Genelec 8351A User Manual

Operating Manual

8260A, 8351A, 8250A and 8240A

Introduction

Congratulations and a thank-you for the purchase of this Genelec SAM system. All Genelec SAM systems are designed to integrate easily into the digital production environment. There are

several ways to configure and operate SAM systems for a wide

variety of high quality audio applications. The SAM monitors

also have analog inputs, making them versatile and intelligent

replacements for standard analog monitors.

This manual addresses the setup and use of the 8240A, 8250A,

8351A and 8260A SAM monitors in stand-alone mode without

the Genelec Loudspeaker Manager GLM™ and the proprietary

Genelec monitor control network. Use with the GLM™ is described in the GLM™ System Operating Manual.

LISTENING

POSITION

MICROPHONE

GLM

NETWORK

GLM

NETWORK

USB

GLM

NETWORK

System

Genelec 8240A, 8250A, 8351A and 8260A are designed for

precise monitoring of 24 bit/192 kHz AES/EBU digital audio signal or line level analog audio signal. They are fully compatible

with Genelec Loudspeaker Manager GLM™ and the proprietary

Genelec monitor control network, and Genelec 7260A, 7270A

and 7271A SAM Subwoofers, but can also be used independently of these. The 8240A, 8250A, 8351A and 8260A feature

high SPL output, low colouration and broad bandwidth in a small

enclosure size. They are suitable for a wide variety of tasks,

such as near field monitoring, mobile vans, broadcast and TV

control rooms, multichannel sound systems and home studios.

The Minimum Diffraction Enclosure™ (MDE™), advanced Directivity Control Waveguide™ (DCW™) and Minimum Diffraction Coaxial (MDC™) technologies provide excellent frequency

balance even in difficult acoustic environments.

Amplifiers

The amplifier unit is mounted in the rear of the monitor enclosure.

The unit incorporates special circuitry for driver thermal overload

protection. Variable input sensitivity allows accurate level matching to console output section.

