Page 1

DEH–40034

g

ProTrip™ Trip Units

for Low-Voltage Power Circuit Breakers

User’s Guide

Page 2

ProTrip™ Trip Units

Getting Started

Since this Trip Unit is available in a variety of configurations, please take a moment to compare the catalog number of

your purchased Trip Unit with the catalog number key below.

Example

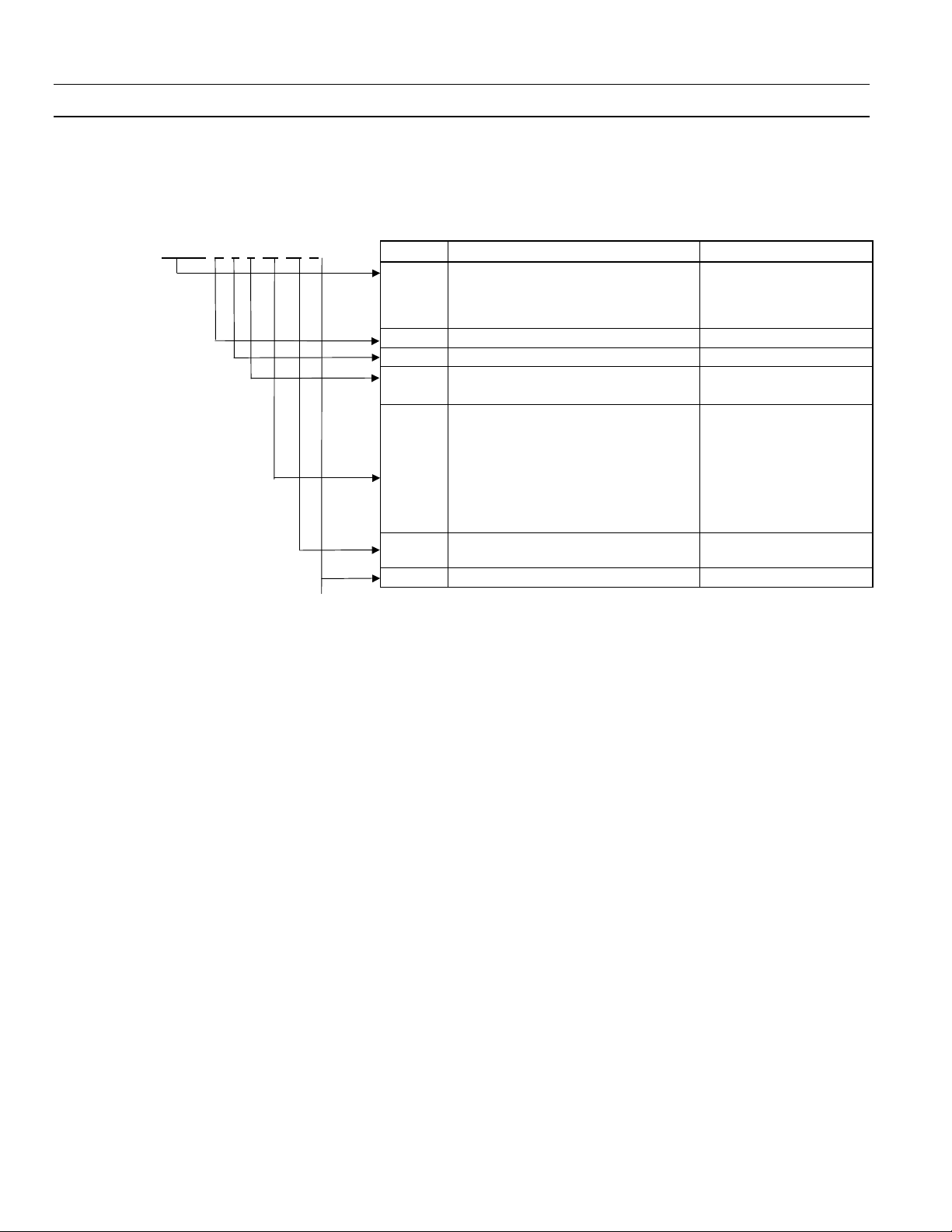

PKO50 D 3 F 16 08 R Code Description Function

PK###

PIK##

PD###

PSL##

GE AK Breaker

I-T-E® Breaker

Westinghouse® Breaker

Allis-Chalmers® Breaker

D ProTrip Trip Unit Trip Unit Model

3 3-Wire Breaker Wiring

Fixed Cts Sensor Type

F

01

150 A

02

225 A

06

600 A

08

800 A

16

1600 A

20

2000 A

32

3200 A

40

4000 A

Long-Time , Short-Time, Instantaneous,

08

Switchable Ground-Fault

R Replacement unit Ordered as Replacement

Breaker Family

Installed CT

Overcurrent Protection

Example – a Trip Unit with catalog number PKO50D3F1608R has the following features:

