arrives at the closing position

• Now the procedure has finished, the menu C21 reappears blinking (without Y).

• If you want to repeat the operation, press OK.

• If you want to finish the times learning operation and save the data, press ESC as long as the horizontal lines appear on

the display.

2 motors configuration

• START

• START

the leaf starts opening.

leaf 1 starts opening

leaf 2 starts opening

START the leaf stops.

START

START the leaf stops.

the leaf starts closing.

BA230

39

UK

• When leaf 1 arrives at the desired opening position

• When leaf 2 arrives at the desired opening position

• Counting of the pause time in opening starts

• When the desired pause time has elapsed

• START

• When leaf 2 arrives at the closing position

• When leaf 1 arrives at the closing position

• Now the procedure is over, the menu C21 reappears blinking (without Y)

• If you want to repeat the operation, press OK

• If you want to finish the times learning operation and save the data, press ESC as long as the horizontal lines appear on the display

Leaf 1 starts closing. (phase shift time setting)

START leaf 1 stops

START

START

START

START ·leaf 1 stops

leaf 2 stops

leaf 2 starts closing

·leaf 2 stops

WARNING:

During the times self-learning phase, motion always occurs at a non-decelerated speed.

If decelerations are needed, stop the leaves before the stroke, then remember to enable the decelerations option

(menu C6) and set the decelerations times (menu H3 and H6).

During the times self-learning phase, the limit switches and the amperometric thresholds are not considered.

The microcontroller does not consider fractions of times of less than 1 second, so the real time is rounded up or

down.

The times set following this procedure can be modified later by entering the proper menus and modifying the

numeric value.

If the instalment is configured as double sliding, the motors will move as indicated in the procedure with the

phase shift in opening and closing.

During normal working, phase shifts are zeroed.

USING THE LIMIT SWITCHES

If the deceleration function is enabled, the limit switches mark the start of the deceleration time. The gate

continues the decelerated motion for the time set in menus H3 and H6.

If 2 limit switches are used, the first one starts the deceleration and the second one ends it.

The deceleration, if enabled, will start upon reaching the limit switches and will last for the time H3 and H6 until

the second limit switch has been reached, ending the deceleration phase.

Make sure that the times set are higher than the time necessary to reach the limit switch.

If deceleration is not enabled, the limit switches lock the motion.

The additional time T3 and the final opening/closing stroke, if enabled, work even when there are limit switches.

RESET

The simultaneous pressure of the + and – keys for 3 seconds when the writing PASS is displayed will reset all

values, and the default settings will be loaded (only the number of performed cycles are still stored).

FLASHING LIGHT SIGNALS SUMMARY

Device

Photo 2 intercepted in stand-by after a

start command

Edge intercepted in stand-by after a

start command

Edge intercepted in pause after a start

command or at closing

Signal

5 fast flashings

3 slow flashings

3 fast flashes

Effect

When released, it opens

Blocked closed door

Blocked open door

40

BA230

UK

Photo 1 test failed at opening

Photo 1 test failed at closing

TRIAC test failed at opening

TRIAC test failed at closing

Edge N.C. test failed at opening

Edge N.C. test failed at closing

Edge 8K2 test failed at opening

Edge 8K2 test failed at closing

Expired maintenance

4 fast flashings

4 fast flashings

4 slow flashings

4 slow flashings

3 slow flashings

3 slow flashings

2 slow flashings

2 slow flashings

1 minute slow flashing

with closed door

Blocked closed door

Blocked open door

Blocked closed door

Blocked open door

Blocked closed door

Blocked open door

Blocked closed door

Blocked open door

None

(*) If the flashing light setting is with fixed light (C15 d), the blinking is not present but only the fixed

switching on.

DEFAULT SETTINGS

• Active parameters type A:

A2

A5 Y

A8

• Parameters type C:

C1

C2

C3

C4

C5 E1

C6

C7

C8 N

C9

C11

C13

C14

C15

C16

C17

C18

C19

C20

Y

SWING GATE/OVERHEAD DOOR/BARRIER TYPE

2 MOTORS

Y

AUTOMATIC-CONDOMINIUM USING

YT

GENERAL AND PEDESTRIAN AUTOMATIC CLOSING ENABLED

FAST CLOSING DISABLED

N

Y

PREFLASHING ENABLED

N

SAFETY DEVICES TEST DISABLED

LIMIT SWITCH ENABLED (single pair)

