Page 1

g

DEH 40012

GE PowerVac ® 5kV VL

for PowerV ac ® V acuum Circuit Breakers

Type PV VL 4.16-250-0

with ML-19 Mechanism

Instructions

1

Page 2

DEH-40012

WARNINGS, CAUTIONS AND NOTES

AS USED IN THIS PUBLICATION

This document is based on information available at the time of this publication. While effor ts have

been made to ensure accuracy, the infor mation contained herein does not cover all details or variations in hardwar e and softwar e, nor does it provide for every possible contingency in connection

with installation, operation, and maintenance. Features may be described herein that are not

present in all hardware and software systems. GE Industrial Systems assumes no obligation of

notice to holders of this document with respect to changes subsequently made.

WARNINGS

Wa rning notices are used in this publication to emphasize that hazar dous voltages,

cur rents, or other conditions that could cause personal injur y or death ar e present

in this equipment or may be associated with its use.

W ar ning notices ar e also used for situations in which inattention or lack of equipment knowledge could cause either personal injury or damage to equipment.

CAUTIONS

Caution notices are used for situations in which equipment might be damaged if

care is not taken.

NOTES

Notes call attention to information that is especially significant to understanding

and operating the equipment.

GE Industrial Systems makes no repr esentation or war ranty, expressed, implied, or statutor y , with

respect to, and assumes no responsibility for the accuracy completeness, sufficiency, or usefulness of the information contained her ein. No warranties of mer chantability or fitness for purpose

shall apply.

The following is a trademark of GE Company: PowerV ac

®

© 2000 GE Company

All Rights Reserved

2

Page 3

PowerV ac ® 5kV Vertical Lift

Table of Contents

Chapter 1. Introduction

1-1 Safety ...................................................................................................................... 6

1- 2 Maintenance ........................................................................................................... 6

Chapter 2. Description....................................................................................................................7

Chapter 3. Receiving, Handling & Storage

3-1 Receiving ................................................................................................................ 8

3-2 Handling .................................................................................................................. 8

3-3 Storage .................................................................................................................... 8

3- 4 Safety Precautions ..................................................................................................8

3- 5 Unpacking the Breaker ............................................................................................ 8

3- 6 Safety Interlocks......................................................................................................9

Positive Interlock System .......................................................................................9

Interference Bolts ..................................................................................................10

Chapter 4. Installation

4- 1 Breaker Preparation ...............................................................................................11

4- 2 Equipment Test Position .......................................................................................11

4- 3 Positive Interlock System .................................................................................... 11

4- 4 Checking for Pr oper Interlock ............................................................................... 12

4- 5 Primary Contact Penetration ................................................................................. 14

4- 6 Stationary Auxiliar y Switch (MOC)....................................................................... 1 6

4-7 Stops......................................................................................................................16

4- 8 Ground ...................................................................................................................16

4- 9 Secondary Coupler................................................................................................ 17

4-10 Position Switch .....................................................................................................17

Chapter 5. Operation

5-1 Description ............................................................................................................ 18

5-2 Close Spring Charging ....................................................................................... 19

5- 3 T rip-Free Operation .............................................................................................. 20

5- 4 Closing Operation ................................................................................................. 2 0

5- 5 Opening Operation................................................................................................ 2 1

Chapter 6. Control Cir cuit

6- 1 Typical Wiring Controls ........................................................................................2 2

Chapter 7. Mechanical Check and Slow Close

7-1 Visual Inspection .................................................................................................. 25

7-2 Closing Spring Charging...................................................................................... 25

7-3 Closing Spring Gag ..............................................................................................25

7-4 Slow Closing ......................................................................................................... 25

7- 5 Gag Tool Removal ................................................................................................. 2 5

Chapter 8. Dimensional Checks

8- 1 Primary Contact Er osion ....................................................................................... 26

8- 2 Spring Wipe Indicator .......................................................................................... 26

8- 3 Contact Gap........................................................................................................... 2 7

3

Page 4

PowerV ac® 5kV Vertical Lift

Table of Contents

Chapter 9. Electrical Checks

9- 1 Electrical Operation............................................................................................... 28

9- 2 High Potential Test ................................................................................................ 28

Primary Cir cuit....................................................................................................... 2 8

Secondary Cir cuit.................................................................................................. 28

9- 3 Primar y Cir cuit Resistance.................................................................................... 28

9- 4 V acuum Integrity T e st............................................................................................ 28

9-5 Insulation T ests .....................................................................................................29

Chapter 10. Maintenance

10-1 General ..................................................................................................................30

10-2 Service Conditions ................................................................................................ 31

10-3 Fault Interr uptions .................................................................................................31

10-4 Contact Erosion..................................................................................................... 3 1

10-5 Transfer Finger W ear............................................................................................. 3 1

10-6 Mechanism ............................................................................................................ 31

10-7 Primary Insulation Par ts........................................................................................ 3 1

10-8 Lubrication ............................................................................................................ 32

10-9 Recommended Maintenance ................................................................................ 32

10 -1 0 Breaker Timing and Speed Check ........................................................................ 32

Chapter 11. Mechanical Adjustments

11-1 General ..................................................................................................................35

11-2 Wipe Adjustment................................................................................................... 35

11-3 Contact Gap Adjustment....................................................................................... 3 6

11-4 Trip Coil Plunger................................................................................................... 37

11-5 Close Coil Plunger ................................................................................................ 38

11-6 Control Switch Adjustment .................................................................................. 3 9

11-7 Adjustment of MOC Switch ..................................................................................39

11-8 Positive Interlock................................................................................................... 40

Chapter 12. Repair and Replacement

12-1 General ..................................................................................................................44

12-2 Replacing Interr upters...........................................................................................44

12-3 Primary Bushing.................................................................................................... 4 5

12-4 Mechanism ............................................................................................................ 45

12-5 Contr ol Switches................................................................................................... 45

12-6 Trip Coil Replacement .......................................................................................... 45

12-7 Closing Coil Replacement .................................................................................... 47

12-8 Auxiliary Switch Replacement.............................................................................. 47

12-9 Motor Replacement............................................................................................... 49

12 -1 0 “Y” Relay Replacement ........................................................................................49

Chapter 13. Renewal Parts

13-1 Ordering Instructions............................................................................................ 51

Chapter 14. Stationary Cubicle Subassembly

14-1 Introduction ........................................................................................................... 53

14-2 Major Components ............................................................................................... 53

14-3 Testing and Inspection.......................................................................................... 5 4

14-4 Compartment Maintenance................................................................................... 58

4

Page 5

List of Figur es

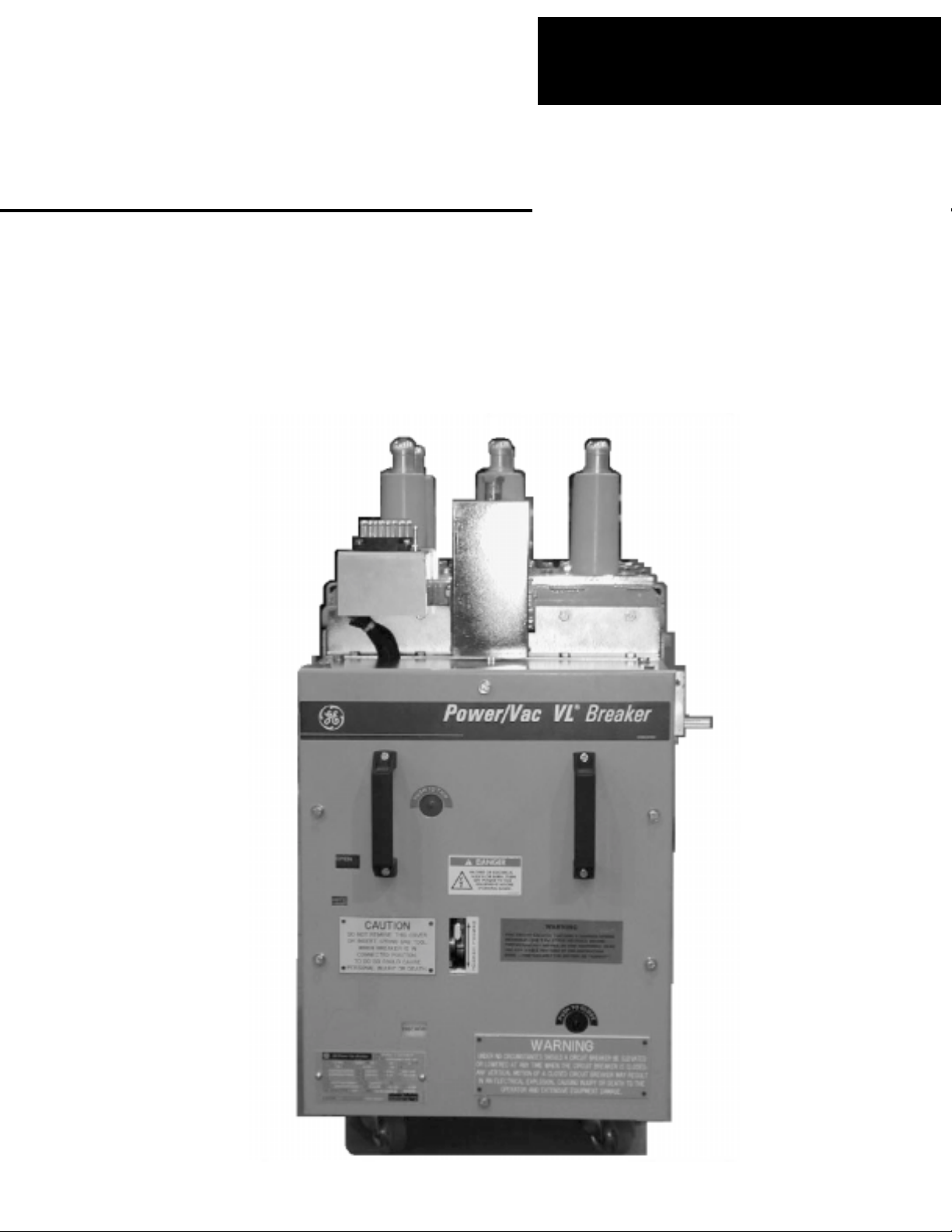

1. View of the 5kV ‘VL’ Breaker with Front Cover ............................................................................... 7

2. Hooking lifting eyes........................................................................................................................... 8

3. Manual Trip & Close .......................................................................................................................... 9

4. Positive Interlock ............................................................................................................................... 9

5. Rating Interference Bolt .................................................................................................................. 10

6. Positive Interlock system ................................................................................................................ 12

7. Manual char ge handle..................................................................................................................... 13

8. Primar y Contact Inser tion ............................................................................................................... 14

9. Primar y contact penetration and wipe........................................................................................... 15

10. MOC switch...................................................................................................................................... 16

11. Secondary disconnect coupler........................................................................................................ 17

12. Front View of ML-19 Mechanism with Front Cover Removed ..................................................... 18

13. Char ging & Trip system left side view ............................................................................................ 19

14. Manual Char ging system right side view.......................................................................................19

15. Electrical Char ging system right side view .................................................................................... 20

16. Closing linkage left side view.......................................................................................................... 20

17. Opening spring & auxiliary switch left side view........................................................................... 21

18. Wipe Spring assembly left side view ............................................................................................. 21

19. T ypical ML-19 mechanism internal wiring connections ................................................................ 22

20. T ypical breaker wiring diagram (Replacement for br eakers with MS mechanisms................... 23

21. T ypical br eaker wiring diagram (Replacement for breakers with ML mechanisms ................... 24

22. Closing spring with gag tool inserted ............................................................................................. 25

23. Contact Er osion Indicator ................................................................................................................ 26

24. Primary contact erosion measurement-rear view ........................................................................ 26

25. Wipe indicator check and wipe measurement-rear view ............................................................. 27

26. Sample Operating Speed Graphs .................................................................................................. 33

27. Opening Speed Adjustment............................................................................................................ 33

28. Travel Transducer Installation (Part#0144D1235G00X) ............................................................... 34

29. Wipe Insulator.................................................................................................................................. 35

30. Contact Gap Adjustment—Opening Buffer.................................................................................... 36

31. Contact Gap measurement, wipe indicator check and wipe measurement ................................ 36

32. T rip coil gap adjustment .................................................................................................................. 37

33. T rip coil button with gage................................................................................................................ 37

34. T rip coil assembly............................................................................................................................ 37

35. Close coil assembly-fr ont view ....................................................................................................... 38

36. Close coil gap adjustment-fr ont view ............................................................................................. 38

37. SM/LS & CHG switch adjustment-left side view............................................................................ 39

38. CL/MS and positive Interlock switch adjustment-right side view ................................................. 39

39. Positive Interlock ............................................................................................................................. 40

40. Adjustment of MOC Switch/Plunger Interlock................................................................................ 41

41. Toggle Linkage Positions ................................................................................................................. 42

41A T oggle Linkage Positions (View fr om Right Side) .......................................................................... 42

42. T oggle Linkage Positions (View from Right Side) .......................................................................... 42

42A T oggle Linkage Positions (View fr om Right Side) .......................................................................... 42

43. Pole Assembly ................................................................................................................................. 44

44. T rip Coil and Linkage (Closing Spring Removed) .......................................................................... 46

45. Front View of ML-19 Breaker Mechanism (Lower) ....................................................................... 48

46. Front View of ML-19 Breaker Mechanism (Upper) ....................................................................... 49

47. Motor Cutoff Switch ........................................................................................................................ 50

48. Closing Spring Gag .......................................................................................................................... 50

49. Front View of ML-19 Mechanism with Front Cover Removed ..................................................... 51

50. Schematic of ML-19 Mechanism .................................................................................................... 52

51. T ypical stationar y structur e wiring ................................................................................................. 56

52. Electrical schematic diagram for vertical lift elevating mechanism ............................................ 57

53. Positive interlock M-26 units........................................................................................................... 59

Appendix A .............................................................................................................................................. 63

PowerV ac ® 5kV Vertical Lift

Table of Contents

List of T ables

1. Measurements ....................................................................................................43

2. Adjustments........................................................................................................ 43

3. ML-19 Control Devices and Voltages ................................................................ 47

4. Elevating Motor Troubleshooting......................................................................57

T r ouble Reporting Form.......................................................................................... 66-67

5

Page 6

PowerV ac® 5kV Vertical Lift

Chapter 1. Introduction

1-1 Safety

IT IS IMPERATIVE THAT ALL PERSONNEL

ASSOCIATED WITH THIS EQUIPMENT READ

AND COMPLETELY UNDERSTAND THE

WARNINGS LOCATED THROUGHOUT THIS

INSTRUCTION BOOK. FAILURE TO DO SO

CAN RESULT IN DAMAGE TO PROPERTY OR

PERSONAL INJURY.

