General Machine Products 5-8 Break-Away Swivel User Manual

5/8 in. Break-Away Swivel

Disassembly Procedure

The following disassembly operation will deal with

small parts. Disassembly and re-assembly should be

done in an area where parts will not be lost if accidentally dropped.

1. Retrieve both halves of the broken swivel.

2. Loosen the #6-32 x 1/8 in. (3.18 mm) set screw

located in the swivel body with the 1/16 in. (1.59

mm) Allen wrench provided and back it off 2-3

turns.

3. Unscrew and remove the remnant stud of the bro-

ken tension bolt.

4. Unscrew the stationary body where it joins the

housing and remove the head of the broken tension bolt and the four bearings.

5. Place the four bearings on a new tension bolt of

the desired tension value.

6. Place the new tension bolt with bearings through

the housing and screw the bolt into the swivel

body.

IMPORTANT: Do not over tighten the tension bolt,

because premature fracture may occur. Tighten the

bolt lightly until it bottoms (don't use excessive force).

Do not apply torque to the head of the ten-

!

sion bolt as over-stressing the bolt may

cause a lower breaking point.

7. Re-tighten the set screw into the side of the swivel body.

8. Screw the stationary body and housing together

and tighten.

Questions? Comments? Call us!

We want you to be completely satisfied with cable

placing products you get from GMP.

If you have a problem or need additional information,

please call us at 1-215-357-5500 or our toll free tech

support line at 1-800-345-6009 from 8:00 AM to 5:00

PM EST on any USA business day; you can also fax

us any time at 1-215-357-6216. We would be happy to

help!

