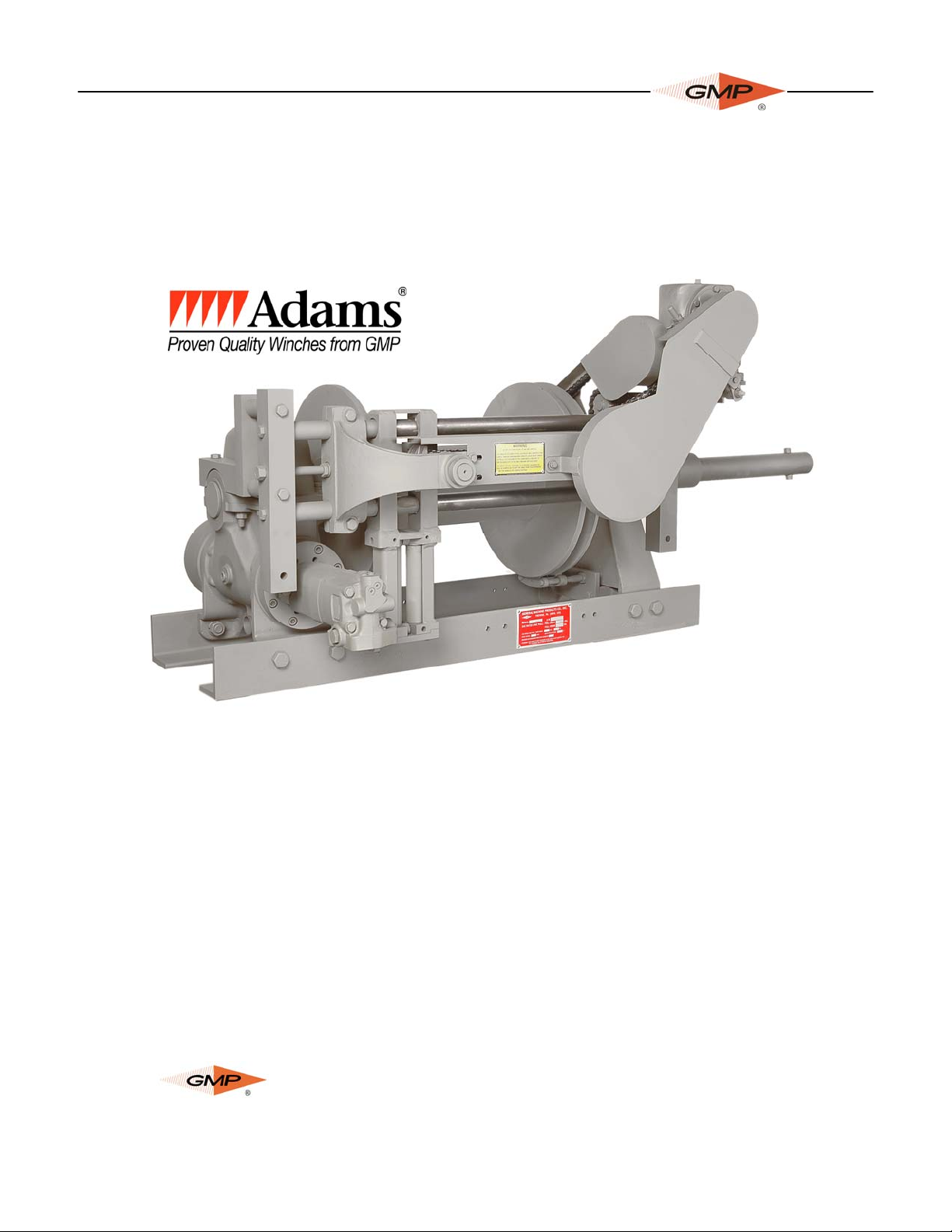

Adams Model WG Worm Gear Winch

INSTALLATION, OPERATION & MAINTENANCE

P/N 70530

WG INTERMITTENT DUTY WINCH

Copyright 2012 by General Machine Products Co., Inc

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form

whatsoever without the written permission of

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: www.gmptools.com

General Machine Products Co., Inc.

Page 1 of 28

www.gmptools.com

June 12 2012 USA Ver 6

Manual P/N 32194

TABLE OF CONTENTS

SCOPE ........................................................................................................................................ 3

1.00 GENERAL....................................................................................................................... 3

1.01 WINCH APPLICATION.................................................................................................... 3

1.02 WINCH MAJOR COMPONENTS .................................................................................... 3

1.03 WINCH CLUTCH GENERAL INFORMATION................................................................. 3

1.04 CALIPER TYPE, FREE SPOOL CONTROL (DRAG) BRAKE ........................................ 3

1.05 FULL LOAD BRAKE ........................................................................................................ 4

1.06 2 SPEED HYDRAULIC MOTOR .....................................................................................4

1.07 LEVEL WIND MECHANISM ............................................................................................ 4

1.08 ACCESSORIES ............................................................................................................... 4

2.00 IMPORTANT PRECAUTIONS......................................................................................... 5

3.00 INSTALLATION ...............................................................................................................6

3.01 GENERAL........................................................................................................................ 6

3.02 HYDRAULIC REQUIREMENTS ...................................................................................... 7

3.03 WINCH CLUTCH ............................................................................................................. 8

3.031 OPTIONAL CLUTCH POSITION SENSING.................................................................... 8

3.04 CALIPER TYPE DRAG BRAKE ...................................................................................... 9

3.041 GENERAL GUIDELINES................................................................................................. 9

3.042 CALIPER BRAKE ASSEMBLY...................................................................................... 10

3.043 RESERVOIR AND ACTUATOR .................................................................................... 10

3.05 WIRE ROPE INSTALLATION........................................................................................ 11

3.06 WINCH DRUM DIRECTION OF ROTATION ................................................................12

3.07 WINCH IDENTIFICATION ............................................................................................. 12

4.01 PRE-OPERATIONAL CHECKS..................................................................................... 12

4.02 WINCH BREAK-IN......................................................................................................... 13

5.00 WINCH OPERATION..................................................................................................... 13

5.01 EXTENSION SHAFT OPERATION ............................................................................... 13

6.00 MAINTENANCE............................................................................................................. 14

6.01 GENERAL...................................................................................................................... 14

6.02 LUBRICATION............................................................................................................... 15

6.03 WINCH IDENTIFICATION ............................................................................................. 16

6.04 CALIPER BRAKE ..........................................................................................................16

7.01 LEVEL WIND INTRODUCTION ................................................................................... 17

7.02 LEVEL WIND DESCRIPTION ....................................................................................... 17

7.03 WIRE ROPE INITIAL INSTALLATION ..........................................................................17

7.04 LEVEL WIND ADJUSTMENT........................................................................................ 18

7.05 LEVEL WIND LUBRICATION........................................................................................ 18

7.06 LEVEL WIND SPOOLING .............................................................................................18

7.07 INSTALLATION OF WIRE ROPE IN USE..................................................................... 18

7.08 WIRE ROPE LUBRICATION ......................................................................................... 18

DETAILS OF AIR SHIFT CLUTCH & CALIPER BRAKE............................................... 19

2 SPEED MOTOR CONTROL SCHEMATIC DWG. 28824 .......................................... 20

AIR SHIFT CLUTCH ELECTRICAL CONTROL SCHEMATIC DWG. 25687................ 21

AIR SHIFT CLUTCH PNEUMATIC CONTROL SCHEMATIC DWG. 25686.................22

AIR SHIFT CLUTCH WITH SENSORS WIRING DIAGRAM 25777 .............................23

COMPLETE WG WINCH DIMENSIONAL DRAWING .................................................. 24

MODEL WG WINCH SPECIFICATIONS....................................................................... 25

WARRANTY .................................................................................................................. 26

Page 2 of 28

www.gmptools.com

SCOPE - This document contains information pertinent to the Installation, Operation and Maintenance of the Ad-

ams® Model WG Worm Gear Winch. The WG winch manufactured by General Machine Products Co., Inc. commencing in January 1, 2005 differ significantly from prior generations of Adams Winches in equipment design and

components. To obtain information on earlier model CD, LCD or UG winches, please see our website at

www.gmptools.com.

1.00 GENERAL - The information contained in this revision pertains exclusively to the Adams

®

Model WG

Winches manufactured after January 1, 2005 which have serial numbers of 05-3000 and higher.

1.01 WINCH APPLICATION - The winch has been specifically designed for placing communication cable and

electrical conductors. However, its robust construction makes the WG suitable for most applications where an

intermittent pull is required. Worm gear winches are designed and intended for intermittent duty application only;

using them in extremely long pulls may generate excessive heat and shorten the life of the winch.

CAUTION -THE WINCH WAS NOT DESIGNED FOR, NOR INTENDED TO BE USED FOR THE MOVEMENT OF PEOPLE. NEVER USE THE WINCH FOR MOVING PEOPLE.

In the typical automotive application, the winch is driven hydraulically. The truck engine provides the prime

source of power connected through a split shaft or side mount power take-off to a hydraulic pump. The pump provides hydraulic pressure and flow sufficient to drive the winch hydraulic motor that is coupled to the worm gear

and load holding brake. The load holding brake and motor are coupled directly to the winch gear box.