Each user must maintain a safety program for

the protection of personnel, as well as other

equipment, from the potential hazards associated with electrical equipment.

The following requirements are intended to augment the user’s safety program but NOT supplant the user’s responsibility for devising a

complete safety pr ogram. The following basic

industry practiced safety requirements are applicable to all major electrical equipment such

as switchgear or switchboards. GE neither condones nor assumes any responsibility for practices which deviate fr om the following:

1. ALL CONDUCTORS MUST BE ASSUMED

TO BE ENERGIZED UNLESS THEIR POTENTIAL HAS BEEN MEASURED AS TO

GROUND.

Many accidents have been caused by

power system back feeds fr om a wide variety of sources.

2. It is str ongly recommended that all equipment be completely de-ener gized, verified

to be “dead”, then grounded with adequate

capacity grounding assemblies prior to any

maintenance. The grounding cable assemblies must be able to withstand ener gizing

fault levels so that protective equipment

may clear the circuit safely. Additional discussion on this concept is covered in Chapter 20 of ANSI/NFPA 70B, Electrical Equipment Maintenance.

3. Although interlocks to reduce some of the

risks are pr ovided, the individual’ s actions

while performing service or maintenance

are essential to prevent accidents. Each

person’s knowledge; his mental awar eness;

and his planned and executed actions often determine if an accident will occur.

The most important method of avoiding

accidents is for all associated personnel

to carefully apply a thor ough understanding of the specific equipment fr om the viewpoints of its purpose, its construction, its

operation and the situations which could

be hazardous.

1-2 Maintenance

All personnel associated with installation, operation and maintenance of electrical equipment, such as power circuit breakers and other

power handling equipment, must be thor oughly

instructed, with periodic retraining, regarding

power equipment in general as well as the par ticular model of equipment on which they are

working. Instr uction books, actual devices and

appropriate safety and maintenance practices

such as OSHA publications, National Electric

Safety Code (ANSI C2), and National Fire Protection Association (NFPA) 70B Electrical Equipment Maintenance must be closely studied and

followed. During actual work, supervision

should audit practices to assure confor mance.

6

Page 7

2-1 Description

PowerVac® 5kV Vertical Lift

Chapter 2. Description

The PowerVac® 5kV VL vacuum circuit br eaker

is a vertical lift, r emovable and interchangeable

interrupting element, for use in metal-clad

switchgear to pr ovide pr otection and contr ol of

electrical apparatus and power systems. The

PowerVac 5kV VL Type PV-VL1 circuit breaker

with ML-19 mechanism is available in continuous current ratings of 1200 and 2000 amperes

in accordance with industr y standards.

Refer to the breaker nameplate for complete rating information of any particular breaker. The

nameplate also describes the contr ol power requirements for that br eaker. The application of

a breaker must be such that its voltage, cur rent

and interrupting ratings are never exceeded.

Since this book is written to include all ratings

of the breaker, as well as several design variations, the instructions will be of a general character and all illustrations will be typical unless

otherwise specified.

3

Figure 1. V iew of 5kV ‘VL ’ Br eaker with Front Cover

1 Nameplate 5 Charge/Dischar ge Indicator 9 Manual Charge Lever

2 Cover Mounting Bolts 6 Counter 10 Secondary Coupler

3 Fr ont Removable Cover 7 Manual Trip Button 11 Positive Interlock Roller

4 Open/Close Indicator 8 Manual Close Button 12 Plunger Interlock (MOC)

13 Primary Bushings (1200 Amp shown)

7

Page 8

PowerV ac® 5kV Vertical Lift

Chapter 3. Receiving, Handling & Storage

3-1. Receiving

Each breaker is carefully inspected before shipment. Immediately upon receipt of the circuit

breaker, an examination should be made for any

damage sustained in transit. If injury or rough

handling is evident, a claim should be filed immediately with the transportation company, and

the nearest GE Sales Office should be notified.

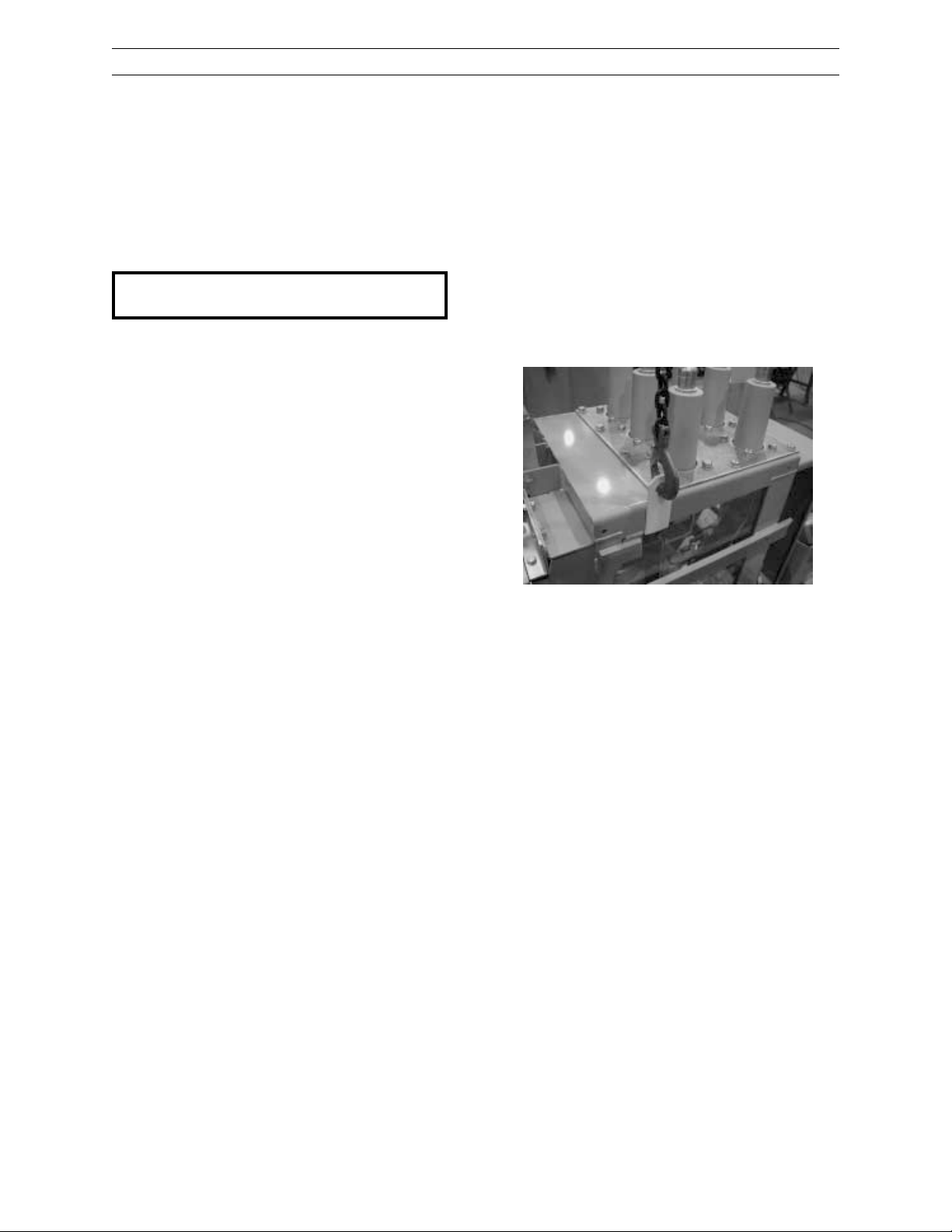

CAUTION: THE BREAKER HAS BEEN

SHIPPED IN THE CLOSED POSITION.

3-2. Handling

It is expected that care will be exercised during

the unpacking and installation of breakers so

that no damage will occur from careless or

rough handling, or from exposure to moisture

or dirt. Loose par ts associated with the breaker

are sometimes included in the same crate. Check

all parts against the packing list to be sur e that

no parts have been overlooked.

3-3. Storage

It is recommended that the breaker be put into

service immediately in its permanent location.

If this is not possible, the following precautions

must be taken to assure the proper storage of

the breaker .

The breaker should be stored in a clean location, free from corrosive gases or fumes. Particular care should be taken to pr otect the equipment from moisture and cement dust, as this

combination has a very cor r osive effect on many

parts.

Breakers should be car efully protected against

condensation, preferably by storing in a war m,

dry r oom of moderate temperature such as 40 to

100° F. High humidity may have an adverse effect on the insulating parts and should be

avoided. Circuit breakers for outdoor metalclad switchgear should be stored in the equipment only when power is available and the heaters are in operation to prevent condensation.

Rollers, latches, etc. of the operating mechanism

should be coated with GE part No.

0282A2048P009 (Mobil 28 red) grease to prevent

rusting.

If the breaker is stored for any length of time, it

should be inspected periodically to see that

corrosion has not started. Should the breaker

be stored under unfavorable atmospheric conditions, it should be serviced befor e being placed

on line.

3-4 Safety Precautions

This circuit breaker uses powerful springs for

ener gy storage. DO NOT WORK ON THE INTERRUPTERS OR THE MECHANISM UNLESS THE

CIRCUIT BREAKER IS IN THE “OPEN” POSITION AND BOTH THE CLOSING AND OPENING

SPRINGS ARE EITHER DISCHARGED OR

GAGGED AND ALL ELECTRICAL POWER IS REMOVED.

The precautions are required to prevent accidental operation. Anyone working on the circuit breaker should be familiar with the contents of this instr uction book.

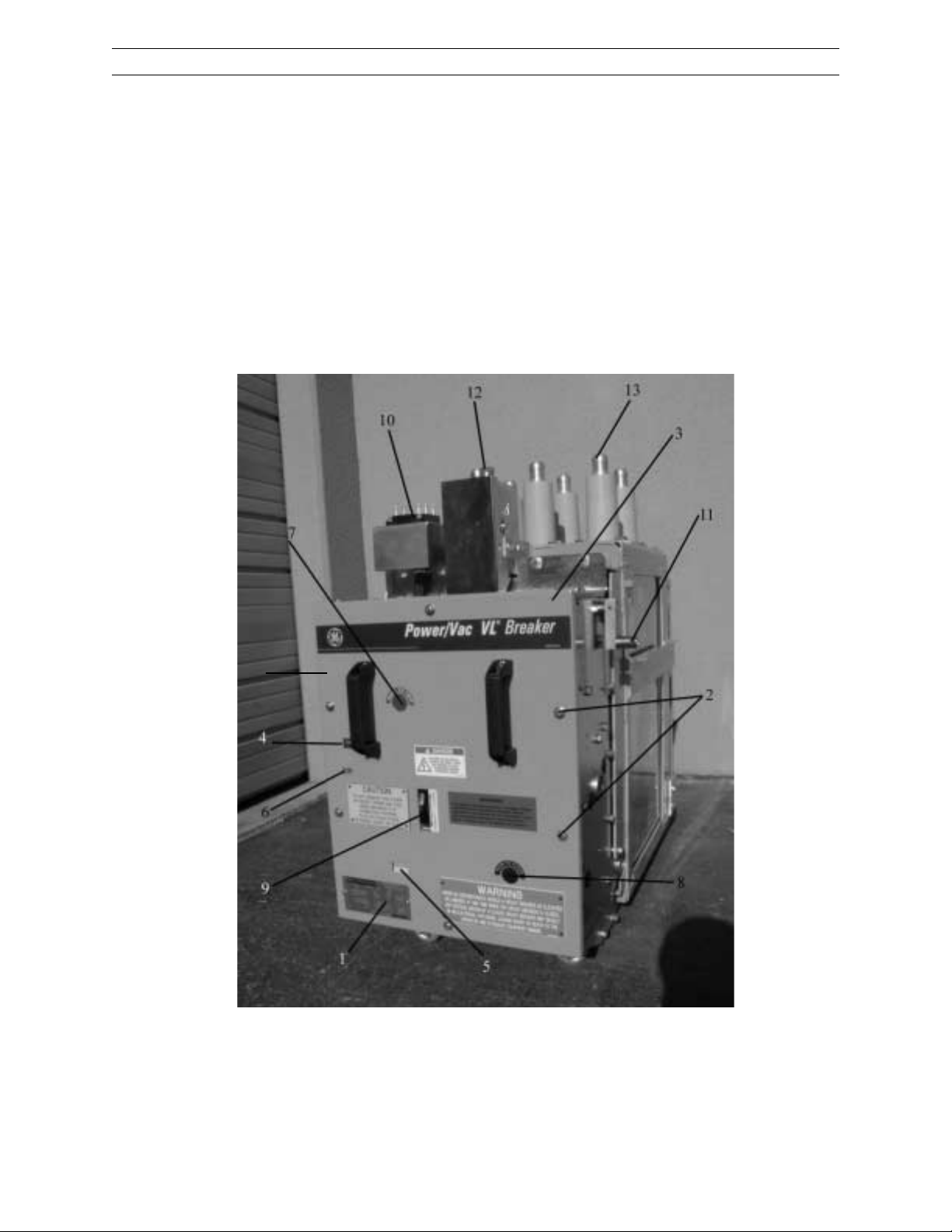

Figure 2. Hooking lifting eyes

3-5 Unpacking the Breaker

The circuit breaker has been supplied with a

box of maintenance items. After removing the

protective cardboard, locate this package and

remove two each breaker lifting eyes. After removing the cleats that attach the breaker to the

