POWERED DUCT ROD PUSHER

OPERATION & MAINTENANCE

89004 – USA

POWERED DUCT ROD PUSHER

Copyright 2008 by General Machine Products Co., Inc

QC Final Inspection by:_________________________ Date:__________________

Unit Serial Number:__________________

Build Date:__________________

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form

whatsoever without the written permission of

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: info@gmptools.com

General Machine Products Co., Inc.

Page 1 of 40

General Machine Products Co., Inc.

August 29 2009 USA Ver 3

Manual P/N 32297

REVISION HISTORY

Rev # Date Details Author

01 07.27.05 Original issue A. Sibun

02 10.16.08 US Version 1 A. Konschak

03 05.26.09 US Version 2 A. Konschak

04 08.29.09 US Version 3 A. Konschak

Page 2 of 40

General Machine Products Co., Inc.

CONTENTS

1. Safety Instructions

2. Critical Points

3. General Description

4. Specification

5. Operating procedures

6. Maintenance

7. Procedure for Replacement of Chain Drives

8. Procedure for Replacement of sub-duct clamp collets

9. Procedure for Adjusting the sub duct clamp and collet type rod infeed guide assembly height

10. Monthly Service – Check List

11. Service History Record

12. Troubleshooting Guide

13. Recommended Spares List

APPENDICES

Appendix 1 Layout of Rod Pushing Machine

Appendix 2 Drawing – Rod Pushing Machine

Appendix 3 Hydraulic & Electrical Panel Layout

Appendix 4

Warranty

Counter programming parameters

Page 3 of 40

General Machine Products Co., Inc.

INTRODUCTION

Founded by engineer George M. Pfundt in 1936, GMP started operations in a downtown Philadelphia building as a specialty machine shop doing work for the local Bell Telephone company and

for the electric utility company. GMP expanded to a production

shop after landing a contract

with Western Electric Company and, subsequently, forming a close relationship with Bell Telephone Laboratories in Murray

Hill, N.J., which enabled it to manufacture prototypes of products for experimental use within the

Bell System.

Having outgrown the original factory building, the

company built a 100,000 square foot plant in

Trevose, PA (a Philadelphia suburb) and moved

there in 1957. Today GMP is recognized as a premier worldwide supplier of specialty tools and equipment for the outside plant marketplace. The company's products are known for their robust design and durability to withstand many years of frequent use.

Page 4 of 40

General Machine Products Co., Inc.

1. SAFETY INSTRUCTIONS

This Equipment should be used only by personnel who have been given the appropriate training and who are competent to use it.

These instructions are to be made available to operators of this equipment at all times.

Failure to observe these safety instructions could result in serious personal injury and/

or property damage.

CAUTION:

This machine is designed to work with one piece, continuous rod with no breaks. Rods that

have been repaired and have a coupling at any point along its length, cannot be used since

!

the coupling cannot safely pass through the Duct Rod Pusher.

FAILURE TO DO SO MAY RESULT IN PERSONAL INJURY

WORK AREA AND GENERAL SAFETY

1. Read and understand the operation and maintenance manual supplied with this equip-

ment. Keep it in a convenient place for future reference.

2. Keep children and untrained personnel away from this equipment while in operation.

3. Keep all guards and safety devices in place. Do not operate this equipment with guards

removed or damaged.

4. Keep hands, feet and loose clothing away from moving parts, especially at cable entry

points.

5. Always stop the machine and isolate hydraulic and electrical services to carry out lubrica-

tion and servicing.

6. Check machine before starting for worn or damaged parts. Check for signs of loose nuts

and bolts etc.

7. If machine is left unattended, insure that unauthorized use is prevented.

8. Never leave the machine unattended while in use.

9. Consider the use of safety barriers, especially when used in public places, observe all

statutory requirements for working environments.

10. Beware of pinch points involved with rotating components.

11. Beware of hot surfaces, machine uses hydraulics.

12.

When operating machine always wear eye protection, hard hat, safety shoes and leather

gloves, machine operates with hydraulic oil at 2030 psi.

Page 5 of 40

General Machine Products Co., Inc.

13. Some component and assembly parts are in excess of 55 lbs. (25kg) . When lifting care must

be taken, insure sufficient man power/lifting gear is available, to prevent personal injury and

damage to the machine.

Beware of exposed electrical contacts. Do not touch, or allow

metal objects to come into contact.

14.

Prior to installation insure the sub-duct route is connected properly.

15. Beware of exposed electrical contacts. Do not touch. Or allow metal objects to come into

contact. Waste hydraulic oils are to be disposed of via an environmentally acceptable

method.

16. Wear hearing protection when noise level are above acceptable limits. To reduce noise,

position Power Pack away from user.

17. Machine may cause additional fire hazard if involved in an existing fire due to hydraulic

oils.

18. No personnel are to be in manholes or ducts when the duct rod pusher is in operation.

19. The machine must be operated on firm ground.

20. Stay clear of rods or lines under tension.

21. Only use the machine for its intended purpose.

22. Do not place duct rod carrier too close to the powered duct rodder.

23. Do not tamper with pressure relief valves or pressure reducing valves.

24. Never operate the rod pushing machine with the electronic control panel immersed in wa-

ter.

25. To prevent damage to the hydraulic hoses and the emergency stop cable never leave

them on the ground when not in use.

Page 6 of 40

General Machine Products Co., Inc.

