Page 1

FE6A THRU FE6D

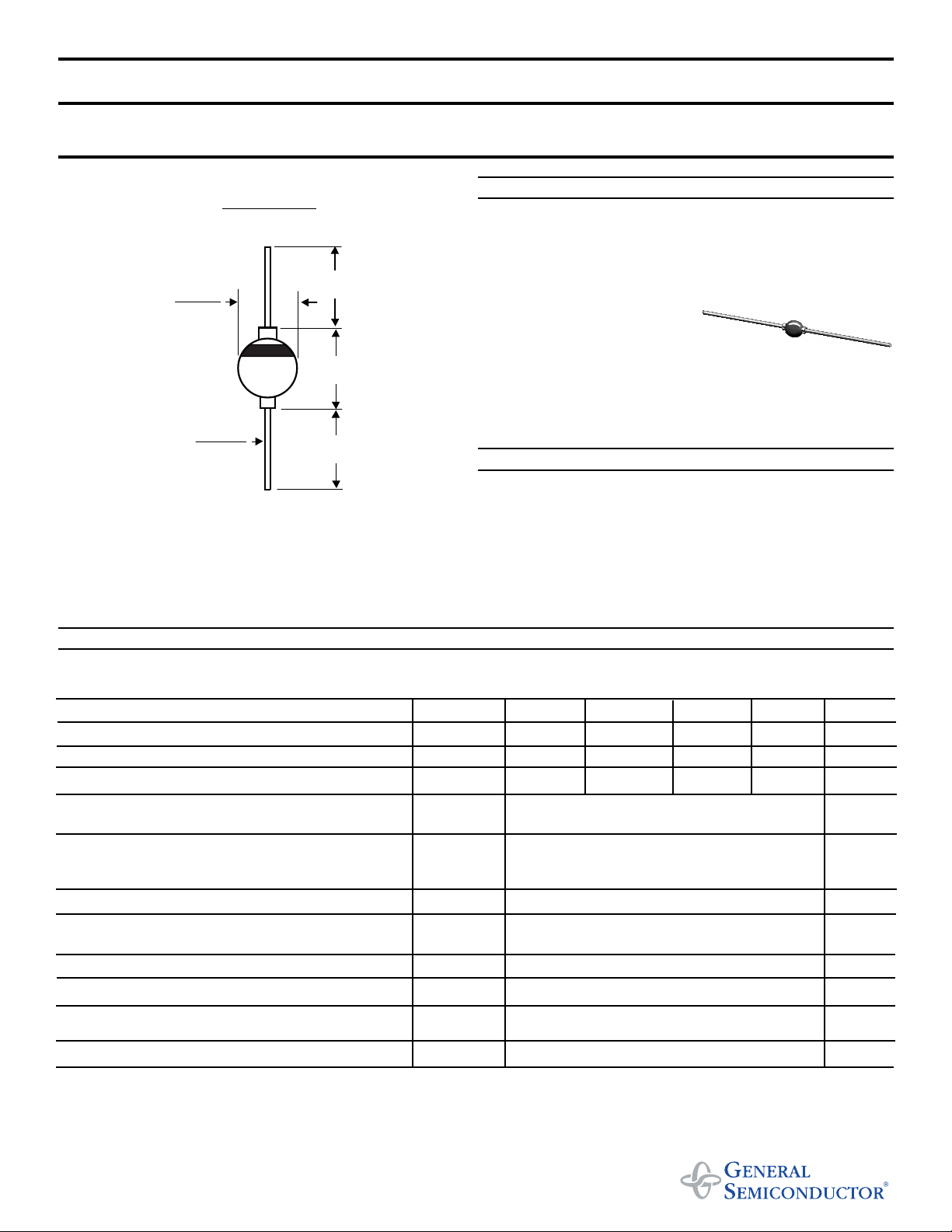

0.180 (4.6)

0.115 (2.9)

0.042 (1.07)

0.038 (0.962)

DIA.

DIA.

MAX.

0.300 (7.6)

1.0 (25.4)

MIN.

1.0 (25.4)

MIN.

