Apollo Cable Lasher

Operation and Maintenance

All rights reserved. No part of this publication may be copied, reproduced or

transmitted in any form whatsoever without the written permission of General

Machine Products Co., Inc.

General Machine Products Co., Inc. • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • www.gmptools.com

U.S. Patents: 6,062,542 and 6,389,989

General Machine Products Co., Inc.

Manual P/N 30757 ver 2

AK 08-2013

1

Apollo Lasher

REVISION HISTORY:

Rev Date Details Author

01 Original issue Adspeak

02 07-2013

Revised format for clarity

A. Konschak

Removed repair parts

2

Table of Contents

1.0 General Page 3

2.0 Precautions Page 3

3.0 Description Page 4

4.0 Operating instructions Page 7

5.0 Troubleshooting Page 18

6.0 Maintenance Page 19

7.0 Options and other information Page 20

8.0 Layout Page 22

1.0 General

This manual covers the care, operation and maintenance of your GMP

Apollo cable lasher, which you can use to lash cables up to 3.5 in. (89

mm) dia. to suspension strand, or smaller cable sizes to an existing lashed cable and strand. The Apollo has the capability to lash up to a 4 in. (100 mm)

bundle of any assortment of innerduct, fiber, copper and coaxial cables as

well. The strand sizes range from .25 to .38 in. (6 to 10 mm) diameter, inclusive.

This machine is intended for use only by properly trained journeyed

lines-people or other craftspeople under the direct supervision and responsibility of those individuals.

As such, this manual’s scope is specifically limited to the machine’s functions,

and no attempt is made to describe the proper procedures for placing and lashing aerial cable plant.

We cannot be held liable for any direct or indirect consequences arising from

use of this product by any individuals not already properly trained in its use.

The following conventions will be used in the manual:

Warnings - must be followed to avoid bodily injury.

Cautions - must be followed to avoid damage to equipment

Notes - contain important information and useful tips on the operation of your

Apollo lasher.

2.0 Precautions

2.1 Observe the following precautions when operating the Apollo lasher.

Read all of the instructions and save them for later reference. Before beginning any cable work, first check the cable run you want to make in order

to find out what local conditions might be while you are lashing. Among the

factors you should look for are:

● vehicle and pedestrian safety

● conditions of poles, anchors, guys and strand

● proper bonding and grounding of strand and attachments

● obstructions such as trees, limbs, and drop wires

● clearances and separations on poles shared by other utilities

● clearances over roads, driveways, walkways and crossings

3

Apollo Lasher

Protect

points

Check your Apollo

make

semblies

properly maintained,

sary

In case your Apollo

to

overknow our

round.)

Use the

your

pair. And

strap

rear

the

Also, you

line or a

transferring

assembly

dropped.

than

Avoid

drop

Keep your

Protect

any

Avoid

3.0

3.1

The

●

●

● big

●

●

your work site with

to

warn

traffic and

lasher

sure it is in good

are

intact

and in good

risk to both you and the

lasher

our

Lasher Department

haul.

(In case you are c

Department

proper safety equipment!

climbing

securely attached

verti

lasher

that of the

abuse

your

your

other foreign matter.

placing

Description

General

following features make

parallel

lightweight

bundle capacity

constant tension

rotation section rotates

and

safety equipment

while you are aloft,

cal cable

on the side of a

should always raise

truck

as a

Doing this lets you

lasher.

lasher

pull

rollers

lift. Use the bridle

your

lasher around

tether

machine.

or

rough handling

in its

lasher

the Apollo on the

capability

advance signaling devices

pedestrians

first! Before

repair,

it

is set up to give you the

to

protective

from

in the

and all of the

might

property

ever

needs attention,

so it can get a

oncerned about downtime,

ALWAYS

to help

are set to their

bucket.

prevent damage

concentrate

unnecessary exposure

your Apollo

lashing wire

in a

of any

using

working order.

be

unsafe

and

Before

to

make certain

wear a

prevent

and lower the Apollo

of the Apollo

ground whenever possible.

single direction

you from

widest opening before placing

assembly

a pole or

on your own

case

when

4

at

strategic

obstructions

your

machine,

parts

and

If your

to use and pose an

personnel

you

professional repair and/or

fastest possible

working

safety

falling. Ensure

at pole

obstruction,

to the

machine

lashers

not in

to dirt, grit and

lasher

an

in the

area.

check

mechanical

machine

in your work

should forward

you

aloft,

inspect

it is in good

belt with a

lasher

transfers! When

use the

in case it

safety rather

and never

use.

outstanding

unneces-

should

safety

with a

is

area.

turna-

all

hand-

bridle

value:

to

as-

the

not

it

re-

is

Figure 2

Figure 3

The

machine weighs approximately

and

provides

exceptionally

Note: Please see

3.2 Cable

You can use the Apollo to lash a

ing

telephone

The Apollo has the

any

assortment

The strand sizes range

or

6 mm

3.3

Lashing wire

The Apollo

hold a

5.38

use

either

(365

m) of

dia.

