Page 1

GE

Measurement & Control

Aurora 19

Reliable Moisture Measurement

GE’s Aurora 19 analyzer uses tunable diode laser

absorption spectroscopy (TDLAS) to accurately

measure moisture in a variety of background gases.

The Aurora 19 analyzer is suitable for installation

in safe areas and operates over a wide range of

environmental conditions. Aurora 19’s fast response

immediately alerts when moisture concentrations are

out of compliance; once corrected, gas can be quickly

cleared for process normalization.

The Aurora 19 analyzers have an intuitive interface

that makes them easy to learn, congure and

operate. With a local service team to support them,

you have the condence of knowing that Aurora 19

analyzers are always ready for immediate moisture

measurement. With power and gas lines easily

connected, the Aurora 19 moisture analyzer provides

a wide range of reliable measurement with accuracy

and fast response you need for immediate alerts

to process upsets or out-of-compliance moisture

concentrations.

Page 2

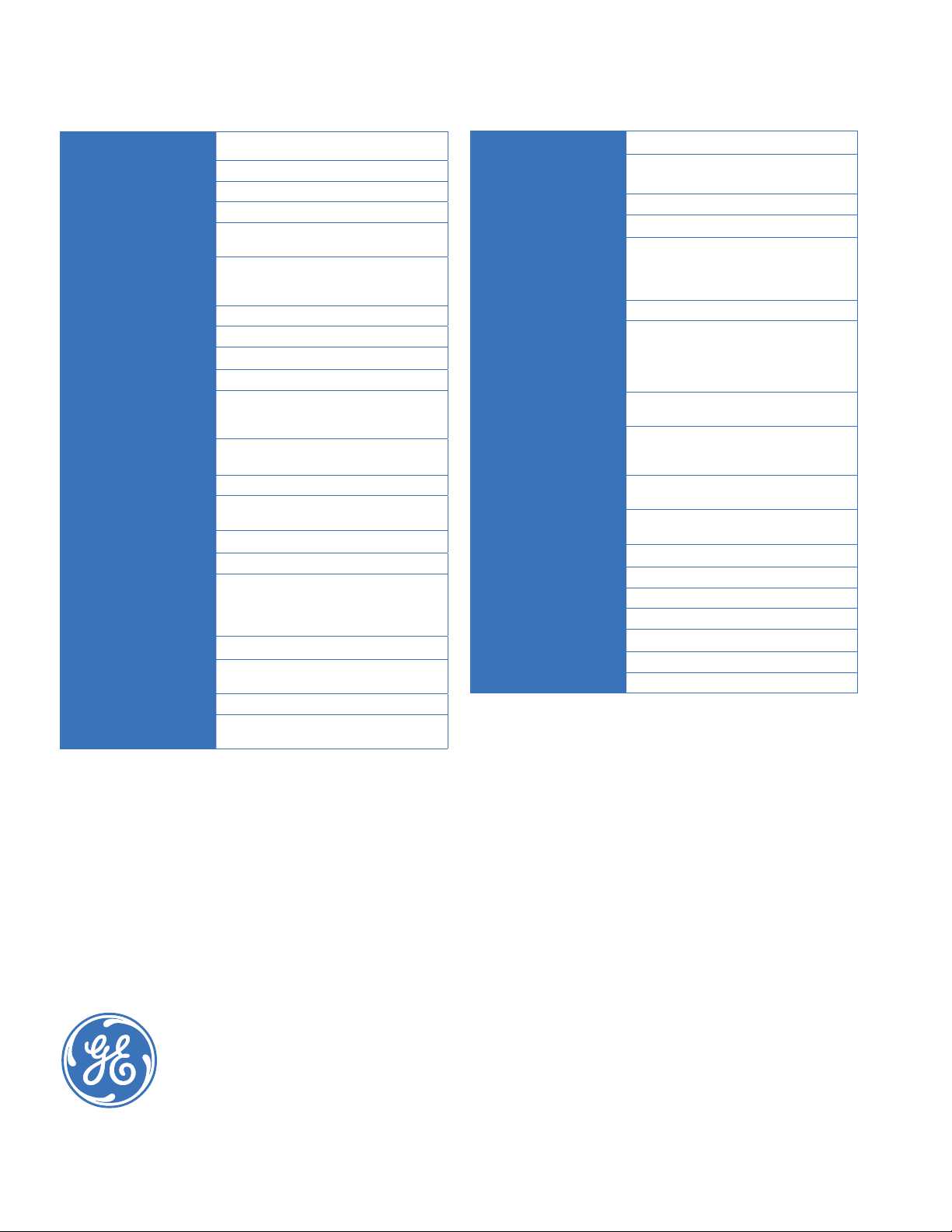

Specications

Range

Calibrated Range 0 to 5000 ppm

Lower Detect Level 5 ppm

For CO2 applications: 50 ppm

Dew/Frost Point

Process Dew/Frost Point

Absolute Humidity 0.24 to 237 (3.8 to 3,803 mg/m

1

-85.9° to 27.3°F (-65.5° to –2.6°C) frost point

@ STP of 25°C, 14.696 psia

1

Process or equivalent dew point/frost point by

calculation with process pressure signal (4-20

mA) or constant

v

v

v

3

) lbs/MMSCF

Accuracy

Parts Per Million by Volume +2% of reading or 4 ppm

For CO2 applications: +3% of reading or 5 ppmv

(Accuracy of other parameters derived from

)

ppm

v.

Repeatability ±2 ppm

Calibration Certication NIST or equivalent NMI traceable certication

Calibration Options Nitrogen, standard natural gas and 3

(parts per billion by volume) below 200

v

ppm. 1% above 200 ppm

customizable calibration curves

v

Response Time

Response Time Optical system <2 seconds

System Response The system response is dependent on the

length of sample tubing, sample system

components, ow rate and pressure, as well as

the change in moisture concentration.

Pressure

Operating Sample Cell

Pressure

Process Pressure 102 psig (0.69MPa)

69 to 172 Kpa (10 to 25 psia)

Higher pressure available with application of

additional sampling system components.

Flowrate

Sample Cell Flowrate 10 to 60 SLH (0.4 to 2 SCFH ); 30 SLH (1 SCFH)

nominal

By-pass Fast Loop 5 to 10X of owrate through sample cell

I/O

Display Backlit LCD. Three programable simultaneous

parameters. Alphanumeric status and

diagnostic display. LEDs for power, laser

temperature stability, keypad lockout

Power Analyzer: 100-240 VAC, 50-60 Hz

Analog Outputs Three 0/4-20 mA DC (source) with 500 ohm

load. User programmable for any parameter

and scalable. Complies with NAMUR protocol

for analog signals.

Analog Input Loop powered 4-20 mA input for remote

pressure transmitter. Aurora supplies 24 VDC.

Digital Interface Two programmable digital communications

ports RS232, RS485 with multidrop capability

and assignable address, MODBUS RTU protocol.

User Interface Programmable “through-the-glass” via

magnetic stylus

Laser Class 1 product. Conforms to IEC 60825-1.

Edition 2.0 Safety of Laser Products

Enclosure

Ingress Protection IP-54

Net Weight 37 kg (100 lb)

Dimensions 6.97 H (177) x 19.92 L (506) x 18.86 W (479)

Temperature

Operating -20 to 65°C (-4 to 149°F)

Storage -20 to 70°C (-4 to 158°F)

www.ge-mcs.com

920-647B

© 2014 General Electric Company. All Rights Reserved. Specications are subject to change without notice. GE is a registered trademark of General Electric Company. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their respective companies, which are not aliated with GE.

Loading...

Loading...