Page 1

GE

Sensing & Inspection Technologies

AquaTrans™ AT868

Panametrics Liquid Flow Ultrasonic Transmitter

Abridged Manual

Page 2

GE

Sensing & Inspection Technologies

AquaTrans™ AT8688

Panametrics Liquid Flow Ultrasonic Transmitter

Abridged Manual

914-218D

September 2004

The AquaTrans AT868 is a GE Panametrics product. GE Panametrics has joined other GE high-technology

businesses under a new name—GE Sensing & Inspection Technologies.

Page 3

September 2004

Warranty Each instrument manufactured by GE Infrastructure Sensing, Inc. is

warranted to be free from defects in material and workmanship.

Liability under this warranty is limited to restoring the instrument to

normal operation or replacing the instrument, at the sole discretion of

GE Infrastructure Sensing, Inc. Fuses and batteries are specifically

excluded from any liability. This warranty is effective from the date of

delivery to the original purchaser. If GE Infrastructure Sensing, Inc.

determines that the equipment was defective, the warranty period is:

• one year for general electronic failures of the instrument

• one year for mechanical failures of the sensor

If GE Infrastructure Sensing, Inc. determines that the equipment was

damaged by misuse, improper installation, the use of unauthorized

replacement parts, or operating conditions outside the guidelines

specified by GE Infrastructure Sensing, Inc., the repairs are not

covered under this warranty.

The warranties set forth herein are exclusive and are in lieu of

all other warranties whether statutory, express or implied

(including warranties of merchantability and fitness for a

particular purpose, and warranties arising from course of

dealing or usage or trade).

iii

Page 4

September 2004

Return Policy If a GE Infrastructure Sensing, Inc. instrument malfunctions within the

warranty period, the following procedure must be completed:

1. Notify GE Infrastructure Sensing, Inc., giving full details of the

problem, and provide the model number and serial number of the

instrument. If the nature of the problem indicates the need for

factory service, GE Infrastructure Sensing, Inc. will issue a RETURN

AUTHORIZATION number (RA), and shipping instructions for the

return of the instrument to a service center will be provided.

2. If GE Infrastructure Sensing, Inc. instructs you to send your

instrument to a service center, it must be shipped prepaid to the

authorized repair station indicated in the shipping instructions.

3. Upon receipt, GE Infrastructure Sensing, Inc. will evaluate the

instrument to determine the cause of the malfunction.

Then, one of the following courses of action will then be taken:

• If the damage is covered under the terms of the warranty, the

instrument will be repaired at no cost to the owner and returned.

• If GE Infrastructure Sensing, Inc. determines that the damage is not

covered under the terms of the warranty, or if the warranty has

expired, an estimate for the cost of the repairs at standard rates

will be provided. Upon receipt of the owner’s approval to proceed,

the instrument will be repaired and returned.

iv

Page 5

September 2004

Table of Contents

Chapter 1: Installation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Site Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Electronics Enclosure Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Flowcell Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Transducer Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Transducer Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Installing a Flowcell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

CE Mark Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

LVD Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Making Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Preliminary Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Wiring the Line Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Wiring Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Wiring Standard 0/4-20 mA Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Wiring the Totalizer/Frequency Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Wiring the Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Wiring an External Totalizer Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Programming the AT868 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Chapter 2: Programming Site Data

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Activating a Channel [CHx-ACTIV Menu] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Accessing the ACTIV Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Entering System Data [CHx-SYSTM Menu] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Accessing the CHx-SYSTM Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Selecting the Volumetric Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Selecting the Totalizer Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Selecting Mass Flow Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Entering Transducer and Pipe Parameters [CHx-PIPE Menu] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Accessing the PIPE Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Special Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Special Clamp-On Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Pipe Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Pipe Outside Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Path and Axial Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Lining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Setting Up a Tracking Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Fluid Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Reynolds Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

KV Input Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Number of Traverses and Transducer Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Entering the Zero Cutoff Value [CHx-I/O Menu]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Activating Mass Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

v

Page 6

September 2004

Table of Contents (cont.)

Entering Global System Data [GLOBL-SYSTM Menu]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Selecting the GLOBL-SYSTM Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Selecting the System Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Setting Up the External Totalizer Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Selecting Mass Flow Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Setting Up the Outputs [GLOBL-I/O Menu] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Accessing the Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Setting Up the Analog Output Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Accessing the Totalizer/Frequency Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Setting Up a Frequency Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Setting Up a Totalizer Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Configuring the Communications Port [GLOBL-COMM] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Taking Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Chapter 3: Displaying Data

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Adjusting LCD Contrast and Brightness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Accessing the Display Submenu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Configuring the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Resetting the Totalizers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Resetting Totalizers Using the Internal Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Resetting Totalizers Using an External Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Chapter 4: Calibration

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibrating and Testing the Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Testing Linearity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Calibrating the Totalizer/Frequency Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Calibrating the Frequency Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Calibrating the Totalizer Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Appendix A: Menu Maps

Appendix B: Measuring P and L Dimensions

Measuring P and L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

vi

Page 7

Chapter 1

Page 8

Installation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Site Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

CE Mark Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Making Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Programming the AT868 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Page 9

September 2004

Introduction To ensure safe and reliable operation of the AT868, the system must

be installed and programmed in accordance with the guidelines

established by GE. Those guidelines are explained in detail in this

chapter.

!WARNING!

Be sure to follow all applicable local safety codes and

regulations for installing electrical equipment. Consult

company safety personnel or local safety authorities to

verify the safety of any procedure or practice.

!ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed

as described later in this chapter.

Site Considerations Because the relative location of the flowcell and the electronics

enclosure is important, use the guidelines in this section to plan the

AT868 installation.

Electronics Enclosure Location

The standard AT868 electronics enclosure is a powder-coated

aluminum NEMA 4X, IP66 weatherproof enclosure (see Figure 1-4

on page 1-15). Typically, the enclosure is mounted as close as

possible to the transducers. When choosing a site, make sure the

location permits easy access to the electronics enclosure for

programming, maintenance and service.

Note: For compliance with the European Union’s Low Voltage

Directive (73/23/EEC), this unit requires an external power

disconnect device such as a switch or circuit breaker. The

disconnect device must be marked as such, clearly visible,

directly accessible, and located within 1.8 m (6 ft) of the unit.

Installation 1-1

Page 10

September 2004

Flowcell Location A flowcell is the section of pipe where the transducers are mounted. It

can be created either by mounting the transducers on the existing

pipeline or by mounting them on a spoolpiece. A spoolpiece is a

separately manufactured pipe section, matched to the existing pipe,

which contains ports for mounting the transducers. A spoolpiece

allows the transducers to be aligned and calibrated before inserting

the flowcell into the pipeline.

Ideally, install the flowcell in a section of pipe with unlimited access,

such as a long section of pipe that is above ground. However, if the

flowcell must be installed in an underground pipe, dig a pit around the

pipe to facilitate installation.

Transducer Location For a given fluid and pipe, the accuracy of the AT868 depends

primarily on the location and alignment of the transducers. In addition

to accessibility, when planning for transducer location, follow these

guidelines:

• Locate the transducers so that there are at least 10 pipe diameters

of straight, undisturbed flow upstream and 5 pipe diameters of

straight, undisturbed flow downstream from the measurement

point. Undisturbed flow means avoiding sources of turbulence in

the fluid such as valves, flanges, expansions, and elbows; avoiding

swirl; and avoiding cavitation.

• Locate the transducers on a common axial plane along the pipe.

Install the transducers on the side of the pipe instead of the top or

bottom, because the top of the pipe accumulates gases and the

bottom of the pipe accumulates sediment. These conditions cause

attenuation of the ultrasonic signal. There is no similar restriction

with vertical pipes. However, vertical pipes with downward flow

should be avoided to ensure a full pipe at the measurement point.

1-2 Installation

Page 11

September 2004

Cable Lengths Locate the electronics enclosure as close as possible to the flowcell,

preferably directly on the flowcell. However, GE can supply

transducer cables up to 1,000 ft (300 m) in length for remote location

of the electronics enclosure. If longer cables are required, consult the

factory for assistance.

Transducer Cables When installing the transducer cables, always observe established

standard practices for the installation of electrical cables. Do not route

transducer cables alongside high amperage AC power lines or any

other cables that could cause electrical interference. Also, protect the

transducer cables and connections from the weather and corrosive

atmospheres.

Note: If you are using your own cables to connect the transducers to

the electronics console, they must have electrical

characteristics identical to the cables supplied by GE. For

transducer frequencies up to 2 MHz, the cables in each pair

must be the same length within ±4 in. (±10 cm). For

transducer frequencies above 2 MHz, the cables in each pair

must be the same length within ±0.5 in. (±1.25 cm).

Installing a Flowcell A flowcell is the section of pipe where the transducers are mounted. It

can be created either by mounting the transducers on the existing

pipeline or by mounting them on a spoolpiece. A spoolpiece is a

separately manufactured pipe section, matched to the existing pipe,

which contains ports for mounting the transducers. A spoolpiece

allows the transducers to be aligned and calibrated before inserting

the flowcell into the pipeline.

Installation 1-3

Page 12

September 2004

CE Mark Compliance For CE Mark compliance, the AT868 must meet both the EMC and

LVD directives.

IMPORTANT: CE Mark compliance is required for all units intended

for use in EEC countries.