1.02 WINCH MAJOR COMPONENTS

● Gearbox ● Full Load Holding Brake

● Wire Rope Drum ● 2 Speed Hydraulic Motor

● Clutch Assembly ● Hanger

● Free Spool Control Brake ● Drum Shaft Extension

● Level Wind Assembly

1.03 WINCH CLUTCH GENERAL INFORMATION - The clutch provides a means of transferring the torque

from the drum shaft to the winch drum. The clutch plate is actuated by an air cylinder. When the winch clutch is

disengaged, the drum will rotate freely on the drum shaft. Power can still be transmitted through the drum shaft

to the drum shaft extension to drive a capstan or reel while the clutch is disengaged. To help determine clutch

position, engaged or disengaged, electronic clutch position sensing is an available option. See section 3.03.

1.04 CALIPER TYPE, FREE SPOOL CONTROL (DRAG) BRAKE - Under rapid winch line payout conditions,

it is extremely important to operate the caliper brake properly, taking care to maintain sufficient tension on the

wire rope. This will enable the level-wind assembly to operate properly, minimize over-spinning of the drum, and

help to prevent erratic lays of winch line on the drum.

All WG units are factory equipped with a caliper type drag brake assembly. The caliper brake is controlled by a

hydraulic actuator (supplied) that is intended to be mounted with the winch controls.

The purpose of the caliper brake is to control the speed of the winch drum when in the free spool mode. Movement of the actuator lever will force the brake pads together, applying friction to the drum brake rotor thereby re-

ducing the drum speed. Continued movement of the control lever will eventually force drum rotation to

stop.

CAUTION THE DRAG BRAKE IS USED TO CONTROL THE DRUM SPEED IN FREE SPOOL ONLY.

IT IS NEVER TO BE USED TO HOLD THE LOAD.

The brake assembly is mounted at the factory on two studs attached to the hanger on the right side of the winch.

The brake disc rotor is mounted at the factory on the clutch end drum flange.

Page 3 of 28

www.gmptools.com

The remote actuator, reservoir, and flexible hose section are shipped loose with other winch hardware in the parts

box. These components are to be installed by the dealer or truck body builder. The closed circuit hydraulic system is shipped void of any fluid. Prior to operation, fill the system with only the exact type of fluid that was origi-

nally specified for your winch. This will be so designated on the caliper brake components and will be brake fluid

only on specific units or hydraulic oil only on specific units. Bleed and replenish with additional fluid of the correct

formulation, as required. Refer to section 3.04 of this manual.

1.05 ADJUSTABLE MULTIPLE DISC LOAD HOLDING OIL BRAKE - The load holding brake, which is

mounted on the gearbox, is an automatic device designed to hold the rated load of the winch, 20,000 lbs. (89 kN),

on a bare drum. The load holding brake is designed to release when the winch drum is rotating in the pull direction. The brake automatically engages when the winch drum rotates in reverse or payout direction. In order to relax the tension in the pulling line a small amount of reverse power is necessary. The load holding brake is factory

set and should be tightened only to the amount necessary to maintain desired tension on the pulling line.

The WG winch is equipped with an adjustable multiple disc oil

brake. This style of brake can be adjusted by turning hex adjuster counter-clockwise to increase brake and clockwise to

decrease brake.

In general, worm brakes on WG winches should only be

adjusted enough to hold the load you are currently working

with. Over adjustment will result in excessive heat

generation and brake wear.

Full Load Brake

1.06 2-SPEED MOTOR - The WG winch comes equipped with a 2-speed motor. The WG winch defaults to low

speed and can be shifted into high speed mode requiring a pilot pressure of 100 PSI to 150 PSI. The pilot pressure should come from a tee in the line from the hydraulic pump and the directional control valve via a twoposition, three-way selector valve which can be either manually or solenoid operated. For more information on

speed and pull values, please refer to the specification sheet on page 24.

There is a case drain on the motor with a 7/16-20 o-ring port and it MUST be connected to the tank using a

separate dedicated hydraulic line. For more information, see section 3.02 Hydraulic Requirements on page 7.

1.07 LEVEL WIND MECHANISM - The levelwind assembly is a derivative of Bell System specification 8414

and is a familiar sight on other Adams winches. The levelwind distributes the wire rope onto the drum with tight,

even lays. The tight, compact layers help to extend wire rope life by eliminating the upper layers from pulling

down into lower layers. The strain and damage to the wire rope from this action can lead to premature wire rope

failure. The levelwind also helps in maximizing the drum storage capacity. The even and compact layers allow for

more efficient wire rope storage.

1.08 ACCESSORIES - The drum shaft extension is an accessory that makes the WG winch even more versa-

tile. The shaft extension has a diameter of 2

7

/16 inch (Bell System standard) and is mounted on the winch drum

shaft by means of a coupling secured by a connecting pin. Designed with the conventional bayonet type of connection, it is ideally suited for driving a power reel or capstan. To mount a device onto the shaft extension, slide

the device spindle over the shaft extension, push all the way in, turn counter clockwise and pull out into the locked

position.

Page 4 of 28

www.gmptools.com

The drum shaft extension projects from the curb side (right) of the winch only. The required shaft length

is determined by the width of the body.

The maximum allowable pull of the standard drum shaft extension is 1,000 pounds (4,7 kN) using a

standard 7 in. (18 cm) diameter capstan (GMP P/N 10727). Allowable pulls will be less when using a

larger diameter accessory and/or using a longer drum shaft extension.

2.00 IMPORTANT PRECAUTIONS

2.01 You must read, understand and observe the following precautions at all times when operating the winch:

CAUTION -THE WINCH WAS NOT DESIGNED FOR, NOR INTENDED TO BE USED FO R

THE MOVEMENT OF PEOPLE. NEVER USE THE WINCH FOR MOVING PEOPLE.

CAUTION -THE DRAG BRAKE IS USED TO CONTROL THE DRUM SPEED IN FREE SPOOL

ONLY.

IT IS NEVER TO BE USED TO HOLD THE LOAD.

CAUTION - SHIFTING OF THE CLUTCH SHOULD ONLY BE DONE WHEN THE DRUM ROTATION HAS STOPPED AND NO TENSION IS ON THE WIRE ROPE.

As required by OSHA, it is imperative, and the responsibility of the employer, to properly instruct the

winch operator and the crew relative to the safe working capabilities and operational limitations of the

winch, its accessories and especially the winch controls. The operator should never leave his posi-

tion at the controls while the winch is in operation or the winch line is under load.

Maintain complete coordination with other members of the crew, giving them clear instructions by hand

signal or reliable radio communication.

Stand clear of loads suspended by the winch line.

Do not stand inside of angles formed by the winch line.

As much as possible, do not stand where there is the danger of being struck by the wire rope if it

should fail or snag.

Never place hands on a moving winch line. Always stand clear of moving winch line.

When working around the winch, wire rope and the tail sheave, do not wear loose fitting clothing that

may become entangled with moving parts and cause possible serious injury.

Make certain that the wire rope is properly attached to the drum and that no less than one-half of the

first lay remains on the drum at all times.

Make certain that the eye at the end of the winch line is properly spliced or swaged.

Precautions continue on next page

Page 5 of 28

www.gmptools.com

Wire rope (winch line) may be old, damaged or weakened by such defects as kinks, cuts, extreme bends

or loops. Such conditions are potentially dangerous and detrimental to safe operation of the winch. The

wire rope must be routinely inspected at regular intervals and replaced when worn. See Maintenance

Section 6.01 on page 15 for replacement criteria.

Make certain that the winch clutch is positively engaged before starting the pull.

Operate the winch as smoothly as possible. Sudden jerking pulls can place extreme loads on equipment,

causing damage or injury.

Do not operate the winch at speeds faster than necessary.

When pulling in, do not allow the wire rope to build up in one location on the drum. This can cause wire

rope "roll-over" and possible erratic, damaging pulls.

Loads on the winch, winch line or extension shaft must not exceed their rated capacity.

3.00 INSTALLATION

3.01 GENERAL - The following procedures are recommended to assure safe, trouble-free operation:

For typical automotive applications, the winch is normally mounted behind the chassis cab in the forward section

of the body load area, directly to the chassis frame.

For standard installations, orient the winch assembly on the chassis frame so that the level-wind is facing rearward and the drum shaft is projecting toward the right (curb) side as viewed from the rear of the vehicle looking

forward. The winch must be positioned on the truck chassis with the centerline of the drum upon the centerline of

the chassis. Sufficient clearance should be allowed between the front body panel or other restrictive members

and the winch to permit normal maintenance.

It is recommended that the winch be directly mounted only to the truck chassis frame. It is not recommended to

mount the winch to any other structural member, as on a sub-frame, without first contacting the factory for specific

application engineering support.

The hydraulic actuator for the caliper drag brake and the drum shaft extension are shipped in a parts box attached

to the winch or shipping crate.

IMPORTANT - To avoid corrosion problems when storing winches outside the parts boxes MUST be removed and

stored in an indoor area.

To protect the entire winch assembly against rust, the winch is prime painted and the drive housing is filled with oil

when shipped from the factory.

IMPORTANT - If the winch will be placed in outdoor inventory for an indefinite period, care should be taken to prevent oil contamination or rusting of internal components due to condensation.

CONTROLS - When the winch has been mounted, consideration must be given to the control of:

● Drum direction of rotation ● Winch clutch control

● Drum speed ● Drag brake caliper/actuator

Because of the wide variation in the type of controls available, it is the responsibility of the dealer to furnish and

install the controls in conformance with the customer's specifications. Proper sizing of each hydraulic component,

and by extension the complete hydraulic system, will avoid potential problems such as overheating, and will provide for economical operation throughout the service life of the system.

