ADAMS

MODEL CD-22

MODEL CD-28

CONTINUOUS DUTY WINCH

Installation, Operation and

Maintenance Manual

General Machine Products Co., Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA

Tel: +1.215.357.5500 Fax: +1.215.357.6216 Email: info@GMPtools.com

TABLE OF CONTENTS

GENERAL ………………………………………………………………….. Page 2

MAJOR COMPONENTS …………………………………………………... Page 3

ACCESSORIES …………………………………………………………….. Page 3

USE …………………………………………………………………………. Page 3

HYDRAULIC REQUIREMENT …………………………………………... Page 3

INSTALLATION …………………………………………………………... Page 3

CONTROLS ………………………………………………………………... Page 4

WINCH CLUTCH AND DRAG BRAKE INFORMATION .……………... Page 4

CALIPER BRAKE ASSEMBLY INSTALLATION ………………………. Page 6

AUTOMATIC BRAKE …………………………………………………….. Page 6

PREPARING FOR OPERATION………………………………………….. Page 7

OPERATING THE WINCH ………………………………………..………. Page 7

MAINTENANCE …………………………………………………………... Page 8

LUBRICATION ………………………………………………..…………... Page 8

PRECAUTIONS ……………………………………………………………. Page 9

WIRE ROPE INFORMATION …………………………………………….. Page 10

WINCH IDENTIFICATION ……………………………………………….. Page 11

ACCESSORIES …………………………………………………………….. Page 11

BASIC DETAILS CD-22 CD-28

Maximum Rated Pull-Bare Drum 20,000 lbs. 20,000 lbs.

Maximum Rated Pull-Full Drum 9,000 lbs. 9,000 lbs.

Drum Width 22.5” 28”

Net Weight 925 lbs. 935 lbs.

Cube Dimension 24” High X 24” Wide X 60” long 65” long

BASIC DETAILS …………………………………………………………... Page 2

GENERAL

The Model CD-22 and CD-28 winches are derived from Bell System Spec. 8003LlB and 8003-L2B. Differing only in the drum width, they are suitable for applications involving stationary or mobile mounting. Driven by a series of highly

efficient helical gears, these units will not generate excessive heat under long,

maximum pull conditions.

