Page 1

AquaTrans™ AT600

User’s Manual

Flow

bhge.com

910-312 Rev. D

September 2017

Page 2

Page 3

AquaTrans™ AT600

Panametrics Ultrasonic Flow Meter for Liquids

User’s Manual

910-312 Rev. D

September 2017

bhge.com

© 2017 Baker Hughes, a GE company – All rights reserved.

Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product

described at any time without notice or obligation. Contact your BHGE representative for the most current information. The

Baker Hughes logo is a trade mark of Baker Hughes, a GE company. The GE Monogram is a trademark of the General Electric

Company.

Page 4

[no content intended for this page]

Page 5

Contents

Product Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Terms and Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Safety Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Auxiliary Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Environmental Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Chapter 1. General Installation Instructions

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Unpacking the AT600 system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Installing the Electronics Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 Calculating the Transducer Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.7 Choosing a Clamp-On Fixture/Transducer Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 Mounting the Clamp-on Fixture and Transducer System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2. Clamp-On Fixture and Transducer Installation

2.1 Installing an AT600 Clamp-On Fixture and Transducer System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.1.1 Transducer Spacing = 32 to 250 mm or 50 to 320 mm, Traverses = 2, Fixtures = 1 . . . . . . . . . . . . . . . . . 11

2.1.2 Transducer Spacing = 320 to 940 mm, Traverses = 2, Fixtures = 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.3 Transducer Spacing = 0 to 250 mm or 0 to 320 mm, Traverses = 1, Fixtures = 2 . . . . . . . . . . . . . . . . . . . .17

2.1.4 Transducer Spacing >320 mm, Traverses = 1, Fixtures = 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Installing a CF-ES Clamp-On Fixture and Transducer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

2.3 Installing a General Clamping Fixture and Transducer System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.1 Installing C-RS or C-PT Transducers with an RG316 Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3.2 Installing C-RS or C-PT Transducers with an RG62 Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3. Wiring the AT600 Electronics

3.1 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3.2 Wiring the Line Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.3 Wiring the Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.4 Wiring the System Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5 Wiring the Analog Output for HART Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.6 Wiring the Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.7 Wiring the Frequency/Totalizer/Alarm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.8 Wiring the Gate Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 4. Initial Setup and Programming

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 AT600 Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.3 Display Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

AquaTrans™ AT600 User’s Manual iii

Page 6

Contents

4.3.1 Changing the Display for One- or Two-Variable Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.3.2 Changing the Measurement Type for One- or Two-Variable Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.3.3 Changing the Measurement Type or Units for the Totalizer Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.3.4 Starting or Stopping the Totalizer Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.3.5 Resetting the Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.4 Entering the Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.4.1 Display Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.4.2 Keypad Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.3 Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.4.4 Program and Program Review Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.5 User Preferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5.1 Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5.2 Units Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.5.3 Density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5.4 Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.5.5 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.6 Inputs/Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.6.1 Programming the Analog Output Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.6.2 Programming the Digital Output Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.6.3 Programming the Modbus/Service Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.6.4 Programming Digital Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.7 Sensor Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.7.1 Meter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.7.2 Mounting Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.7.3 Programming the Pipe Menu when Wetted selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.7.4 Programming the Pipe Menu when Clamp-on selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.7.5 Programming the Transducer when Clamp-on selected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.7.6 Programming the Transducer when Wetted selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.7.7 Programming the Number of Traverses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

4.7.8 Programming the Fluid Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.7.9 Programming the Fluid Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4.7.10 Calculating the Path when Clamp-on selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.7.11 Enter the Path when Wetted selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Chapter 5. Error Codes and Troubleshooting

5.1 Error Display in the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.1.1 Error Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

5.1.2 Flow Error String. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

5.2.2 Flowcell Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

iv AquaTrans™ AT600 User’s Manual

Page 7

Contents

Chapter 6. Communication

6.1 MODBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

6.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

6.1.2 MODBUS Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.2 HART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

6.2.1 Device Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

6.2.2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

6.3 Additional Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

6.4 Device Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

6.5 HART Engineering Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Appendix A. Specifications

A.1 Overall Operation and Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

A.2 Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

A.3 Clamp-On Ultrasonic Flow Transducers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

A.4 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

A.4.1 Wiring Cable Specifications and Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

A.4.2 Cable Fixing Requirement and Gland Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

A.4.3 Display Languages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

A.4.4 Product Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Appendix B. Data Records

B.1 Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

B.2 Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

B.3 Initial Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

B.4 Diagnostic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Appendix C. Updating the Firmware in the Field

C.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

C.1.1 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

C.1.2 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

C.2 Performing the Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

C.2.1 Check the Current Firmware Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

C.2.2 Update Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

C.3 Clearing an S2 Warning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

C.4 Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Appendix D. Menu Maps

D.1 The Display Measurement Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

D.2 The Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .188

D.3 The Main Menu > User Preferences Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .189

D.4 The Main Menu > Inputs/Outputs Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

D.5 The Main Menu > Sensor Setup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

AquaTrans™ AT600 User’s Manual v

Page 8

Contents

D.6 The Main Menu > Calibration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

D.7 The Main Menu > Advanced Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

D.8 The Main Menu > Factory Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

[no content intended for this page]

vi AquaTrans™ AT600 User’s Manual

Page 9

Preface

Product Registration

Thank you for purchasing your AquaTrans™ AT600 from Baker Hughes, a GE Company. Please register your

product at www.gemeasurement.com/productregistration

software/firmware upgrades, product information and special promotions.

for product support such as the latest

Services

BHGE provides customers with an experienced staff of customer support personnel ready to respond to

technical inquiries, as well as other remote and on-site support needs. To complement our broad portfolio of

industry-leading solutions, we offer several types of flexible and scalable support services including:

Training, Product Repairs, Extended Warranties, Service Agreements and more. Please visit

www.gemeasurement.com/services

for more details.

Terms and Conditions

Sales Terms and Conditions for your recent purchase of a BHGE product, including the applicable product

Warranty, can be found on our website at the following link:

www.gemeasurement.com/sales-terms-and-conditions

Typographical Conventions

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper

setup of the equipment. Failure to follow these instructions carefully may cause unreliable

performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these

instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national

codes, regulations, rules and laws related to safety and safe operating conditions are met for each

installation.

Attention European Customers! To meet CE Marking requirements for all units intended for use in

the EU, all electrical cables must be installed as described in this manual.

AquaTrans™ AT600 User’s Manual vii

Page 10

Preface

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As

equipment can move suddenly and without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work envelope of this equipment during manual

operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures on this equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary

equipment. Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

viii AquaTrans™ AT600 User’s Manual

Page 11

Preface

Environmental Compliance

RoHS

The AquaTrans™ AT600 fully complies with RoHS regulations (Directive 2011/65/EU).

Waste Electrical and Electronic Equipment (WEEE) Directive

BHGE is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE) take-back

initiative (Directive 2012/19/EU).

The equipment that you bought has required the extraction and use of natural resources for its production. It

may contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on

the natural resources, we encourage you to use the appropriate take-back systems. Those systems will reuse

or recycle most of the materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or

regional waste administration.

Please visit http://www.gemeasurement.com/environmental-health-safety-ehs

more information about this initiative.

for take-back instructions and

AquaTrans™ AT600 User’s Manual ix

Page 12

Preface

[no content intended for this page]

x AquaTrans™ AT600 User’s Manual

Page 13

Chapter 1. General Installation Instructions

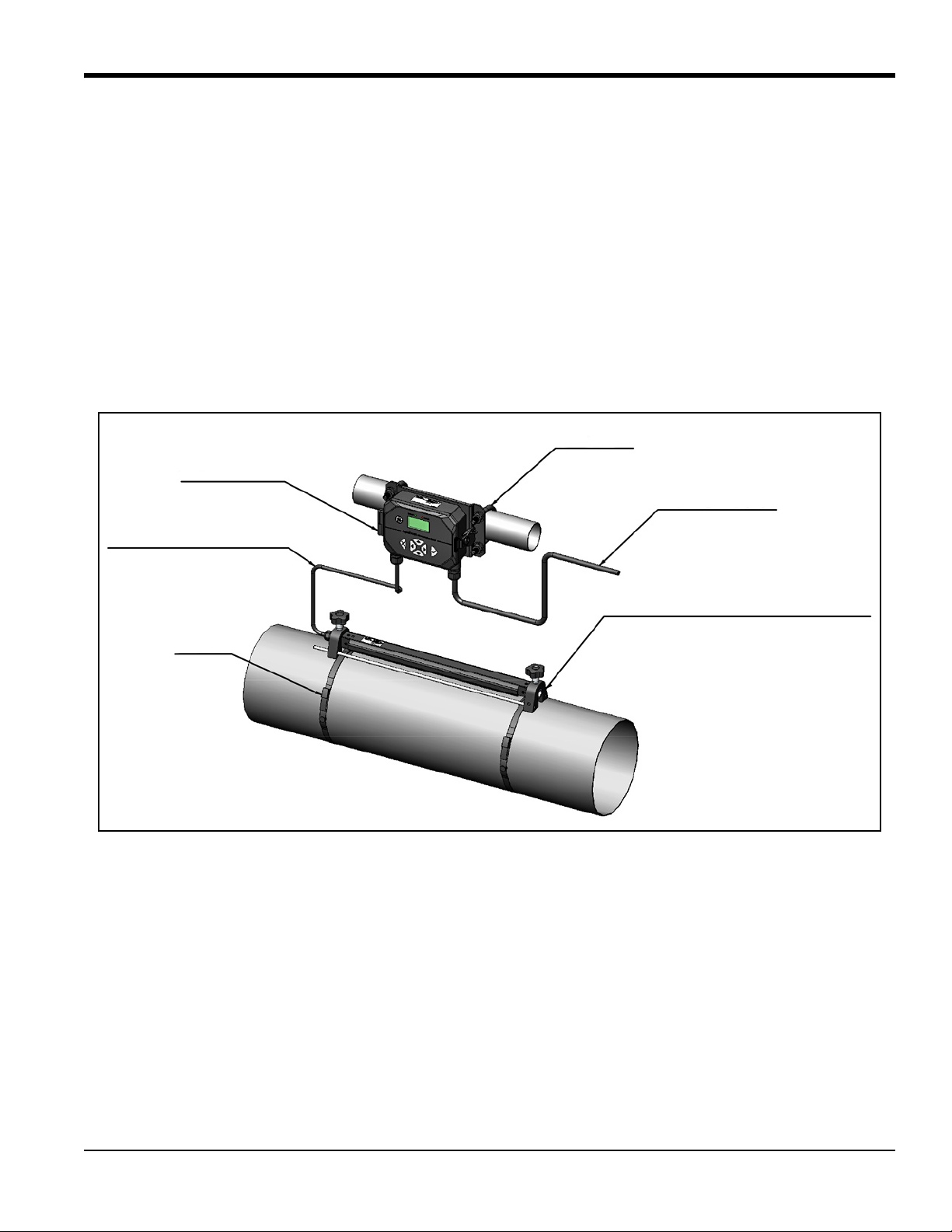

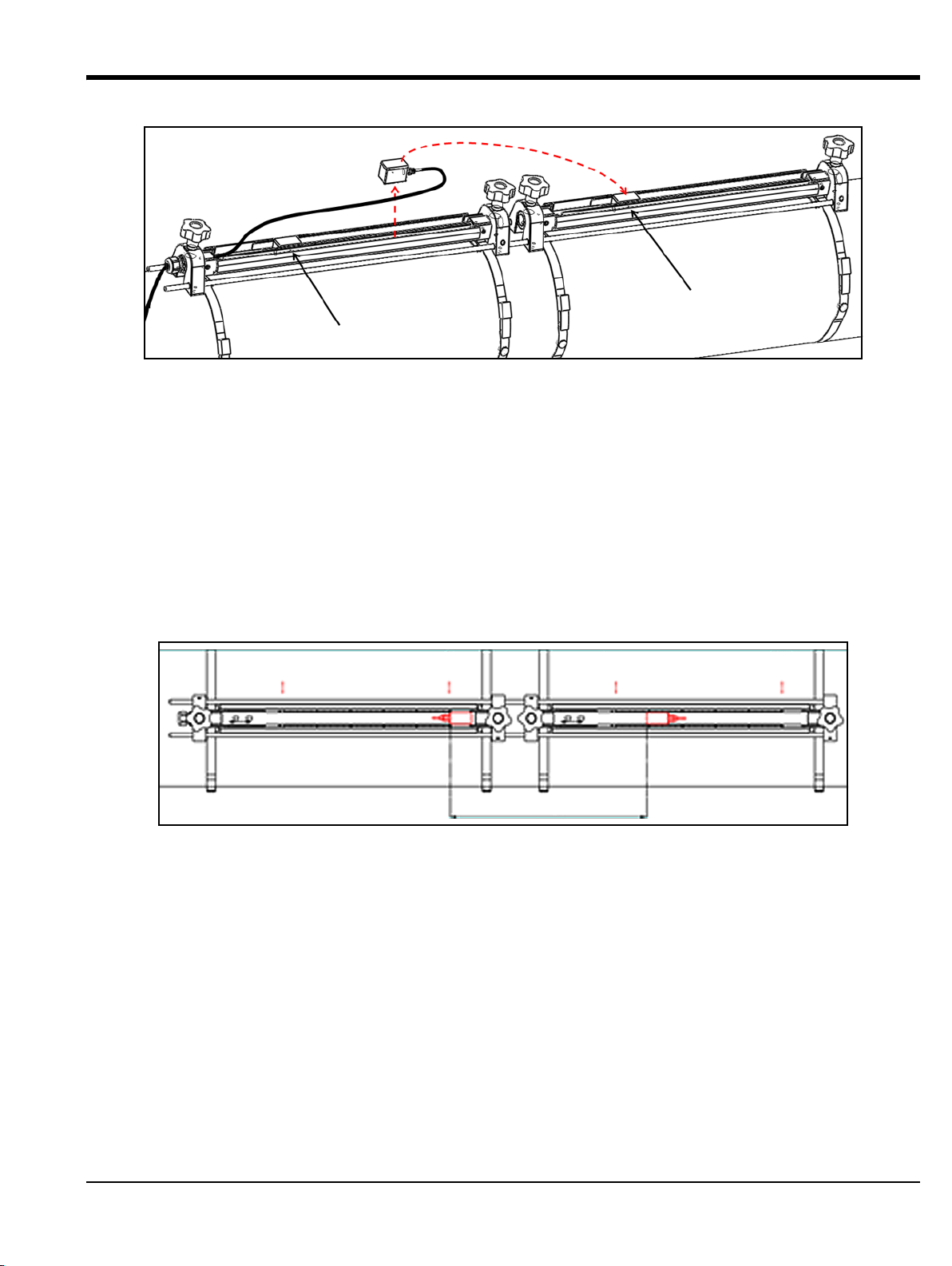

Electronics

Transducer Cable

Strap

U-Bolt

Power Cable

Fixture

With Transducer Installed

Chapter 1. General Installation Instructions

1.1 Introduction

Thank you for purchasing the AT600 ultrasonic flow meter. The AT600 is a clamp-on ultrasonic flow meter

for the measurement of liquid products. It is designed for the industrial applications, including water,

wastewater, steel, campus energy, and others. The AT600 utilizes a new electronics platform and industrial

design to make it extremely simple to install and use in the field.