EMC Compliance For EMC compliance, the electrical connections must be shielded and

grounded as in Tabl e 1-1 below. Also refer to Figure 1-1 on the next

page an example of acceptable wiring. After all the necessary

electrical connections have been made, seal any unused cable entry

holes with standard conduit plugs or equivalent.

Note: If the instructions in this section are followed, the unit will

comply with the EMC Directive 89/336/EEC.

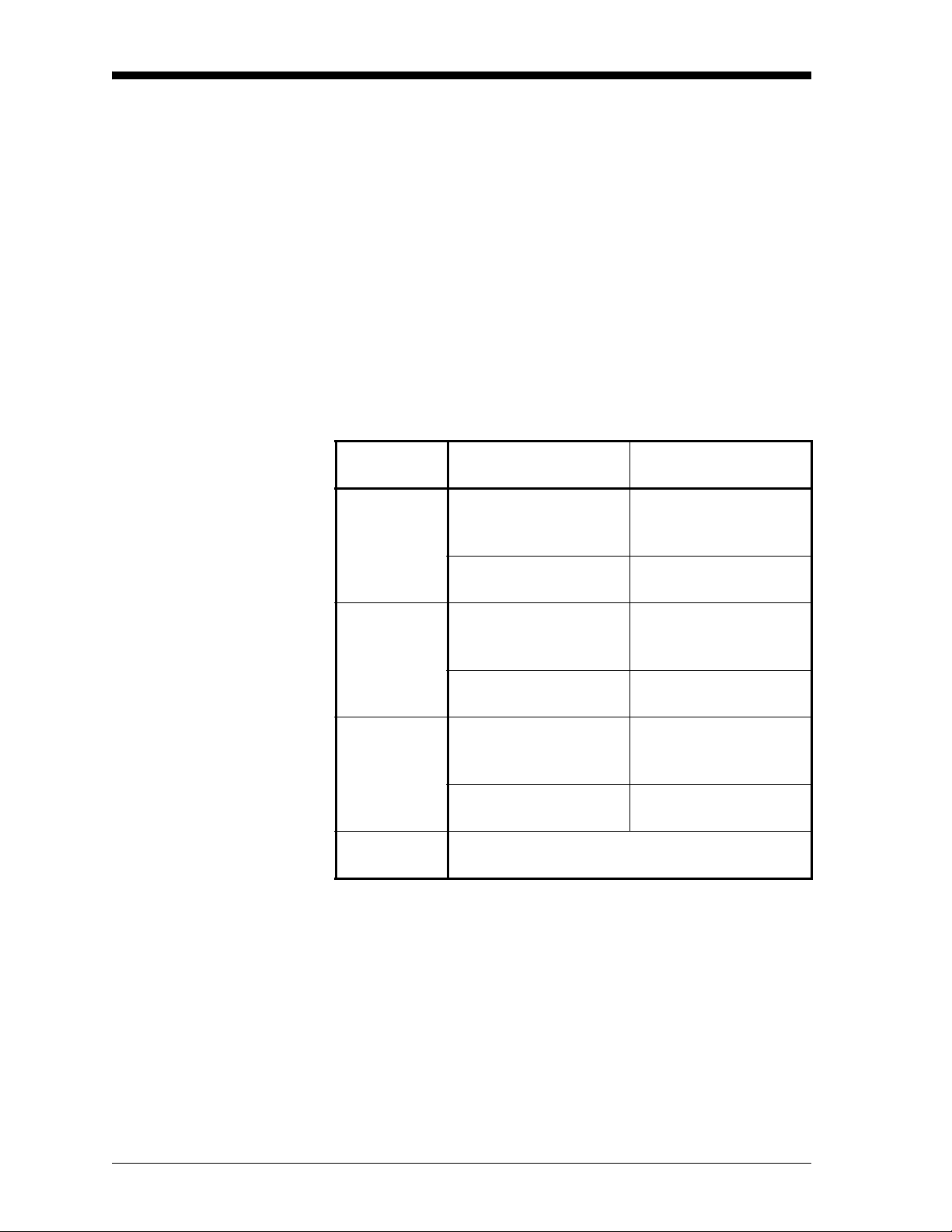

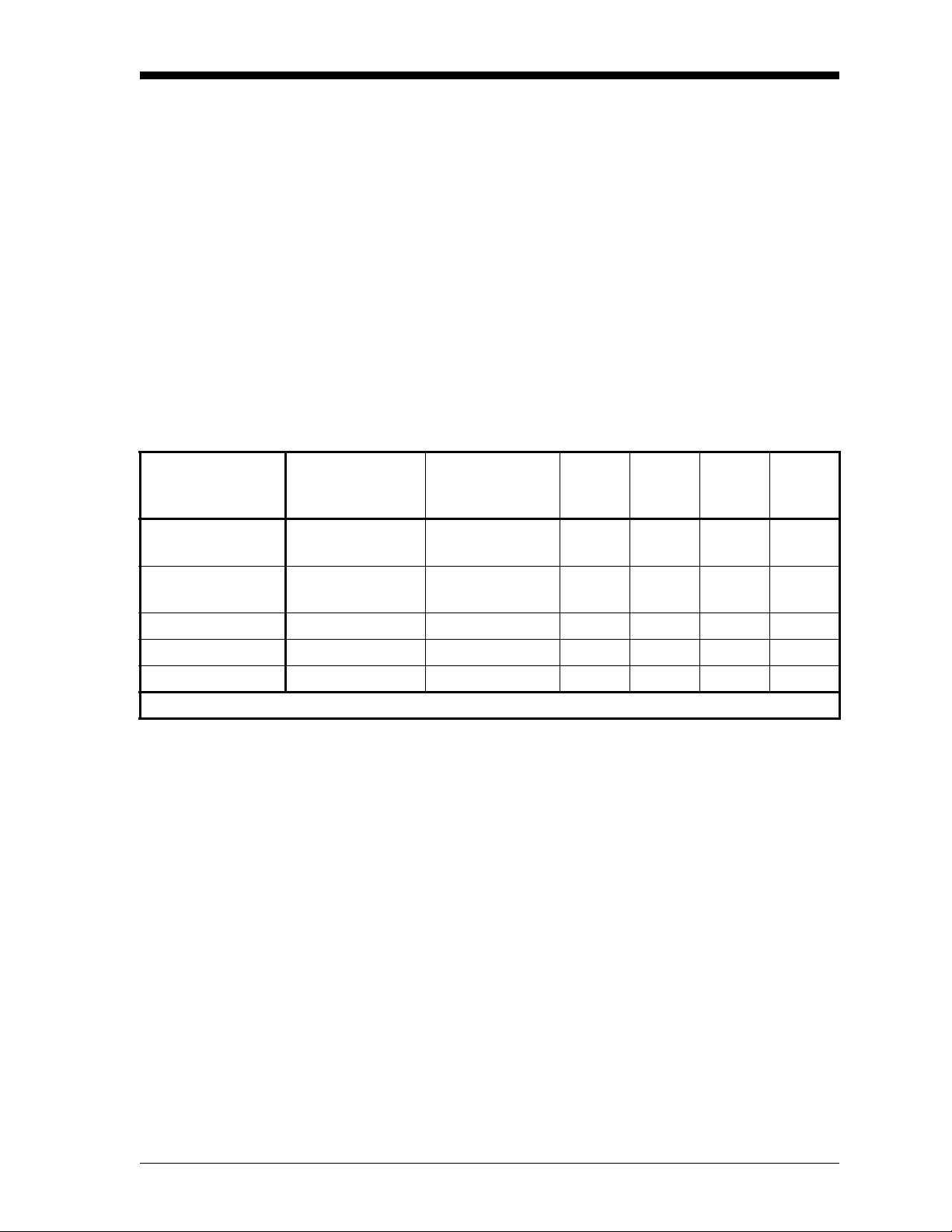

Table 1-1: Wiring Modifications

Termination

Connection Cable Type

Transducer RG62 a/u Add metallic cable clamp

Modification

from braid to chassis

ground.

Armored RG62 a/u or

conduit

Input/Output 22 AWG Shield

(e.g. Baystate #78-1197)

Armored conduit None - grounded via

Power 14 AWG, 3 conductor,

shielded

(e.g. Belden #19364)

Armored Conduit None - grounded via

Shielding Wires enclosed in a properly-grounded metal

conduit do not require additional shielding.

Terminate RG62 a/u

shield to chassis ground.

Terminate shield to

chassis ground at the

AT868.

cable gland.

Terminate shield to

chassis ground at the

AT868.

cable gland.

1-4 Installation

Page 13

September 2004

LVD C omp li anc e For compliance with the European Union’s Low Voltage Directive

(73/23/EEC). the analyzer requires an external power disconnect

device such as a switch or circuit breaker. The disconnect device must

be marked as such, clearly visible, directly accessible, and located

within 1.8 m (6 ft) of the unit.

Note: If the instructions in this section are followed, the unit will

comply with the Low Voltage Directive (73/23/EEC).

Figure 1-1: Properly Wired AT868

Installation 1-5

Page 14

September 2004

Making Electrical Connections

This section contains instructions for making all the necessary

electrical connections to the AT868 electronics console. Refer to

Figure 1-5 on page 1-16 for a complete wiring diagram.

!ATTENTION EUROPEAN CUSTOMERS!

To meet CE Mark requirements, all cables must be installed

as described in the previous section

!WARNING!

Always disconnect the line power from the AT868 before

removing the front cover.