Page 6 of 28

www.gmptools.com

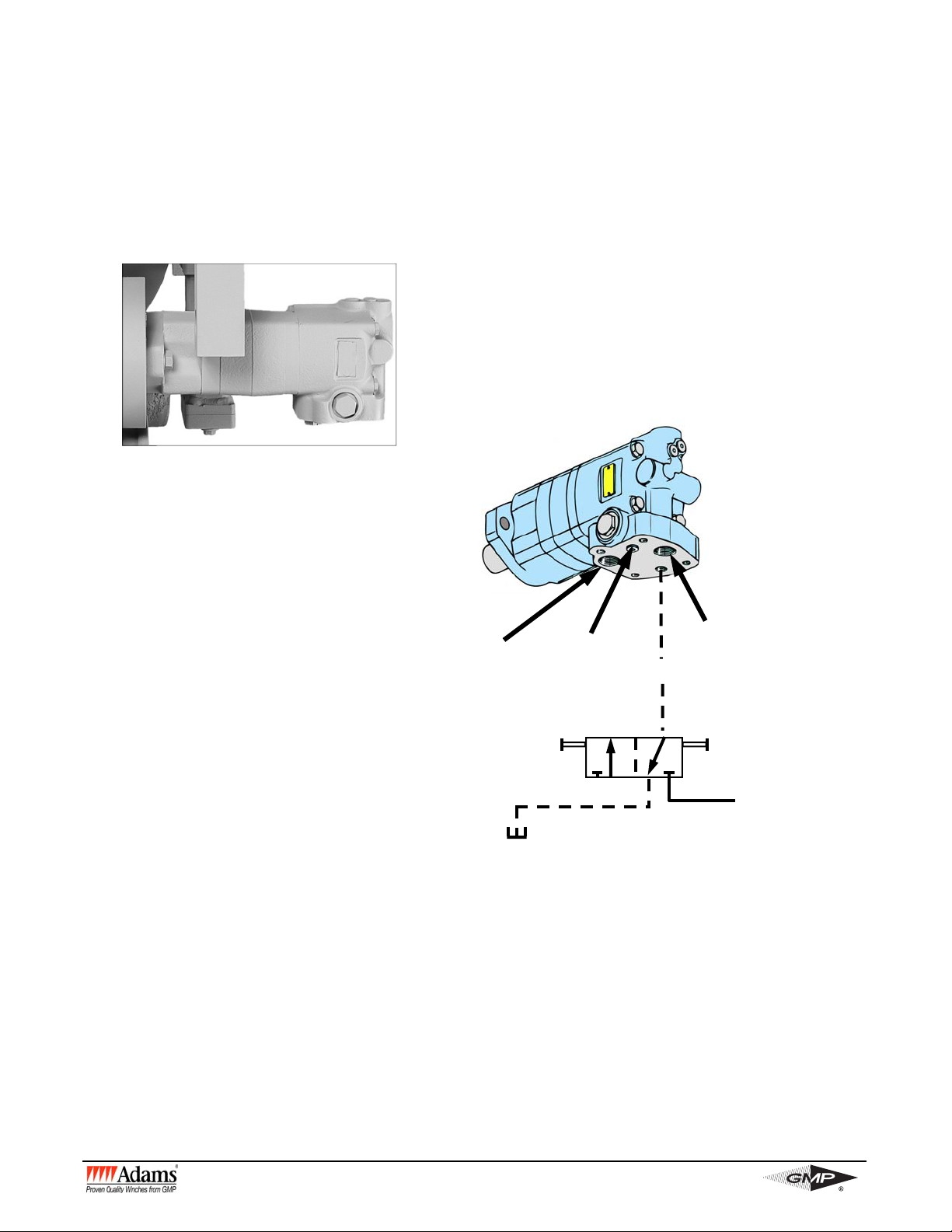

3.02 HYDRAULIC REQUIREMENTS - To obtain the maximum rated pull and line speed using the 2-

speed motor supplied with the WG winch, the hydraulic system shall have a rated flow of 20 GPM (75 l/

min.) maximum. Hydraulic system pressure shall be 1750 psi (12066 kPa) operating with 2000 psi

(13790 kPa) maximum relief valve setting. The recommended hydraulic oil reservoir capacity for the

WG winch is 60 gallons (227 liters) of petroleum-based hydraulic fluid. For additional details and information concerning the 2-speed motor, refer to the illustration below and drawing # 28824 on page 19 of

this manual.

Port B

Two Position 3 Way Valve

Case

Drain

-4 port

Port A

Pilot Port

Pilot Pressure

100 psi min

Page 7 of 28

www.gmptools.com

Recommended hydraulic line diameters are:

● Pump to control valve: 5/8 in. (16 mm)

● Control valve to tank: 5/8 in. (16 mm)

● Control valve through power beyond to hydraulic system: 5/8 in. (16 mm)

● Control valve work ports to hydraulic motor ports: 5/8 in. (16 mm)

● Pump to two-position, three-way selector valve for high speed feature: 1/4 in (6.4 mm)

● Two-position, three-way selector valve to pilot control valve for high speed feature: 1/4 in (6.4 mm)

Suggested Filtration, based on the hydraulic motor requirements, is 10 micron (nominal) filters. Consult a filter

supplier for specific filter recommendation.

The hydraulic motor case drain port must be ported to tank using a separate, dedicated

hydraulic line. Failure to do so could result in improper winch operation.

There are two connections from the control valve to the motor ports.

In order for the winch to operate correctly, connect the output from the control valve to port A of the motor, the port

farthest from the winch, and connect the return from the control valve to port B, the port closest to the winch.

Identification of connections from the individual valve ports to the motor ports is shown in drawing # 28824 on

page 19 and the illustration shown on previous page.

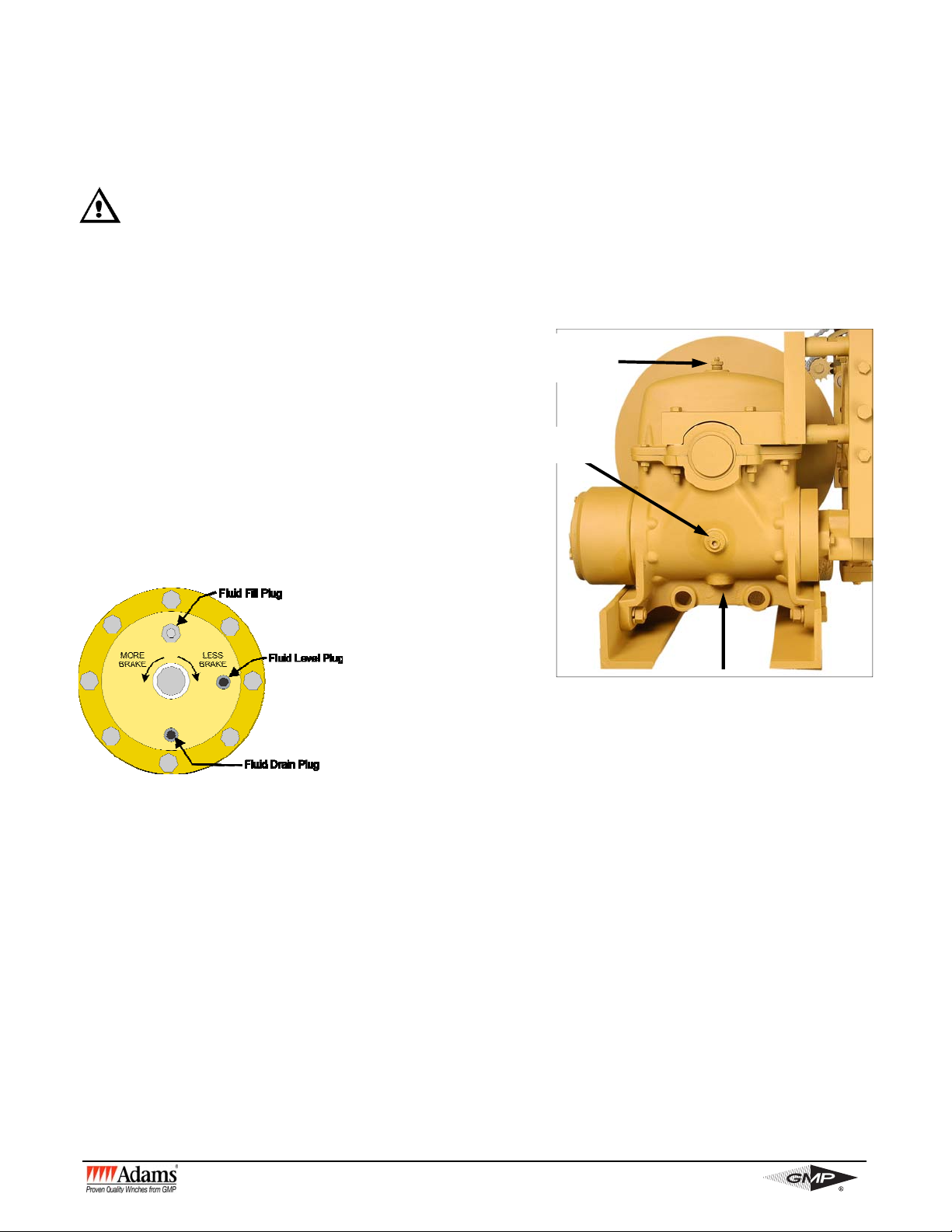

3.03 WINCH CLUTCH - The clutch plate is motivated by an air cylinder assembly that is mounted to the

hanger assembly. A fork is connected to the piston rod in the air cylinder and the fork contains 2 cam followers

which ride in a groove on the clutch plate. The air cylinder is plumbed to a two-position four-way directional control valve. The directional control valve is electrically operated, and is rated for 12 volts DC with a continuous duty

rating of 100%. A regulator is provided for maintaining a normal setting of 30-psi (207 kPa) supply pressure to the

directional control valve. The regulator is equipped with a Schrader valve stem to attach a pressure gauge (not

provided) to monitor input pressure to the cylinder as required.