2

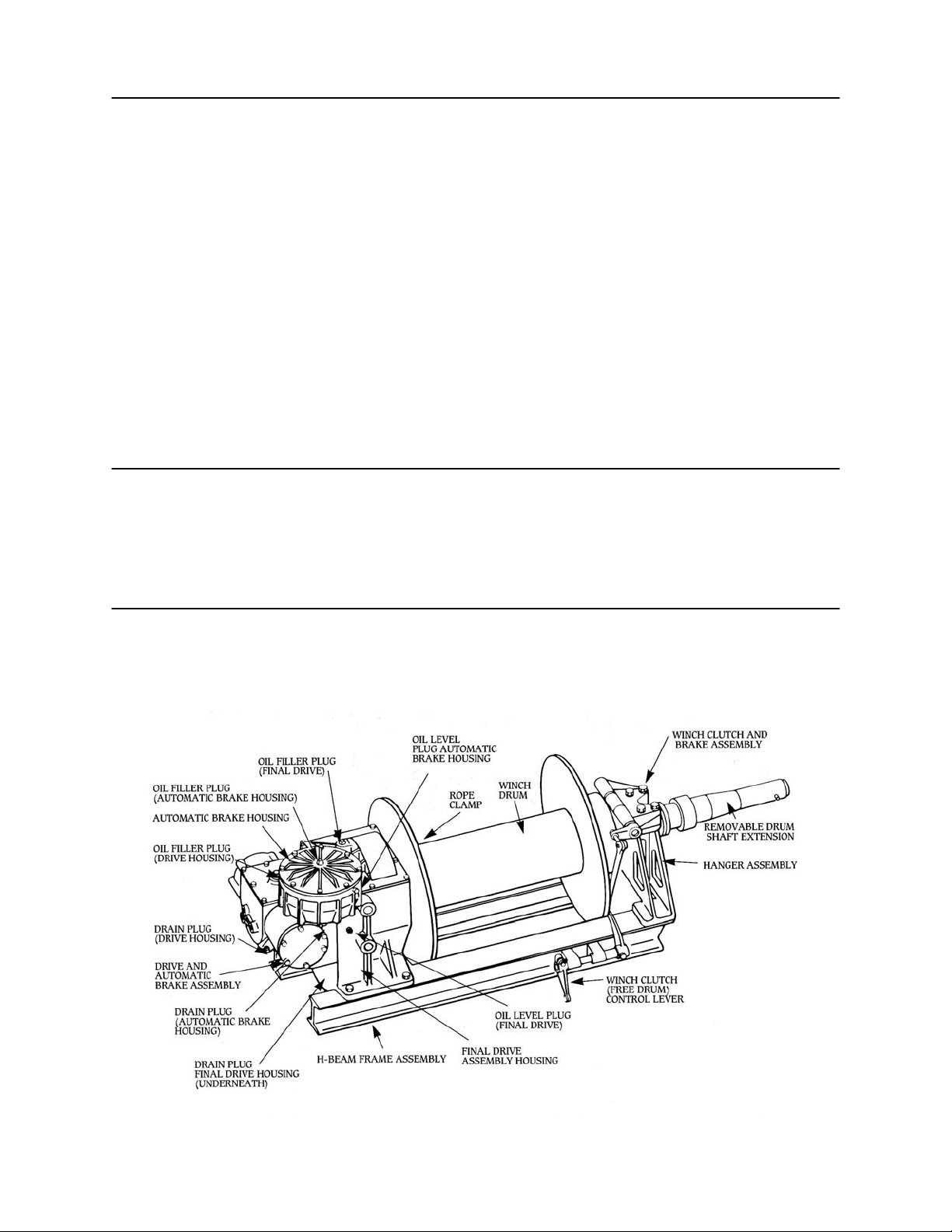

MAJOR COMPONENTS

ACCESSORIES

• Winch Drive Assembly

• Final Drive Assembly

• Safety Brake Assembly

• Drum Assembly

• Clutch Assembly

• Drag Brake Assembly

• Hanger

• Frame

Levelwind Model CH-22 or CH-28, Overw i nd o r Un der wind

(Derived from Bell System Spec. 8414).

Three speed transmission-hydromechanical Model 240-584

(Derived from Bell System Spec. 8111).

Three speed transmission-hydraulic Model 230-1600

Drum shaft extension

USE

HYDRAULIC

REQUIRMENT

INSTALLATION

The Models CD-22 and CD-28 can be driven mechanically, hydromechanically

or hydraulically. Both winches have been primarily designed for placing underground communication cable or electrical conductor. However, they can be used

for most applications where a long, continuous pull is required.

Mechanically - for mobile mounting, using the truck engine as the prime source of

power, through a split shaft or side mount power take-off and silent chain drive to

the winch input shaft.

Hydromechanically - for mobile mounting, using the truck engine as the prime

source of power, through a split shaft or side mount power take-off coupled to a

hydraulic pump, driving a hydraulic motor integrally mounted to the mechanically

shifted three speed transmission and silent chain drive to the winch input shaft.

Hydraulically - for mobile mounting, using the truck engine as the prime source of

power, through a split shaft or side mount power take-off, coupled to a hydraulic ;

pump, driving a three speed hydraulic motor and silent chain drive to the winch

input shaft.

Stationary mounted units can also be driven mechanically, hydromechanically or

hydraulically. The prime source of power can vary.

Hydromechanical - to obtain the maximum rated pull and line speed, using the

three speed transmission model 240-584, the system should have an operating pressure of 2,000 psi and a flow of 55 GPM. The pressure relief should be set at 2,200

psi.

Hydraulic - to obtain the maximum rated pull and line speed, using the three speed

transmission Model 230-1600, the system should have an operating pressure of

2,000 psi and a flow of 30 GPM. The pressure relief should be set at 2,100 psi.

Suction line hoses are 1" diameter minimum; return line hoses are IV" diameter.

The recommended hydraulic oil reservoir capacity for the Model 240-584 three

speed transmission is eighty gallons; for the Model 230-1600, sixty gallons.

The suction line is fitted with a 100 mesh strainer; the return line is fitted with a 10

micron by-pass type filter.

For additional details and information concerning the Model 240-584 three speed

transmission, see drawings 15669-1 and 15669-2; for Model 230-1600, see drawings 230-1600-1 and 230-1600-2.