skid, hook the lifting eyes on both sides of the

breaker in line with the front edge of the primary bushing plate at the point of the lifting

arr ows (see Figur e 2). Connect a 1,000 lb. minimum rated chain fall or sling (not pr ovided) to

these lifting hooks and remove the br eaker from

the skid.

Packing List

With your breaker, you should have received:

1. Manual charging handle. (Part No.

0282A7227P001)

2. Gag tool. (Part No. 0209B8043G003)

3. Br eaker Instr uction Book DEH 40012

4. Elemenatary Wiring Diagram per breaker

summary.

5. (1)Tube of GE red grease. (Part No.

0282A2048P010)

6. (2) Breaker lifting hooks . (Part No.

0348A3356P001)

7. (6) MOC adjustment washers. (Part No.

0348A3185P001

8

Page 9

Chapter 3. Receiving, Handling & Storage

CAUTION: THE CIRCUIT BREAKER HAS

BEEN SHIPPED IN THE CLOSED POSITION.

After removing packing material, open the

breaker by pushing in firmly on the manual trip

button (Figure 2, Item 8), while keeping hands

away fr om moving parts. A safe way to do this

is to push on the trip button with the r ound side

of the maintenaince handle. Verify that the operation counter advances one count.

Figure 3. Manual T rip & Close

Closing and opening springs are now in their

dischar ged positions. Check this by first pr essing the manual close button, then the manual

trip button. The indicator flags on the front of

the breaker should show “OPEN” and

“DISCHGD”.

PowerVac® 5kV Vertical Lift

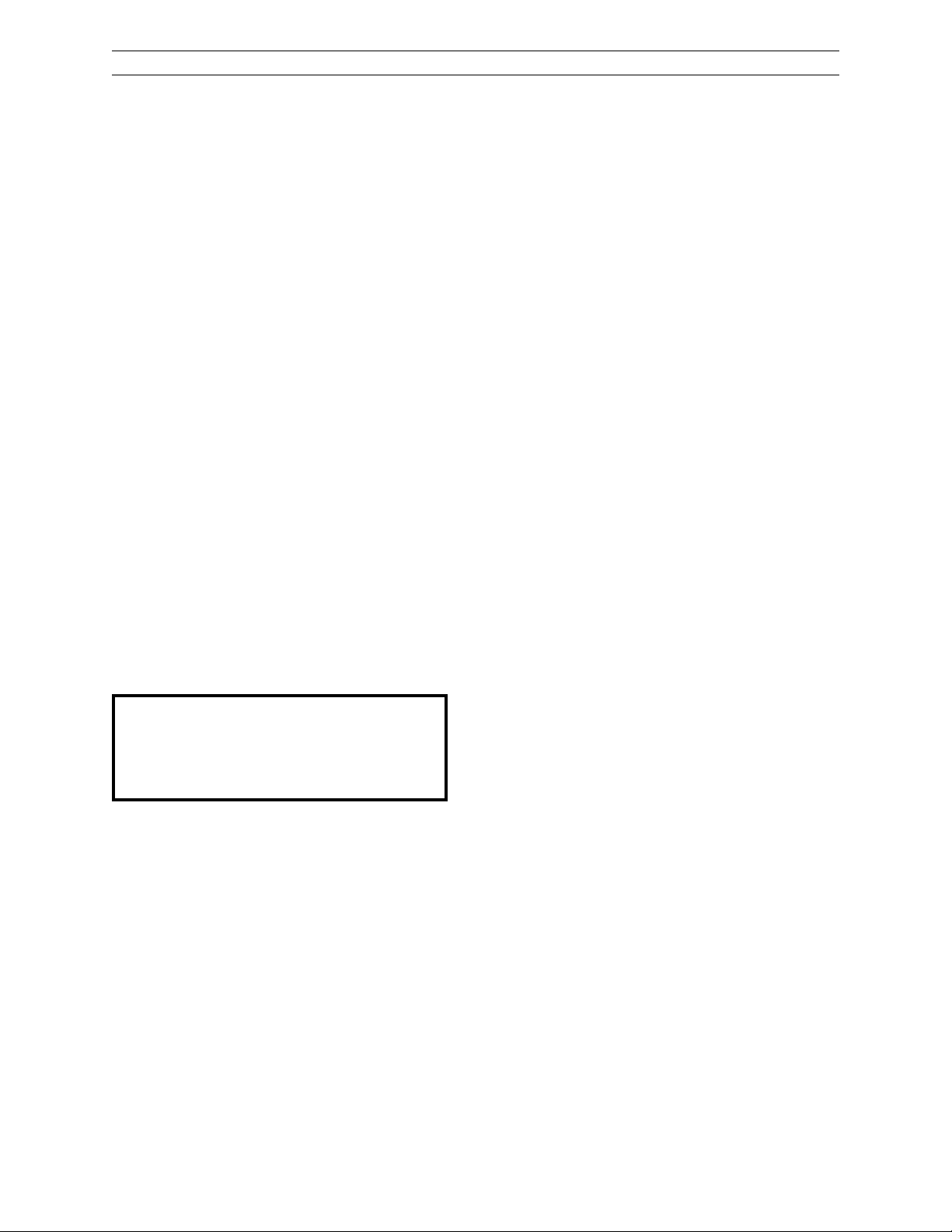

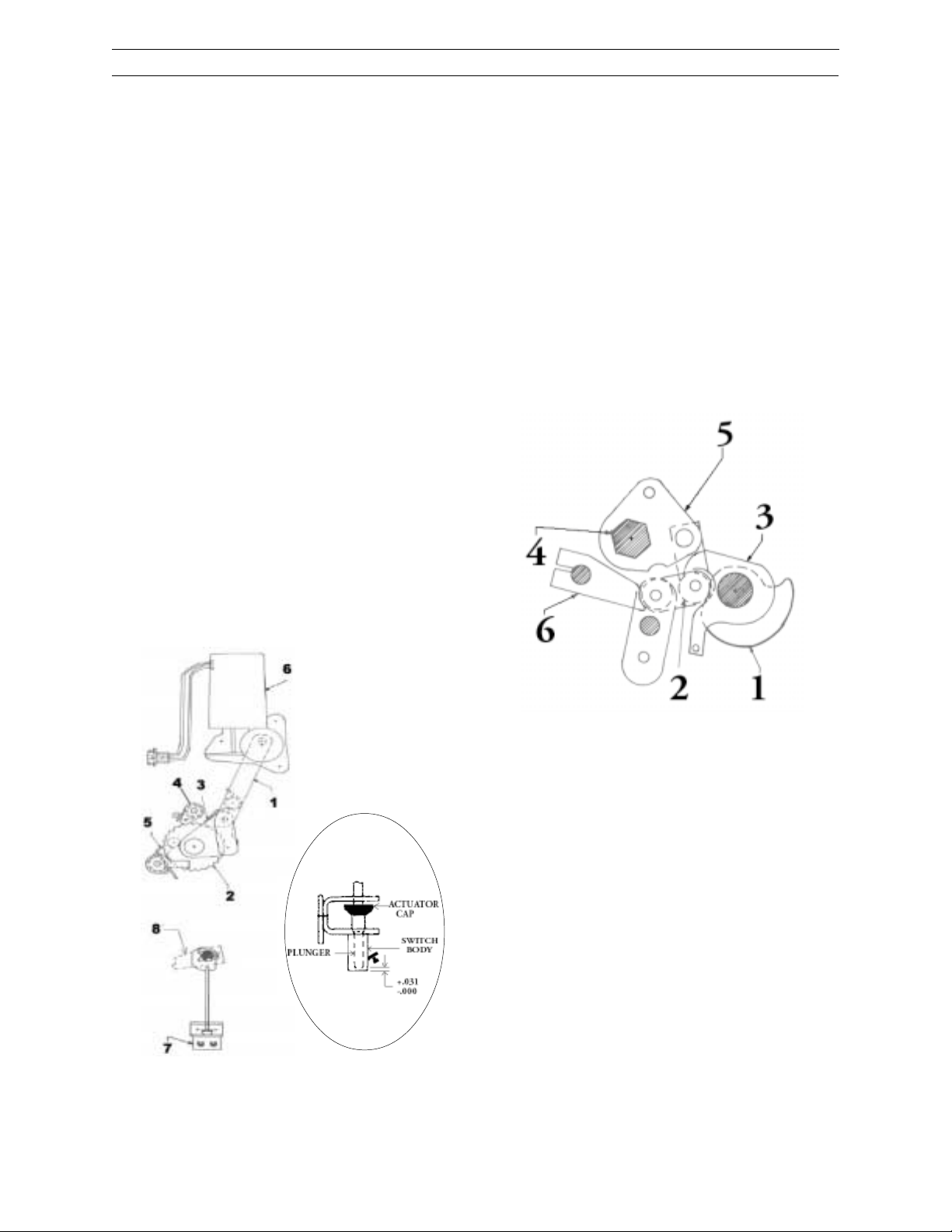

Figure 4.

Positive

Interlock

A major goal in the design of switchgear has

always been the interchangeabililty of breakers. GE Switchgear has been very successful

in achieving that goal for many years. Analysis of instr uction book adjustments, shop tolerances, and service advice letters issued in

recent years, however, has demonstrated that

tolerances in switchgear equipment installed

and presently operating can change, resulting in situations where it is impossible to meet

all adjustments. Also, when an adjustment

is brought into specification it can cause a

pr oblem with another interface or adjustment.

All mechanical and electrical checks listed in

Chapter 4 should be completed before putting

breakers in ser vice.

3-6 Safety Interlocks

Each PowerVac® VL vacuum circuit breaker is

pr ovided with the following interlocks:

Positive Interlock System

The purpose of the positive interlock is to prevent moving the breaker to or fr om the connected

position while the main contacts are closed, and

to prevent closing the contacts unless the

breaker is in the fully connected position. These

important safety features ar e achieved by means

of the positive interlock roller on the right side

of the breaker and positive interlock cam and

stationary “flag” in the switchgear cell.

Although GE has made every effort to assure

interchangability and satisfactory inter face with

existing equipment. Older equipment and field

modifications that may have been made over

the years, may require additional procedures

before the new vacuum breaker can be installed

in the cubicle. At a minimum, all breaker-toswitchgear interfaces as explained in this section should be verified for pr oper operation prior

to energizing. The interfacing parts on all ratings of type AM breakers are functionally the

same.

The following section defines the essential dimensions relating to the interfacing

elements of the breaker and switchgear,

to assure reliable performance. Some of

these elements also affect the other important interfaces required for reliable operation of the equipment, such as:

1. Positive interlock safety feature.

2. Mechanism operation.

3. Primary disconnect penetration.

4. Secondary coupler penetration.

9

Page 10

PowerV ac® 5kV Vertical Lift

Chapter 3. Receiving, Handling & Storage

Interfer ence Bolts

This interlock permits only a breaker with a

matching continuous current rating to be inserted into a metal-clad compartment of identical rating. The rating interference bolt has been

assembled to match the current rating of the

compartment. This assembly is done by fastening a bolt on the lower left side of the breaker

truck to align with the proper cubicle interference plate. This bolt should not be removed.

Figure 5.

