Page 1

GE

Oil & Gas Moisture

Aurora H2O

User’s Manual

ATTENTION!

This manual is intended for units with S/N 3999

(software v.001.A through v.001.U) or lower only.

[For units with S/N above 3999, use manual 910-317.]

910-284 Rev. J

April 2017

Page 2

Page 3

GE

Oil & Gas

Aurora H2O

Moisture Analyzer for Natural Gas

User’s Manual

910-284 Rev. J

April 2017

ATTENTION!

This manual is intended for units with S/N 3999

(software v.001.A through v.001U) or lower only.

[For units with S/N above 3999, use manual 910-317.]

www.gemeasurement.com

©2017 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Preface

Product Registration

Thank you for purchasing a model Aurora H2O from GE. Please register your product at

www.gemeasurement.com/productregistration

product information and special promotions.

for product support such as the latest software/firmware upgrades,

Services

GE provides customers with an experienced staff of customer support personnel ready to respond to technical inquiries,

as well as other remote and on-site support needs. To complement our broad portfolio of industry-leading solutions, we

offer several types of flexible and scalable support services including: Training, Product Repairs, Service Agreements

and more. Please visit www.gemeasurement.com/services

for more details.

Typographical Conventions

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper setup of

the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these

instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national

codes, regulations, rules and laws related to safety and safe operating conditions are met for each

installation.

Attention European Customers! To meet CE Mark requirements for all units intended for use in the

EU, all electrical cables must be installed as described in this manual.

Aurora H2O User’s Manual iii

Page 6

Preface

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures on this equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

iv Aurora H2O User’s Manual

Page 7

Preface

Environmental Compliance

RoHS

The Aurora H2O fully complies with RoHS regulations.

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE)

take-back initiative, directive 2012/19/EU.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end of life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Please visit http://www.gemeasurement.com/environmental-health-safety-ehs

information about this initiative.

for take-back instructions and more

Aurora H2O User’s Manual v

Page 8

Preface

[no content intended for this page]

vi Aurora H2O User’s Manual

Page 9

Contents

Product Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Safety Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Auxiliary Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Environmental Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Chapter 1. Features and Capabilities

1.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.1 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.4.2 Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.3 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.4 Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.4.5 Operating Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.6 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.4.7 Flow Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.4.8 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.4.9 Inputs/Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.4.10 Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.4.11 Laser Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

1.4.12 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4.13 Weight and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4.14 Hazardous Area Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4.15 European Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4.16 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4.17 Sampling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

1.4.18 Wetted Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Chapter 2. Installation

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.2 Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.3 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4 Choosing A Site for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.5 Low Voltage Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2.6 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Aurora H2O User’s Manual vii

Page 10

Contents

2.7 Optional Insertion Probe/Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.7.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.7.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.7.3 Setting the Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2.8 Making Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

2.9 Specific Conditions of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Chapter 3. Operation and General Programming

3.1 Using the Aurora H2O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.2 Sample System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.2.1 Aurora H2O Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.2.2 Aurora H2O Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.2.3 Aurora H2O Purge Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.3 Keypad Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.3.1 Indicator Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.3.2 The Magnetic Stylus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.3.3 The Default Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.3.4 Unlocking the Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.3.5 Keypad Lock-Out Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.3.6 Accessing the Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.3.7 Entering Numeric Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.3.8 Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4 Setting Up the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.4.1 Selecting Primary Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4.2 Selecting Alt 1 and Alt 2 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.4.3 Setting Decimal Places. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.4.4 Data/Scan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.4.5 Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.4.6 Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.5 Setting Up the Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.5.1 Selecting an Output for Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.5.2 Selecting Output Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3.5.3 Selecting an Output Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3.5.4 Changing the Upper Output Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3.5.5 Changing the Lower Output Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3.5.6 NAMUR Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3.5.7 Testing the Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

3.5.8 Trimming the Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

viii Aurora H2O User’s Manual

Page 11

Contents

3.6 Setting Up the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.6.1 Selecting an Alarm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.6.2 Selecting Alarm Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3.6.3 Selecting Alarm Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3.6.4 Selecting an Alarm Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

3.6.5 How the Alarm Types Work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

3.6.6 Changing the Upper Alarm Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

3.6.7 Changing the Lower Alarm Span. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Chapter 4. Programming Advanced Features

4.1 Comm Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.1.1 Selecting a Comm Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.1.2 Setting the Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.1.3 Setting Parity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.1.4 Selecting Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.1.5 Setting the Network ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.2 Adjust Offset Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.2.1 Adjusting the PPMv Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.2.2 Adjusting the Smoothing Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.2.3 Adjusting the Scan Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.2.4 Setting the Dew Point Calculation Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.3 Set Up the Background Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4.3.1 Selecting the Type of Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4.3.2 Setting the Z Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.3.3 Entering a Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.3.4 Adjusting the Gas Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.4 Clock Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.4.1 Resetting the Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.4.2 Resetting the Minutes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.4.3 Resetting the Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.4.4 Resetting the Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4.4.5 Resetting the Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4.5 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.5.1 Setting Pressure Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.5.2 Setting the Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.5.3 Changing the Constant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.5.4 Editing Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Aurora H2O User’s Manual ix

Page 12

Contents

4.6 Regional Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

4.6.1 Setting the Country Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

4.6.2 Setting the Decimal Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.6.3 Setting the Date Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

4.6.4 Setting the Unit System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

4.7 User Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

4.8 Service Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4.9 Aurora H2O Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.9.1 Checking the ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.9.2 Checking the System Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.9.3 Checking the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

4.9.4 Checking the Gas Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

4.9.5 Checking the Alternate Gas Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

4.10 Locking/Unlocking the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Chapter 5. AuroraView Interface Software

5.1 Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.2 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

5.3 Installing AuroraView. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

5.4 Starting AuroraView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

5.5 Using the Main Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

5.6 Datalogging with AuroraView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

5.7 Working with Trend Plots, Trend Tabular Data and Scan Plots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Chapter 6. Maintenance

6.1 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

6.2 Cleaning the Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

6.2.1 Instructions for Optical Absorption Cell Style 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.2.2 Instructions for Optical Absorption Cell Style 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.3 Replacing the Filter Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Chapter 7. Troubleshooting

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7.2 Blank Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7.3 Display Dim or Hard to Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7.4 Status Messages and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

7.5 No Flow Measurement Indicated on Aurora H2O Measurement Cell Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.6 Verifying Aurora H2O Performance in the Field. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.6.1 Using A Portable Hygrometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

7.6.2 Using a Moisture Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7.7 Background Selection Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

x Aurora H2O User’s Manual

Page 13

Contents

Appendix A. MODBUS RTU/RS485 Communications

A.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.2 Modbus Functions and Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A.3 Modbus Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

A.4 Modbus System Status Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Aurora H2O User’s Manual xi

Page 14

Contents

[no content intended for this page]

xii Aurora H2O User’s Manual

Page 15

Chapter 1. Features and Capabilities

Chapter 1. Features and Capabilities

1.1 Overview

GE’s Aurora H2O Moisture Analyzer for Natural Gas makes it possible for natural gas processing and transportation

facilities to monitor moisture content in real-time with high precision and reliability.

Aurora H2O analyzer uses tunable diode laser absorption spectroscopy (TDLAS) to measure moisture in natural

The

gas at the speed of light. The analyzer is suitable for installation in hazardous areas and operates over a wide range of

environmental conditions.

compliance. Once process upsets are corrected and the gas dries out, the fast response quickly enables natural gas to be

cleared for entry into the “energy grid”.

CLASS 1 LASER PRODUCT

WARNING! Use of controls or adjustments or the performance of procedures other than those

specified herein may result in hazardous laser exposure.

Aurora’s fast response quickly alerts and documents when moisture concentrations are out of

1.2 Features

Optical response: < 2 seconds after flow cell is purged.

•

• No cross sensitivity to glycols or amines.

• Direct readout in lbs/mmscf, mg/m

3

or ppm.

• Reads process pressure dew point (with user programmable constant or live auxiliary input for process

pressure).

• Turnkey sampling system specifically designed for natural gas applications ensures measurement integrity.

• Magnetic Stylus enables through-glass programming – hot permit not required to field program.

• Explosion-proof/Flameproof design

• 4-20 mA signals and RS-232/485 MODBUS RTU for connection to SCADA or plant monitoring system.

• Supplied with AuroraView software for remote configuration, data logging and data retrieval capacity.

• NIST traceable calibration.

• In conformance with IEC 60825-1 Edition 2.0, Safety of Laser Products.

Aurora H2O User’s Manual 1

Page 16

Chapter 1. Features and Capabilities

AIn

I

o

I

---

SLN==

1.3 Theory of Operation

The GE Aurora H2O (Tunable Diode Laser Absorption Spectroscopy) hygrometer for natural gas is a system designed

to continuously monitor the moisture content in natural gas. It fundamentally measures the partial pressure of water

vapor (water in the gas state), and with the simultaneous measurement of pressure and temperature, provides readings

and both analog and digital signal transmission of user-selectable moisture parameters including dew point

temperature, volume ratio and absolute humidity (lbs/MMSCF or mg/m

Aurora H2O is supplied with an integrated sampling system which includes an optional pipe-mounted liquid

The

separator and pressure reducing valve/regulator, and the following components mounted within a stainless steel

enclosure: isolation valve, coalescing filter, coalescer flow control valve, sample cell control valve, second pressure

reducing valve/regulator, and flow indicator (rotameter), as well as an optional electrical heater and thermostat.

The fundamental water vapor pressure measurement is based on the Beer-Lambert Law:

where: A = Absorbance

I = Light intensity transmitted through a sample gas

= Incident light intensity

I

o

S = Absorption coefficient*

L = Absorption path length (a constant)

N = Concentration of the water vapor in the absorption cell

3

) in addition to temperature and pressure.

* The absorption coefficient is a constant for a specific gas composition at a given pressure and temperature.