For mobile applications, the winch is normally mounted behind the chassis cab in

the forward section of the body load area, directly to the chassis frame or subframe. Two standard cast steel mounting brackets are furnished with each winch.

3

CONTROLS

Sufficient clearance should be allowed between the front body panel or other restrictive members and the winch to permit normal maintenance.

For standard installations, place the winch assembly on the chassis frame so that the

levelwind is facing rearward and the drum shaft is projecting toward the right or

curb side.

The normal direction of drum rotation for pulling in is clockwise when viewed

from the right side of the vehicle. The wire rope is wound onto the drum from the

top. Deviation from this standard mounting procedure could cause severe heat and

operational difficulties.

With the two mounting brackets on the winch frame, locate the winch drum centerline on the chassis frame center-line. Slide the mounting brackets tight to the chassis frame. Using the eight %" diameter pre-drilled holes in each bracket as a guide,

finish drill all holes in both brackets for a tight fit, using the %" -18 x 2" long class

five hardened steel bolt furnished in the winch mounting kit.

Weld both sides of the mounting bracket to both winch frame rails. Do not weld

the mounting brackets to the chassis frame.

All of the mounting hardware and, if ordered, the drum shaft extension, are

shipped in a parts box attached to the winch or shipping crate.

To protect the entire winch assembly against rust, various parts are sprayed with a

rust inhibitor and both drive housings are filled with oil when shipped from the

factory. If the winch will be placed in outside stock for an indefinite period, care

should be taken to prevent oil contamination or rust due to condensation.

When the winch has been mounted, consideration must be given to the control of:

Drum direction of rotation

Drum speed

Winch clutch and drag brake (disc type)

Drag brake (band or ca liper type)

Because of the wide variation in the type of controls available, it is the responsibility of the dealer to furnish and install those required in the bid specifications,

whether they are conventional or automatic. This is particularly true for drum

rotation direction and speed.

On all units there is a drag brake assembly. The brake is either a disk, band or caliper type, depending on the date of manufacture. Disk or band type brakes are controlled by a push-pull handle at the right rear of the vehicle. Caliper type brakes are

controlled by a hydraulic actuator at the left rear. For correct brake identification,

check the winch serial number, the date of manufacture and additional information

found on pages 4, 5, and 6 of this booklet.

WINCH CLUTCH

AND DRAG BRAKE

GNERERAL INFORMATION

SHIFTING OF THE CLUTCH SHOULD ONLY BE DONE WHEN THE DRUM

AND DRAG BRAKE ROTATION HAS STOPPED.

When shifting from the disengaged to the engaged position, the operator should

make certain that full engagement is accomplished. Normally, proper engagement

is identified by a characteristic clang of the clutch plate and the drum.

When the winch clutch is disengaged, the drum will rotate freely on the drum

shaft. It should also be noted that power can still be transmitted through the drumshaft to the drum shaft extension to drive a capstan or reel.

Under present mechanized, high winch line speed conditions, it is extremely important to operate the disc, band or caliper type drag brake properly, maintaining sufficient tension on the wire rope. This will enable the levelwind assembly to operate

properly, minimize over-spinning of the drum and help provide suitable coils and

lays of wire rope.

THE DRAG BRAKE IS USED TO CONTRO L THE DRUM SPEED ONLY. IT IS

NEVER TO BE USED TO HOLD THE LOAD.

4

DISC TYPE DRAG

BRAKE

On units manufactured before February 15, 1980, there are th ree control

positions for the winch clutch and disc type drag brake. Using the mechanical pushpull shift, with the control lever installed at the rear of the vehicle, operation is as

follows:

Control handle all the way in - clutch engaged for pulling.

Control handle partially out - clutch disengaged for free spool operation.

Control handle all the way out and holding - applies drag brake to drum.

The winch clutch consists of a clutch plate, brake lining, detent sleeve and shifter

fork. Teeth in the clutch plate match similar teeth in the drum flange. The clutch

plate is faced with a brake lining. The detent sleeve slides on the hub of the clutch

plate to release the detent, locking the clutch assembly in the clutch engaged position. The winch is now ready to pull.