Preliminary Steps Before making any electrical connections, prepare the AT868 by

completing the following steps:

1. Disconnect any previously wired power line from the unit.

2. Remove the screws on the front cover.

3. Loosen the two screws and remove the plastic shroud that protects

the electrical connections.

Note: For compliance with the European Union’s Low Voltage

Directive (73/23/EEC), a transparent plastic shroud protects

the electrical connections. The shroud must remain in place,

except while wiring the unit. Reinstall the shroud after the

wiring has been completed.

4. Install any required cable clamps in the appropriate conduit holes

on the bottom of the enclosure.

5. Note the labels inside the enclosure to assist in wiring.

Proceed to the appropriate section of this chapter to make the required

wiring connections.

1-6 Installation

Page 15

September 2004

Wiring the Line Power The AT868 may be purchased for operation with power inputs of

85-265 VAC or 12-28 VDC. The label on the side of the electronics

enclosure lists the required line voltage and power rating. The fuse

rating is listed on label located under the fuse.

IMPORTANT: Be sure to connect the meter only to the specified line

voltage.

Note: For compliance with the European Union’s Low Voltage

Directive (73/23/EEC), this unit requires an external power

disconnect device such as a switch or circuit breaker. The

disconnect device must be marked as such, clearly visible,

directly accessible, and located within 1.8 m (6 ft) of the unit.

Refer to Figure 1-5 on page 1-16 to locate the power input terminal

block and connect the line power as follows:

!WARNING!

Improper connection of the line power leads or connecting

the meter to the incorrect line voltage may damage the

unit. It may also result in hazardous voltages at the

flowcell and associated piping as well as within the

electronics enclosure.

1. Prepare the line power leads by trimming the line and neutral AC

power leads (or the positive and negative DC power leads) to a

length 0.5 in. (12 mm) shorter than the ground lead. This ensures

that the ground lead is the last to detach if the power cable is

forcibly disconnected from the meter.

2. Install a suitable cable clamp in the conduit hole where the line

power wires will enter the enclosure. If possible, avoid using a

conduit hole containing any other cables cables, to minimize any

interference in the circuitry from the AC power line.

3. Strip 1/4-in. of insulation from the end of each of the three line

power leads.

4. Route the cable through the conduit hole and connect the line

power leads to the power terminal block as shown in Figure 1-5

on page 1-16.

Installation 1-7

Page 16

September 2004

Wiring the Line Power

5. Leaving a bit of slack, secure the power line with the cable clamp.

(cont.)

Caution!

Do not apply power to the AT868 until after the

transducers have been properly wired.

6. Do one of the following:

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

Wiring Transducers !WARNING!

Before connecting the transducers, discharge any static

buildup by shorting the center conductor of the transducer

cables to the metal shield on the cable connector.

Note: For transducer frequencies below 2 MHz, the cable lengths

must be within ±4 in. (±10 cm) of each other. If the transducer

frequency exceeds 2 MHz, the cable lengths must be within

±0.5 in. (±1.25 cm) of each other.

1. Locate the CH1 transducer cables and connect them to the two

CH1 transducers. Route the free ends of the cables through the

selected conduit hole in the electronics enclosure.

2. If an optional lightening protector is being installed, connect it

between the meter and the transducers.

3. Refer to the wiring diagram in Figure 1-5 on page 1-16 and

connect the transducer cables to the terminal block labeled DN and

UP for Channel 1. Then, secure the cable clamp.

Note: The RED cable leads are the SIG(+) leads and the BLACK

cable leads are the RTN(-) leads.

Note: The AT868 can use two channels or paths to make more

accurate flow measurements by averaging, subtracting or

adding the the two readings.

1-8 Installation

Page 17

September 2004

Wiring Transducers (cont.) 4. For a 2-Channel AT868, repeat steps 1-3 to connect the CH2

transducers to the DN and UP terminal block for Channel 2.

Wiring Standard 0/4-20 mA Analog Outputs

Note: It is not

connected.

5. Do one of the following:

required that both channels of a 2-Channel unit be

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

IMPORTANT: Each channel must be activated before it can begin

taking measurements. See Chapter 2, Programming

Site Data, for instructions.

The AT868 has one isolated 0/4-20 mA analog output per channel

(designated as Output A and Output C). These outputs can be

configured independently. Typically, Output A is used for Channel 1

and Output C is used for Channel 2. However, either analog output

can be configured for use with either channel.

Connections to the analog outputs may be made with standard

twisted-pair wiring, but the current loop impedance for these circuits

must not exceed 600 ohms. To wire the analog outputs, complete the

following steps:

1. Refer to Figure 1-5 on page 1-16 for the locations of the

appropriate terminal blocks and wire the analog outputs as shown.

Then, secure the cable clamp.

IMPORTANT: Outputs 1 and 2 in the wiring diagram correspond to

Outputs A and C in the AT868 software.

2. Do one of the following:

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

IMPORTANT: Prior to use, the analog outputs must be calibrated as

described in Chapter 4, Calibration.

Installation 1-9

Page 18

September 2004

Wiring the Totalizer/Frequency Output

The AT868 also provides a second output for each channel

(designated as Output B and Output D) that can be configured as a

totalizer or frequency output using the Instrument Data Manager

(IDM) software. These outputs can be configured independently.

Typically, Output B is used for Channel 1 and Output D is used for

Channel 2. However, either output can be configured for use with

either channel.

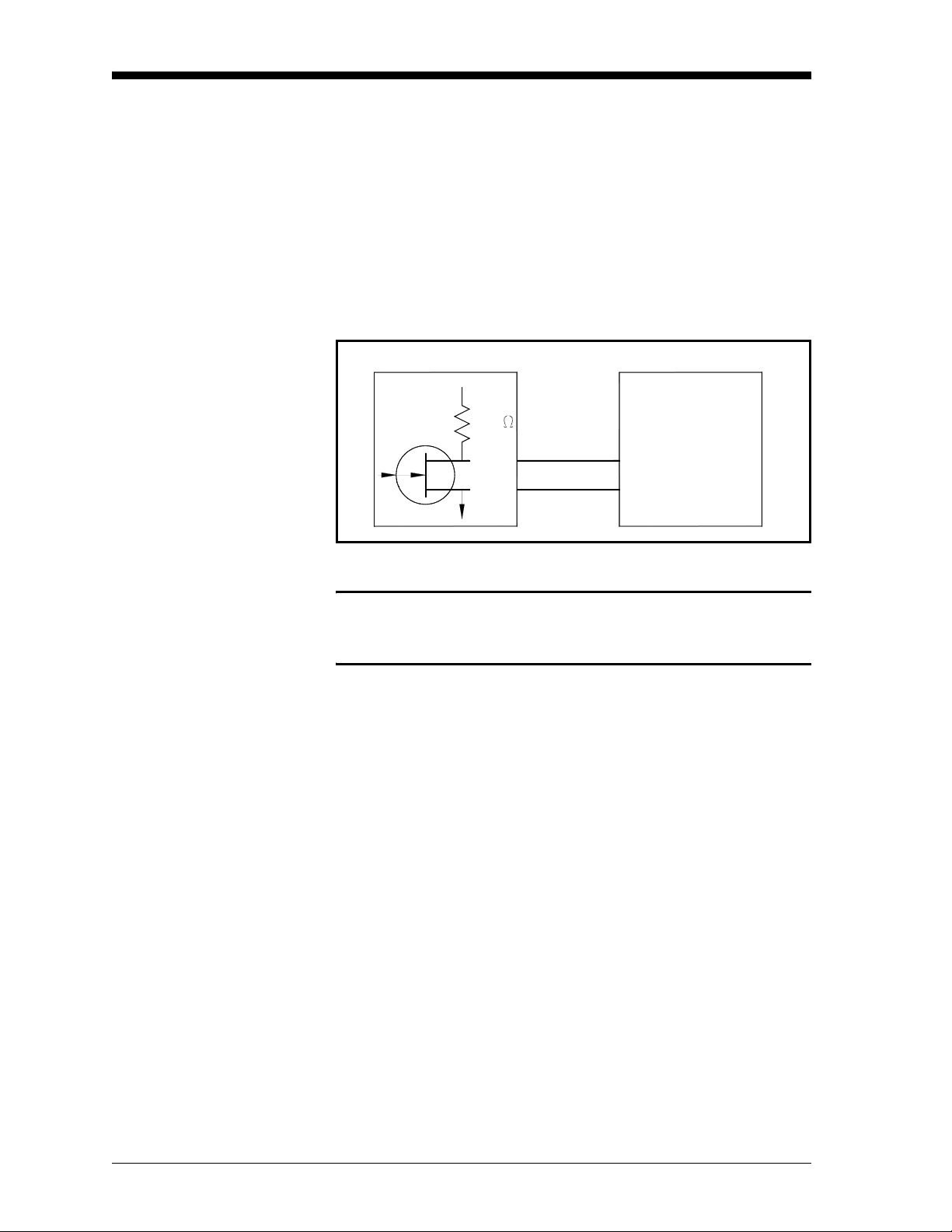

Figure 1-2 below shows a wiring diagram for a typical totalizer or

frequency output circuit.

Model AT868 Pulse/Frequency Counter

+5V

200

OUT

RTN

Figure 1-2: Totalizer/Frequency Output Wiring

IN

Common

!WARNING!