• So easy to use, it practically installs itself

The AT600 consists of the new AT600 electronics, a metal enclosure, the field proven AT transducer system,

and a clamp-on transducer fixture (see Figure 1 below).

AquaTrans™ AT600 User’s Manual 1

Figure 1: Typical AT600 System Mounted on a Pipe

Page 14

Chapter 1. General Installation Instructions

1.2 Theory of Operation

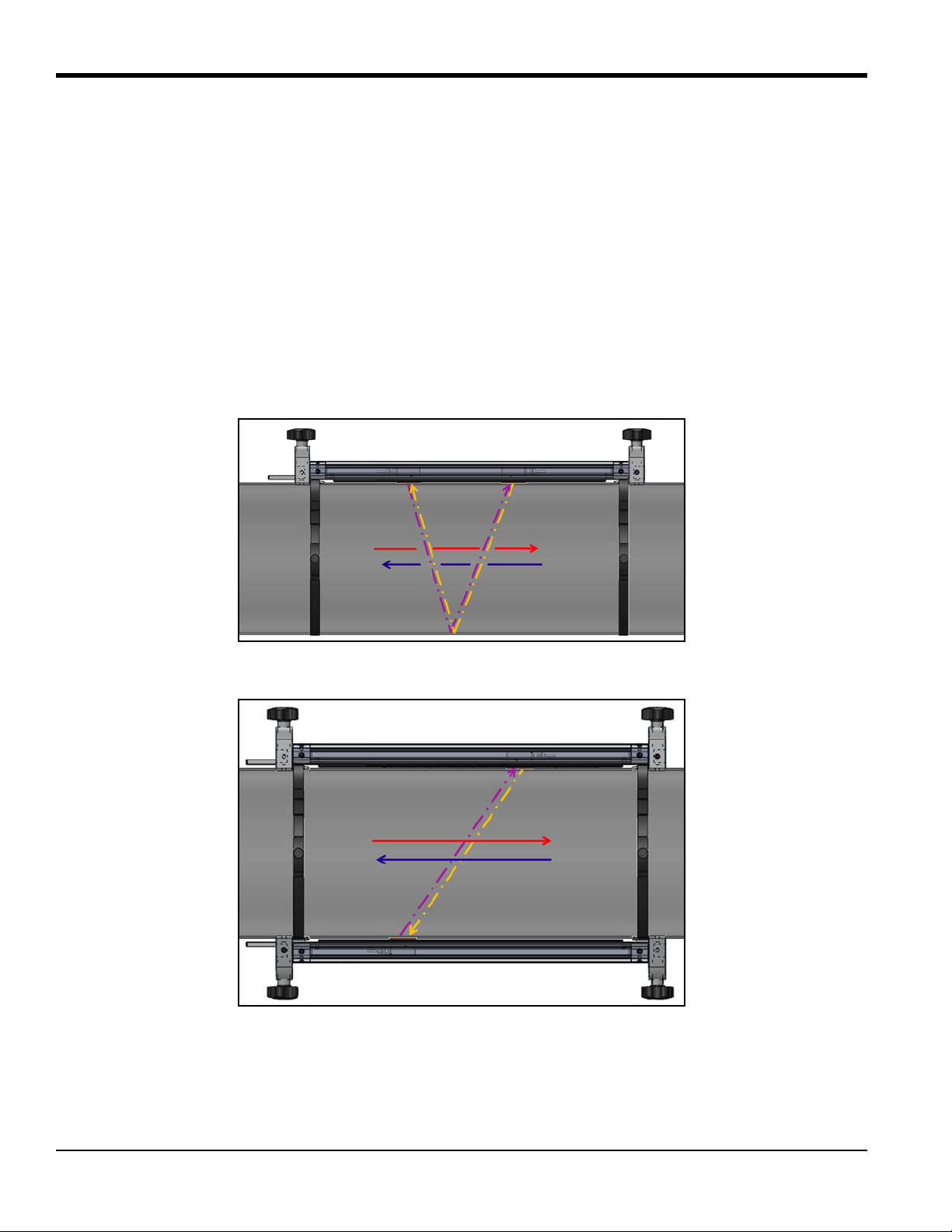

The AT600 flow meter uses a procedure called Transit-Time Flow Measurement. In this method, two

transducers, which are in acoustic communication with each other, serve as both ultrasonic signal

generators and receivers. That is, the second transducer can receive ultrasonic signals transmitted by the

first transducer and vice versa.

In operation, each transducer functions as a transmitter, generating a certain number of acoustic pulses, and

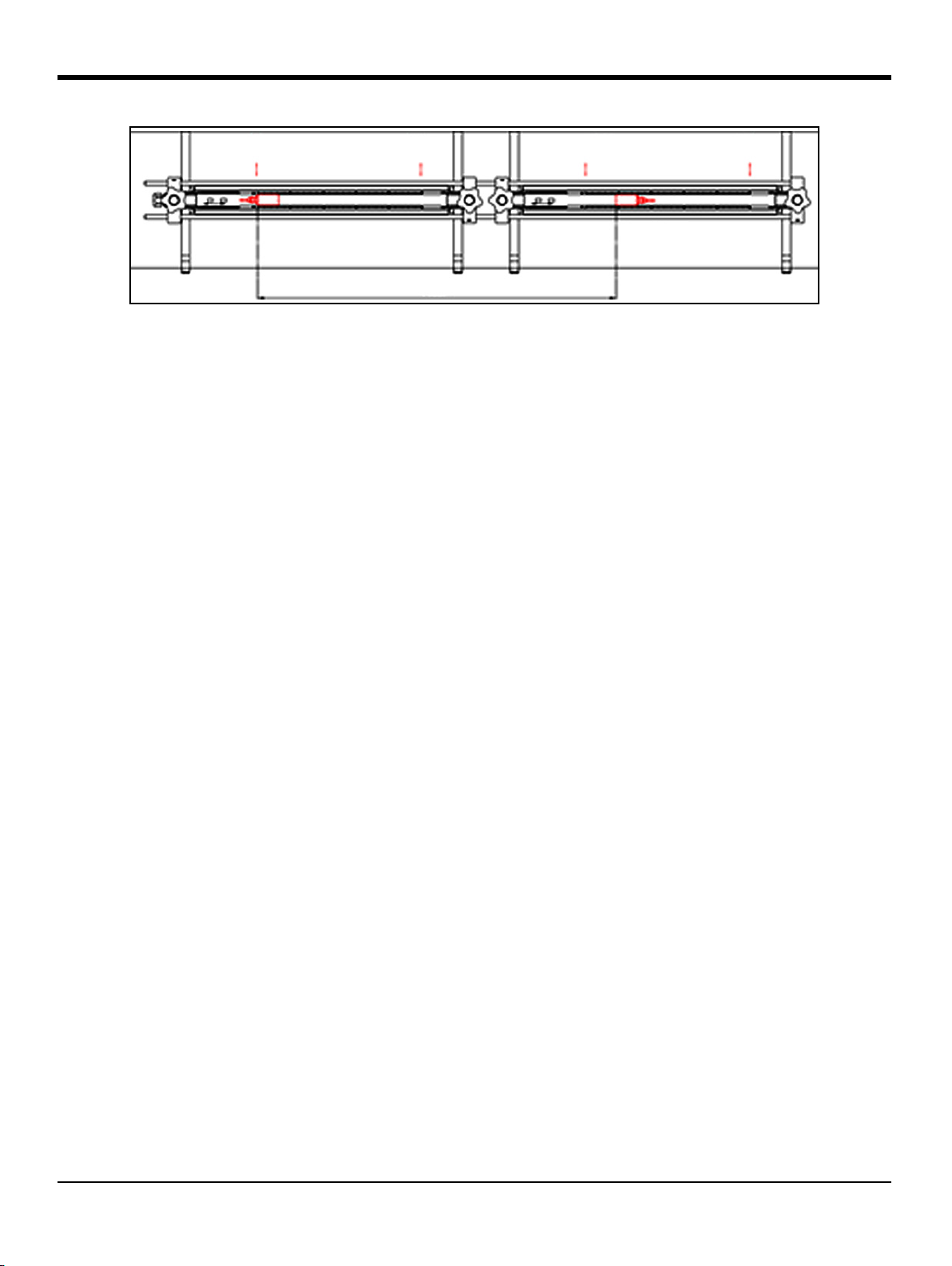

then as a receiver for an identical number of pulses (see Figure 2 and Figure 3 below). The time interval

between transmission and reception of the ultrasonic signals is measured in both directions. When the

liquid in the pipe is not flowing, the transit-time downstream equals the transit-time upstream. However,

when the liquid is flowing, the transit-time downstream is less than the transit-time upstream. The

difference between the downstream and upstream transit times is proportional to the velocity of the flowing

liquid and its sign indicates the direction of flow.

Figure 2: Flow and Transducer Paths (Two Traverses)

Figure 3: Flow and Transducer Paths (One Traverse)

2 AquaTrans™ AT600 User’s Manual

Page 15

Chapter 1. General Installation Instructions

1.3 Safety Guidelines

To ensure safe and reliable operation of the AT600, the system must be installed in accordance with the

guidelines discussed in this manual. This chapter includes the following topics:

• “Unpacking the AT600 system” on page 4

• “Installing the Electronics Enclosure” on page 5

• “Choosing a Clamp-On Fixture/Transducer Location” on page 7

• “Mounting the Clamp-on Fixture and Transducer System” on page 8

WARNING! The AT 600 flow transmitter can measure the flow rate of many fluids, some of which

are potentially hazardous. The importance of proper safety practices cannot be overemphasized.

WARNING! Be sure to follow all applicable local safety codes and regulations for installing electrical

equipment and working with hazardous fluids or flow conditions. Consult company safety personnel

or local safety authorities to verify the safety of any procedure or practice.

ATTENTION EUROPEAN CUSTOMERS! To meet CE Marking and UL Marking requirements, all cables

must be installed as described in “Wiring Cable Specifications and Requirements” on page 177.

AquaTrans™ AT600 User’s Manual 3

Page 16

Chapter 1. General Installation Instructions

1.4 Unpacking the AT600 system

Before removing the AT600 system from the crate, please inspect the flow meter. Before discarding any of

the packing materials, account for all components and documentation listed on the packing slip. The

discarding of an important item along with the packing materials is all too common. If anything is missing

or damaged, contact BHGE Customer Care immediately for assistance.

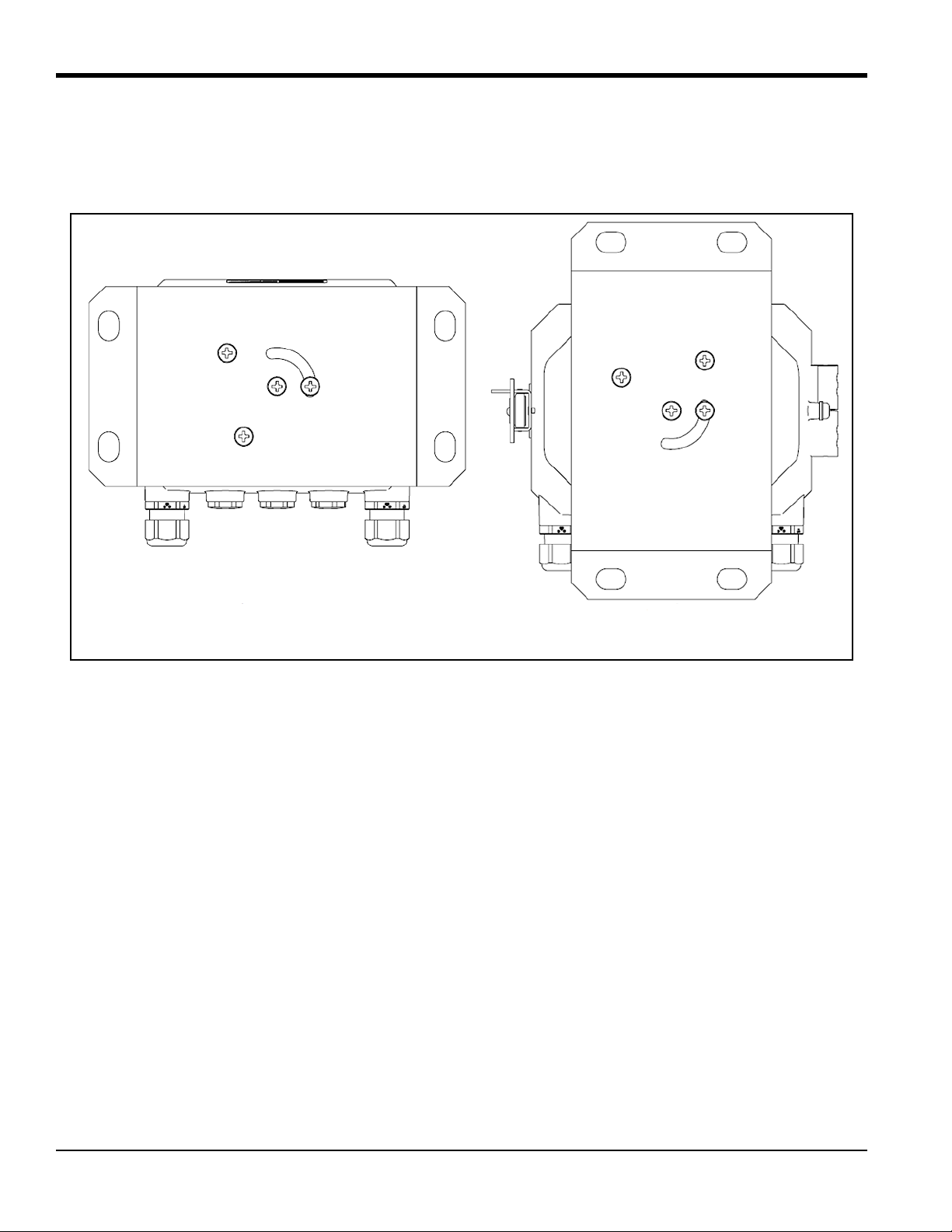

Please note that the AT600 system (see Figure 4 below) is available in a variety of configurations to meet your

needs, so the packing list will vary for each system. As an example, a typical packing list is:

1. One AT600 electronics enclosure

2. Two clamp-on fixtures

3. Two transducers (installed in one of the two clamp-on fixtures)

4. One transducer cable (installed on fixture with transducers)

5. Two clamp-on fixture mounting straps for each fixture

6. Two “U” bolts for pipe mounting of the AT600 electronics enclosure

7. One USB flash drive with user’s manual and calibration sheet

8. One inner hexagon spanner

9. Three M16 cable glands (installed on the AT600 electronics enclosure)

10. Two pieces of Solid Couplant

11. Quick installation guide

12. Calibration Sheet

13. Cabling tools

Figure 4: Typical AT600 Shipping Container

4 AquaTrans™ AT600 User’s Manual

Page 17

Chapter 1. General Installation Instructions

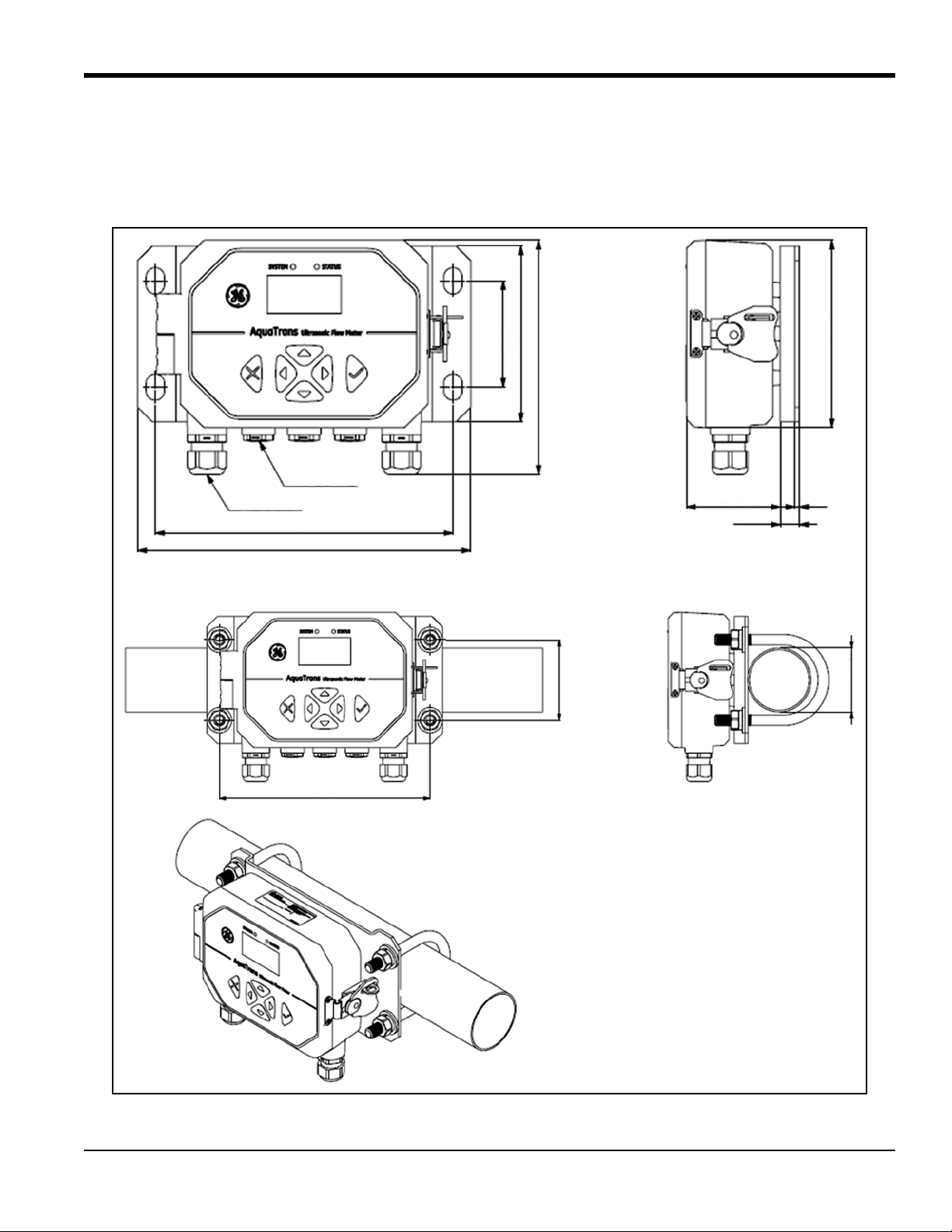

Weight is about 1.5 kg

Pipe Mount

Wall Mount

for the whole meter Assembly

M16 GLAND x3

202

13

3

63.50

128

120

160

72.50

M20 GLAND x2

202

226

2 Inch Pipe

72.50

1.5 Installing the Electronics Enclosure

The AT600 electronics is housed in a powder-coated, aluminum, NEMA type 4X/IP67 enclosure suitable for

indoor or outdoor use. See Figure 5 below for the mounting dimensions and weight of the AT600 electronics

enclosure.

Figure 5: Mounting the AT600 Electronics Enclosure

AquaTrans™ AT600 User’s Manual 5

Page 18

Chapter 1. General Installation Instructions

Horizontal

Vertical

1.5 Installing the Electronics Enclosure (cont.)

The installation base of AT600 electronics enclosure can be rotated 90° to keep a horizontal view of the user

interface in any mounting orientation. See Figure 6 below for drawings of the AT600 mounting base.

Figure 6: The AT600 Mounting Base

1.6 Calculating the Transducer Spacing

Before installing the clamp-on fixture(s) and transducers, you must program the AT600 to calculate the

required transducer spacing for your planned installation. To accomplish this task, go to “Sensor Setup” on

page 66 and follow the instructions in that section. After obtaining the required transducer spacing value,

return here and continue to the next section.

6 AquaTrans™ AT600 User’s Manual

Page 19

Chapter 1. General Installation Instructions

Flow Direction

D

DOWNSTREAM

UPSTREAM

10 X D (in.)

5 X D (min)

Good

Good

Good

Bad

Bad

Flow

Flow

Flow

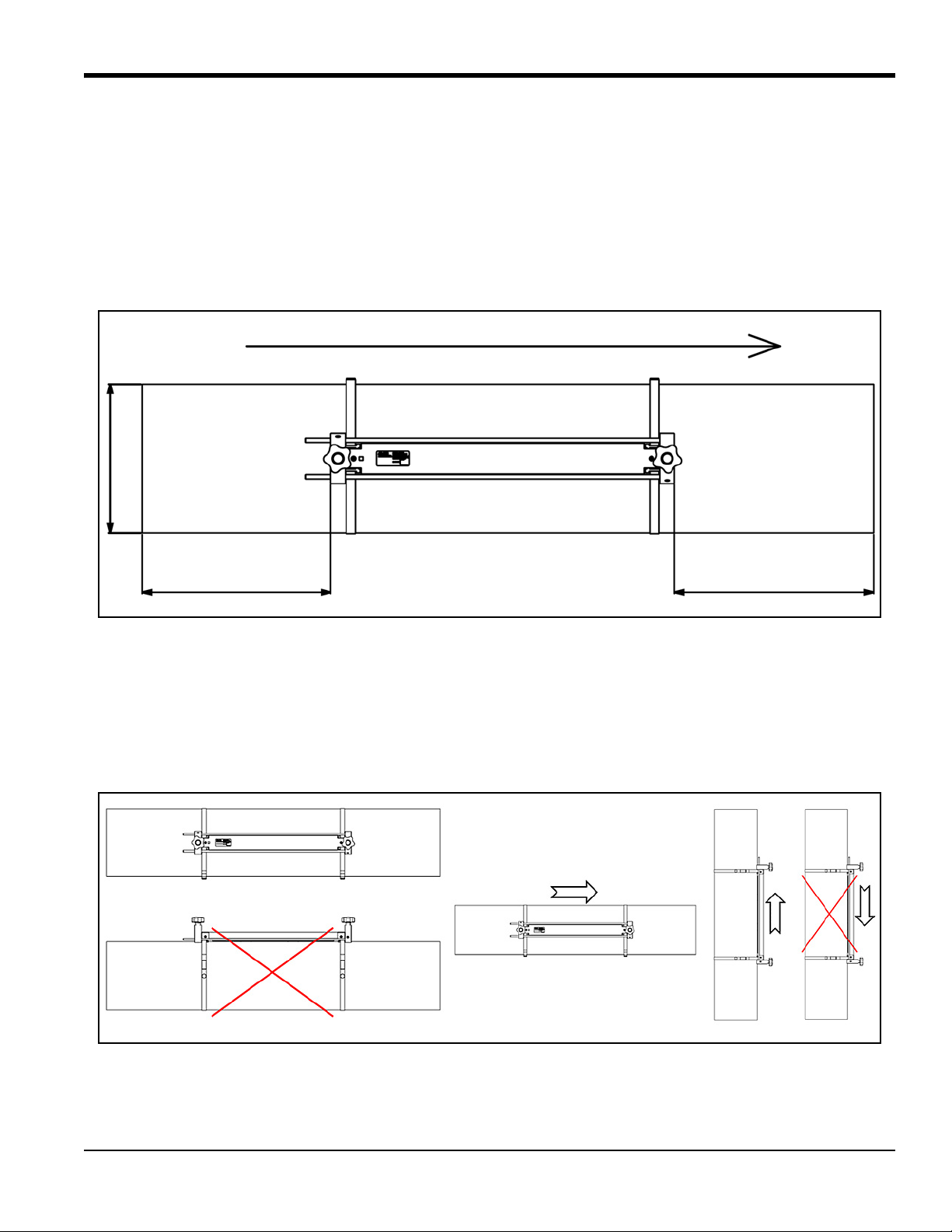

1.7 Choosing a Clamp-On Fixture/Transducer Location

For a given fluid and pipe, the accuracy of AT600 depends on the location and alignment of the transducers.

In addition to accessibility, when choosing a transducer location, follow these guidelines:

• Position the clamp-on fixture(s) and transducer system so that there are at least 10 pipe diameters of

straight, undisturbed flow upstream and 5 pipe diameters of straight, undisturbed flow downstream

from the measurement point (see Figure 7 below). Undisturbed flow means avoiding sources of

turbulence in the fluid such as valves, flanges, expansion joints, elbows, swirl, and cavitation.

Figure 7: AT600 Clamp-On Fixture/Transducer Location

• Locate the transducers on a common axial plane along the pipe (see Figure 8 below). The transducers

should be mounted on the side of the pipe, rather than the top or bottom, because the top of the pipe

tends to accumulate gases and the bottom tends to accumulate sediment. Either condition may cause

excessive attenuation of the ultrasonic signal. There is no similar restriction with vertical pipes, as

long as the flow direction is upward to prevent free falling of the fluid in a partially filled pipe.

Figure 8: Good and Bad Transducer Locations

AquaTrans™ AT600 User’s Manual 7

Page 20

Chapter 1. General Installation Instructions

1.8 Mounting the Clamp-on Fixture and Transducer System

The AT600 transducer system includes one or two clamp-on fixtures, two transducers and one transducer

cable. One clamp-on fixture is shipped with both transducers installed and the transducer cable connected

to the transducers. This fixture is the default setup for most applications. If a second fixture has been

ordered, it is shipped empty.