The concentration of the water is directly related to the partial pressure. At certain specific frequencies, light energy

will be absorbed by water molecules. As the concentration of water increases, the absorption also increases. The

H2O

sweeps the diode laser output across a narrow band in the near infrared spectrum and, by measuring the light

Aurora

intensity with a photo detector, is able to provide a direct indication of the partial pressure of water. The partial

pressure, multiplied by 10

6

and divided by the total pressure, yields the volume ratio in ppmv (parts per million by

volume).

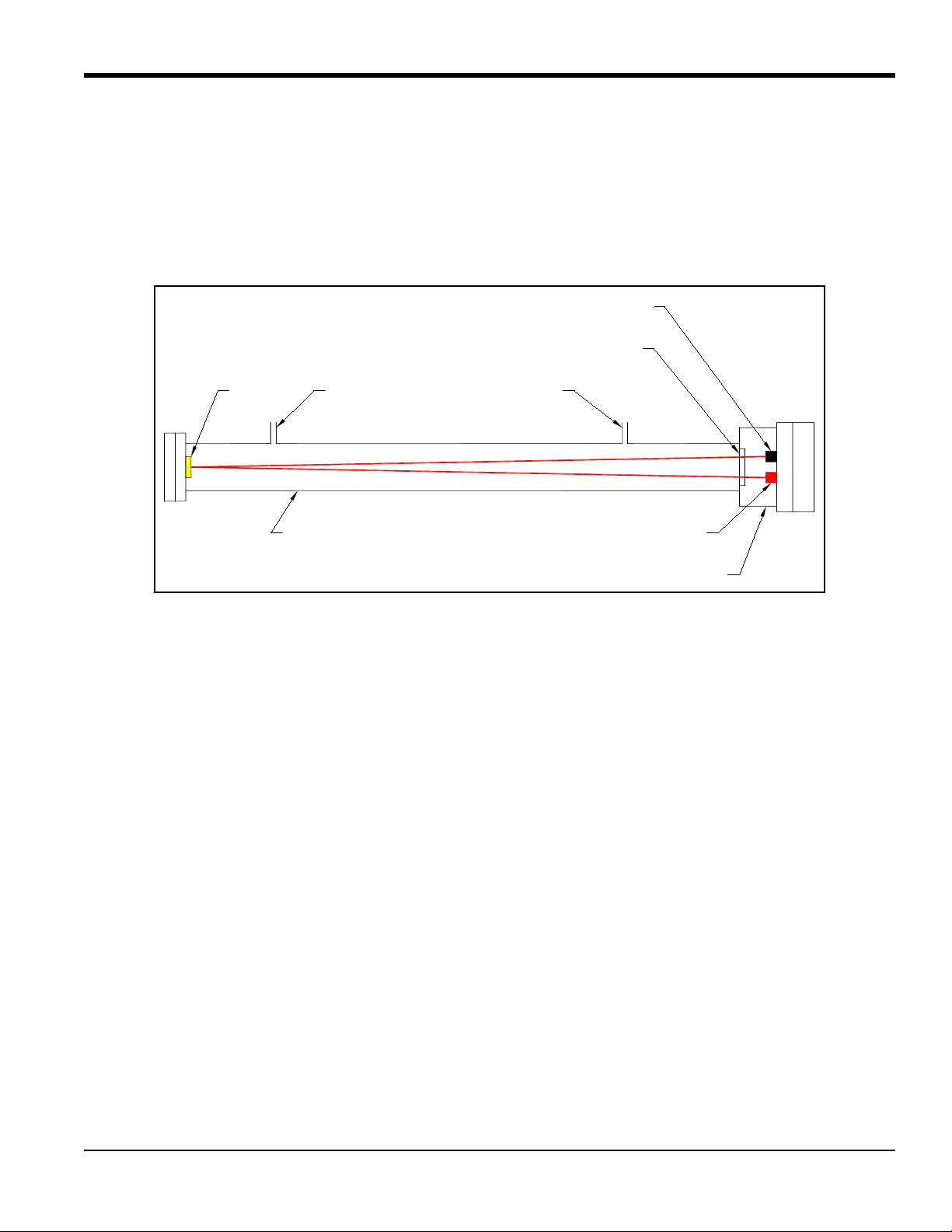

The laser diode is housed in a hermetically sealed and dry housing. The light is transmitted through a window made of

proprietary transparent material. The light travels through a stainless steel cell and is reflected off a gold-plated mirror

and returned to a photo detector, where the light intensity is measured.

2 Aurora H2O User’s Manual

Page 17

Chapter 1. Features and Capabilities

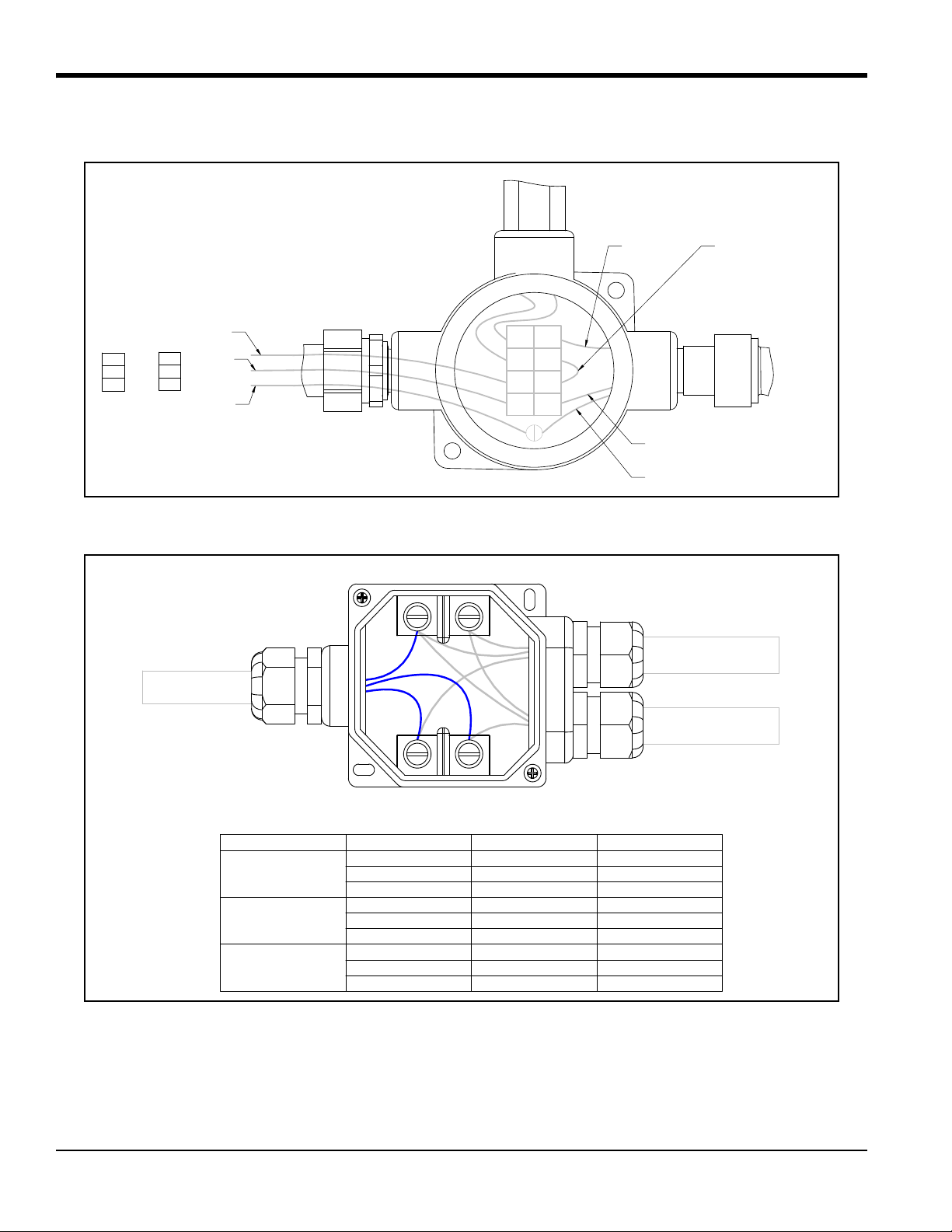

Gas Inlet

Mirror

Stainless Steel Absorption Cell

Gas Outlet

Optical Window

Photodetector

Tunable Diode Laser

Hermetically Sealed Housing

1.3 Theory of Operation (cont.)

Since only light comes in contact with the sample of natural gas, and all of the wetted materials are made of

non-corrosive and inert materials, this technology does not exhibit the drift associated with gas contacting sensor-based

hygrometers. The diode laser emits low energy light, and therefore the system will not ignite the gas. The complete

system is rated explosion-proof, and the

Figure 1 below) is purged, the response time is a matter of a few seconds.

Aurora H2O provides very fast response time. Once the absorption cell (see

Figure 1: Laser Absorption Cell, Basic Elements

The control of the laser, power supply and signal conditioning circuitry are housed in an explosion-proof transmitter

enclosure. A backlit, three-parameter, LCD display provides digital indication of user-programmable parameters. The

Aurora H2O has three user-programmable (4-20 mA) analog outputs and two programmable digital ports that may be

configured as either RS-485 or RS-232 with Modbus protocol. The analyzer has an auxiliary analog input (4-20 mA)

input that is used for connection to an optional process pressure transmitter. Measurement of the process pressure

enables the

Aurora H2O to display and transmit the process dew point. AuroraView software is provided and enables

remote readings, programming data logging and data logging with a personal computer.

Aurora H2O hygrometer is calibrated against an NIST (or other national metrological institute) traceable reference

The

dew/point generator and hygrometer. Each system is supplied with a certificate of calibration with functional test data.