NEVER CONNECT EXTERNAL POWER TO THE

PULSE/FREQUENCY OUTPUT TERMINALS.

To wire the totalizer/frequency outputs, complete the following steps:

1. Refer to Figure 1-5 on page 1-16 for the location of the terminal

blocks and wire the totalizer/frequency outputs as shown. Then,

secure the cable clamp.

Note: Outputs 1 and 2 in the wiring diagram correspond to Outputs

B and D in the AT868 software.

2. Do one of the following:

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

1-10 Installation

Page 19

September 2004

Wiring the Serial Port The AT868 is equipped with a built-in serial communications port.

The standard port is an RS232 interface, but an optional RS485

interface is available upon request. Proceed to the appropriate section

for wiring instructions.

Wiring an RS232 Interface Use the serial port to connect the AT868 to a printer, an ANSI

terminal or a personal computer. The RS232 interface is wired as

Data Terminal Equipment (DTE), and the signals available at the

COMMUNICATION terminal block are shown in Table 1-2 below.

To wire the RS232 output, complete the following steps:

1. Use the information in Tabl e 1-2 below to construct a suitable

cable for connecting the AT868 to the external device. If desired,

an appropriate cable may be purchased from GE.

Table 1-2: RS232 Connection to DCE or DTE Device

COMMUNICATION

TB

5WhiteDTR (Data

Colors for

GE Cable

(flying leads)*

Signal

Description

Terminal Ready)

DCE

DB25

Pin #

20 4 20 4

DCE

DB9

Pin #

DTE

DB25

Pin #

DTE

DB9

Pin #

4 Yellow CTS

(Clear to Send)

3 Green COM (Ground)7575

2 Red RX (Receive)2332

1 Black TX (Transmit)3223

*For standard GE cables 704-659, -660, -661 and -662.

Note: Signal names that imply direction (e.g., transmit and receive)

are named from the point of view of the DTE device (the GE

meter is usually considered the DTE device). When the RS232

standard is strictly followed, these signals are labeled with the

same name and pin # on the DCE device side. Unfortunately,

the convention is not followed because the DTE and DCE side

get confused. Therefore, connections that imply direction are

changed to reflect their direction on the DCE side.

4758

Installation 1-11

Page 20

September 2004

Wiring an RS232 Interface

(cont.)

2. Route the flying leads end of the cable through the conduit hole

and wire the leads to the COMMUNICATION terminal block as

shown in Figure 1-5 on page 1-16. Connect the other end of the

cable to the printer, ANSI terminal or personal computer. Then,

secure the cable clamp.

3. Do one of the following:

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

Note: Consult the User’s Manual for the external device to configure

it for use with the AT868.

Wiring an RS485 Interface Use the optional RS485 serial port to network multiple AT868 flow

transmitters to a single computer terminal. Upon request, the standard

RS232 port on the AT868 may be configured as a two-wire,

half-duplex RS485 interface, through a device such as the INMAC

Model 800052 RS232-RS422/RS485 converter.

Note: If the AT868 is configured at the factory for RS485 operation,

the INMAC converter is not necessary.

Proceed to the appropriate following section to wire the RS485

interface.

1-12 Installation

Page 21

September 2004

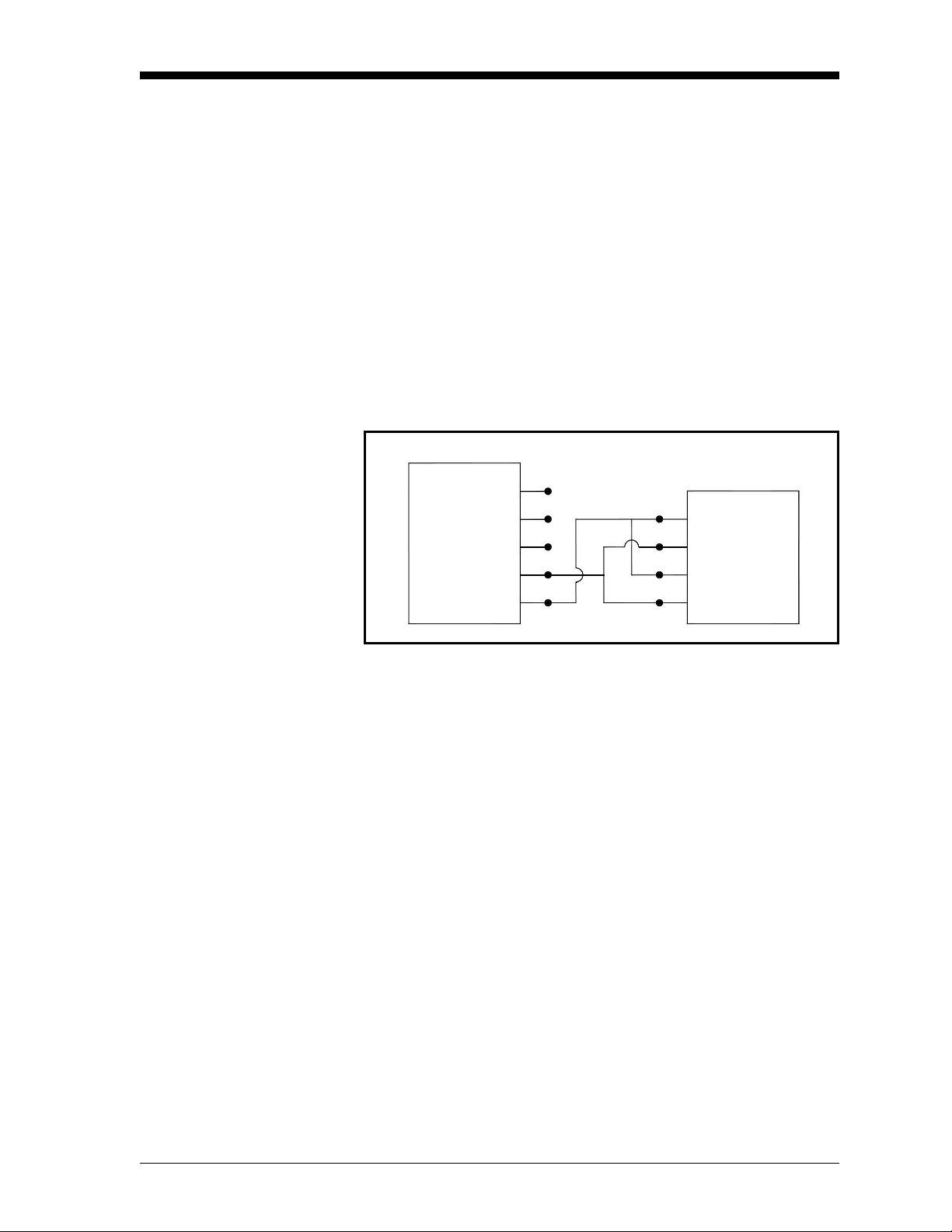

Using an INMAC Converter To wire the RS485 serial port using an INMAC converter, refer to

Figure 1-5 on page 1-16 and complete the following steps:

1. Route one end of the cable through the conduit hole and wire the

leads to the COMMUNICATION terminal block as shown in

Figure 1-5 on page 1-16. Then, secure the cable clamp.

2. Connect the other end of the cable to the converter, as shown in

Figure 1-3 below.

3. Do one of the following:

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

Model AT868

Using a Factory Serial

Interface

N.C. 5

N.C. 4 1 TD OUT

N.C. 3 2

RX 2 3

TX 1

Figure 1-3: Typical RS485 Connections

Use the following steps to link the AT868 to the control system using

a factory-installed RS485 serial interface:

1. Route the wires through the conduit hole and connect the TMT+

lead to Pin 2 (RX) on the COMMUNICATION terminal block

(see Figure 1-5 on page 1-16).

2. Connect the TMT- lead to Pin 1 (TX) on the COMMUNICATION

terminal block. Then, secure the cable clamp.

3. Connect the other end of the cable to the control system.

4. Do one of the following:

Converter

4 RD IN

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

Installation 1-13

Page 22

September 2004

Wiring an External Totalizer Reset Switch

The AT868 can be wired with an external switch for resetting the

totalizer values. When properly configured, pressing the switch will

reset the totalizer values to zero for both Channel 1 and Channel 2.

IMPORTANT: The AT868 has the capability to use a reset switch, but

the user must supply all the hardware.

Complete the following steps to connect an external reset switch:

1. Refer to Figure 1-5 on page 1-16 to properly connect the external

reset switch to the AT868.

2. Configure the the external reset switch for use, as described in

Chapter 2, Programming Site Data.

3. Do one of the following:

• Proceed to another section to continue wiring the AT868.

• Reinstall the plastic shroud, replace the front cover on the

enclosure and tighten the screws.

Programming the AT868 After the AT868 has been completely installed and wired, reconnect

line power and proceed to Chapter 2, Programming Site Data, to

program the meter for taking flow rate measurements.