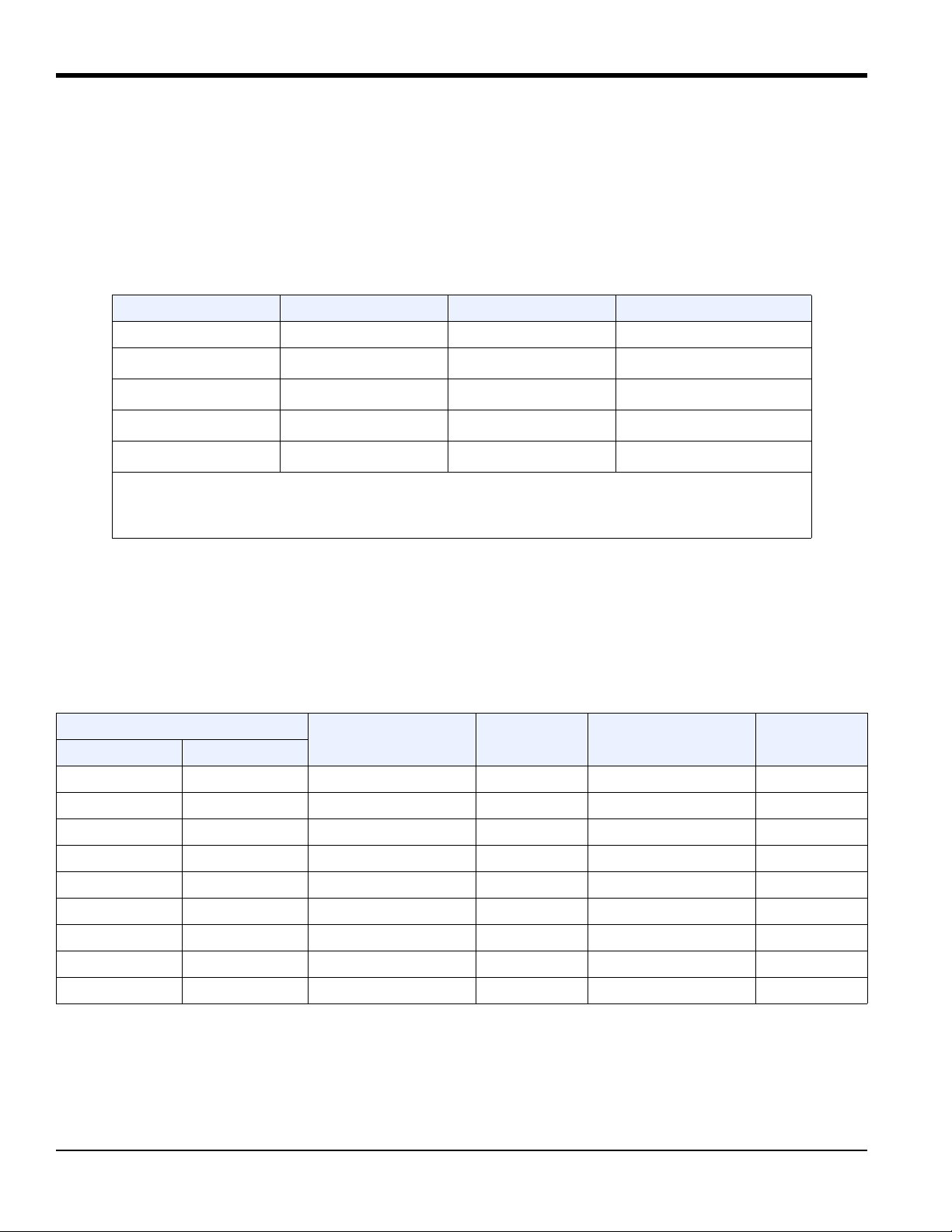

Transducers available for use with the AT600 flow meter are listed in Table 1 below.

Table 1: Available Transducers

Model Frequency Fixture Pipe Sizes

AT6 2, 1, 0.5 MHz AT600 2 in. (50 mm)

1

CF-LP

C-RS

C-PT

1

2

2

UTXDR

1

Go directly to: “Installing a CF-ES Clamp-On Fixture and Transducer System” on page 20.

4 MHz CF-ES 0.5-2 in. (15-50 mm)

4 MHz SPCF 0.5-8 in. (15-200 mm)

1, 0.5 MHz GCF 2 in. (50 mm)

2, 1, 0.5 MHz GCF 2 in. (50 mm)

2

Go directly to: “Installing a General Clamping Fixture and Transducer System” on page 20.

The AT600 clamp-on fixture and AT6 transducer system can be installed on pipe sizes 2 in. (50 mm). For

optimum performance in any specific application, either a two-traverse or one-traverse installation can be

chosen. Because the maximum pipe size for a single clamp-on fixture is 250 mm for 2 MHz transducers or

320 mm for 1 MHz and 0.5 MHz transducers, the detailed installation requirements differ based on the

calculated transducer spacing and the chosen number of traverses. Refer to Table 2 below to find the

parameters for your specific configuration.

Table 2: AT600 Clamp-On Fixture Installation

Pipe Size Range

mm inches

Transducer

Frequency (MHz)

Number of

Traverses

Transducer Spacing

(mm)

Number of

Fixtures

50 to 100 2 to 4 2 4 32 to 250 1

100 to 150 4 to 6 2 2 32 to 250 1

50 to 150 2 to 6 2 1 0 to 250 2

100 to 300 4 to 12 1 2 50 to 320 1

300 to 600 12 to 24 1 2 320 to 940 2

600 to 1500 24 to 60 1 1 >320 2

200 to 300 8 to 12 0.5 2 50 to 320 1

300 to 900 12 to 36 0.5 2 320 to 940 2

>900 >36 0.5 1 >320 2

IMPORTANT: See “Sensor Setup” on page 66 to calculate the required transducer spacing. A two traverse

installation is recommended for most applications.

IMPORTANT: If there is any type of coating or protective layer on the outer pipe surface, it must be removed at

the locations where the transducers and couplant contact the pipe surface.

8 AquaTrans™ AT600 User’s Manual

Page 21

Chapter 1. General Installation Instructions

1.8 Mounting the Clamp-on Fixture and Transducer System (cont.)

From the information on the previous page and the documentation included with your AT600 flow meter

system, you should already know the following details about your installation:

• Pipe Size

• Transducer Model

• Transducer Frequency

• Number of Traverses

• Calculated Transducer Spacing

• Number of Clamp-On Fixtures

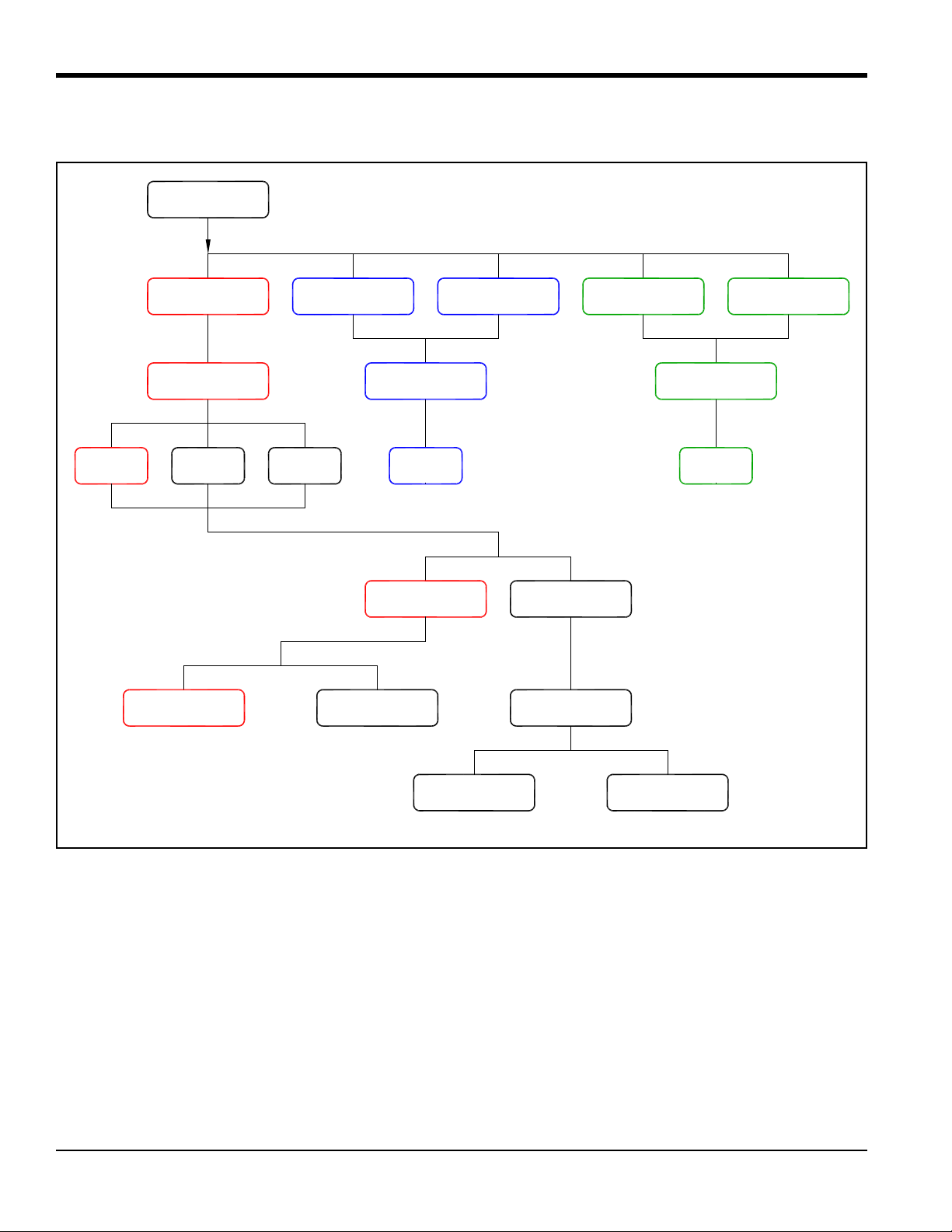

Based on the known information, proceed directly to one of the following sections in the next chapter for

instructions on installing your AT600 clamp-on fixture(s) and transducers on the pipe:

Note: See the flowchart in Figure 9 on page 10 to assist in choosing the appropriate instructions for your

specific configuration.

• “Transducer Spacing = 32 to 250 mm or 50 to 320 mm, Traverses = 2, Fixtures = 1” on page 11

• “Transducer Spacing = 320 to 940 mm, Traverses = 2, Fixtures = 2” on page 14

• “Transducer Spacing = 0 to 250 mm or 0 to 320 mm, Traverses = 1, Fixtures = 2” on page 17

• “Transducer Spacing >320 mm, Traverses = 1, Fixtures = 2” on page 19

AquaTrans™ AT600 User’s Manual 9

Page 22

Chapter 1. General Installation Instructions

AT6 Trans. C-RS Trans. C-PT Trans.

UTXDR Trans.

CF-LP Trans.

2 MHz 1 MHz

0.5 MHz

2 Traverses 1 Traverse

AT600 Fixture CF-ES Fixture GCF Fixture

[Section 2.2 on page 19] [Section 2.3 on page 19]

START HERE

4 MHz 4 MHz

Note: The red boxes are the recommended configuration, which works for most applications.

1 Fixture 2 Fixtures 2 Fixtures

[Section 2.1.1 on page 11] [Section 2.1.2 on page 14]

Spacing to 320 Spacing >320

[Section 2.1.3 on page 16] [Section 2.1.4 on page 18]

1.8 Mounting the Clamp-on Fixture and Transducer System (cont.)

Figure 9: Flowchart to Transducer Installation Instructions

10 AquaTrans™ AT600 User’s Manual

Page 23

Chapter 2. Clamp-On Fixture and Transducer Installation

Move

Align

Screw Tighten

Chapter 2. Clamp-On Fixture and Transducer Installation

2.1 Installing an AT600 Clamp-On Fixture and Transducer System

The instructions in this section are for installations using the AT600 clamp-on fixture only. For installations

using other clamp-on fixtures, see “Installing a CF-ES Clamp-On Fixture and Transducer System” on page 20

or “Installing a General Clamping Fixture and Transducer System” on page 20.

2.1.1 Transducer Spacing = 32 to 250 mm or 50 to 320 mm, Traverses = 2, Fixtures = 1

Note: A two traverse installation with one clamp-on fixture is the standard AT600 configuration.

When the required transducer spacing is 32 to 250 mm for a 2 MHz transducer or 50 to 320 mm for a 1 MHz

or

0.5 MHz transducer, one clamp-on fixture is needed for a dual traverse installation. Proceed as follows:

1. Install the AT600 clamp-on fixture with transducers on the pipe using two mounting straps.

a. Choose a location with enough straight pipe run (refer to Figure 7 on page 7).

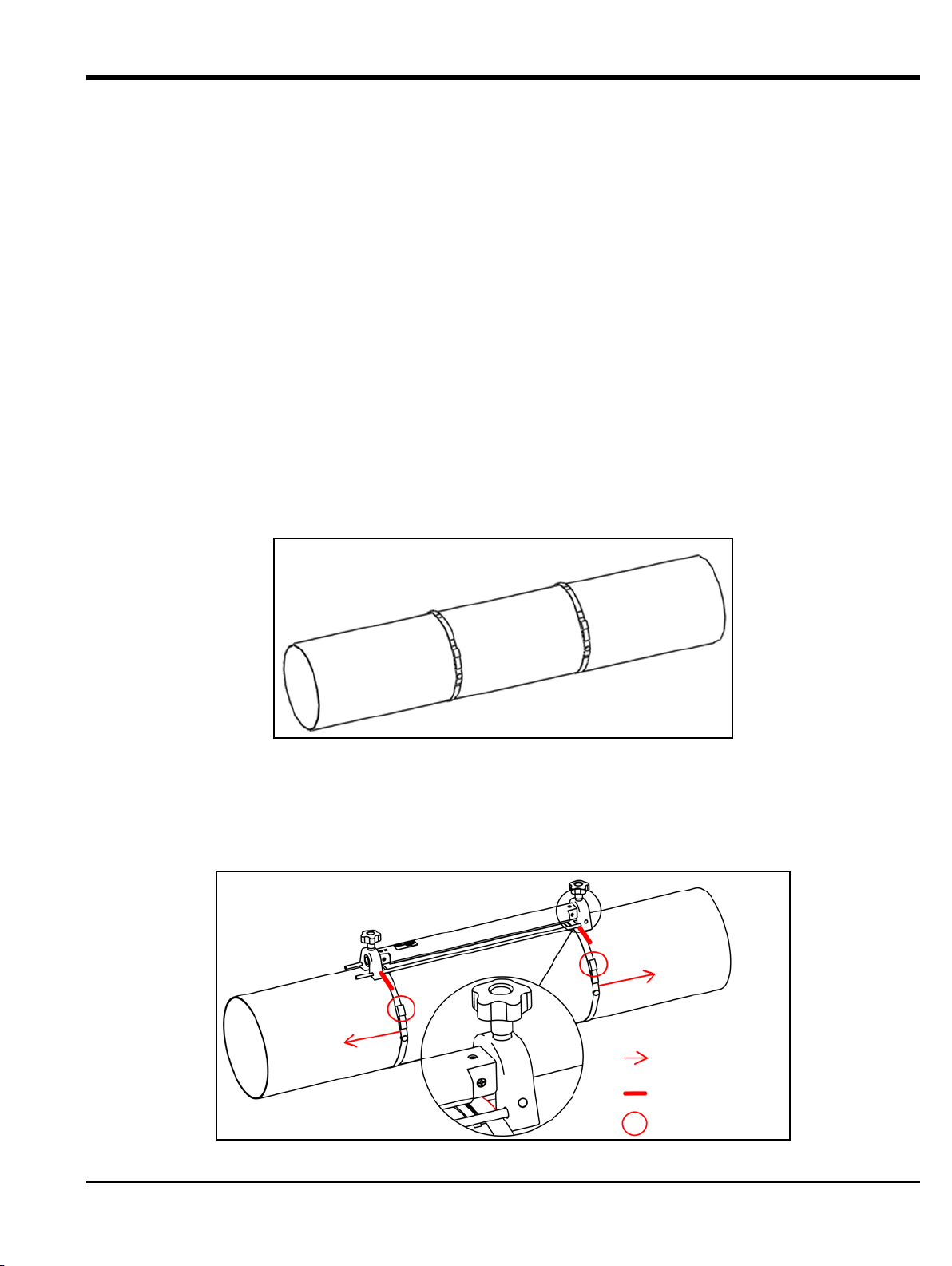

b. Install the two mounting straps on the pipe about 12 in. (30 cm) apart (see Figure 10 below).

