General Machine Products 70202 User Manual

Model UV-25

Universal Swivel Sheave

P/N 70202

GMP

Installation, Lubrication and

Parts Manual

Table of

Contents

General 2

Precautions 2

Installation

4

Lubrication 5

Ball Bearing Chamber 5

Sheave 5

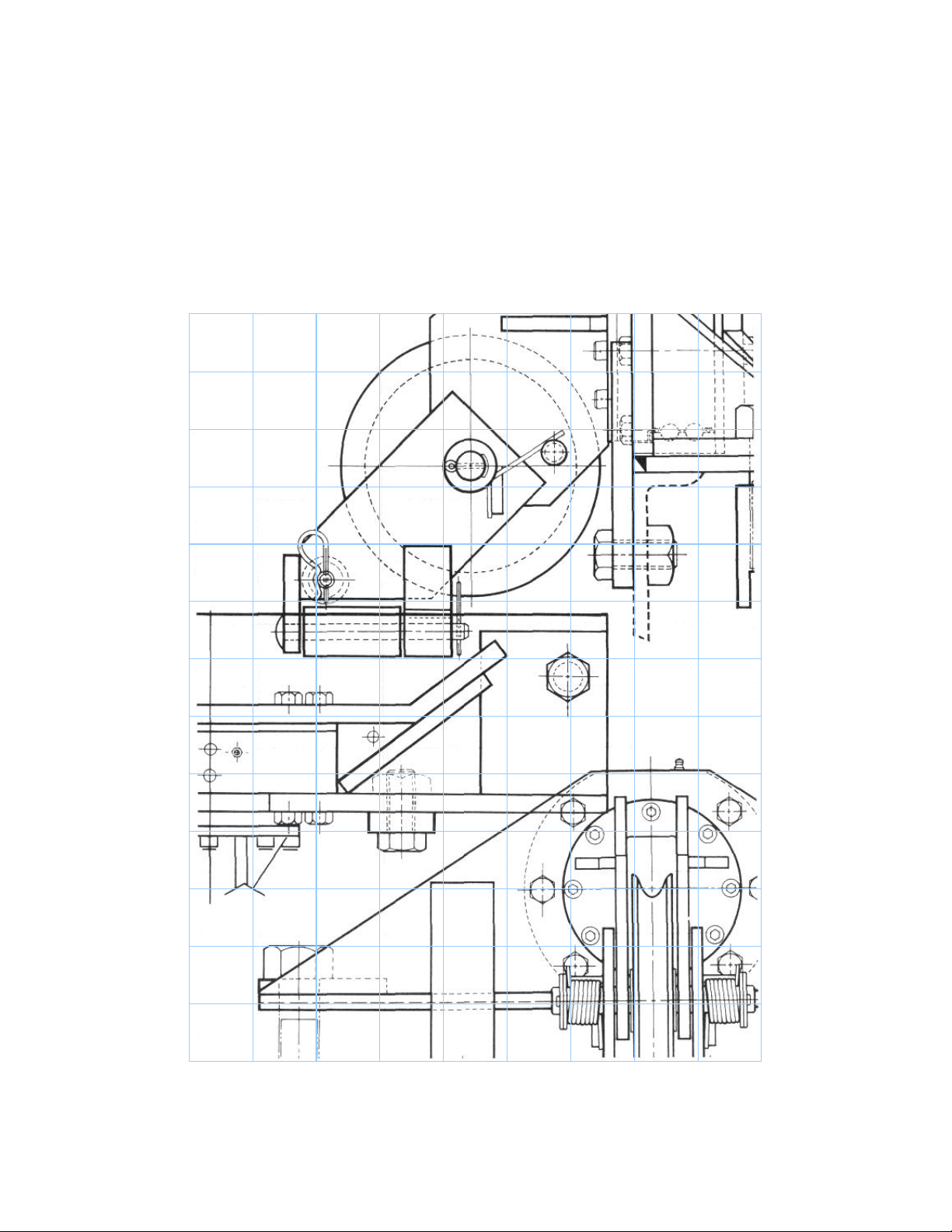

Drawings

Parts

6

7

Specifications 7

General

Precautions

!

The Model UV-25 Universal Swivel Sheave is designed

to swivel 360° and accept wire rope up to 9/16, in. (14

mm) diameter. The maximum-rated winch line pull for

underground applications is 25,000 pounds-force

(111,205 N-force); and for over head applications 14,000

pounds-force (62,000 N-force). The unit weighs 130 lbs.

(59kg).

GMP has designed and manufactured the Model

UV-25 sheave consistent with sound engineering and

manufacturing procedures. However, because of the nature of the product's use, extreme caution should be exercised during installation and operation.

Use only the recommended mounting sockets and bolts

described on page 4 of this manual. Check each mounting bolt for tightness periodically depending on the

amount of use.

Make certain that the body structure to which the

sheave is to be mounted is sufficiently strong to withstand the 25,000 pounds maximum allowable load to the

sheave.

2

Never load the UV-25 Swivel Sheave or the wire rope

beyond their rated capacity.

The Model UV-25 Swivel Sheave should not be used

when the required rope diameter exceeds 9/16 in.

(14mm).

Stand clear of loads suspended by the winch line. Do not

stand inside of angles formed by the winch line. As

much as possible, do not stand where there is the danger

of being struck by the wire rope if it should fail or snag.

Never place hands on a moving winch line. Always

stand clear of moving winch line. To prevent entanglement in moving parts and possible serious injury, do not

wear loose-fitting clothing when working around the

swivel sheave, wire rope and winch.

Wire rope (winch line) passing through the swivel

sheave may be old, damaged or weakened by such defects as kinks, cuts, extreme bends or loops. Such conditions are potentially dangerous and detrimental to safely

operating the sheave. The wire rope must be routinely

inspected at regular intervals and replaced when worn.

Make certain that the eye at the end of the winch line is

properly spliced or swaged.

It is imperative, and the responsibility of the operating

company, that the crew be properly instructed about the

safe working capabilities and operational limitations of

the sheave, the winch and especially the winch controls.

The operator should never leave his position at the controls while the winch line is under load.

3

Loading...

Loading...