Figure 5. Rating Inter ference Bolt

10

Page 11

PowerVac® 5kV Vertical Lift

Chapter 4. Installation

4-1 Breaker Preparation

Prior to interfacing the breaker into the

switchgear cell, rub a small amount of

0282A2048P009 red grease, provided with the

breaker, on the silvered portion of the breaker

studs, gr ound shoe, and 16 secondary coupler

pins, to form a thin coating for contact purposes.

4-2 Equipment Test Position

In most AM breaker Metal-Clad Switchgear

units, there is a breaker “Test Position” which

allows you to functionally test the breaker without connecting to the bus. This position is lowered fully down fr om the br eaker being fully connected into the cubicle. When in the “test position”, a secondary coupler cable must be used

to connect the secondary control circuits for

electrical breaker operation.

While in the test position, the breaker interlock

is not activated. The interlock roller will not

rest in the lower “Vee” notch in the equipment

interlock cam plate allowing the operator to

close and open the breaker electrically or manually (see Figure 6).

The breaker positive interlock system should

be checked while in the test position prior to

elevating the breaker .

WARNING: FAILURE TO PROPERLY VERIFY

ALL BREAKER SWITCHGEAR INTERFACES

AND PROPER POSITIVE INTERLOCK OPERATION COULD RESULT IN A BREAKER OPERATIONAL FAILURE.

4-3 Positive Interlock

The positive interlock system prevents connecting or disconnecting the breaker in the cubicle,

when the breaker is in the closed position and

the vacuum contacts are closed.

the positive interlock r oller and lever are forced

forward by the postitive interlock cam on the

right side of the switchgear cell. The interlock

r oller and lever are held in this for ward position

during raising and lowering operations, preventing the breaker from being closed in any intermediate position between the connect and the

fully lowered position. Any attempt to charge

the breaker will cause the stor ed energy springs

to automatically dischar ge without the br eaker

contacts closing or moving. The breaker must

be fully connected (raised) and the clutch handle

must be released before the breaker can be

closed. Releasing the clutch handle allows the

interlock cam plate in the cell to move downward allowing the interlock roller and lever to

return to their normal vertical positions. The

breaker may then be closed.

The following positive interlock adjustments are

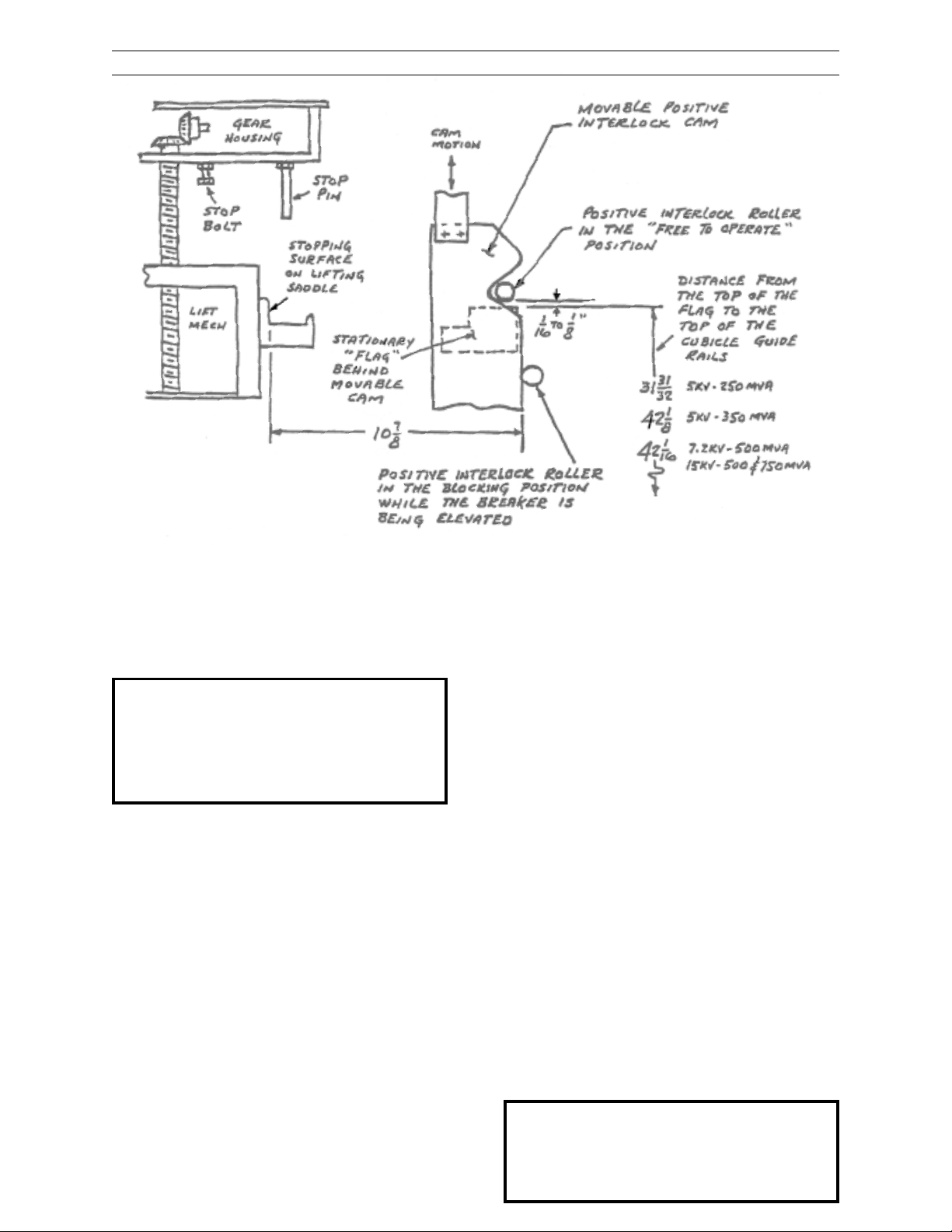

made at the factory and verified for proper operation per Figure 6. The distance fr om the top

of the stationary flag to the top of the switchgear

guide rails is set. This maintains the surface

upon which the breaker wheels rest when the

breaker is lowered. The upper elevating motor

limit switch is then adjusted to achieve a r oller

to flag clearance of 1/16" to 1/8" as shown in

Figure 6. The limit switch de-energizes the elevating motor circuit and should be activated

when the primary disconnects and secondary

coupler reach their nominal contact penetration

position. If the timing of this sequence is off,

the cell must be adjusted back to factory specifications.

T ypical instructions for making adjustments to

the cell positive interlock cam as pr ovided with

the original equipment are outlined in Figure 6

and Figure 53.

This interlock feature is accomplished by a r oller

and lever located on the interlock shaft, on the

right side of the breaker. (Figures 1, 4 and 6)

The positive interlock lever (roller) provides a

trip-free and discharged condition when racking the breaker in the connected or disconnect

position. When the breaker is raised or lowered,

11

Page 12

PowerV ac® 5kV Vertical Lift

Chapter 4. Installation

(-0, + 1/16”)

Figure 6. Positive Interlock system

4-4 Check for Proper Interlock

and Trip-free Functions Before

Energizing the Breaker

WARNING: THE PRIMARY EQUIPMENT

SHOULD BE COMPLETELY DE-ENERGIZED

WHILE THE TESTS ARE IN PROGRESS.

DO NOT INSTALL OR REMOVE THE

BREAKER OR MAKE ADJUSTMENTS UNLESS THE BREAKER IS OPEN.

T o test the function of the positive interlock system and trip free function, the following checks

should be made:

1. Verify that red gr ease has been r ubbed on

the silvered portion of the breaker studs,

ground shoe, and 16 secondary coupler

pins, forming a thin coating for contact

purposes.

2. Before inserting the New VL vacuum

breaker into the cubicle, verify the cubicle

interlock position by measuring the distance between (Figure 6) the movable positive interlock cam to the back of the lifting

saddle of the racking mechansim. This distance should be 10 7/8” minus 0, plus

1/16”.

12

3. Lower the elevating mechanism lifting

brackets until the lifting brackets are in the

fully lowered position. The breaker should

then enter the housing freely. After first

assuring that the breaker is in the open

position, push the breaker into the unit until

it rests against the rear of the front lifting

saddle of the elevating mechanism.The

clearance between the interference block

on the breaker and the interference block

on the interlock mechanism should be fr om

.063" to .125".

4. With the breaker in the lowered position,

the positive interlock r oller engages in the

lower Vee notch, in the interlock cam plate.

The br eaker should be in the opened position and the closing springs discharged

as indicated by the flag indicators. (Figure

1, items 4 and 6) Using the manual char ging handle, char ge the breaker. Then close

the breaker and recharge. (Figure 7, Item

1). With the elevating motor switch in a

neutral position engage the clutch to verify

the operation of the positive interlock. The

springs will dischar ge and the breaker will

open.

NOTE: TABLE 3, FIGURES 6, 52, 53, AND

54 HAVE BEEN PROVIDED TO FAMILIARIZE THE OPERATOR WITH THE EQUIPMENT RACKING SYSTEM AND TROUBLESHOOTING.

Page 13

PowerVac® 5kV Vertical Lift

Chapter 4. Installation

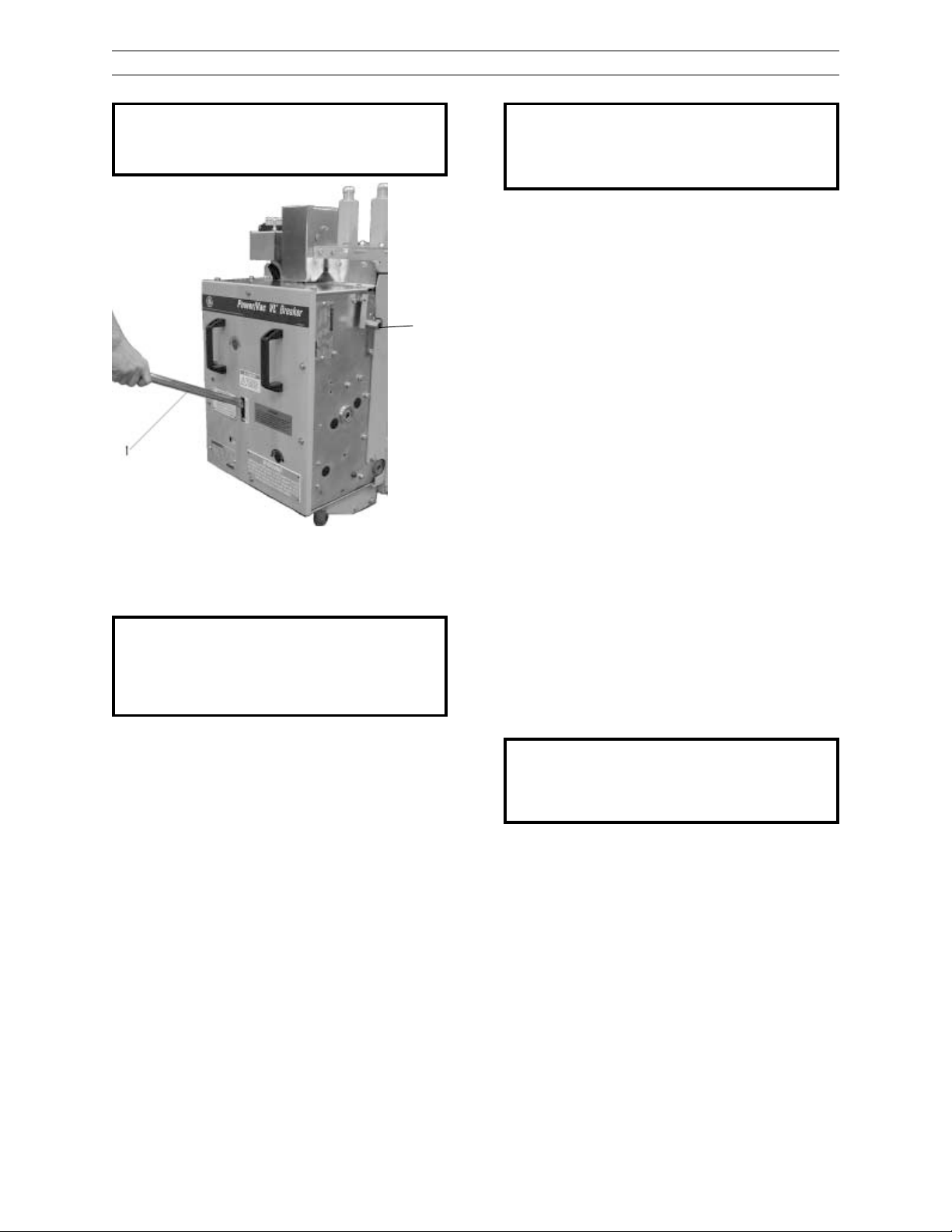

WARNING: AGAIN, BEFORE PROCEEDING

WITH THIS CHECK, IT IS NECESSAR Y THAT

THE PRIMAR Y CIRCUITS BE DE-ENERGIZED.

2

1 Manual char ging handle

2 Positive interlock

Figure 7. Manual char ge handle

WARNING: DO NOT A TTEMPT TO MANUALLY

CHARGE A CHARGED BREAKER. TO DO

SO COULD DAMAGE THE CHARGING

CLUTCH AND MAKE THE MANUAL CHARGING FEATURE INOPERABLE.