(0,97

requirement, however,

an

outstanding strength/weight

long

service life.

figures 31, 32, 33,

capacities

and

fiberoptic

capability

of

innerduct,

through

of the

mm)

10

lasher

in.

.045

has two

(137

mm) dia. by

standard

in.

(1,14

annealed stainless

from .25 to .38 inch

mm.

magazines

wire coil

mm) dia. and

oiled wire is not

Look at your Apollo

ment.

You will see it

rotating section supported

-

tionary carriage:

cable

pass through

carriage

tion.

As you look at the

see it has cable and

front and rear

and an

the

The

variety

to

of

the

-

minum alloys, magnesium, carbon

neered

bearings or needle bearings

drive

Sintered metal

other mov

single

cables up to 3.5 in. (89 mm) in

to lash up to a 4 in.

fiber, copper and

1.81

sizes

steel wire.

during

gates, towing bracket

anti-backroll strand

front.

components

of

materials,

provide

46 lbs

and

cable of

for

in. (46 mm) high wire coil. You

specific

materials

and tool steel as well as

polymers.

shafts

recommended.

and

ing

(20.9 kgs.) without

ratio while

34.

almost

coaxial

diameter (6.6M,

loading lashing

in the

magazines: 1,200

1600

ft.

Wax-coated

lasher

consists

the

this

the

lashing opera-

carriage

strand rollers,

are

made

properties.

are

heat-treated alu

There are ball

rotating sections.

bearings

parts.

any type,

(100

mm)

cables as

(488

m) of

for a mo-

on a

strand

stationary

you

roller on

from

each

selected

engi-

are

used

providing

includ-

diameter

bundle of

well.

6M,

wire, each

.038

wire is not

of

a

sta

and

will

a

Some

on the

wire

an

.

10M)

can

can

ft.

in.

a

on

5

Apollo Lasher

Your lasher can use a single wire or two wires simultaneously (also known as

“double lashing”). Like other GMP lashing machines, the balance of the Apollo is not affected by the amount of wire loaded in either magazine.

Each magazine has two rollers for guiding and tensioning wire during lashing.

The wire tension is developed by the routing of lashing wire and not the tension on the spool. The wire coils mount on a reel attached to the rotating drum.

There is a non-adjustable tension on the reel to prevent overspinning. The

lashing wire exits the tensioning rollers and enters the drive mechanism.

3.4 Drive mechanism

The Apollo is driven by the lashing wire exiting the machine so the lasher can

be pulled from any direction. The lashing wire rotates drive wheels that are

interconnected by a shaft so either single lashing or double lashing will rotate

the lasher. A set of pinion gears drive a segmented ring gear and this configuration is the time-tested design found on other GMP lashers. The direct drive

design eliminates the possibility of slippage.

A one-way clutch in the drive wheel of the gearbox assembly enables the rotation section to rotate in a single direction while lashing. This configuration

allows the lashing wire to remain tensioned when forward motion of the lasher

has ceased. The rotation section of the lasher can be manually rotated in the

opposite direction by actuating the handle to de-clutch and disengage the drive

wheel.

3.5 Adjustable rear gate and cable lifter

The rear gate is adjustable by the use of a D shaft and locking collar. The rear

gate is easy and fast to use and the locking collar provides a positive lock to

keep the rear gate in place. To open the rear gate, push the button and the rear

gate rotates to its open position. When the rear gate is open, the rotating drum

will automatically lock in its detented position when the pin registers with the

receptacle in the rotating housing. The pin is retracted from the receptacle in

the rotating housing when the rear gate is closed.

3.6 Front gate

The front of the Apollo is designed to provide the maximum in cable protection. There are 4 rollers to help prevent cable damage regardless of cable orientation. The top roller has two one-way clutches that ensure the lasher only

moves in the forward direction, providing anti-backroll capability. The bottom

roller pivots out of the way for easy cable installation into the lashing machine,

and locks positively in place for the cable lashing operation. There are two sets

of towing eyes for the Apollo for pulling in any direction. The top set of holes

is most suited for parallel pulling and normal operation and the bottom set is

most suited for situations requiring more sideward or downward pull.

