Strand Tensionmeter

Operation and

GMP

Maintenance Manual

1

2

Table of

General 3

contents

General

Precautions 5

Calibration Chart 6

Temperature Compensation Charts 8

Dial 16

Using the Tensionmeter 16

Accessory Saddle 18

Re-calibration 19

An intensive study by the National Electric Safety

Code Clearances Subcommittee has resulted in a

completely new "Uniform System of Clearances"

adopted in the 1990 and subsequent editions of the

NESC. This revision places renewed emphasis on

utilities' practices for engineering and stringing of

aerial cables to maintain proper cable clearances

under the various specified conditions. The ability

to accurately measure strand tensions in the field is

essential for compliance with the code.

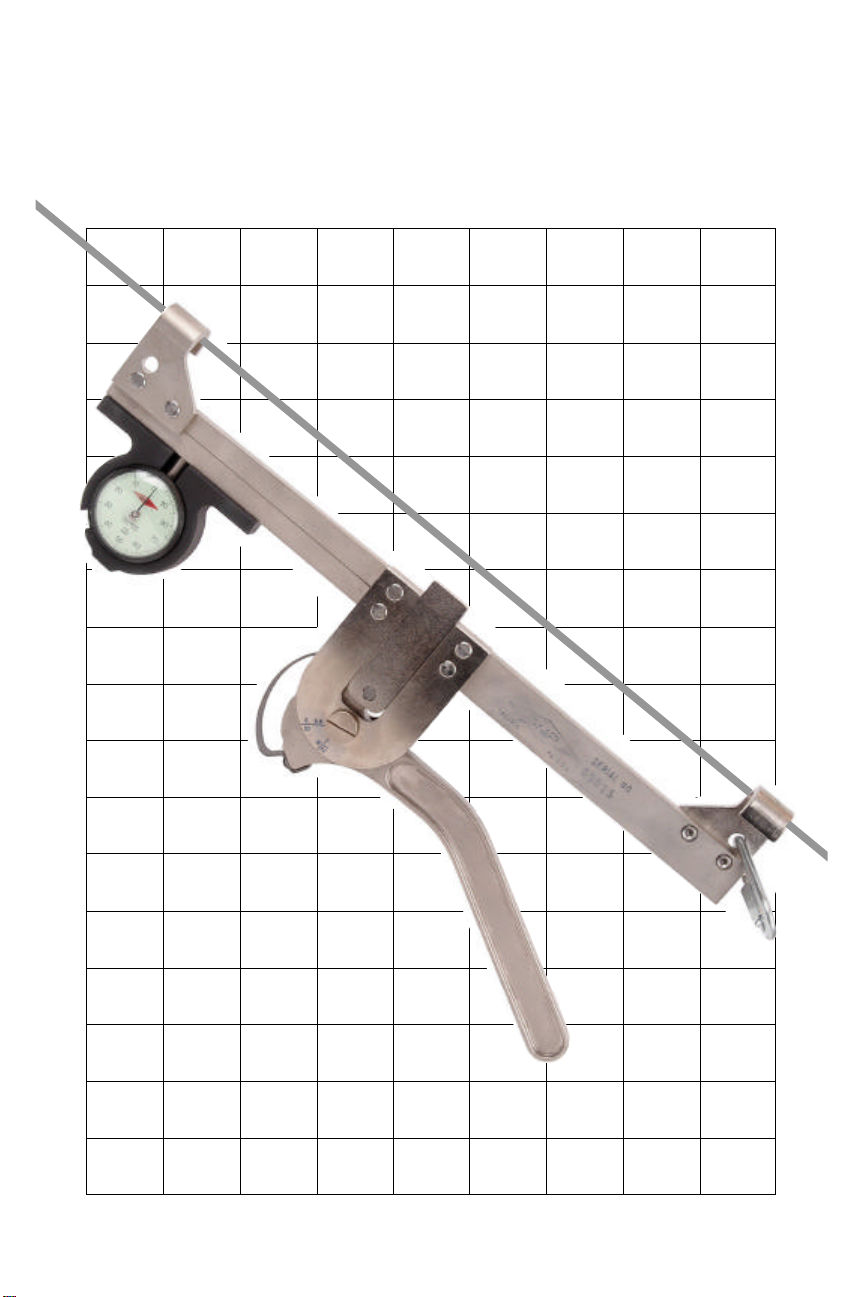

The GMP Strand Tensionmeter, also called a B

Strand Dynamometer, is a precision instrument designed to measure the tension of certain specific