GENERAL HYDRAULICS SAFETY INSTRUCTIONS

Escaping fluids under pressure can penetrate the skin and cause serious personal injury. Observe the following precautions to avoid hydraulic hazards: -

1. Insure all hydraulic connections are securely tightened before operating the machine.

2.

Check for leaks with a piece of cardboard. Do not use your hands!

3. Do not exceed working pressure of hydraulic hoses.

4. Visually inspect hoses regularly and replace if damaged.

GENERAL ELECTRICAL SAFETY INSTRUCTIONS

The machine has electronic and electrical power and control circuits. Electric shock hazards

exist that could result in severe personal injury. Observe the following precautions to avoid

electrical hazards:

1. Do not operate in water.

2. Do not expose the machine to rain.

3. Do not remove cover of electronic control assembly.

There are no user serviceable parts inside.

4. Refer servicing to qualified service personnel.

Page 7 of 40

General Machine Products Co., Inc.

2. CRITICAL POINTS THAT DRAMATICALLY AFFECT THE

OPERATION OF THE ROD PUSHING MACHINE

a. Two (2) turns on the rod clamping screw.

b. Tractor drive to be closed at all times when rod is installed into machine.

c. Sub-Duct clamp height adjustment correctly set.

d. Rod in-feed bracket height adjustment correctly set.

e. Sub-duct fully connected.

f. Rod drum must be located directly behind and in line with the pushing machine.

g. Sub-duct clamp, tractor drive belts/chains, housing framed and rod guide intake assembly must be

clean and free from debris, sludge, dirt, water and lubricant. (Each time the pushing machine is

used.)

h. The hydraulic pressure should be between 290-580 PSI at the start of an installation. If greater do

not proceed. Check rod clamping screw setting, sub-duct, rod, rod collet sizes, sub-duct clamp/infeed guide height setting. Rectify before re-commencing the installation.

i. Lubricate the drive chains before use.

j. Do not repeatedly press the on/off button on the length/speed readout. This may result in irrelevant

digits being displayed or may alter the program. Always fit the hydraulic hose dust caps when the

hose is not in use, clean and check the quick release couplings before use.

NOTE:

This machine is primarily designed to work with the GMP 1/2 Duct Rodder. Other manufacturer’s Duct

Rodders may be able to be modified to work. Please contact the factory for details.

Page 8 of 40

General Machine Products Co., Inc.

3. GENERAL DESCRIPTION

The Duct Rod Pushing machine has been designed to provide an effective and safe method

of rod installation and removal. The system installs rod of 1/2” overall diameter at up to 130 ft/

min into pre-installed sub-ducts.

The machine is protected by preset pressure relief valve and preset pressure sensor.

The hydraulically powered rod feed system controls the rod. The electronic control system

displays speed, distance, direction and the preset pressure sensor provides automatic protection against duct obstruction.

The system comes mounted on a sturdy anti-corrosion, height adjustable, wheeled, tubular

steel trolley unit for ease of site maneuverability, and is powered by a hydraulic supply system

operating at 2030 psi x 5.3 gallons/min.

The rod pushing unit can be easily detached from the trolley and located in a trench or manhole (depending on the size of the manhole).

The unit is supplied with two (2) x hydraulic hoses x 23 feet and a 26 foot long emergency

stop lead.

Page 9 of 40

General Machine Products Co., Inc.

FEATURES

Fully labeled control panel containing:

▪ Power ON/OFF button

▪ Emergency Stop Button

▪ Installation speed and direction readout in m/min or ft/min through a separate calibration

▪ Length counter tracking in feet or meters through a separate calibration

▪ Hydraulic pressure display gauge

▪ Hydraulic on/off control valve

▪ Emergency stop connection socket

▪ Adjustable speed control for drive belts

▪ Battery Charging Connection

Control panels are anti corrosion treated and may be removed independently for repair work.

CHASSIS

▪ Front mounted wheels for ease of maneuverability

▪ Light painted tubular steel frame

▪ Adjustable frame allowing unit to be tilted at 20º to manhole

▪ Adjustable legs for uneven terrain

▪ Detachable rod pushing unit for trench / manhole location

ROD FEEDER

▪ Manufactured from cast aluminum

▪ Hydraulically powered

▪ Unit lifts and splits to allow insertion of rod between drive belts

▪ Drive belts are polyurethane and molded to unit ensuring long life between replacements.

▪ Lifting hook built into adjustable jack screw to allow unit level lift.

▪ Belt tension can be set by means of adjustable chain drive tensioners fitted to the side of

the unit

▪ System relief valve factory set to 1500 psi.

Page 10 of 40

General Machine Products Co., Inc.

4. SPECIFICATIONS

OPERATION CAPACITIES

Pushing Force

Pushing Speed

Rod Size

Sub-Duct Size

HYDRAULIC DRIVE SYSTEM

Operating Pressure

Flow

Pressure Switch Setting

Relief Valve Setting

Initial starting pressure

ELECTRONIC CONTROL SYSTEM

0-300 lbs. (0 - 136 kg)

0-130 ft/min (0 - 40m/m)

1/2” (12.7mm)

1-1/4 SDR

2030 psi (max) (110 Bar)

5.3 gallons/min (recommended)

1450 psi (100 Bar)

1500 psi (103 Bar)

290-580 psi (20-40 Bar) (if greater the set-up

needs checking)

Power requirements:

Fuse Rating

DIMENSION AND WEIGHTS

Height

Length

Width

Weight

Tire Size

Tire Pressure

Drive Chain Lubrication

12 Volts DC

3.15 amp (Slow-Blow)

49”

42”

28”

210 lbs.

