Page 1

TM

AquaTrans

AT600

Panametrics Ultrasonic

Flow Meter for Liquids

Applications

The AquaTrans AT600 flowmeter is a complete

ultrasonic system for the measurement of:

• Potable Water

• Wastewater

• Sewage

• Discharge water

• Treated water

• Cooling and heating water

• Irrigation water

• Other industrial fluids

Features & Benefits

• Economical non-intrusive flow measurement

• Extremely simple setup and installation

• Suitable for a wide range of pipe sizes and materials

• Suitable for lined pipes

• Velocity, volumetric, and totalized flow outputs

• Clamp-on installations

• Permanent solid couplant for clamp-on applications.

Panametrics.com

Page 2

Liquid Flow Ultrasonic Transmitter

Transducers

The AquaTrans AT600 liquid flow ultrasonic transmitter

combines state-of-the-art flow measurement

capability with a low-cost transmitter package that can

be installed right at the process measurement point.

It’s designed specifically for water and wastewater

applications in full pipes. The all-digital AquaTrans

AT600 has no moving parts and requires minimal

maintenance. An onboard microprocessor uses

patented Correlation Transit-Time™ technology for

long-term, drift-free operation. Automatic adjustment

to changing fluid properties and dynamically

configured operating software simplify programming.

Transit-Time Flow Measurement

In this method, two transducers serve as both ultrasonic

signal generators and receivers. They are in acoustic

communication with each other, meaning the second

transducer can receive ultrasonic signals transmitted

by the first transducer and vice versa.

In operation, each transducer functions as a

transmitter, generating a specified number of acoustic

pulses, and then as a receiver for an identical number

of pulses. The time interval between transmission and

reception of the ultrasonic signals is measured in both

directions. When the liquid in the pipe is not flowing,

the transit-time downstream equals the transit-time

upstream. When the liquid is flowing, the transit- time

downstream is less than the transit-time upstream.

The difference between the downstream and upstream

transit times is proportional to the velocity of the flowing

liquid, and its sign indicates the direction of flow.