Aurora H2O User’s Manual 3

Page 18

Chapter 1. Features and Capabilities

1

2

3

4

5

6

7

9

10

8

11

12

13

14

15

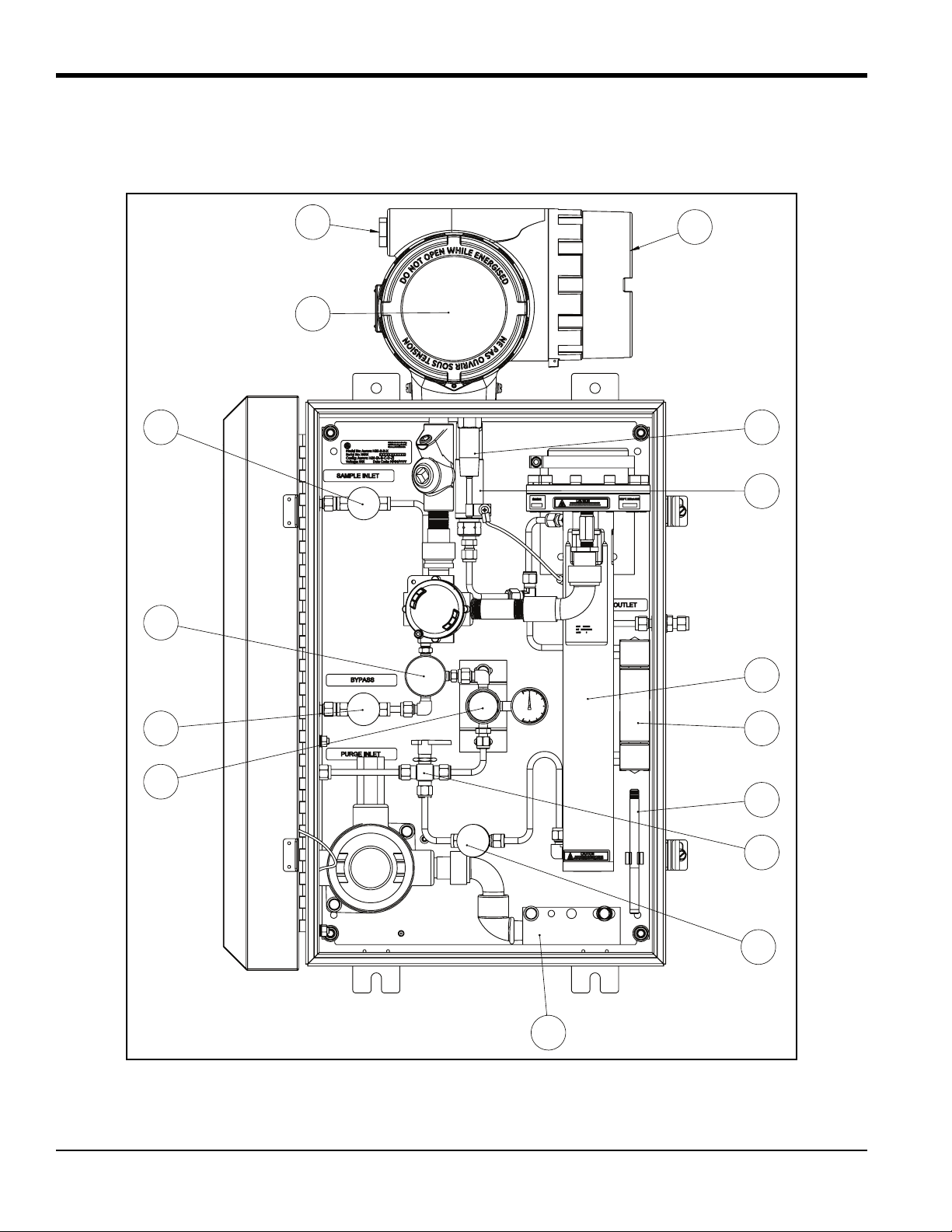

1.3 System Components (cont.)

Note: Refer to Figure 2 below and Table 1 on page 6 to identify your Aurora components.

Figure 2: Aurora H2O System Assembly with Optional USA/CAN Heater

4 Aurora H2O User’s Manual

Page 19

Chapter 1. Features and Capabilities

1

2

3

4

5

6

7

9

10

8

12

13

14

15

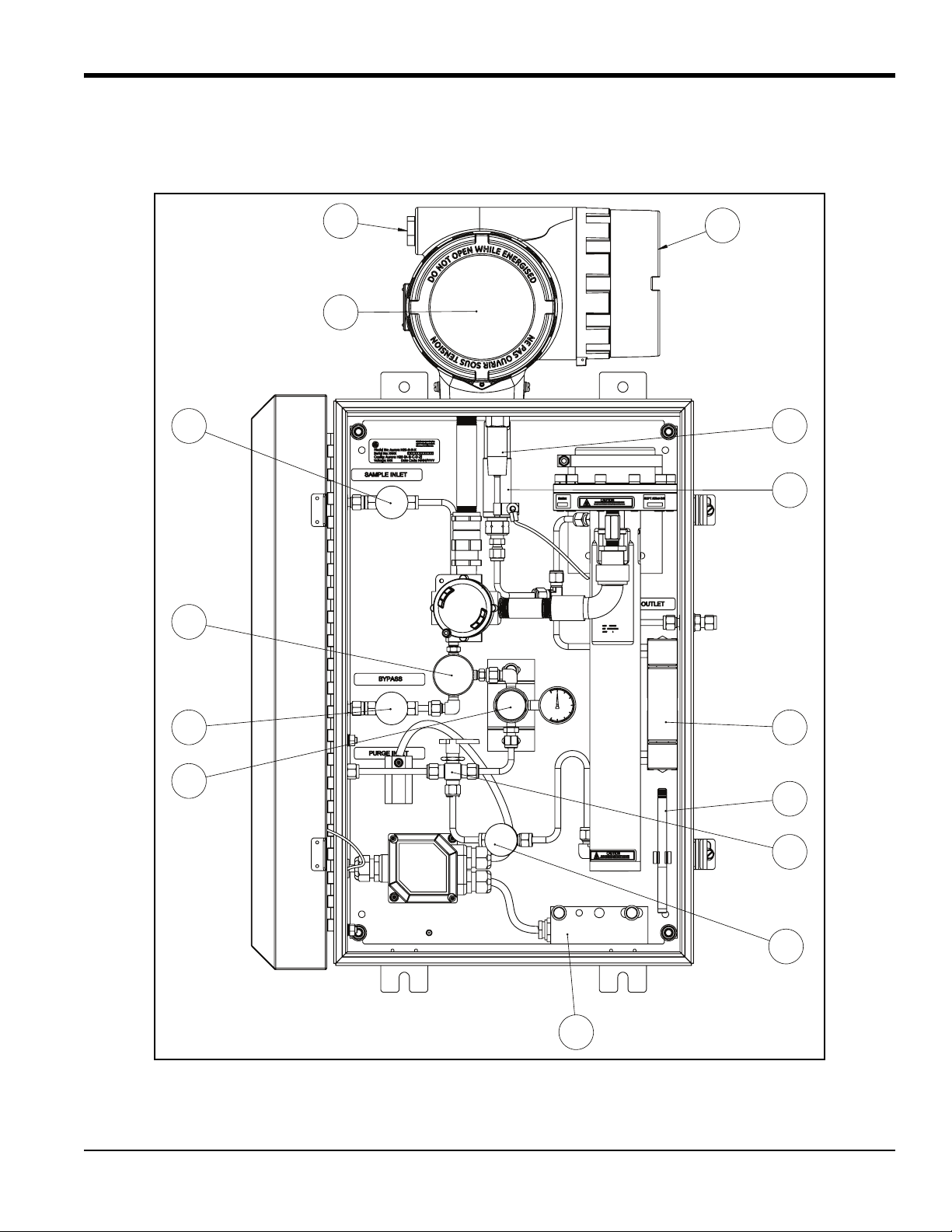

1.3 System Components (cont.)

Note: Refer to Figure 3 below and Table 1 on page 6 to identify your Aurora components.