3.7 Bridle assembly

The Apollo lasher is supplied with a bridle assembly that resists rot. The 5 foot

long rope assembly is equipped with a forged snap hook at each end and a

floating forged steel ring between the snap hooks for the attachment of a suitable towing line. The bridle assembly also provides a safe and easy method to

tether the Apollo while moving it around a pole or obstruction.

6

4.0 Operating instructions

4.1 General

As mentioned at the beginning of this manual, you should never operate a

lasher unless you’ve been properly trained in advance or are being directed by

a properly trained linesperson who is responsible for your work. However,

you should find this section of the book helpful in outlining the correct sequence of steps to take in using your Apollo lasher.

4.2

Preparing a lashing

Figure 4

2. Do not cut all of the cable ties! Leave the cable tie

looped end of the

on

the

lashing

wire

3. Cut the looped end of the wire on the

coil.

This step will help in the

subse

quent steps.

wire

lashing

coil.

coil

The first step in any

a

tion is to

wire

coil. Note: It is

that the

properly to

operation.

1. If the

with

wire ties,

wire

tie

attached

the

lashing

coil (see

the

figure

cutting

step and help

plete

wire tie is

wire, and cut the

inside diameter

loading

of the coil onto the hub and

prepare

lashing

ensure

lashing

rotate

wire to the

4). This

of the wire

ensure

remaining

lashing oper-

the

lashing

important

wire is loaded

proper lasher

wire is

the

wrapped

head

to the looped

center

will

tie

in a later

that

the

removed.

attached

3 cable ties

of the wire

of

the

end

of

of

the

facilitate

com-

to

the

4.3

Install

The

proper installation

lashing.

preparation

the

prepared

Many of the

of the

lashing

wire

coil

of the wire coil is a

problems

wire

in

lashing

coil.