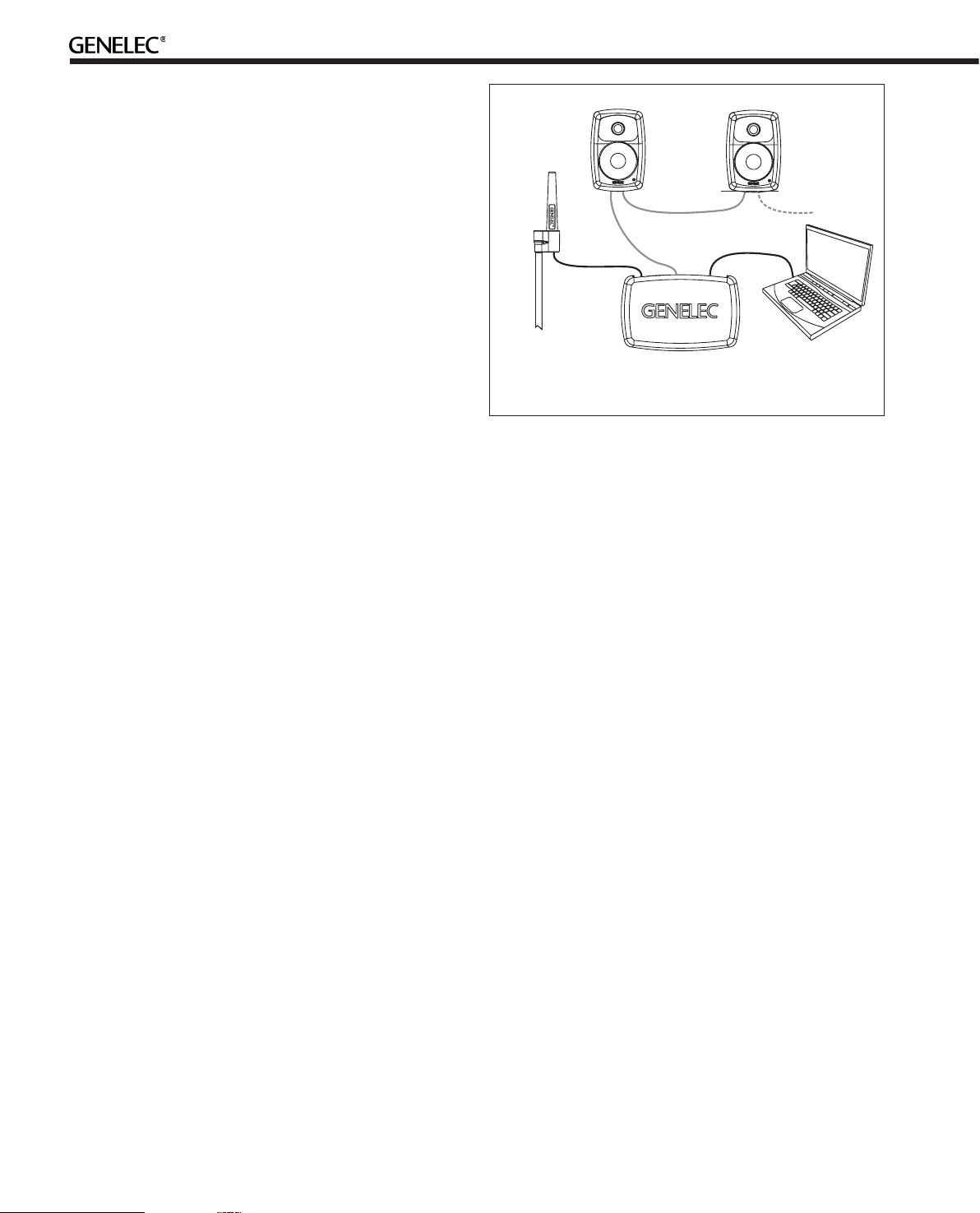

Setting Up the GLM™ Control Network

Although the

without the GLM

their full potential when set up and calibrated using the GLM™

software. The setup is fast and consists of the following steps:

1. Run a CAT5 (RJ45) cable from the monitor control network

to the next monitor (see Figure 1).

2. Run the final cable to control network input of the GLM

Adapter device.

3. Connect the GLM Adapter device to your computer USB

connector. The cable

4. Place the Genelec measurement microphone at the listen-

8240A, 8250A, 8351A and 8260A can be used

™ software and control network, they only reach

is a part of the GLM User Kit

.

Figure 1. GLM control network cabling

ing location of the engineer, on a stand, with the microphone

pointing upwards and the microphone top at the height of the

engineers ear in normal working position. The microphone is

a part of the GLM User Kit.

5. Run the microphone cable to the microphone input in the

GLM Adapter device.

6. Download GLM software at the Genelec web site (www.

genelec.com). Install the GLM software.

7. Follow the GLM software instructions to measure and set

up your monitors.

8. If you plan to not use a computer for controlling the monitors, use the GLM software to write the setting into the monitors (“Store the Settings”).

Using the Monitors in Stand-Alone Mode

When the monitors are not connected to a Genelec monitor control network, they operate in the stand-alone mode. However, settings made with the Genelec Loudspeaker Manager software can

be saved into each monitor and applied even when the network

is disconnected by setting switch 1 “STORED/MANUAL CONTROL” on switch group 2 of each monitor to position “STORED.”

All issues concerning use with the network are explained in detail

in the System Operating Manual provided with the GLM™ Loudspeaker Manager software kit.

Connections

Each monitor is supplied with a mains cable, one 5 m GLM network cable and an operating manual. Before connecting up, ensure that the mains switch is off.

2

Mains power

switch

GLM Control

Network

connectors

Mains input

connector

12V Remote

connector

(8260A only)

SWITCH

1

ROLL-OFF

-2dB -4dB

MAINS INPUT230 V~

50/60Hz 330W

BASS

BASS

TILT

-4dB

-2dB -4dB

+2dB -4dB

160Hz

-6dB -6dB -2dB

REMOTE

SERIALNUMBER

1

2

TREBLE

STOREDDESKTOP

TILT

AB

ON

OFF

MANUAL

ON+ON

OFF+OFF

CTRL

12 V

DIGITALIN

AES/EBU

8260A DSP TRI-AMPLIFIED

MONITORING SYSTEM

MAGNETICALLYSHIELDED

MADE INFINLAND

ON

OFF

ON

OFF

DIGITAL THRU

DRIVERMUTE

WF COAX

SUMAANDB

AES/EBU

www.genelec.com

-8

-6

-10

-4

-2

-12

0

dB

SYSTEMLVL.AES/EBUCH.