Figure 3: Aurora H2O System Assembly with Optional EU/ATEX Heater

Aurora H2O User’s Manual 5

Page 20

Chapter 1. Features and Capabilities

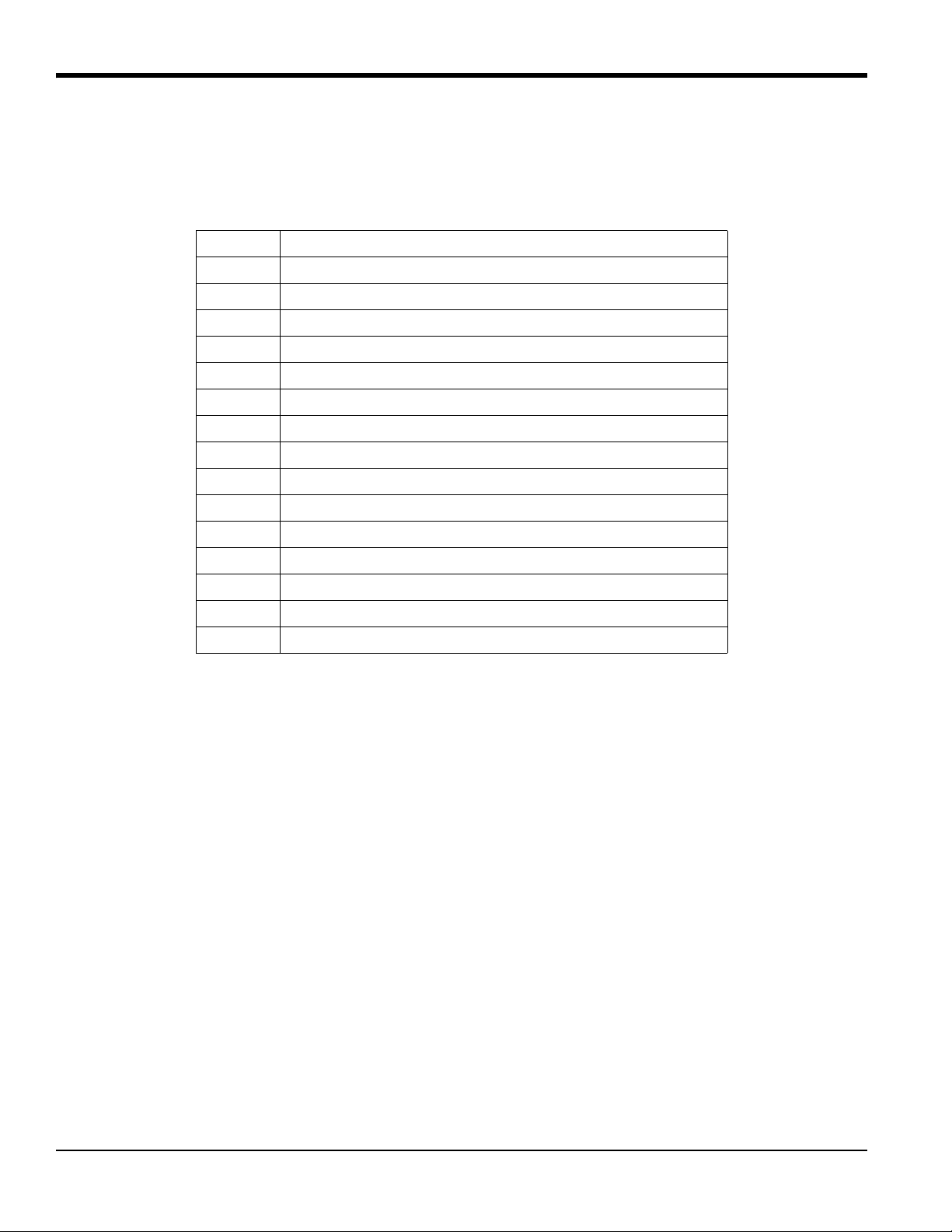

1.3 System Components (cont.)

Note: Refer to Tab l e 1 below and either Figure 2 on page 4 or Figure 3 on page 5 to identify your Aurora

components.

Table 1: Aurora H2O System Parts List

No. Description

1 Conduit I/O

2 Display and Magnetic Stylus Keypad

3 Wiring Terminals

4 Isolation Valve (needle valve)

5 Membrane Filter

6 Membrane Filter Drain & Fast Loop Vent

7 Pressure Regulator w/ 0-10 psig outlet pressure gauge

8 Magnetic Stylus

9 Process or Purge Gas Selector

10 Purge Gas Inlet Needle Valve

11 Absorption Cell

12 Temperature Sensor

13 Pressure Sensor

14 Rotameter

15 Optional Heater, thermostat, junction box

6 Aurora H2O User’s Manual

Page 21

Chapter 1. Features and Capabilities

Overall Length

(See Detail A)

3.42

(86.8)

0.92

2.25 (57.1)

5.60 (142.2)

1.20 - 1.75

(30.48 - 44.45)

Probe Length

(See Detail A)

01

02

03

750-633

750-634

750-635

Probe

Length

Overall

Length

4.00"

7.00"

9.00"

11.80"

14.80"

16.80"

1

2

3

4

NOTES:

1. Sample Process Connection: 3/4" NPTM

3. Dimensions are in inches (millimeters).

3/4" NPTM

2. Sample Outlet Connection: 1/4" Compression Fittings

04

05

06

4.00"

7.00"

9.00"

11.80"

14.80"

16.80"

750-633

750-634

750-635

1

2

3

Probe/filter/regulator assembly

Pressure Gauge, 0 to 600 psig

2-way ball valve

4

Tube fitting

Detail A

Part

Number

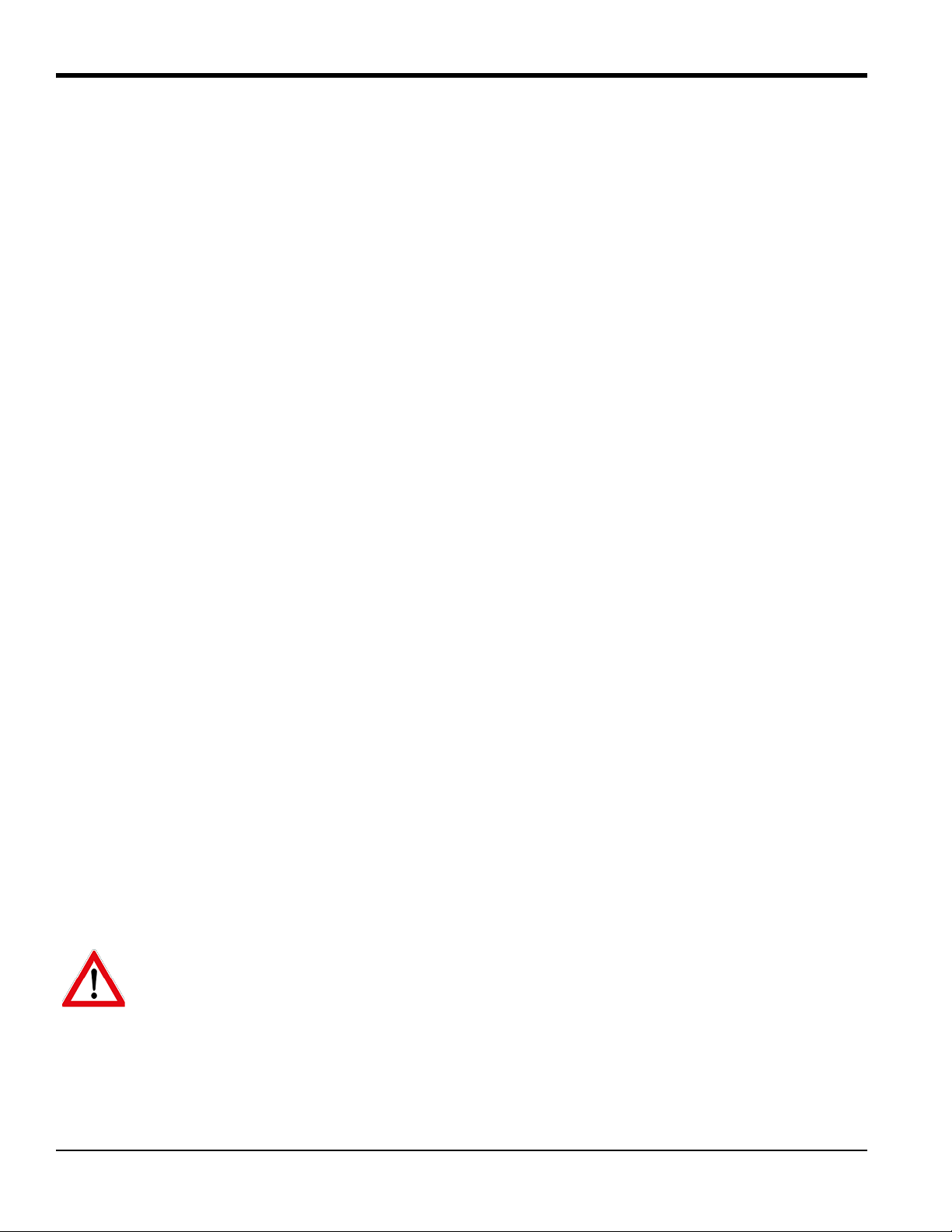

1.3 System Components (cont.)

IMPORTANT: The filter installed within the Aurora is designed to function as a secondary filter. A primary filter or

filter train should be used upstream of the analyzer. Do not sample directly from the process gas to the

Aurora without the use of a primary filter and pressure reduction. The pressure inlet to the Aurora

sample inlet should not exceed 500 psig.

For natural gas, a pipeline insertion membrane filter is recommended as shown in Figure 4 below. The installation of

the insertion filter is described in this manual. The insertion filter also is equipped with a pressure regulator which

functions to reduce the pressure. If it is not possible to install the insertion filter, consult GE application engineers for

information about a sample conditioning system.

Figure 4: Sample System (ref. dwg #733-737)

Aurora H2O User’s Manual 7

Page 22

Chapter 1. Features and Capabilities

THERMOSTAT

HEATER CONNECTION

CUSTOMER CABLE GLAND

1

2

3

45

6

7

8

BROWN

J1

16 AWG BROWN WIRE (2")

STRIP 1/4"

BLUE

GREEN/YELLOW

LINE

NEUTRAL

GROUND

230 VAC 120 VAC

L1

L2

G

L

N

G

12

34

CUSTOMER CABLE

CABLE TO THERMOSTAT

CABLE TO HEATER

CABLE FUNCTION

CONDUCTOR

COLOR

J-BOX TERMINAL

CUSTOMER POWER

LINE 1

BROWN

3

LINE 2

BLUE

4

GROUND

GREEN/YELLOW

1

THERMOSTAT

LINE 1

BROWN

2

LINE 2

BLUE

3

GROUND

GREEN/YELLOW

1

HEATER

LINE 1

BROWN

2

LINE 2

BLUE

4

GROUND

GREEN/YELLOW

1

1.3 System Components (cont.)

Figure 5: USA/CAN Heater Wiring Diagram

8 Aurora H2O User’s Manual

Figure 6: EU/ATEX Heater Wiring Diagram

Page 23

1.4 Specifications

1.4.1 Power

Analyzer:

100-240 VAC, 50-60Hz, 10W

18-32 VDC (24 VDC nominal), 10W

Optional Electrical Heater:

120VAC, 120W

230VAC, 75W

1.4.2 Range

Part Per Million by Volume

5 to 5000 ppm

v

Chapter 1. Features and Capabilities

Dew/Frost Point

*

–65.5°C to –2.6°C (–85.9°F to 27.3°F)

Process Dew/Frost Point

*

Process or equivalent dew point/frost point by calculation with process pressure signal (4-20 mA) or constant

Absolute Humidity

3.8 to 3803 mg/m3 (0.24 to 237 lbs/MMSCF)

*Readings below 0°C (32°F) are in “frost point” temperature, and above 0°C (32°F) are in “dew point” temperature.

