General Machine Products Co.

3111 Old Lincoln Highway

Tel:

Fax: +1.215.357.6216

Email: info@GMPtools.com

Web: www.GMPtools.com

+1.215.357.5500

· Trevose, PA 19053-4996 USA

Installation, Operation and Maintenance Manual for

the Adams® Model CD Lite Continuous Duty Winch

manufactured by General Machine Products Co., Inc.

Scope

This document contains information pertinent to the Installation, Operation and Maintenance of the Adams® model CD Lite - Continuous Duty Winch. Such winches as manufactured by General Machine

Products Co., Inc. commencing in June 1, 1995 were significantly different from the larger Adams model

CD Winches in their equipment design and components. To obtain information on heavy duty models

CD, LCD or UG winches, please contact the factory for the appropriate manual.

Section Contents Page

1 General Information 1

2 Precautions 4

3 Installation 6

4 Pre-operational Checks 16

5 Operating Instructions 17

6 Maintenance 18

7 Replacement Parts 20

1.01 GENERAL - The information contained in this revision pertains exclusively to the Adams®

Model CD Lite Continuous Duty Winches manufactured after June 1, 1995 which have serial numbers

of 95-8000 and higher.

The CD Lite winch has been specifically designed for placing innerduct, fiber optic, coaxial and other

types of communications media where typical pulling forces are not expected to exceed 2000 lbs. (8.9

kN). However, its robust construction and SAE Continuous Duty rating makes the CD Lite suitable for

most applications where a long, continuous pull is required. In its typical automotive application the

winch is driven hydraulically - for mobile mounting, using the truck engine as the prime source of

power, through a split shaft or side mount power take-off, coupled to a hydraulic pump, driving a hydraulic motor that is mounted to the full load brake, which is assembled directly onto the gearbox.

1.02 WINCH MAJOR COMPONENTS

• Gearbox

• Wire Rope Drum

• Drum Guard

• Clutch Assembly

• Free Spool Control Brake

• Level Wind Assembly

• Full Load Brake

• Hydraulic Motor

• Hanger

• Mounting Brackets

• Drum Shaft Extension (available option)

Page 1

1.03 WINCH CLUTCH GENERAL INFORMATION

The clutch provides a means of transferring the torque from the drum shaft to the winch drum. When

the winch clutch is disengaged, the drum will rotate freely on the drum shaft. Power can still be transmitted through the drum shaft to the optional drum shaft extension to drive a capstan or reel, if so

equipped, while the clutch is disengaged. An air shift mechanism actuates the clutch plate in and out.

To help ascertain clutch engagement or disengagement, clutch position sensing is a standard feature.

The clutch plate position is sensed at the end of the stroke of the air cylinder actuating the clutch plate.

1.04 CALIPER TYPE, FREE SPOOL CONTROL (DRAG) BRAKE

Under rapid winch line payout conditions, it is extremely important to operate the caliper brake properly, maintaining sufficient tension on the wire rope. This will enable the level-wind assembly to operate properly, minimize over-spinning of the drum, and help to prevent erratic lays of winch line on the

drum.

All CD Lite units are factory equipped with a caliper type drag brake assembly. The caliper brake is

controlled by a hydraulic actuator (supplied), and is intended to be mounted with the winch controls.

The purpose of the caliper brake is to control the speed of the winch drum when in the free spool mode.

Movement of the actuator lever will force the brake pads together, reducing the drum speed. Continued

movement of the control lever will eventually force drum rotation to stop.

CAUTION! THE DRAG BRAKE IS USED TO CONTROL THE DRUM SPEED ONLY. IT IS NEVER

TO BE USED TO HOLD THE LOAD.

The brake assembly is mounted at the factory onto a bracket attached to the hanger on the right side of

the winch. The brake disc is mounted at the factory on the clutch end drum flange. The remote actuator, reservoir, and flexible hose section are shipped loose with other winch mounting hardware in the

parts box. These components are to be installed by the dealer.