SWITCH

-10-20

2

-30

dB

ANALOG

IN

292-8260T-6

Stand-alone user

interface level control

Stand-alone user

interface switch

groups 1 and 2

Analog input connector

Digital Thru connector

Digital input connector

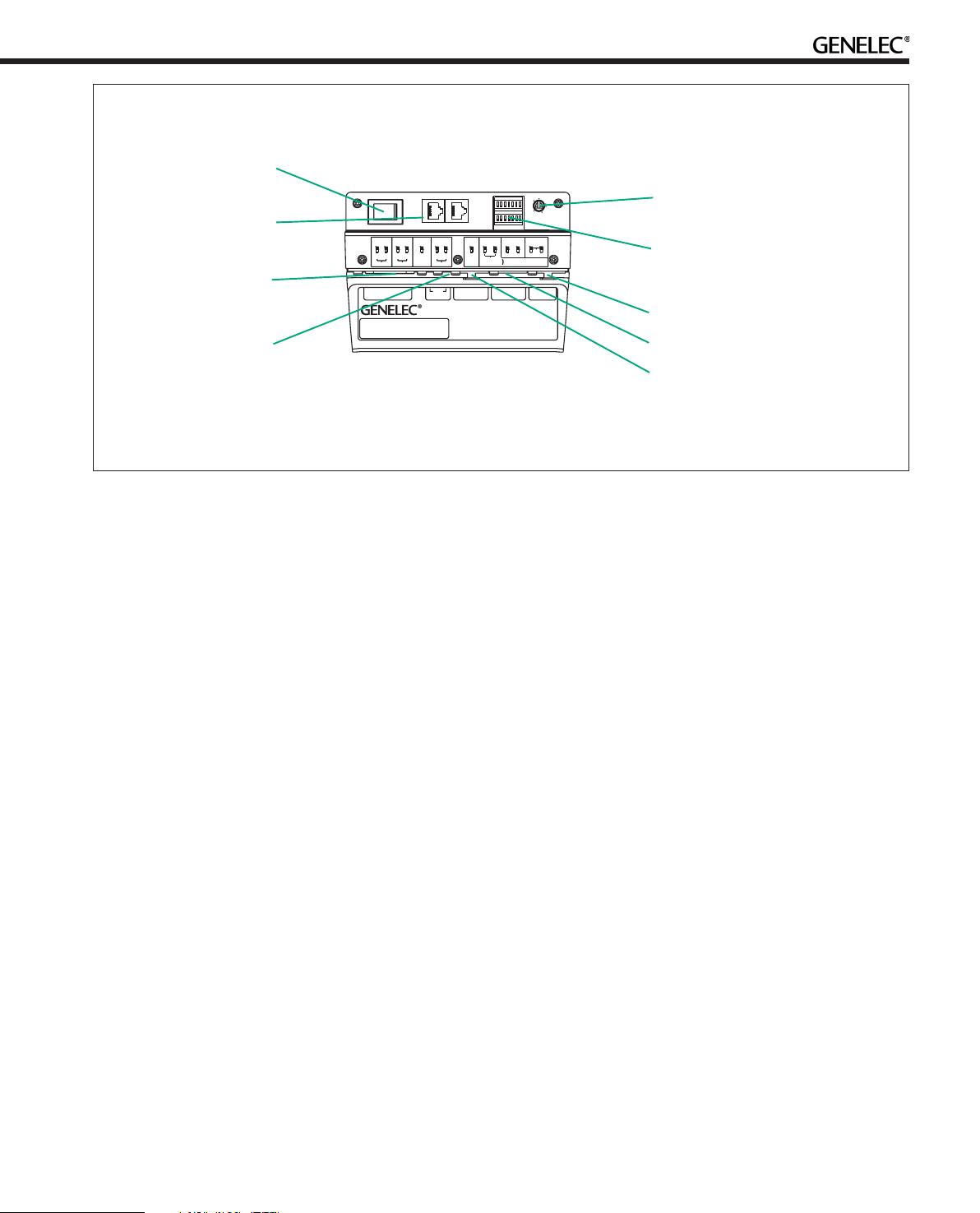

Figure 2. Connectors and controls on the back panel of a 8260A. The 8351A is similar. 8240A and 8250A share the same

layout but without the 12 V trigger voltage connector.