zinc-coated guy wires and messenger cables per

ASTM A-475. The specific sizes and type(s) of

cable(s) with which this unit is compatible are

listed in the calibration chart which has been prepared for this specific serial numbered tensionmeter and which bears that identical serial number.

3

The following list shows the various sizes, types

and designations of messenger cables for which

the tools can be calibrated:

Nominal Diameter

Inches mm Designation Description

1/4 6.35 6.6M 1 X 7 EHS

5/16 7.94 6M 1 X 7 Utility Grade

5/16 7.94 10M 1 X 7 EHS

3/8 9.52 10M 1 X 7 Utility Grade

7/16 11.11 16M 1 X 7 EHS

7/16 11.11 16M 1 X 7 Utility Grade

To obtain an accurate measurement it is imperative

that the strand to be measured be positively identified as to its actual diameter and its grade, either

Utilities Grade or Extra-High Strength. Secondly,

the Strand Tensionmeter to be used must have a

current calibration chart with a corresponding serial number which has a calibration for the specific

strand you have identified.

The Tensionmeter measures the force required to

deflect the strand to an out-of-line position and

registers the amount of force required on the integral dial. The actual strand tension is then determined by referring to the calibration chart specifically prepared for and furnished with each Tensionmeter, which converts the dial indicator reading into the actual tension value.

The instrument measures tension in pounds force

to within an accuracy of three percent (± 3%) or ±

150 pounds, whichever is greater.

4

The Tensionmeter is primarily made from nickelplated steel and is furnished in a hard shell plastic

carrying case; the interior is cushioned with foam

for unit protection.

Each Tensionmeter has a registered serial number

stamped on the unit.

pPrecautions

• Do not measure tensions of 1/2" diameter

strand with the cable in place; these tension

values usually exceed 10,000 pounds.

• Do not drop or jar the Tensionmeter.

• Raise and lower the instrument with a hand

line.

• Keep the device away from dirt, grease, sand

or water.

• Keep foreign material from damaging the dial

or plunger.

• Maintain the unit in the carrying case when-

ever possible.

• Make certain that the correct calibration chart

is always kept in the carrying case.

• Use the Tensionmeter only on strand type and

sizes shown on the calibration chart.

• Do not use this device on strand tensioning

applications exceeding 10,000 pounds.

5

Calibration

Chart

Included with each Tensionmeter is a calibration

chart registered under the same serial number as

the Tensionmeter. This chart is to be used for interpreting the readings for that specific instrument

only.

No other chart should be used. No other type of

strand should be used.

The table across the top of the chart lists the commonly used strand sizes for which the Tensionmeter was calibrated, as well as the handle position

for each type of strand. The data in the chart indicates the dial reading of the Tensionmeter corresponding to the amount of strand tension in 100

pound increments for the normal tension range of

each strand size.

The chart indicates the date when the initial calibration was made. If the chart is lost, the Tensionmeter must be returned for re-calibration.

Temperature

Compensation

Charts

Strand tension is affected by ambient temperature.

Generally speaking, strand tension increases as

temperature decreases due to the strand contraction

and, conversely, strand tension decreases as temperature rises, due to expansion. The Strand Tensionmeter will measure the actual tension at the

ambient temperature at the time of the measurement. You should consult with the Outside Plant

Facilities Engineer as to the proper strand tension

for the ambient temperature at the time of measurement.