N

DECELERATIONS DISABLED

N

WATER HAMMER DISABLED

FINAL CLOSING STROKE DISABLED

NC

SAFETY DEVICE (EDGE) WITH N.C. CONTACT

N

COURTESY LIGHT DISABLED

N

T3 EXCLUDED

N

IN PEDESTRIAN CLOSING, IT ENABLES COMPLETE OPENING

Y

INTERMITTENT FLASHING LIGHT

N

EXTERNAL CLOCK CONTACT DISABLED

N

EXTERNAL CLOCK CONTACT DISABLED

N

EXTERNAL CLOCK CONTACT DISABLED

N

OLEODYNAMIC BLOCK MAINTENANCE DISABLED

N

PHOTO 1 TEST DISABLED

• Parameters type F:

F1

10

MOTOR 1 FORCE

BA230

41

UK

F2 05

F5

F6

• Parameters type H:

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H11

H12

H13

H14

H15

• Parameters type E:

E1

E2

E3

10

05

25

25

20

25

25

20

5

5

5

5

5

0000

0000

xxxx

0000

Y

Y

Y

MOTOR 1 DECELERATION

MOTOR 2 FORCE

MOTOR 2 DECELERATION

MOTOR 1 OPENING TIME

MOTOR 1 CLOSING TIME

MOTOR 1 DECELERATION TIME

MOTOR 2 OPENING TIME

MOTOR 2 CLOSING TIME

MOTOR 2 DECELERATION TIME

LEAF 2 PHASE SHIFT IN OPENING

LEAF 1 PHASE SHIFT IN CLOSING

PAUSE TIME

PEDESTRIAN OPENING TIME

PEDESTRIAN PAUSE TIME

NUMBER OF CYCLES

INSTALLER CODE

SOFTWARE VERSION (format: R__xx)

NUMBER OF CYCLES DONE

PHOTOCELL 1 ENABLED

PHOTOCELL 2 ENABLED

SAFETY DEVICE (EDGE) ENABLED

FINAL CHECKS AND TESTING

Before powering the control unit, run the following tests:

1- Check the electrical connections: improper connection may be harmful to both the control unit and the

operator.

2- Check proper position of the limit switches.

POWER THE DEVICE

3- Check that the red LEDs of the normally closed contacts are on and the green LEDs of the normally open

contacts are off

4- Check that the writing SAF does not appear on the LCD (intercepted or faulty edge).

5- Check that the relative LEDs turn off when limit switches work.

6- Check that the relative LED turns off when the photocells ray is intercepted.

7- Check that the relative LED turns off when the safety devices work.

8- Check that the motors are locked and ready to work with the “GATE COMPLETELY CLOSED”.

9- Remove possible obstacles in the operating area of the gate, then give the command START. At the first

command, the equipment starts opening, then check that the motion direction is correct. If not invert the wires

in the terminals M1 and/or M2.

42

UK

BA230 DISPOSAL

Gi.Bi.Di advises recycling the plastic components and to dispose of them at special

authorised centres for electronic components thus protecting the environment from

polluting substances.

SIMPLIFIED PROGRAMMING

1-

Connect all the connections (wire motors using a 1,5 mm² wire)

2-

Enter the installation code, and then set the type of function desired from menu A2/A3.

3-

Set the number of motors used. Menu A4/A5.

4-

Set the operation mode. Menu A6/A7/A8/A9.

5-

Go to menu C21, and select «Y» to activate automatic time programming, then press «START» (+ key) (see

page 20 "Time learning procedure")

Go to menu C5 to choose the number of limit switches. We recommend programming a single limit switch

6-

when stopping points are present.

Go to menu C6 to program slowdowns.

7-

Use the dedicated menus to adjust each time parameter.

8-

Press «ESC» to exit programming.

9-

Check whether the force used by operators on the gate is either sufficient or excessive. Go to menu F to

10-

adjust, if necessary.

BA230

BA230

CE Declaration of conformity

The manufacturer:

GI.BI.DI. S.r.l.

Via Abetone Brennero, 177/B,

46025 Poggio Rusco (MN) ITALY

Declares that the products:

ELECTRONIC CONTROL UNIT BA230

are in conformity with the following CEE Directives:

LVD Directive 2006/95/CE and subsequent amendments;

•

• EMC Directive 2004/108/CE and subsequent amendments;

43

UK

and that the following harmonised standards have been applied:

• EN60335-1

• EN61000-6-2, EN61000-6-3

Date 23/03/09

Managing Director

Oliviero Arosio

Cod. AIC6509 - 02/2009 - Rev. 01

GI.BI.DI. S.r.l.

Via Abetone Brennero, 177/B

46025 Poggio Rusco (MN) - ITALY

Tel. +39.0386.52.20.11

Fax +39.0386.52.20.31

E-mail: comm@gibidi.com

Numero Verde: 800.290156

w w w . g i b i d i . c o m

Loading...

Loading...