1-14 Installation

Page 23

Note:

1. All dimensions are in inches (millimeters).

September 2004

10.00

(254.0)

9.00

(228.6)

Figure 1-4: Outline and Installation - Wall Mount (Ref. #712-1106C, sht 1)

2.86 (72.6)

.41 (10.40)

Ø

4.11 (104.4)

4 Holes

5.88 (149.3)

Installation 1-15

Page 24

September 2004

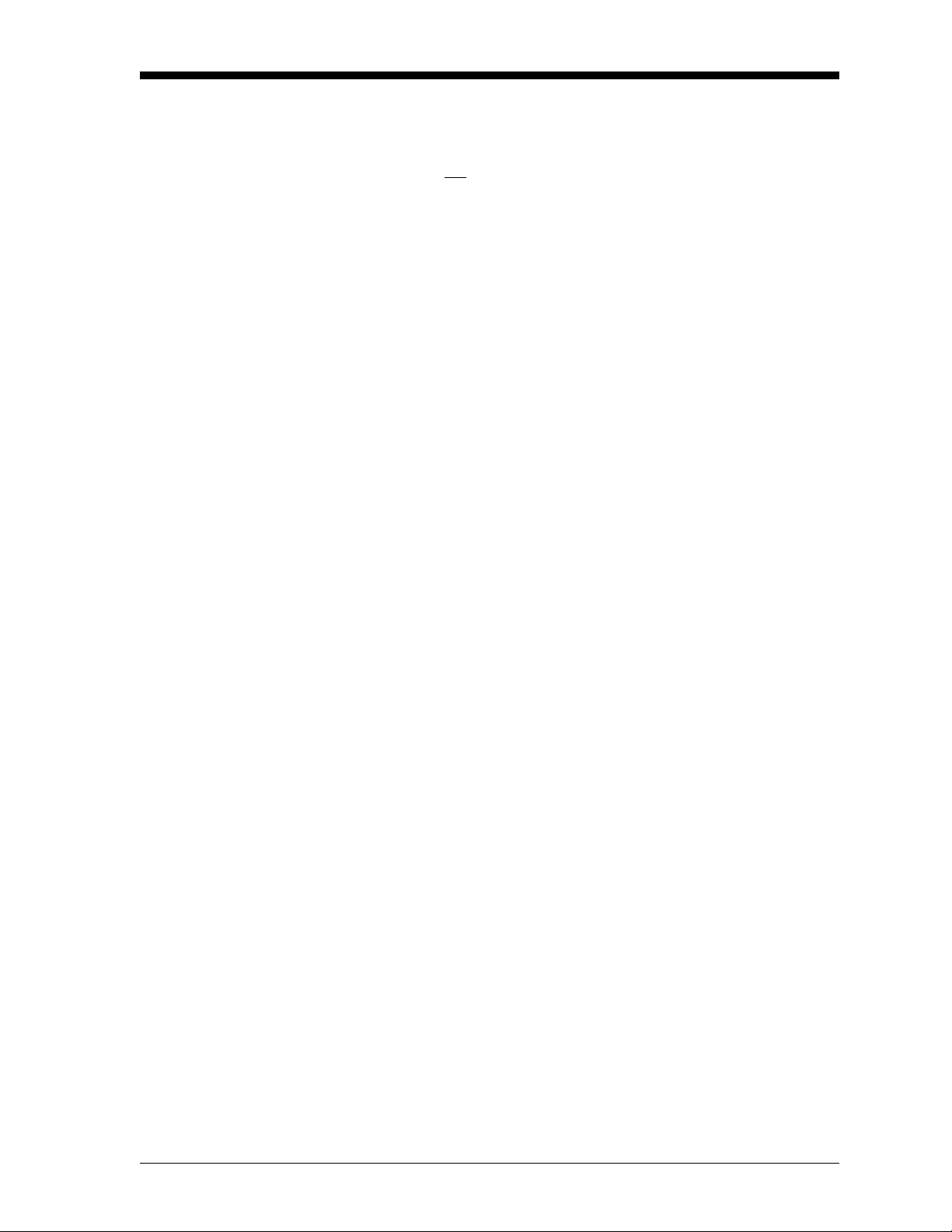

NOTE: For compliance with the European

Union's Low Voltage Directive (73/23/EEC),

this unit requires an external power disconnect

device such as a switch or circuit breaker. The

disconnect device must be marked as such,

clearly visible, directly accessible and located

within 1.8 m (6 ft) of the unit.

NOTE: For compliance with the European

Union's Low Voltage Directive (73/23/EEC),

a transparent plastic shroud protects the

electrical connections. The shroud must remain

in place, except while wiring the unit. Reinstall

the shroud after the wiring has been completed.

TB3: 0/4-20 mA Analog Outputs

Pin No.

7 OUT1-

6 OUT1+

TB3: Frequency/Totalizer Outputs

Pin No.

9 FREQ1-

8 FREQ1+

TB1: CH1 Transducer

Pin No.

4 SIGDN

3 RTNDN

1 SIGUP

TB2: CH2 Transducer

Pin No.

4 SIGDN

3 RTNDN

TB4: Frequency/Totalizer Outputs

Pin No.

4 FREQ1-

3 FREQ1+

Description

Output 1 RTN (-)

Output 1 SIG (+)

Description

Output 1 RTN (-)

Output 1 SIG (+)

Description

Downstream SIG (+)

Downstream RTN (-)

Upstream RTN (-)2 RTNUP

Upstream SIG (+)

Description

Downstream SIG (+)

Downstream RTN (-)

Upstream RTN (-)2 RTNUP

Upstream SIG (+)1 SIGUP

Description

Output 1 RTN (-)

Output 1 SIG (+)

Contrast Adjustment

Protective Conductor Terminal

Backlight Adjustment

E5

E9

Grounding Jumper

TB3: RS232/RS485 Serial Port

Pin No.

5 DTR

4 CTS

3 COM

2 RX Black

* for standard factory cables 704-659, 660, 661, 662

External Totalizer Reset Switch*

Test Point

E5

E9

*Switch hardware is user-supplied.

Pin No.

LINE

NEUT

GND

Pin No.

1

2

3

TB4: 0/4-20 mA Analog Outputs

Pin No.

2 OUT2-

Color*

White

Yellow

Green

Red1 TX

Description

Pole 1 of Switch

Pole 2 of Switch

AC Power Input

Description

Line Power

Line Neutral

Earth Ground

DC Power Input

Description

Line Positive

Line Negative

No Connection

Description

Output 2 RTN (-)

Output 2 SIG (+)1 OUT2+

Description

Data Terminal Ready

Clear to Send

Ground

Receive

Transmit

Figure 1-5: Wiring Diagram (Ref. #702-425)

Installation 1-16

Page 25

Chapter 2

Page 26

Programming Site Data

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Activating a Channel [CHx-ACTIV Menu]. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Entering System Data [CHx-SYSTM Menu] . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Entering Transducer and Pipe Parameters [CHx-PIPE Menu]. . . . . . . . . 2-4

Entering the Zero Cutoff Value [CHx-I/O Menu] . . . . . . . . . . . . . . . . . . . 2-11

Activating Mass Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Entering Global System Data [GLOBL-SYSTM Menu] . . . . . . . . . . . . . . . 2-12

Setting Up the Outputs [GLOBL-I/O Menu] . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Configuring the Communications Port [GLOBL-COMM] . . . . . . . . . . . . 2-18

Taking Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Page 27

September 2004

Introduction The AT868 has a user program that provides access to the various

programmable features of the unit. To program the AT868 you can

use either the internal keypad or Panaview™, which is a PC-based,

non-resident software program that communicates with the AT868

through its serial port.

Note: Only the internal keypad programming methods are described

in this manual. See the PanaView manual for instructions on

using that software.

To begin taking measurements with the AT868, you must at least:

• activate the channels

• enter the channel data

• enter the global system data

• enter the pipe parameters

As a programming aid, a complete set of menu maps are included in

Appendix A, Menu Maps. The specific figure numbers are referenced

throughout this chapter.

Activating a Channel [CHx-ACTIV Menu]

Note: Only the programming required for initial setup is described

in this manual, but the menu maps show all available

programming features for the AT868.

The CHx-ACTIV submenu (see Figure A-1 on page A-1) is used to

activate or deactivate the channels. All installed channels should be

activated when you receive your unit. However, you should verify

that the channels are active before you begin programming.

Note: In this manual, only the programming of Channel 1 is

described. To program Channel 2 of a 2-channel meter, simply

repeat the same procedures described for Channel 1.

Programming Site Data 2-1

Page 28

September 2004

Accessing the ACTIV Submenu

Entering System Data [CHx-SYSTM Menu]

1. Press [ESC], [ENTER], [ESC] in sequence to enter the user program.

2. Press [

3. Press [

4. Press [

5. Press [

6. If you have a 2-channel unit, you can also disable a channel.

After completing the above step, the user program returns to the

Channel PROGRAM menu. To continue entering your initial setup

data, proceed to the next section.

The CHx-SYSTM submenu (see Figure A-1 on page A-1) is used to

enter system parameters for the individual channels. In situations

where the channels operate independently, the AT868 uses the system

parameters in this menu. When channels are averaged together, the

AT868 uses the parameters entered in the

X] until PROG appears and press [ENTER].

X] until the desired channel appears. Press [ENTER] at CH1

or CH2.

X] until ACTIV appears and press [ENTER].

X] until TRANS appears and press [ENTER]. Selecting

TRANS activates the channel.

However, if you select

program that channel.

OFF for a channel, you will not be able to

GLOBL-SYSTM submenu.

Accessing the CHx-SYSTM Submenu

1. Press [ESC], [ENTER], [ESC] in sequence to enter the user program.

2. Press [

3. Press [

4. Press [

5. Enter the desired

6. Use the arrow keys to enter the desired

X] until PROG appears and press [ENTER].