1.4.3 Accuracy

Parts per Million by Volume

±2% of reading in ppmv or 4 ppmv (Accuracy of other parameters derived from ppm

)

v

1.4.4 Response Time

Optical Response

<2 seconds

System Response

The system response is dependent upon the length of sample tubing, sample system components, flowrate and pressure,

as well as the change in moisture concentration.

1.4.5 Operating Pressure

Operating Sample Cell Pressure:

69 to 172 kPa (10 to 25 psia)

Maximum Pressure

1380 kPa (200 psi)

Process Pressure

10,342 kPa (1500 psig) maximum [Higher pressure available using additional sampling system components]

Aurora H2O User’s Manual 9

Page 24

Chapter 1. Features and Capabilities

1.4.6 Temperature

Operating

–20° to +65°C (–4° to 149°F)

Storage

–20° to +70°C (–4° to +158°C)

Optional Heater/Thermostat Setpoint

20°±5°C (68°±9°F) for U.S. and Canada

10°±5°C (50°±9°F) for EU and elsewhere

1.4.7 Flow Rate

Sample Cell Flowrate

10 to 60 SLH (0.4 to 2 SCFH); 30 SLH (1 SCFH) nominal

Coalescer By-pass Fast Loop

5 to 10X of flowrate through sample cell

1.4.8 Display

Backlit LCD, three programmable simultaneous parameters, alphanumeric status and diagnostic display,

LEDs for power, laser temperature stability, keypad lockout

1.4.9 Inputs/Outputs

Analog Outputs

Three programmable 0/4-20 mA, 500 Ω maximum load

Analog Input

Loop-powered 4-20 mA input for remote pressure transmitter (Aurora H2O supplies 24 VDC)

Digital Interface

Two programmable digital communications ports

RS-232 and RS-485 with multi-drop capability and assignable address, Modbus RTU protocol

1.4.10 Enclosure

Ingress Protection

IP-66

1.4.11 Laser Certification

Class 1 product, conforms to IEC 60825-1 Edition 2.0, Safety of Laser Products

WARNING! Use of controls or adjustments or the performance of procedures other than those

specified herein may result in hazardous laser exposure.

10 Aurora H2O User’s Manual

Page 25

Chapter 1. Features and Capabilities

1.4.12 User Interface

Programmable “through-the-glass” via magnetic stylus

1.4.13 Weight and Dimensions

Net Weight

45 kg (100 lb)

Overall Dimensions

34”H x 18”W x 14”D (87 cm x 46 cm x 36 cm) [see drawings]

1.4.14 Hazardous Area Certification

USA/Canada

Explosion-Proof for Class I, Division 1, Groups B, C&D

Dust-Ignitionproof for Class II/III, Division 1, Groups E, F&G (Canada only)

EU and Elsewhere

ATEX and IECEx: Ex d e IIB+H2 T6 Gb IP66; Tamb = –20°C to +65°C. Flameproof with increased safety

compartment

Evaluated against standards EN 60079-0:2012, EN 60079-1:2007, EN 60079-7:2007, IEC 60079-0:2011, IEC

60079-1:2007, IEC 60079-7:2006.

1.4.15 European Certification

CE

Complies with EMC Directive 2004/108/EC, Low Voltage Directive 2006/95/EC and

Pressure Directive 97/23/EC for DN<25

1.4.16 Software

Displays all key parameters. Provides time-base graphing, data logging ability, export data as ASCII text.

Software has lockout/passcode.

1.4.17 Sampling System

Integrated sampling system to filter out physical contaminants, remove glycol carry over, control temperature

condition, regulate pressure and flow rate. Optional thermostatically controlled heater.

1.4.18 Wetted Components

316/316L stainless steel for tubing and fittings. Other wetted components such as the optical window and mirror are

proprietary materials and are compatible with natural gas and typical contaminants found in natural gas. Other sample

system components wetted parts include PTFE, PFA, Inconel, Hastelloy, PVDF, glass, Viton.

Aurora H2O User’s Manual 11

Page 26

Chapter 1. Features and Capabilities

[no content intended for this page]

12 Aurora H2O User’s Manual

Page 27

Chapter 2. Installation

Chapter 2. Installation

2.1 Introduction

The Aurora H2O analyzer provides direct indication of moisture concentration in natural gas. Temperature and pressure

sensors are used to provide high precision enhancement. It may be installed in a wide variety of environmental

conditions, and meets the requirements for operation in hazardous areas.

Be sure that the ambient temperature is at least 10°C higher than the maximum dew/frost point temperature you expect

to measure. This will ensure that you will not have liquid condensation in the sample transport line or the

sampling system components. Heat tracing the sample line will aid in elevating the sample temperature above the dew

point. An optional heater installed within the enclosure is also available.

2.2 Bill of Materials

The following items should have been received with your shipment:

• Aurora H2O Unit • Aurora H2O Calibration Data Sheet

•

Aurora H2O User’s Manual on CD ROM • Maintenance/Accessories Kit

•

AuroraView Software on CD ROM • Optional: Pipeline Insertion Filter/Regulator Assembly

Aurora H2O

2.3 Unpacking

The Aurora H2O is shipped in a packing box with a plywood base (see Figure 7 below), and the Aurora H2O analyzer is

secured to the plywood base with mounting bolts. Transport the shipping package with the plywood base on the

bottom, and according to the warning labels on the exterior packaging. Open the packing box from the top, and remove

the foam packing material. Collect any separate components such as the

other items contained in the shipment.

AuroraView CD, the User Manual CD, and

Figure 7: Unpacking the

Aurora H2O User’s Manual 13

Aurora H2O

Page 28

Chapter 2. Installation

2.3 Unpacking (cont.)

Remove the mounting studs at the bottom of the enclosure. Using two people, lift the Aurora H2O from the bottom of

the enclosure and from the top of the enclosure where the analyzer electronics is located. A typical

Aurora H2O weighs

approximately 100 pounds (45 kg). Use a proper lifting technique to avoid injury.

Check all the received components and record the model numbers and serial numbers for your records. If anything is

missing, contact GE immediately.

2.4 Choosing A Site for Installation

You should have discussed environmental and installation factors with a GE Sales, Application or Service Engineer by

the time you receive the analyzer.

Before installing the analyzer, read the guidelines below on installation recommendations:

1. Choose an installation site for the

Aurora H2O analyzer as close to the actual sample point (sample take-off

point) as possible, to minimize transport time to the analyzer.

2. Avoid unnecessarily long lengths of sample transport tubing to minimize transport time to the analyzer.

3. Avoid dead-legs in the sample transport tubing to minimize the possibility of liquid build-up.

4. Use stainless steel tubing. Avoid using copper tubing, as the water molecule has greater absorption capabilities

for copper compared to stainless steel. Avoid rubber tubing at all costs, as water molecules interact with the

rubber, and ambient moisture can permeate through the tube wall into the sample gas.

5. Mount the

Aurora H2O analyzer at grade, or at a location that is easily accessible for maintenance (on a

platform or other structure).

6. Be sure that the ambient temperature is at least 10°C higher than the maximum dew/frost point temperature

you expect to measure. This will ensure that you will not have liquid condensation in the sample transport line

nor in the

Aurora H2O. Heat tracing the sample line will aid in elevating the sample temperature above the dew

point. An optional heater installed within the enclosure is also available.