6

Temperature

Compensation

Charts

(continued)

Line charts are provided in these instructions in order for the user to determine how to compensate for

changes in ambient temperature. The charts are derived from the recommended values expressed in

the referenced industry standard practices. They are

not intended to supersede any tension calculations

which might be provided to the user by the utility's

plant engineering department.

For example, assume that the engineering specifications for tensioning a certain 300 ft. span of 1/4"

Extra-High Strength strand (i.e. Bell System 6.6M)

calls for the strand to be at 600 lbs. at 60 degrees F.

When you are at the work site, your thermometer

indicates an ambient temperature of 86 degrees. Referring to the Temperature Compensation Chart for

that specific strand, you will see three lines. Find

the one which corresponds to spans 250-450 feet.

Notice that 600 pounds on the vertical axis corresponds to 60 degrees on the horizontal axis. Now

continue right along the horizontal axis to 86 degrees. With a straight edge, follow from that point

vertically until you intersect with the 250-450 ft.

line. 86 degrees corresponds to just over 500

pounds. That is the strand tension compensated for

86 degrees ambient. On the Tensionmeter Calibration Chart for 1/4" EHS, locate 500 Ibs. and convert

to the dial indicator reading. That is the dial indicator number to shoot for when tensioning this particular strand.

An analog thermometer is provided in each Strand

Tensionmeter storage case for the purpose of accurately determining the ambient temperature at the

time of the measurement. Be sure to hold the thermometer by the dial and not by the sensing stem

and to allow at least two minutes for the thermometer to stabilize itself.

7

1000

900

800

700

1/4” Extra High Strength

Temperature Compensation Chart

Per BSP 627-210-018 iss. 1

Tension Pounds Force

600

500

400

0 20 40 60 80 100

Temperature F

SPANS < 250' SPANS 250-450' SPANS >450'

8

1400

1350

1300

1250

1200

1150

1/4” Extra High Strength

Temperature Compensation Chart

Per GTEP 627-100-200 iss.2

1100

Tension Pounds Force

1050

1000

950

900

0 20 40 60 80 100

Temperature F

SPANS < 250' SPANS 250-450' SPANS >450'

9

2500

Tension Pounds Force

2400

2300

2200

2100

5/16” Extra High Strength

Temperature Compensation Chart

Per GTEP 627-100-200 iss.2

2000

1900

1800

1700

0 20 40 60 80 100

Temperature F

SPANS <400 SPANS >400

10

4400

Tension Pounds Force

4300

4200

4100

4000

3900

7/16” Extra-High Strength

Temperature Compensation Chart

Per GTEP 627-100-200 iss.2

3800

3700

3600

3500

3400

0 20 40 60 80 100

Temperature F

ALL SPANS

11

1600

1500

1400

1300

1200

5/16” Utilities Grade

Temperature Compensation Chart

Per BSP 627-210-018 iss. 1

Tension Pounds Force

1100

1000

900

800

0 20 40 60 80 100

Temperature F

SPANS < 250' SPANS 250-450' SPANS >450'

12

2700

2600

2500

2400

2300

2200

3/8” Utilities Grade

Temperature Compensation Chart

Per BSP 627-210-018 iss. 1

2100

Tension Pounds Force

2000

1900

1800

1700

0 20 40 60 80 100

SPANS <400 SPANS >400

Temperature F

13

4400

4200

4000

3800

7/16” Utilities Grade

Temperature Compensation Chart

Per BSP 627-210-018 iss. 1

3600

3400

3200

3000

0 20 40 60 80 100

Temperature F

ALL SPANS

14

9200

9000

8800

8600

8400

8200

1/2” Utilities Grade

Temperature Compensation Chart

Per BSP 627-210-018 iss. 1

8000

7800

7600

7400

7200

0 20 40 60 80 100

Temperature F

ALL SPANS

15

Dial

The calibrated dial reads 0 to 100. The majority of

recorded measurements will be within this range

and are readjust as the graduation appears on the

dial.