Figure 10: Mounting Straps Installed on Pipe

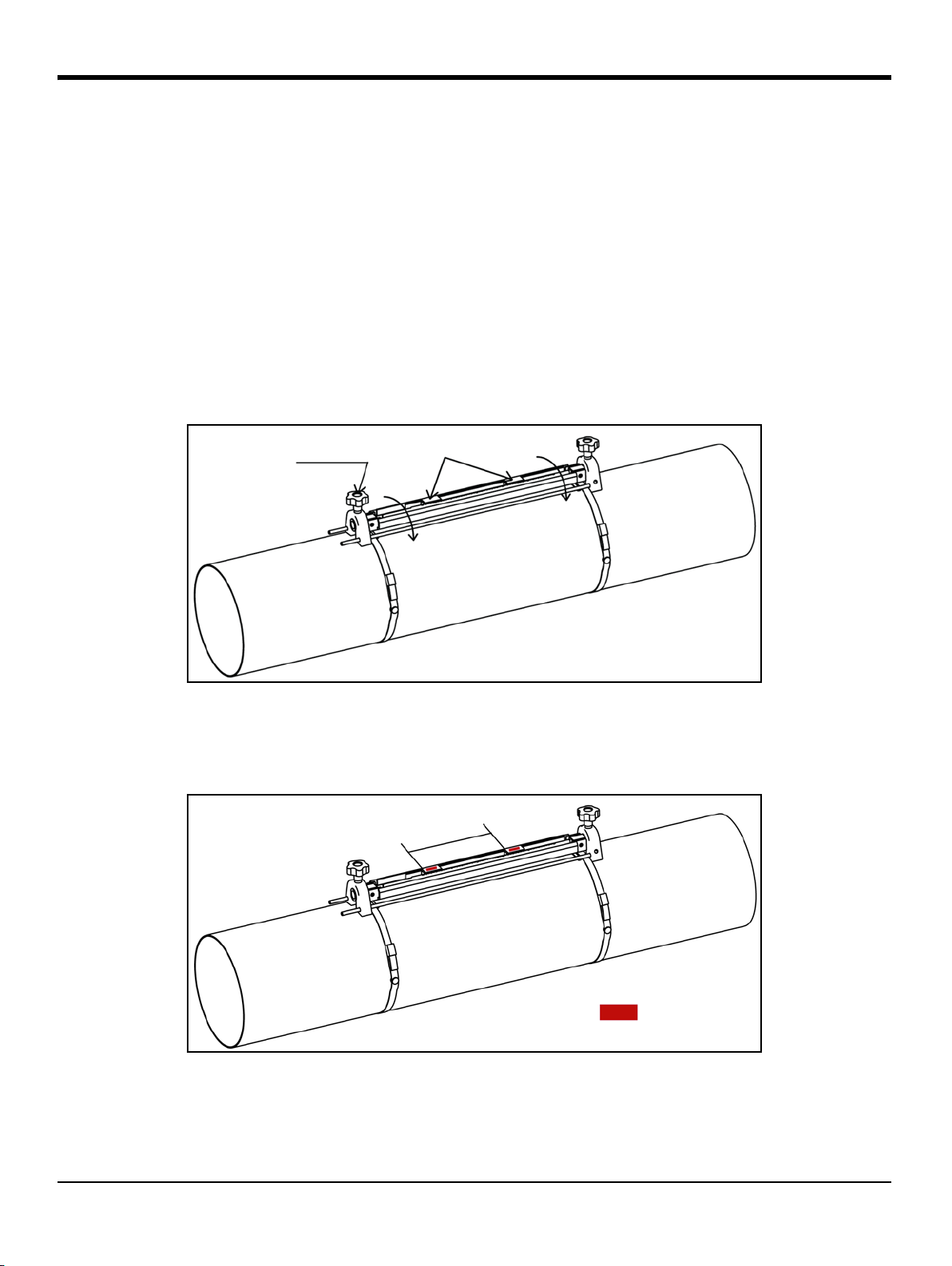

c. Hold the fixture against the pipe and move the mounting straps onto the fixture. Then, tighten

the screws on the straps, and verify that the straps remain in place on the fixture (see Figure 11

below).

AquaTrans™ AT600 User’s Manual 11

Page 24

Chapter 2. Clamp-On Fixture and Transducer Installation

Hand Wheel

Transducers

Sp

a

c

i

n

g

Couplant

Figure 11: 2 Traverse Installation with 1 Clamp-On Fixture

2.1.1 Transducer Spacing = 32 to 250 mm or 50 to 320 mm, Traverses = 2, Fixtures = 1 (cont.)

IMPORTANT: If there is any type of coating or protective layer on the outer pipe surface, it must be removed at

the locations where the transducers and the couplant contact the pipe surface.

2. Connect the power and transducer cables to the AT600, as shown in Figure 23 on page 23.

3. If you haven’t already done so, power the meter On and program your site data to determine the

required transducer spacing (see “Sensor Setup” on page 66).

4. Set the two transducers at the spacing calculated by the meter and tighten them in place, as follows:

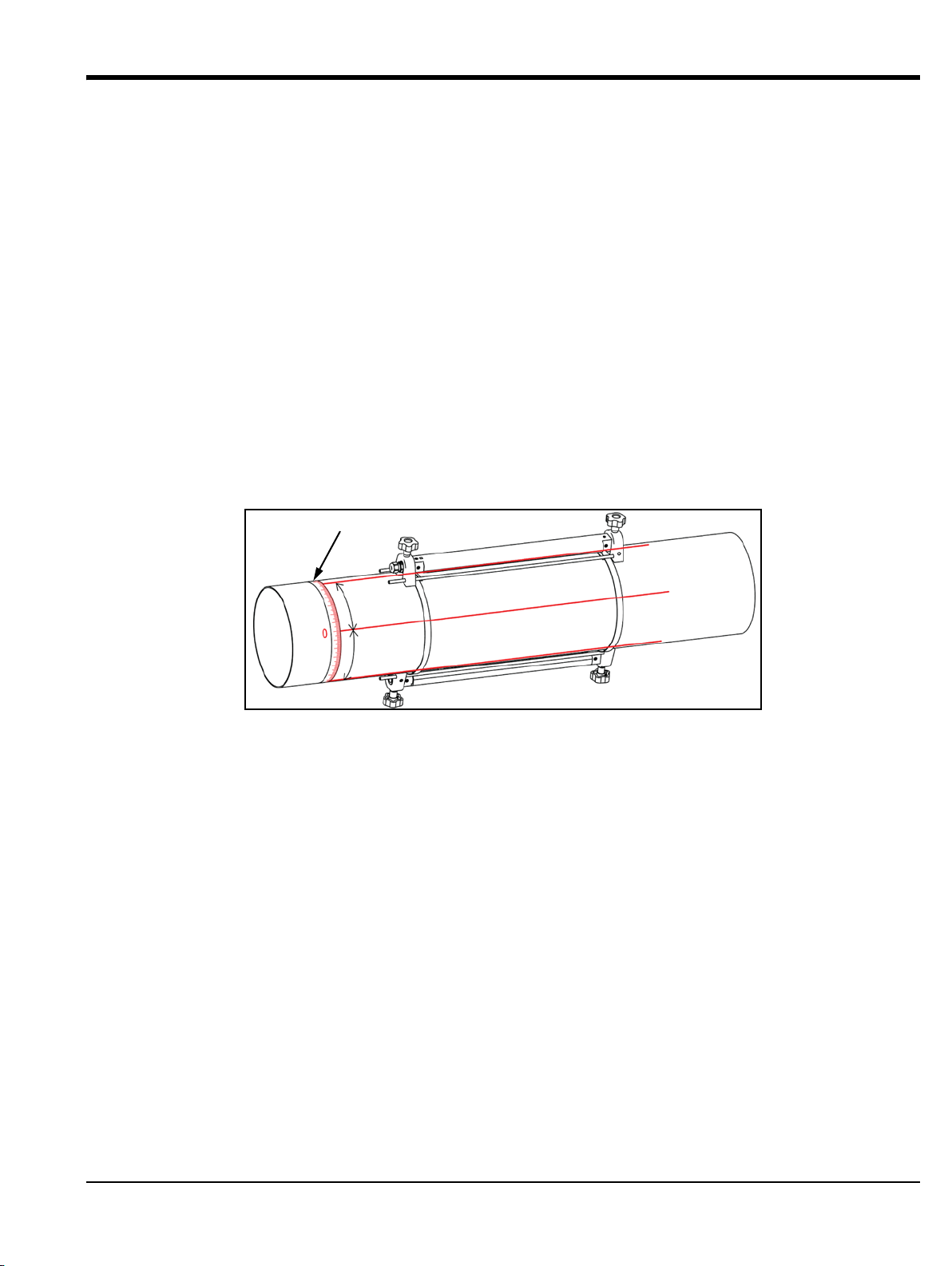

a. Loosen both transducers and rotate the fixture so that the transducers are in view (see Figure 12

below).

Figure 12: Transducers Rotated into View

b. Set the transducers to the spacing calculated by the meter. If you are using solid couplant, apply it

to both transducer faces. Then, rotate the transducers back onto the rail (see Figure 13 below).

Figure 13: Set Transducer Spacing and Apply Couplant

12 AquaTrans™ AT600 User’s Manual

Page 25

Chapter 2. Clamp-On Fixture and Transducer Installation

UPSTREAM DOWNSTREAM

Spacing

LSL USL

2.1.1 Transducer Spacing = 32 to 250 mm or 50 to 320 mm, Traverses = 2, Fixtures = 1 (cont.)

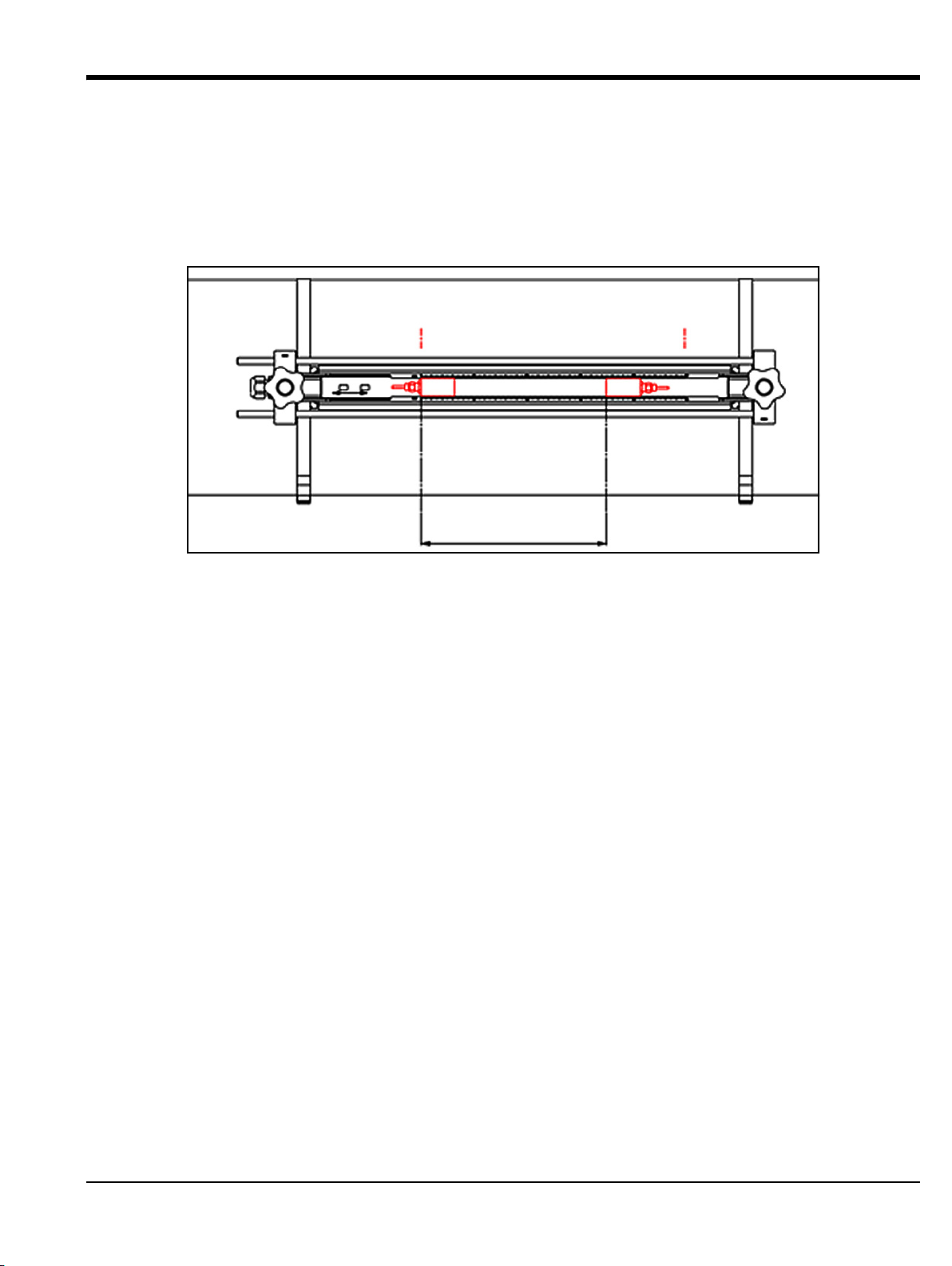

5. See Figure 14 below for an example of a completed installation. In this drawing, LSL is the Lower

Specified Limit and

USL is the Upper Specified Limit for the installation.