3.00-4/260x85

25 psi (1.72 Bar)

Metaflux 70-88 Chain Spray

Page 11 of 40

General Machine Products Co., Inc.

5. OPERATING PROCEDURE

It is imperative that all persons using, operation or maintaining this cable blowing machine:

Have received comprehensive training in the use of this machine.

Are competent and authorized to use it and have read and understand this manual.

General Machine Products Co., Inc. cannot be held responsible for misuse of this equipment.

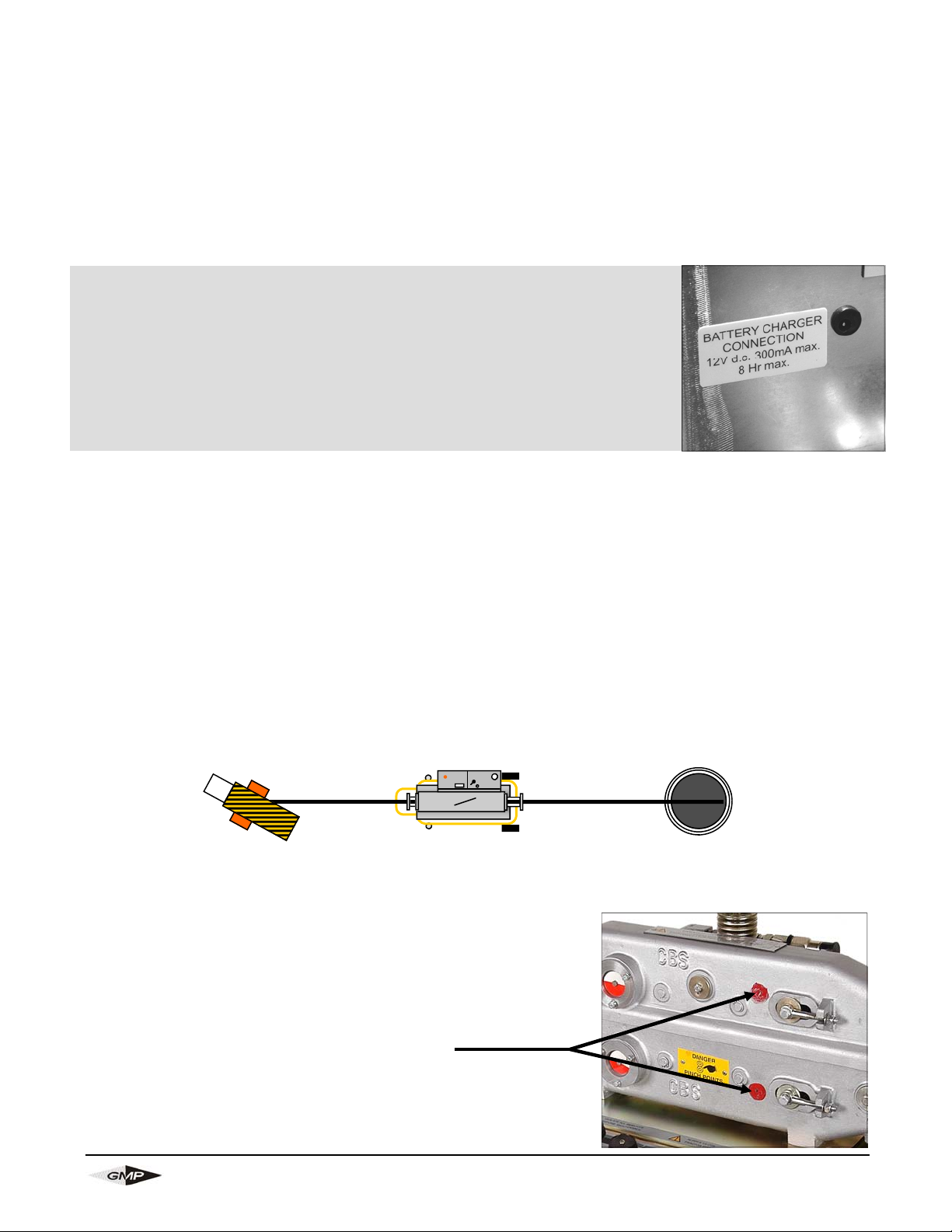

Charging the 12 volt battery before use:

Plug in the supplied battery charger in the charging jack found on the

right of the control panel. Initially charge the battery for 8 hours before

use (to approximately 13 volts). Continuous charging of the battery with

your charger will reduce the life of the battery. Remove the charger

when charging is complete. When voltage dips to 12 volts, recharge the

battery. Optimize battery life by turning off the display when not in use.

1. Position the Rod Pushing Machine in a suitable position in line with the proposed sub-duct.

2. Adjust the mounting frame to the desired height and angle by means of the front frame supports. Withdraw the front ‘R’ clip and retaining pin while supporting the weight of the rod

pushing unit. Raise or lower the pushing unit and locate onto the support bar for the desired

position. Refit the retaining pin and ‘R’ clip. Alternatively the pushing unit may be detached

from the trolley frame by withdrawing both ‘R’ clips and retaining pins, while supporting the

weight of the pushing unit.

3. Stabilize the frame on uneven ground by adjusting the height on the pivoting feet at the rear

of the unit and locking in position.