Continued movement of the control lever to the rear moves the clutch assembly

toward the drum, disengaging the meshed clutch teeth. The drum is now disengaged and can rotate freely. The clutch will remain disengaged until the con trol

lever is again moved. The winch is now ready for free spool operation.

Application of the disc type drag brake is accomplished by moving the clutch plate

toward the drum to the limit of its travel. This action is normally achieved by pulling the control lever rearward, forcing the clutch plate brake lining into the machined surface of the drum flange.

Pressure between the brake lining and the drum must be maintained to ke ep the

brake on. Or, the amount of braking is in direct proportion to the amount of pull

exerted.

Release of the control handle allows a coiled spring to push the brake plate away

from the drum into the pull position.

BAND TYPE DRAG

BRAKE

CALIPER TYPE

DRAG BRAKE

Units manufactured between February 15, 1980 and July 31, 1991 incorporate a

band type drag brake.

This brake, mounted on the outside hub of the right hand drum flange, is completely separate from the clutch assembly. Using the mechanical push-pull method

of control, the handle is located at the rear to the right of the clutch control. Pulling

the control handle will slow down or stop the drum rotation.

When designing the drag brake control handle, be sure to specify a straight pushpull type and not an overcenter type. This will prevent the operator from setting the

brake and using it to hold the load.

Winch assemblies manufactured after August 1, 1991 will include the caliper

brake. The assembly shown on parts drawing 230-1970 includes:

1-Brake Assembly, Caliper P/N 17134

1-Bracket, Brake Mounting 15277

1-Actuator Assembly 17135

1-Reservoir 17136

1-Flexible Hose 17137

1-Disc, Brake 24117

The purpose of the caliper brake is to control the speed of the winch drum when in

the free spool mode. Movement of the actuator lever will force the brake pads together, reducing the drum speed. Continued movement of the control lever will

eventually force drum rotation to stop.

5

CALIPER BRAKE

ASSEMBLY

INSTALLATION

The primary brake assembly P/N 17134 will be mounted at the factory on the left

side, top surface of the forward winch frame rail using mounting bracket -P/N

15277 with four bolts, nuts and lockwashers.

The brake disc P/N 24117 will be mounted at the factory on the outboard surface of

the left side drum flange using eight machine screws.

The remote actuator P/N 17135, reservoir P/N 17136 and flexible hose section P/N

17137 are shipped loose with other winch mounting hardware. These components

are initially installed in the field by the dealer.

The remote actuator is normally mounted at the rear of the body, under the tailshelf. Find a location that is safe and convenient to the operator and within sight of

the winch operation. Alternate mounting would be in accordance with end user

specifications.

The reservoir is mounted above and as close as possible to the inlet fitting of the

actuator.

The flexible hose section is connected to the outlet fitting of the actuator.

At the time of installation and prior to operation, refer to information received with

each brake component and hydraulic schematic drawing 230-1700.

The closed circuit hydraulic system is shipped void of any oil. Prior to operation,

fill the system with brake fluid; bleed and add fluid as required.

The caliper brake pads P/N 25237 are adjusted at the factory. Subsequent adjustment will be required to compensate for normal wear. See the Model CD Winch

Parts Book for component identification.

AUTOMATIC BRAKE

The automatic brake, located on the left side above the winch, is an automatic device designed to hold a maximum load of five thousand pounds.

The brake mechanism consists of a double threaded worm and worm wheel, an

overrunning clutch and a multiple disc type friction brake. The latter operates in a

bath of oil to aid in the dissipation of heat.

When the winch is operated in the pull-in direction, the brake is inoperative since

the input shaft runs freely in the overrunning clutch. When the power is cut off, the

load attempts to drive the drum in the opposite direction. This causes the sprags in

the overrunning clutch to lock, forcing the worm wheel to drive the worm. The

multiple disc brake on the worm shaft supplements the braking action. The pressure

on the brake plate determines the load holding capabilities.

Removal of the automatic brake cover will locate four studs, springs, nuts and

washers. The amount of compression of the four springs is in direct proportion to

the amount of braking effort that will be achieved. Torque the four nuts until the

winch will support a maximum braking load of five thousand pounds or less to satisfy your particular requirement.