Note: For a one-fixture installation,

for a 1 MHz or 0.5 MHz transducer. The transducer spacing is measured from

LSL is 0 on the scale and USL is 250 mm for a 2 MHz transducer or 320 mm

LSL to a point USL.

Figure 14: Installation for 2 Traverses with 1 Fixture

6. Your clamp-on fixture and transducer installation is now complete. To wire your AT600 flow meter,

proceed to “Wiring the AT600 Electronics” on page 23.

AquaTrans™ AT600 User’s Manual 13

Page 26

Chapter 2. Clamp-On Fixture and Transducer Installation

Bar

2.1.2 Transducer Spacing = 320 to 940 mm, Traverses = 2, Fixtures = 2

For a two traverse installation with a calculated transducer spacing of 320 to 940 mm for a 1 MHz or 0.5 MHz

transducer, two fixtures are installed on the same side of the pipe. To do so, complete the following steps:

1. Install the four mounting straps on the pipe with a spacing of 12 in. (30 cm) between each pair of

straps.

2. Hold one of the clamp-on fixtures, with two transducers and one cable, against the pipe between the

upstream pair of straps and move the two mounting straps onto the fixture (see Figure 15 below).

Then, tighten the screws on the mounting straps, and verify that the straps remain in place on the

fixture.

Figure 15: 2 Traverse Installation with 2 Clamp-On Fixtures

3. Repeat step 2 to install the second clamping fixture, with no transducers or cable, on the pipe

between the downstream pair of straps. Use the bar on the second fixture to connect the two fixtures.

Then, move the straps onto the second fixture and tighten the screws.

IMPORTANT: Be sure the bar on the left side of the second fixture is in close contact with the bar on the first

fixture.

4. Set the spacing between the two transducers in the upstream clamping fixture to the value

calculated by the meter and tighten them back onto the pipe, as follows:

a. Rotate the fixture so that the transducers are in view (see Figure 12 on page 12).

b. Remove the downstream transducer from the first fixture (see Figure 16 below), disconnect the

transducer cable, and route the cable into the second fixture. Then, install the downstream

transducer into the second fixture and reconnect the transducer cable. If you are using solid

couplant, apply it to both transducer faces. Then, rotate the transducers back onto the rail

14 AquaTrans™ AT600 User’s Manual

Page 27

Chapter 2. Clamp-On Fixture and Transducer Installation

UPSTREAM

DOWNSTREAM

UPSTREAM DOWNSTREAM

Spacing

LSL1

USL1 LSL2

USL2

0

300

620

Figure 16: Moving the Downstream Transducer

2.1.2 Transducer Spacing = 320 to 940 mm, Traverses = 2, Fixtures = 2 (cont.)

IMPORTANT: Tight contact must be made between the bars on the two fixtures to ensure an accurate spacing.

5. See Figure 17 and Figure 18 below for examples of a completed installation in the following

situations:

Note: In this drawing,

a. For a calculated transducer spacing of 320 to 620 mm for a 1 MHz or 0.5 MHz transducer, locate

the upstream transducer at the

transducer at the calculated transducer spacing position (

b. For a calculated transducer spacing of 620 to 940 mm for a 1 MHz or 0.5 MHz transducer, locate

the upstream transducer at the

transducer at the calculated transducer spacing position (between

fixture.

LSL is the Lower Specified Limit and USL is the Upper Specified Limit for each fixture.

USL1 position on the first fixture. Then, locate the downstream

USL2) on the second fixture.

Figure 17: Transducer Spacing of 320 to 620 mm with 2 Fixtures

LSL1 position on the first fixture. Then, locate the downstream

LSL2 and USL2) on the second

AquaTrans™ AT600 User’s Manual 15

Page 28

Chapter 2. Clamp-On Fixture and Transducer Installation

UPSTREAM DOWNSTREAM

250

Spacing

LSL1

USL1 LSL2

USL2

320

620

940

0

Figure 18: Transducer Spacing of 620 to 940 mm with 2 Fixtures

6. Your clamp-on fixture and transducer installation is now complete. To wire your AT600 flow meter,

proceed to “Wiring the AT600 Electronics” on page 23.

16 AquaTrans™ AT600 User’s Manual

Page 29

Chapter 2. Clamp-On Fixture and Transducer Installation

+

1

/

4

c

i

r

c

u

m

f

e

r

e

n

c

e

-

1

/

4

c

i

r

c

u

m

f

e

r

e

n

c

e

Band Tape

2.1.3 Transducer Spacing = 0 to 250 mm or 0 to 320 mm, Traverses = 1, Fixtures = 2

For a one traverse installation with a calculated transducer spacing of 0 to 250 mm for a 2 MHz transducer or

0 to 320 mm for a 1 MHz or 0.5 MHz transducer, two clamp-on fixtures are installed on opposite sides of the

pipe. To install this configuration, complete the following steps:

1. Mark a straight line parallel to the pipe centerline on the top of the pipe (i.e., the 12 o’clock position).

2. Use a band tape to measure the circumference of the pipe. Then, mark two additional lines on the

pipe parallel to the first line. Locate these lines 1/4 of the way around the pipe in each direction from

the original line (i.e., at the 3 o-clock and 9 o’clock positions).

3. Install two mounting straps on the pipe about 12 in. (30 cm) apart (see Figure 19 below).

4. Hold one clamp-on fixture, with two transducers and one cable, on the pipe along one of the lines

marked in step 2. Then, move the two straps onto the ends of this fixture.

5. Hold the remaining (empty) clamp-on fixture on the opposite side of the pipe from the first fixture.

Then, move the two straps onto the ends of this clamp-on fixture.

6. Align the two fixtures to be equal distances from the band tape. Tighten both straps securely.

Figure 19: 1 Traverse Installation with 2 Fixtures

AquaTrans™ AT600 User’s Manual 17

Page 30

Chapter 2. Clamp-On Fixture and Transducer Installation

UPSTREAM

DOWNSTREAM

2.1.3 Transducer Spacing = 0 to 250 mm or 0 to 320 mm, Traverses = 1, Fixtures = 2 (cont.)

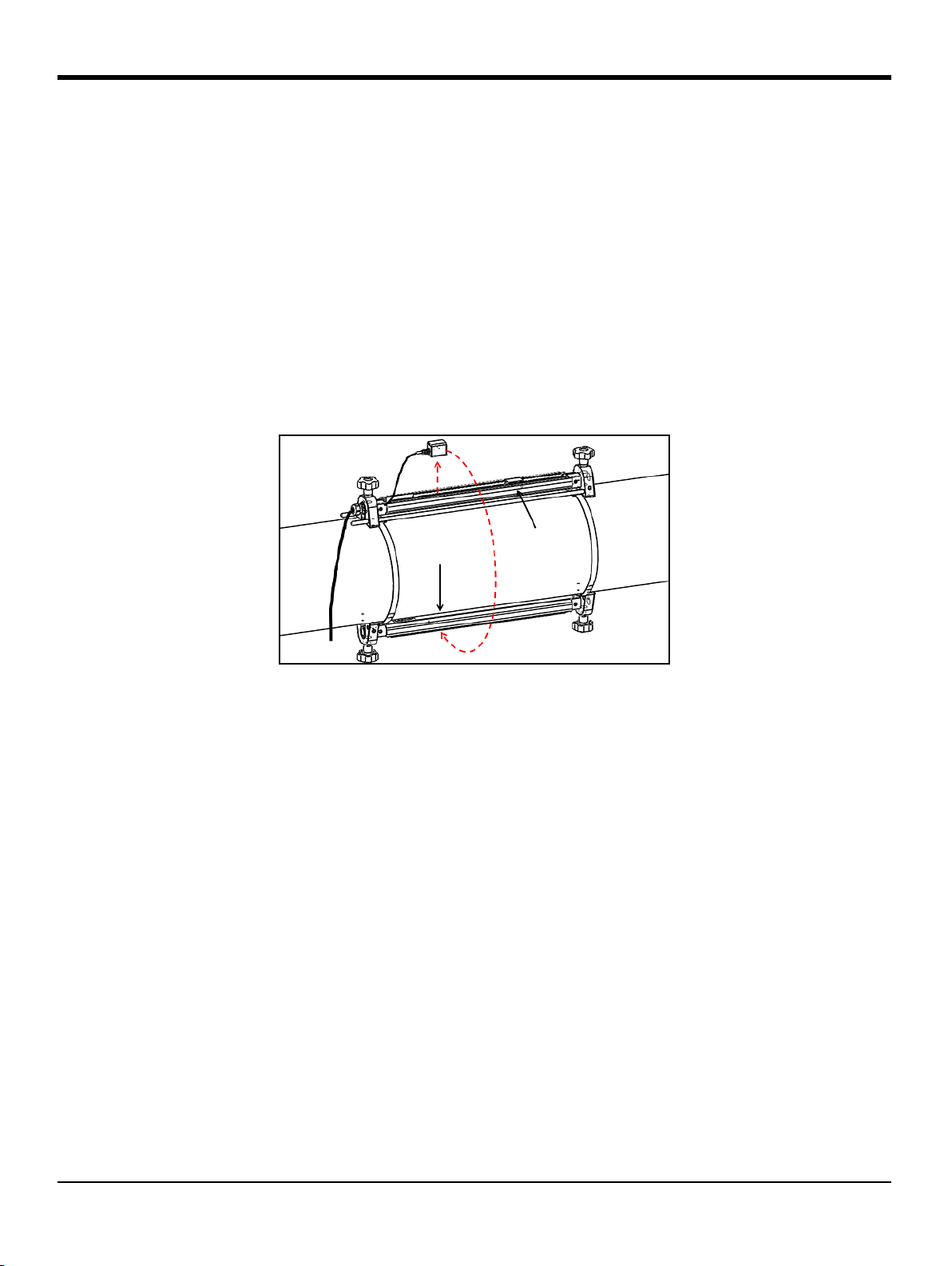

7. Set the spacing between the two transducers to the value calculated by the meter as follows:

a. Loosen the fixture rails and rotate the rails so the transducers are in view.

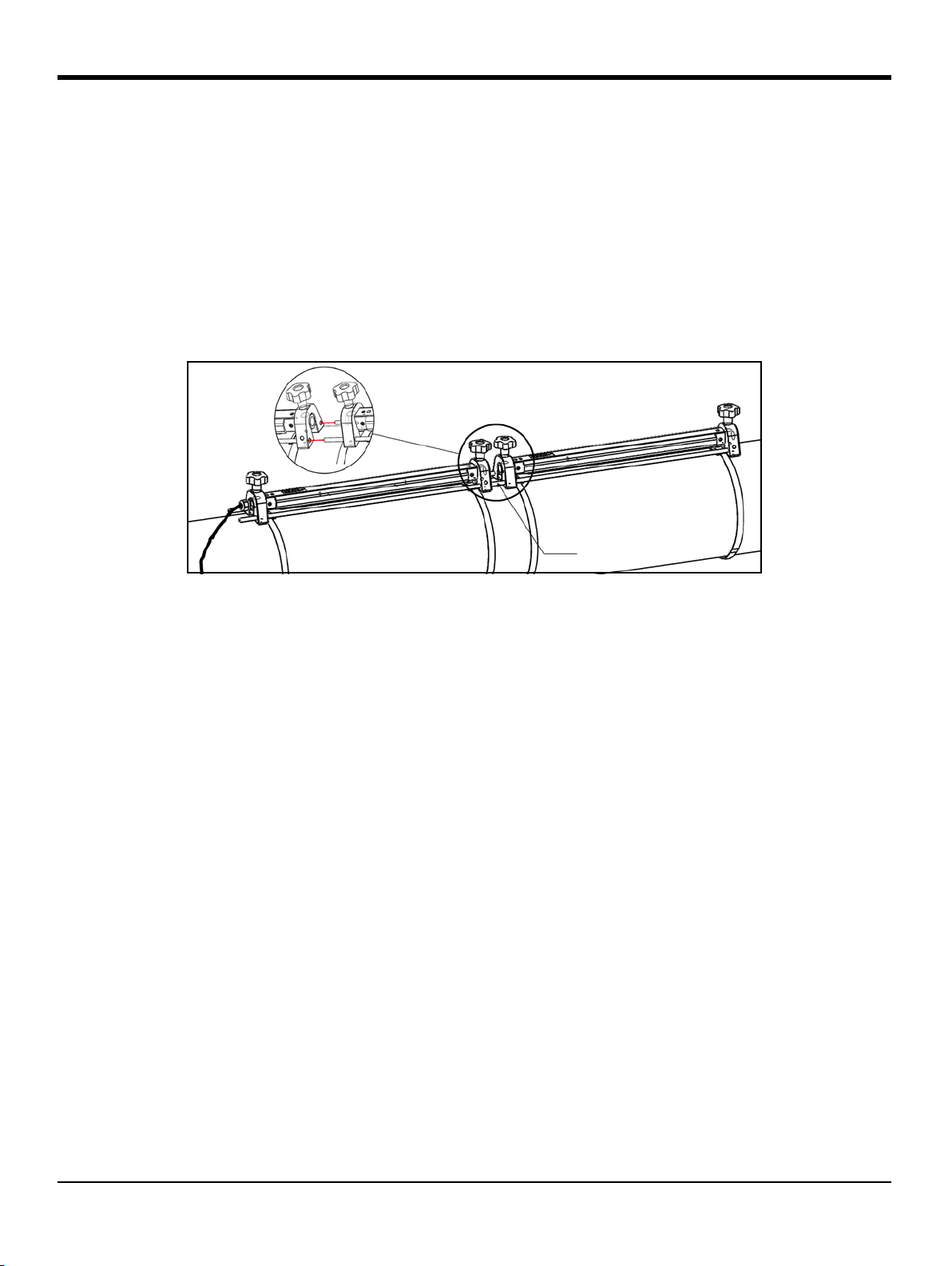

b. Remove the upstream transducer from the first fixture (see Figure 20 below). Disconnect the

transducer cable and route the cable into the second fixture.