X] until the desired channel appears. Press [ENTER] at CH1

CH2.

or

X] until SYSTM appears and press [ENTER].

CHANNEL LABEL (up to 5 characters) by using

the arrow keys. Press [

desired location and press

[ENTER].

press

characters) and press

is called

CHANNEL MESSAGE.)

W] and [X] to move the cursor to the

[S] and [T] to change a letter. Then

SITE MESSAGE (up to 16

[ENTER]. (For a 2-channel meter, this prompt

2-2 Programming Site Data

Page 29

September 2004

Selecting the Volumetric Units

Selecting the Totalizer Units

1. Use the arrow keys to select the desired volumetric units for the

flow rate display and press

2. Use the arrow keys to select the desired number of digits to the

right of the decimal point in the volumetric flow rate display and

[ENTER].

press

1. Use the arrow keys to select the desired units for the totalized flow

rate display and press

2. Use the arrow keys to select the desired number of digits to the

right of the decimal point in the totalized flow rate display and

[ENTER].

press

3. Do one of the following:

[ENTER].

[ENTER].

• If MASS FLOW is ON and both channels are active (for

2-channel units only), proceed to Selecting Mass Flow Units below.

• If MASS FLOW is OFF or only one channel is active, the meter

returns to the Channel PROGRAM menu. Go to Entering

Transducer and Pipe Parameters on the next page.

Selecting Mass Flow Units 1. Press [W] and [X] to select the desired mass flow units for the

flow rate display and press

prompt are determined by the selection made at

2. Press [

3. Press [

4. Press [

5. Press [

W] and [X] to select the desired time units for the mass

flow rate display and press

W] and [X] to select the desired number of digits to the

right of the decimal point in the mass flow rate display and press

[ENTER].

W] and [X] to select the desired units for the totalized mass

flow rate display and press

prompt are determined by the selection made at

W] and [X] to select the desired number of digits to the

right of the decimal point in the totalized mass flow rate display

and press

[ENTER].

[ENTER]. The available units for this

SYSTEM UNITS.

[ENTER].

[ENTER]. The available units for this

SYSTEM UNITS.

Programming Site Data 2-3

Page 30

September 2004

Entering Transducer and Pipe Parameters [CHx-PIPE Menu]

Accessing the PIPE Submenu

Enter the transducer and pipe parameters via the PIPE submenu (see

Figure A-1 on page A-1).

1. Press [ESC], [ENTER], [ESC] in sequence to enter the user program.

2. Press [

3. Press [

4. Press [

5. Do one of the following:

X] until PROG appears and press [ENTER].

X] until the desired channel appears. Press [ENTER] at CH1

or

CH2.

X] until PIPE appears and press [ENTER].

• For standard transducers, use the arrow keys to enter the

transducer number. Press [

the desired location and press

decrease the number. Then press

next step.

W] and [X] to move the cursor to

[S] and [T] to increase or

[ENTER] and proceed to the

• For special transducers, proceed to the next section.

6. Go to one of the following sections:

• Standard clamp-on transducers - proceed to Pipe Material on

page 2-6.

• Standard wetted transducers - proceed to Pipe Outside

Diameter on page 2-7.

2-4 Programming Site Data

Page 31

September 2004

Special Transducers 1. For a special transducer, press [X] to move the cursor to STD and

[S] until SPEC appears and press [ENTER].

press

2. Assign a number between 90 and 99 to the special transducer.

Enter the number by using the arrow keys. Press [

move the cursor to the desired location and press

increase or decrease the number. Then press

W] and [X] to

[S] and [T] to

[ENTER].

Special Clamp-On Transducers

3. Press [

4. Press [

5. Enter the special transducer time delay value (supplied by GE) by

The following two prompts appear only if special clamp-on

transducers are being used. If special wetted transducers are being

used, proceed to Pipe Outside Diameter on page 2-7.

1. Enter the wedge angle (supplied by GE) of the transducer by using

2. Enter the wedge sound speed (supplied by GE) of the transducer

W] and [X] to select the wedge type (supplied by GE) and

press

[ENTER].

W] and [X] to select the transducer frequency (supplied by

GE) and press

using the arrow keys. Press [

desired location and press

the number and press

the arrow keys. Press [

desired location and press

the number. Then press

by using the arrow keys. Press [

the desired location and press

decrease the number. Then press

Material on the next page.

[ENTER].

W] and [X] to move the cursor to

[S] and [T] to increase or decrease

[ENTER].

W] and [X] to move the cursor to the

[S] and [T] to increase or decrease

[ENTER].

W] and [X] to move the cursor to

[S] and [T] to increase or

[ENTER] and proceed to Pipe

Programming Site Data 2-5

Page 32

September 2004

Pipe Material If a standard or special clamp-on transducer is being used, the

programming sequence should be rejoined here.

1. Press [

Al (Aluminum) no additional selection required

(Copper Nickel)

W] and [X] to select the pipe material and press [ENTER].

Some of the pipe materials require additional selections. See a

complete list of choices in Tabl e 2-1 below.

Table 2-1: Pipe Material Choices

Material Types

STEEL Carbon Steel

Stainless Steel

IRON Ductile

Cast

Cu (Copper) no additional selection required

BRASS no additional selection required

CuNi

GLASS Pyrex

Plastic Nylon

70% Cu 30% Ni

90% Cu 10% Ni

Heavy silicate flint

Light borate crown

Polyethylene

Polypropylene

PVC, CPVC

Acrylic

OTHER Enter the sound speed of the pipe material by

using the arrow keys. Press [

move the cursor to desired location and press

W] and [X] to

[S] and [T] to increase or decrease the

number and press

[ENTER].

2-6 Programming Site Data

Page 33

September 2004

Pipe Outside Diameter The programming sequence should be rejoined here for all

transducers.

1. Press [

X] to move the cursor to the outside diameter units. Press

[S] and [T] to select the desired units and press [ENTER].

2. Measure either the pipe outside diameter

the transducer installation site. Enter the measured dimension by

using the arrow keys. Press [

desired location and press

the number. Then press

3. Enter the know thickness of the pipe wall by using the arrow keys.

W] and [X] to move the cursor to the desired location and

Press [

[S] and [T] to increase or decrease the number. Then

press

press

[ENTER]. If the pipe wall thickness cannot be measured

directly, look up the value in a table of standard pipe size data.

4. Do one of the following:

W] and [X] to move the cursor to the

[S] and [T] to increase or decrease

[ENTER].

(OD) or circumference at

• wetted transducers - proceed to Path and Axial Length below.

• clamp-on transducers - proceed to Lining on the next page.

Path and Axial Length Note: If a spoolpiece was ordered with the meter, the transducer

signal path length

are engraved on the flowcell and are included in the

documentation supplied with the meter. For on-site transducer

installations, refer to Appendix B, Measuring P and L

Dimensions, for instructions.

(P) and the transducer signal axial length (L)

1. Enter the path length (P) of the ultrasonic signal.

2. Select the desired units and press

3. Enter the axial length (L) of the ultrasonic signal and press

[ENTER].

4. Select the desired units and press

5. Proceed to Setting Up a Tracking Window on the next page.

Programming Site Data 2-7

[ENTER].

[ENTER].

Page 34

September 2004

Lining 1. Press [W] and [X] to select Yes if your pipe has a lining or No if

your pipe does not have a lining. Then, press

2. Do one of the following:

[ENTER].

• If you selected No, proceed to Setting Up a Tracking Window

below.

• If you selected Yes, continue with the next step.

Setting Up a Tracking Window

3. Press [

4. If you selected

5. Enter the lining thickness by using the arrow keys. Press [

W] and [X] to select the lining material and press [ENTER].

OTHER, enter the lining sound speed by using the

arrow keys. Press [

location and press

number. Then press

W] and [X] to move the cursor to the desired

[S] and [T] to increase or decrease the

[ENTER].

W] and

X] to move the cursor to the desired location and press [S] and

[

[T] to increase or decrease the number. Then press [ENTER].

The Tracking Window feature enables you to make accurate

measurements when the fluid sound speed is unknown or when the

fluid sound speed varies due to changing process conditions.

1. At the

TRACKING WINDOWS prompt select:

• YES - If you do not know the fluid sound speed, proceed to

Step 2.

• NO - If you do know the fluid sound speed, proceed to Fluid

Type on the next page.

2. Do one of the following:

• If the fluid sound speed is variable, the Tracking Window must

remain active. Proceed to Fluid Type on the next page to

complete the programming your meter.

• If the sound speed is constant or if you want to determine if the

sound speed is constant, continue with Step 3.

3. Proceed to Fluid Type on the next page to complete the

programming your meter.

2-8 Programming Site Data

Page 35

September 2004

Fluid Type 1. The selections for fluid type vary depending on whether the

Tracking Window is enabled or disabled. Press [

select the desired fluid and press

below for a list of available fluids.

Table 2-2: Fluid Types

Tracking Window = NO Tracking Window = YES

WATER W100 (Water, 0°-100°C)

OTHER W260 (Water, 0°-260°C)

[ENTER]. Refer to Tabl e 2- 2

W] and [X] to

Oil, Tracking

OTHER

2. If you selected

by using the arrow keys. Press [

the desired location and press

decrease the number. Then press

OTHER, enter the additional information required

W] and [X] to move the cursor to

[S] and [T] to increase or

[ENTER].