must

for

hassle-free

can be

traced

to

improper

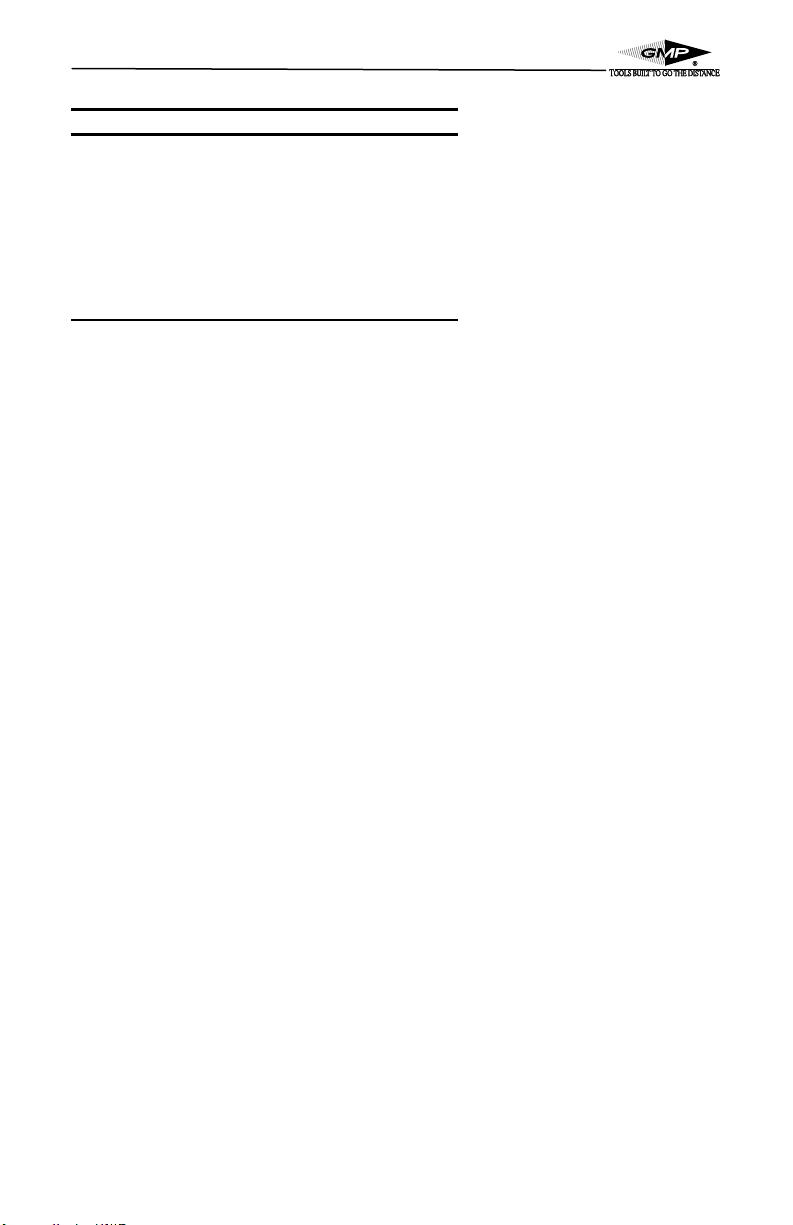

1. Open the cover with a

or

7/16

in.

socket

216C tool, or any tool

the

bugnut.

turn

(counter-clock wise)

fastener

cover

should

ing

wire

Turn

unseats.

open to

reel.

screw- driver

as

found

on the

used

to

the fastener

until the

The

spring loaded

expose

tighten

1/4

the

lash-

Figure 5

7

Apollo Lasher

Figure 6

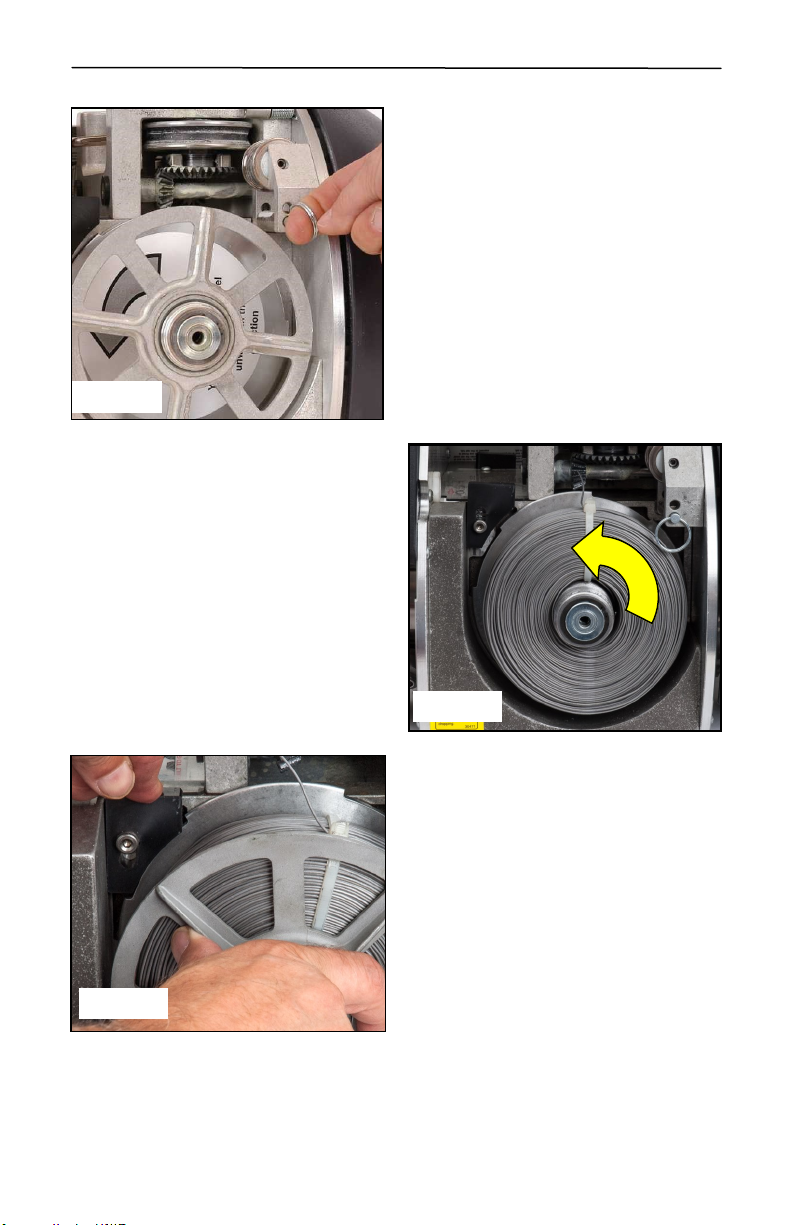

3.