The regulator has a

plumbed at the factory. At the time of installation, the only connection required is the air supply line to the aforementioned regulator port. Refer to drawing 25686 on page 21.

A terminal strip is provided for the electrical connection to the directional control valve. The terminal strip is located

on the hanger assembly. A two-position switch should be used to energize the solenoids in the directional control

valve. The solenoids control the positioning of the valve spool thereby directing the airflow to the two ports on the

air cylinder. There are three screws on the terminal strip, the center screw is for connection to the ground or common. The other two screws are for the connection to the switch. Each of the two connections from the terminal

strip should lead to one side of the two-position switch. Refer to drawing 25687 on page 20 for additional details.

3.031 OPTIONAL CLUTCH POSITION SENSING

Optional clutch position sensing is available. The electrical output can be wired to a load, such as a coil in a DC

relay, and the switch in the DC relay can control a set of lights to provide the operator with an indication of clutch

engagement or disengagement.

When the clutch position sensing option is ordered, the air cylinder that actuates the clutch is equipped with a

solid-state digital output limit sensor at each end of the cylinder. When the sensor detects the magnetic piston,

the current sinking device completes the circuit by connecting the load to the ground. The sensors are magnetically activated and while they work on the same principle as Hall effect sensors, they are exceedingly sensitive.

The sensors are 100% solid-state devices with no moving parts to wear, break, bounce or stick and they are fully

encapsulated in plastic resin.

The sensors must be wired as per drawing no. 25777 on page 23. Since the sensors detect the magnetic piston

in the air cylinder and not the switch used to activate the directional control valve, even manual actuation of the

clutch is detected by the sensors.

Warning - Reverse wiring will destroy the solid-state electronic components in the sensors.

1

/8 in. NPTF port for the incoming air supply. The directional control valve and the cylinder are

Page 8 of 28

www.gmptools.com

3.04 CALIPER TYPE DRAG BRAKE - For reasons of safety and convenience, the drag brake is equipped with

a remote actuator. The remote actuator, reservoir and flexible hose section are shipped loose with other winch

mounting hardware in the parts box. These components are to be installed by the dealer.

3.041 GENERAL GUIDELINES - Hydraulic brake components are precision built mechanisms and must be

treated as such. Certain procedures must be followed at the time of installation to ensure their optimum performance, and a few of the more common procedures are listed below:

To properly locate the brake component or brake line, the installer must consider the following:

● Make it convenient for the operator.

● Use the shortest and most protected route.

● Avoid mounting near the engine, exhaust lines, muffler or anywhere that heat may be generated.

NOTE: Excessive heat transferred to the brake fluid may result in damage to the lines or seals.

● Mount the reservoir higher than the brake component to facilitate bleeding.

To properly mount components and brake lines to withstand the most severe vibration and service conditions, the

installer must consider the following:

● Use the right size bolt for the hole and secure with a steel lock washer.

● Secure tubing to frame with proper size tube clamps to avoid possible fractures or fittings loosening and

leaking.

● Use good, factory-flared lengths of steel tubing. Hand-made flares, when used, should be double flared.

Any flash or loose particles must be removed.

● Use flexible brake line between frame and body.

● If tubing passes through frame or firewall, a grommet or some other means should be used to protect line

from chafing.

● Use tubing rated for 1500-psi minimum for the line between the actuator and the caliper brake assembly.

The proper removal of air from the brake system is very important. A common problem occurs when air remains

trapped in the system causing a "spongy" actuator and inadequate braking. The bleeder screw in the brake assembly must be toward the top. The air in the system will always seek the highest level.

To properly bleed system:

1. Be certain that fittings are tight to avoid leaking.

2. Depress the actuator and open up the bleeder screw to allow the air to escape.

3. Re-tighten the bleeder screws and allow the actuator to return.

4. Repeat the cycle until actuator is firm.

5. Make several static brake applications and then repeat the cycle once more.

The closed circuit hydraulic system must not leak. Even the smallest leak could defeat what would otherwise be a

well operating and effective brake system. It could eventually deplete the reservoir and reduce the braking pressure.

To avoid leaks:

● Check connections during the bleeding and static brake processes to be sure they are tight.

● Always re-install new hoses, lines and fittings if they look the least bit questionable.

Page 9 of 28

www.gmptools.com

The importance of cleanliness during installation cannot be over-emphasized.

● Caliper Drag Brakes on Adams Winches may be specified by the customer for brake fluid only or hydraulic oil only. Installation and service personnel must verify which fluid to use for a specific winch, as the two

different fluids are not interchangeable. Always use good, clean, quality fluid that conforms to what is

specified on the brake components.

● Be sure all fittings and seats are clean before making connections.

● Clean the top of the reservoir before removing filler cap.

CAUTION: As a part of routine maintenance, it is recommended that brake hoses and brake

lines be inspected regularly. All damaged or worn parts should be replaced. The reservoir

should be checked for sufficient fluid level and clean fluid added as required.

3.042 CALIPER BRAKE ASSEMBLY - The caliper brake assembly is mounted at the factory on two studs at-

tached to the hanger (steps 1- 4 have already been performed if the brake assembly was mounted at the factory).

1. Screw in brake module assembly (item 7) until a total clearance of approximately .012 in. (0,3 mm) is obtained between the disc and lining.

2. Back off brake module assembly as required to position ports in vertical alignment.

3. Tighten lock screw with 1/8 in. Allen wrench.

4. Move bleeder screw to higher of 2 ports for ease of bleeding (both ports

1

/8 - 27 NPTF).

5. Install hydraulic line from hydraulic actuator in lower port. The line should be rated for 1500-psi minimum.

6. Bleed the system making sure all air is eliminated. Apply hydraulic pressure and check for leaks.

3.043 RESERVOIR AND ACTUATOR - The remote actuator is normally mounted at the rear of the body, under

the tail shelf. Find a location that is safe and convenient to the operator and within sight of the winch operation.

Alternate mounting would be in accordance with end user specifications.

The reservoir should be mounted above, and as close as possible to the inlet fitting of the actuator. Both the inlet

and outlet fittings of the actuator are 1/8 - 27 NPTF

The reservoir should be mounted higher than the caliper brake assembly to facilitate bleeding. The flexible hose

should be connected to the outlet fitting of the actuator.

1. Mount actuator assembly, using four

5

/16 in. diameter bolts, lock washers and locking nuts, as required.

Note: bracket may be used as template for drilling mounting holes.

2. Make necessary hydraulic connections to reservoir and caliper brake.

3. The closed circuit hydraulic system is shipped void of any oil. Fill the system with the correct fluid as

specified on the brake components: Brake Fluid or Hydraulic Oil. Note: Caliper Drag Brakes on Adams

Winches may be specified by the customer for brake fluid only or hydraulic oil only. Installation and ser-

vice personnel must verify which fluid to use for a specific winch, as the two different fluids are not inter-

changeable.

4. Bleed the system making sure all air is removed from the system. Apply hydraulic pressure and check for

leaks. Make several applications to be sure actuator is working properly.

5. After bleeding is complete, check reservoir for sufficient fluid level and add correct type fluid if necessary.

Page 10 of 28

www.gmptools.com

3.05 WIRE ROPE INSTALLATION – When installing the wire rope, observe the following recommendations:

Note: The WG winch is designed to accept 7/16” diameter wire rope only.

It is important to select the correct winch and wire rope for a particular application. Wire rope is specified in terms

of diameter, length, number of strands, number of wires per strand, composition of center core and direction of

lay.

There is a definite advantage in applying wire rope of the proper direction of lay when spooling onto the smooth

surface of the winch drum. Wire rope with an improper lay will permit the coils to spread apart each time the load

is removed. Using wire rope with the proper lay will tend to keep the coils together when tension is removed. The

correct lay will develop tight coils and even layers.

It is important to install the wire rope onto the winch drum with care. Kinking of the rope, caused by the rope taking a spiral shape as a result of an unnatural twist, should be avoided.

When removing wire rope from the reel and spooling onto the winch drum, the reel must be supported on its horizontal axis and free to rotate. Spool the rope onto the drum with the natural bend in the same direction as it

comes off the reel.

If wire rope is received in a coil, it should be unwound with the coil in the vertical plane. Again, spool the rope

onto the winch drum with the natural bend in the same direction as it was on the coil. Reverse bending of the wire

rope should always be avoided or kept to a minimum.

IMPORTANT! WIRE ROPE MUST ALWAYS BE UNDER CONSTANT TENSION WHEN SPOOLING

ONTO THE WINCH DRUM.