Reynolds Correction 1. Using [W] and [X], select Activ to activate the Reynolds

Correction Factor or select

Correction Factor. Then press

Note: usually, Reynolds Correction should be set to

2. Do one of the following:

Off to deactivate the Reynolds

[ENTER].

Activ.

• If you selected OFF, enter the Calibration Factor and press

[ENTER]. Then, proceed to one of the following sections:

• Clamp-on Transducers - proceed to Number of Traverses

and Transducer Spacing on the next page.

• Wetted Transducers - The meter returns to the

Channel PROGRAM window. To complete initial setup of

the AT868, you must enter data in the

submenu on page 2-12.

GLOBL-SYSTM

• If you selected ACTIV, proceed to KV Input Selection on the next

page.

Programming Site Data 2-9

Page 36

September 2004

KV Input Selection 1. Press [W] and [X] to enter a static kinematic viscosity or a table of

values and press

2. Do one of the following:

[ENTER].

• If you selected Table, enter the Calibration Factor by using the

arrow keys. Press [

desired location and press

the number. Then press

W] and [X] to move the cursor to the

[S] and [T] to increase or decrease

[ENTER].

• If you selected STATC, the AT868 will select and automatically

display the Kinematic Viscosity (see note below). If you want

to enter a different number use the [

cursor to the desired location and press

increase or decrease the number. Then press

Calibration Factor in a similar manner and press

W] and [X] to move the

[S] and [T] to

[ENTER]. Enter the

[ENTER].

Number of Traverses and Transducer Spacing

Note: If you select

Kinematic Viscosity. The AT8 6 8 will only approximate the

Kinematic Viscosity if you select one of the specific available

fluid options.

3. Proceed to one of the following sections:

OTHER as the fluid type, you must enter the

• Clamp-on Transducers - proceed to Number of Traverses and

Transducer Spacing below.

• Wetted Transducers - The meter returns to the Channel

PROGRAM

must enter data in the

1. Press [W] and [X] to select the number of traverses and press

[ENTER].

2. Enter the value for the transducer spacing by using the arrow keys.

W] and [X] to move the cursor to the desired location and

Press [

[S] and [T] to increase or decrease the number. Then

press

[ENTER].

press

window. To complete initial setup of the AT868, you

GLOBL-SYSTM submenu on page 2-12.

2-10 Programming Site Data

Page 37

September 2004

Entering the Zero Cutoff Value [CHx-I/O Menu]

Near a zero flow rate, the AT868 readings may fluctuate due to small

offsets caused by thermal drift or similar factors. To force a zero

display reading when there is minimal flow, enter a zero cutoff value

as described below (see Figure A-1 on page A-1):

1. Press

2. Press [

3. Press [

4. Press [

5. Enter a value from 0 to 1 ft/sec (0 to 0.30 m/sec) for the zero

[ESC], [ENTER], [ESC] in sequence to enter the user program.

X] until PROG appears and press [ENTER].

X] until the desired channel appears. Press [ENTER] at CH1

CH2.

or

X] until I/O appears and press [ENTER].

cutoff by using the arrow keys. The recommended setting is 0.1

ft/sec (0.03 m/sec). Press [

desired location and press

the number. Then press

W] and [X] to move the cursor to the

[S] and [T] to increase or decrease

[ENTER].

Activating Mass Flow Use this option to calculate mass flow from a static fluid density.

Complete the following steps (see Figure A-3 on page A-3) to enter

the static density of the fluid:

1. Press

2. Press [

3. Press [

4. Press [

5. Press [

6. Press [

7. Press [

8. If you have activated mass flow, enter the fluid density by using

[ESC], [ENTER], [ESC] in sequence to enter the user program.

X] until PROG appears and press [ENTER].

X] until the desired channel appears. Press [ENTER] at CH1

or

CH2.

X] until SETUP appears and press [ENTER].

X] until ADVAN appears and press [ENTER].

X] until MASS appears and press [ENTER].

X] to activate or deactivate mass flow (mass flow is

calculated from a static density) and press

the arrow keys. Press [

desired location and press

the number. Then press

W] and [X] to move the cursor to the

[S] and [T] to increase or decrease

[ENTER].

[ENTER].

Programming Site Data 2-11

Page 38

September 2004

Entering Global System

Data [GLOBL-SYSTM

Refer to Figure A-2 on page A-2, and complete the steps below to

enter system information in the

GLOBL menu.

Menu]

Selecting the GLOBL-SYSTM Units

1. Press [ESC], [ENTER], [ESC] in sequence to enter the user program.

2. Press [

3. Press [

4. Press [

5. Enter a short message (up to 16 characters) by using the arrow

X] until PROG appears and press [ENTER].

X] until GLOBL appears and press [ENTER].

X] until SYSTM appears and press [ENTER].

keys. Press [

and press

[ENTER].

W] and [X] to move the cursor to the desired location

[S] and [T] to select the desired character. Then press

Selecting the System Units 1. Press [X] to select the system units and press [ENTER].

2. Do one of the following:

• 1-Channel Meters - go to Setting Up the External Totalizer

Reset Switch on the next page.

• 2-Channel Meters - continue with the next step.

3. Press [

4. Press [

5. Press [

6. Press [

X] to select the volumetric units for the flow rate display

and press

[ENTER].

X] to select the number of digits to the right of the decimal

point in the volumetric flow rate display and press

X] to select the desired units for the totalized flow rate

display and press

[ENTER].

X] to select the desired number of digits to the right of the

decimal point in the totalized flow rate display and press

[ENTER].

[ENTER].

2-12 Programming Site Data

Page 39

September 2004

Setting Up the External Totalizer Reset Switch

If you have installed an external totalizer reset switch as described in

Chapter 1, Installation, the

the switch.

1. At the

GATE OPTION prompt, press [X] to select one of the

following and press

GATE OPTION enables you to configure

[ENTER].

• RESET - the meter resets totals to zero for both channels and

then immediately begins to count again.

• HOLD - the meter holds totals at the current point for both

channels. The meter will not count as long as the switch

remains closed. This option is typically used for calibration.

2. Do one of the following:

• If MASS FLOW is ON and both channels are active, proceed to

Selecting Mass Flow Units below.

• If MASS FLOW is OFF or only one channel is active, the meter

returns to the

Outputs on the next page.

Selecting Mass Flow Units 1. Press [W] and [X] to select the desired mass flow units for the

flow rate display and press

prompt are determined by the selection made at

the previous page.

Global PROGRAM menu. Go to Settings Up the

[ENTER]. The available units for this

SYSTEM UNITS on

2. Press [

3. Press [

4. Press [

5. Press [

W] and [X] to select the desired time units for the mass

flow rate display and press

[ENTER].

W] and [X] to select the desired number of digits to the

right of the decimal point in the mass flow rate display and press

[ENTER].

W] and [X] to select the desired units for the totalized mass

flow rate display and press

prompt are determined by the selection made at

the previous page.

[ENTER]. The available units for this

SYSTEM UNITS on

W] and [X] to select the desired number of digits to the

right of the decimal point in the totalized mass flow rate display

and press

[ENTER].

Programming Site Data 2-13

Page 40

September 2004

Setting Up the Outputs [GLOBL-I/O Menu]

Accessing the Analog Outputs

Setting Up the Analog Output Scale

To set up the AT868 analog outputs and totalizer/frequency outputs,

refer to Figure A-2 on page A-2 and follow the instructions in this

section.

Output A and Output C are analog outputs that can be configured

independently. To configure these outputs, complete the following

steps:

1. Press

2. Press [

3. Press [

4. Press [

5. Press [

6. Press [

1. Press [X] to select the desired output scale and press [ENTER].

2. Do one of the following:

[ESC], [ENTER], [ESC] in sequence to enter the user program.

X] until PROG appears and press [ENTER].

X] until GLOBL appears and press [ENTER].

X] until I/O appears and press [ENTER].

X] until OPTN appears and press [ENTER].

X] to select A or C and press [ENTER].

• If you selected OFF, the meter returns to the Global I/O menu.

Go to Accessing the Totalizer/Frequency Outputs on the next

page.

• If you are using a 1-channel meter, go to step 4.

• If you are using a 2-channel/path meter, go to step 3.

Channel, press [X] to select the desired channel and press

3. At

[ENTER].

4. Press [

Note: The measurement units that appear in these prompts are those

5. At

X] to select the desired measurement parameter and press

[ENTER].

selected in the

BASE, enter a flow rate value for the low end of the analog

output range by using the arrow keys. Press [

the cursor to the desired location and press

increase or decrease the number. Then press

GLOBL-SYSTM menu earlier in this chapter.

W] and [X] to move

[S] and [T] to

[ENTER].

2-14 Programming Site Data

Page 41

September 2004

Setting Up the Analog

Output Scale (cont.)

Accessing the Totalizer/Frequency Outputs

6. At FULL, enter a flow rate value for the high end of the analog

output range by using the arrow keys. Press [

the cursor to the desired location and press

increase or decrease the number. Then press

Error Handling, press [X] to select the desired option for

7. At

handling errors (

OTHER is selected, the Forced milliamps display appears. This

8. If

allows the user to impose a set value for this option. Enter the

desired forced milliamps value by using the arrow keys. Press [

and [X] to move the cursor to the desired location and press [S]

HOLD, LOW, HIGH, or OTHER) and press [ENTER].