Depress

cutout

screw

reel cover

ing

onto the reel

that it spools out to the rear

of the lasher as shown by

arrow.

the reel

on rear

and

wire coil over

flange. Un-

remove

and

slide the

making sure

brake

the

into

the wire

lash-

hub and

2.

Verify that the

sion

roller is in the correct

position for

ing.

The

the

lower- most position

normal lashing wire tension,

including lashing

coaxial cables. The

should

position

wire

tension.

adjustable ten-

the type of

roller should

be in the

for

upper- most

higher lashing

broadband

lash-

be in

for

roller

Figure 8

Figure 7

4.

8

Install

and

onto the

against

important

the

against

vent

“snagging”

the wire reel cover

thread completely

reel

until snug

the wire coil.

to

reel

cover is tight

the wire

the

lashing

on

ensure

coil

wire

itself.

It

that

to

from

is

pre-

Figure 9

Make certain that the head or knot on

the cable tie is not pulled through the

coil and that the entire cable tie is removed, because portions of the cable

tie may cause snagging of the lashing

wire.

Note: As a check for proper cover tightness, at least 1 full thread on the hub

should be exposed after the wire reel

cover has been installed and tightened.

5. Hold on to the looped end of the

coil. Cut and remove the remaining cable tie and then continue to

snug the reel cover against the

wire coil ensuring a tight fit. The

reel brake can be depressed into

cutout on rear flange to hold the

reel stationary as you tighten the

reel cover.

Figure 10

Figure 11

7. Feed the wire behind the sec-

ond tension roller (top roller).

Pull the wire out from behind

the roller.

8. Pull up on the handle to de-

clutch and disengage the drive

wheel.

6. Make a hook with the end of

the lashing wire. Feed the

wire over the first tension

roller (bottom roller).

Figure 12

9

Apollo Lasher

Figure 13

10. Continue feeding wire until it

exits the drive wheel. The

wire exiting the drive wheel

must be below the wire entering the drive wheel.

9. Feed the wire into the drive

wheel from the rearward direction so the wire moves

around the drive wheel toward the front of the lasher.

Figure 14

Figure 15

11. Pull up on the handle to dis-

engage the drive wheel and

feed wire into the exit rollers

on the end of the machine.

Figure 16

10

12. Ensure the wire is captivated be-

tween the roller and the housing.

13. If more wire is needed, disengage

the drive wheel to pull out more

lashing wire. (See Figure 15)

Figure 17

14. Close the cover and using a screwdriver or 7/16 in. socket as found on the

216C tool, or any tool used to tighten the bugnut, tighten the fastener

(clockwise) 1/4 turn until the fastener seats and can’t be tightened further.

Ensure that the cover is secure to the hub.

4.4 Lashing to bare suspension strand

1. Check the lashing wire coils to ensure there is enough lashing wire for the

span, if the lashing wire wasn’t loaded recently.

Figure 18

Figure 19

2. Lower the rear gate to its lowest

position. Ensure that the rear gate

is open and the drum is locked in

position.

3. Set the rear vertical cable rollers to

their widest opening.

4. Open both the front and rear strand

locks by pulling up on the release

knob. There should be an audible

“click” when the locks travel from

the locked position to the open

position. (See Figure 18)

5. Open the front gate by actuating

the release lever towards the front

of the lashing machine. The roller

on the front gate will pivot 180

degrees and out of the way.

6. Attach a handline to the lasher

handle and raise the lasher to the

strand. Attach one of the lasher

bridle snap hooks to one of the

lasher towing eyes. Attach the other snap hook to the strand to serve

as a tether.

11

Apollo Lasher

7. Place the lasher on the strand and ensure that the strand is centered in the

grooves of both of the front and rear rollers.

Figure 20

10. Using the proper cable raising procedure for your application, lift the cable

or cables up to the strand, close the front gate and let the cable(s) rest on

the horizontal roller.

11. Adjust the position of the vertical rollers on the rear gate so that they bare-

ly touch the sides of the cable(s). This step will have to be done every time

the bundle size changes.

12. Close the rear gate until it locks in its detented position.

13. Raise the rear cable lifter by pushing up on the bottom of the lifter that

contacts the D shaft. The lock doesn’t have to be activated to raise the

cable lifter. If the rear cable lifter is too high, press the locking lever to

lower the rear cable lifter and try again.

8. Close the front strand locks by depress-

ing simultaneously on both hooks until audibly and visibly locked.

9. Close the rear strand locks by simulta-

neously depressing on both hooks until audibly and visibly locked. The lasher is now

secured to the strand.

