General Machine Products 70605 User Manual

SIDEWINDER

PULL AND ASSIST CAPSTAN WINCH

OPERATION & MAINTENANCE

70605 – USA

SIDEWINDER

Copyright 2013 by General Machine Products Co., Inc

QC Final Inspection by:_________________________ Date:__________________

Unit Serial Number:__________________

Build Date:__________________

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form

whatsoever without the written permission of General Machine Products Co., Inc.

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • WEB: www.gmptools.com

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

January 30 2014 USA Ver 5

Page of 24

General Machine Products Co., Inc.

Manual P/N 27918

REVISION HISTORY:

Rev

No.

01 03-2006 Original issue A Miller

02 05-2007 US Version A Konschak

03 09-2009 Update manual to be consistent with others A Konschak

04 03-2010 Added figure 8 instruction and illustrations A Konschak

05 01-2014 Added new filter information A Konschak

Date Details Author

Page 2 of 24

General Machine Products Co., Inc.

CONTENTS

1.0 Introduction

2.0 Safety Instructions

3.0 General Description

4.0 Specification

5.0 Operating Procedure

6.0 Maintenance and Servicing

7.0 Towing Instructions

8.0 Equipment Layout

9.0 Spare Parts

APPENDICES

Appendix 1 Hydraulic Circuit Drawing

Page 3 of 24

General Machine Products Co., Inc.

1.0 INTRODUCTION

Founded by engineer George M. Pfundt in 1936, GMP started operations in a downtown Philadelphia building as a specialty machine shop doing work for the local Bell Telephone company and

for the electric utility company. GMP expanded to a production

shop after landing a contract

with Western Electric Company and, subsequently, forming a close relationship

with Bell Telephone Laboratories in Murray Hill,

N.J., which enabled it to manufacture prototypes

of products for experimental use within the Bell

System.

Having outgrown the original factory building, the

company built a 100,000 square foot plant in Trevose, PA (a Philadelphia suburb) and moved there

in 1957. Today GMP is recognized as a premier

worldwide supplier of specialty tools and equipment for the outside plant marketplace.

The company's products are known for their robust design and durability to withstand

many years of frequent use.

Page 4 of 24

General Machine Products Co., Inc.

2.0 SAFETY INSTRUCTIONS

THIS EQUIPMENT MUST ONLY BE USED BY AUTHORIZED PERSONNEL, WHO

HAVE BEEN SUITABLY TRAINED AND COMPETENT TO DO SO.

THESE INSTRUCTIONS ARE TO BE MADE AVAILABLE TO

OPERATORS OF THIS EQUIPMENT AT ALL TIMES, FAILURE TO

OBSERVE THESE SAFETY INSTRUCTIONS COULD RESULT IN

SERIOUS PERSONAL INJURY AND / OR PROPERTY DAMAGE.

1. Read and understand the operation and maintenance manual supplied with this

equipment. Keep it in a convenient place for future reference.

2. Keep children and untrained personnel away from this equipment while in operation.

3. Keep all guards and safety devices in place. Do not operate this equipment with

guards removed or damaged.

4. Keep hands, feet and loose clothing away from moving parts.

5. Always stop the machine to carry out lubrication or servicing.

6. Check machine before starting for worn or damaged parts. Check that all nuts and

bolts are tight.

7. If machine is left unattended, ensure that unauthorized use is prevented.

8. Never leave the machine unattended while in use.

9. Consider the use of safety barriers, especially when used in public places.

10. Beware of pinch points involved with rotating components, e.g. rope/cable drums,

capstans, bullwheels, shafts and chain drives.

11. Beware of hot surfaces, especially around the engine, engine exhaust pipe and hy-

draulic oil tank.

12.Some component and assembly parts are in excess of 55lb (25kg) . When lifting

care must be taken, ensure sufficient man power/lifting gear is available, to prevent personal injury and damage to the machine.

13.Beware of exposed electrical contacts especially around the engine. Do not

touch, or allow metal objects to come into contact.

14. Waste engine and hydraulic oils are to be disposed of via an environmental-

ly acceptable method – e.g. passed on for recycling.

15. Wear ear protection when engine is running to prevent ear damage.

16. Machine may cause additional fire hazard if involved in an existing fire due to gaso-

line, diesel, oil and hydraulic oils involved.