Note: The cable for the upstream transducer needs to be pulled out through one side of the rail on the first

fixture and inserted through the side of the rail on the second fixture.

c. Install the upstream transducer into the second fixture, and reconnect the transducer cable.

d. Locate the upstream transducer at the zero position of the second fixture, and then move the

downstream transducer to the required position on the first fixture. If you are using solid

couplant, apply it to both transducer faces. Then, rotate the transducers back onto the rail

Figure 20: Relocate the Upstream Transducer

8. Your clamp-on fixture and transducer installation is now complete. To wire your AT600 flow meter,

proceed to “Wiring the AT600 Electronics” on page 23.

18 AquaTrans™ AT600 User’s Manual

Page 31

Chapter 2. Clamp-On Fixture and Transducer Installation

+

1

/

4

c

i

r

c

u

m

f

e

r

e

n

c

e

-

1

/

4

c

i

r

c

u

m

f

e

r

e

n

c

e

U

P

S

T

R

E

A

M

D

O

W

N

S

T

R

E

A

M

2.1.4 Transducer Spacing >320 mm, Traverses = 1, Fixtures = 2

For a one traverse installation with a calculated transducer spacing of >320 mm for a 1 MHz or 0.5 MHz

transducer, two clamp-on fixtures are installed on opposite sides of the pipe. To install this configuration,

refer to Figure 21 below and complete the following steps:

1. Mark a straight line parallel to the pipe centerline on the top of the pipe (i.e., the 12 o’clock position).

2. Use a band tape to measure the circumference of the pipe. Then, mark two additional lines on the

pipe parallel to the first line. Locate these lines 1/4 of the way around the pipe in each direction from

the original line (i.e., at the 3 o-clock and 9 o’clock positions).

3. Install the four mounting straps on the pipe with a spacing of about 12 in. (30 cm) between each pair

of straps. Then, mark a fixture position on each of the straight lines, using the band tape as a

reference point.

4. Hold one clamp-on fixture, with two transducers and one cable, on the pipe between the pair of

downstream straps and along one of the lines marked in step 2. Then, move the two downstream

straps onto the ends of this clamp-on fixture. Tighten the strap screws and verify that the straps

remain on the ends of the fixture.

5. Hold the remaining (empty) clamp-on fixture along the line on the opposite side of the pipe from the

first fixture and between the upstream pair of straps. Then, move the two upstream straps onto the

ends of this clamp-on fixture. Tighten the strap screws and verify that the straps remain on the ends

of the fixture.

6. Set the spacing between the two transducers to the value calculated by the meter as follows:

a. Loosen the fixture rails and rotate the rails so the transducers are in view.

b. Remove the upstream transducer from the first fixture (see Figure 21 below). Disconnect the

transducer cable and route the cable into the second fixture.

c. Install the upstream transducer in the second fixture, and reconnect the transducer cable.

d. Locate the upstream transducer at the zero position of the second fixture, and then move the

downstream transducer to the required position on the first fixture. If you are using solid

couplant, apply it to both transducer faces. Then, rotate the transducers back onto the rail

Figure 21: 1 Traverse Installation for Transducer Spacing >320 mm

7. Your clamp-on fixture and transducer installation is now complete. To wire your AT600 flow meter,

proceed to “Wiring the AT600 Electronics” on page 23.

AquaTrans™ AT600 User’s Manual 19

Page 32

Chapter 2. Clamp-On Fixture and Transducer Installation

Transducer

BNC to SMA Adapter

AT6 Cable with SMA Plug

with BNC Connector

2.2 Installing a CF-ES Clamp-On Fixture and Transducer System

To use the AT600 flow meter on 0.5 to 2 in. (15 to 50 mm) pipes, the CF-ES clamp-on fixture must be used.

UTXDR or CF-LP transducers are available for installation in this fixture. Note the following specifications:

• UTXDR Transducer: Use cable adapter p/n 704-1678-LF with the AT6 transducer cable,

-40 to +120°C (-40 to +248°F) Temperatures, 4 MHz Frequency

• CF-LP Transducer: Use cable adapter p/n 210-410-LF with the AT6 transducer cable,

up to 230°C (446°F) Temperatures, 4 MHz Frequency.

Detailed installation instructions for this fixture and transducer are available in BHGE document #916-082.

2.3 Installing a General Clamping Fixture and Transducer System

Both the C-RS and C-PT transducers are mounted on the pipe with the BHGE General Clamping Fixture (GCF).

For detailed installation instructions refer to following:

• C-RS Transducer Installation Guide (BHGE document #916-077)

• C-PT Transducer Installation Guide (BHGE document #916-074)

2.3.1 Installing C-RS or C-PT Transducers with an RG316 Cable

The standard AT6 transducer cable is an RG316 cable with an SMA connector on the transducer end. To

connect the

cable, a BNC to SMA Adapter is needed. See Figure 22 below and install the cable adapter on the transducer

end of your AT6 cable.

BNC connector on the C-RS or C-PT transducer to the SMA connector on the AT6 transducer

Figure 22: BNC to SMA Cable Adapter Installation

20 AquaTrans™ AT600 User’s Manual

Page 33

Chapter 2. Clamp-On Fixture and Transducer Installation

2.3.2 Installing C-RS or C-PT Transducers with an RG62 Cable

The AT600 flow meter can be connected directly to a C-RS or C-PT transducer with an optional RG62 cable,

which has a BNC connector at transducer end. Thus, the BNC to SMA Adapter is not needed.

This RG62 cable has a submersible cable option for the C-RS transducer. Also, there is a junction box option

for the C-RS and C-PT transducers, which provides extra physical protection for the BNC connection on the

transducer.

AquaTrans™ AT600 User’s Manual 21

Page 34

Chapter 2. Clamp-On Fixture and Transducer Installation

22 AquaTrans™ AT600 User’s Manual

Page 35

Chapter 3. Wiring the AT600 Electronics

GROUNDING 4

A

GROUNDING 2

GROUNDING 1

GROUNDING 3

DETAIL A

Transducer Terminals

W/E >ĂďĞů ĞƐĐƌŝƉƟŽŶ

ϭ E ŽǁŶƐƚƌĞĂŵdƌĂŶƐĚƵĐĞƌ

Ϯ hW hƉƐƚƌĞĂŵdƌĂŶƐĚƵĐĞƌ

WŽǁĞƌdĞƌŵŝŶĂůƐ

W/E >ĂďĞů ĞƐĐƌŝƉƟŽŶ

ϭ >ϭ;нͿ >;нͿ>ŝǀĞWŽǁĞƌWŽƐŝƟǀĞ

Ϯ >ϮE;ͲͿ E;ͲͿEĞƵƚƌĂůEĞŐĂƟǀĞ

/ŶƉƵƚKƵƚƉƵƚdĞƌŵŝŶĂůƐ

>ĂďĞů ĞƐĐƌŝƉƟŽŶ

Ϭ ŶĂůŽŐKƵƚƉƵƚϰͲϮϬŵ,ZdWŽƐŝƟǀĞ

ϭ ŶĂůŽŐKƵƚƉƵƚϰͲϮϬŵ,ZdEĞŐĂƟǀĞ

Ϯ ^ĞƌǀŝĐĞDŽĚďƵƐWŽƌƚWŽƐŝƟǀĞ

ϯ ^ĞƌǀŝĐĞDŽĚďƵƐWŽƌƚEĞŐĂƟǀĞ

ϰ ^ĞƌǀŝĐĞDŽĚďƵƐWŽƌƚZĞƚƵƌŶ'ƌŽƵŶĚ

ϱ ƵƐƚŽŵĞƌDŽĚďƵƐWŽƌƚWŽƐŝƟǀĞ

ϲ ƵƐƚŽŵĞƌDŽĚďƵƐWŽƌƚEĞŐĂƟǀĞ

ϳ ƵƐƚŽŵĞƌDŽĚďƵƐWŽƌƚZĞƚƵƌŶ'ƌŽƵŶĚ

ϴ ŝŐŝƚĂůKƵƚƉƵƚWŽƌƚWŽƐŝƟǀĞ

ϵ ŝŐŝƚĂůKƵƚƉƵƚWŽƌƚEĞŐĂƟǀĞ

ŝŐŝƚĂůKƵƚƉƵƚWŽƌƚWŽƐŝƟǀĞ

ŝŐŝƚĂůKƵƚƉƵƚWŽƌƚEĞŐĂƟǀĞ

E

'ĂƚĞ/ŶƉƵƚWŽƌƚWŽƐŝƟǀĞ

'ĂƚĞ/ŶƉƵƚWŽƌƚEĞŐĂƟǀĞ

& E

EŽƚĞŶĂůŽŐŽƵƚƉƵƚƐĂƌĞEĂŵƵƌEϰϯĐŽŵƉůŝĂŶƚ

Chapter 3. Wiring the AT600 Electronics

3.1 Wiring Diagram

ATTENTION EUROPEAN CUSTOMERS! To meet CE Mark requirements, all cables must be installed

as described in “Wiring Cable Specifications and Requirements” on page 177.

This section includes instructions for making all the necessary electrical connections to the AT600 flow

meter. Refer to Figure 23 below for the complete wiring diagram of the meter.

IMPORTANT: Except for the transducer connector, all electrical connectors are stored in their terminal blocks

during shipment and may be removed from the enclosure for more convenient wiring. Feed the

cables through the cable gland holes on the bottom of the enclosure, attach the wires to the

appropriate connectors and plug the connectors back into their terminal blocks.

After the AT600 is completely wired, proceed to “Initial Setup and Programming” on page 31 to configure the

meter for operation.

Note: The HART and Modbus communication options must be selected when ordering the AT600.

AquaTrans™ AT600 User’s Manual 23

Figure 23: Wiring Diagram

Page 36

Chapter 3. Wiring the AT600 Electronics

GLAND HOLE 5

GLAND HOLE 4

GLAND HOLE 2

GLAND HOLE 1

GLAND HOLE 3

DETAIL B

B

CABLE GLAND HOLES

Hole Num. Feed-Through Cables

1 Power Lines

2 Digital Output B Cable Lines

Digital Output C Cable Lines

Gate Input Cable Lines

3 Service Modbus Cable Lines

Customer Modbus Cable Lines

4 Analog Output A Cable Lines

5 Transducer Cable Lines

3.1 Making the Electrical Connections (cont.)

For proper wiring, the power lines, transducer cable and I/O lines must be routed through the appropriate

cable glands (see Figure 24 below). Also, refer to “Wiring Cable Specifications and Requirements” on page 177

for the required cable specifications.

IMPORTANT: Any unused cable glands must be plugged with the cable gland inserts provided with meter.

Figure 24: Recommended Cable Gland Usage

24 AquaTrans™ AT600 User’s Manual

Page 37

Chapter 3. Wiring the AT600 Electronics

3.2 Wiring the Line Power

ATTENTION EUROPEAN CUSTOMERS! To meet CE Marking requirements, all cables must be

installed as described in “Wiring Cable Specifications and Requirements” on page 177.

The AT600 may be ordered for operation with power inputs of either 85-264 VAC or 12-28 VDC. The label on

the shroud inside the electronics enclosure lists the required line voltage for your meter.

WARNING! Be sure to connect the AT600 only to the specified line voltage.

Examples of AT600 labels indicating the required line voltage are shown in Figure 25 below.

ATTENTION EUROPEAN CUSTOMERS! For compliance with the European Union's Low Voltage

Directive, this unit requires and external power disconnect device such as a switch or circuit breaker.

The disconnect device must be marked as such, clearly visible, directly accessible, and located within

1.8 m (6 ft) of the unit.

Figure 25: Typical Meter S/N Label (AC and DC Versions)

AquaTrans™ AT600 User’s Manual 25

Page 38

Chapter 3. Wiring the AT600 Electronics

3.2 Wiring the Line Power (cont.)

Refer to Figure 23 on page 23 to locate the terminal block and connect the line power as follows:

WARNING! Improper connection of the line power leads or connecting the meter to the incorrect

line voltage will damage the unit. It will also result in hazardous voltages at the flowcell and

associated piping and within the electronics console.

1. Strip 1/4” of insulation from the end of the line and neutral AC leads (or the positive and negative DC

leads), and 1/2” of insulation from the end of the ground lead.

2. Connect the ground lead to the internal ground connection (

panel of the electronics enclosure (See Figure 23 on page 23).

IMPORTANT: The incoming ground lead must be connected to the internal ground connection.

3. Connect the neutral AC lead (or the negative - DC lead) to

DC lead) to

IMPORTANT: Do not remove the existing PC board ground wire or the cover ground wire.

L1(+), as shown in Figure 23 on page 23.

GROUNDING 1) located on the bottom

L2/N(-) and the AC line lead (or the positive

3.3 Wiring the Transducers

ATTENTION EUROPEAN CUSTOMERS! To meet CE Mark requirements, all cables must be installed

as described in “Wiring Cable Specifications and Requirements” on page 177.

Wiring a typical AT600 system requires interconnection of the following components:

• Upstream and downstream transducers Installed in the clamping fixtures)

• The electronics console

To wire the transducers, complete the following steps:

WARNING! Before connecting the transducers, take them to a safe area and discharge any static

build-up by shorting the center conductor of the transducer cables to the metal shield on the cable

connector.