NOTE: CARE SHOULD BE TAKEN WHEN WHEELING THE TROLLEY AROUND NOT TO

CATCH THE ADJUSTABLE FEET PADS ON CURBS OR BOULDERS, THIS MAY DAMAGE THE PIVOTING FOOT.

4. Position Duct Rod approximately 5’ behind the Duct Rod Pusher at about a 35° angle.

Duct Rod

5. Insure the battery is fully charged before commencement of installation.

6. Open tractor drive.

CLEAN ANY DEBRIS, SLUDGE, DIRT, WATER, LUBRICANT,

ETC, FROM FRAME HOUSINGS AND ROD INTAKE GUIDE

BRACKET ASSEMBLY EACH TIME BEFORE USE.

LUBRICATE BOTH CHAINS BEFORE USE.

CLEAN BOTH TRACTOR DRIVE BELTS BEFORE USE.

5ft 1 1/4” Duct 1 1/4” Duct

Duct Rod Pusher

Lubrication Points

Page 12 of 40

General Machine Products Co., Inc.

7. Open tractor drive enough to feed the

duct rod through the pusher.

TIP:

If the duct that is to be rodded is larger

than 1 1/4”, insert a piece of 1 1/4 subduct from the out-feed of the Duct Rodder into the larger duct causing the

smaller duct to act like a feeder.

Tie off the small duct to a ladder or some

other permanent fixture if possible. This

prevents the sub-duct from kicking back

should the duct rod encounter and obstruction.

8. Place sub-duct from the manhole into

out-feed sub-duct clamp and tighten with

3/4” wrench (provided).

9. Take a 5’ piece (approx) of 1-1/4 subduct and lay it into the opened infeed

sub-duct clamp. Feed the rod thru the

duct so that it’s about a foot into the

duct rodder, ensuring that the connector on the end of the rod is past

the infeed clamp. Now tighten the

clamp on the duct.

10. Clamp the other end of the 1 1/4” subduct into the supplied duct rodder carriage clamp.

Page 13 of 40

General Machine Products Co., Inc.

11. Feed the duct rod through the

pusher and into the sub-duct that’s

placed in the manhole.

12. The correct rod clamping force is

vital to the performance of the machine. It should be set as follows:

Tighten the handle with one hand

rotating the clamp washers with

the other. The clamp washers will

turn easily until the handle begins

to clamp them. When the clamp

washers become almost impossible to turn with one hand, this is

the start point for the clamp force

setting. Continue to turn the handle

a further 2 full turns. This will insure the correct force.

13. Connect the hydraulic hoses

and emergency stop connector to

the duct rod pusher taking note

that the connector is female on the

pusher side and male on the power

pack side.

Page 14 of 40

General Machine Products Co., Inc.

14. Insure that the hydraulic control

lever is in the “OFF” position and

the speed control knob is in the

“Min” position (fully rotated

counter-clockwise).

15. The emergency stop button is set

to on (upper most position). If not

set, twist counter-clockwise to reset.

16. Start the engine on the power

pack. Insure that you have

enough fuel for the duration of the

pushing operation.

17. Select desired pushing direction

from the valve to the rear of the

machine. Direction is indicated.

Page 15 of 40

General Machine Products Co., Inc.

18. Turn the Hydraulic lever valve to

the “ON” position.

19. Turn on the digital display by pressing the “power on/off” button. Allow approx. five

(5) seconds for the display to appear. Pressing SEL toggles between installation distance (ft) and speed (ft/min) (designated by R). Pressing RST will reset the distance

reading to zero (0).

20. Turn the speed control valve

clockwise (towards ‘max’) until the

desired speed (130 ft/min max) is

achieved.

21. Continue to install rod into sub-duct. The operator wearing work gloves should insure the

rod enters the machine without debris. Care must be taken to avoid injury by clothing or

fingers being dragged into the machine. Failure to do so may result in damage to the rod

form the drive belts and/or jamming of the rod.

24. To prevent dirt from entering the

machine when pulling back the

rod, use a felt wiper at the subduct out feed side and clamp it

tightly to the rod as shown in

photo.

23. On completion screw the speed

control knob to the min to stop the

machine, (counter clockwise),

press the reset button and select

neutral from the direction control

valve.

Page 16 of 40

General Machine Products Co., Inc.

24. IF THE PUSHING MACHINE STOPS SUDDENLY

If the rod pushing machine stops suddenly during the pushing operation it is likely that

the pressure switch has tripped, the probable reasons for this are: A) The rod has become jammed, has hit an obstruction in the duct or the rod pushing

operation has reached its maximum capability.

B) The power pack has developed a problem or has run out of fuel.

IN THE EVENT OF AN EMERGENCY

1. Push the emergency stop push button.

Turn the speed control knob to “Min”

3.

position (fully counter clockwise)

2. Turn the hydraulic valve to the ‘off’ position.

4. Press the on/off button (to turn off the

electric’s off, if required).

Page 17 of 40

General Machine Products Co., Inc.

TO RESTART

1. Take machine out of emergency stop by

turning the red button counter clock wise.

Restart the hydraulic power pack.

2. Turn the hydraulic on/off valve to “on’”

position.

3. Turn on the digital display by pressing

the “power on/off” button. (If the electric’s

have been switched off)

4. Turn the speed control valve clockwise

until the desired speed (up to 130 ft/min

max) is achieved.

Page 18 of 40

General Machine Products Co., Inc.