17. No personnel are to be in manholes or ducts when the winch is being operated.

18. The machine must be operated on firm ground.

19. Stay clear of cables or lines under tension.

20. Only use the machine for its intended purpose.

21. Do not tamper with pressure relief valves or pressure reducing valves.

22. Rear stabilizing props must be down and on solid surface before use.

Page 5 of 24

General Machine Products Co., Inc.

3.0 GENERAL DESCRIPTION

The GMP SideWinder is a trailer mounted pull and assist capstan winch,

mounted on a sturdy all-steel fabricated chassis. It is equipped with torsional

suspension axles, stabilizing prop legs, a front telescopic jockey wheel and a

tow bar with a Lunette Ring. The unit is easily pulled by a standard pickup

truck.

The power source is a gasoline engine which drives the fixed displacement

tandem mounted hydraulic pumps. The hydraulic pump is attached to the engine via a bell housing and flexible coupling. One pump powers a hydraulic

motor, through an in-line planetary gearbox, to the capstan. The second pump

drives the rope take-up drum again through a hydraulic motor.

The hydraulic oil tank is fitted with double filtration protection, sight glass and

filler/breather.

Controls are operator friendly and very simple to use. A spring centered lever

controls the direction of rotation of the capstan, while a detented lever engages the take-up drum drive. A control knob is used to limit the rope/cable tension using the panel mounted tension indicator.

The rope take-up drum is removable and can be split to enable removal of

rope. The capstan can be rotated through 90° on a swivel bracket from the inline working position to the transverse transit position when in tow.

When the winch is in the working mode the rear props are extended out of the

chassis to provide greater stability.

Page 6 of 24

General Machine Products Co., Inc.

4.0 SPECIFICATION

Max. Pulling Capacity 1100 lbs (500 kg)

Rope Speed Max. 200 ft/min (60 m/min)

Capstan Diameter 32” (813 mm)

Dimensions: Length: 123” (3124 mm)

Overall Width: 69” (1753 mm)

Height: 57” (1450 mm)

Weight: 1400 lbs. (635 kg)

Track: 60” (1676 mm)

Coupling: Lunette Ring (Pintle hook)

Power Supply: Honda GX390 13 HP, Recoil Start, Overhead Valve, Cast Iron

Load Indication: Calibrated gauge bezel

Main Drive: Fixed displacement tandem pumps to fixed displacement high

Gear Box: In-line planetary gearbox (capstan drive)

Gear Oil Grades: MobileLube HD Plus 85W-140

Controls: (a) Pay-in / pay-out spring centered control valve.

(see section 8) (b) Detented take-up drum drive control valve.

(c) Tension control knob

(d) Tension indicator

Hydraulic Circuit: Closed circuit system with full filtration and overload protection

Hydraulic Oil Tank Capacity: 16.5 Gal. (63 Liters)