“MAINS INPUT” Connector

Connect the mains supply to this connector.

“DIGITAL IN AES/EBU” Connector

Use this female XLR connector for AES/EBU formatted digital

audio input signals. This input is selected automatically when a

valid digital audio signal is present, and overrides the analog input.

Depending on the digital hardware, transmission of a 192 kHz

sample rate is achieved using a double speed, single channel/

cable interface. This is called dual-wire mode. In this case one

cable per channel is used and no channel selection is required.

Dual-wire mode is automatically detected by the input stage.

If the digital source device has a volume fader that controls the

digital level, it may be advantageous to lower the level control

either on the computer interface or on the monitor’s back panel

controls, which in turn will force the use of more of the digital [bit]

resolution in the volume control.

If the digital inputs are used, all audio outputs are referenced to 0

dBFS (digital Full Scale, the largest level that may be represented in the AES/EBU signal). These monitors produce 100 dB SPL

at 1 meter in free space for a digital input signal of –30 dB FS.

“DIGITAL THRU AES/EBU” Connector

This male XLR carries an unaltered copy of the digital signal fed

into the “DIGITAL IN AES/EBU” connector. It can be used for

daisy-chaining up to four monitors together.

level is +7.0 dBu RMS on models 8240A and 8250A and +22.0

dBu RMS on models 8351A and 8260A. When A/D converter

input clip occurs the front panel light turns momentarily red, indicating the overload condition.

“CONTROL NETWORK” Connectors

Use these RJ-45 sockets to connect the monitor to the proprietary Genelec Loudspeaker Manager™ (GLM™) network only.

This connector is not Ethernet LAN compatible. Do not connect

to Ethernet LAN.

“12 V REMOTE” Connector (8260A only)

You can set up remote controlled powering up and down of the

8260A with 12 V voltage connected to this connector. The minimum current needed to actuate this function is 70 mA.

Front Panel Warning Light

Normally the light on the front panel of a SAM monitor is green,

indicating that the monitor is in normal operational mode.

The overload light (red) is activated by several events:

• exceeding the maximum input range of the analog input

• the digital input level is less than 0.1 dB from the digital full

scale

• exceeding the output capacity of the power amplifier

(clipping in the power amplifier) and thermal

overload of the power amplifier or drivers (thermal

protection has activated)