6. MAINTENANCE

To insure reliable service from your Rod Pushing Machine, we recommend the unit be completely serviced every 6 months.

TRACTOR DRIVE

Inspect the chain drive blocks for wear each week.

CHECK the chain tension weekly and adjust if necessary with the two

external adjustment screws (do not over tension). The chain should

slightly lift off the chain guides, when pulled at the center by finger.

THE CHAIN SHOULD BE LUBRICATED EACH TIME USED by application of Metaflux

spray grease 70-88. This is achieved by running the rod pushing machine at about 130ft/min

without any rod and carefully inserting the spray tube from the canister into the holes on the

operator side of the aluminum drive castings (2). The spray tube should be carefully inserted

until the chain can just be felt and then withdrawn about 3/4 – 1” and spraying for approximately 1 second.

DO NOT OVER LUBRICATE, AS THIS MAY LEAD TO THE DRIVE BELTS BEING

CONTAMINATED WITH LUBRICANT.

If contamination does result, wipe the belts clean thoroughly before attempting any pushing

operation. (This is based on normal use where the chains are not exposed to excessive

contamination).

Bottom frame chain lubrication

point

Page 19 of 40

Top frame chain lubrication point

General Machine Products Co., Inc.

GENERAL

The machine should be stored under cover when not in use. The machine should be wiped

clean after each time used.

ALWAYS insure that the service battery and spare battery (if available) are fully charged,

before this rod-pushing machine is to be used. The machine uses a conventional lead – acid

batterie, this may be charged using the supplied battery charger for a maximum of 8 hours.

CHECK the tire pressures and tire condition weekly. Oil the frame pivot points and lubricate

the oilite bearings with light machine oil every month. Apply grease to the jacking screw

thread each month clean out any dirt/debris from the rod-measuring wheel, measuring disc

and speed pick up probe.

Oil sub duct clamp adjusting screw and rod infeed guide adjusting screw monthly.

Grease axles every month. Check function of electrical panel each time.

SERVICE CONNECTIONS

CHECK the condition of the hydraulic hoses each time used and replace if worn or damaged.

CHECK the condition of the emergency stop cable each time used and replace if worn or

damaged.

Page 20 of 40

General Machine Products Co., Inc.

6.1. MAINTENANCE SCHEDULE

PROCEDURE DAILY WEEKLY MONTHLY

Clean all assemblies and components thoroughly

Inspect hydraulic hoses for leaks and cracks

Inspect fasteners, screws and retaining pins / wire

Check / adjust chain tension

Check tractor drive pads for wear / damage

Tire pressure / condition

Check condition of emergency stop lead

Clean rod infeed guide bracket and collets

Clean measuring wheel measuring disc and speed pick

up probe

Function of electronic panel

Oil the frame pivot points

Grease jacking screw thread

Oil sub duct clamp adjusting screw

Oil oilite bearings with light machine oil

Grease mounting frame axles

Clean and lubricate chain*

Clean and lubricate the chain support slide bars

Check the condition of service and spare 12V DC battery

* Should be more often if subjected to abnormal use and / or excessive

contamination.

Page 21 of 40

General Machine Products Co., Inc.

6.2. TYPICAL PROBLEMS EXPERIENCED WHEN ROD

PUSHING:

PROBLEM SOLUTION

Tractor feed does not pull the rod off the

drum

The Rod Pushing Machine stops. Hydraulic pressure gauge reads zero.

It is difficult to keep the rod moving near

the end of a duct run

Assist the drum by turning it or pulling the rod

off the drum by hand. Loosen friction brake.

Machine has tripped out on pressure switch,

rod has hit an obstruction or become jammed.

Turn hydraulic valve to off position. Turn

speed control knob to ‘min’. If rod is jammed

try restarting the Rod Pushing Machine, if this

fails it may be necessary to pull the rod out a

short distance and start again. Investigate

obstruction in duct. If all else fails it may be

necessary to remove the sub-duct and remake the bad connection.

Assist the Rod Pushing Machine by manually

pushing the rod into the tractor drive. DO NOT

BEND OR CRIMP THE ROD.

6.3. BASIC TOOL KIT SUPPLIED WITH ROD PUSHING

MACHINE:

Part No. Description Qty.

32837 3/32” Allen Wrench 1

32838 1/8” Allen Wrench 1

89142 3mm Allen Wrench 1

89143 4mm Allen Wrench 1

89144 5mm Allen Wrench 1

89145 6mm Allen Wrench 1

89153

89150

87096

89146 3/4” Wrench 1

Metaflux 70-88 chain spray

Pliers 6”

Screwdriver 6” (slot)

1

1

1

Page 22 of 40

General Machine Products Co., Inc.

7. PROCEDURE FOR REPLACEMENT OF CHAIN DRIVES

Tools required:

6mm Allen Key 13mm wrench

INSURE THE HYDRAULIC HOSES ARE DISCONNECTED FROM THE PUSHING

MACHINE BEFORE CARRYING OUT THIS PROCEDURE.

Step 1

a. Disconnect the hydraulic motor from the top frame – using 6mm Allen Key.

b. Remove the stop washer on the bottom of the main jacking screw – using a 6 mm allen

key.

c. Unscrew the main clamping screw and separate the top and the bottom of the pusher unit.