Hydraulic Oil Grade: Tellus T-32

Tire Size: F78-14 205/75D14

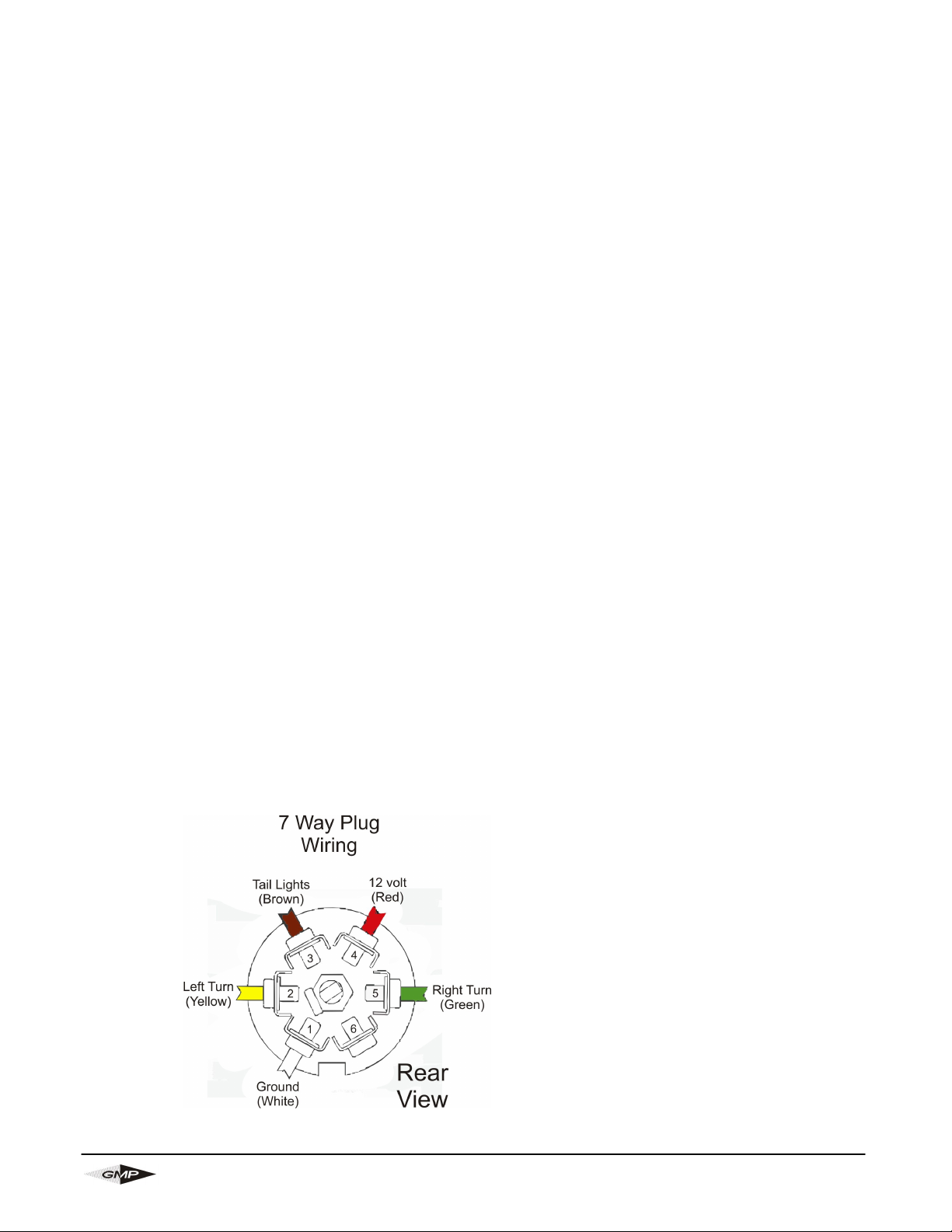

Lighting Adapter: 7-Way (others available by request)

Cylinder Sleeve, 1.5 Gallon tank

torque motors.

Refer to the instruction manual supplied with the gearbox for

alternative oil types and grades

Page 7 of 24

General Machine Products Co., Inc.

5.0 OPERATING PROCEDURE

IT IS IMPERATIVE THAT ALL PERSONS USING, OPERATING OR MAINTAINING

THIS WINCH BE FULLY TRAINED AND COMPETENT TO DO SO, AND HAVE

READ THE ENTIRE OPERATING MANUAL.

GMP CANNOT BE HELD RESPONSIBLE FOR MIS-USE OF THIS EQUIPMENT.

5.1 CONTROLS

The operator controls have been designed to be safe and simple to use, with regard to

ergonomic considerations. The operators control station is complete with the following:

(see section 8)

(a) Control lever for winching in and paying out. This provides bi-directional selection of

capstan rotation. The valve spool has a soft start facility allowing for a limited creep

and inching movement.

(b) Control lever for operation of the rear take-up drum. This lever should be in its oper-

ating position before operating the capstan. If the winch is not being used, this lever

should be returned to its non-operating position, thus saving on fuel and preventing

the hydraulic oil from overheating.

(c) Tension control knob. This can be used to limit the actual pulling tension applied to

the capstan.

(d) Pressure gauge which is also an indication of the pulling tension.

5.2 PRE-WINCHING PROCEDURE

Prior to using the winch for any hauling application, it is important to ensure that the

rear prop legs are extended and lowered in order to level the winch, and that the

front jockey wheel is also lowered to a position where the winch is firm and stable.

The winch should be securely anchored to either a suitable vehicle, ground anchors

or other substantial holding point. The winch should be in line with the direction of

pull.

Refer to the pre-winching maintenance checks in section 6.1.

The capstan must be rotated from the “Transverse” transit position to the In-Line

working position. Ensure that the retaining pin and hair-pin are correctly replaced.

It may be necessary to remove the lighting board. This is accomplished by first

un-plugging the connector from the rear jack on the trailer, and then pulling the

spring loaded release pins. The complete lighting board can then be removed

and stored safely.

Page 8 of 24

General Machine Products Co., Inc.

Loading...

Loading...