• GE AK-50 circuit breaker

• ProTrip Trip Unit

• 3-wire breaker

• Fixed CT sensors

• 1600 A CT installed

• Long-time, short-time, instantaneous, and switchable ground-fault overcurrent protection

• Trip Unit was ordered as a replacement

Page 3

WARNINGS

CAUTIONS

NOTES

DEH–40034

WARNINGS, CAUTIONS, AND NOTES

AS USED IN THIS PUBLICATION

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or

other conditions that could cause personal injury or death are present in this equipment or may be

associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge

could cause either personal injury or damage to equipment.

Caution notices are used for situations in which equipment might be damaged if care is not taken.

Notes call attention to information that is especially significant to understanding and operating the

equipment.

This document is based on information available at the time of its publication. While efforts have

been made to ensure accuracy, the information contained herein does not cover all details or

variations in hardware and software, nor does it provide for every possible contingency in

connection with installation, operation, and maintenance. Features may be described herein that

are not present in all hardware and software systems. GE Industrial Systems assumes no obligation

of notice to holders of this document with respect to changes subsequently made.

GE Industrial Systems makes no representation or warranty, expressed, implied, or statutory, with

respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness

of the information contained herein. No warrantees of merchantability or fitness for purpose shall

apply.

The following are trademarks of GE Company:

ProTrip™, MicroVersaTrip Plus™, MicroVersaTrip PM™

© 1998 GE Company

All Rights Reserved

i

Page 4

ProTrip™ Trip Units

Table of Contents

Chapter 1. Introduction

1–1 Applications............................................................................................................................................1

1–2 General...................................................................................................................................................1

1–3 Trip Unit Functions...............................................................................................................................1

1–4 Trip Unit Catalog Numbers...................................................................................................................2

1–5 Rating Plugs ...........................................................................................................................................3

Ground-Fault Protection.................................................................................................................4

1–6 Equipment Interfaces.............................................................................................................................4

1–7 Trip Unit Information...........................................................................................................................4

Trip Unit Label Information..........................................................................................................4

Selector Switches..............................................................................................................................4

Chapter 2. Trip Unit Setup

2–1 Overview .................................................................................................................................................5

2–2 Long-Time Pickup .................................................................................................................................5

2–3 Long-Time Delay ...................................................................................................................................5

2–4 Short-Time Pickup.................................................................................................................................6

2–5 Short-Time Delay...................................................................................................................................6

2–6 Instantaneous Pickup.............................................................................................................................6

2–7 Ground-Fault Pickup..............................................................................................................................7

2–8 Ground-Fault Delay................................................................................................................................7

2–9 Defeatable Ground Fault .......................................................................................................................7

Chapter 3. Trip Unit Status

3–1 Target Module .......................................................................................................................................8

3–2 Functions................................................................................................................................................8

Trip Targets.....................................................................................................................................8

Long-Time Pickup Status................................................................................................................8

Battery Test......................................................................................................................................8

Health Monitor................................................................................................................................8

Chapter 4. Maintenance and Trouble-Shooting

4–1 Trip Unit Removal and Replacement...................................................................................................9

4–2 Rating Plug Removal and Replacement...............................................................................................9

4–3 Target Module Removal and Replacement..........................................................................................9

Target Module Battery Replacement ...........................................................................................10

4–4 High-Current Testing..........................................................................................................................10

4–4 Trouble-Shooting Guide......................................................................................................................11

ii

Page 5

ProTrip™ Trip Units

List of Figures

1. Front view of the ProTrip Trip Unit.........................................................................................................1

2. ProTrip rating plug................................................................................................................................... 3

3. Time-current curve illustrating long-time pickup.................................................................................... 5

4. Time-current curve illustrating long-time delay.......................................................................................5

5. Time-current curves illustrating short-time pickup.................................................................................. 6

6. Time current curve illustrating short-time delay with I2T OUT.............................................................6