When the winch drum is in free spool and only the drum shaft extension is being used with a capstan or reel, pass

the winch line through the tail shelf sheave and hook the pulling eye to a fixed section of the chassis. This will

prevent the rope from unwinding or "clock-springing."

Likewise, when the winch is not in operation, attach the winch line quick hook to a solid member on the tail shelf

and slowly take up the slack. This will best maintain the rope under a slight amount of tension until its next use

and will prevent the rope from unwinding or "clock-springing."

Page 11 of 28

www.gmptools.com

3.06 WINCH DRUM DIRECTION OF ROTATION -

NOTE: The WG winch is only available in an UNDERWIND configuration.

UNDER-WINDING – refers to the winch drum that rotates in a counterclockwise direction (viewing from the right

side) and the wire rope is spooled onto the winch drum at the bottom. Once again, it is imperative that the wire

rope be attached to the correct side of the drum for the specific direction of the lay of the rope given the direction

of drum rotation. When the drum will be underwinding as the wire rope is spooled in, use the rope clamp on the

side of the drum which is opposite of the lay of the wire rope. For example, if using right lay rope on an under-

wind drum attach the wire rope to the left side rope clamp when viewed from the rear of the truck.

The wire rope must be guided and maintained as it is routed forward under the body deck to the winch drum. This

can be done by using a trough or tube with sufficient width at the front section to allow the wire rope to freely traverse the width of the drum. As the wire rope travels to the drum, and depending on the angle of incline combined

with the body cross-member configuration, a floating sheave or roller may be required. Application engineering

assistance is available from the factory.

WARNING - THE CABLE CLAMP ALONE IS NOT DESIGNED TO HOLD THE RATED LOAD. ½ OF THE

FIRST LAYER OF WINCH LINE MUST BE LEFT ON THE DRUM TO ACHIEVE THE RATED LOAD AND

AVOID CABLE CLAMP FAILURE.

3.07 WINCH IDENTIFICATION – Assistance from the manufacturer or dealer is available to help resolve

unique problems. When contacting your local dealer or the factory, the model and serial number of the winch in

question should be specified so that proper assistance can be offered. This information is stamped on a nameplate affixed to the front mounting rail.

4.01 PRE-OPERATIONAL CHECKS

IMPORTANT - BEFORE PLACING THE WINCH IN SERVICE, THE FOLLOWING CHECKS MUST BE

MADE:

● Make certain that the winch assembly is properly secured to the chassis frame.

● The operator must have a complete understanding of all winch functions and the location and operation of

all controls.

● The winch line should be spooled onto the drum under tension with tight, even, coils and lays.

● It is not necessary to have the drum filled with winch line. Additional pulling capability can be obtained by

only installing a slight excess of the maximum length required for the job, while also improving the laying

of winch line on the drum.

● Refer to the operating manual for the vehicle for specific operational instructions on the hydraulic system.

● Check the hydraulic system reservoir to make certain that it is filled to the correct level with the proper

grade of oil.

● Make certain that the reservoir shut-off valve is OPEN.

● Engage the hydraulic pump drive and allow the oil to circulate and warm up for a few minutes before oper-

ating the winch. This is especially important during extremely cold weather.

● Check the hydraulic system for the correct pressure and flow.

● Check all winch and winch accessory gear housings for the correct oil level and grade. See Section 6.02

LUBRICATION.

● Engage the hydraulic pump drive and allow the oil to circulate and warm up for a few minutes before operating the winch. This is particularly important during extremely cold weather.

● Check the operation of the drag brake.

● Check the truck body load area in a triangular section between the tail shelf sheave and both drum

flanges to see that there are no obstructions that could restrict the travel of the winch line or levelwind.

● Make sure the drag brake has been bled to assure positive activation of the brake. See Section 3 for procedures.

● Ensure that no wire rope has run over the drum flanges and off of the drum. If any wire rope has run off of

the winch drum, put the wire rope back onto the winch drum and spool off the loose wraps. The wire rope

should then be rewound onto the winch drum under tension.

Page 12 of 28

www.gmptools.com

4.02 WINCH BREAK-IN

Winches, like any other kind of machinery, require a “break-in” to perform well and to maximize their life. The following guidelines should be used in the break-in of the WG winch.

DO NOT exceed one half rated load or one half rated line speed for the first thirty minutes of operation. This

will insure that the worm and gear have an opportunity to wear in properly. Periodically, check the gearbox for

temperature rises and allow the winch to cool down between pulls.

5.00 WINCH OPERATION

The following procedures must be observed to assure safe and efficient winch operation:

● Refer to operating manual for the vehicle for specific operational instructions on the hydraulic system.

● Check the body load area to make certain there are no tools or equipment to restrict winch line travel or

level wind movement.

● Check the lay of the winch line on the drum and check for uneven build-up of the winch line.

● Check to be certain that the winch clutch is fully engaged. With rotation stopped, place the winch drum

clutch control switch in the desired position for either paying out or winding in.

● Ensure that the caliper brake is not engaged when the clutch is engaged.

● Operate the directional control valve to achieve the desired direction of drum rotation.

● Pull the load steadily and evenly.

● To stop the winch, release the directional control valve lever.

● When free spool operation is required, stop the drum rotation completely, relieve the wire rope tension

and disengage the clutch by moving the control switch to the free spool position.

● Engage the caliper brake to apply pressure according to the amount of braking required to keep the drum

from over-spooling.

● The caliper brake must be used to slow down and gradually stop the winch drum in the free spool operation. This will prevent overrunning of the winch drum that could result in loose wraps, “clock springing” or

wire rope entanglement.

● If the wire rope becomes loose or tangled, it must be spooled off of the winch drum. The wire rope should

then be rewound onto the winch drum under tension.

● It is important to maintain constant tension on the wire rope at all times to prevent the rope from “clockspringing” resulting in loose and or tangled wraps.

● The free end of the wire rope should be stowed by passing the winch line through the tail shelf sheave

and hooking the pulling eye onto a fixed section of the chassis. A slight amount of tension should be

maintained in the winch line to help prevent the formation of loose wraps on the drum.

CAUTION - THE DRAG BRAKE IS USED TO CONTROL THE DRUM SPEED IN FREE SPOOL ONLY. IT

IS NEVER TO BE USED TO HOLD THE LOAD.

● When finished using the winch, stow the free end of the winch line by passing the winch line through the

tail shelf sheave and hooking the pulling eye onto a fixed section of the chassis. A slight amount of tension should be maintained in the winch line to help prevent the formation of loose wraps on the drum.

5.01 Extension Shaft Operation:

● The caliper brake must be engaged to prevent any drum rotation whenever the drum is declutched from

the drum shaft for extension shaft operation.

● The extension shaft must rotate the accessory, i.e. CR power reel, in a counterclockwise direction when

viewed from the curb side of the truck. This is important because when the extension shaft rotates in a

clockwise direction, it will be working against the winch’s load holding brake causing heating and excessive wear. Also, when the extension shaft rotates in a clockwise direction, it may have a tendency to

loosen the wire rope on the drum.

● When finished using the extension shaft, re-engage the clutch and then release the caliper brake.

● Ensure that no wire rope has run over the drum flanges and off of the drum. If any wire rope has run off of

the winch drum, put the wire rope back onto the winch drum and spool off the loose wraps. The wire rope

should then be rewound onto the winch drum under tension.

Page 13 of 28

www.gmptools.com

6.00 MAINTENANCE

6.01 GENERAL - Inspection of the winch and related components should be a continuing procedure. The op-

erator should be constantly alert to detect clues to a potential problem such as unusual noises, excessive oil leakage or overheating. The operator should report immediately any changes in the normal characteristics of the

winch, winch accessory or the hydraulic system.

If the winch has not been used for an extended period of time, inspect the interiors of the drive housing and final

drive housing for water deposits and rust due to the elements or condensation. Particular attention should be

given to any damaged bearings, seals or gaskets. The oil should be checked for contamination, abrasive foreign

particles and lubrication qualities. As required, oil should be added or completely drained and filled.

The wire rope should be inspected visually for kinks, bends, cuts or broken strands while operating. Wire rope

that does not meet OSHA criteria must be replaced.

Depending on the total length of the wire rope versus the length most often used, it is possible that the top lays will

show the most wear. To obtain additional life, subject to the proper conditions, the rope can be rotated end for

end.

WG winch Maintenance Schedule

Regular Service Period (3). Perform at

indicated month or operating hour interval,

whichever comes first (2).

Item

Wire rope

Oil Cups

Roller chains

Guide Bars

Winch Gearbox

Levelwind speed reducer

Caliper brake components

Grease fittings

Full load brake

Inspect (4)

Lubricate (1)

Inspect

Lubricate (5)

Lubricate

Lubricate

Check level

Change

Check level

Change

Inspect

Check level

Lubricate

Check level

Change

Each use

Every

month

Every 3

months or

75 hours of

operation

Every 24

months or

1000 hours

of opera-

tion

(1) Consult wire rope

manufacturer for

lubrication requirements

(2) Log hours of operation to determine proper

maintenance

intervals

(3) Failure to follow this

maintenance schedule

could result in nonwarrantable failures

(4) Wire rope that doesn't meet OSHA criteria

must be replaced

(5) As necessary

Page 14 of 28

www.gmptools.com

The hydraulic system should be checked periodically for:

● Overheating

● Abnormal noise

● Maintaining a clean, sufficient, quantity of hydraulic oil of the proper grade.