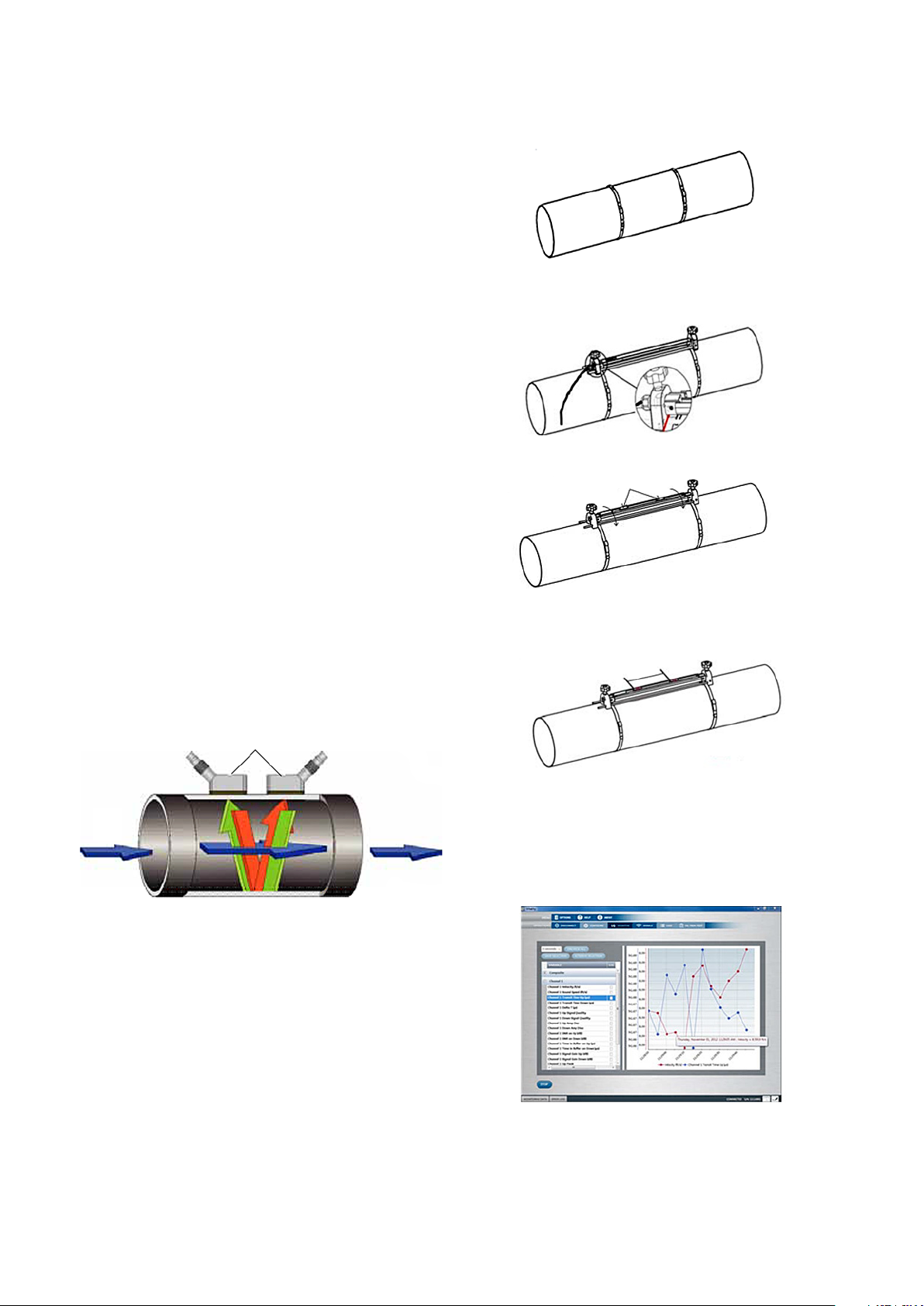

Easy Four Step Installation

Step #1: Install straps onto pipe.

Step #2: Put clamp-on fixture on pipe and move straps

onto sides of fixture.

Step #3: Open fixture to set spacing.

Step 4: Set spacing and lock fixture with transducers

onto pipe.

Spacing

Flow Meter Transducers

Fluid

Flow

Ultrasonic Signal Path

Transit-time Flow Measurement Technique

Clamp-On Transducers

Clamp-on transducers oer maximum convenience, exibility

and a low installation cost compared to traditional ow metering

technologies. With proper installation, clamp-on transducers

provide better than 1% of reading accuracy in most applications.

Vitality™ Software (Optional)

The AquaTrans AT600 can communicate with a PC via

our Vitality interface program. Consult the manual for

details on sites, logs, and other operations with a PC.

Page 3

Specifications

Overall Operation and Performance

Fluid Types

Liquids: acoustically conductive fluids, including most

clean liquids, and many liquids with small amounts of

entrained solids or gas bubbles

Flow Measurement

Patented Correlation Transit-TimeTM mode

Pipe Sizes

0.5 to 300 in. (15 to 7600 mm)

Pipe Materials

All metals and most plastics. Consult Baker Huges for

concrete, composite materials, and highly corroded or

lined pipes.

Accuracy

• ±1% of reading in application, ≥2 in. (50 mm) pipe

and >1 ft/s (0.3 m/s) velocity

• ±2% of reading in application, <2 in. (50 mm) pipe

and >1 ft/s (0.3 m/s) velocity

• ±0.5% in field calibration

Installation assumes a fully developed, symmetrical flow

profile (typically 10 diameters upstream and 5 diameters

downstream of straight pipe run). Final installation

accuracy is a function of multiple factors including fluid,

temperature range, pipe centricity and others.

Calibration

All meters are water calibrated and delivered with a

traceable calibration certificate.

Repeatability

±0.2% of reading

Range (Bidirectional)

-40 to 40 ft/s (-12.19 to 12.19 m/s)

Rangability (Overall)

400:1

Measurement Parameters

Velocity, Volumetric, and Totalized Flow

Electronics

Enclosure

Epoxy-coated aluminum weatherproof

Type 4X/IP67

Dimensions

6.6 x 5.0 x 2.4 in. (168 x 128 x 61 mm)

Weight: 3.5 lb/1.5 kg

Channels

One channel

Display

Graphic LCD (128 x 64 pixels)

Keypad

Six-button keypad for full functionality operation

Error Display Indicator

Green or red light

Power Supplies

• Standard: 85 to 265 VAC, 50/60 Hz

• Optional: 12 to 28 VDC, ± 5%

Power Consumption

10 Watts in-rush

5 Watts normal operation

Operating Temperature

-4°F to 131°F (–20°C to 55°C)

Storage Temperature

–40°F to 158°F (–40°C to 70°C)

Outputs (Based on Configuration)

• 4-20 mA (24VDC powered, 600Ω maximum load,

1500 VDC isolation)

• Frequency, Pulse, Alarm (Passive output, 100 VDC,

1 A/1 W maximum, 1500 VDC isolation)

• HART (FSK modulation, Category Flow, Protocol

Version 7.5, Device Revision 2, MFG ID 157, Device

Type Code 127, Number of device variables 34)

• Modbus/RS485 (Half-duplex, 1500 VDC isolation)

Note: Analog outputs are Namur NE43 compliant.