W] and [X] to move

[S] and [T] to

[ENTER].

W]

and [T] to increase or decrease the number. Then press [ENTER].

A totalizer output issues one pulse per selected volume of flow, and

the meter produces a pulse each time the programmed amount of flow

passes through the pipe. A frequency output issues a frequency that is

proportional to the assigned measurement parameter.

Output B and Output D are totalizer/frequency outputs that can be

configured independently. To configure these outputs, complete the

following steps:

1. Press

2. Press [

3. Press [

4. Press [

5. Press [

6. Press [

7. Do one of the following:

[ESC], [ENTER], [ESC] in sequence to enter the user program.

X] until PROG appears and press [ENTER].

X] until GLOBL appears and press [ENTER].

X] until I/O appears and press [ENTER].

X] until OPTN appears and press [ENTER].

X] to select B or D and press [ENTER].

• Frequency Output - go to Setting Up a Frequency Output on

the next page.

• Totalizer Output - go to Setting Up a Totalizer Output on

page 2-17.

Programming Site Data 2-15

Page 42

September 2004

Setting Up a Frequency Output

1. At Output B or D, select OFF or FREQ and press [ENTER].

2. Do one of the following:

• If you selected OFF, the meter returns to the Global I/O menu.

Go to Setting Up a Totalizer Output on the next page.

• For 1-channel meter, go to step 4.

• For a 2-channel meter, go to step 3.

3. At

Channel, press [X] to select the desired channel and press

[ENTER].

4. Press [

Note: The measurement units that appear in these prompts are those

5. At

6. At

X] to select the desired measurement parameter and press

[ENTER].

selected in the

BASE, enter a value for the low end of the output range

(-2,000,000 to 2,000,000) by using the arrow keys. Press [

[

X] to move the cursor to the desired location and press [S] and

GLOBL-SYSTM menu earlier in this chapter.

W] and

[T] to increase or decrease the number. Then press [ENTER].

FULL, enter a value for the high end of the output range

(-2,000,000 to 2,000,000) by using the arrow keys. Press [

[

X] to move the cursor to the desired location and press [S] and

W] and

[T] to increase or decrease the number. Then press [ENTER].

7. At FULL SCALE FREQ, enter a value for the full scale of the output

(between 10 to 100,000) by using the arrow keys. Press [

[

X] to move the cursor to the desired location and press [S] and

W] and

[T] to increase or decrease the number. Then press [ENTER].

8. At Error handling, press [X] to select the desired option for

handling errors (

OTHER is selected, the Error frequency display appears. This

9. If

allows the user to enter a set value for this option. Enter the

desired error frequency by using the arrow keys. Press [

[

X] to move the cursor to the desired location and press [S] and

HOLD, LOW, HIGH, or OTHER) and press [ENTER].

W] and

[T] to increase or decrease the number. Then press [ENTER].

2-16 Programming Site Data

Page 43

September 2004

Setting Up a Totalizer Output

1. At Output B or D, select OFF or TTLZR and press [ENTER].

2. Do one of the following:

• If you selected OFF, the meter returns to the Global I/O menu.

Go to Configuring the Communications Port on the next page.

• For 1-channel meter, go to step 4.

• For a 2-channel/path meter, go to step 3.

3. At

Channel, press [X] to select the desired channel and press

[ENTER].

4. Press [

5. Enter a value for the minimum pulse on-time (between 50 μsec

Note: A complete pulse consists of equal amounts of

X] to select the desired measurement parameter and press

[ENTER].

and 500,000 μsec) for the frequency of the totalizer pulses and

[ENTER]. Press [W] and [X] to move the cursor to the

press

desired location and press

the number. Then press

times. Choose a value that is compatible with the pulse

counter to be used.

[S] and [T] to increase or decrease

[ENTER].

ON and OFF

UNITS/PULSE enter a value for the number of measurement

6. At

units represented by each pulse and press

[ENTER].

Programming Site Data 2-17

Page 44

September 2004

Configuring the Communications Port [GLOBL-COMM]

The AT868 is equipped with a built-in serial communications port, as

described in Chapter 1, Installation. Refer to Figure A-2 on page A-2

and use the

completing the following steps:

1. Press

2. Press [

3. Press [

4. Press [

5. Enter a meter address (between 1 and 254) by using the arrow

keys. The default number is 1. Press [

cursor to the desired location and press

or decrease the number. Then press

Note: A meter address is only necessary for communication with the

6. Press [

GLOBL-COMM menu to set up the communications port by

[ESC], [ENTER], [ESC] in sequence to enter the user program.

X] until PROG appears and press [ENTER].

X] until GLOBL appears and press [ENTER].

X] until COMM appears and press [ENTER].

W] and [X] to move the

[S] and [T] to increase

[ENTER].

GE Panaview software. See the Panaview User’s Manual for

more information.

X] to select a baud rate and press [ENTER].

Taking Measurements The AT868 has now been totally programmed for taking accurate

flow rate measurements. Proceed to Chapter 3, Displaying Data, for

instructions on configuring the display.

2-18 Programming Site Data

Page 45

Chapter 3

Page 46

Displaying Data

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Adjusting LCD Contrast and Brightness . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Setting Up the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Resetting the Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Page 47

September 2004

Introduction The AT868 is equipped with a Liquid Crystal Display (LCD), which

may be programmed to display up to four variables in sequence. Both

the brightness and the contrast of the LCD are easily adjusted by

following the instructions in this chapter. In addition, instructions are

provided for resetting the totalizers and pausing the measurements.

Adjusting LCD Contrast and Brightness

The AT868 has two adjustment potentiometers located on the LCD

circuit board (see Figure 3-1 below). To make contrast and brightness

adjustments, complete the following steps:

1. Loosen the screws and remove the front cover.

2. With power still applied to the meter, carefully use a small

screwdriver to adjust the

the control completely clockwise yields maximum brightness.

3. In a similar manner, adjust the

set the contrast as desired. At either extreme of the

the display is unreadable. To make the adjustment, turn the control

fully counterclockwise and then turn it clockwise very slowly until

the display is clear and sharp.

4. As there is some interaction, readjust the

5. Replace the front cover and secure it in place with the screws.

BKLT (backlight) potentiometer. Turning

CONT (contrast) potentiometer to

CONT control,

BKLT control if necessary.

CONT Potentiometer

BKLT

Potentiometer

Figure 3-1: CONT and BKLT Potentiometers

Displaying Data 3-1

Page 48

September 2004

Setting Up the Display Follow the instructions in this section to display the desired data on

the display screen (see Figure A-2 on page A-2 in Appendix A, Menu

Maps

Accessing the Display Submenu

1. Press [ESC], [ENTER], [ESC] in sequence to enter the user program.

2. Press [

3. Press [

4. Press [

5. Press [

X] until PROG appears and press [ENTER].

X] until GLOBL appears and press [ENTER].

X] until I/O appears and press [ENTER].

X] until LCD appears and press [ENTER].

Configuring the Display 1. At # of LCD PARAMS, press [X] to select the desired number of

parameters to be sequentially displayed and press

2. For a 1-channel AT868, proceed to Step 4. For a 2-channel AT868,

proceed to Step 3.

3. Press [

4. At

5. Repeat the two previous steps until all of the specified

Note: The measurement units that appear in these prompts are those

X] to select the desired channel option and press [ENTER].

Measurement Name, press [X] to select the desired parameter

and press

PARAMS

[ENTER].

have been set up.

selected in the

2, Programming Site Data.

GLOBL-SYSTM menu as described in Chapter

[ENTER].

# of LCD

After leaving the User Program, the AT868 will reset and will begin

to display the parameters specified in this section. If more than one

parameter was set up, each of the parameters will be displayed in

sequence, with a pause of several seconds between display changes.

3-2 Displaying Data

Page 49

September 2004

Resetting the Totalizers To reset the totalizers, you can use either the internal keypad or an

external switch. When resetting the totalizers, the totals for both

channels are reset. Use the appropriate section below to reset the

totalizers.

Resetting Totalizers Using the Internal Keypad

Resetting Totalizers Using an External Switch

See Figure A-4 on page A-4 in Appendix A, Menu Maps. Then,

1. Press

2. Press [

3. Press [

4. To leave the User Program, press [

If you select

you select

While the meter is operating, press and hold the external reset switch

for 1 second. Both totalizers will reset to zero and will then

immediately begin to resume counting.

IMPORTANT: The external totalizer reset switch must be configured

[ESC], [ENTER], [ESC] in sequence to enter the user program.

X] until RESET appears and press [ENTER].

X] to select YES or NO and press [ENTER].

ESC].

YES, the AT868 resets the totalizers for both channels. If

NO, the totalizers continue to count.

as described in Chapter 2, Programming Site Data.

Displaying Data 3-3

Page 50

Chapter 4

Page 51

Calibration

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibrating and Testing the Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibrating the Totalizer/Frequency Outputs . . . . . . . . . . . . . . . . . . . . . . 4-4

Page 52

September 2004

Introduction Follow the instructions in this chapter to calibrate and test the AT868

analog and totalizer/frequency outputs. Refer to Figure A-4 on page

A-4 in Appendix A, Menu Maps, while following the calibration

instructions.

Calibrating and Testing the Analog Outputs

The AT868 includes one built-in analog output per channel with a

resolution of 5.0 μA (0.03% full scale). Typically, Output A is used