However, on high load measurements, it is possible for the needle to make one complete revolution

past zero. For these readings, it is necessary to add

100 to the graduation indicated by the needle.

Using the

Tensionmeter

Accurate strand tension measurement requires that

a section of strand be at least twenty feet long and

free from damage or corrosion. If cable is in place,

remove one ring or cable support or un-lash sufficiently to obtain about two feet of unobstructed

strand.

Suspend the instrument on the strand by the hooks

located at each end of the tension bar with the handle projecting downward.

With the unit in position, always check to make

certain that the dial indicator reads zero. If the dial

indicator does not read zero, loosen the slotted

screw located in the dial shroud. Rotate the dial

slightly until the dial indicator reads zero and retighten the screw. As an alternate to "re-zeroing"

the unit each time the installed position of the Tensionmeter is changed, place the unit in the position

in which it is to be used and note the number of

graduations above or below the zero mark. Once

the Tensionmeter is installed and set, add or subtract those graduations to/from the dial reading before referring to the chart.

16

Using the

Tensionmeter

(continued)

Locate the column on the calibration chart for the

grade and diameter of strand to be tested and note

the correct handle position. (An asterisk alongside

of the handle position number means that the accessory saddle must be used.* See the next section

titled Accessory Saddle before proceeding.) Pull

the handle down until the bottom edge of the cam

plunger moves upward and stops at the correct position numbered on the cam case. The strand will

be deflected between the suspension hooks when

the handle engages into the detent at the correct

numbered position. Read and record the dial indicator number.

IMPORTANT: The calibrated dial reads 0 to

100. The majority of recorded measurements

will be within this range and are read exactly as

the number appears on the dial. On high load

measurements, however, it is possible for the

needle to make one complete revolution past

zero. For these readings, it is necessary to add

100 to the number indicated by the needle.

Take two additional readings moving the Tensionmeter approximately 1/4" along the strand for each

reading. Read and record each dial indicator number.

Discard the high and low readings and use only the

intermediate reading as the correct value. Refer to

the calibration chart under the specific strand diameter and locate the dial reading closest to the

observed reading. Move to the left column showing the corresponding amount of tension in pounds

force.

* on certain older design units

17

Accessory

Saddle

Certain Strand Tensionmeters manufactured and

sold between Jan. 1991 and July 1992 had cam

plungers of a different design than either the

AT&T units which preceded them or the current

GMP design which follows them. These units bear

serial numbers in the range 1700-2300 stamped on

the handle. When checking the tension on 1/4”,

5/16” or 3/8” diameter strand, a part called the accessory saddle block must be used to achieve dial

indicator movement and a correct tension reading.

This accessory saddle block is a rectangular steel

block which mounts on top of the cam plunger and

is held in place by two 7/16" head hex screws. The

calibration charts furnished with these units have

an asterisk (*) alongside the handle position numbers for the strand sizes where the accessory saddle must be used. A handle position number with

no asterisk means that the accessory saddle must

not be used. The accessory saddle applies only to

the units described above and does not apply to

AT&T units, nor does it apply to GMP units with

5 digit serial numbers.

18

Recalibration

To maintain optimum service, the Tensionmeter

should be re-calibrated periodically. With moderate to heavy use, a calibration check should be performed every year. The initial calibration date is

shown on each calibration chart. No attempt

should be made to disassemble, repair or recalibrate in the field. If a unit is not responding to

normal use, it should be placed in the carrying case

with the calibration chart and returned to General

Machine Products Co., Inc. for service. Please supply a contact name, address, phone number and a

reason for return.

Calibration

Dates

19

General Machine Products Co., Inc.

3111 Old Lincoln Highway

Trevose, PA 19053-4996 USA

TEL: 215-357-5500

FAX: 215-357-6216

E-MAIL: info@GMPtools.com

WEB: http://www.GMPtools.com

GMP reserves the right, without notice, to make changes in

equipment design or components as progress in engineering or

manufacturing methods may warrant.

All contents ©2005 GMP

20

Loading...

Loading...