GLASS PASSIVATED FAST EFFICIENT RECTIFIER

Reverse Voltage - 50 to 200 Volts Forward Current - 6.0 Amperes

PATENTED*

Dimensions in inches and (millimeters)

*

Brazed lead assembly is covered by Patent No.3,930,306

Case Style G4

♦ High temperature metallurgically bonded construction

♦ Glass passivated cavity-free junction

♦ Superfast recovery time-for high efficiency

♦ Low forward voltage, high current capability

♦ Capable of meeting environmental standards

of MIL-S-19500

♦ Hermetically sealed package

♦ Low leakage current

♦ High surge current capability

♦ High temperature soldering guaranteed:

350°C/10 seconds, 0.375" (9.5mm) lead length,

5 lbs, (2.3kg) tension

MECHANICAL DATA

FEATURES

Case: Solid glass body

Terminals: Plated axial leads, solderable per MIL-STD-750,

Method 2026

Polarity: Color band denotes cathode end

Mounting Position: Any

Weight: 0.037 ounce, 1.04 grams

MAXIMUM RATINGS AND ELECTRICAL CHARACTERISTICS

.

Ratings at 25°C ambient temperature unless otherwise specified.

SYMBOLS FE6A FE6B FE6C FE6D UNITS

Maximum repetitive peak reverse voltage V

Maximum RMS voltage V

Maximum DC blocking voltage V

Maximum average forward rectified current

0.375" (9.5mm) lead length at T

=55°C

L

RRM

RMS

I

(AV)

DC

Peak forward surge current

8.3ms single half sine-wave superimposed I

FSM

on rated load (JEDEC Method)

Maximum instantaneous forward voltage at 6.0A V

Maximum DC reverse current T

at rated DC blocking voltage T

Maximum reverse recovery time

Typical junction capacitance

Typical thermal resistance

(NOTE 1)

(NOTE 2)

(NOTE 3, 4)

=25°C 5.0

A

=100°C

A

Operating junction and storage temperature range T

NOTES:

(1) Reverse recovery test conditions:IF=0.5A, IR=1.0A, Irr=0.25A

(2) Measured at 1.0 MH

(3) Thermal resistance from junction to lead at 0.375" (9.5mm) lead length with both leads attached to heatsinks

(4) Thermal resistance from junction to ambient at 0.375" (9.5mm) lead length and mounted on P.C.B.