When making a brake adjustment, the springs must be compressed equally or the

resultant braking action will be erratic. To obtain an initial brake setting with optimum holding action, it is recommended that the four nuts be rotated until contact is

made with the washers and springs. Then rotate the four nuts equally an additional

one and one half turns. Check for the maximum braking action of five thousand

pounds or less for your particular requirement.

Braking action will be increased by rotating the nuts in a clockwise direction. Conversely, braking action is decreased by rotating the nuts counter-clockwise.

6

IMPORTANT NOTE: WHEN THE WIRE ROPE IS BEING PAYED-OUT UNDER POWER, THE WINCH IS BEING DRIVEN AGAINST THE BRAKE.

CONSEQUENTLY, EXCESSIVE HEAT WILL DEVELOP IN THE AUTOMATIC BRAKE HOUSING, POSSIBLY CAUSING THE O IL TO BOIL OVER.

If it is necessary to pay the wire rope out under power, do not operate in this manner for more than one hundred feet. Drive the winch at slow speed only.

To pay-out wire rope over one hundred feet in length, the winch drum should be

placed in the free spool position. Care should be taken to operate the drag brake

properly to prevent wire rope entanglement.

PREPARING FOR

OPERATION

OPERATION THE

WINCH

Before placing the winch in service the following checks should be made:

Make certain that the winch assembly is properly secured to the chassis frame.

The operator should have a complete understanding of all functions and the loca-

tion and operation of all controls.

The wire rope should be spooled on the drum with tight, even coils and lays.

It is not necessary to have the dram filled with wire rope. Additional pulling capa-

bility can be obtained by only installing a slight excess of the maximum length required for the job.

Check the hydraulic system for the correct pressure and flow.

Check the hydraulic system to make certain that the reservoir is filled to the correct

level with the proper grade of oil.

Make certain that the reservoir shut-off valve is open.

Check all winch and winch accessory gear housings for the correct oil level and

grade (see lubrication section - page 8).

Engage the hydraulic system and allow the oil to circulate and warm up for a few

minutes before operating the winch. This is particularly important during extremely

cold weather.

Check the body load area in a triangular section between the tail shelf sheave and

both drum flanges for obstructions that will restrict the travel of the wire rope.

Start the truck engine and engage the power take-off.

Check the body load area to make certain there are no tools or equipment to restrict

wire rope travel or level wind movement.

Check the winch dram for extreme wire rope entanglement or erratic build-up in

any location.

With rotation stopped, place the winch clutch control lever in the clutch engaged or

pull-in position.

Operate the directional control valve for the desired direction of drum rotation. ;

Pull the load steadily and adjust the truck engine speed to satisfy conditions.

To stop the winch, release the directional control lever; return the engine to idle.

When free spool is required, stop the drum rotation and pull the clutch control lever

out.

7

To control the drum speed in free spool:

For winches with a disc type drag brake, pull the single clutch control lever all the

way out and hold according to the amount of braking required.

For winches with a band or caliper type drag brake, actuate the separate control

lever and hold according to the amount of braking required.

Shifting - when shifting the clutch, the long practiced standard method of using

mechanical controls actuated manually, allows the operator to obtain a combined

feel for rotational speed and thrust. This procedure avoids damage caused by the

unnecessary clashing of clutch components and enhances greater winch life expectancy.

Conversely, there are many shifting requirements that are satisfied through the use

of automatic controls such as hydraulic, pneumatic or electric. For these applications, it is important to keep in mind that when actuating this type of control, a

complete action takes place and the ability to feel is lost. Unless properly designed

and carefully operated, the sudden thrust attempt to engage the clutch when not

necessarily in the correct position could prove to be detrimental to component life.

When finished with the winch, pass the wire rope through the tail shelf sheave and

hook into a fixed section of the chassis frame. A slight tension can thus be maintained in the wire rope, preventing entanglement on th e drum.

MAINTENANCE

LUBRICATION

Inspection of the winch and related components should be a continuing procedure.

The operator should be constantly alert to detect unusual noises, excessive oil leakage and overheating. He should report immediately any changes in the normal characteristics of the winch, winch accessory or the hydraulic system.

Oil levels, oil cups, grease fittings and chain adjustments should be checked after

each seventy-five hours of operation.

