How to Use Your New...

Fiber Optic Pulling Capstans

Description & Use

Your new GMP Fiber Optic Pulling Capstan is a

versatile and highly productive tool for placing

fiber optic cable. It is based on GMP's accessory

approach to fiber cable placing that lets you use

your existing pulling equipment, winches and

capstan drives, without special modifications or

expensive new pulling equipment.

Virtually anywhere you have used a CR Collapsible Reel or RS Power Reel you can now use this

fiber puller. Its durable construction and minimum number of components give it a remarkably

long, trouble-free service life. The large working

diameter of the capstan translates into good pulling speed and you can pull with rope, tape, or pull

the fiber cable itself. This means that the Fiber

Optic Pulling Capstan can be used both as an end

puller or a mid-assist booster puller.

Any of these units can be easily mounted on a 27/16 in. (62 mm) diameter drive shaft with either

a bayonet or a cross pin type of connection.

IMPORTANT PRECAUTIONS

!

Before you begin placing cable, you should be

completely familiar with the control and operation of the vehicle, power take-off, winch or capstan drive controls and all of the other pulling

equipment you will be using. The operator should

never leave his position at the controls while the

pulling line is under load or the winch power

take-off is engaged. All members of the crew

along the entire length of the intended pull should

be in visual communication by hand signals or

voice communication at all times.

Make certain that all vehicles and trailers are secured with wheel chocks. Make sure your work

area is properly posted with signs, flaggers and

other advance warning devices in accordance

with company practices. Federal, State and local

regulations for the protection of the crew and the

public. You'll find everything you need in our

Safety Catalog.

If you are pulling from a drum shaft extension on

a bed winch, de-clutch so that the drum is in freespool, wind all of the wire rope onto the drum and

secure it using a winch line holder. This will keep

the wire rope from spooling off the drum and becoming entangled.

Do not stand inside of angles formed by the pulling line or cable. As much as possible, do not

stand where there is the danger of being struck by

the pulling line if it should fail or snag. Never

place hands on a moving pulling line. To prevent

entanglement in moving parts and possible serious injury, do not wear loose fitting clothing

when working around the winch, capstan, sheaves

and pulling line.