14. Now the final steps. Pull up on the handle to de-clutch and disengage the drive

wheel to pull some lashing wire from the

lasher. Secure the lashing wire to the strand

by using a GMP D or E lashing wire clamp.

Attach the bridle assembly to the towing eyes

on the Apollo lasher and you are ready to

lash.

See section 4.6 for more information on terminating lashing wire.

Figure 21

12

4.5 Over-lashing procedure

Here is the proper way to overlash onto existing cable installations using the

Apollo lasher:

1. Check the lashing wire coils to ensure there is enough lashing wire for the

span.

2. Lower the rear gate to its lowest position by fully depressing the thumb latch

and sliding the roller down. Ensure that the rear gate is open and the drum is

locked in position.

3. Open both the front and rear strand

locks by pulling up on the release knob.

There should be an audible “click” when

the strand locks travel from the locked

position to the open position. The strand

locks aren’t used in the over-lashing procedure and should remain in the open

position.

Figure 22

Figure

23

6. Attach one of the snap hooks on the lasher bridle to one of the towing eyes.

Attach the other snap hook around the strand and existing cables to serve as a

tether.

7. Place the lasher on the strand and ensure that the strand is centered in the

grooves of both of the front and rear rollers.

8. Using the proper cable raising procedure for your application, lift up to the

strand the cable or cables you want to lash, close the front gate and let the cable(s) rest on the horizontal roller.

4. Open the front gate by actuating the

release lever towards the front of the lashing machine. The roller on the front gate

should pivot 180 degrees and out of the

way.

5. Attach a handline to the lasher handle

and raise the lasher to the strand.

13

Apollo Lasher

9. Raise the rear cable lifter by pushing up on the bottom of the lifter that

contacts the D shaft. The thumblatch doesn’t have to be activated to raise

the cable lifter.

10. Adjust the position of the vertical rollers so that they barely touch the

sides of the cable(s). This will have to be done as the bundle size changes.

See section 4.6 for more information on terminating lashing wire.

Figure 24

4.6 Lashing wire termination

4.6.1 General

A common cause of lashing wire failure is improper termination. The following steps outline the suggested method for proper lashing wire termination.

1. Lashing wire termination should be accomplished and cable supports in-

stalled as soon as practical after the cable is placed.

2. Measurement marks made in making terminations should be made on the

strand rather than on the cable sheath. Avoid scoring the cable sheath with

the lashing wire end when terminating lashing wire.

3. Cable guards should be used to prevent abrasion of the cable sheath where

the separation is less than 1/2 inch between the cable and suspension

clamps.

While the D lashing wire grip and D and E lashing wire clamps may be used

on strand sizes up to and including 7/16 in (11mm) (16M) or larger, the discussion on lashing wire termination will only cover the strand sizes of .25 to .38

in. diameter (6 to 10 mm) (6M, 6.6M and 10M), the only strand sizes compatible with the Apollo lasher.

11. Now the final steps. Pull up on the handle to de-clutch and disengage the drive

wheel to pull some lashing wire from the

lasher. Secure the lashing wire to the strand

by using a GMP D or E lashing wire clamp.

Attach the bridle assembly to the towing

eyes on the Apollo lasher and you are ready

to lash.

14

4.6.2 Lashing wire termination

1. Secure the lashing wire to the strand with a lashing wire grip before cutting

or otherwise releasing tension in the lashing wire. The lashing wire grip should

be placed far enough from where the supports, spacers and lashing wire clamps

are to be installed to avoid having to move the grip.

Note: The situation can exist where the .038 in. (0,97 mm) dia. lashing wire

may nest in the space between the wires of the 10M strand. Ensure that the D

lashing wire grip is securely contacting both the lashing wire and the strand to

prevent loss of tension in the lashing wire.

4.6.3 Lashing wire clamps

Clamping Nut

Shoulder

Threaded Stud

Grooved Plates 2nd Washer

1st Washer

Figure 25, D Lashing Wire Clamp

1. The D or E lashing wire clamp may be used with .038 (0,97 mm) and .045

(1,1 mm) dia. lashing wire on strand sizes of .25 to .38 in. (6 to 10 mm) diameter (6M, 6.6M and 10M).

2. The nuts of the clamp are tightened and loosened with the 7/16 in. end of a

216C tool or B ratchet wrench.

Form the end of the lashing wire

around the end of the clamp as shown

Figure 26, Terminating Lashing Wire

4.6.4 Terminating lashing wire using D or E lashing wire clamps

See figure 26 for steps 1, 3 and 4.