The closed circuit hydraulic system is shipped void of any fluid. Prior to operation, fill the system with

brake fluid (do not

use hydraulic oil); bleed and replenish with additional fluid as required.

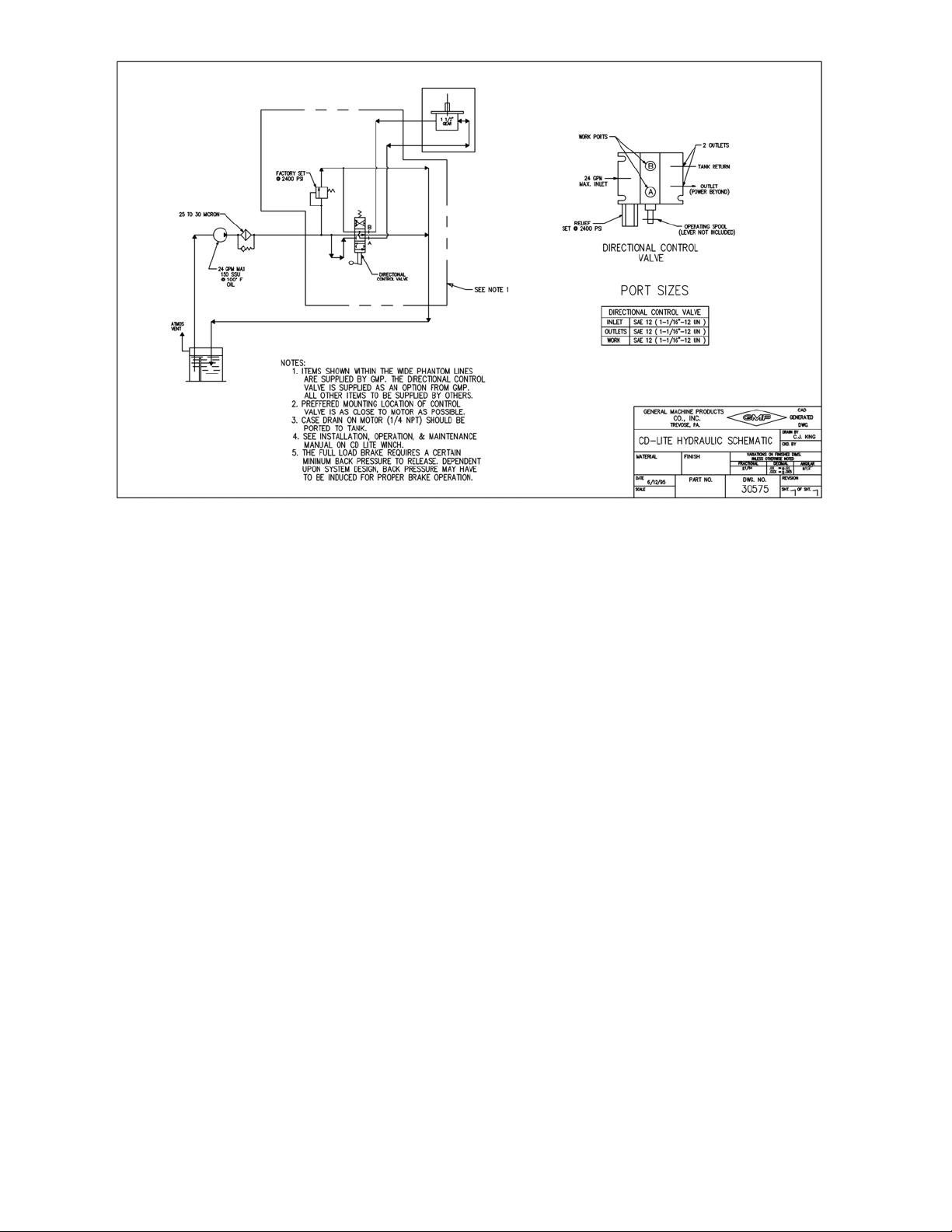

1.05 FULL LOAD BRAKE

The full load brake, which is mounted on the gearbox, is an automatic device designed to hold the rated

load of the winch, up to 7,400 pounds (32.9 kN) on a bare drum.