Step 2

Bottom Housing – Chain Removal

a. Slacken the chain adjusters – using a 13mm wrench.

b. Remove the swing bolt from the side of unit – using a 13mm wrench.

c. Push the tensioner pin out through the sprocket assembly.

d. Remove the tension sprocket assembly.

e. Remove the chain-connecting link.

f. Remove the chain.

g. Check the chain support slide bars for wear and check the tension sprocket rotates freely,

prior to fitting the new chains.

h. Clean and re-lubricate the chain support slide bars.

Step 3

Bottom Housing – Chain Replacement

a. Pass the pre-lubricated chain round the drive sprocket. Feed the chain along the unit and

reconnect the chain-connecting link.

b. Align the tension sprocket with the chain and locate into position.

c. Insert the tension pin through the tension sprocket, placing the tensioner pin spacer on the

tension pin. Refit swing bolt – using a 13mm wrench.

d. Adjust the chain evenly via the swing bolts, checking free rotation of the chain. Do not

over tighten the chain.

Step 4

Top Housing – Chain Removal

a. Slacken the chain adjusters – using a 13mm wrench.

b. Remove the swing bolt from the side of unit – using a 13mm wrench.

c. Push the tensioner pin out through the sprocket assembly.

d. Remove the tension sprocket assembly.

e. Remove the chain-connecting link.

f. Remove the chain.

g. Check the chain support slide bars for wear and check the tension sprocket rotates freely,

prior to fitting the new chains.

h.

Clean and re-lubricate the chain support slide bars.

Page 23 of 40

General Machine Products Co., Inc.

Step 5

Top Housing – Chain Refitting

a. Pass the pre-lubricated chain round the drive sprocket. Feed the chain along the unit and

reconnect the chain-connecting link.

b. Align the tension sprocket with the chain and locate into position.

c. Insert the tension pin through the tension sprocket, placing the tensioner pin spacer on the

tension pin. Refit swing bolt – using a 13mm wrench.

Step 6

Top Housing – Chain Refitting

a. Reassembling the top and the bottom parts of the pusher unit.

b. Refit the main clamping screw.

c. Replace the stop washer on the bottom of the main clamping screw – using a 6mm allen

key.

d. Reconnect the hydraulic motor using the 6mm allen key. Adjust top chain, do not over

tighten chain.

e. Connect the power pack hoses and run the pusher unit to check the chain tension

Page 24 of 40

General Machine Products Co., Inc.

8. PROCEDURE FOR REPLACEMENT OF SUB-DUCT COLLETS

THE MACHINE IS SUPPLIED WITH COLLETS FITTED FOR 1 1/4” SDR SUB DUCT.

SUB-DUCT CLAMP COLLETS

Tools Required 4mm Allen Key

Step 1 Collet Removal

a. Open the sub-duct clamp.

b. Remove the socket head cap screws (2) – using a 4mm allen key and remove the collet

(2).

Step 2 Collet Refitting

a. Select he replacement collets

b. Clean the sub-duct clamp with a dry cloth.

c. Fit the required collets and secure with a socket head cap screws – using a 4mm allen

key.

d.

Close the sub-duct clamp.

Page 25 of 40

General Machine Products Co., Inc.

9. PROCEDURE FOR THE OUTFEED AND INFEED SUB DUCT

CLAMP

INFEED AND OUTFEED SUB DUCT CLAMP:

a. To adjust the sub duct clamp bracket in either direction, release the adjusting knob locking

ring and turn the knob placed directly under the sub duct clamp.

b. Select the adjustment required – using the increment gauge on the side of the unit.

c. Tighten the locking ring to prevent any movement during installation.

10. MONTHLY SERVICE – CHECK LIST

a. Remove the drive chains from the pusher unit. Check both of the chains for excessive

wear. Replace, if required – and lubricate with the spray grease provided.

b. Remove any debris from the housings.

c. Check the chain supports slide bars for excessive wear and lubricate with the spray

grease provided. Replace, if required.

d. Check all other moving parts e.g. bearings, shafts, sprockets etc. – and lubricate.

e. Check main jacking screw – and lubricate.

f. Check all hydraulic fittings and check for leaks.

g. Check the electrical lead for external damage.

h. Check the electrical plug and sockets.

i. Check the function of the electronic control module.

j. Check the operation of the emergency stop button.

k. Check the operation of the rod measuring device.

l. Check the wheel tire pressures and free rotation. Inflate and lubricate, as necessary.

m. Clean the infeed rod guide bracket.

n. Complete service history record.

Page 26 of 40

General Machine Products Co., Inc.

11. SERVICE HISTORY RECORD

Service no Date Carried out by Record of service/repair

Page 27 of 40

General Machine Products Co., Inc.

12. TROUBLESHOOTING GUIDE

INITIAL STARTING HYDRAULIC PRESSURE AT THE POINT OF STARTING A ROD

INSTALLATION THE HYDRAULIC PRESSURE MUST BE BETWEEN 290-580 psi (20-40

BAR). IF NOT DO NOT CONTINUE, SEE SECTIONS ‘WILL NOT ACHIEVE MAX

PRESSURE’ AND ‘RUNS AT HIGHER THAN EXPECTED PRESSURE’ TO RECTIFY

PROBLEM BEFORE COMMENCING ROD INSTALLATION.