A typical

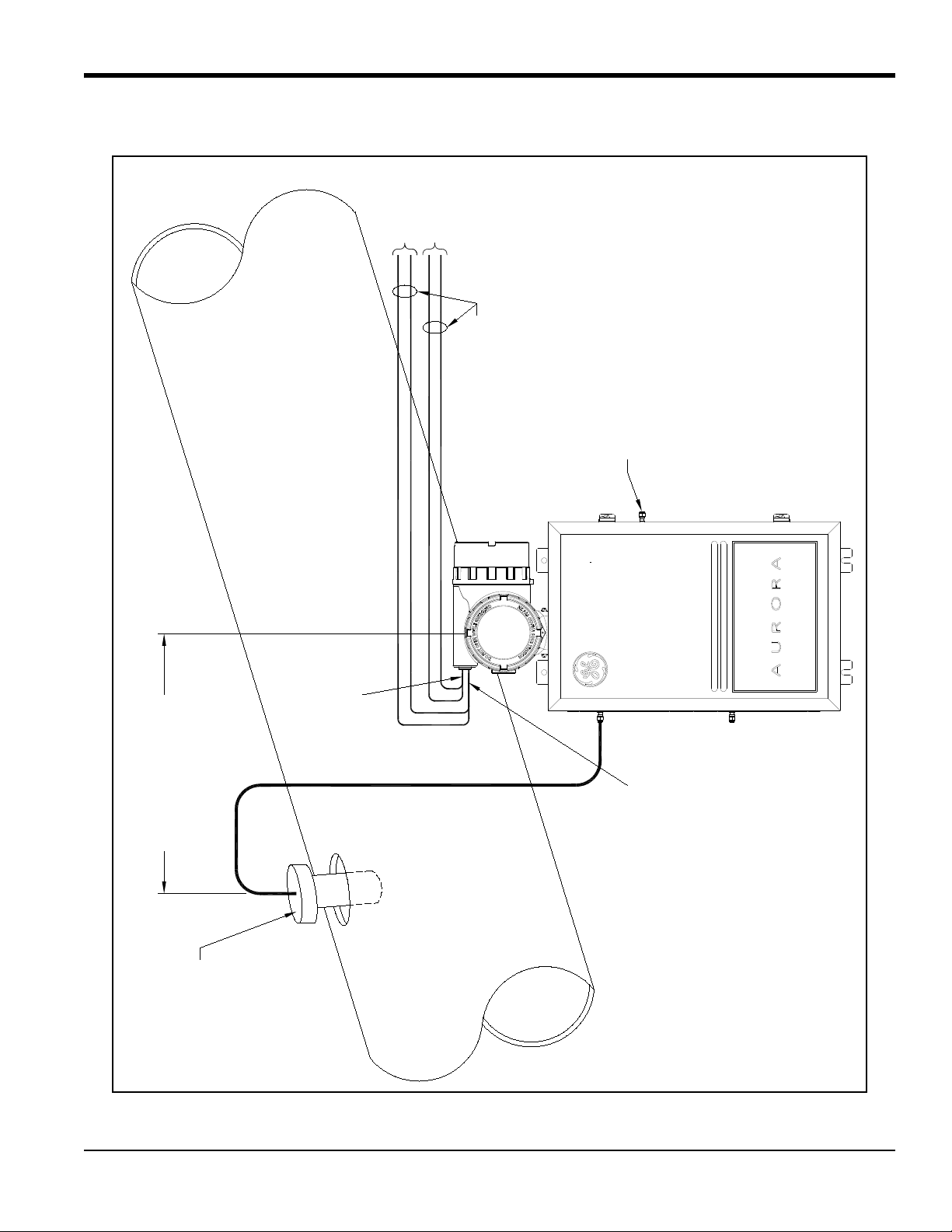

Aurora H2O system for monitoring moisture off a natural gas pipeline is shown in Figure 8 on page 15.

14 Aurora H2O User’s Manual

Page 29

2.4 Choosing A Site for Installation (cont.)

Input/Output

Power

Conduit or Armored Cable

suitable for area rating

Sample Transport Line

Minimize distance.

Tie to Vent/Flare

(Do not restrict.)

Install at a 12 o'clock, or

optionally 3 o'clock or

9 o'clock position, on a

horizontal pipe run.

Note: There is no

orientation preference

on vertical pipe runs.

Optional

Insertion Regulate

Sample Tap

Power Conduit

entering 1 of 3 inlets.

Input/Output Conduit

entering 2nd of 3 inlets.

Chapter 2. Installation

Figure 8: Aurora H2O Analyzer Monitoring Moisture Off a Natural Gas Pipeline

Aurora H2O User’s Manual 15

Page 30

Chapter 2. Installation

2.5 Low Voltage Directive

To comply with the Low Voltage Directive, you must install a switch or circuit breaker on the input power line. For

greatest safety, locate the circuit breaker or power switch near the electronics console.

IMPORTANT: Installation must be done in accordance with the National Electrical Code, the Canadian Electric Code,

and/or any other applicable local codes.

2.6 Mounting

Use the four mounting tabs to mount the Aurora H2O System Assembly in the desired location (see Figure 31 on

page 31).

IMPORTANT: The

Aurora H2O should only be mounted vertically.

16 Aurora H2O User’s Manual

Page 31

Chapter 2. Installation

2.7 Optional Insertion Probe/Regulator

2.7.1 Description

For natural gas applications that may have entrained particulate and liquid contaminants (especially TEG carry-over

from TEG dryers), GE recommends the use of a Insertion Probe/Regulator (see Figure 9 below) to serve as the first

part of particulate and condensate filtration where the gas is sampled off the pipe. The device combines the features of

a sample tap, a membrane filter and an integral pressure regulator (0-500psig outlet), adjustable at the sample take-off

point. The sample tap housing includes a foot-valve so that, once installed, the assembly can be removed from a line

under pressure for membrane filter replacement as needed.

Figure 9: Insertion Probe/Regulator

Note: A 29/32” (0.907 inch, 23.1 mm) minimum bore-through clearance is needed on the customer nozzle for

insertion of a 3/4” NPT insertion membrane liquid separator/pressure regulator.

2.7.2 Installation

Note that the Optional Insertion Probe/Regulator can be installed only on unpressurized lines. There is no hot-tap

installation for this device.

This procedure is broken down into two steps:

• Installing the Housing

• Installing the Insertion Probe/Regulator Assembly

Aurora H2O User’s Manual 17

Page 32

Chapter 2. Installation

Slots

Locking

Mechanism

Foot Valve

Vertical

Set Screws

Horizontal

Set Screw

Horizontal

Set Screw

Locking Mechanism

Thread Sealant

2.7.2a Installing the Housing

The housing, as shown in Figure 10 below, is supplied with a Locking Mechanism to ensure that housing can only be

removed intentionally.

Figure 10: Installing the Housing and Locking Mechanism

1. Turn the locking mechanism counter-clockwise until it is at its extreme upper position. Apply thread sealant to

the threaded area below vertical slots in the threads (see Figure 11 below). Do not allow the thread sealant to

enter the slot, as it may interfere with the mechanism.

Figure 11: Applying Thread Sealant

18 Aurora H2O User’s Manual

Page 33

Chapter 2. Installation

¾” NPTF Thread-O-Let

Housing

Wrench

Flats

180° apart

2.7.2a Installing the Housing (cont.)

2. Confirm that the pipeline has been unpressurized. Refer to Figure 12 below and insert the housing into the

pipeline through a ¾” NPTF thread-o-let (The minimum ID of the thread-o-let is 0.91”).

Figure 12: Inserting Housing into Pipeline

3. Using a wrench on the wrench flats, turn the housing until it is secure and sealed (see Figure 13 below). This

will require between three and five turns.

DO NOT OVERTIGHTEN! The housing may be damaged if it is

over-tightened, causing the housing to deform.

Figure 13: Tightening the Housing

Aurora H2O User’s Manual 19

Page 34

Chapter 2. Installation

2.7.2a Installing the Housing (cont.)

4. Turn the locking mechanism clockwise until it first touches the top of the thread-o-let.

5. Turn the locking mechanism counterclockwise until the Allen screw is aligned with the thread slot (see

Figure 14 below). Using a 1/8” Allen wrench, tighten the Allen screw until its tip is tight against the slot.

NOT OVERTIGHTEN THE ALLEN SCREW

as this will cause the housing wall to be indented.

DO

Figure 14: Aligning and Tightening the Allen Screw

6. Using a 3/32” Allen wrench, tighten the Allen screws on the locking mechanism's surface until their tips are

firmly set into the thread-o-let’s upper surface (see Figure 15 below).

Figure 15: Tightening the Allen Screws

The housing is now installed. The locking mechanism should prevent the housing from becoming unintentionally

unscrewed from the thread-o-let. The pipeline my now be pressurized.

20 Aurora H2O User’s Manual

Page 35

Chapter 2. Installation

Allen Cap Screw

Pressure Adjustment Screw

Pressure Gauge

Isolation Ball Valve

2.7.2b Installing the Insertion Membrane Liquid Separator/Pressure Regulator Assembly

1. Confirm that the Allen cap screw head’s hex cavity is clean and free from foreign material. Confirm that the

Allen cap screw that holds the membrane ferrule is torque-wrench tight (see Figure 16 below). The torque

value should be 10 inch-lbs. If the Allen cap screw is only hand-tight, the screw may protrude excessively,

which could result in foot valve actuation when the probe is installed into the housing.

Figure 16: Checking/Tightening the Allen Cap Screw

2. Rotate the pressure adjustment screw on the pressure regulator fully counterclockwise until it rotates freely.

Close the isolation ball valve (see Figure 17 below).

Aurora H2O User’s Manual 21

Figure 17: Rotating the Pressure Adjustment Screw

Page 36

Chapter 2. Installation

Membrane

Housing

Slot

Membrane

Spring

Guard

Insertion

Nut

Insertion

Washer

Housing

Vertical

First

Second

Vertical

Slot

Insertion

Nut

Insertion

Washer

Pin

Housing

2.7.2b Installing the Insertion Membrane Liquid Separator/Pressure Regulator Assembly (cont.)

3. Refer to Figure 18 below and position the membrane end of the probe above the installed housing. Slowly

lower the probe into the housing. Avoid membrane contact with the upper section of the housing. DO NOT

APPLY DOWNWARD FORCE. The probe should slide easily into the housing. Lower the probe only enough

to thread the insertion nut one complete turn of thread engagement.

Figure 18: Installing the Probe

4. Thread the insertion nut down by hand, lowering the probe until the insertion washer pins slide to the bottom of

the first vertical slot (see Figure 19 below).

Note: The threaded nut on the housing ensures that if all other safety procedures are disregarded, it is mechanically

impossible to remove the probe.

22 Aurora H2O User’s Manual

Figure 19: Threading the Insertion Nut

Page 37

Chapter 2. Installation

2.7.2b Installing the Insertion Membrane Liquid Separator/Pressure Regulator Assembly (cont.)

5. Rotate the probe counterclockwise until the pins are to the far right in the horizontal slot. At this point, the

probe is sealed against the housing interior wall. The pins will be in the middle of the second vertical slot (see

Figure 20 below).

Figure 20: Rotating the Probe

6. Loosen the insertion nut until it is above the top of the second vertical slot (see Figure 21 below). The probe

should not rise to the top of the second vertical slot. If the probe rises in the slot, the foot valve o-ring may have

been damaged or attacked by the process.