7. Time current curve illustrating short-time delay with I2T IN..................................................................6

8. Time-current curve illustrating instantaneous pickup............................................................................. 6

9. Time-current curve illustrating ground-fault pickup...............................................................................7

10. Time-current curve illustrating ground-fault delay with I2T OUT.........................................................7

11. Time-current curve illustrating ground-fault delay with I2T IN..............................................................7

12. Target module........................................................................................................................................... 8

13. Removing the interchangeable rating plug. ............................................................................................9

14. Removing the target module. .................................................................................................................10

iii

Page 6

ProTrip™ Trip Units

List of Tables

1. Breaker type referred to by the first character of the Trip Unit catalog number.................................... 2

2. Trip Unit type referred to by the sixth character of the Trip Unit catalog number............................... 2

3. Wiring type referred to by the seventh character of the Trip Unit catalog number............................... 2

4. Sensor type referred to by the eighth character of the Trip Unit catalog number................................. 2

5. Installed CT, as indicated by the ninth and tenth characters of the Trip Unit catalog number .......... 2

6. Trip unit functions, as indicated by the eleventh and twelfth characters of the Trip Unit catalog

number. ..................................................................................................................................................... 3

7. Catalog numbers for rating plugs............................................................................................................. 3

8. Summary of protective functions and setting values for each. ................................................................ 5

9. Nominal delays for the long-time delay bands......................................................................................... 5

10. Settings available for ground-fault pickup according to breaker frame size........................................... 7

iv

Page 7

ProTrip™ Trip Units

Chapter 1. Introduction

1–1 Applications

The ProTrip™ Trip Units described in this publication

are used on GE; I-T-E® and ABB®; Allis Chalmers®,

Siemens/Allis®, and Siemens®; and Westinghouse and

Cutler-Hammer® low-voltage power circuit breakers.

Figure 1 shows the ProTrip Trip Unit.

ProTrip Trip Units are removable from the circuit

breaker. For instructions on installing and removing the

Trip Unit, see Chapter 4.

CAUTION: Removal of a Trip Unit from its breaker must

be performed with the breaker in the OPEN or TRIPPED

position. Draw-out breakers should be racked out first.

ATTENTION: Pour retirer déclencheur, le disjoncteur

doit être en position ouverte ou déclenchée. Les

disjoncteurs débrochables doivent ètre en position

débrochée.

CAUTION: Do not attempt to operate the breaker without

its assigned Trip Unit. Installation of an incorrect Trip

Unit may result in unsafe operation of the breaker.

ATTENTION: Ne pas utiliser le disjoncteur sans son

déclencheur. Une mauvaise installation du déclencheur

peut être dangereuse.

NOTE: Trip Units as received may have settings that are

undesirable for the specific application. Ensure that

settings are appropriately adjusted before energizing.

Figure 1. Front view of the ProTrip Trip Unit.

1–2 General

ProTrip Trip Units are the same size and have the same

50-pin male D-sub connector as the RMS9D series of

MicroVersaTrip Plus™ and MicroVersaTrip PM™ Trip

Units.

ProTrip Trip Units may be tested with the Trip Unit

installed in the circuit breaker, the rating plug installed in

the Trip Unit, and the breaker carrying current. The Test

Kit plugs into the test socket of the rating plug. The Test

Kit catalog number is TVRMS2 and its operation is

described in GEK–97367.

NOTE: Les disjoncteurs sont livrés avec des réglages

standards qui peuvent être inadéquates pour certaines

applications. Vérifier ces réglages avant de mettre le

disjoncteur sous tension.

1–3 Trip Unit Functions

ProTrip Trip Units have specific standard functions, with

the current rating determined by installation of the rating

plug. The functions of the Trip Unit are as follows:

• Overcurrent protection

– Long-time protection

– Instantaneous protection

• Protection

– Short-time protection, with or without I2T

– Ground-fault protection, with or without I2T

• Status

– Trip targets

– Health monitor

1

Page 8

ProTrip™ Trip Units

Chapter 1. Introduction

1–4 Trip Unit Catalog Numbers

A simple catalog-numbering system defines all of the

standard and optional Trip Unit functions. A catalog

numbering key is found inside the front cover (but see

Table 1 for the complete list of supported breakers). Each

of the segments of the catalog number is described below.

The first five-character group indicates the breaker type

for which the Trip Unit is configured, as listed in Table 1.