5. Raise the breaker to the connect position.

This can be done manually with an elevating wrench or electrically with an elevating motor pr ovided with the original equipment.

CAUTION: THE MOTOR RAISE/LOWER SE-

LECTOR SWITCH MUST NOT BE USED TO

ENERGIZE OR INTERRUPT MOTOR CIRCUIT

AT ANY TIME.

7. When the breaker is fully elevated, the clear ance between the breaker lifting rail and

the upper stop bolts should not be more

than .125" and not less than .094".

8. The positive interlock roller should be centered in the upper “VEE” and the interlock

roller should have 1/16" clearance to the

stationary plate dir ectly under it.

9. In order to lower the breaker fr om the connected position, the breaker should be

open. The closing springs will be discharged when the clutch handle is engaged.

To lower the breaker, place the elevating

control selector switch on the elevating

motor to “lower”. A clutch handle in back

of the elevating motor is then pulled forward until a limit switch engages, to lower

the breaker to the bottom of the cubicle.

10.To raise or lower the breaker, the clutch

must be held in the engaged position, otherwise a spring will return it to its disengaged position and open the electrical cir cuit to the motor.

CAUTION: THE POSITIVE INTERLOCK LE-

VER ROLLER WILL DISCHARGE THE OPENING AND CLOSING SPRINGS AS THE ELEV ATING MOTOR CLUTCH IS ENGAGED.

To elevate the breaker, first–verify the

breaker is in the open position and the closing springs are discharged. Place the elevating control selector switch on the elevating motor to “RAISE”. A clutch handle

under the elevating motor is then pulled

forward until a limit switch engages to raise

the breaker into the unit. Carefully raise the

breaker and while elevating, note that the

shutter slides open and the breaker studs

center with respect to the openings in the

stationary disconnecting devices or damage to the contacts may result.

6. Hold the clutch handle in the forward position until a limit switch on the structure

opens to stop the motor at the end of the

upward travel of the breaker. The springs

will charge when the clutch handle is released.

11. The breaker may be raised or lowered by

an emergency hand crank which can be

inserted after r emoving the motor . The motor is removed by unlatching the motor

assembly fr om its support and disconnecting the motor lead plug. After removing

the motor, inser t the manual crank and pull

the clutch forward. Rotate the crank until

the coupling engages the clutch. The

clutch handle will be held in the down

position by a latch on the crank assembly .

The breaker must be open before the crank

can be inserted and held in the clutch coupling.

13

Page 14

PowerV ac® 5kV Vertical Lift

Chapter 4. Installation

When the breaker is in the fully elevated and in

the connected position, releasing the motor

operating handle will return the positive interlock r oller into the upper Vee notch in the inter lock cam plate. The breaker positive interlock

switch will close and ener gize the motor char ging circuit allowing the closing spring to

char ge. The br eaker may now be closed.

In order to lower the breaker fr om the connected

position, the breaker should be opened. If the

breaker has not been opened, operating the

motor elevating clutch will open the contacts

and discharge the springs.

4-5 Primary Contact Penetration

After completing the Positive Interlock and trip

free functional checks, lower the break and withdraw it from the cell. Inspect the contact surfaces of both the breaker studs and the stationary disconnecting devices. The primar y disconnect devices utilize silver to silver contacts to

insure against r eduction of cur r ent car r ying capacity due to oxidation of the contact surfaces.

These contacts are of the high pressure line

contact tube and socket design, the tube being

backed up by heavy garter springs.

1. Each segment of the stationary disconnecting device should make a heavy impression in the contact lubricant on the

breaker studs as shown in Figure 9. Contact wipe should start not less than .125"

from the top of the contact ball, although

each contact need not start at the same

location.

2. The penetration of the breaker stud inside the stationary disconnecting device,

as indicated by the contact lubricant,

should be 3/4” to 7/8” as shown in Figure 9. This indicates that the breaker studs

contacted at the full pressure center of

the silver band on the stationary disconnecting device corr ectly.

3. Should the inspection of the contacts

show that the breaker is not being raised

to the proper position, readjust the upper stop bolts and limit switches to raise

or lower the breaker to the proper location (See Figure 6 and 53). Lock the stop

bolts in the new position.

4. If proper contacting cannot be attained

by the above methods, additional adjustments may be necessary.

Contact the local GE Sales Office for factory

assistance.

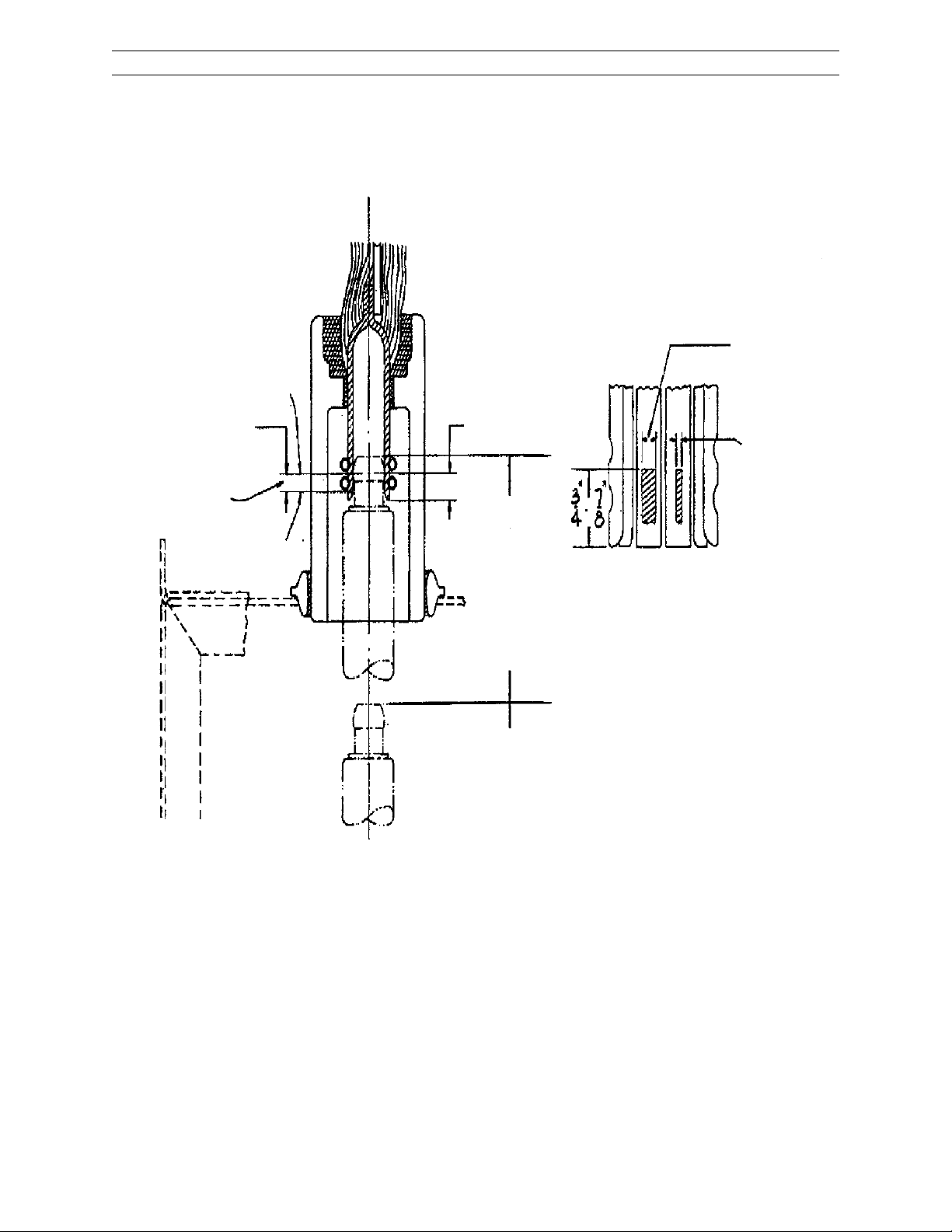

Figure 8. Primary Contact Insertion

14

Page 15

Final

Position

1/2” to 5/8”

Electrical

Wipe

Initial

Electrical

Contact

PowerVac® 5kV Vertical Lift

Chapter 4. Installation

3000A Contact

Wipe area should

be a minimum of

60% contact width

3/4” to 7/8”

1200A & 2000A

Contact Wipe

should be a line

1/16” to 1/8”

wide.

(grease wipe)

9 3/4 M 36

8 3/16 M 26

12 3/4 M 36HH

T ravel

Figure 9. Primary contact penetration and wipe

15

Page 16

PowerV ac® 5kV Vertical Lift

Chapter 4. Installation

4-6 Stationary Auxiliary Switch

(MOC)

The Stationary Auxiliar y Switch is a Mechanism

Operated Contact (MOC) which is an optional

switch mounted in the switchgear cell. When

the breaker has been elevated to the fully connected position, the MOC switch will be actuated whenever the breaker is closed. The MOC

switch is actuated by the plunger mounted on

the top of the breaker mechanism. (Figure 10

Item 1). The MOC switch has a number of “a”

contacts (closed when the breaker is closed and

open when the breaker is open) and “b” contacts (open when the breaker is closed and

closed when the breaker is open).

The following paragraph defines the essential

dimensions relating to the interfacing elements

of the beaker and switchgear, to assure r eliable

performance.

The following elements are important factors

which commonly affect the operation of the stationary auxiliar y switch.

1. Adjustment

washer

2. Operating

switch rod

1. Plunger travel on the br eaker .

2. The gap between the top of the plunger

on the breaker and the bottom of the r od

on the stationary auxiliar y switch mechanism.

3. V ariations between breakers in the distance

from the underside of the lift rail and the

top of the plunger .

4. Variations in the r otation requir ements to

“make” and “break” the stationar y auxiliary switch contacts.

5. Condition of the plunger interlock components on the breaker .

6. Elevating mechanism limit switch consistency.

7. Break elevating mechanism positive stops.

8. Seismic events.

Some of these elements also affect the other

important inter faces requir ed for r eliable operation of the equipment, such as:

1. Primar y disconnect penetration.

2. Secondar y coupler penetration.

3. The positive interlock mechanism.

A major goal in the design of switchgear has

always been the interchangeability of breakers.

GE Switchgear has been very successful in

achieving that goal for many years. Analysis of

instr uction book adjustments, shop tolerances,

and service advice letters issued in r ecent years,

however , have demonstrated that tolerances in

switchgear equipment installed and presently

operating can result in situations where it is

impossible to meet all adjustments or that an

adjustment is br ought into specification and it

causes a pr oblem with another interface.

Figure 10. MOC switch

3. Plunger

interlock

4-7 Stops

The stop pins and stop bolts on the elevating

mechanism are emergency mechanical stops

which would come into use only if the upper

elevating motor switch is completely out of adjustment or has failed. Elevating against these

stops may be quite audible and the operator

should release the clutch handle immediately,

de-ener gizing the elevating motor circuit or the

elevating motor circuit pr otective fuse will open

to protect the motor. The stop bolts should be

set to 3/32" to 1/8" clearance and only changed

or reset after all other elevating adjustments are

made and verified. Figure 6 and 53.

4-8 Ground

A visual check should be made to observe the

ground connection. The ground shoe on the

moveable breaker is designed to have a nominal engagement of 1-1/2" +1/4" vertically with

the steel and copper spring loaded disconnects

of the gr ound device in the switchgear.

