General Machine Products Co., Inc.

Visit www.GMPtools.com for the Tools to help you

Apollo Cable Lasher

Parallel-pull capability

up to 4” bundle

J2 Cable Lasher

Time tested workhorse for

up to 3” bundle

Stainless Lashing Wire

Highest quality lashing wire

that’s guaranteed to work with

our lashers.

70336 B Overlash

Block

This block lets you over-lash

to cable bundles up to 2 in.

(50 mm) across ... and its

affordability lets you use

more blocks for smoother,

neater lashing on new or

rebuild construction.

87265 Clip-On

Block

This tempered

spring steel block

is used to support

cable up to

1” (2.54 cm) during cable pullout.

10701 Cable

Block with

Rubber Roller

This economical

block has a rubber

roller & is used for

new strand & over

lash work

10700 Cable

Block with

Aluminum Roller

This economical

block has a Aluminum roller & is used

for new strand & over

lash work

General Machine Products Co.

3111 Old Lincoln Highway

Trevose, PA 19053 USA

Tel: +1.215.357.5500

Fax: +1.215.357.6216

Email: info@GMPtools.com

Web: www.gmptools.com

“get the job done right”

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form whatsoever

without the written permission of General Machine Products Co., Inc.

Corner Block Instructions Manual P/N 29567 Rev 3 10/7/2013

General Machine Products Co., Inc.