Character Trip Unit Type

D ProTrip

Table 2. Trip Unit type referred to by the sixth character of the

Trip Unit catalog number.

The seventh character of the catalog number indicates the

wiring type of the breaker, as listed in Table 3.

Characters Breaker Type

GE

PK115

PKO15

PK125

PKO25

PK150

PKO50

PKO75

PKO10

PKW10

AK-1-15

AK-15

AK-1-25

AK-25, AKU-25

AK-1-50

AK-50, AKU-50, AKT-50, AKS-50, AKSU-50, AKST-

50

AK-75

AK-100

AKW10

I-T-E®, ABB®

PIK22

PIK60

PIKC8

PIK80

PIK1B

PIK16

PIKN1

K-225

K-600, KDON-600

KC (800 A)

K-800, KDON-800

K-1600 (black), KDON-1600 (black)

K-1600 (red) KDON-1600 (red, rect. primary

disconnects)

KDON-1600 (red, circ. primary disconnects)

Westinghouse®, Cutler-Hammer®

PDB15

PDB25

PDA50

PDB50

PDA75

PDB75

PDA10

PDB10

DB-15, DBL-15

DB-25, DBL-25

DA-50

DB-50, DBL-50

DA-75

DB-75

DA-100

DB-100

Allis/Chalmers®, Siemens/Allis®, Siemens

PSL6B

PSL6G

PSL1B

PSL1G

LA-600 (blue), LAF-600 (blue)

LA-600 (gold), LAF-600 (blue)

LA-1600 (blue), LAF-1600 (blue)

LA-1600 (gold), LAF-1600 (gold)

Table 1. Breaker type referred to by the first five characters of the

Trip Unit catalog number.

The sixth character of the catalog number is always the

letter D, indicating the Trip Unit type, as shown in Table

2.

Character Wiring Type

3 3 Wire

Table 3. Wiring type referred to by the seventh character of the

Trip Unit catalog number.

The eighth character of the catalog number indicates the

sensor type, as listed in Table 4, and is always an F, for

fixed CTs.

Character Sensor Type

F Fixed CTs

Table 4. Sensor type referred to by the eighth character of the

Trip Unit catalog number.

The ninth and tenth characters of the catalog number

indicate the CT that is installed in the circuit breaker, as

listed in Table 5.

Characters Installed CT

01 150 A

02 225 A

06 600 A

08 800 A

16 1600 A

20 2000 A

30 3000 A

32 3200 A

40 4000 A

Table 5. Installed CT, as indicated by the ninth and tenth

characters of the Trip Unit catalog number.

The eleventh and twelfth characters of the catalog

number indicate the trip functions provided by the Trip

Unit, as listed in Table 6.

2

Page 9

ProTrip™ Trip Units

Chapter 1. Introduction

Characters Protective Function

08

Long-time, short-time, instantaneous, and

switchable ground fault

Table 6. Trip unit functions, as indicated by the eleventh and

twelfth characters of the Trip Unit catalog number.

Finally, if the Trip Unit was ordered as a replacement, the

letter R is appended to the catalog number.

For example, a Trip Unit with catalog number

PK050P3F1608R has the following functions:

PK050 – Trip Unit for AK-50 circuit breaker with a

frame rating of 1600 A

D – ProTrip Trip Unit

3 – 3-wire configuration

F – Fixed CT sensors

16 – 1600 A sensors

08 – Long-time, short-time, instantaneous, and

switchable ground fault protection functions

R – Trip Unit was ordered as a replacement

1–5 Rating Plugs

Interchangeable rating plugs are used to establish or

change the trip rating of the breaker. A built-in rejection

feature prevents the insertion of a rating plug with an

incorrect sensor rating into a Trip Unit. Rating plug

catalog numbers are listed in Table 7. A rating plug is

shown in Figure 2.

Figure 2. ProTrip rating plug.

CAUTION: Removal of the rating plug while the breaker

is carrying current reduces the breaker’s current-carrying

capacity to approximately 25% of the current sensor

rating. This may result in undesired tripping.

ATTENTION: Si le calibreur est retiré alors que le

disjoncteur est sous tension, le déclencheur se régle

automatiquement à approximativement 25% du calibre

du transformateur de courant. Ceci peut entrainer un

déclenchement indésirable.

Cat. No.