• an error is detected in the AES/EBU audio data

“ANALOG IN” Connector

Use this connector for analog audio signals. The maximum input

If a red warning light appears, turn the analog source down! If

the levels are already modest and a digital signal is being used,

3

h

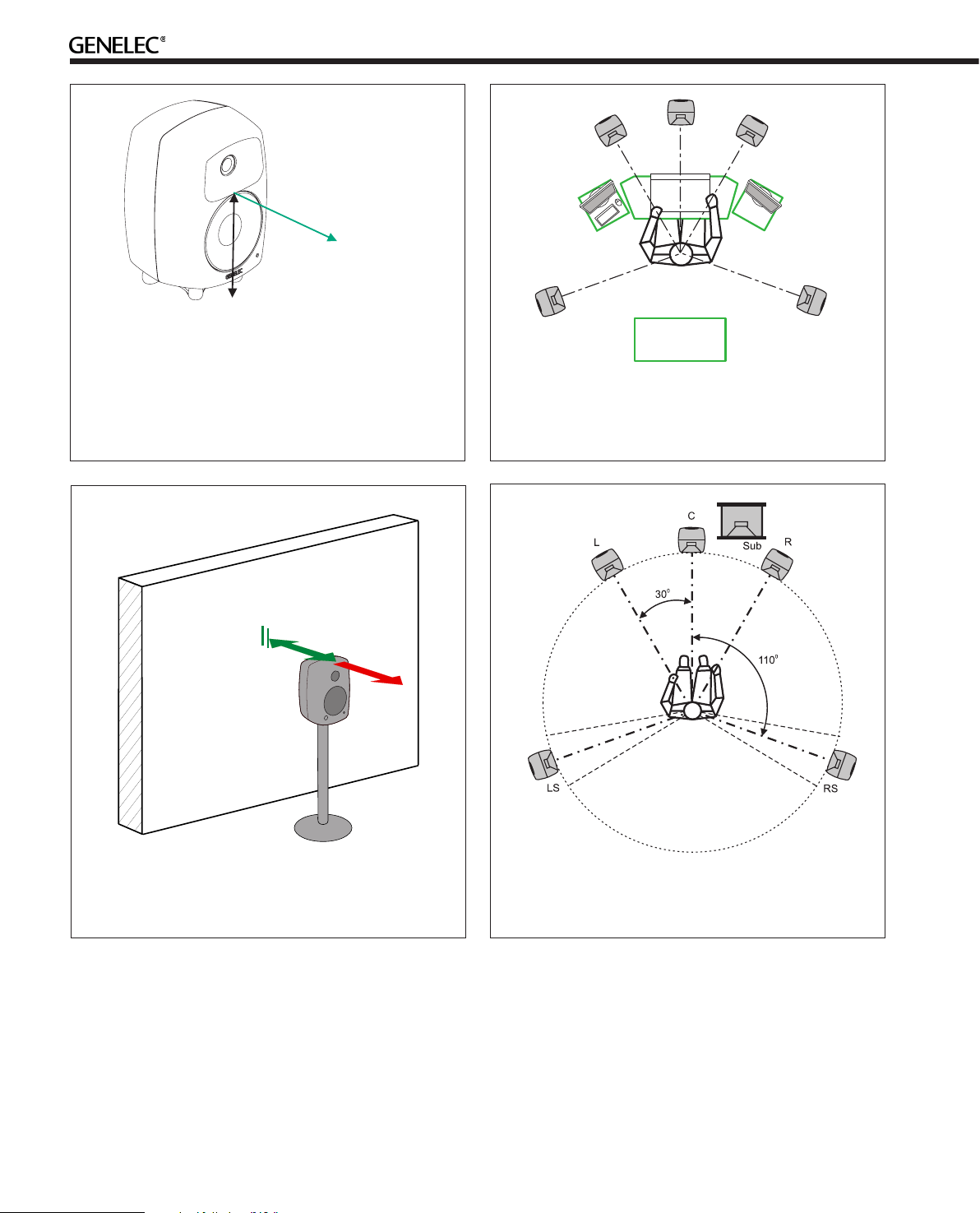

> 0,7 m

ACOUSTIC

AXIS

8240A: h=240 mm (9 7/16 )

8250A: h=290 mm (11 1/2 )

8351A: h=235 mm (9 1/4 in)

8260A: h=448 mm (17 5/8 )

Figure 3. The location of the acoustic axis is on the centerline of the monitor at the given height “h”. The acoustic

axis of the 8351A and 8260A is located at the center of the

coaxial driver.

in

in

in

Max

60 cm

Min 5 cm

Avoid

> 60 cm

Figure 4. Symmetrical layout and keeping the acoustic axis

clear from obstructions minimizes reflection surfaces and

maintains accurate localisation because reflections are symmetrical.

Figure 5. Recommended distances from a single wall to the

front baffle of free-standing monitors. Correct (green) and

not recommended (red).

ensure that there are no bit errors in the AES/EBU digital audio

data.

Mounting Considerations

Align the Monitors Correctly

Place the monitors so that their acoustic axes are aimed towards

the listening position (see Figure 3). Vertical placement is prefer-

4

Figure 6. Recommended monitor positioning for 5.1 multichannel audio reproduction

able, as it minimises acoustical cancellation problems around the

crossover frequency.

Maintain Symmetry

Check that the monitors are placed symmetrically and at an

equal distance from the listening position. If possible, place the

system so that the listening position is on the centerline of the

room and the monitors are placed at an equal distance from the

centerline (See Figure 4).

Loading...

Loading...