The full load brake assembly is spring loaded and requires hydraulic pressure to release the brake. The

hydraulic pressure is applied on the piston, which exerts the force on the primary disc, which compresses the springs into the brake housing. When the disc stack (comprising of both rotating and stationary discs) is not compressed, the rotating discs are free to turn and the brake is released. The pressure to release the brake is sensed at the hydraulic motor. The pressure from either side of the motor

can release the brake. This feature enables the winch to pull in as well as power out, i.e. the brake is not

direction sensitive. Hydraulic pressure passes through a cartridge type shuttle valve diverting pressure

to release the brake as well as relieving the pressure on the brake after the system pressure is ported to

the tank.

Page 2

A counterbalance valve is a part of the brake system and helps to increase the responsiveness of the

brake and improve the load control capabilities of the winch. The counterbalance valve and hoses are

shipped loose in the parts box and require mounting and plumbing at the time of the winch installation.

Refer to section 3.05.

1.06 WINCH MOTOR

The winch drive consists of a hydraulic motor with a single 1.75 in. (44 mm) wide gear section. The motor is mounted to the full load brake which in turn is mounted to the gearbox. Therefore, the enclosed

drive requires no maintenance of a silent chain drive. For more information on speed and pull values

please refer to the specification sheet.

There is a case drain on the motor with a

1

/4 NPT fitting and it should be connected to tank. For more

information see section 3.02 Hydraulic Requirements.

The control valve is a necessary component of the winch drive, however, the control valve must be ordered as a separate item from the winch, either from the factory or from the installing dealer.

The specifications for the control valve are as follows:

• open center design

• internal relief valve set at 2500 psi (17237 kPa)

• sized for 30 gpm (114 l/min.) maximum winch flow rating with minimal pressure drop

• spool must be of the self-centering design

A control valve that meets all the requirements for compatibility is available as a purchased option from

GMP as part number 70611. The open center control valve has the ability to be used in a ʺpower be-

yondʺ function.

There are several optional methods to control the control valve remotely. Contact the factory for more

specific information.

1.07 LEVELWIND MECHANISM

The levelwind assembly is a scaled-down version of the Adams rope winder and is a familiar sight on

Adams CD winches. The levelwind distributes the wire rope onto the drum with taut, even lays. The

tight, compact layers help to extend wire rope life by eliminating the upper layers from pulling down

into lower layers. The strain and damage to the wire rope from this action can lead to premature wire

rope failure. The levelwind also helps in maximizing the drum storage capacity. The even and compact

layers allow for more efficient wire rope storage.

The levelwind mechanism is designed in the underwind configuration and is mounted at the factory.

1.08 ACCESSORIES

The drum shaft extension is a factory option that affords a 2

diameter coupled to the winch drum shaft and extending outward through an outboard hanger bearing

7

/16 inch (62 mm) Bell System standard shaft

Page 3

to the curb side of the vehicle and is mounted on the winch drum shaft by means of a coupling secured

by self-locking nuts. Designed with the conventional bayonet type of connection, it is suitable for driving a reel or capstan. To mount a device onto the shaft extension, slide the device spindle over the shaft

extension, push all the way in, turn counter clockwise and pull out into the locked position.

The drum shaft extension projects from the right side of the winch only, the required shaft length is determined by the width of the body.

The maximum allowable pull on the drum shaft extension for a typical 94 in. (2.38m) wide truck body is

2000 pounds (8.9 kN) using a standard 7 in. (18 cm) diameter capstan (GMP P/N 10727). Allowable

pulls will be less when using a larger diameter pulling surface.

For additional versatility, the drum shaft extension can be an ideal means to drive the P/N 15472 Torque

Limiting Capstan to place fiber optic or coaxial cable. A wide range of capstans and reels are available

from GMP.