WILL NOT ACHIEVE MAX PRESSURE

a. Hydraulic control valve not open fully

b. Speed control not positioned fully

c. Faulty power pack (check performance)

d. Jacking screw not tight enough (producing belt slip)

e. Worn pads due to rod slip

f. Excessive lubrication of chains (on to pads causing belt slip)

RUNS AT HIGHER THEN EXPECTED PRESSURE

a. Chains too tight / excessive clamping force.

b. Poor lubrication

c. Seized chain links

d. Over tightening of jacking screw

e. Misalignment of sub duct clamp slider

f. Rod drum not rotating freely

g. Misalignment of entry guide

h. Poor duct, installation / friction

i. Dirt/debris in pusher housings

ROD PUSHING MACHINE STOPS SUDDENLY DURING ROD INSTALLATION

a. Max pressure achieved

b. Obstacle in duct installation

c. Power Pack out of fuel

d. Emergency button pressed

e. Damaged lead between Power Pack and Duct Rod Pusher

ENGINE DOES NOT STOP AT MAX PRESSURE

a. Emergency lead not connected

b. Electrical control panel not switched on

c. Battery low on power

d. Pressure switch unplugged

e.

Fuse blown in control panel

Page 28 of 40

General Machine Products Co., Inc.

13. RECOMMENDED SPARES LIST

Part No Description Qty Required

89191 Chain ½ Duplex (Blue) 2

89158 Motor (32 cc/rev) 2

89156 Wheel (Pneumatic) 2

OR

89151 Wheel (Solid) 2

31727 Chain Support Slide Bar 2

89153 Metaflux chain spray 70-88 1

32512 Battery 12 V.dc 1

For spare parts always quote the machine type and serial number and contact:

General Machine Products Co.

3111 Old Lincoln Highway, Trevose PA 19053 USA

TEL: +1 215 357 5500

FAX: +1 215 357 6216

E-MAIL: info@GMPtools.com

Website: www.GMPtools.com

Page 29 of 40

General Machine Products Co., Inc.

Appendix 1

LAYOUT OF ROD PUSHING MACHINE

2

5

12

1

4

7

13

3

8

6

11

10

1 Rod Pusher

2 Sub-Duct Outfeed Clamp

3 Sub-Duct Infeed Clamp

4 Unit Lifting Point & Clamping Handle

5 Hydraulic Control Panel

6 Electronic Control Panel

7 Hydraulic Hose Connection (at rear of unit)

8 Emergency stop socket (on side of unit)

9 Frame Leveling Foot

10 Tool Box

11 Mounting Frame

12 Tractor Drive Movement Indicator

13 Directional Valve

Page 30 of 40

9

General Machine Products Co., Inc.

Appendix 2

Page 31 of 40

General Machine Products Co., Inc.

Appendix 3

HYDRAULIC AND ELECTRONIC CONTROL PANEL LAYOUT

2

3

6

5

1

7

1 Hydraulic Pressure Gauge

2 Speed Control Knob

3 Hydraulic “On / Off” Lever

4 Power “On / Off” Button

5 Emergency Stop Button

6 Length / Speed Digital Display

7 Hydraulic Control Panel

8 Electronic Control Panel

4

8

Page 32 of 40

General Machine Products Co., Inc.

Appendix 4

Programming Parameters for CUB5R counter/rate meter fitted to Rod

Pushing machines – REV 2

The device must be wired and installed into the machine prior to programming.

The Duct Rod Pusher is fitted with CUB5R, reflective version

The DIP switch positions are as follows:

1. ON

2. OFF

3. ON

4. ON

Please see the attached CUB5 Programming

Overview attached to this document.

a. Press and hold SEL for 2 seconds to enter

programming mode

b. Enter the Pro-Code – 222 by pressing RST to change numbers

and SEL to skip to the next number.

c. Once correct Press and Hold SEL for 2 seconds

d. Pro-no should now be flashing, press RST

e. Press RST to move through the various sections 1-input, 2-rate 3-dsplay, sections 4 and 5

will be unavailable, see the next page of instructions for the parameters required.

f. Press SEL to enter that section

g. To change the value of a parameter press RST

h. Press SEL to move to the next parameter (You will have to hold for 2 seconds on certain

parameters).

i. When all the parameters in the section have been scrolled through you will return to the

Pro-no display, press RST to scroll to another section else press SEL to exit programming

mode.

DIP Switch

CUB5R counter/rate meter

Page 33 of 40

General Machine Products Co., Inc.

Counter programming parameters for the Duct Rod Pusher

Scroll to 3-DSPLAY

Skip through the parameters until FACT SET is displayed. Change this to YES by pressing RST

PRO NO should be displayed, Press SEL.

Continue to re-program the Counter by pressing and holding SEL to re-enter programming

mode. Pro-no will be displayed, press RST to move through the relevant sections. The following

parameters are required for the counter:

Press RST Once:

Counter Parameters (1-INPUT)

INPA-B = QUAD 4 – if correct press SEL.

CNT A DP = 0.00 (for metric metres) or 0.0 (for imperial feet) - if correct press SEL.

CNT A SCF = 00.4167 (for metric, m) or 00.1353 (for feet)– once correct press & Hold SEL.

CNT A RST = TO ZERO - if correct press SEL.

CNT A DIR = NOR - if correct press SEL.

CNT A LD = 0 – once correct press & Hold SEL.

CNT B BAT = NO - if correct press SEL.

RST P-UP = NO - if correct press SEL.

USER INP = NO - if correct press SEL.

Press RST Twice:

Rate Parameters (2-RATE)

RATE ENB = YES - if correct press SEL.

RATE DP = 0 - if correct press SEL.

RATE DSP = 60 - once correct press & Hold SEL.