General Physical

Features

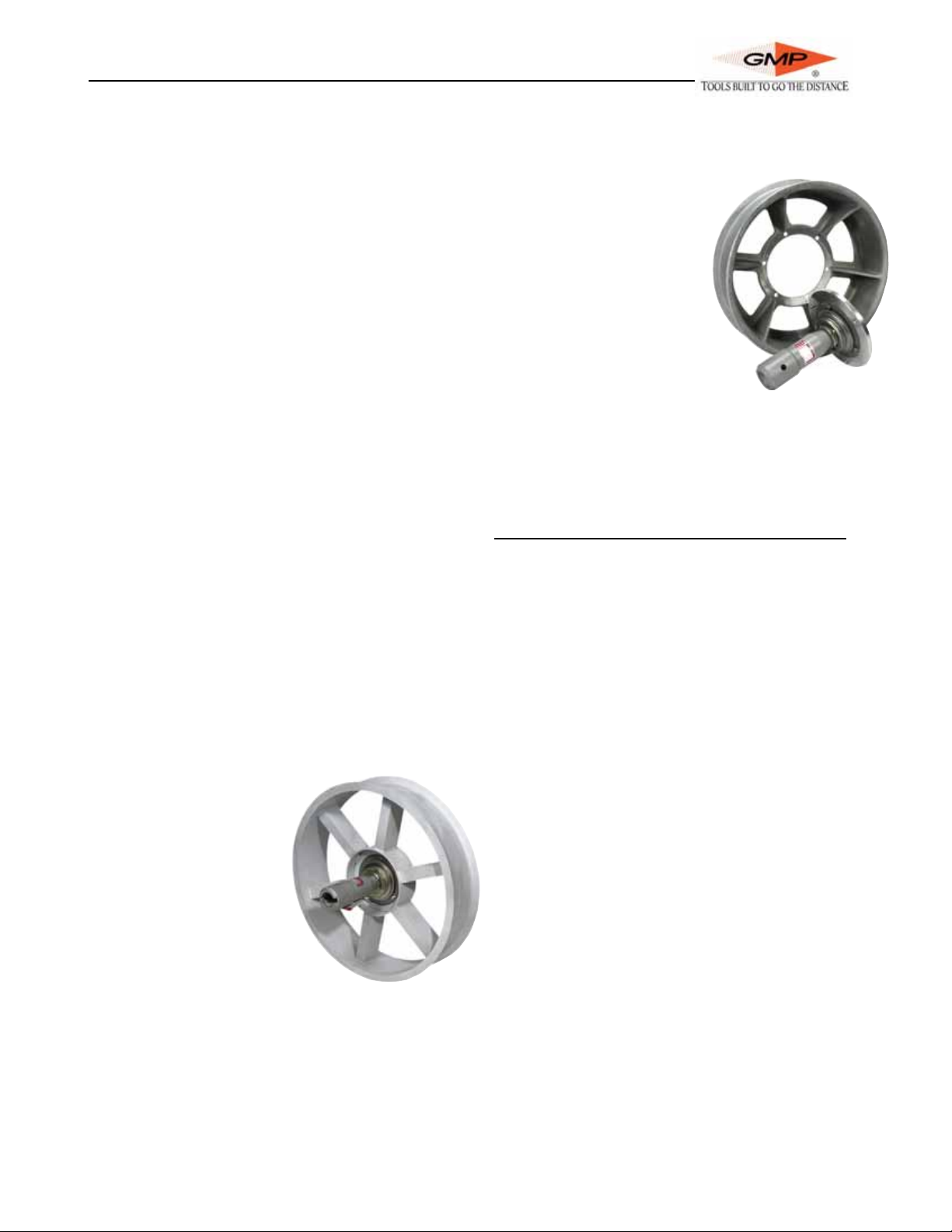

There are several models

of capstans available:

P/N 15470 P/N 15472 and

P/N 15479 each consist of

an aluminum alloy capstan

drum measuring 27-1/2 in.

(698 mm) outside flange

diameter and a 25 in. (635

mm) diameter X 5 in. (127

mm) wide working surface. The capstan drum is

bolted to an inner hub and

drive spindle by means of

three 1/2 -13 x 1-1/4 in.

cap screws with 3/4 in. (19 mm) hex heads.

P/N 15470 is a capstan mounted directly to the

inner hub and drive spindle with no torque limiting capability. With this unit the pulling tension

must be limited by means of a break-away swivel

or by limiting the hydraulic system pressure to

achieve a maximum allowable torque.

P/N 15472 is a capstan equipped with an integral

torque limiter between the driving spindle and the

inner hub. The torque limiter limits the pulling

tension to a calibrated maximum that has been set

at the factory to 600 pounds-force (2669 N).

P/N 15479 is a capstan equipped with an integral

torque limiter between the driving spindle and the

inner hub. The torque limiter limits pulling tension to a calibrated maximum that has been set at

the factory to 1000 pounds-force (4448 N).

P/N 70351 consists of an aluminum alloy capstan

drum measuring 34-3/4 in. (883 mm) outside diameter and a 32 in. (813 mm) diameter X 7-1/2

in. (191 mm) wide working surface. The unit is

equipped with an integral torque limiter between

the driving spindle and the inner hub. The torque

limiter limits the pulling tension to a calibrated

maximum that has been set at the factory to 600

pounds-force (2669 N).

P/N 70381 is same as 70351, but provides pulling

tension of 750 pounds-force (3336 N).

Setting Up for Pulling

First, mount the capstan to the 2-7/16 in. (62 mm)

drive shaft. Because of the combined weight of

the drive section and the capstan drum assembled

(see summary chart below) it is recommended

that two people mount the assembled unit.

Push the drive spindle onto the drive shaft and

rotate it counter-clockwise 1/8 turn until the bayonet pin locks.