2. PRECAUTIONS

2.01 Observe the following precautions when operating the winch:

CAUTION! THE WINCH WAS NOT DESIGNED FOR, NOR INTENDED TO BE USED FOR THE

MOVEMENT OF PEOPLE.

CAUTION! THE DRAG BRAKE IS USED TO CONTROL THE DRUM SPEED ONLY. IT IS NEVER

TO BE USED TO HOLD THE LOAD.

CAUTION! SHIFTING OF THE CLUTCH SHOULD ONLY BE DONE WHEN THE DRUM ROTA-

TION HAS STOPPED.

As required by OSHA, it is imperative, and the responsibility of the employer, to properly instruct the

winch operator and the crew relative to the safe working capabilities and operational limitations of the

winch, its accessories and especially the winch controls. The operator should never leave his position at

the controls while the winch is in operation or the winch line is under load.

Maintain complete coordination with other members of the crew, giving clear instruction by hand signal

or radio communication.

Stand clear of loads suspended by the winch line. Do not stand inside of angles formed by the winch

line. As much as possible, do not stand where there is the danger of being struck by the wire rope if it

should fail or snag. Never place hands on a moving winch line. Always stand clear of moving winch

line. When working around the winch, wire rope and the tail sheave, do not wear loose fitting clothing

that may become entangled with moving parts and cause possible serious injury.

Operate the winch as smoothly as possible. Sudden jerking pulls can place extreme loads on equipment,

causing damage or injury. Make certain that the wire rope is properly attached to the drum and that no

less than one half of the first lay remains on the drum at all times. Make certain that the eye at the end

Page 4

of the winch line is properly spliced or swaged. Wire rope (winch line) may be old, damaged or weakened by such defects as kinks, cuts, extreme bends or loops. Such conditions are potentially dangerous

and detrimental to safe operation of the winch. The wire rope must be routinely inspected at regular

intervals and replaced when worn. See Maintenance Section 6.01 for replacement criteria.

Loads on the winch, winch line or extension shaft should not exceed their rated capacity.

Make certain that the winch clutch is positively engaged before starting the pull.

Do not operate the winch at speeds faster than necessary.

When pulling in, do not allow the wire rope to build up in one location on the drum. This can cause

wire rope ʺroll-overʺ and possible erratic, damaging pulls.