● Keeping all connections sufficiently tight to prevent oil leakage and air from entering the system.

● Changing the hydraulic system oil filter at the frequency recommended by the filter manufacturer.

IMPORTANT - THE LOAD HOLDING ABILITY OF THE LOAD HOLDING BRAKE SHOULD BE TESTED

ON A PERIODIC BASIS.

6.02

the overall maintenance program.

The gearbox oil reservoir must be checked and maintained every 75 hours of operation or every 3 months. To

check for the proper oil level, the truck must on level ground. Remove the oil level plug on the side of the gearbox.

A small amount of oil may drip from the oil level hole. If no oil

is visible, remove the oil fill plug/breather on top of the gear

box and add 80W140 oil until the oil level reaches the oil level

hole. Do not overfill! Screw the level plug and filler plug back

into the gearbox.

The gearbox oil should be completely drained and filled with

new oil every 1000 hours of operation or at least every other

year. The drain plug is located on the underside of the gearbox. To drain the gearbox, remove the oil drain plug and

remove the filler plug in the gearbox cover. After the gearbox is

completely drained, reinstall the oil drain plug. Add three (3) U.S.

Quarts (2,8 l) of fresh 80W140 oil as described above and reinstall

filler and level plugs.

GEARBOX LUBRICATION - An ongoing routine for assuring proper lubrication should be a part of

Oil fill

Plug/Breather

Oil Level Plug

Full Load Brake Cover

Oil Drain Plug

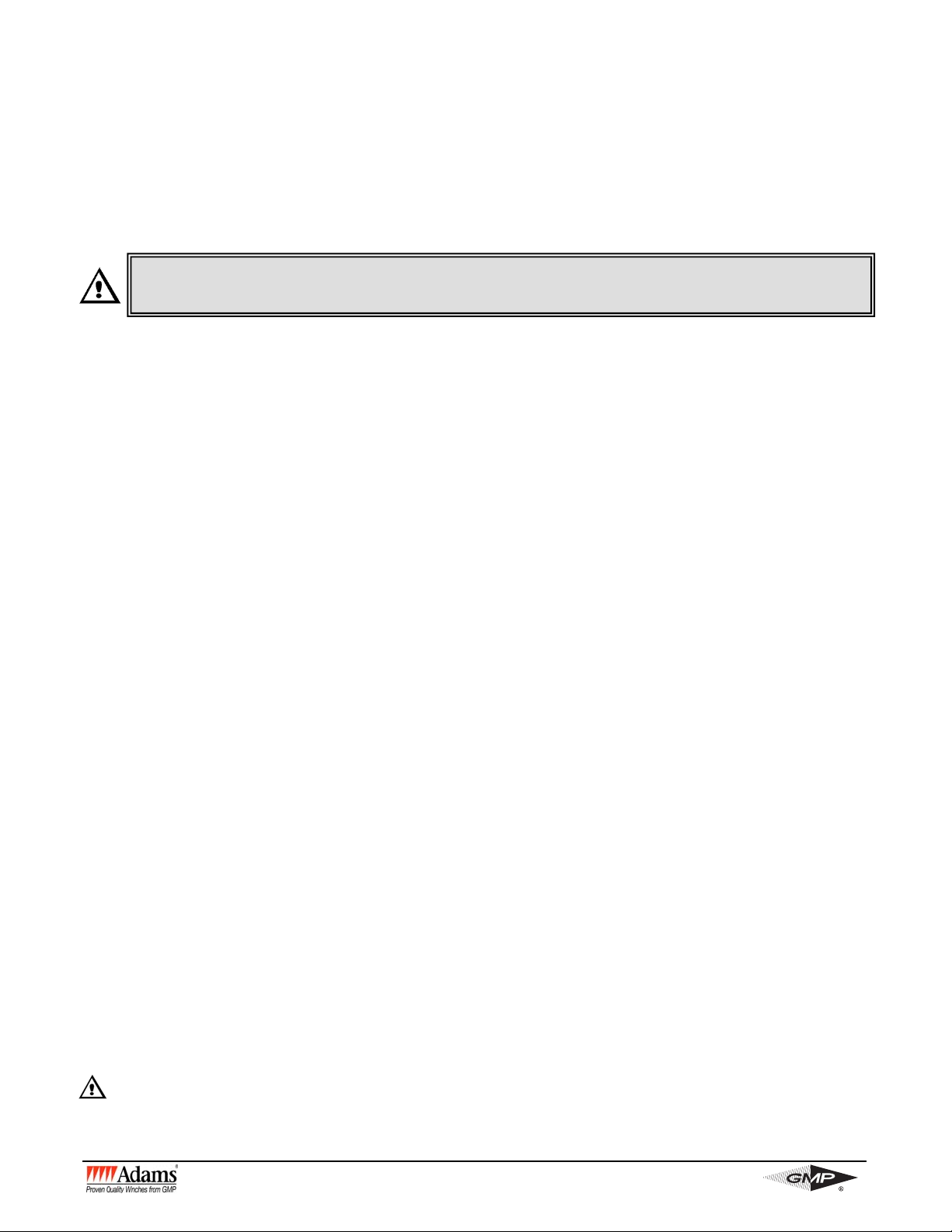

SAFETY BRAKE LUBRICATION - The brake housing must be checked and maintained every 75 hours of

operation or every 3 months. To check for the proper fluid level, the truck must be on level ground. Remove the

fluid level plug on the cover of the brake. A small amount of fluid may drip from the fluid level hole. If no fluid is

visible, remove the fluid fill plug on the cover and add automatic transmission fluid (Conoco Phillips Super ATF or

equivalent) until the fluid level reaches the fluid level hole. Do not overfill. Screw the fluid level plug and fluid fill

plug back into the brake cover.

The brake should be completely drained and filled with new automatic transmission fluid (Conoco Phillips Super

ATF or equivalent) every 1000 hours of operation or every other year. The drain plug is located on the lower portion the brake cover. To drain the brake, remove the fluid drain plug, the fluid level plug and the fluid fill plug. After the brake is completely drained, reinstall the fluid drain plug. Add new automatic transmission fluid until the

fluid level reaches the fluid level hole. Do not overfill. Screw the fluid level plug and fluid fill plug back into the

brake cover.

The (2) grease fittings on the gear box must be maintained every 75 hours of operation or every 3 months with an

EP type chassis grease.

Page 15 of 28

www.gmptools.com

6.03 WINCH IDENTIFICATION - Assistance from the manufacturer or dealer is available to help resolve

unique problems. When contacting your local dealer or the factory, the model and serial number of the winch in

question should be specified so that proper assistance can be offered. This information is stamped on a nameplate affixed to the front mounting rail of the winch.

6.04 CALIPER BRAKE - It is recommended that brake hoses and brake lines be inspected regularly. All dam-

aged or worn parts should be replaced. The reservoir should be checked for sufficient fluid level and clean fluid of

the correct formulation added as required. See Section 3.04 Caliper Brake for special instructions on bleeding and

determining whether to use brake fluid or hydraulic oil for a specific winch.

NOTE: Lining assemblies (3) can be replaced without removing brake module

housing (6).

1. Remove cap screw (1) and spring clip (2), allow

lining assemblies (3) to drop out of housing (4).

2. Make sure piston (5) is bottomed out in brake

module

housing (6) and thread brake module housing out

of

housing (4) so that piston is flush with housing.

3. Install new lining assemblies (3) in housing (4).

4. Install new spring clip (2), and cap screw (1).

Torque cap screw (1) 13.6-16.3 N·m (10-12 lb·ft).

5. Thread in brake module housing (6) until a total

clearance of approximately .31 mm (.012 in) is

obtained between disc and linings. NOTE: Make

sure piston (5) is bottomed out in brake module

housing (6).

6. Back off brake module housing (6) as required

to position ports in vertical alignment.

7. Tighten set screw.

8. Move bleeder screw (7) to higher of two ports

for ease of bleeding. Torque 6.8-7.9 N·m (60-70 lb·in).

9. Install hydraulic line in lower port.

10. Bleed system making sure all air is eliminated.

Page 16 of 28

www.gmptools.com

7.01 LEVEL WIND INTRODUCTION

The level wind is a chain driven device specifically designed to distribute wire rope coils or wraps evenly across

the winch drum.

Level winding the wire rope onto the drum has several advantages:

1. Increases drum storage capacity

2. Prevents wire rope pile-up

3. Permits smooth, steady pulls

4. Makes accurate alignment of the truck with the pull unnecessary

5. Establishes tight, even wraps preventing the wire rope from cutting down through the lower lays resulting

in damage to the rope and difficulty in unwinding.