PT1C80GFD 80

PT1C100 GFD 150 100

PT1C125 GFD 125

PT1C150 GFD 150

PT225C150 GFD 225 150

PT225C225 GFD 225

PT4C200GFD 200

PT4C225GFD 225

PT4C250GFD 400 250

PT4C300GFD 300

PT4C400GFD 400

PT6C300GFD 300

PT6C400GFD 400

PT6C450GFD 600 450

PT6C500GFD 500

PT6C600GFD 600

PT8C400GFD 400

PT8C450GFD 450

PT8C500GFD 800 500

PT8C600GFD 600

PT8C700GFD 700

PT8C800GFD 800

PT16C800GFD 800

PT16C1000GFD 1000

PT16C1100GFD 1600 1100

PT16C1200GFD 1200

PT16C1600GFD 1600

PT20C1000GFD 1000

PT20C1200GFD 1200

PT20C1500GFD 2000 1500

PT20C1600GFD 1600

PT20C2000GFD 2000

PT30C1200GFD 1200

PT30C1600GFD 1600

PT30C2000GFD 3000 2000

PT30C2500GFD 2500

PT30C3000GFD 3000

PT32C1200GFD 1200

PT32C1600GFD 3200 1600

PT32C2400GFD 2400

PT32C3200GFD 3200

PT40C1600GFD 1600

PT40C2000GFD 2000

PT40C2500GFD 4000 2500

PT40C3000GFD 3000

PT40C3600GFD 3600

PT40C4000GFD 4000

Sensor

Rating, A

Table 7. Catalog numbers for rating plugs.

Plug Rating,

A

3

Page 10

ProTrip™ Trip Units

Chapter 1. Introduction

Ground-Fault Protection

Ground-fault protection with ProTrip Trip Units is provided in the rating plug. The pickup and delay settings

available with the switches on the rating plug are

described in Chapter 2, Trip Unit Setup.

1–6 Equipment Interfaces

ProTrip Trip Units do not usually require connections

within the equipment, since all wiring is contained within

the circuit breaker. The only connection is for the neutral

sensor, which uses a special dedicated disconnect.

CAUTION: Neutral current sensors are required for

single-phase, three-wire and three-phase, four-wire

systems. When the Trip Unit is connected to a threephase, three-wire system, the neutral sensor terminals of

the breaker are left open. Do not short any neutral

current sensor terminals in a three-phase, three-wire

system, as this could result in damage to, or malfunction

of, the electrical system.

ATTENTION: Un transformateur de courant de neutre

est nécessaire pour les réseaux 3 phases + neutre. Si le

neutre n’est pas distribué, les bornes de neutre du

déclencheur doivent être laissées ouvertes. Ne pas les

court-circuiter (ceci peut endommager le déclencheur et

entrainer un mauvais fonctionnement du système

électrique.

1–7 Trip Unit Information

Trip Unit Label Information

Following are descriptions of the various numbers on the

front of the Trip Unit, as shown in Figure 1.

• Top-left corner – Serial number of the Trip Unit, such

as RMS71234567.

• Top-right corner – Date of manufacture code, such as

P1121=.

• Right center above rating plug – Catalog number of the

Trip Unit, such as PK050D3F1608R.

• Right center, below catalog number – Current sensor

rating in amperes.

There are two more labels on the Trip Unit that are not

generally visible when it is plugged into a breaker.

• Side of unit – Bar code giving the catalog number of

the Trip Unit.

• Rear of unit – Yellow caution label.

Selector Switches

The following selector switches are present on the front of

the Trip Unit. See Chapter 2, Setup Mode, for a complete

description of each function.

• Long-time pickup

• Long-time delay

• Short-time pickup

• Short-time delay

• Instantaneous pickup

• Ground-fault pickup (on the rating plug)

• Ground-fault delay (on the rating plug)

4

Page 11

2–1 Overview

All of the Trip Unit protective functions are set with the

rotary selector switches on the front of the unit. Table 8

contains a summary of the functions and the available

settings.

Most of the selector switch scales (all but instantaneous

pickup) have a heavy curved line, with an arrowhead on

one end, connecting the low and high ends of the scale.

When the switch points anywhere within this region, the

highest value at the end of the line opposite the

arrowhead is the active setting.

ProTrip™ Trip Units

Chapter 2. Trip Unit Setup

2–2 Long-Time Pickup

The long-time pickup set point establishes the breaker’s

nominal ampere rating, C, as a fraction of the rating plug

current, X. The choices for C are .5, .6, .7, .8, .9, .95, 1.0,

and 1.1 times X. Figure 3 illustrates the long-time pickup

settings.