Note: The threaded nut on the housing ensures that if all other safety procedures are disregarded, it is mechanically

impossible to remove the probe. Perform the next step regardless of the status of the foot valve o-ring.

Figure 21: Loosening the Insertion Nut

Aurora H2O User’s Manual 23

Page 38

Chapter 2. Installation

2.7.2b Installing the Insertion Membrane Liquid Separator/Pressure Regulator Assembly (cont.)

7. Tighten the insertion nut by hand until it is against the insertion washer again. Using a wrench, tighten the

insertion nut against the insertion washer so that the pins are at the bottom the second vertical slot (see

Figure 22 below). At this point the foot valve opens and the insertion process is complete.

Figure 22: Tightening the Insertion Nut

24 Aurora H2O User’s Manual

Page 39

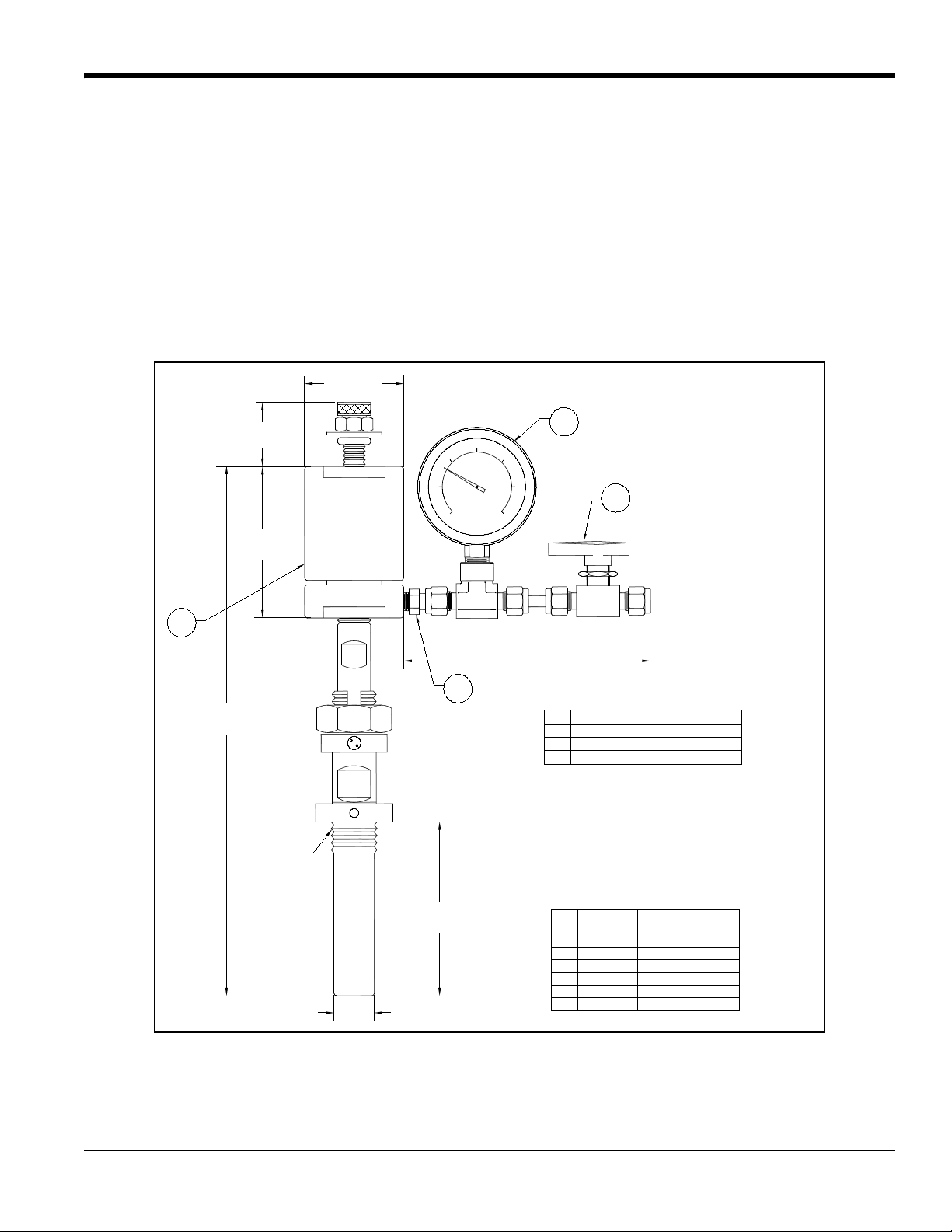

2.7.3 Setting the Pressure

Pressure

Adjustment

Screw

Lock

Nut

Pressure

Gauge

Note: Perform these steps only after the entire system has been plumbed, including the Aurora H2O.

Chapter 2. Installation

1. Ensure the inlet sample gas isolation valve on the

Aurora H2O sample system is closed. Open the isolation ball

valve at the Optional Pipeline Insertion Membrane Liquid Separator/Pressure Regulator.

2. Turn the pressure adjustment screw clockwise to increase the pressure (see Figure 23 below). The optional

pipeline insertion membrane liquid separator/pressure regulator is the FIRST STAGE pressure reduction of the

system when used. Depending upon your source pressure, you should step down the pressure to a value in the

range listed in Ta bl e 2 below.

3. Tighten the lock nut down to the top of the pressure regulator to avoid future possible changes in pressure

regulator setting, once the pressure is set.

Table 2: Pressure Settings

Source Pressure Outlet Pressure Setting

750 psig < source < 1500 psig 400-500 psig

500 psig < source < 750 psig 300 psig

< 500 psig 50% of the average source pressure

Figure 23: Turning the Pressure Adjustment Screw

Aurora H2O User’s Manual 25

Page 40

Chapter 2. Installation

2.8 Making Electrical Connections

Refer to Figure 32 on page 32 for wiring connections.

Aurora H2O has three ¾” NPT conduit inlet ports for power and I/O (see Figure 24 below). These will

1.

normally be shipped plugged from the factory. Follow the applicable wiring code and requirements for wiring

the unit.

Figure 24: Conduit Inlet Ports

Note: Use one conduit inlet for power. Use the two other conduit inlets for input/output as needed. All unused conduit

inlet ports should be sealed with suitable blanking elements.

2. Select one conduit for inlet power to the

Aurora H2O based on your configuration. The Aurora H2O comes with

a universal power supply, or optionally, as a 24VDC powered unit. Remove the wiring cover to view the wiring

terminal block (see Figure 25 below).

Figure 25: Wiring Terminal Blocks

26 Aurora H2O User’s Manual

Page 41

Chapter 2. Installation

2.8 Making Electrical Connections (cont.)

Note: Supply connection wiring shall be rated at least 10°C above the rate maximum service temperature of 85°C, be

stripped back 5/16 in. (8 mm) and torqued to a minimum of 4.4 in. lb. (0.5 Nm).

3. Run the AC power connections to the Power Terminal Block shown in Figure 26 below. It is recommended to

use 12-18 AWG (3.3 - 0.82 mm

2

) power wiring.

Figure 26: Power Terminal Block

4. Use wiring conduit runs, separate from the

three 4-20mA outputs to the terminals labeled A, B, and C. The three analog outputs A, B and C (0-20mA or

4-20mA) are internally powered by the

wire, and ground the shield at one end only. Wire up digital communications to Port 1 and/or Port 2 as labeled.

5. Either digital port may be configured for RS-232 or RS-485. Port 1 is designated as “SCADA.” Port 2 is

designated as “SERVICE.” For operation on RS-485, 2-wire, half-duplex bus, attach the RS-485(+) to (+), and

the RS-485(–) to (–). Per Modbus-IDA specifications, a third, common conductor must also interconnect all

the devices of the bus. Attach the common conductor to RTN.

Note: For an RS-485 Multi-drop Network, a terminating resistor must be installed across the

terminals, or an internal terminating resistor can be applied. See below.

Aurora H2O main power, for all I/O (Input/Output) leads. Wire up to

Aurora H2O. Use shielded 18-22 AWG (0.82–0.33 mm

Aurora H2O RS-485

2

) twisted pair

• When using the Aurora H2O in RS-485 mode, and to prevent signal reflections on the high-speed RS-485

connections, it is recommended that the far end of the RS-485 lines be terminated properly. The termination

can be accomplished in one of two ways:

• Connect 120 Ω, 1/4 W leaded resistors across the + and – terminals of ports 1 and 2 (both ports or

whichever one will be in use)

• Using long-nose pliers, move jumpers J15 and J16 from pins 2 and 3 (default setting from factory) to pins

1 and 2 (see Figure 27 on page 28). J16 is the termination for port 1 and J15 is the termination for port 2. It

is also recommended that basic ESD precautions such as grounded wrist straps be used for this procedure.

Aurora H2O User’s Manual 27

Page 42

Chapter 2. Installation

J16

123

J15

1

2

3

2.8 Making Electrical Connections (cont.)

Multi-drop RS-485:

For multiple Aurora H2O units connected in daisy-chain fashion to the RS485 interface, it is important that the farthest

unit away from the transmitting device be the only unit incorporating any termination (see Figure 27 below). All other

units must have jumpers J15 and J16 in positions 2 & 3 (default setting from the factory). For more details on RS-485

wiring or operation, refer to TIA/EIA-485-A Specification.

Figure 27: RS-485 Mode Termination - Install Jumpers at J15 and J16, Pins 1 and 2

Note: The internal terminations MUST be in the default (unterminated) position for operation in RS-232 mode.

• For operation on RS-232, connect RS-232(TXD) to (+), RS-232(RXD) to (–), and RS-232(GND) to RTN (see

Figure 28 below).