Page 5

3. INSTALLATION

3.01 GENERAL

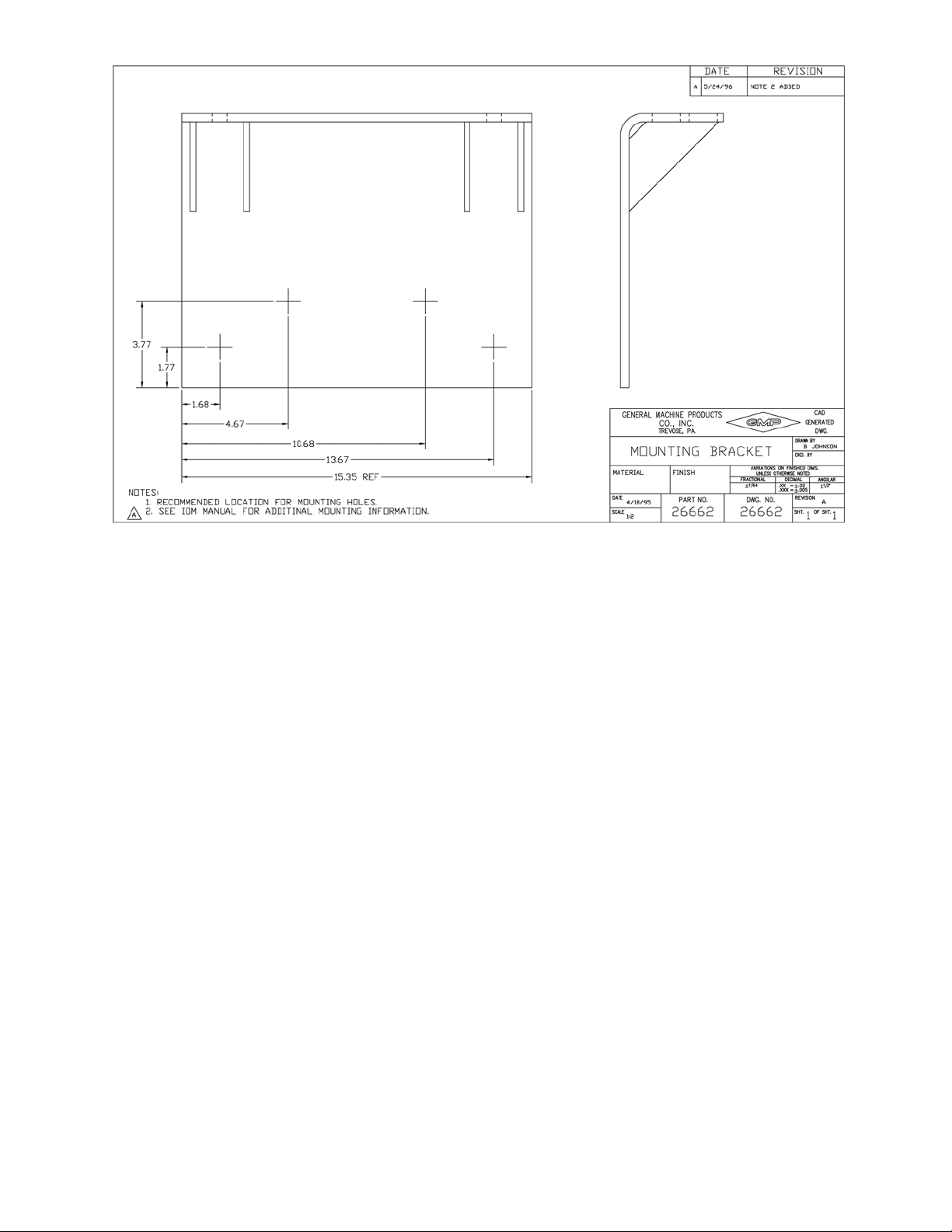

For typical automotive applications, the winch is normally mounted behind the chassis cab in the forward section of the body load area, directly to the chassis frame. Two steel mounting brackets are furnished with each winch.

Sufficient clearance should be allowed between the front body panel or other restrictive members and

the winch to permit normal maintenance.

For standard installations, orient the winch assembly on the chassis frame so that the level-wind is facing rearward and the drum shaft is projecting toward the right (curb) side as viewed from the rear of the

vehicle looking forward.

The CD Lite is designed in an underwind configuration, that is, the direction of drum rotation for pulling in is counter-clockwise when viewed from the right side of the vehicle. The wire rope is wound

onto the drum from the bottom.

The SAE rated mounting brackets supplied with the Adams® Model CD Lite Continuous Duty Winch

are of a ʺbolt-onʺ design with no welding required. First, the winch must be positioned on the truck

chassis with the center line of the drum upon the center line of the chassis. Attach the mounting brackets to the bottom of the winch frame on each side using the quantity eight (8)

bolts with disc spring washers. Finger tighten only until the remaining fastners are installed.

Clamp the mounting brackets to each side of the truck chassis.

- The following procedures are recommended to assure trouble-free operation:

5

/8 - 11 HHCS grade 8

Page 6

Refer to drawing 26662 for recommended mounting hole locations. The factory does not supply mounting fasteners to attach the winch mounting brackets to the vehicle chassis. Recommended fasteners are

four (4)

per winch installation. Using a drill diameter

1

/2 - 20 HHCS grade 8 bolts per each of the two mounting brackets for a total of eight fasteners

1

/32 in. greater than the nominal bolt diameter, drill a clearance hole through the mounting brackets and through the truck chassis. After the clearance diameter is

drilled, install the recommended fasteners into each hole and hand tighten with a lock washer and nut.

