7/8 in. Break-Away Swivel

Disassembly Procedure

The following disassembly operation will deal with

small parts. Disassembly and re-assembly should be

done in an area where parts will not be lost if accidentally dropped.

1. Retrieve both halves of the broken swivel.

2. Loosen the #6-32 x 1/4 in. set screw located in the

swivel body with the 1/8 in. Allen wrench provided

and back it off 2-3 turns.

3. Unscrew and remove the remnant stud of the

broken tension bolt.

4. Unscrew the stationary body where it joins the

housing and remove the head of the broken tension

bolt and the five thrust washers.

5. Place the five thrust washers on a new tension bolt

of the desired tension value, making sure to follow

this sequence: steel, plastic, steel, plastic, steel. Now

check to see that every other washer is steel.

6. Replace the O-ring (if missing) where the swivel

body mates with the housing.

7. place the new tension bolt with washers through the

housing and screw the bolt into the swivel body.

IMPORTANT: Do not over tighten the tension bolt,

because premature fracture may occur. Tighten the

bolt lightly until it bottoms (don't use excessive

force) ... then, unscrew 1/2 turn to achieve proper

bearing clearance and swivel action.

Do not apply torque to the head of the

!

tension bolt as over-stressing the bolt may

cause a lower breaking point.

8. Re-tighten the set screw into the side of the swivel

body.

9. Screw the stationary body and housing together and

tighten.

Questions? Comments? Call us!

We want you to be completely satisfied with cable

placing products you get from GMP.

If you have a problem or need additional information,

please call us at 1-800-345-6009 (in AK, HI, PA and

outside the USA: call 1-215-357-5500 Ext: 251) from

8:00 AM to 5:00 PM EST on any USA business day;

you can also send us a facsimile message any time at

1-215-357-6216. We would be happy to help!

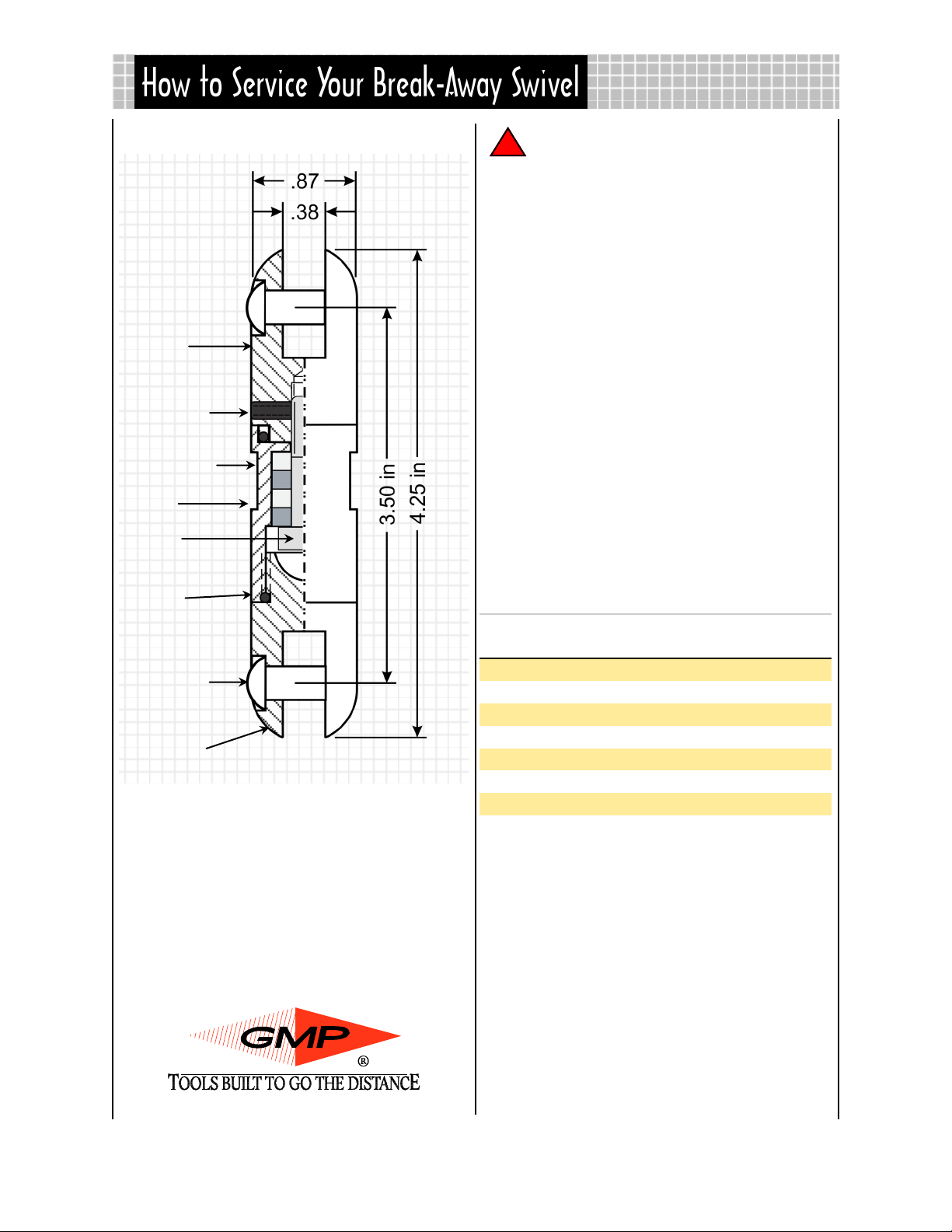

7/8 in. Break-Away Swivel

Swivel Body

#6-32 Set Screw

P/N 17530

Thrust Washer Kit

P/N 15380

Housing

Tension Bolt

See Chart

(2) “O” Ring

P/N 17534

(2) Shoulder Screw

P/N 25300

Staonary Body

!

IMPORTANT NOTICE

Users are cautioned to ensure appropriate safeguards

exist especially during aerial cable placing. Should the

swivel break there must be sufficient support to prevent the cable from reversing direction and creating

slack in an uncontrolled and potentially hazardous

manner. This is critically important when crossing

rights-of-way such as roadways, waterways or power

lines. Refer to your employer's work practices or consult the factory for detailed information pertaining to

this most important safety procedure.

All personnel should stand clear of the pulling line

when using any break -away swivel, in the event that

excessive pulling resistance causes the swivel to break

apart and possibly exit the duct at great speed.

Notes:

1. Breaking tolerance ±5%

2. Warning!! Do not over tighten the tension bolt, be-

cause premature fracture may occur. Tighten the

bolt lightly until it bottoms (not using excessive

force). Then unscrew ½ turn to achieve proper bearing clearance and swivel action.

3. See other side for disassembly procedure.

Aluminum 7/8 in. (22.2mm) Diameter

Break-Away Swivel

Break Point

lbs. kgs Color Code Swivel Repl Bolt

Part Number

340 154 White 53700 30332

450 204 Orange 53701 34786

500 277 Violet 53706 34787

600 272 Yellow 53702 34341

800 364 Blue 53703 34342

1000 454 Green 53704 34343

1200 544 Red 53705 34344

P/N 15380 Replacement Thrust Washer Kit

General Machine Products Co., Inc.

3111 Old Lincoln Highway Trevose, PA 19053

TEL: 215-357-5500 FAX: 215-357-6216

E-Mail: info@GMPtools.com

http://www.GMPtools.com

GMP reserves the right, without notice, to make changes in equipment design

or components as progress in engineering or manufacturing methods may

warrant. All information contained herein is subject to such change.

P/N 24590 AK 060513

Loading...

Loading...