If the winch has not been used for an extended period of time, the interior should be

inspected for water deposits and rust due to the elements or condensation. Particular attention should be given to any damaged bearings, seals or gaskets. The oil

should be checked for contamination, abrasive foreign particles and lubrication

qualities. As required, oil should be added or completely drained and filled.

The wire rope should be inspected visually for kinks, bends, cuts or broken strands

while operating.

Depending on the total length of the wire rope vs. the length most often used, it is

possible that the top lays will show the most wear. To obtain additional life, subject

to the proper conditions, the rope can be rotated end to end.

The hydraulic system should be checked periodically for:

Overheating

Abnormal noise

Maintain a clean sufficient quantity of hydraulic oil of the proper grade.

Keeping all connections sufficiently tight to prevent oil leakage and air from entering the system.

Change the oil filter periodically.

The winch has two reservoirs that must be checked and maintained.

Automatic Brake Housing

To check for the proper oil level, remove the oil level plug in the side of the hous-

ing. The lubricant should be maintained to the height of the oil level opening.

To add oil, remove the oil level plug in the side of the housing. Remove the oil

filler plug in the housing cover. Add type "A" automatic transmission fluid as required to the height of the oil level opening.

8

The oil level plug should always be removed before adding oil to avoid over-filling.

The automatic brake housing should be checked after se ven ty -fi ve ho u rs o f ope ra-

tion. It should be completely drained and filled with new transmission oil at least

once each year.

Drive and Final Drive Housing

The oil level in these two housings will be the same because of the flow-through

lubrication design.

To check for the proper oil level, remove the oil level plug on the front side of the

final drive housing. The lubricant should be maintained to the he ight of the oil level

opening. To add oil, remove the oil level plug on the front side of the final drive

housing. Remove the filler plug in the drive housing cover. Add 80W140 oil as

required to the height of the oil level opening.

Always remove the oil level plug before adding oil to prevent overfilling.

Make certain the oil has had sufficient time to equalize between the two housings.

The drive and final drive oil level should be checked every seventy-five hours of

operation. Both should be completely drained and filled with new oil at least once

each year.

Miscellaneous Lubrication

Grease fittings - there are five grease fittings that should be checked every seventyfive hours of operation, i.e., two on the clutch shaft, one on the h ang er bearing and

two on the clutch control.

Grease - grease the drum clutch splines every seventy -fi ve hours of operation.

Engine Oil - apply engine oil to all linkage pivot points every seventy-five hours of

operation.

Apply engine oil to all chain drives every seventy-five hours of operation. The lubricant should be applied on the inside surface of the roller or silent chain by means

of a spray or brush.

Lubricating the wire rope periodically will extend life expectancy. Consult your

local wire rope representative for proper instructions.

PRECAUTIONS

!

THE WINCH WAS NOT DESIGNED FOR, NOR INTENDED TO BE USED

FOR THE MOVEMENT OF PEOPLE.

It is imperative, and the responsibility of the operating company, to properly instruct the winch operator and the crew relative to the safe working capabilities and

operational limitations of the winch, its accessories and especially the winch controls. The operator should never leave his position at the controls while the winch

line is under load or the winch power take off is engaged.

Maintain complete coordination with other members of the crew, giving clear instruction by hand signal or radio communication.

Stand clear of loads suspended by the winch line. Do not stand inside of angles

formed by the winch line. As much as possible do not stand where there is the ::

danger of being struck by the wire rope if it should fail or snag. Never place hands

on a moving winch line. Always stand clear of moving winch line. When working

around the winch, wire rope and the tail sheave, do not wear loose fitting clothing

to prevent entanglement in moving parts and possible serious injury.

Operate the winch as smoothly as possible. Sudden jerking pulls can place extreme

loads on equipment causing damage or injury.

9

WIRE ROPE

GENERAL INFORMATION

OVERWINDING

UNDERWINDING

INSTALLATION

Make certain that the wire rope is properly attached to the drum and that no less

than one half of the first lay remains on the drum at all times. Make certain that the

eye at the end of the winch line is properly spliced or swaged. Wire rope (winch

line) may be old, damaged or weakened by such defects as kinks, cuts, extreme

bends or loops. Such conditions are potentially dangerous and detrimental to safe

operation of the winch. The wire rope must be routinely inspected at regular intervals and replaced when worn.

Load demands on the winch, wire rope or extension shaft should not exceed their

rated maximum pulling capacity.