RATE INP = 60 (Metric, m/min) or 18 (Imperial, ft/min) – once correct press & Hold SEL.

LO-UDT = 1.0 - if correct press SEL.

HI-UDT = 2.0 - if correct press SEL.

Press RST Three times:

DISPLAY (3-DSPLAY)

SEL ENB = YES - if correct press SEL.

RST ENB = YES - if correct press SEL.

D-SCROLL = NO - if correct press SEL.

PRO CODE = 222 – CODE REQUIRED TO RE-PROGRAM - once correct press & Hold SEL.

CODE VER = NO - if correct press SEL.

FACT SET = NO – Press SEL Twice

Page 34 of 40

General Machine Products Co., Inc.

Page 35 of 40

General Machine Products Co., Inc.

GMP Limited Warranty

1a. General Machine Products Co., Inc. ("GMP") warrants to the purchaser and/or end user:

(1) that a new product sold and manufactured by GMP will be free from original defects in material and

workmanship for one year from the date the product was delivered to the purchaser and/or end user,

or for the lifetime of the Modular Plug Presser;

(2) that a new product sold and not manufactured by GMP will be covered exclusively by the manufacturer's warranty. However, if that warranty coverage shall provide less coverage than the GMP Warranty for its manufactured products, then the warranty set forth in Paragraph 1(a)(1) above shall apply

instead;

(3) that a reconditioned used GMP product sold by GMP, or a non-owned product repaired by GMP,

or a new part sold by GMP, will be free from original defects in material and workmanship for ninety

days from the date the product was delivered to the purchaser and/or end user.

1b. The above warranties are contingent upon and subject to the condition that: (1) the end user sub-

stantiates the date it purchased and received delivery of the product or part, and (2) the product or

part shall have been installed, maintained and used in accordance with GMP's or the manufacturer's

written instructions.

2. The end user shall determine the suitability of GMP's product or part for intended use, and the end

user assumes all risk and liability whatsoever in connection therewith except to the extent set forth in

this Limited Warranty.

3a. GMP reserves the right to request that the product or part be returned to us for examination and

cannot be responsible for user charges incurred in the replacement of any product. GMP's agreement

to repair or replace is also subject to its inspection of the product and verification of the defect.

3b. Subject to immediate written notification of a defect or malfunction, GMP will repair or replace that

product or part, at GMP's option, returned freight prepaid to Trevose, PA.

3c. To obtain repair or replacement service under the Limited Warranty, the purchaser must contact

the factory for a Return Material Authorization (RMA). Once obtained, send the RMA along with the

defective part or product, transportation prepaid to:

General Machine Products Co., Inc.

3111 Old Lincoln Highway

Trevose, PA 19053-4996 USA

Tel: 215.357.5500

Fax: 215.357.6216

3d. The field labor and material charges incurred by an authorized GMP dealer or an end user to dis-

assemble, inspect, repair and reassemble our product or part at their respective prime locations will

not be reimbursed unless GMP has first reviewed and approved those charges.

3e. Incidental repair charges incurred by an authorized dealer or an end user for items such as labor,

transportation, tolls, lodging and meals at a location remote from its prime facility, or to demount our

product or part from its remote location and forward to its prime facility, are not the responsibility of

GMP, and are not covered by this Warranty.

3f. Incidental repair charges incurred by an authorized GMP dealer or end user to remove construc-

tion hardware, modify a vehicle or otherwise gain access to GMP's product or part, is a condition beyond GMP's control, and is not covered by this Warranty.

Page 36 of 40

General Machine Products Co., Inc.

4a. GMP products or parts which become part of a total assembly which has been designated and/or

manufactured by others, are not covered by this Warranty unless GMP reviews the total assembly and

expressly extends its warranty.

4b. Design, material and workmanship furnished by others to install or operate a GMP product or part

are not covered by this Warranty with respect to GMP's products or parts which are used in that particular assembly.

4c. Hydraulic, pneumatic, electrical or mechanical control equipment which is not manufactured by

GMP and which becomes a part of a GMP assembly, is not covered by this Warranty.

4d. This warranty does not cover a GMP product or part which others have subjected to abuse,

improper installation, improper operation, alteration or negligence in storage or handling.

5a. THE ABOVE WARRANTIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PURPOSE OR OTHER WARRANTIES OR GUARANTEES OF

ANY KIND OR DESCRIPTION, EXPRESS OR IMPLIED.

5c. GMP'S SOLE LIABILITY AND THE PURCHASER'S SOLE REMEDY FOR A FAILURE OF A

PRODUCT OR PART UNDER THIS LIMITED WARRANTY, AND FOR ANY AND ALL CLAIMS

ARISING OUT OF THE PURCHASE AND USE OF THE PRODUCT OR PART SHALL BE LIMITED

TO THE REPAIR OR REPLACEMENT OF THE PRODUCT OR PART THAT DOES NOT CONFORM

TO THIS WARRANTY.

6. GMP reserves the right, without notice, to make changes in equipment design or components as

progress in engineering or manufacturing methods may warrant.

7. This Warranty shall be construed in accordance with the laws of the State of Pennsylvania, of The

United States of America.

8. This Limited Warranty may not be modified, in whole or in part, except by writing signed by an au-

thorized officer of GMP.

Page 37 of 40

General Machine Products Co., Inc.

Page 38 of 40

General Machine Products Co., Inc.

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: info@gmptools.com

Page 39 of 40

General Machine Products Co., Inc.

Loading...

Loading...