2–3 Long-Time Delay

The long-time delay function allows normal momentary

overloads without nuisance tripping. The nominal time

delays at the lower limits of the bands for 600% of the

long-time current set point, C, for the four selectable

bands are listed in Table 9. Figure 4 illustrates the effect of

this delay on the trip time.

Figure 3. Time-current curve illustrating long-time pickup.

Figure 4. Time-current curve illustrating long-time delay.

Band Delay, sec

1 2.4

2 4.9

3 9.8

4 20

Table 9. Nominal delays for the long-time delay bands.

Parameter Pickup Settings Delay Settings Delay Curve

Long-Time Trip .5, .6, .7, .8, .9, .95, 1.0, 1.1

multiple of Rating Plug Current (X)

Short-Time Trip 1.5, 2, 2.5, 3, 4, 5, 7, 9

multiple of Long-Time setting (C)

Instantaneous Trip 1.5, 2, 3, 5, 7, 9, 101, 131, 15

multiple of Rating Plug Current (X)

Ground-Fault Trip .2, .25, .3, .35, .4, .45, .5, .6

1

Maximum setting is limited by the frame size.

2

Maximum setting is limited to 1200 A. Pickup settings are determined by the breaker frame size

Table 8. Summary of protective functions and setting values for each.

multiple of Sensor rating (S)

1

2

2.4, 4.9, 9.8, 20 seconds

(Bands 1, 2, 3, 4)

.10, .21, .35 second

(Min, Int, Max)

No delay N/A

.10, .21, .35 seconds

(Min, Int, Max)

I2T In, I2T Out

I2T In, I2T Out

5

Fixed

Page 12

ProTrip™ Trip Units

Chapter 2. Trip Unit Setup

2–4 Short-Time Pickup

The short-time pickup function establishes the current at

which short-time trip is activated. Short-time pickup is

coupled with long-time pickup and the choices of pickup

settings are 1.5, 2, 2.5, 3, 4, 5, 7, and 9 times the long-time

setting. The time-current curves for short-time pickup is

illustrated in Figure 5.

Figure 6. Time current curve illustrating short-time delay with I2T

OUT.

Figure 5. Time-current curves illustrating short-time pickup.

2–5 Short-Time Delay

This function delays the breaker trip when the short-time

pickup function is activated. The switch settings MIN, INT,

and MAX correspond to nominal time delays of .10, .21,

and .35 second, respectively. The delay with I

2

T IN is for a

current of 600% of C at the lower limit of the band. The

delay with I

The I

constant time delay. I

2

T OUT is for the lower limit of each band.

2

T OUT function, illustrated in Figure 6, establishes a

2

T IN biases the delay with a constant

slope, as shown in Figure 7.

2–6 Instantaneous Pickup

Instantaneous overcurrent protection causes an immediate breaker trip when the chosen current setting is

reached. The pickup current may be set to 1.5, 2, 3, 5, 7,

and 9 times the rating plug current, X. Additional settings

of 10, 13, and 15 times X are also available, depending on

the breaker frame size.

Note the difference from short-time pickup, which is based

on a multiple of the long-time pickup setting, C, while

instantaneous pickup is based on the rating plug current,

X. The time-current characteristic is illustrated in Figure 8.

Figure 7. Time current curve illustrating short-time delay with I2T

IN.

Figure 8. Time-current curve illustrating instantaneous pickup.

6

Page 13

2–7 Ground-Fault Pickup

This function sets the pickup current for ground-fault

protection. The available settings are listed in Table 10 as

multiples of X, the current sensor rating. The maximum

setting may be less than 0.6, depending on the breaker

frame size. Figure 9 illustrates the time-current curve for

ground-fault pickup.

Breaker Frame Settings as Multiple of X

800–2000 A .20, .25, .30, .35, .40, .45, .50, .60

3200 A .20, .22, .24, .26, .28, .30, .34, .37

4000–5000 A 20, .22, .24, .26, .28, .30

Table 10. Settings available for ground-fault pickup according to

breaker frame size.

ProTrip™ Trip Units

Chapter 2. Trip Unit Setup

Figure 10. Time-current curve illustrating ground-fault delay with

I2T OUT.

Figure 9. Time-current curve illustrating ground-fault pickup.