Make certain that the winch clutch is positively engaged before starting the pull.

Do not operate the winch at speeds faster than necessary.

When pulling in, do not allow the wire rope to build up in one location on the

drum. This can cause wire rope "roll-over" and possible erratic, damaging pulls.

It is important to select the correct winch and wire rope for a particular application.

Wire rope is specified in terms of diameter, length, number of strands, number of

wires per strand, type of center and type of lay. Refer to table on back cover for

winch drum capacities.

There is a definite advantage in applying wire rope of the proper direction of lay

when spooling onto a smooth surface winch drum.

Wire rope with an improper lay will permit the coils to spread apart each time the

load is removed. Using wire rope with the proper lay will tend to keep the coils

together when tension is removed. The correct lay will develop tight coils and even

layers.

Overwinding is when the winch drum is rotating in the clockwise direction (viewing from the right side) and the wire rope is spooled onto the winch drum at the top.

This is the standard method for the CD-22 or CD-28 winches.

It should be noted that on these winches the rope clamp is located on the left side of

the drum. Or, the rope is attached at the left and spools to the right. This condition

requires the wire rope to have a left lay.

Underwinding is when the winch drum rotates in a counterclockwise direction

(viewing from the right side) and the wire rope is spooled onto the winch drum at

the bottom. While this is a standard requirement, "underwind application" should

be specified on the initial order. Caution should be taken to check the assembly of

the one-way clutch relative to the drum direction of rotation.

For underwind applications, the wire rope must be guided and maintained as it is

routed forward under the body deck to the winch drum. This can be done by using a

trough or tube with sufficient width at the front section to allow the wire rope to

freely traverse the width of the drum. As the wire rope travels to the drum, and depending on the angle of incline combined with the body crossmember configuration, a floating sheave or roller may be required.

It is important to install the wire rope onto the winch drum with care. Kinking of

the rope, caused by the rope taking a spiral shape as a result of an unnatural twist,

should be avoided.

When removing wire rope from the reel and spoolin g o nt o the wi nch drum, the reel

must be supported on a horizontal axis and free to rotate. Spool the rope onto the

drum with the natural bend in the same direction as it comes off the reel.

If wire rope is received in a coil, it should be unwound with the coil in the vertical

plane. Again, spool the rope onto the winch drum with the natural bend in the same

direction as it was on the coil.

10

LUBRICATION

Reverse bending of the wire rope should always be avoided or kept to a minimum.

Wire rope should always be under tension whe n sp ool ing onto the winch drum.

When the winch drum is in free spool and the drum shaft extensio n only is being

used with a capstan or reel, the wire rope pulling end should be affixed to the drum.

This will prevent the rope from unwinding or clock-springing. Drum rotation can

be controlled with the drag brake applied.

When the winch is not in operation, attach the winch line quick hook to a so lid

member on the tail shelf. Slowly take up the slack. This will best maintain the rope

under a slight amount of tension until required again.

Wire rope is considered to be a machine, having many moving parts. Each time

the rope bends or flexes, the various wires and strands slide over each other. Lubrication is required to facilitate this movement.

The type of lubricant, method of applying and frequency of application is dependent on each particular circumstance. For specific lubrication details contact the

wire rope manufacturer.

WINCH IDENTIFICATION

ACCESSORIES

When contacting your local dealer or the factory, proper assistance can be offered if

the model and serial number of the winch in question is specified.

On all Adams winches this information is stamped on a nameplate affixed in the

top center of the winch frame rail nearest the rear of the vehicle.

Drum shaft extension - this accessory, having a 27A" diameter, is mounted on the

winch drum shaft by means of a male-female connection, spindle and roll pin assembly.

Designed with the conventional bayonet type of connection, it is most suitable for

driving a reel or capstan. Mount the product hub on the shaft extension, push and

turn to left.

Mounted on and projecting only to the right side of the winch, the shaft length is

determined by the width of the body.

The maximum allowable pull of the drum shaft extension is 1,500 pounds using a

standard 7" diameter capstan (GMP 10727). Allowable pulls will be less when using a larger diameter accessory and/or using a longer drum shaft extension. See

details below.

MAXIMUM ALLOWABLE PULLS BASED ON A

7" DIAMETER CAPSTAN AND BODY WIDTHS:

Body Width Allowable Pull

92" l,500lbs.