USER MANUAL

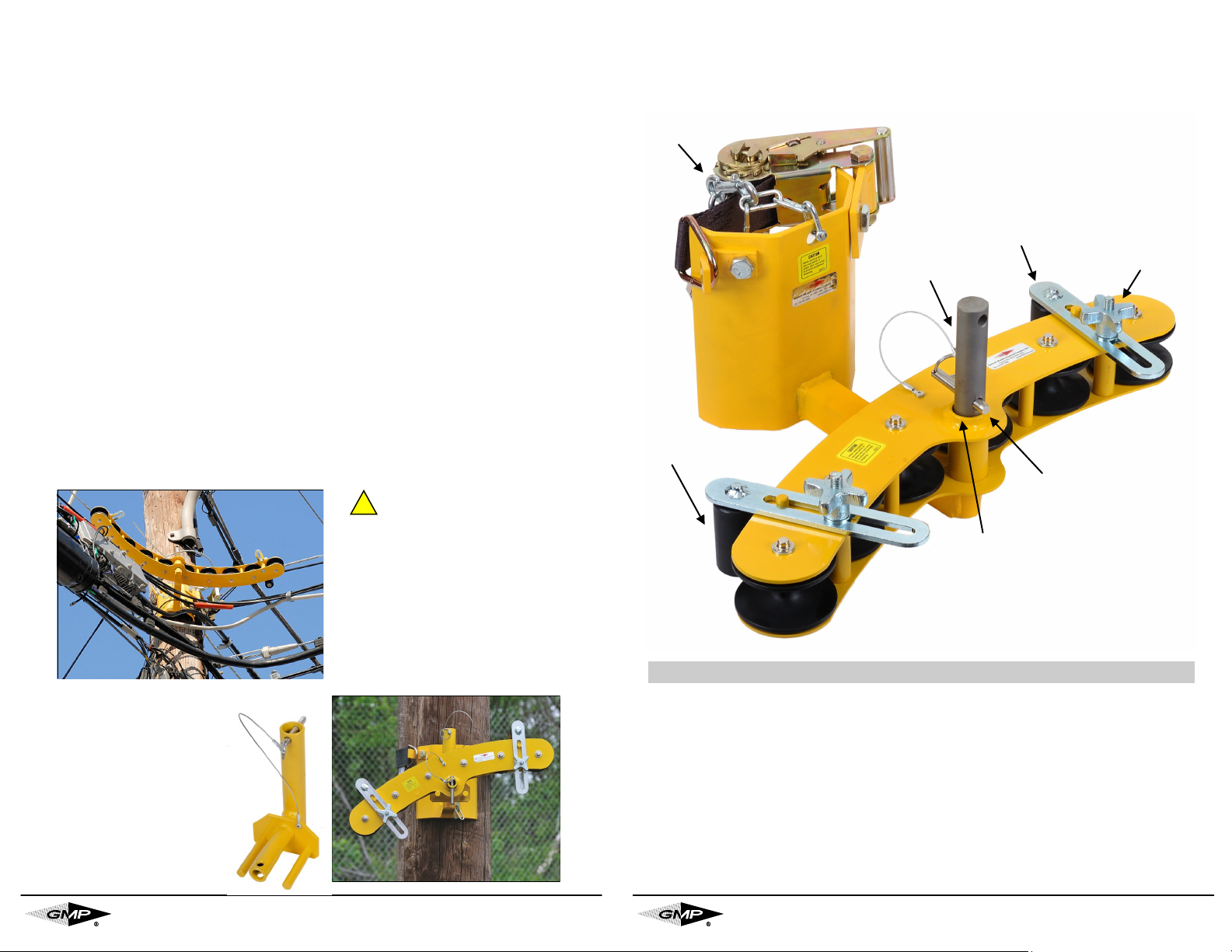

45 AND 90 DEGREE CORNER BLOCKS

General Machine Products Co., Inc. • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: info@gmptools.com

70439

45° Corner Block w/

High Strength Plastic

Rollers

70450

45° Corner Block

Aluminum Rollers

70438

90° Corner Block w/

High Strength Plastic

Rollers

70449

90° Corner Block

Aluminum Rollers

70454

Double 45° Corner

Block w/High Strength

Plastic Rollers

70455

Double 90° Corner

Block w/High Strength

Plastic Rollers

General Machine Products Co., Inc.

Typical installation

CORNER BLOCKS 45° & 90°

• Used to guide up to 1-3/8” diameter cable on inside or outside

corners.

• Offers a bending radius of 23” (584 mm).

• Mounts on Pole Bracket GMP # 70372.

INSTALLATION PROCEDURE

1. Install Pole Bracket GMP #70372 by ratcheting until a tight fit to the

pole. Attach the safety clip to the messenger strand after unit is attached to the pole.

2. Slide the Corner Block center tube over the axle of the Pole Bracket.

Insert the safety pin, attached to the top of the block by lanyard into

the axle’s hole closest to the block. The pin prevents Corner Block

from falling off the mount and allows the block to swivel with the cable.

3. Loosen both knobs at top of the block to loosen the cable retaining

rollers.

4. Set up the cable retaining rollers approximately ¼” above the cable to

retain cable on Corner Block’s rollers.

5. Reverse the installation procedure to remove the Corner Block.

WARNING: This equipment must only be used by

authorized personnel who

have been suitably trained and

competent to do so. These instructions are to be made available to operators of this equipment at all times. Failure to observe these safety instructions

could result in serious personal

injury and or property damage.

!

Optional Vertical Angle

Adapter GMP # 70440

(for use with single rollers only)

General Machine Products Co., Inc.

Retaining

Roller

Knob

Accessory Pole

Bracket

GMP # 70372

Safety

Pin

Tube

Opening

Safety

Clip

Pole

Bracket

Axle

Retaining

Roller

Specifications

Max Load Weight GMP #

90° Corner Block w/HS Plastic Rollers 1000 lbs. 13 lbs. 12 oz 70438

90° Corner Block w/Aluminum Rollers 1000 lbs. 15 lbs. 14 oz 70449

45°Corner Block w/HS Plastic Rollers 850 lbs. 8 lbs. 14 oz 70439

45°Corner Block w/Aluminum Rollers 850 lbs. 10 lbs. 1 oz 70450

90°Dble Corner Block w/HS Plastic Rollers 17 lbs. 9 oz 70455

45°Dble Corner Block w/HS Plastic Rollers 11 lbs. 5 oz 70454

Pole Mount Bracket * 12 lbs. 7 oz 70372

Vertical Angle Adapter * 5 lbs 70440

Loading...

Loading...