Assembly Procedure for the CD28/CD22 Detented Clutch

1. Rotate winch drum shaft so that the hole in the spline is at 12 and 6 o’clock.

2. Place large spring on shaft and followed by clutch assembly (clutch plate and

sleeve) with the holes in its spline also aligned at 12 and 6 o’clock.

3. Push clutch against spring as close to drum as possible. Rotate drum so that

the drive lugs are in line with clutch’s lugs to prevent the spring from pushing

the clutch back out. Place wedge between any pair of lugs to place more pressure on spring and move plate as close as possible to

the drum.

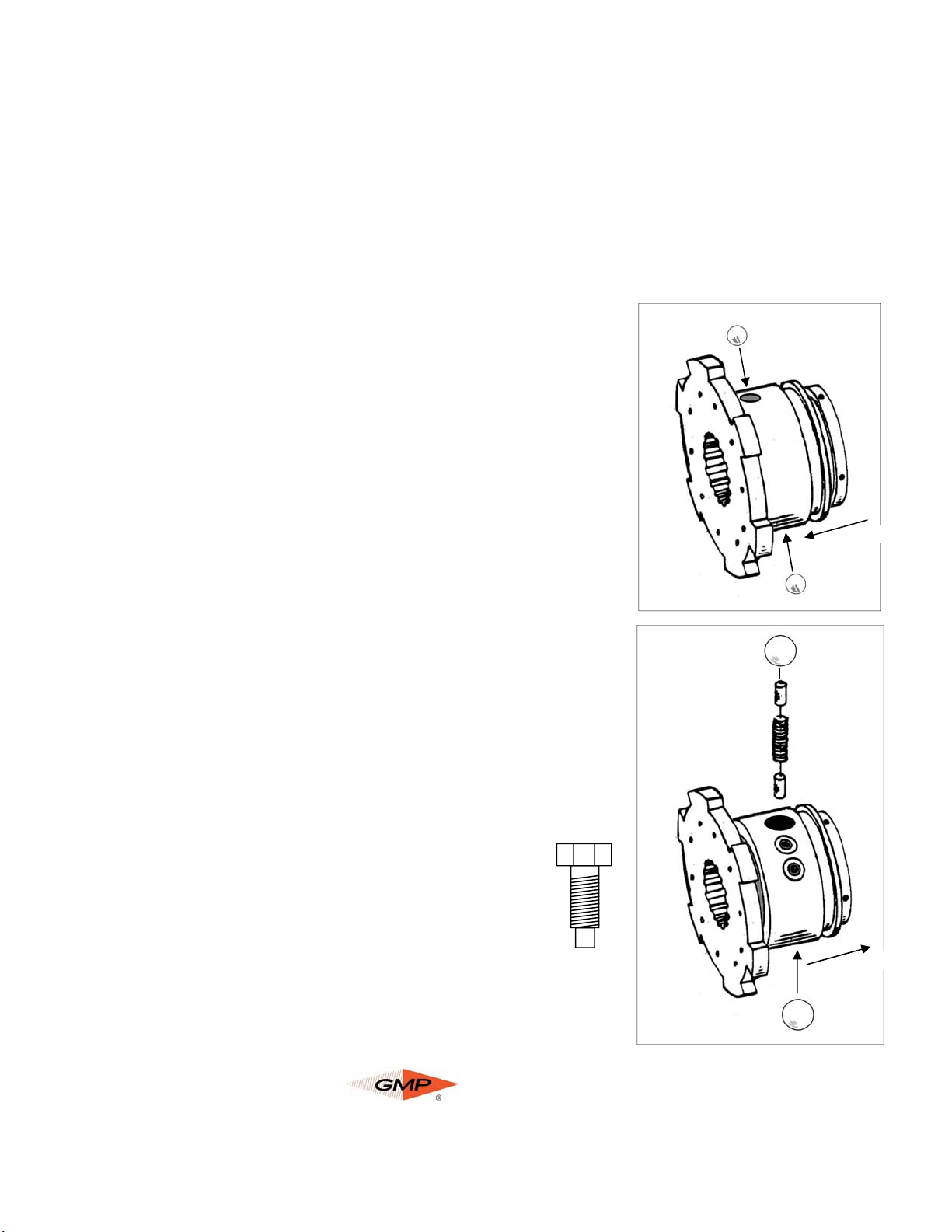

4. Refer to illustration 1. Rotate the sleeve and slide towards drum so that the 17/32 hole is on the bottom (6

o’clock). Push one 17/32 ball up in the hole until

seated in clutch plate. Rotate sleeve around to top (12

o’clock). Place second 17/32 ball in hole and let it

drop in sleeve.

5. Refer to illustration 2. Slide the sleeve away from the

o

f

drum. Rotate sleeve so that the large hole is at the

bottom 6 o’clock position. Push one 11/16 ball up in

hole until seated in clutch plate.. Rotate the sleeve so

that the large hole is now on the top at 12 o’clock.

6. Looking down through the hole, place one detent with

rounded end down through the hole in the shaft.

7. Next place detent spring into the hole.

8. Place second detent over spring with rounded end up.

9. Push second 11/16 ball over detent and rotate sleeve

so that the ball puts pressure on the spring.

10.Rotate sleeve so that either one of the 1/2 x 20

threaded holes are aligned with the slot in the clutch

plate.

11.Insert the sleeve locking screw with lock

washer. Tighten making sure that the unthreaded tip aligns with the slot in the clutch

plate.

12.Plug second hole with the 1/2-20x5/8

Locking Screw

screw and star washer.

13.Screw in pipe plug flush with top of sleeve.

Illustration 1

Illustration 2

e

v

e

e

l

S

c

a

b

e

v

e

e

l

S

d

r

a

w

r

s

d

r

a

w

k

General Machine Products Co., Inc.

3111 Old Lincoln Highway

Trevose, PA 19053-4996 USA

TEL: 215-357-5500

FAX: 215-357-6216

E-MAIL: info@GMPtools.com

WEB: http://www.GMPtools.com

9/4/2007 AK

Loading...

Loading...