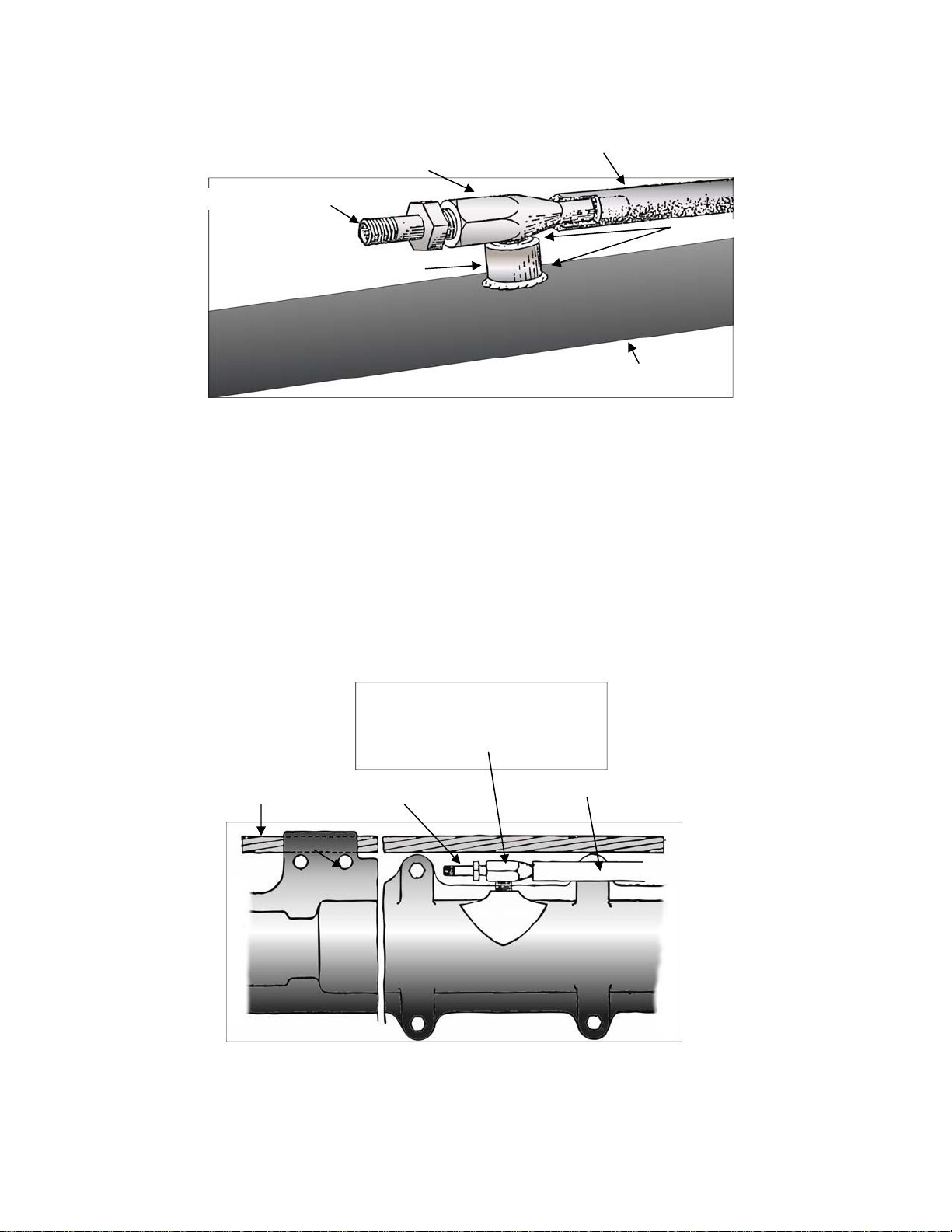

B Pressure Ell Typical Usage

B Pressure Ell (GMP 07713)

F Valve Stem (GMP 69146)

Flange (GMP 75493)

The B Pressure Ell may also be used on a splice case or "T" type cable

terminal. When used on a splice case or "T" type terminal approximately

3/8 inch of the pipe stem on the B Pressure Ell should be cut off. This is

necessary to allow the end of the pipe stem to clear the projections on the

splice case when it is being screwed into the flange on the case. A hack

saw may be used for cutting off the pipe stem, but care should be taken to

remove all metal deposits after sawing is completed. To install the B Pressure Ell in a splice case, clean the pipe stem of the ell and coat it with

stearine. Coat the threads of the ell with an approved pipe joint compound

and screw the Ell into the pressure testing flange on the splice case. Make

certain the lead pipe is clean and dry. Push the end of the lead pipe onto

the pipe stem of the B Pressure Ell and solder in place, using C Stearine

Core Solder. Insert the F Valve Stem after soldering of the lead pipe and

pipe stem. (See illustration below.)

Lead Pipe

Solder (GMP 72411)

Cable

B Pressure Ell—the pipe stem of

the B-Pressure Ell should not exceed 3/8 inch in length when used

in a splice case

Strand

Where required, install an F Valve Stem into the female threaded hole of

the B Pressure EIl. Otherwise, close the Ell with a C Pressure Flange Plug.

In either event coat the threads with pipe joint compound before assembly.

F Valve Stem

Lead Pipe

B Pressure Ell Flange 12/3/2009 AK

Loading...

Loading...