94" l,4251bs.

96" l,350lbs.

98" l,275lbs.

100" l,200lbs

For additional versatility, the drum shaft extension can be used as a means to drive

various types of equipment to place fiber optic cable. A wide range of components

are available; see the applicable brochure.

11

SPECIFICATIONS

Line pull & line speed capacities

Hydraulic Tri-Drive Three-Speed

Transmission (Model 230-1600)

Winch Input

Gear Ratio

19.9:1 High 10,000 4,500 82 177

19.9:1 Intermediate 16,100 7500 49 106

19.9:1 Low 12,000 27 58

• Rated working capacity: 20,000 lbs. bare drum pull

• Hydraulic flow: 30 GPM maximum

• Hydraulic system pressure: 2,000 psi operating

2,100 psi maximum bypass relief

1

If actual operating pressure exceeds recommended maximum, in low control valve position, the winch will generate a pulling force beyond its rated

working capacity. Such a condition can damage the winch, cause wire rope

failure or result in injury to persons or property. It is most important that the

maximum operating pressure be restricted to permit a specifically limited

winch line pull.

Control Valve

Position

Maximum Rated Line

Pull (lbs.)

Bare drum Full Drum Bare Drum Full Drum

1

Winch Line Speed

(ft./min.)

30 GPM

Hydromechanical Three-Speed Transmission (Model 240-584)

Winch

Gear

Ratio

19.9:1 20,000 9,000 Input RPM

• Rated working capacity: 20,000 lbs. bare drum pull

• Winch input torque: 4,750 in./lbs. max. at 600 RPM

• Winch input speed: 1,600 RPM max.

• IMPORTANT NOTE: Winch line speed based on 9/16"

dia. wire rope for all drive types.

Maximum Rated

Line pull (Ibs.)

Bare drum Full drum Bare drum Full drum

Winch Line Speed*

(Ft./min.)

Input RPM

9

4.1

Winch Input

Gear Ratio

19.9:1 High 7,400 3,400 107 229 149 321 213 459

19.9:1 Intermediate 18,700 8,700 42 91 59 127 85 182

19.9:1

• Rated working capacity: 20,000 Ibs. bare drum pull • Hydraulic system flow: 55 GPM maximum

• Hydraulic system pressure: 2,000 psi operating 2,200 psi maximum bypass relief

In low gear, this winch can generate a pulling force beyond the maximum rated capacity of the winch and possibly the wire rope. Such a condi-

2

tion can damage the winch, cause wire rope failure or result in injury to persons or property. Use low gear with extreme caution for slow speed

operation only. It is most important that the maximum operating pressure be restricted to permit a specifically limited winch line pull.

Gear Position Maximum Rated Line Pull

Bare drum Full drum Bare drum Full drum Bare drum Full drum Bare drum Full dram

Low

(Ibs.)

2

30 GPM 40 GPM

20,000

18 39 25 54 36 77

Winch Line Speed* (ft./min.)

55 GPM

Wire rope drum storage capacities (by rope size)

Winch model 5/16"Dia. 3/8"Dia. 7/16" Dia. 1/2" Dia. 9/16" Dia.

CD-22 4,600 2,600 2,100 1,600 1,300

CD-28 5,800 3,600 2,700 2,000 1,700

• Wire rope lengths are based on the winch being equipped with a Model CH Level-Wind.

• Selection of the proper wire rope diameter, with a maximum breaking strength and allowable pull

appropriate for use on winches such as the CD-22 and CD-28, is the responsibility of the user.

Basic winch dimensions (in inches)

General Machine Products Co., Inc.

3111 Old Lincoln Hwy.

Trevose, PA 19053

Tel: 215-357-5500

Fax: 215-357-6216

Winch

Model A B C D E F G H J K L

CD-22 22.5 11.25 8 19 46.5 36.37 26.37 14.37 25.75 4 24 925

CD-28 28 14 8 19 52 35.25 29.37 14.37 25.75 4 24 935

Wt.

(lbs.)

Email: info@gmptools.com

GMP reserves the right, without

notice, to make changes in

equipment design or components as progress in engineering

or manufacturing methods may

warrant.

12

Loading...

Loading...