1. The lashing wire clamp should be located 2 inches outside of the first lashed

cable support or cable suspension clamp. The lashing wire should be wrapped

twice around the strand and then terminated on the cable lashing clamp.

15

Apollo Lasher

See figure 25 steps 2, 3, 5 and 6.

2. Terminate one lashing wire using a lashing wire clamp by placing the wire

below the stud and between the second washer and stud shoulder.

3. Remove any slack in the lashing wire by maintaining tension on the wire

and tapping the strand sharply. Form the wire over the stud and tighten the

nut. Cut the free end of the lashing wire off 1/4 in. (6 mm) beyond the end

of the clamp.

4. Form the end of the lashing wire 90 degrees around the end of the clamp

to minimize exposure of the free end of the lashing wire.

5. Terminate a second lashing wire (if used) with the D lashing wire clamp as

outlined above; however, temporarily clamp the first lashing wire using a

D lashing wire grip to maintain lashing wire tension.

6. Loosen the nut on the lashing wire clamp and terminate the second lashing

wire between the first and second washers. Tighten the nut to complete the

termination.

7. Remove the D lashing wire grip(s).

4.7 Moving your lasher around a pole

When you need to move your Apollo lasher around a pole or other obstruction,

follow these steps.

Figure 27

Warning: While aloft, ALWAYS wear a safety belt with a safety strap securely

attached to help prevent you from falling.

Caution: Ensure the rear vertical cable rollers are set to their widest opening

before placing the lasher on the side of a bucket.

16

1. Before doing anything, make sure you are working from a secure

!

See section 4.6 for more information on terminating lashing wire.

2. Clamp the lashing wire to the strand.

3. To pull a length of lashing wire from the Apollo lasher without rotating

the drum, actuate the de-clutch lever and pull out enough lashing wire

from your machine so you can terminate it with a clamp or continue lashing past the obstruction.

4. Attach one of the lasher bridle snap hooks to a lasher towing eye on the

front of the machine.

5. Now pass the bridle under the strand, past the obstruction and attach the

other snap hook to another lasher pulling eye.

Figure 28

perch where you can safely move your Apollo lasher without

overreaching. This is extremely important.

6. Open the front gate by actuating the

release lever towards the front of the

lashing machine. The roller on the front

gate will pivot 180 degrees and out of

the way.

7. Open the rear gate making sure it is

fully open in the detented position.

8. Open both the front and rear strand

locks by pulling up on the release knob.

There should be an audible “click” when

the locks travel from the locked position

to the open position.

Figure 29

17

Apollo Lasher

Figure 30

1. attach a secured handline to the lasher handle;

2. disconnect the lasher bridle only after completing step 1; and

3. carefully lower the lasher to the ground.

5.0 Troubleshooting

5.1 General

Most problems you encounter while operating your Apollo lasher have

simple solutions. Read through the section to find your problems, then

follow the recommended steps. If you can’t solve the problem, then call

the factory.

Problem: The lasher won’t rotate.

Is the rear gate closed?

If not, close the rear gate.

Is the lashing wire routed properly? Check Figure 14.

If not, reroute the wire properly.

Is the lashing wire snagged on a pulley?

If so, free wire and reroute the wire.

Is the lashing wire pulled through itself?

If so, remove wire until the wire reel is straightened out again.

Is the lashing wire of proper dimension? Is it .038 in. (.9 mm) diameter

or .045 in. (1 mm) diameter or is it larger?

If the wire diameter is incorrect, use the correct wire size.

Problem: The lashing wire is too tight or too loose.

Is the tensioning roller set at the correct position?

If not, move the roller to the correct position. (See Figure 6)

Problem: The rotation section needs to be rotated in the opposite direction

to clear a jam or remove a foreign object from the lasher.

The rotation section of the lasher can be manually rotated in the opposite

direction by actuating the handle to de-clutch and disengage the

drive wheel. The rotation section can be rotated bi-directionally as long

as the drive wheel is disengaged.

9. Carefully lift the lasher off the strand and

move it over to the strand on the other side of

the obstruction. If you accidentally drop the

lasher while making this transfer, the bridle

assembly will keep the lasher from falling to

the ground.

4.8 Removing the lasher from the strand

The procedure for taking your lasher off the

strand is basically the same as for moving it

around a pole, except that you should also:

18

6.0 Maintenance

6.1 General

It is easy to care for the Apollo and keep it in good operating condition, but to

make sure it stays in adjustment and operates properly, always follow these

simple precautions:

Never drop your lasher or expose it to any kind of abuse.