2–8 Ground-Fault Delay

This function sets the delay before the breaker trips when

the ground-fault pickup current is detected. The switch

settings MIN, INT, and MAX correspond to nominal time

delays of .10, .21, and .35 second, respectively. The delay

2

with I

T OUT is for the lower limit of each band. The delay

2

with I

T IN is at 200% of the pickup setting at the lower

limit of the band.

2

The I

T OUT function, illustrated in Figure 10, establishes

a constant time delay. I

constant slope, as shown in Figure 11.

2

T IN biases the delay with a

Figure 11. Time-current curve illustrating ground-fault delay with

I2T IN.

2–9 Defeatable Ground Fault

All rating plugs have the additional setting OFF on the

Pickup switch, which defeats ground-fault protection.

These rating plugs are not UL listed.

7

Page 14

ProTrip™ Trip Units

Chapter 3. Trip Unit Status

3–1 Target Module

Trip Unit status information is provided by the target

module, shown in Figure 12. This module indicates

whether a breaker trip was caused by a short circuit, an

overload, or a ground fault, as well as whether the Trip

Unit is functioning properly. The catalog number of the

target module is TARGET02P.

Figure 12. Target module.

3–2 Functions

The front of the target module contains two push buttons

and either four or five LEDs. The following functions are

provided by the target module.

operation and are not required to store targets or for any

protection functions.

Health Monitor

The Trip Unit can be tested for proper functioning if the

Trip Unit is powered by one of the following sources:

• A Test Kit (catalog number TVRMS2) is plugged

into the jack on the front of the rating plug.

• A Portable Battery Pack (catalog number TVPBP) is

plugged into the jack on the front of the rating plug.

• The breaker is carrying a load current of at least 20%

of its current sensor rating.

• External +24 Vdc control power is connected.

Press and hold the VIEW button for at least five seconds. If

the Trip Unit is operating properly, the LTPU LED will

blink slowly. Note that if the Trip Unit is not powered by

one of the above sources, this test will not give a true

indication of Trip Unit functioning.

Trip Targets

To determine the condition causing a breaker trip, press

the VIEW button. One of the three target LEDs will light,

as follows:

SC – Short circuit (instantaneous or short-time trip)

OVL – Overload (long-time trip)

GF – Ground fault

The RESET button clears the trip target indication.

Long-Time Pickup Status

Whenever the circuit breaker is carrying at least 95% of

the long-time pickup current (C), the LTPU (STATUS)

LED begins to blink. Above 100% of the long-time pickup

current, the LED is lit continuously, indicating an

imminent overload trip.

Battery Test

If the breaker has not tripped or if the trip target has been

cleared, pressing the VIEW button performs a battery test.

The BAT LED will light if the batteries are okay. If the BAT

LED is dim or does not light, replace the batteries as

described in Chapter 4, Maintenance and Trouble-Shooting.

Note that the only function of the Target Module batteries

is to power the LEDs; they have no effect on Trip Unit

8

Page 15

4–1 Trip Unit Removal and Replacement

Rejection pins are installed on the rear of all Trip Units to

prevent installation of an incorrect Trip Unit into a

breaker. Do not use excessive force when installing a Trip

Unit.

To install the Trip Unit, perform the following procedure:

1. Unscrew the brass knob in the center of the rear of

the trip unit. Lineup the mounting bracket to engage

the rejection posts. Screw the brass knob through the

bracket and into the trip unit.

2. Plug the wiring harness into the trip unit and screw it

to the bracket.

3. Attach the mounting bracket to the adapter plate,

previously installed on the breaker.

4–2 Rating Plug Removal and Replacement

CAUTION: Removal of the rating plug while the breaker

is carrying current reduces the breaker’s current-carrying

capacity to approximately 25% of the current sensor

rating.

ATTENTION: Si le calibreur est retiré le disjoncteur et

traversé par un courant, le niveau de protection s’ajuste à

approximativement 25% du calibre du transformateur

d’intensité.

Interchangeable rating plugs are removed with a rating

plug removal tool, Catalog No. TRTOOL. (Suitable

equivalents are commercially available as “integrated

circuit (DIP) extractors.”) Grasp the rating plug tabs with

the extractor and pull the plug out as illustrated in Figure

13. Be sure to grab the tabs and not the front cover of the

rating plug, or the plug may be damaged.

ProTrip™ Trip Units

Chapter 4. Maintenance and Trouble-Shooting

Figure 13. Removing the interchangeable rating plug.