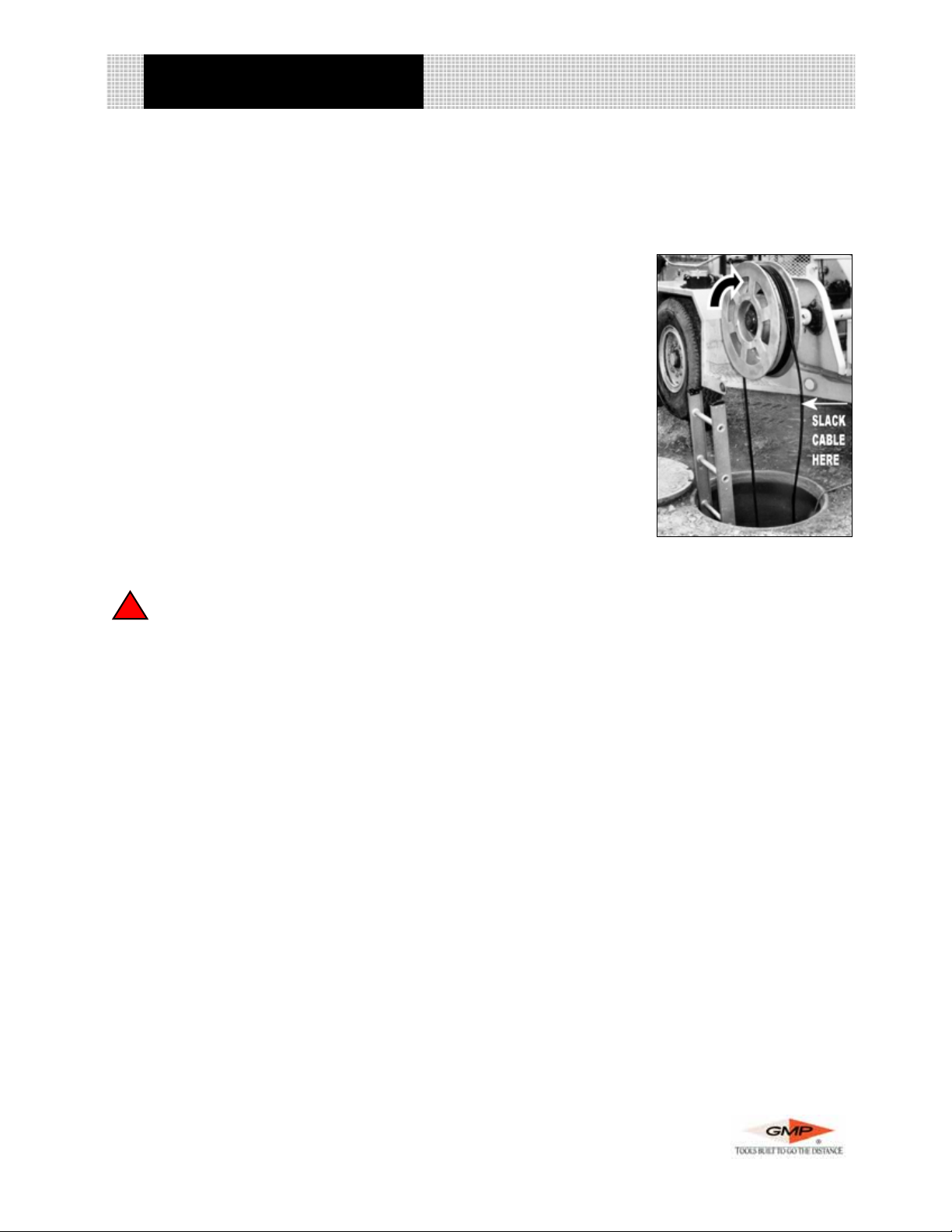

Now wrap the pulling rope or tape around the

working surface of the capstan four turns in an

over-wind direction. This dissipates the pulling

tension of the pulling line across the capstan's surface area. When the appropriate signal comes to

begin the pull slowly start the driving shaft, rotating the capstan clockwise and gradually increasing the shaft speed until the desired line speed is

obtained.

Observe the lay of the pulling line on the capstan

surface for any binding that might occur as the

tape or rope enters and leaves the capstan. If binding begins to occur the line exiting the capstan

should be manually peeled off of the capstan.

Binding can often be minimized by changing the

angle of approach of the pulling line to the capstan. It is usually best to have the pulling line approach the capstan close to the inboard flange. As

the capstan rotates, the tape will move outward

along the working surface and exit the capstan.

If the pulling line tends to slip on the capstan surface due to excessive lubricant, make additional

wraps until slippage stops.

Torque Limiting Models P/N 15472; 15479, 70351

& 70381

The torque limiter is calibrated at the factory.

This pre-set value is

stamped onto the serial

number plate. It is recommended that the unit

be subjected to a static

line pull periodically to

cause the capstan to stall

and the torque limiter to slip

for about 30 seconds only.

This will verify that the torque limiter is functioning and has not become frozen due to lack of use.

This is best accomplished with a dynamometer

installed in line to verify the torque limiter setting. If the capstan stalls occasionally during pulling due to elevated tension levels this is sufficient

to assure the user that it is working properly

Re-calibration of the Capstan Torque Limiter

The simplest and most certain way to have the

unit re-calibrated is to return it to the

factory. Here it can be disassembled

by competent mechanics with the

proper tools, the parts evaluated

for excessive wear and replaced

or reconditioned as needed and

the re-calibration performed on

our certified test stand. Please

remove and return the clutch and

spindle assembly for calibration.

Include your contact information

and the size capstan the unit is to be

calibrated for. Factory turn around

will be within 5 working days or

sooner if your needs dictate.

Summary of Model Features

Working Dia Pull Weight

P/N In. mm Lbs-

force

15472

15479

15470

70351

70381

70471

70472

70473

70475

70478

*Models less torque limiter: Max rated load 1500 lbs 6672 N

25 635

25 635

25 635

32 813

32 813

32 813

32 813

40 1016

40 1016

40 1016

600 2669

1000 4448

n/a* n/a*

600 2669

750 3336

1000 4448

n/a* n/a*

600 2669

1000 4448

n/a* n/a*

new-

tons

lbs kgs

80 34

100 45

86 39

80 37

80 37

80 37

86 39

135 61

135 61

100 45

How To Reach Us

Our support lines are open every USA business

day from 8:00 a.m. to 5:00 p.m. eastern time.

To reach technical support call 1-800-345-6009.

Outside of the continental U.S. call 1-215-357-

5500 ext. 409

Our FAX is always available at 1-215-357-6216.

Our email address is info@GMPtools.com

General Machine Products Co., Inc.

3111 Old Lincoln Hwy

Trevose, PA 19053

GMP Manual

P/N 09208

Loading...

Loading...