16

Page 17

PowerVac® 5kV Vertical Lift

Chapter 4. Installation

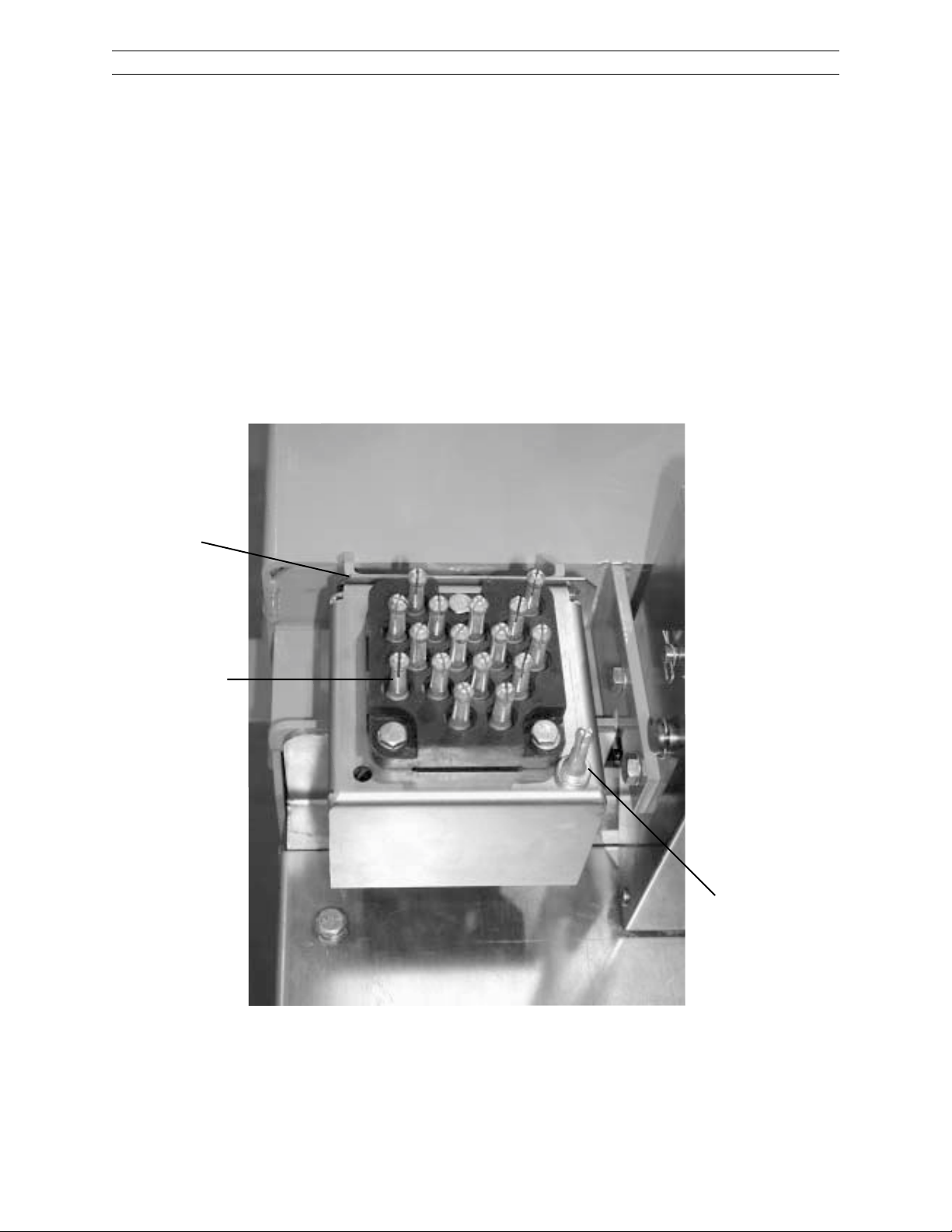

4-9 Secondary Coupler

On the top left front of the breaker, there is a

plastic block which holds the male secondary

coupler pins. This block should make contact

with, and slightly raise a spring loaded plastic

block which holds female secondary coupler

sockets on the switchgear . The contact depression should be 1/8". It is not always possible

to have the plastic blocks in contact over their

entire flat surface. Often, the rear of the blocks

are engaged while a gap exists along the front

edge. This is an acceptable condition. The contacting block surfaces should touch and the female block edge move upward between1/32" to

1/8". See Figure 11.

1

4-10 Position Switch (TOC)

The position switch is an optional device

mounted in the rear left side of the switchgear

cubicle. The switch contacts operate when the

lifting mechanism is in either the fully raised or

fully lowered position. Switch operation should

be checked with the breaker withdrawn manually and the equipment de-energized, and again

electrically, with the breaker in the cubicle.

2

3

1 Secondary disconnect block shims

2 16 Secondary disconnect pins

3 Ground pin for use with a test cabinet

Figure 11. Secondary disconnect coupler

17

Page 18

5-1 Description

PowerV ac® 5kV Vertical Lift

Chapter 5. Operation

The PowerV ac® 5kV VL vacuum circuit br eaker

uses a sealed vacuum power interrupter to establish and interrupt a primary circuit. Primary

connections to the associated metal-clad

switchgear are made by pole assemblies, electrically and mechanically connected to the

vacuum interr upters. The operating mechanism

provides vertical motion at each pole location

in order to move the lower contact of the

vacuum inter r upters fr om an open position to a

spring-loaded closed position and then back to

the open position on command.

The ML-19 mechanism (Figure 12) is a storedener gy type mechanism and uses a gear motor

to char ge a closing spring. During a closing operation, the ener gy stored in the closing spring

is used to close the vacuum interr upter contacts,

charge the wipe springs which load the contacts, char ge the opening springs, and overcome

bearing and other frictional forces.

The energy then stored in the wipe and opening springs will open the contacts during an

opening operation.

Closing and opening operations are contr olled

electrically by the control switch on the metalclad door or remote relaying.

Mechanical contr ol for maintenance or emergencies is provided by manual close and trip buttons on the circuit br eaker.

Also, the closing spring may be manually

char ged (Figure 7) for de-energized checks and

maintenance.