When using Huckbolt® fasteners drill the mounting brackets and truck chassis with the manufacturerʹs

recommended clearance drill.

When all of the bolts, lock washers, and nuts are in place, torque to the appropriate values for the fasteners used to mount the brackets to the chassis then torque to 160 - 180 ft.-lbs. (217 - 244 N·m) all eight

5

(8)

/8 - 11 HHCS grade 8 bolts.

It is recommended that the winch be directly mounted only to the truck chassis frame. It is not recommended to mount the winch to any other structural member, as on a sub-frame, without first contacting

the factory for specific application engineering support.

CAUTION! DO NOT WELD THE MOUNTING BRACKETS TO THE CHASSIS FRAME.

All of the mounting hardware (and the drum shaft extension if so equipped) is shipped in a parts box

attached to the winch or shipping crate.

IMPORTANT! To avoid corrosion problems when storing winches outside the parts boxes MUST be

removed and stored in an indoor area.

To protect the entire winch assembly against corrosion, various parts are sprayed with a corrosion inhibitor and the gearbox is filled with oil when shipped from the factory.

IMPORTANT! If the winch will be placed in outdoor inventory for an indefinite period, care should be

taken to prevent oil contamination or corrosion due to condensation.

IMPORTANT! BEFORE THE WINCH IS ACTUATED, THE ʺFULL LOAD BRAKEʺ MUST BE BLED.

See the instructions in Section 3.05 under the heading for ʺFULL LOAD BRAKEʺ.

CONTROLS - When the winch has been mounted, consideration must be given to the control of:

• Drum direction of rotation

• Drum speed

• Winch clutch control

• Drag brake caliper/actuator

A word on winch controls. The CD Lite may be ordered in one of three configurations: 1. Without controls for situations where the dealer is responsible for furnishing controls in conformance with Adams

CD Lite specifications and the customers requirements; 2. With an optional, manual control valve furnished by the factory and; 3. With an optional, remote fiber optic pendant control package furnished by

the factory.

Page 7

The control valve available from the factory as an option for the CD Lite winch has been selected specifically for this application. The internal piloted relief valve is pre-set at the factory, and needs no field adjustment. The porting on the control valve was selected to minimize the amount of reducing fittings

needed. The spool is spring loaded in both directions so when the operator releases the lever or handle

(not provided), the spool automatically centers and stops the flow of oil out of the work ports. There is

a ʺpower beyondʺ port on the valve for additional valves downstream.

The fiber optic pendant control allows the operator to be tethered to the vehicle via a fiber optic cord to

operate the winch by remote control. The system has been engineered and designed to provide a holistic approach to the design problem.

The system consists of a pressure generating valve, directional control valve with back cap, transmitter

with joystick, receiver and cabling. The joystick on the transmitter allows the operator to choose the direction and speed of the winch drum rotation. The fiber optic cable connects the transmitter and receiver. The fiber optic cable, being non-conductive, helps electrically isolate the operator from unintended electrical contact. The receiver accepts the signal from the transmitter and sends a digital signal

to the stepper motor in the back cap on the control valve. The control valve has all the features mentioned in the above section, plus the spool is positioned by the stepper motor. There are preprogrammed values (non- field adjustable) in the receiver for deadband position, ramps up and down

and flow adjustment. The values have been optimized for use with the CD Lite winch.

3.02 HYDRAULIC REQUIREMENTS

To obtain the maximum rated pull and line speed using the hydraulic motor supplied with the CD Lite,

the hydraulic system shall have a rated flow of 30 GPM (114 l/min.) maximum. Hydraulic system pressure shall be limited by a relief valve with a maximum setting of 2500 psi (17237

recommended hydraulic oil reservoir capacity is 60 gallons (227 l) of petroleum-based hydraulic fluid.

Recommended hydraulic line diameters are

3

/4 in. (19 mm) for: Pump to control valve; Control valve to

kPa). The minimum

Page 8

Loading...

Loading...