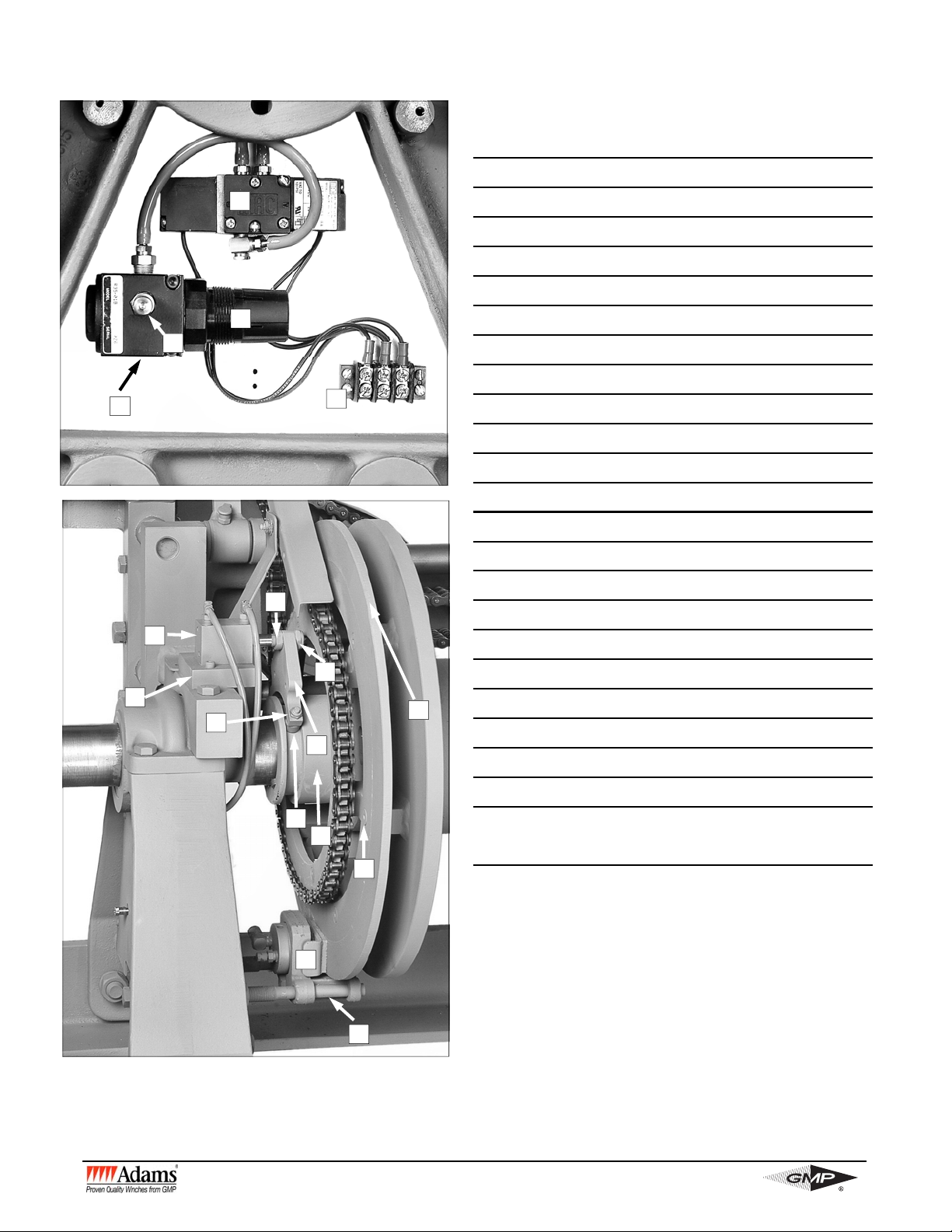

7.02 DESCRIPTION

The level wind assembly includes a carriage/roller cage, guide bars, speed reducer, two single width and one triple width roller chain drive. The carriage is mounted on the two guide bars and is driven back and forth across the

drum by an endless triple width cross chain.

The carriage is connected to the cross chain by a drive pin which projects into a vertical slot in the carriage. As

the cross chain rotates, it carries the drive pin and carriage across the drum. When the drive pin reaches the end

sprocket, it rotates around the sprocket moving up or down in the slot as required.

Accordingly, the carriage/roller cage and wire rope moves to the end of its travel and starts back again across the

drum.

Mounted below the carriage, is a roller cage assembly thru which the rope passes for final storage on the drum.

Since the level-wind is driven directly from the winch drum, the carriage remains properly aligned with the wraps

on the drum. This is consistent regardless of whether the rope is being wound onto the drum under power or off

the drum under free spool conditions.

The speed of the carriage is regulated. For each revolution of the winch drum, the carriage advances across the

drum a distance equal to the diameter of the rope

The Level-Wind is automatic. Although absolute perfection is not necessary when winding, the best results will be

obtained if care is taken to maintain uniformity and compactness of those wraps and lays left on the drum at the

start of the pull.

When operating the level-wind, constant tension must be maintained on the rope. The amount is sufficient to

eliminate "clock-springing" that will lead to loose or tangled wraps and lays.

Under free spool conditions, if the drum has been permitted to over-run, resulting in loose or tangled wraps, it will

be desirable to remove several feet of improperly wrapped rope and rewind, under tension, prior to starting the

actual pull. To insure good operation, the wraps and lays must always be straight and compact.

It should be noted that the winch is furnished with a drag brake. The purpose of this brake is not to hold the load

but to control the drum rotation speed when paying-out wire rope under free-spool conditions. Slowing down and

gradually stopping the drum, with tension on the rope, will prevent backlash, clock-springing and eventual entanglement of the rope.

Although the level wind will guide the rope onto the drum from a relatively wide fleet angle, there will be less bending of the rope at the roller cage assembly if the line of pull is as straight as possible. The use of a universal or

universal swivel sheave on the tail shelf is advisable.

The roller cage assembly has only a suitable amount of clearance for the rope to pass. When pulling-in the wire

rope, it is important that the operator stops drum rotation at a point to keep the spliced eye or quick hook several

feet from the roller cage. Otherwise, the eye and hook will be drawn into the rollers, causing damage to the levelwind.

7.03 PLACING WIRE ROPE ONTO THE WINCH DRUM

When placing rope onto the drum, rotate the drum until the carriage reaches a position of maximum travel at the

drum end where the rope is to be attached. The extreme end of the carriage travel is when the guide link is on the

outside of the end sprocket and at the mid-point of the vertical slot in the carriage.

Thread the end of the rope through the rollers and attach it to the drum by means of the rope clamp. Drive the

winch forward at a low speed, keeping sufficient tension on the rope. It is extremely important that the first lay of

rope be straight and compact. Slowly increase the drum speed and spool on the remaining rope.

It is suggested that the rope length be less than full drum capacity. This will assist in preventing rope roll-off from

the drum onto adjacent equipment. Whenever possible, a winch line holder should be used to prevent the rope

from unwinding.

Page 17 of 28

www.gmptools.com

7.04 ADJUSTMENT

The speed reducer input and output single width roller chain drives should be tight enough to prevent back lash

but not excessively tight to cause bending of the reducer shafts.

The triple width cross chain should be sufficiently tight to prevent tipping of the guide link. An unsteady movement

of the carriage could indicate a loose cross chain or lack of lubrication on the guide bars.

If the cross chain requires tightening, it should be adjusted an equal amount at both ends by the corresponding

adjusting screw. Or, the distance from the back of the chain to the inside of the drum must be equally spaced.

Before any adjustment is made to the cross chain, the chain drive from the speed reducer must be loosened.

To check for equal spacing, rotate the drum one revolution taking a measurement at four locations. The mean dimension will compensate for any distortion in the drum flanges. The cross chain assembly can then be shifted by

turning the adjusting screws at each end after the lock nuts have been loosened.

If the rope has a tendency to pile up at one end and leave an opening at the other end, the cross chain should be

shifted slightly away from the end where the rope piles up.

The cross chain length is for an average width drum. If the rope piles up at both ends of the drum, the cross travel

speed is too slow. Or, the cross chain length is too long. Remove one pitch and check.

If the rope leaves an opening at both ends of the drum, the cross chain length is too short. Add one pitch and

check.

7.05 LUBRICATION

The level-wind assembly should be lubricated every 3 months or 75 hrs of operation. Use a good grade of engine

oil in four oil cups, three roller chains (lubricated on the Inside surface of the chain).

Coat the guide bars with a rust inhibitor such as LPS 3 Premier rust inhibitor or equivalent. Reapply the rust inhibitor to prevent corrosion once every month.

The speed reducer should be filled to the proper oil level with heavy gear oil or equal.

To check for the proper oil level in the reducer, remove the oil level plug in the side of the housing. The lubricant

should be maintained to the height of the oil level opening.

To add oil, remove the oil level plug in the side of the housing. Remove the oil filler plug at the top of the housing.

Add oil to the height of the oil level opening. Fill lo level plug using the same type lubricant that’s used in the winch

drive case.

7.06 SPOOLING

Wire rope is specified by length, diameter, number of strands, and number of wires per strand, type of center and

type of lay. The purpose here is to stress the importance of selecting the correct type of lay.

There is a distinct advantage in applying wire rope of the proper direction of lay when spooling onto a smooth surface winch drum. When rope, having an improper lay, is used the coils will spread apart each time the load is removed. Using rope with the proper lay will keep the coils together when the load is removed, developing a tight,

even layer.

Under winding is when the wire rope is spooled onto the winch drum at the bottom.

When wire rope is under wound onto the drum, a right lay rope should attach to the left side of the drum and spool

to the right. A left lay rope should attach to the right side of the drum and spool to the left.

7.07 INSTALLATION

It is important to install the wire rope onto the winch drum with care. Kinking of the rope, caused by the rope taking

a spiral shape as a result of an unnatural twist, should be avoided.

When removing wire rope from the reel and spooling onto the winch drum, the reel must be in a vertical plane and

free to rotate.

Spool the rope onto the drum with the natural bend in the same direction as it was on the reel.

If the wire rope is received in a coil, it should be unwound with the coil in the vertical plane. Spool the rope onto

the drum with the natural bend in the same direction as it was on the coil.