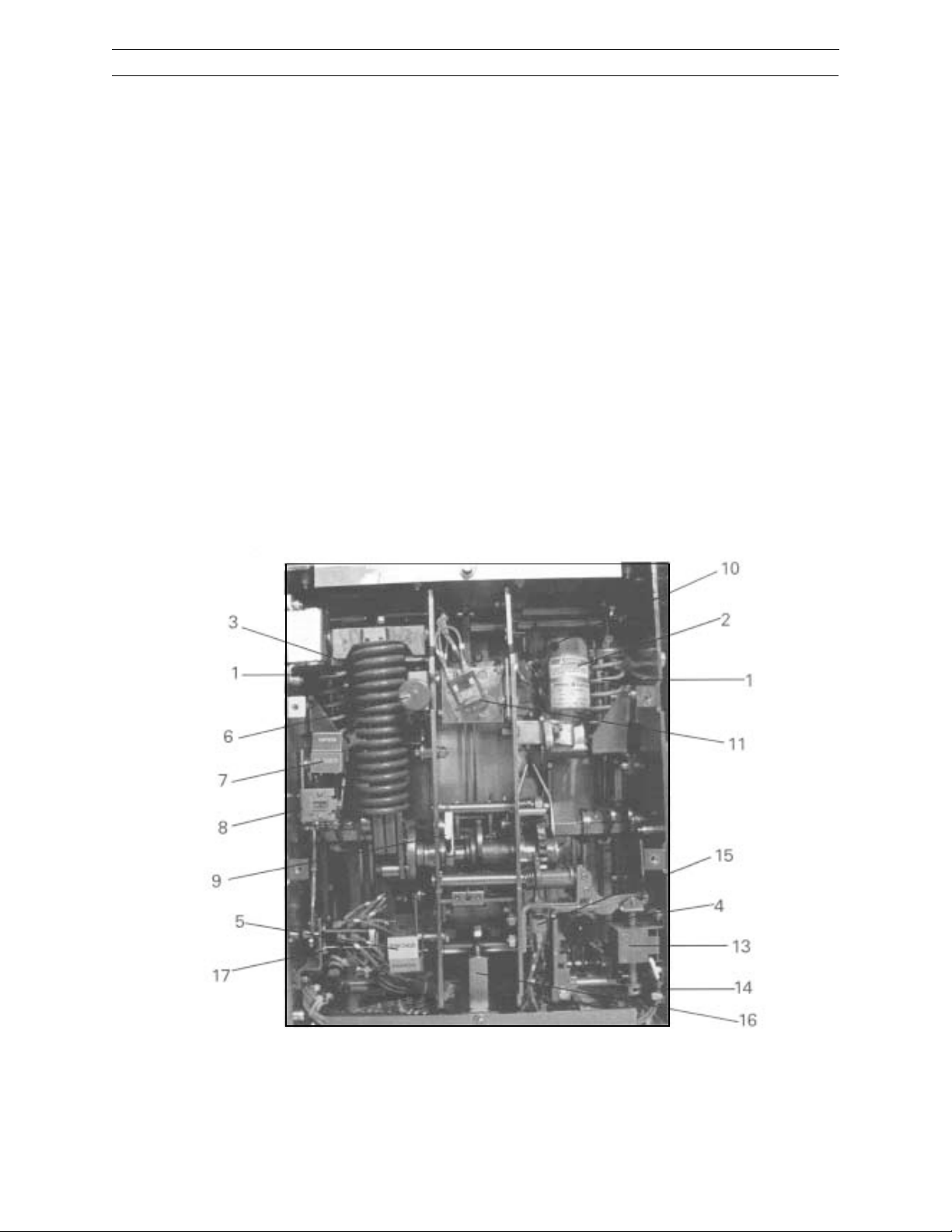

Figure 12. Fr ont View of ML-19 Mechanism with Fr ont Cover Removed

1 Opening Spring

2 Char ging Motor

3 Close Spring

4 Manual Close Button

5 Char ge/Dischar ge Indicator

6 Manual T rip Button

7 Open/Close Indicator

8 Counter

9 Manual Charge Lever

10 Positive Interlock Switch

11 Close Relay

12 Cam shaft

13 Close coil

18

14 Close coil adjustment collar

15 Close latch check switch

16 Opening dashpot

17 Auzilary switch

18 MOC Plunger linkage

19 Positive interlock bar

Page 19

PowerV ac® 5kV Vertical Lift

Chapter 5. Operation

5-2 Close Spring Charging

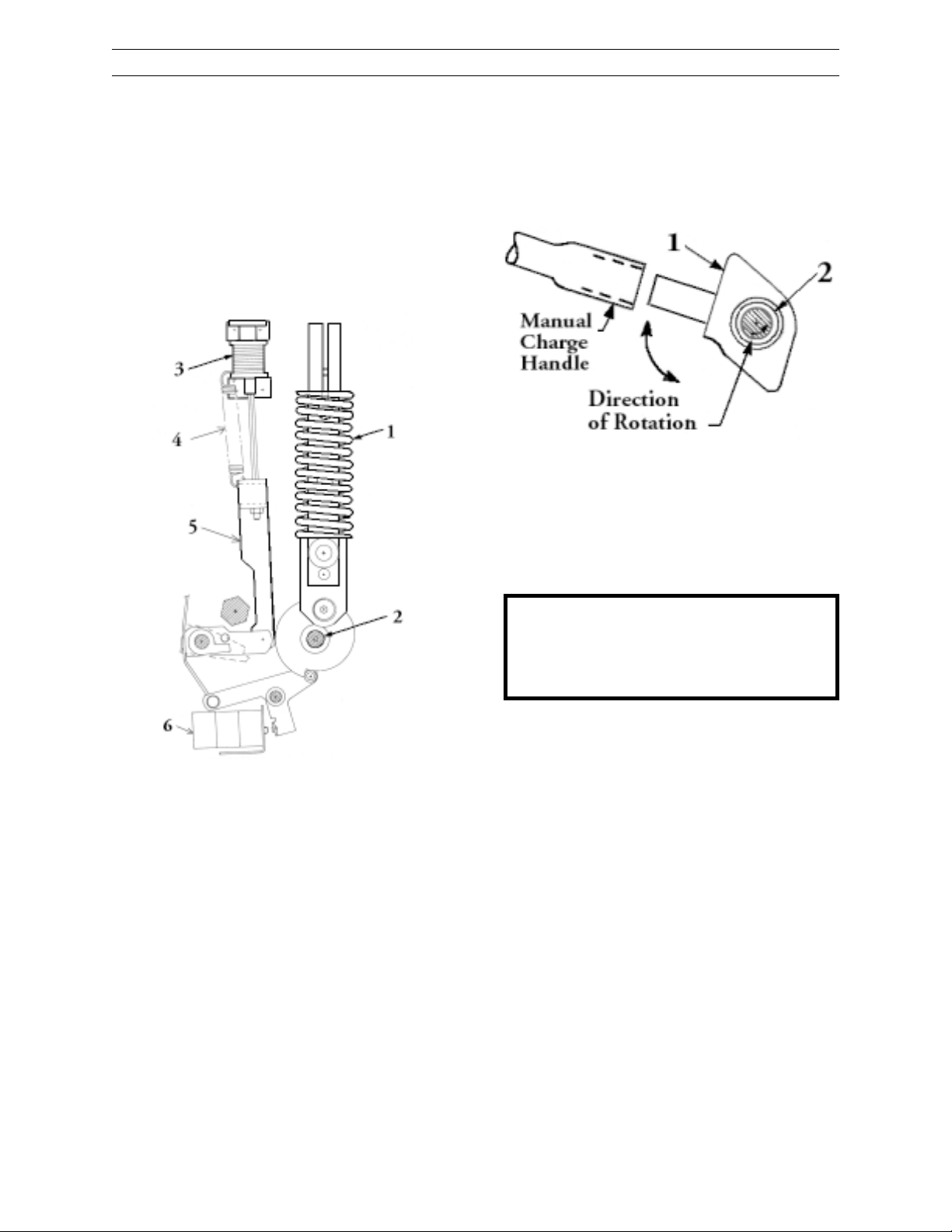

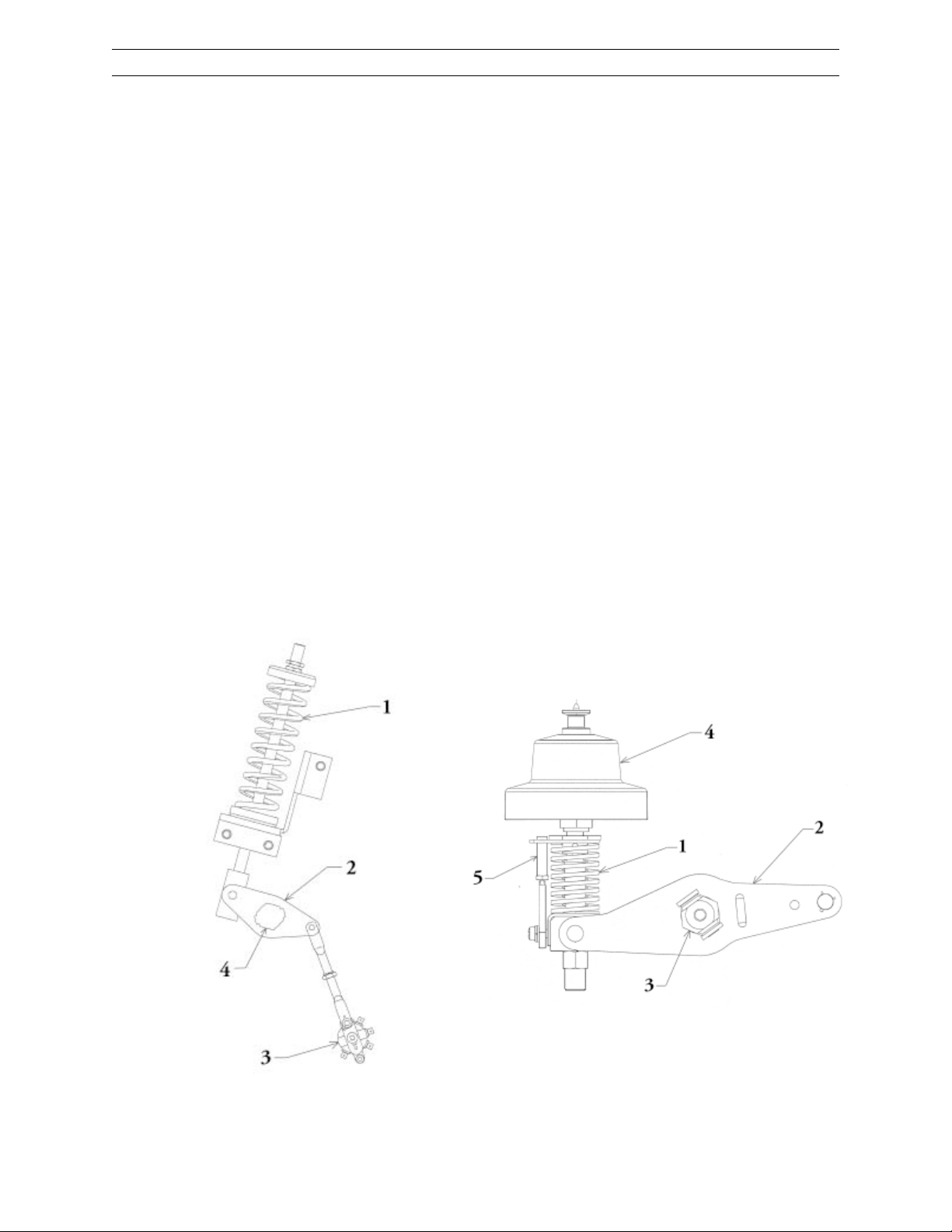

Figure 13 shows a left side view of the closing

spring. The closing spring is char ged and ready

to close. The closing spring charging system

consists of a closing spring mounted on the

left side of the breaker and the electrical char ging system mounted on the right side of the

breaker. Both components are fastened to the

cam shaft (Figure 13, Item 2).

A manual char ging system is provided to manually char ge the br eaker, or while under maintenance so that the mechanism can be slow

closed and the closing spring can be charged.

(Figure 14, Item 1)

Figure 14. Manual Char ging system

right side view

1 Manual char ging crank

2 One way clutch

Figure 13. Charging & Trip system left side view

1 Closing spring 4 Trip r eturn spring

2 Cam shaft 5 Trip linkage

3 T rip Solenoid 6 52 Chg & SM/LS switch

WARNING: DO NOT ATTEMPT TO MANUALLY CHARGE A CHARGED BREAKER. TO

DO SO COULD DAMAGE THE CHARGING

CLUTCH AND MAKE THE MANUAL CHARGING FEATURE INOPERABLE.

The manual char ging system (Figure 14) works

directly on the cam shaft where a one-way

clutch (Figure 14, Item 2), driven by a manual

handle, pr ovides rotation of the ratchet wheel.

Manual pumping of the handle advances the

ratchet wheel and the holding pawl prevents

counter -r otation while the handle is retur ning

for another str oke. Approximately eight complete str okes of the manual handle are requir ed

for one complete spring-char ging operation.

When the spring charge indicator (Figure 1,

Item 5) shows “CHARGED”, MANUAL CHARGING MUST BE DISCONTINUED TO AVOID

MECHANISM DAMAGE.

19

Page 20

PowerV ac® 5kV Vertical Lift

Chapter 5. Operation

Spring char ging is accomplished electrically by

a rotating eccentric on the output shaft of a

gear motor (Figure 15, Item 6) which in turn

drives pivoted charging arms (Figure 15, Item

1). The charging arms oscillate about the

centerline of a ratchet wheel (Figure 15, Item 2).

A driving pawl (Figure 15, item 3), mounted

within the charging arms, oscillates with the

char ging arms. Star ting fr om its rear-most position, the charging arms rotate forward, while

spring forces engage the driving pawl with a

tooth on the ratchet wheel. The ratchet wheel is

advanced by the r otating char ging arms and pawl

assembly . Advancement of one tooth spacing

is provided for each oscillation of the system.

The ratchet motion is restricted to one direction by a spring-loaded holding pawl (Figure

15, Item 4) that prevents the ratchet wheel fr om

going backwards as the charging arm oscillates back to pick up the next tooth. Thirteen

complete cycles of the char ging arms ar e needed

for a full char ge of the closing spring. The efficient, compact gear motor accomplishes this

action in about two seconds. When the charging cycle is complete, the ratchet wheel is positioned so that a missing tooth is adjacent to the

driving pawl and any motor overspin will not

drive the ratchet wheel, thus preventing damage to the system.

The closing coil cannot be electrically energized

unless the closing spring is completely char ged.

This action is prevented by the 52/CHG switch

in the closing circuit. (Figure 13, Item 6)

5-3 Trip Free Operation

The linkage is mechanically trip-free in any location on the closing stroke. Electrically energizing the trip coil while closing will, after the

auxiliary switch contacts change position, rotate the trip latch and permit the cir cuit breaker

to open fully . The linkage will r eset as in a normal open operation and the closing spring will

rechar ge as described under “CLOSE SPRING

CHARGING”.

View rotated

90 degrees

1 Charging arms 5 Close latch

2 Ratchet wheel 6 Charging motor

3 Driving pawl 7 52 LCS switch

4 Holding pawl 8 T rip latch

Figure 15. Electrical Char ging system

right side view

1 Closing cam 4 Primary cross shaft

2 Closing roller 5 Primary drive crank

3 Close prop latch 6 Trip latch

Figure 16. Closing linkage left side view

5-4 Closing Operation

By either energizing the close solenoid or depressing the manual close button(Figure 1 , Item

8) the close latch (Figure 15, Item 5) is r otated,

releasing the closing spring (Figure 13, Item 1).

This action releases the energy in the closing

spring and transmits it to the closing cam (Figure 16, Item 1) and closing r oller (Figure 16, Item

2) causing the linkage to rise until the close prop

(Figure 16, Item 3) can slip under the close r oller

(Figure 16, Item 2) and hold the linkage in place.

As the linkage moves, the primary drive crank

(Figure 16, Item 5) r otates the primary cr oss shaft

(Figures 16 & 17, Item 4) which in turn rotates

the outer phase bell cranks. (Figure 17, item 2)

20

Page 21

PowerVac® 5kV Vertical Lift

Chapter 5. Operation

The rotation of the primary cross shaft rotates

two outer phase bell cranks which compress

the outer opening springs (Figure 17, Item 1).

The primary cr oss shaft also rotates two sets of

inner drive cranks that in turn rotate two outer

sets of secondary drive cranks, (Figur e 18, Item

2) As the outer secondary drive cranks rotate

about the secondary cr oss shaft, the center drive

cranks are rotated. The rotation of the secondary drive cranks close the vacuum inter r upters,

and compresses the wipe springs on all three

phases . (Figure 18, Item 1) The inter r upters are

driven closed through insulated operating rods.

(Figure 18, Item 4). This inter rupters are driven

closed through insulated operating rods (Figure 18, Item 4)

The rotation of the primary cross shaft (Figure

17, Item 4) also changes the auxiliary switch

position. (Figure 17, Item 3) The position flag

on the front panel will then indicate “CLOSED”.

After the breaker is closed, the char ging motor

is again energized and the closing spring is

charged as described under “CLOSE SPRING

CHARGING”. Spring char ging is possible when

the breaker is in the closed position because

the linkage is held in place by the prop.

5-5 Opening Operation

By either ener gizing the trip solenoid (Figure 13

Item 3) or depressing the manual trip button

(Figure 1, Item 7), the trip latch (Figure 16, Item

6) is r otated, permitting the linkage to collapse.

The vacuum inter rupter contacts will then open

under the force of the wipe springs (Figure 18,

item 1) and opening springs (Figure 17, item 1).

At the end of the opening stroke, the center

phase secondary drive cranks hit the dashpot

limiting overtravel and r ebound.

Rotation of the Primary cross shaft from the

closed to the open position operates the auxiliary switch (Figur e 17, Item 3) opening the trip

coil circuit. When the closing spring has been

recharged,( Figure 13, Item 1) the linkage is reset allowing the trip latch (Figure 16, Item 6) to

rest in place on the trip r oller, ready for another

closing operation. If the closing spring has not

been recharged, the trip latch will be held out

of position. A latch-checking switch, 52 LCS

(Figure 15,Item 7) will not close unless the latch

is in its normal position. The contacts of the

latch-checking switch are par t of the closing cir cuit and will not allow for an electrical close

until the latch is reset.

1 Opening Spring 3 Auxilliar y switch

2 Outer bell cranks 4 Primar y cross shaft

Figure 17. Opening spring & auxialliary

switch left side view

1 Wipe spring 4 Insulated operating rod

2 Secondary drive crank 5 Wipe indicator

3 Secondary cross shaft

Figure 18. Wipe Spring assembly-

left side view

21

Page 22

PowerV ac® 5kV Vertical Lift

Chapter 6. Control Circuit

6-1 Controls

A Standard inter nal wire har ness for a PowerVac

VL circuit breaker ML-19 mechanism is shown

in Figure 19. The wiring from the breaker

internals to the secondary disconnect varies

with each breaker. Two typical breaker wiring

diagrams have been pr ovided (Figure 20 and Figure 21). Always follow the wiring diagram supplied with the actual circuit breaker for trouble

shooting purposes.

The close spring-charging motor circuit is established through the CL/MS (Close Latch Monitor Switch) Switch, if the close latch is reset

and the SM/LS (Spring Motor Limit Switch)

Switch is closed, the motor will char ge the closing spring. When the closing spring is char ged,

the SM/LS interrupts the circuit.

®

The close coil circuit is established thr ough two

normally closed 52Y r elay contacts, and the Latch

Checking Switch (LCS). If the trip latch is reset,

an auxiliary switch contact 52b is also in series

with the close coil and closes when the breaker

is open and opens when the breaker is closed.

During a close operation, the cam r otation closes

the SM/LS contact allowing the 52Y relay to be

ener gized. The 52Y relay opens its contacts, in

the close coil circuit and seals itself in thr ough

one of its own contacts. This seal-in action prevents re-closing on a sustained close command.

The close signal must be removed to drop out

the 52Y relay and reestablish the closing circuit. This pr ovides the anti-pump feature.

Circuit breaker-mounted auxiliary switch contacts that are not used in the control circuit are

br ought out for contr ol and indication functions.

The metal-clad equipment may provide a br eaker operated stationary auxiliary switch for additional contacts.

Figure 19. T ypical ML-19 mechanism internal wiring connections.

22

Page 23

PowerVac® 5kV Vertical Lift

Chapter 6. Control Circuit

Figures 20 and 21 show typical wiring diagrams

for PowerV ac® VL breakers.

Replacement breakers for old units with solenoid mechanisms (AM breakers with MS type

mechanisms) are typically wired per the drawing in Figure 20.

Replacement breakers for old units with stored

ener gy mechanisms (AM breakers with ML type

mechanisms) are typically wired per the drawing in Figure 21.

The wiring on your breakers may be different.

Consult your nameplate for the corr ect drawing

number and call your local GE office when additional copies of this drawing are required.

Figure 20. T ypical breaker wiring diagram

(Replacement for breakers with MS mechanisms)

23

Page 24

PowerV ac® 5kV Vertical Lift

Chapter 6. Control Circuit

Figure 21. T ypical breaker wiring diagram

(Replacement for breakers with ML mechanisms)

24

Page 25

PowerVac® 5kV Vertical Lift

Chapter 7. Mechanical Checking and Slow Closing

7-1 Visual Inspection

Visually inspect the circuit breaker for any signs

of damage or loose hardware.