Keep your lasher in its protective case when not in use.

Protect your lasher from unnecessary exposure to dirt, grit and any other foreign matter.

Avoid placing the Apollo on the ground whenever possible.

6.2 Preventative maintenance

Lubricate the following points with a white lithium grease on a periodic basis:

D shaft and locking collar

rear vertical roller shaft and trunions

vertical rollers

front gate roller shaft

front gate spring

rear gate roller shaft

bevel gears

ring gear and pinion gears

needle bearings

strand lock shaft and springs

Caution: If your Apollo lasher doesn’t rotate freely, have it repaired at the

GMP facility.

6.3 Maintenance notes

The front and rear gates should swing freely without binding and securely latch

when closed. Likewise, the spring on the front and rear gates should keep them

open unless intentionally closed. The towing bracket is designed to be an integral part of the safety of the Apollo lasher when it is being transferred. So, inspect the towing bracket for cracks or other degradation. Check the screws to

ensure their tightness. Check the bridle assembly for wear or rope strand breakage. Verify proper functioning of the forged snap hooks. Check the loose ring

to make sure it isn’t bent or damaged. The tensioning rollers should rotate

freely without binding. The screws and nuts on your lasher should be checked

periodically for tightness. Check all of the rollers for signs of abnormal wear.

6.4 Scheduled maintenance

The Apollo should be returned to the factory every 10-12 months for an inspection and “tuneup.”

19

Apollo Lasher

7.0 Options and other miscellaneous information

7.1 General

The Apollo lasher has been designed to minimize the snag and catch points

and therefore requires no optional halo.

7.2 GMP lashing accessories

The following items will help to increase your productivity and bottom line.

Description

D lashing wire grip

D lashing wire clamp (100/pack)

E lashing wire clamp (100/pack)

lashing wire .045 430 SS 1200 ft/spool, 6 spools/ctn

lashing wire .045 302 SS 1200 ft/spool, 6 spools/ctn

lashing wire .038 302 SS 1600 ft/spool, 6 spools/ctn

polypropylene lashing tow rope 3/8 in. dia by 35 ft.

bridle assembly 5 ft.

216C tool

B ratchet wrench

7.3 Other available GMP products

Did you know that GMP is the world’s oldest and largest supplier of aerialtools and accessories? In fact, our selection and quality have always been second to none. We helped invent many of the aerial tools you use everyday, including aerial lashers like the C2, J2 and G, and a broad line of cable blocks

and rollers. And it doesn’t stop there. We provide tools and accessories for

almost every cabling function: aerial, underground, even in-building. Chances

are, if you are looking for a tool, we have it, and many more like it as well.

Contact us for our catalog that lists our complete selection of over 800 products. Questions? Comments? Call us! Fax us!

E-mail us at Info@GMPtools.com

Also, visit our web site at http://www.GMPtools.com

8.0 Repair/Replacement parts list

If the need for repair parts should arise please contact the factory for

genuine GMP replacement parts. Parts are also available online at

www.Craftworktools.com

Item

08605

07886

81460

71530

71533

71535

70190

05817

15439

07511

20

D Lashing Wire Grip

08605

E Lashing Wire Grip

81460

Poly Tow Rope

70190

D Lashing Wire Clamp

07886

Lashing Wire

Towing Bridle Assy

05817

216C Tool

15439

B Ratchet Wrench

07511

21

Apollo Lasher

LOWER

TENSION

ROLLER

SHAFT

REEL COVER

Fig. 31, Side View

EXIT ROLLER (LH)

REAR GUIDE

ROLLER

VERTICAL

ROLLER ASSY

REAR STRAND

RELEASE KNOB

LOWER REAR

ROLLER ASSY

Fig. 32, Rear View

22

EXIT ROLLER (RH)

LOWER SHAFT

SUPPORT ASSY

FRONT STRAND

RELEASE KNOB

Fig. 33, Front View

TOWING

BRACKET

LOWER FRONT

ROLLER

TOWING

BRACKET

FRONT ROLLER

W/O CLUTCH

TOWING

BRACKET

DOOR ASSY LH

REAR ROLLER

ASSY

DOOR ASSY RH

Fig. 34, Top View

23

Apollo Lasher

General Machine Products Co., Inc. • 3111 Old Lincoln Hwy

Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • www.gmptools.com

24

Loading...

Loading...