Certification

CE, UL, CSA, (MCert approval pending)

Clamp-On Ultrasonic Flow

Transducers

Temperature Ranges

• Standard: -40 to 302°F (-40 to 150°C)

• Optional: -328 to 752°F (-200 to 400°C)

See specific transducer for exact temperature range.

Mounting Fixture

Anodized aluminum with stainless steel strapping

Couplant

Standard: Solid couplant

Optional: Liquid couplant

Rating

Standard: General purpose (IP66 or IP68)

Note: See specific transducer model for exact rating.

Page 4

Ordering Information

A B C D E F G H I J K L

AT6

C1

AT05

AT10

AT20

UTX40

CFLP

CR05

CR10

CR05SUB

CR10SUB

CR05JB

CR10JB

CP05JB

CP10JB

CP20JB

< >

IN

MM

1

2

3

4

7

1

2

A

H

M

Model:

Clamp-on liquid ultrasonic flow meter cocsisting of an AT600, transducers,

clamping fixture, transducer cable and coupling

Clamp-On System:

Single-channel clamp-on system

Transducer System:

AT05: C-AT transducers, 0.5 MHz, IP68, 12 in./300 mm or greater typ., Tprocess:

-40 to 150°C

AT10: C-AT transducers, 1 MHz, IP68, 4 to 24 in./100 to 600 mm typ., Tprocess:

-40 to 150°C

AT20: C-AT transducers, 2 MHz, IP68, 2 to 6 in./50 to 150 mm typ., Tprocess: -40

to 150°C

UTX40: UTXDR transducers, 4 MHz, IP67, 0.5 to 2in/15 to 50 mm, Tprocess: -20

to 120°C

CFLP: CF-LP transducers, 4 MHz, IP66, 0.5 to 2 in./15 to 50 mm, Tprocess: -40 to

230°C

CR05: C-RS transducers, 0.5 MHz, IP66, 12 i.n/300 mm or greater typ., Tprocess:

-40 to 150°C

CR10: C-RS transducers, 1 MHz, IP66, 4 to 24 in./100 to 600 mm typ., Tprocess:

-40 to 150°C

CR05SUB: C-RS submersible transducers, 0.5 MHz, IP68, 12 in./300 mm or

greater typical, Tprocess: -40 to 150°C

CR10SUB: C-RS submersible transducers, 1 MHz, IP68, 4 to 24 in./100 to 600 mm

typ., Tprocess: -40 to 150°C

CR05JB: C-RS with junction box transducers, 0.5 MHz, IP66, 12 in./300 mm or

greater typ., Tprocess: -40 to 150°C

CR10JB: C-RS with junction box transducers, 1 MHz, IP66, 4 to 24 in./100 to 600

mm typ., Tprocess: -40 to 150°C

CP05JB: C-PT with junction box transducers, 0.5 MHz, IP66, 12 i.n/300 mm or

greater typ., Tprocess: -20 to 210°C

CP10JB: C-PT with junction box transducers, 1 MHz, IP66, 4 to 24 in./100 to 600

mm typ., Tprocess: -20 to 210°C

CP20JB: C-PT with junction box transducers, 2 MHz, IP66, 2 to 6 in./50 to 150

mm typ., Tprocess: -20 to 210°C

Pipe Size:

Nominal outside diameter

Pipe Units:

Inches

Millimeters

Cable Length:

10 ft (3 m) of transducer cable

25 ft (7.5 m) of transducer cable

50 ft (15 m) of transducer cable

100 ft (30 m) of transducer cable

300 ft (90 m) of transducer cable

AT Power:

85 to 265 VAC

12 to 28 VDC

Analog and Digital Output:

4-20 mA analog output only

4-20 mA output with HART

4-20 mA output and Modbus

Page 5

A B C D E F G H I J K L

AA

AF

AT

FF

FT

TT

01

02

03

04

05

06

07

08

09

M

E

Discrete Output:

Two alarm contacts

One alarm contact and one frequency output

One alarm contact and one totalizer (pulse) output

Two frequency outputs

One frequency output and one totalizer (pulse) output

Two totalizer (pulse) outputs

Language:

English

German

French

Italian

Spanish

Portuguese

Russian

Japanese

Chinese

Default Units:

Metric

English

Special:

0

No specials

S

Special

AT6- C1 –AT05 – 5 - IN - 1 - 2 - A- AA- 01- M- 0 (Example Part Number)

Page 6

Panametrics.com

Copyright 2020. Baker Hughes Company. This material contains one

or more registered trademark of Baker Hughes Company and its

subsidiaries in one or more countries. All third-party product and

company names are trademarks of their respective holders.

920-653E

Loading...

Loading...