7-2 Closing Spring Charging

Manually char ge the breaker closing spring using the char ging handle provided. (Figur e 7, Item

1) The closing spring is charged by a

ratcheting mechanism that advances one

ratchet tooth at a time. Approximately eight

complete strokes ar e requir ed. When the spring

is fully charged, the spring load is held by the

closing latch. The spring indicator (Figure 1,

Item 5) changes from “DISCHGD” to

“CHARGED”, and a positive snap is heard as

the spring travels over center.

CAUTION: AFTER THE SPRING IS COM-

PLETELY CHARGED, AS INDICATED ABOVE,

FURTHER FORCING THE CHARGING

HANDLE MAY CAUSE DAMAGE TO THE

CLOSING LATCH AND ITS ASSOCIATED

PARTS.

7-3 Closing Spring Gag

Remove the mechanism front and top covers

and insert the tip of the closing spring gag tool

(Figure 22, Item 2) between the end of the spring

and the spring guide, engaging the détentes

(Figure 22, Item 3) on the gag tool into the slots

in the closing spring guide. (Figure 22, Item 4)

Reference also Figure 48.

With the gag tool in position depress the

manual close button. This action will partially

discharge the closing spring and also partially

close the vacuum interr upter contacts.

7-4 Slow Closing

To manually slow close the breaker contacts,

remove the top plate of mechanism. Install the

closing spring gag, as described above. Put the

manual charge handle on the manual charge

lever and move the handle up and down. The

breaker will be fully closed when the spring

char ge indicator shows “CHARGED”

CAUTION: WITH THE GAG TOOL INSTALLED,

THE BREAKER CLOSED, AND OPENING

SPRINGS CHARGED, THE BREAKER CAN BE

TRIPPED AT FULL SPEED.

1 2

3

4

5

6

1 Tie bar 4 Closing spring guide

2 Gag tool 5 Spring pin

3 Gag tool détentes 6 Closing spring

Figure 22. Closing spring with gag tool

inserted

CAUTION: DO NOT REMOVE TIE BAR (FIGURE 18, ITEM 1) UNLESS SPRING HAS BEEN

REMOVED FROM THE BREAKER.

CAUTION: DO NOT ENERGIZE THE SEC-

ONDARY CONTROL CIRCUIT AT THIS TIME.

USE OF THE GAG TOOL SHOULD ONLY BE

ATTEMPTED WHEN THE BREAKER IS OUT

7-5 Gag Tool Removal

T o r emove the gag tool, the closing spring must

be fully char ged. If the spring charge indicator

does not show “CHARGED” in the window,

manually char ge the spring until it does. Lift up

and push down and away on the gag tool to

clear the détentes on the gag tool from the slots

in the closing spring guide. For safety, first close

the breaker by depressing the manual “CLOSE”

button and then depress the manual “TRIP”

button. All stored ener gy is now r emoved fr om

the breaker .

25

Page 26

PowerV ac® 5kV Vertical Lift

Chapter 8. Dimensional Checks

8-1 Primary Contact Erosion

The vacuum inter r upter is a sealed unit and the

contacts are not visible. The contacts are designed for 0.125” total wear. When 0.125” of

wear has occured , the vacuum inter r upter must

be replaced. V acuum inter r upters are typically

good for 25 full rated interruptions before the

0.125” wear has been reached. Vaccum interrupters are also good for in excess of 10,000

no- load operations and 5,000 load operations.

The mechanical seal system will develop a leak

in the bellows before the contacts will reach

0.125” wear . See Chapter 9 for vacuum integrity

test..

6

Each inter r upter has been premeaseur ed at the

factory for the primar y contact gap and this measurement has been recorded on the ceramic

bottle. This measurement varies fr om phase to

phase and from breaker to breaker but is appr oximately 4 inches. The actual measurement

“A” is the distance from the bottom of the insulated operating r od to the bottom of the lower

stainless steel inter r uptor suppor t as shown in

Figure 24. To determine contact wear r epeat

this measurement on each phase and subtract

the measurement fr om the factory r ecorded measurement. If the difference is 0.125“ or greater

then the vacuum interr uptor should be replaced.

See Chapter 12.

8

1

2

3

5

4

1 Operating Rod Insulator

2 Wipe Indicator

3 Wipe Gap

4 Wipe Spring

5 Lock Nut and Lock Washer

6 Coupling Clamps and Screws

7 Hexagon Pr ojection

8 Interrupter Movable Contact Rod

Figure 23. Contact Er osion Indicator

1

7

2

3

4

5

6

1. Lower Interrupter support 4. Insulated

2. Moving contact rod operating rod

3. Coupling clamp 5. Masking Tape

6. Reference block

Figure 24. Primary contact er osion

measurment - rear view .

8-2 Spring Wipe Indicator

The wipe springs are preloaded to a length of

2.25 inches When the breaker is closed, the secondary drive cranks will continue to move upwards after the primary contacts in the vacuum

inter ruptor have been closed. This over travel

is taken up by compressing the wipe springs.

The over travel distance is pre-adjusted at the

factory to be 0.125” minimum. The spring wipe

can be verified by viewing the wipe indicator.

(Figure 23, Item 2) The wipe indicator has four

red lines that make up a total distance of 0.125”.

The wipe indicator was preset at the factor y so

that when the breaker is char ged and closed all

four red lines should be visible above the wipe

plate.

26

Page 27

PowerVac® 5kV Vertical Lift

Chapter 8. Dimensional Checks

With the breaker closed and

char ged and the closing spring

gagged for safety (Chapter 7-3),

verify that each phase has sufficient spring wipe. If more

then two red lines are showing

the breaker wipe is sufficient.

The minimum wipe, 0.050”, has

been reached when the white

space between the second and

third line is no longer visible

above the wipe plate. Adjustment is not required until wipe

is 0.050 inch or less.

If adjustment is required see

WIPE ADJUSTMENT in MECHANICAL ADJUSTMENTS

Chapter 11-2.

1 Operating rod insulator

2 Operating rod nut

3 Wipe indicator

Figure 25. Wipe indicator check and wipe measur ement -

rear view .

4 Wipe Indicator adjustment nut

5 Actual Wipe measurement

1

2

3

4

5

8-3 Contact Gap

The method of measuring the contact gap is as

follows: First with the breaker in the open position, the closing springs char ged, and the closing spring gag tool installed for safety (Chapter

7-3), apply a piece of masking tape to the surface of the operating r od insulator as shown in

Figure 24. Using a reference block, make a mark

on the tape near the top on all three poles. The

reference block should be 6 23/32” long, if the

breaker mechanism has been r emoved from the

breaker tr uck, or X” if verifying the gap with the

element installed in the truck. It is also advisable to put a reference mark on the tape to identify to which pole the tape is applied.

Remove the closing spring gag tool and close

the breaker . Using the same pr ocedure as above,

re-mark the tape. This new mark will be near

the bottom of the tape. T rip the breaker, remove

the tapes and re-apply them to a flat surface.

Measure the distance between the two lines. A

caliper will give an accurate reading of the contact gap.

and 0.600” for all three phases.

A properly adjusted br eaker will generally have

less gap and wipe on the center pole than on

the outside poles. Due to the fact that the outer

phases are dir ectly driven by the secondary drive

cranks by the primary cross shaft and the center phase is driven by the secondary drive cranks

by the secondary cross shaft, the center phase

tends to lag the outer phase during opening and

closing. See Chapter 5-4 and 5-5 for a thor ough

description on opening and closing. It is important that the three phases do not open or

close more than two milliseconds apart from

each other . In general the center phase will need

a gap of 0.020” less than the outer phases to

prevent any phase stagger. If the center phase

measures 0.550” nominally then the outer phase

should be appr oximately 0.570”.

Dimension B: The gaps must be between 0.480”

27

Page 28

PowerV ac® 5kV Vertical Lift

Chapter 9. Electrical Checks

9-1 Electrical Operation

Electrical checking consists of electrical breaker

operation primary and seconar y wiring high-potential testing (if required), primary circuit

reistance (if requir ed), PowerV ac interr upter highpotential testing, and insulation resistance to

ground.

T o check the electrical operation with the br eaker

removed from the cubicle, attach a secondary

test coupler to the circuit breaker connector and

the other end to the secondary coupler mounted

in the cubicle. Check the contr ol voltage on the

nameplate and close and open the breaker several times.

CAUTION: REPEATED OPERATIONS AT A RATE

EXCEEDING TWO PER MINUTE MAY CAUSE

CHARGING MOTOR OVERHEATING AND FAILURE.

Leave the circuit breaker in an open and spring

dischar ged condition after checks are complete

and before inserting the circuit breaker into a

metal-clad unit. Reinstall the front cover if it

has been removed.

9-2 High-Potential Test

If hi-potential tests to check the integrity of the

insulation are required, the AC hi-potential test

described below is strongly r ecommended. DC

high-potential testing is not recommended. The

following pr ocedure must be adher ed to.

If the test should experience a failure, STOP,

turn off the test set and discharge the breaker

circuit.

1. Check the test setup and leads for connection er rors.

2. Wipe down the breaker to remove any

moisture, dust and contamination.

3. Retest the breaker at the pr oper test voltage.

Secondary Circuit

Prior to hi-potting the breaker secondar y circuit,

disconnect the motor leads and thread a wire

connecting all secondary coupler pins. Connect the hi-pot machine fr om this wire to gr ound.

Increase the voltage to 1125 volts (rms) 60 Hz

and maintain for 60 seconds. Reduce the voltage to zero and r emove the hi-pot machine connections from the cir cuit. Remove the wir e connecting the secondary coupler pins and r econnect the motor leads.

9-3 Primary Circuit Resistance

A resistance check of the primary circuit may

be made with the breaker closed. Use a low

resistance measuring instrument which measures micro-ohms. The 100 ampere reading

should be less than 40 micr o-ohms when connected.

CAUTION: IF DC HIGH-POTENTIAL TESTING IS

REQUIRED, THE DC HIGH POTENTIAL MACHINE

MUST NOT PRODUCE PEAK VOLT AGES EXCEEDING 50 KV.

NOTE: ALWAYS RECHECK WITH AN AC TEST

SET, IF INITIAL RESULTS ARE QUESTIONABLE.

Primary Circuit

The breaker should be AC hi-potted in the closed

breaker mode to verify the insulation system.

An AC hi-pot machine capable of producing the

test voltages shown below may be used to hipot the breaker phase to phase and phase to

ground.

BREAKER VOLTAGE TEST VOLTAGE

4.16 kV 14 kV

CAUTION: DISCONNECT THE SURGE SUPPRES-

SORS BEFORE HI-POTTING THE CIRCUIT BREAKER.

The machine should be connected with its output potential at zero and the voltage incr eased

at 500 vps to the test voltage and that voltage

maintained for 60 seconds. The voltage should

then be retur ned to zer o and the hi-pot machine

removed from the circuit. Do not exceed the

test voltage indicated for the applicable breaker

voltage rating.

9-4

Vacuum Interrupter Integrity T est

NOTE: USE OF A DC HI-POT IS NOT RECOMMENDED,

BUT CAN BE USED FOR QUICK FIELD CHECKS ONLY.

ALW AYS RECHECK WITH AN AC TESTER IF INITIAL RESULTS ARE QUESTIONABLE. PRIOR TO PERFORMING

ANY VACUUM INTERRUPTER INTEGRITY TEST, THE

OUTSIDE (EXTERNAL SURFACE) OF THE V ACUUM INTERRUPTERS SHOULD BE WIPED CLEAN OF ANY

CONTANMINATES WITH A NON-LINTING CLOTH OR

INDUSTRIAL TYPE WIPER. THIS IS

TIRE EXTERNAL SURFACE IS TO BE COMPLETELY FREE

OF ALL DIRT, DEBRIS, DUST , OIL, ETC.

CAUTION: X-RADIATION WILL BE PRODUCED IF AN

ABNORMALLY HIGH VOLT AGE IS APPLIED ACROSS A

PAIR OF ELECTRODES IN A V ACUUM. X-RADIATION

WILL INCREASE AS VOLTAGE INCREASES AND/OR

AS CONT ACT SEPARATION DECREASES. ONLY TEST

A CORRECTLY -ADJUSTED CIRCUIT BREAKER.

DURING A HIGH-POTENTIAL OR A VACUUM INTEGRITY TEST, ANY X-RADIATION WHICH MAY BE PRODUCED WILL NOT BE HAZARDOUS AT A DISTANCE

SAFE FOR HIGH-POTENTIAL TESTING, IF THE TEST IS

CONDUCTED AT THE REC-OMMENDED VOLTAGE

AND WITH THE NORMAL OPEN CIRCUIT BREAKER GAP.

DO NOT APPLY VOLTAGE THAT IS HIGHER THAN

THE RECOMMENDED VALUE OR USE CONTACT

SEPARATION THAT IS LESS THAN THE RECOMMENDED OPEN-POSITION BREAKER CONTACT

28

GAP.

CRITICAL: THE EN-

Page 29

PowerVac® 5kV Vertical Lift

Chapter 9. Electrical Checks

This test of the vacuum interrupter will determine its internal dielectric condition and vacuum

integrity.