1. Locate the two transducer cables and connect them to the transducers.

2. Connect the cable connector with yellow

connector with white

3. Secure the cable gland.

IMPORTANT: Be sure to insert all cable connectors straight into the PCB receptacles to avoid damaging the

connector and/or the receptacle.

26 AquaTrans™ AT600 User’s Manual

UP jacket on the cable to the UP terminal, as shown in Figure 23 on page 23.

DN jacket on the cable to the DN terminal, and connect cable

Page 39

3.4 Wiring the System Ground

DETAIL C

SYSTEM GROUNDING SCREW

Model AT600

(Int. Pwr. Sup.)

HART Master/

Ampere Meter

Volts +

(Common)

Volts -

600 ohms)

(maximum

Load

PIN: 1

PIN: 0

WARNING! The AT600 must always be connected to a proper earth ground, using the system

grounding screw shown in Figure 26 below.

Figure 26: System Grounding Screw

3.5 Wiring the Analog Output for HART Communication

Chapter 3. Wiring the AT600 Electronics

The standard configuration of the Model AT600 flow meter includes one isolated 0/4-20mA analog output.

Connections to this output may be made with standard twisted-pair wiring. The current loop impedance for

this circuit must not exceed 600 ohms.

Figure 27: Analog Output/HART Communication Wiring

AquaTrans™ AT600 User’s Manual 27

Page 40

Chapter 3. Wiring the AT600 Electronics

3.5 Wiring the Analog Output for HART Communication (cont.)

WARNING! Always be sure to disconnect the main power supply from the AT600 before proceeding

with these instructions.

To wire the analog output, refer to Figure 27 on page 27 and complete the following steps:

1. Verify that the main power has been disconnected from the unit, and then open the enclosure.

2. Install the required cable gland in the chosen gland hole on the bottom of the enclosure.

3. Refer to Figure 23 on page 23 for the location of terminal block

shown above.

4. Secure the cable clamp.

Note the following:

I/O, and wire the terminal block as

• The standard analog output port provides only a 0/4-20mA analog output. If the HART

communication option is desired, it must be specified at the time of purchase.

• The AT600 analog output is an active mode type, with power provided internally by the meter. Do not

connect an external 24V power supply to this circuit.

• Prior to use, the analog output must be set up and calibrated (see “Inputs/Outputs” on page 48).

• When in meter is in configuration mode, the analog output is locked at 3.6 mA. After exiting from

configuration mode, the meter will resume normal operation.

3.6 Wiring the Modbus Communication

The optional AT600 Modbus port is a two-wire, half-duplex RS485 interface. If this option was specified at

the time of purchase, proceed with the wiring instructions below.

WARNING! Always be sure to disconnect the main power supply from the AT600 before proceeding

with these instructions.

To wire the Modbus RS485 serial port, refer to Figure 23 on page 23 above and complete the following steps:

1. Verify that the main power has been disconnected from the unit, and then open the enclosure.

2. Install the required cable clamp in the chosen gland hole on the side of the electronics enclosure.

3. Route one end of the cable through the gland hole and wire it to terminal block.

4. Secure the cable clamp.

28 AquaTrans™ AT600 User’s Manual

Page 41

Chapter 3. Wiring the AT600 Electronics

Model AT600

Totalizer/Frequency Counter

or Alarm Detector

PIN: 9/B

PIN: 8/A

C: Isolated Return

(Int. Pwr. Sup.)

Volts +

(Common)

Volts -

10 Kohms)

(minimum

Load

Max. Current:

Max. Voltage:

Isolation Voltage:

Max. Load Power:

1A

100 V

500 V

2W IN

3.7 Wiring the Frequency/Totalizer/Alarm Output

The AT600 can accommodate up to two digital outputs. Each of these outputs can be configured as either a

totalizer, frequency or alarm output (see “Programming Digital Communications” on page 61 for instructions).

Each totalizer/frequency/alarm output requires a twisted pair cable. Wire the terminal block as shown in

Figure 23 on page 23 and Figure 28 below.

Figure 28: Totalizer/Frequency/Alarm Output Wiring

AquaTrans™ AT600 User’s Manual 29

Page 42

Chapter 3. Wiring the AT600 Electronics

Model AT600

PIN: E

PIN: D

Switch

C

NO

+5 V

3.8 Wiring the Gate Input

The AT600 provides a Gate Contact Input port. This port is designed to start/stop the totalizer. During normal

measurement mode, thee operator can start or stop the totalizer functionality by toggling the gate switch.

WARNING! Always be sure to disconnect the main power supply from the AT600 before proceeding

with these instructions.

To wire the Gate input, refer to Figure 23 on page 23 and Figure 29 below and complete the following steps:

1. Verify that the main power has been disconnected from the unit, and then open the enclosure.

2. Install the required cable clamp in the chosen gland hole on the side of the electronics enclosure.

3. Route one end of the cable through the gland hole and wire it to terminal block.

4. Secure the cable clamp.

Figure 29: Gate Input Wiring

30 AquaTrans™ AT600 User’s Manual

Page 43

Chapter 4. Initial Setup and Programming

Display

Main Menu

Display Format

Program

Password

xxxx

User Preferences

Input/Output

Sensor Setup

Calibration

Advanced Factory

Program Review Keypad Lockout

Language

Save Changes?

No

Yes

Display

Chapter 4. Initial Setup and Programming

4.1 Introduction

This chapter provides instructions for programming the AT600 flow meter to place it into service. Before the

AT600 can begin taking measurements, at least the following menus must be programmed:

• “User Preferences” on page 43

• “Inputs/Outputs” on page 48

• “Sensor Setup” on page 66

Refer to the Main Menu map in Figure 30 below, and proceed to the appropriate section for instructions.

Figure 30: Main Menu Map

AquaTrans™ AT600 User’s Manual 31

Page 44

Chapter 4. Initial Setup and Programming

AT600

INITIALIZE . .

0.0

Velocity

m/s

Soundspeed

m/s

0.0

4.2 AT600 Keypad Operation

There are six keys and two LEDs on the AT600 keypad. The green light is a system health indicator and is on

when the meter is operational and not in error. The red light is a system status indicator and is on when the

meter is in error. Both lights being off indicates that the system is in configuration mode or no power has

been applied to the meter.

Figure 31: The AT600 Keypad

The six keys on the keypad enable users to program the AT600:

• [] - confirms the choice of a specific option and all data entry within that option

• [] - enables users to exit from a specific option without saving unconfirmed data

• [] and [] - enable users to highlight a specific window in the display option or to scroll through a

list of options. They are also used to change individual characters in a text string.

• [] and [] - enable users to scroll to a specific menu option, or to highlight a specific character in a

text string.

When powered On, the AT600 initialization screen is shown, followed by a measurement display (see below).

As a guide in following the programming instructions in this chapter, the complete AT600 menu maps can be

found in “Menu Maps” on page 187, and the relevant portions are reproduced throughout this chapter.

IMPORTANT: If no key has been pressed for 5 minutes, the AT600 exits the Keypad Program and returns to

32 AquaTrans™ AT600 User’s Manual

displaying measurements. Any unconfirmed configuration changes are discarded.

Page 45

Chapter 4. Initial Setup and Programming

Velocity

m/s

0.0

0.0

Velocity

m/s

Soundspeed

m/s

0.0

Total m^3

Forward 0.0

Reverse 0.0

Velocity

m/s

0.0

Measurement Type

Value

Error Code

Value Units

Velocity

m/s

0.0

m/s

Velocity

0.0

4.3 Display Programming

The AT600 keypad has six keys (see “AT600 Keypad Operation” on page 32) and the following two LEDs:

• Green: The green LED is a system health indicator and it is On when the meter is operating without

error.

• Red: The red LED is a system status indicator and it is On whenever the meter is in error.

Note: When both LEDs are Off, the meter is either in configuration mode or no power is applied.

4.3.1 Changing the Display for One- or Two-Variable Screens

An outline of a typical one- or two-variable screen is shown below.

To change the number of decimal places in the displayed value:

From the display screen, press either the [] or [] keys until the value is

highlighted.

AquaTrans™ AT600 User’s Manual 33

After the value is highlighted, press

option.

[] to open the Display/Decimal

Page 46

Chapter 4. Initial Setup and Programming

Display/Decimal

2

3

4

Sci

Velocity

m/s

0.0

m/s

Velocity

0.000e+00

Velocity

Measurement Type

Act Volumetric

Std Volumetric

Mass

4.3.1 Changing Display for One- or Two-Variable Screens (cont.)

Use the [] and [] keys to scroll to the desired value. (Available

options include 0, 1, 2, 3, 4, and Sci (Scientific Notation). Press [

select the value, and then press [

t

o cancel the selection.

] again to confirm the selection or []

4.3.2 Changing the Measurement Type for One- or Two-Variable Screens

To change the measurement type:

From the display screen, press either the [] or [] keys until the

measurement type is highlighted.

] to

After the value is highlighted, press

option.

The screen changes to Display/Measurement Type. Press the [] and []

keys to scroll to the desired parameter. Available parameters include:

Velocity, Act Volumetric, Std volumetric, Mass, Batch Totals, Inventory

Totals, Soundspeed, Reynolds, KFactor, and Diagnostics. After you have

chosen the measurement type, press

press [

Note: To select a particular measurement unit, go to “Units Setting” on page 44.

] again to confirm the selection or [] to cancel the selection.

[] to open the Measurement Type

[] to select the value, and then

34 AquaTrans™ AT600 User’s Manual

Page 47

Chapter 4. Initial Setup and Programming

Total m^3

Forward 0.000e+00

Reverse 0.000e+00

Totalizer

Reset Totalizer

Error Code

Values

Measurement Type

Start/Stop Totalizer

Totalizer Units

TOTAL m^3

Forward 0.000e+00

Reverse 0.000e+00

Total m^3

Forward 0.000e+00

Reverse 0.000e+00

Display/Decimal

2

3

4

Sci

4.3.3 Changing the Measurement Type or Units for the Totalizer Screens

The totalizer screen opens similar to Figure 32 below.

Figure 32: The Totalizer Screen

To change the number of decimal places in the value displayed on a totalizer screen, proceed as follows:

From the display screen, press either the [] or [] keys until the value

is highlighted.

After the value is highlighted, press

[] to open the Display/Decimal option.

Use the [] and [] keys to scroll to the desired number of decimal

places. (Available options include 0, 1, 2, 3, 4, and Sci (Scientific Notation).

Press [

selection or

] to select the value, and then press [] again to confirm the

[] to cancel the selection.

AquaTrans™ AT600 User’s Manual 35

Page 48

Chapter 4. Initial Setup and Programming

TOTAL m^3

Forward 0.000e+00

Reverse 0.000e+00

Total m^3

Forward 0.000e+00

Reverse 0.000e+00

Forward Totals

Totalizer Type

Reverse Totals

Net Totals

Time

TOTAL Seconds

Time 0.0000

Reverse 0.000e+00

Display/Unit

Seconds

Minutes

Hours

Days

4.3.3 Changing the Measurement Type or Units for the Totalizer Screens (cont.)

To change the totalizer measurement type, proceed as follows:

From the display screen, press either the [] or [] keys until the

measurement type is highlighted.

After the type is highlighted, press

[] to open the Display/Decimal option.

The screen changes to Totalizer Type. Press the [] and [] keys to scroll to

Forward Totals,

If the first value is set to

Reverse Totals,

or Net Totals, the meter displays the selected unit in the Units Setting selection. The available

the desired parameter. Available parameters include:

Reverse Totals, Net Totals and Time

[] to select the value, and then press [] again to confirm the selection or

[

] to cancel the selection.

Time, the meter displays the time unit. If the first value is set to Forward Totals,

. After you have chosen the type, press

time measurement units are seconds, minutes, hours or days. To choose the appropriate units, from the

highlighted measurement type, press the [] or [] keys until the desired measurement unit is highlighted.

After the unit is highlighted, press

[] to open the Display/Unit option.

36 AquaTrans™ AT600 User’s Manual

Press the

[] and [] keys to scroll to the desired units, and press [] to

select the unit, and then press [

cancel the selection.

Note: If you selected

Time, the available units are seconds, minutes, hours

and days.

] again to confirm the selection or [] to

Page 49

4.3.4 Starting or Stopping the Totalizer Measurement

TOTAL m^3

Forward 0.000e+00

Reverse 0.000e+00

TOTAL m^3

Forward 0.000e+00

Reverse 0.000e+00

TOTAL m^3

Forward 0.000e+00

Reverse 0.000e+00

To start or stop totalizer measurements:

Chapter 4. Initial Setup and Programming

From the display, press either the [] or [] keys until the

(either an arrow icon for

After the value is highlighted, press [

Start or a two-bar icon for Stop) is highlighted.

] to start or stop totalizing.

The display icon then changes to indicate the new status (

Start/Stop icon

Start or Stop).

AquaTrans™ AT600 User’s Manual 37

Page 50

Chapter 4. Initial Setup and Programming

TOTAL m^3

Forward 0.000e+00

Reverse 0.000e+00

TOTAL m^3

Forward 0.000e+00

Reverse 0.000e+00

4.3.5 Resetting the Totalizer

To reset the totalizer, proceed as follows:

From the display screen, press either the [] or [] keys until the

icon (a partial circle with an arrow) is highlighted.

After the

Reset icon has been highlighted, press [] to reset the totalizer to 0.

Reset

38 AquaTrans™ AT600 User’s Manual

Page 51

4.4 Entering the Main Menu

Display Format

Program

Program Review Keypad Lockout

Language

ѝ᮷

Français

ᰕᵜ䃎

English

Deutsch

Italiano

ƴǗǕǕǎnjǍPortuguês

Española

Yes

No

Svenska

1 Variable

2 Variables

Totalizer

Turkish

Main Menu

Esc > Enter > Esc

Display

Locked

Unlocked

Velocity