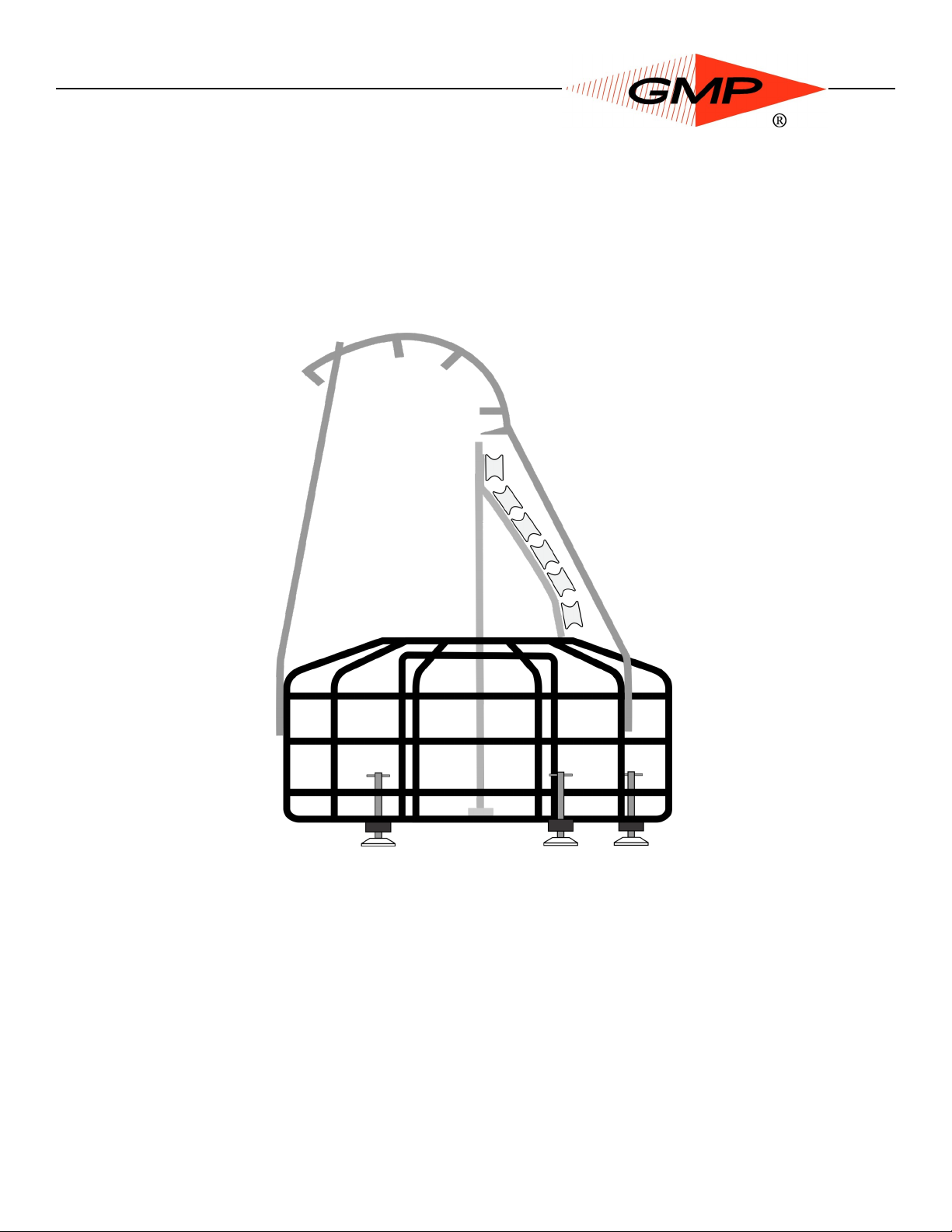

M ICRO CABLE FLEETER

Operation and Maintenance

Model 89002

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form whatsoever without the written permission of General Machine Products Co., Inc.

General Machine Products Co., Inc. • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: info@gmptools.com

P/N 30180 Ver2

Page 1 of 14

AK 08/28/13

REVISION HISTORY:

Rev

No.

Date Details Author

01 11-2007 Original issue A. Miller

02 6-2011 US Version A. Konschak

Page 2 of 14

CONTENTS

1.0 Introduction and Safety Instructions

2.0 General Description

3.0 Specification

4.0 Cable Threading and Operating Procedure

5.0 Equipment Layout

6.0 Spare Parts

7.0 Maintenance

Page 3 of 14

1.0 SAFETY INSTRUCTIONS

THIS EQUIPMENT MUST ONLY BE USED BY AUTHORIZED

PERSONNEL, WHO HAVE BEEN SUITABLY TRAINED AND

COMPETENT TO DO SO

THESE INSTRUCTIONS ARE TO BE MADE AVAILABLE TO

OPERATORS OF THIS EQUIPMENT AT ALL TIMES.

1. Read and understand the operation and maintenance manual

supplied with this equipment. Keep it in a convenient place for future

reference.

2. Keep children and untrained personnel away from this equipment

while in operation.

3. Keep all guards and safety devices in place. Do not operate this

equipment with guards removed or damaged.

4. Keep hands, feet and loose clothing away from moving parts.

5. Always stop the machine to carry out lubrication servicing.

6. Check machine before starting for worn or damaged parts. Check that

all nuts and bolts are tight.

7. If machine is left unattended, ensure that unauthorized use is

prevented.

8. Never leave the machine unattended while in use.

9. Consider the use of safety barriers, especially when used in public

places.

10. Beware of pinch points involved with rotating components, e.g.

rope/cable drums, capstans, bull wheels, shafts and chain drives.

11. Some component and assembly parts are in excess of 70lb (32kg).

When lifting care must be taken, ensure sufficient man power/lifting gear is available, to

prevent personal injury and damage to the machine.

Page 4 of 14

INTRODUCTION

Founded by engineer George M. Pfundt in 1936, GMP started operations in a downtown Philadelphia building as a specialty machine shop doing work for the local Bell

Telephone company and for the electric utility company. GMP expanded to a produc-

tion shop after landing a contract with Western Electric Company

and, subsequently, forming a close relationship with Bell Telephone

Laboratories in Murray Hill, N.J., which enabled it to manufacture

prototypes of products for experimental use within the Bell System.

Having outgrown the original factory building, the company built a 100,000 square foot plant in Trevose, PA

(a Philadelphia suburb) and moved there in 1957. Today GMP is recognized as a premier worldwide supplier of specialty tools and equipment for the outside

plant marketplace. The company's products are known

for their robust design and durability to withstand many

years of frequent use.

Page 5 of 14

Loading...

Loading...