Figure 28: Input/Output Connections

28 Aurora H2O User’s Manual

Page 43

Chapter 2. Installation

2.8 Making Electrical Connections (cont.)

6. For connection to a PC to interface with AuroraView software, you may use the supplied 704-688 cable

(RS-232 w/ SUB-D-9 connector to tinned leads). Wire the cable as follows:

Color Code Aurora H2O Terminal

White Tx +

Red Rx –

Green Ground RTN

The as-shipped default configuration is as follows:

BAUD Rate: 115,200

Parity: Even

Network ID: 1 for Port 1, 2 for Port 2

7. Use a separate wiring conduit run for any 4-20mA pressure transmitter input. This input is used when a live

input pressure reading for the main process pressure is desired, to determine an equivalent dew point by the

Aurora H2O analyzer. Wire the 4-20mA pressure transmitter to the Pressure Transmitter terminal block (see

Figure 29 below). The

Aurora H2O supplies 24VDC for use with a loop-powered, 2-wire pressure transmitter.

Figure 29: Pressure Transmitter Connections

IMPORTANT: Use of an external pressure transmitter is not covered by the

Aurora H2O hazardous area certifications.

The external pressure transmitter should be suitably rated for the area classification. Its associated

wiring should be done in accordance with local codes and regulations, and suitably rated for the area

classification.

8. If the

Aurora H2O has been supplied with an optional electrical heater, there are two possible configurations:

USA/CAN or EU. Connect the AC power using a separate conduit from the power for the

Aurora H2O

analyzer. The heater is equipped with a thermostat preset to 25°C (77°F) nominal. Use 12-18 AWG (3.3 - 0.82

2

mm

) wires. The heater terminals are located within a junction box (item 15 in Figure 2 on page 4 or Figure 3

on page 5).

Aurora H2O User’s Manual 29

Page 44

Chapter 2. Installation

2.8 Making Electrical Connections (cont.)

9. Lastly, the Aurora H2O analyzer requires a connection to ground from the electronics

explosion-proof/flame-proof enclosure. As shown in Figure 30 below, there are two external ground

connections available for the user (on the left and right hand sides of the enclosure). Wire this connection to

earth ground, local to the

Aurora H2O analyzer installation site.

Figure 30: Earth Ground Connection

2.9 Specific Conditions of Use

Before operating your Aurora system, be sure the following conditions are met:

• In the event of repair or replacement of any components, the manufacturer, GE Infrastructure Sensing, shall be

contacted for information on the controlled materials and dimensions of the flameproof characteristics of the

Aurora H2O Moisture Analyzer.

• The laser head assembly of the Aurora H2O Moisture Analyzer shall be inside a tool secured enclosure with

IP20 or better to ensure the factory installed laser head assembly bolts are inaccessible from the outside.

• Consult the manufacturer for genuine replacement flange fasteners. 5/16 inch-24 x 1-1/4 inch 18-8 stainless

steel socket head cap bolts or better with a minimum tensile strength of 70,000 psi are acceptable alternatives.

• To reduce the potential of an electrostatic charging hazard, do not rub painted aluminum parts with a dry cloth.

30 Aurora H2O User’s Manual

Page 45

33.12

26.16

24.26

.95

15.66

1.62210.92

18.31

10.24

13.08 .125

9.29 TYP 3.18 TYP

24.91

Chapter 2. Installation

Aurora H2O User’s Manual 31

Figure 31: Aurora H2O Outline and Mounting (ref. dwg #712-1456)

Page 46

CUSTOMER GROUND

AC OPTION SHOWN

DC WIRING + –

SEE NOTE 2

GROUND BAR

I/O CONNECTIONS

SEE NOTE 1

SEE NOTE 1

NOTES:

I/O CONNECTIONS AND PRESSURE TRANSMITTER WIRE GAUGE RANGE 12-24 AWG.

1.

AC AND DC CONNECTION WIRE GAUGE RANGE 12-18 AWG.

2.

[OUTPUT]

4-20mA

A B C PORT 1 PORT 2

RS-485

+

2

4

V

+ –+ –+ –+ – + –

L1 L2/N G

50-60Hz 0.5A

100-240 VAC

Chapter 2. Installation

Figure 32: Aurora H2O Electronic Assembly Wiring Diagram (ref. dwg #702-8976)

Aurora H2O User’s Manual 32

Page 47

Chapter 3. Operation and General Programming

Chapter 3. Operation and General Programming

3.1 Using the Aurora H2O

Follow the information in this chapter to operate the Aurora H2O system.

CLASS 1 LASER PRODUCT

WARNING! Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous laser exposure.

3.2 Sample System

See the instructions below and Figure 33 on page 35 to operate the Aurora H2O sample system.

3.2.1 Aurora H2O Startup

1. Supply gas inlet pressure should be <400 psig (2760 kPa).

2. Confirm that there are no flow restrictions downstream of the analyzer sample outlet.

a. Maximum outlet back pressure: 10 psig

3. Start with all valves in fully closed position and the pressure regulator turned fully counter-clockwise.

4. Turn the sample gas selector valve [1] with the handle indicator pointing fully to the right.

5. Open the bypass gas metering valve [2] 1/4 turn.

6. Fully open the sample gas metering valve [3].

7. Slowly open the supply gas isolation valve [4] 1/4 turn.

8. Slowly turn the supply gas pressure regulator [6] clockwise until the sample gas flow meter [7] indicates

mid-scale.

a. If the pressure is increased to rapidly, it will activate the liquid-block feature of the membrane filter [8]

shutting off gas flow.

b. If this occurs, fully close the Supply gas isolation valve [4].

c. Wait 30 seconds, and then go back to Step 7. (A pop sound can be heard when the liquid-block re-opens to

allow gas flow)

9. Slowly adjust the bypass gas needle valve [2] until the desired flow rate is reached (requires optional flow

meter for precise metering).

10. Fully open the Supply gas isolation needle valve [4].

Aurora H2O User’s Manual 33

Page 48

Chapter 3. Operation and General Programming

3.2.2 Aurora H2O Shut Down

1. Fully close the supply gas isolation valve [4].

2. Turn the supply gas pressure regulator [6] fully counter-clockwise.

3. Fully close the bypass and sample gas metering valves [2 & 3].

3.2.3 Aurora H2O Purge Gas Connection

1. Start with all valves in closed position and the pressure regulator turned fully counter-clockwise.

2. Confirm that there are no flow restrictions downstream of the analyzer sample outlet.

a. Maximum outlet back pressure: 10 psig

3. Turn the sample gas selector valve [1] with the handle indicator pointing fully to the left.

4. Connect the regulated and filtered gas supply.

a. Regulated pressure range: 0-10 psig.

b. Outlet filter size: 7 micron

c. Initial pressure setting: 0 psig (minimum)

5. Fully open the sample gas metering valve [3].

6. Increase the regulated pressure until the sample gas flow meter [7] indicates mid-scale.

34 Aurora H2O User’s Manual

Page 49

3.2 Sample System (cont.)

INLET ISOLATION

NEEDLE VALVE

PRESSURE

REGULATOR

BYPASS

NEEDLE VALVE

SAMPLE/PURGE

3-WAY BALL VALVE

PURGE INLET

NEEDLE VALVE

Chapter 3. Operation and General Programming

Aurora H2O User’s Manual 35

Figure 33: Aurora H2O Sample System (ref. dwg #902-004)

Page 50

Chapter 3. Operation and General Programming

3.3 Keypad Features

Menu Power Indicator

Fault Indicator Laser Indicator

Information

Indicator

Cancel

Main Display

Keypad Lock

Indicator

Enter

Up, Left, Right,

Down Arrows

The Aurora H2O has seven keys: a Menu key, four Arrow keys, a Cancel key, and an Enter key.

• Use the Menu key to open the main menu on the display.

• Use the Arrow keys to navigate among menu choices and to increment/decrement numeric entries.

• Use the Cancel key to cancel a numeric entry change, or exit a menu.

• Use the Enter key to accept a numeric entry or select a menu option.

36 Aurora H2O User’s Manual

Page 51

Chapter 3. Operation and General Programming

3.3.1 Indicator Lights

If the Fault Indicator is lit, an instrument fault is detected. A message will be displayed in the Main Display, top/right.

Information Indicator is lit, the instrument is still operating, but a message will appear in the Main Display

If the

top/right, with information about the instrument.

Keypad Lock Indicator will be lit if either: A) the Keypad Lock-Out Switch, internal to the instrument, has been

The

engaged, or B) the instrument keypad has not been used for a period of several minutes, engaging a software feature to

lock-out inadvertent key usage. Type (B) keypad lock-out is overcome by pressing Cancel, Enter, Cancel in sequence.

Laser Indicator is lit, the laser is powered and operating normally. This indicator will be off if there is a

If the

laser-specific fault. This indicator will also be off for a brief period when the instrument is first powered. After initial

power-up, this indicator may blink several times as the laser temperature is stabilized. The laser indicator will be lit

constantly in normal operation.

Power Indicator is normally lit when the instrument is powered on.

The

3.3.2 The Magnetic Stylus

Each of the keys can be selected using a hand-held magnet called a Magnetic Stylus (see Figure 35 below), which is

included with the meter. By touching the clear window at a key location, that key will be selected and will flash a red

light to verify the contact.

Figure 35: Magnetic Stylus

3.3.3 The Default Display

Figure 36 below shows the default display of the Aurora H2O window.

Primary

Figure 36: Default Display

Alt 1

Aurora H2O User’s Manual 37

Alt 2

Page 52

Chapter 3. Operation and General Programming

Keypad Lock Indicator

Keypad

Lock-Out Switch

3.3.4 Unlocking the Keypad