4–3 Target Module Removal and Replacement

The target module is removed with the rating plug

removal tool, catalog number TRTOOL, also known as an

integrated circuit (DIP) extractor. Grasp the tabs of the

module with the tool, as shown in Figure 14. Be careful to

hold the tabs and not the front cover, as the Target

Module could be damaged otherwise. Gently pull the

Target Module away from the Trip Unit. A gentle leftright motion assists the removal. Insure that the tabs are

held securely until the Target Module is completely

removed.

To install a target module, hold the module between the

thumb and forefinger, then push it into the Trip Unit.

Proper engagement is verified by a click.

To install a rating plug, hold the plug between the thumb

and forefinger, then push it into the Trip Unit. Proper

engagement is verified by a click. Rejection features are

provided on all rating plugs to prevent application

mismatches. Never force a rating plug into place. Refer to

Chapter 1 to find the appropriate rating plugs for each

sensor rating and breaker frame.

Do not attempt to use a rating plug from a different type

of Trip Unit in a ProTrip Trip Unit.

9

Page 16

ProTrip™ Trip Units

Chapter 4. Maintenance and Trouble-Shooting

Figure 14. Removing the target module.

AVERTISSEMENT: La batterie peut exploser en cas de

mauvaise utilisation. Ne pas la recharger, l’ouvrir ou la

jeter dans un feu. Doit être garder hors de portée des

enfants. Une fois usée, la batterie doit être jeté

rapidement.

4–4 High-Current Testing

The TVRMS2 Test Kit does not defeat ground fault on the

ProTrip Trip Unit. If the breaker equipped with a ProTrip

Trip Unit is undergoing high-current testing, then two

poles must be connected in series to prevent ground fault

operation.

Target Module Battery Replacement

To replace the two batteries in the Target Module, remove

the module from the Trip Unit as described above. Slide

the old batteries out from the battery compartment at the

rear of the Target Module. It may help to carefully pry

them out with a small screwdriver blade in the cutout on

top of the module. Slide the new batteries into the battery

compartment. Be careful not to short out the batteries

during removal or installation. Recommended

replacement batteries are Panasonic CR1616, Eveready ECR1616BP, and Duracell DC1616B.

WARNING: Replace the batteries with Panasonic

CR1616, Eveready E-CR1616BP, or Duracell DC1616B

only. Use of a different battery may present risk of fire,

explosion, or damage to equipment. Observe proper

battery polarity when installing in the battery

compartment.

AVERTISSEMENT: Remplacer la batterie avec

uniquement des Panasonic CR1616, Eveready ECR1616BP, ou Duracell DC1616B. L’utilisation d’autres

batteries peut présenter un risque de feu, d’explosion ou

d’endommagement du matériel. Respecter la polarité de

la batterie en l’installant dans son logement.

WARNING: The batteries may explode if mistreated. Do

not recharge, disassemble, or dispose of in fire. Keep the

battery away from children and dispose of the used

battery promptly.

10

Page 17

Chapter 4. Maintenance and Trouble-Shooting

4–4 Trouble-Shooting Guide

The following guide is provided for trouble-shooting and

isolating common problems. It does not cover every

possible condition. Contact the Customer Support Center

at 800-843-3742 if the problem is not resolved by these

procedures.

Symptom Possible Cause Corrective Action

1. The health monitor

function of the target

module does not

operate.

Line current is below 20% of

the breaker sensor rating.

The target module is not

seated properly.

At least 20% of the current sensor rating, X, must be

flowing through the breaker to activate this function.

If the load current is below this level, power the Trip

Unit with the Test Kit or the Portable Battery Pack.

Verify that the target module is fully seated in its slot.

ProTrip™ Trip Units

2. The trip indication

target will not clear.

3. The battery check

(BAT) LED on the

target module does not

light.

4. The circuit breaker trips

at too low a current.

The target module batteries

are low.

The target module batteries

are low.

The rating plug is not fully

seated.

An incorrect rating plug is

installed.

Replace the batteries in the target module.

Replace the batteries in the target module

Verify that the rating plug is fully seated in its slot.

Check the current rating and catalog number of the

rating plug.

11

Page 18

g

GE Industrial Systems

General Electric Company

41 Woodford Avenue, Plainville, CT 06062

DEH40034 R01 1098 © 1998 General Electric Company

Loading...

Loading...