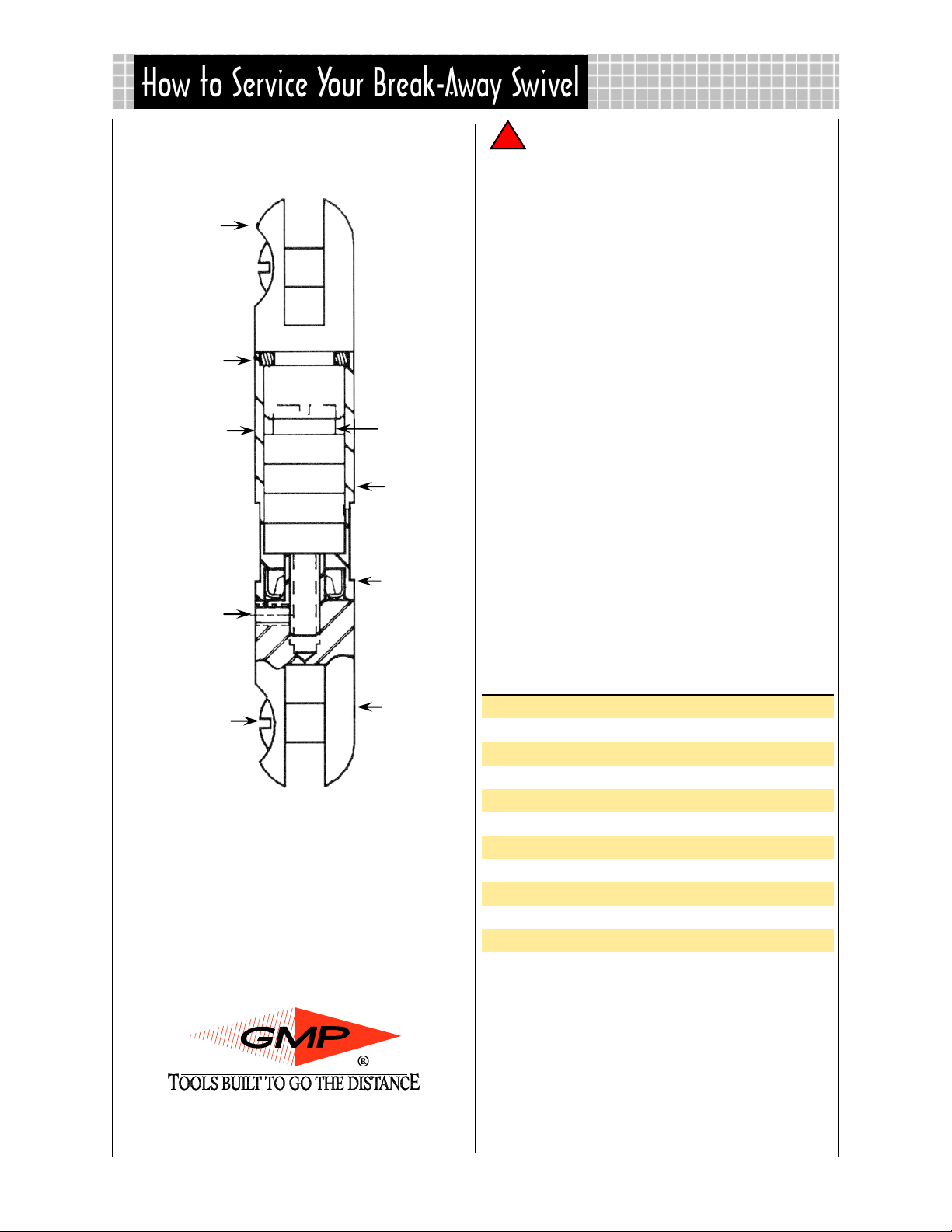

5/8 in. Break-Away Swivel

Staonary Body

P/N 25422

“O” Ring

P/N 25424

Housing

P/N 25420

#6-32x.12 L.G. Brass

Tipped Set Screw

P/N 25426

(2) Shoulder Screw

P/N 25301

Tension Bolt

See Chart

(4) Bearings

P/N 30336

Rubber Seal

P/N 25425

Swivel Body

P/N 25421

IMPORTANT NOTICE

!

Users are cautioned to ensure appropriate safeguards

exist especially during aerial cable placing. Should the

swivel break there must be sufficient support to prevent the cable from reversing direction and creating

slack in an uncontrolled and potentially hazardous

manner. This is critically important when crossing

rights-of-way such as roadways, waterways or power

lines. Refer to your employer's work practices or consult the factory for detailed information pertaining to

this most important safety procedure.

All personnel should stand clear of the pulling line

when using any break-away swivel, in the event that

excessive pulling resistance causes the swivel to break

apart and possibly exit the duct at great speed.

Notes:

1. Breaking tolerance ±5%

2. Warning!! Do not over tighten the tension bolt,

because premature fracture may occur. Tighten

the bolt lightly until it bottoms (not using excessive force). Then unscrew ½ turn to achieve proper bearing clearance and swivel action.

3. See other side for disassembly procedure.

Steel 5/8” (15.9 mm ) Diameter Break-Away Swivel

Part Number Break Point

lbs. kgs Color Code Swivel Repl Bolt

200 91 Orange/White 71399 26309

220 100 Red/White 71400 26310

295 134 Green/White 71401 26305

340 154 White 71402 30333

400 181 Blue/White 71403 26306

420 190 Yellow/White 71404 26307

435 197 Violet/White 71405 26308

450 204 Orange 71406 25494

500 226 Violet 70188 26325

600 272 Yellow 71408 25493

700 317 Brown 70191 26326

P/N 30162 Replacement Ball Bearing Kit

General Machine Products Co., Inc.

3111 Old Lincoln Highway Trevose, PA 19053

TEL: 215-357-5500 FAX: 215-357-6216

E-Mail: info@GMPtools.com

http://www.GMPtools.com

GMP reserves the right, without notice, to make changes in equipment design

or components as progress in engineering or manufacturing methods may

warrant. All information contained herein is subject to such change.

P/N 30370 AK 111408

Loading...

Loading...