Reverse bending of the wire rope should always be avoided or kept to a minimum.

Wire rope should always be under tension when spooling onto the winch drum.

7.08 WIRE ROPE LUBRICATION

Wire rope is considered to be a machine, having many moving parts. Each time the rope bends or flexes, the various wires and strands slide over each other. Lubrication is required to facilitate this movement. The type of lubricant, method of applying and frequency of application is dependent on each particular circumstance. For specific

lubrication details contact the wire rope manufacturer.

Page 18 of 28

www.gmptools.com

Details of Air Shift Clutch and Caliper

Brake Mechanisms

Key P/N Description Qty

Q

A

R

C

D

E

L

25677 Air Cylinder 1

A

28794 Air cylinder Mounting Block 1

B

25678 Air Directional Valve 1

C

25675 Regulator w/Schrader Valve 1

D

25767 Shifter Fork Stud 1

E

26243 Shifter Fork 1

F

25601 Bearing 2

G

25332 1/4 - 20 Elastic Stop Nut 2

H

28792 Clutch Plate 1

J

25333 1/2 - 20 Elastic Stop Nut 1

K

25634 3 - Pair Terminal Block 1

L

25828 Caliper Brake Ring 1

M

17134 Caliper Brake 1

N

28805 Caliper Brake Stud 2

O

25453 5/16 - 18 x 1 Flathead Cap Screw 6

P

Location of air inlet port to regulator

Q

B

H

G

N

F

J

K

O

P

M

Schrader valve for test gauge connection

R

25237 Replacement Brake pads 1 pr

17135 Actuator * 1

17136 Reservoir * 1

17137 Hose * 1

* Caliper Brake items ship in parts box for

installation by the vehicle body builder.

Page 19 of 28

www.gmptools.com

Page 20 of 28

www.gmptools.com

Page 21 of 28

www.gmptools.com

Page 22 of 28

www.gmptools.com

Page 23 of 28

www.gmptools.com

WG W inch Dimensions

Note: example shown of a winch with a

shaft extension sized for a 94” body.

Page 24 of 28

www.gmptools.com

Model WG Winch Specifications

No other winch available anywhere offers you the same time-tested, rugged performance as the Adams winch. Now the best cable pulling winch your money can

buy comes loaded with new performance features, and its more compact design

takes up less than 25 in. of space on either side of the drum centerline with no sacrifice in capacity. What’s more, we’ve simplified the installation to give the Adams the

lower installed cost compared to any other winch in its class.

Rated to a bare drum pulling capacity of 20,000 lbs. (89 kN)

Standard Features

• Integrated 2 speed hydraulic motor

• Pneumatically actuated clutch

• Caliper type drag brake

• Adjustable full load brake with automatic

engagement when power is reversed

Maximum Rated Line Pull & Line

• Level-wind mechanism for 7/16 in. wire

rope which distributes the wire rope onto

the drum in tight, even lays

• 2 7/16 in. (Bell Standard) shaft extension

rated at 1000 lb

Control Valve

Position

Lbs. Force (kN) Lbs. Force (kN) Ft./min.(m/

High 10000 (44.5) 4600 (20.5) 26.8 (8.2) 66 (20.1) 14

Low 20000 (89) 9200 (41) 14.4 (4.4) 35 (10.7) 7.5

Max. Rated Line Pull Winch Line Speed Shaft Speed

Bare Drum Full Drum Bare Drum Full Drum

Ft./min.(m/

min.)

min.)

@ 20 GPM

● Hydraulic system flow 20 GPM (76 l/min.) maximum; Hydraulic system pressure 1750 psi (12066 kPa) operating with 2000 psi (13790 kPa) maximum relief

valve setting.

● Winch line speed is based on 7/16 in. (11.1 mm) diameter wire rope.

● The line pull ratings shown are the winch only. Consult the wire rope manufac-

General Machine Products Co., Inc.

3111 Old Lincoln Highway

Trevose, PA 19053 USA

TEL: 215-357-5500

FAX: 215-357-6216

E-MAIL: info@GMPtools.com

WEB: http://www.GMPtools.com

RPM

Page 25 of 28

www.gmptools.com

1a. General Machine Products Co., Inc. ("GMP") warrants to the purchaser and/or end user:

(1) that a new product sold and manufactured by GMP will be free from original defects in material and workmanship for one year from the date the product was delivered to the purchaser and/or end user, or for the lifetime of

the Modular Plug Presser;

(2) that a new product sold and not manufactured by GMP will be covered exclusively by the manufacturer's warranty. However, if that warranty coverage shall provide less coverage than the GMP Warranty for its manufactured

products, then the warranty set forth in Paragraph 1(a)(1) above shall apply instead;

(3) that a reconditioned used GMP product sold by GMP, or a non-owned product repaired by GMP, or a new part

sold by GMP, will be free from original defects in material and workmanship for ninety days from the date the

product was delivered to the purchaser and/or end user.

1b. The above warranties are contingent upon and subject to the condition that: (1) the end user substantiates the

date it purchased and received delivery of the product or part, and (2) the product or part shall have been installed, maintained and used in accordance with GMP's or the manufacturer's written instructions.

2. The end user shall determine the suitability of GMP's product or part for intended use, and the end user assumes all risk and liability whatsoever in connection therewith except to the extent set forth in this Limited Warranty.

3a. GMP reserves the right to request that the product or part be returned to us for examination and cannot be

responsible for user charges incurred in the replacement of any product. GMP's agreement to repair or replace is

also subject to its inspection of the product and verification of the defect.

3b. Subject to immediate written notification of a defect or malfunction, GMP will repair or replace that product or

part, at GMP's option, returned freight prepaid to Trevose, PA.

3c. To obtain repair or replacement service under the Limited Warranty, the purchaser must contact the factory for

a Return Material Authorization (RMA). Once obtained, send the RMA along with the defective part or product,

transportation prepaid to:

General Machine Products Co., Inc.

3111 Old Lincoln Highway

Trevose, PA 19053 USA

Tel: 215.357.5500

3d. The field labor and material charges incurred by an authorized GMP dealer or an end user to disassemble,

inspect, repair and reassemble our product or part at their respective prime locations will not be reimbursed unless

GMP has first reviewed and approved those charges.

3e. Incidental repair charges incurred by an authorized dealer or an end user for items such as labor, transportation, tolls, lodging and meals at a location remote from its prime facility, or to demount our product or part from its

remote location and forward to its prime facility, are not the responsibility of GMP, and are not covered by this

Warranty.

3f. Incidental repair charges incurred by an authorized GMP dealer or end user to remove construction hardware,

modify a vehicle or otherwise gain access to GMP's product or part, is a condition beyond GMP's control, and is

not covered by this Warranty.

4a. GMP products or parts which become part of a total assembly which has been designated and/or manufactured by others, are not covered by this Warranty unless GMP reviews the total assembly and expressly extends

its warranty.

4b. Design, material and workmanship furnished by others to install or operate a GMP product or part are not cov-

Page 26 of 28

www.gmptools.com

4c. Hydraulic, pneumatic, electrical or mechanical control equipment which is not manufactured by GMP and

which becomes a part of a GMP assembly, is not covered by this Warranty.

4d. This warranty does not cover a GMP product or part which others have subjected to abuse, improper

installation, improper operation, alteration or negligence in storage or handling.

5a. THE ABOVE WARRANTIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR PURPOSE OR OTHER WARRANTIES OR GUARANTEES OF ANY KIND OR DESCRIPTION, EXPRESS OR IMPLIED.

5b. GMP ASSUMES NO LIABILITY WHATSOEVER, INCLUDING WITHOUT LIMITATION, ANY INJURY, LOSS

OR DAMAGE, IN CONNECTION WITH THE INSTALLATION OR USE OF THIS PRODUCT OR PART, EXCEPT

AS STATED IN THIS LIMITED WARRANTY. GMP WILL IN NO EVENT BE LIABLE FOR DIRECT, INDIRECT,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR INABILITY TO

USE THE PRODUCT OR PART.

5c. GMP'S SOLE LIABILITY AND THE PURCHASER'S SOLE REMEDY FOR A FAILURE OF A PRODUCT OR

PART UNDER THIS LIMITED WARRANTY, AND FOR ANY AND ALL CLAIMS ARISING OUT OF THE PURCHASE AND USE OF THE PRODUCT OR PART SHALL BE LIMITED TO THE REPAIR OR REPLACEMENT

OF THE PRODUCT OR PART THAT DOES NOT CONFORM TO THIS WARRANTY.

6. GMP reserves the right, without notice, to make changes in equipment design or components as progress in

engineering or manufacturing methods may warrant.

7. This Warranty shall be construed in accordance with the laws of the State of Pennsylvania, of The United

States of America.

8. This Limited Warranty may not be modified, in whole or in part, except by writing signed by an authorized officer

of GMP.

Page 27 of 28

www.gmptools.com

General Machine Products Co., Inc.

3111 Old Lincoln Highway

Trevose, PA 19053 USA

TEL: 215-357-5500

FAX: 215-357-6216

E-MAIL: info@GMPtools.com

WEB: http://www.GMPtools.com

GMP reserves the right, without notice, to make changes

in equipment design or components as progress in engineering or manufacturing methods may warrant.

All contents ©2010 GMP

Page 28 of 28

www.gmptools.com

Loading...

Loading...