and applied reverse voltage of 4.0 Volts

Z

F

I

R

t

rr

C

J

R

ΘJA

R

ΘJL

J, TSTG

50 100 150 200 Volts

35 70 105 140 Volts

50 100 150 200 Volts

6.0 Amps

135.0 Amps

0.975 Volts

50.0

µA

35.0 ns

100.0 pF

55.0

18.0

°C/W

-65 to +175 °C

4/98

Page 2

0.1 1 10

0

50

100

150

200

250

1.00.4 0.6 0.8 1.2 1.4 1.6 1.8

0.01

0.1

1

10

100

1 10 100

0

25

50

75

100

125

150

175

25 50 75 100 125 150 175

0

1.5

3.0

4.5

6.0

7.5

9.0

0

100

1,000

02040 6080

0.01

0.1

1

10

100

100

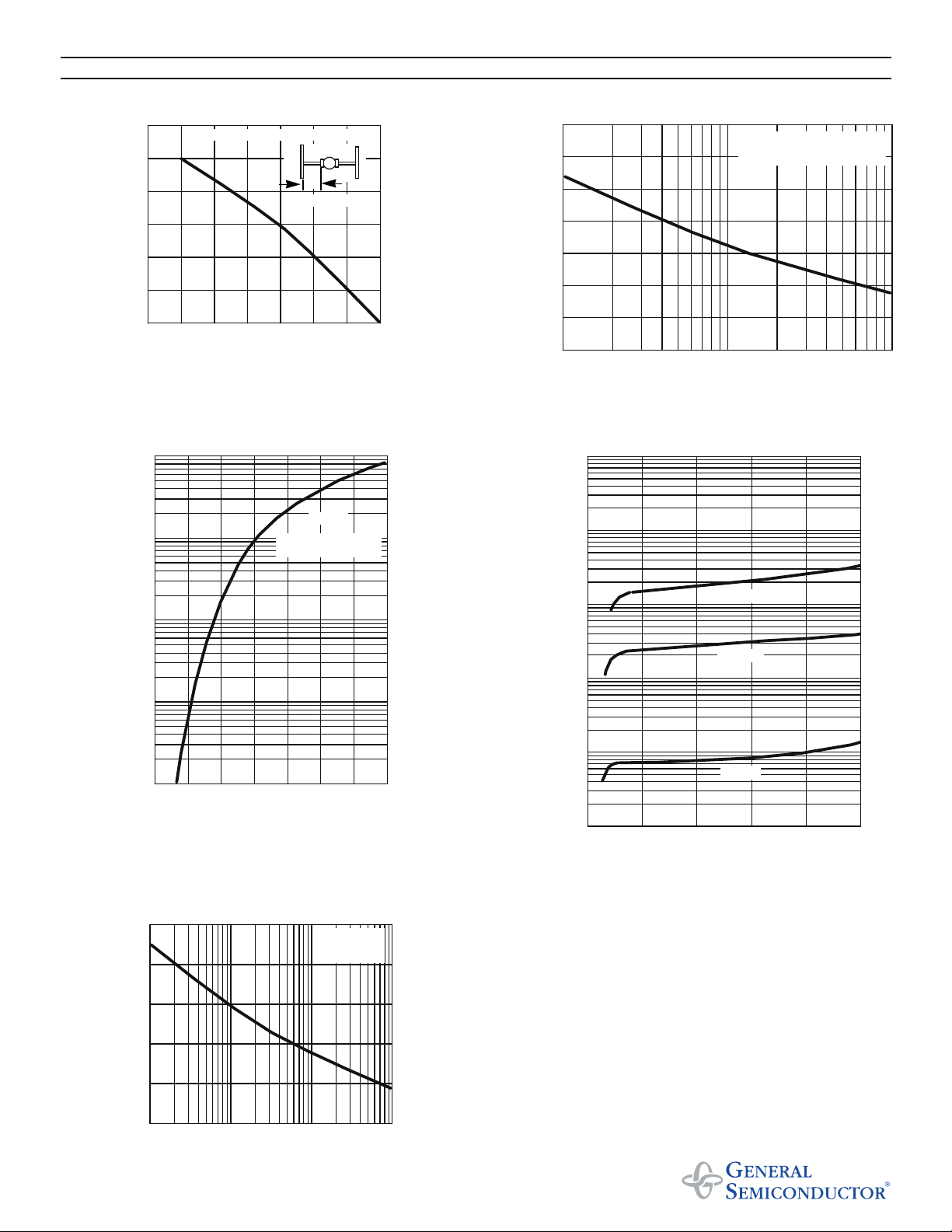

RATINGS AND CHARACTERISTIC CURVES FE6A THRU FE6D

FIG. 1 - MAXIMUM FORWARD CURRENT

DERATING CURVE

RESISTIVE OR INDUCTIVE LOAD

T

L

L

0.375" (9.5mm)

FIG. 2 - MAXIMUM NON-REPETITIVE PEAK

FORWARD SURGE CURRENT

TJ=TJmax.

8.3ms SINGLE HALF SINE-WAVE

(JEDEC Method)

CURRENT, AMPERES

AVERAGE FORWARD RECTIFIED

AMPERES

LEAD TEMPERATURE, °C

FIG. 3 - TYPICAL INSTANTANEOUS

FORWARD CHARACTERISTICS

TJ=25°C

PULSE WIDTH=300µs

1% DUTY CYCLE

AMPERES

PEAK FORWARD SURGE CURRENT,

NUMBER OF CYCLES AT 60 H

FIG. 4 - TYPICAL REVERSE LEAKAGE

CHARACTERISTICS

TJ=125°C

TJ=100°C

MICROAMPERES

Z

INSTANTANEOUS FORWARD CURRENT,

INSTANTANEOUS FORWARD VOLTAGE,

FIG. 5 - TYPICAL JUNCTION CAPACITANCE

JUNCTION CAPACITANCE, pF

REVERSE VOLTA GE, VOLTS

VOLTS

TJ=25°C

f=1.0 MH

Z

Vsig=50mVp-p

INSTANTANEOUS REVERSE LEAKAGE CURRENT,

TJ=25°C

PERCENT OF RATED PEAK REVERSE

VOLTAGE, %

Loading...

Loading...