Page 1

g

GE

Lighting Solutions

UltraStar® Luminaire

INSTRUCTIONS

T5 / T8 Fluorescent Luminaire

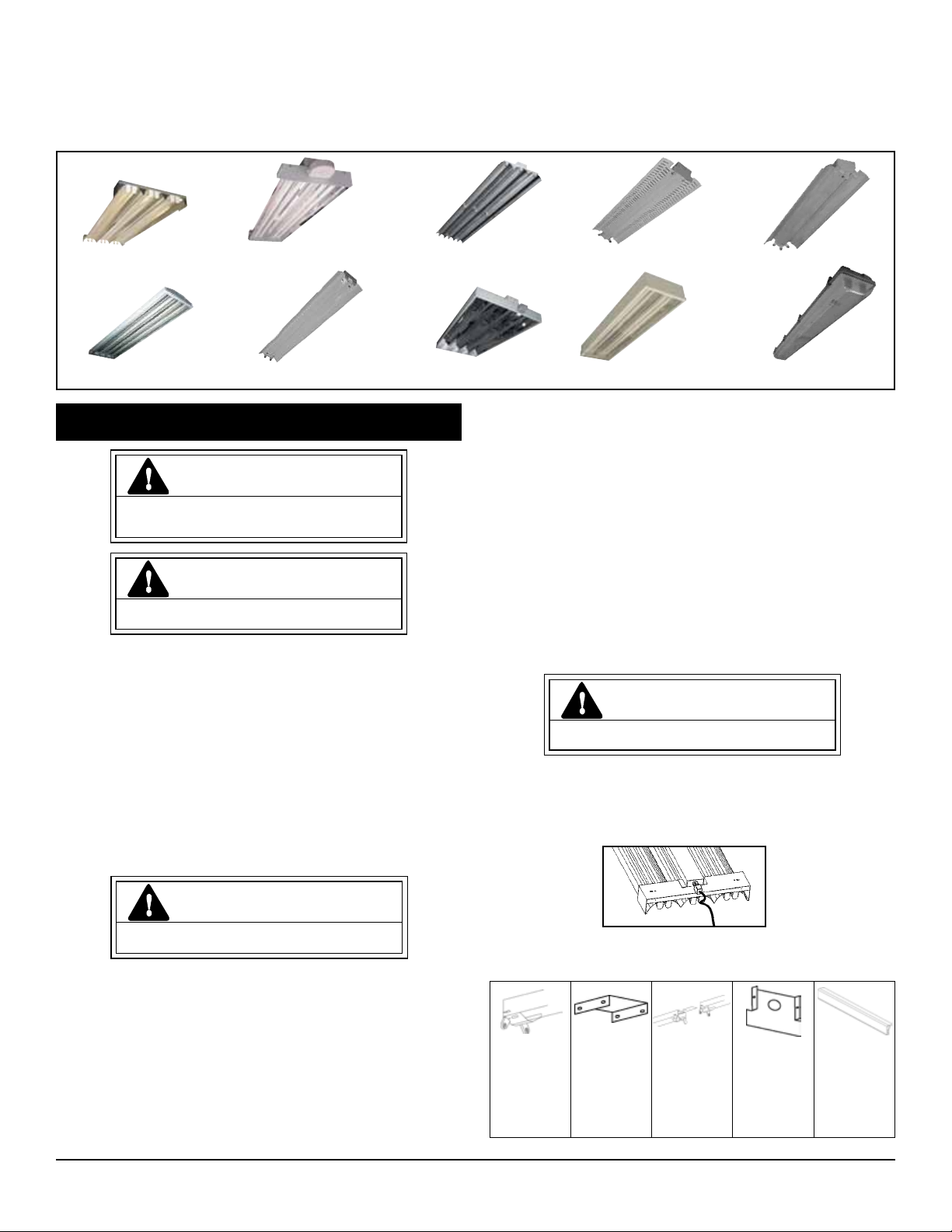

VH Series HB Series AL Series SS Series ES Series

FH Series SR Series NH Series EH Series VP Series

GEH-5983

READ THOROUGHLY BEFORE INSTALLING

WARNING

Risk of electric shock

• Turn power o before servicing

– see instructions

WARNING

Sharp edges may be present

• Gloves should be worn during installation

GENERAL

This luminaire is designed for indoor applications only and should be installed and maintained

according to the following recommendations. Check label for damp or wet location suitability.

Any part damaged or broken during or after assembly or installation should be replaced.

UNPACKING

This Luminaire has been properly packed so that no parts should havebeen damaged

during transit. Inspect to conrm. No damaged parts should be installed.

Attention: Sheet metal parts may have sharp edges that may cause injury. The

manufacturer recommends caution during installation and the use of gloves when

possible. Remove all protective lm from reectors before energizing xture.

WIRING

Make all electrical connections in accordance with the National Electrical Code and any

applicable local code requirements. Check to be sure that labeled ballast voltage matches

supply voltage. Use supply wire rated minimum 90°C.

FIXTURE INSTALLATION (VH, HB, AL, SS, ES, FH, SR, NH, VP and EH Series)

a. EZ Leveling stright-cable or EZ Leveling Y-toggle cable can be used to mount

xture.

b. Attach EZ leveling cable to each end of xture, attaching through mounting slot.

2. S-Hook Hanging

Fixtures can be installed using S-hook (not supplied) using mounting detail on top

ends of xture.

3. NH series xture has integral threaded inserts and supplied eye-bolts.

Attach EZ level cable to eye-bolts for mounting of xture.

4. VP series xtures are supplied with mounting brackets. Attach EZ level cable to

mounting brackets for mounting of xture.

5. After xture is mounted access ballast for wiring as follows:

a. SR, ES, SS, AL Series: Remove reector/ballast cover by twisting reector

fasteners quarter-turn,

b. HB, NH Series: Remove top-access ballast cover by unsnapping ballast cover.

c. FH, VH Series: Plug directly into Modular Wiring Plug at side of ballast channel.

d. VP Series: Remove reector clips.

6. Make connection to ballast leads per wiring diagram on ballast.

7. Reinstall reector/ballast cover.

8. Peel protective covering from reector (Miro nish reectors).

9. Install lamps

LAMP

CAUTION

Risk of burn

• Allow lamp/xture to cool before handling

Use only lamps specied on nameplate. Observe lamp manufacturer’s recommendations

and restrictions on lamp operation, particularly ballast type, burning position, etc.

Attaching Modular Wiring Harness (optional component)

Insert supplied modular plug wiring harness into the receptacle on the end of the xture

and tie the wire to the cable hanger up to main power source.

WARNING

Unit will fall if not installed properly

• Follow installation instructions

Installing SR, ES, SS, AL series xtures

1. EZ Leveling cable (see EZ Leveling cable attachment instructions below).

a. Four EZ Leveling straight- cables required to hang xture.

b. Attach EZ Leveling cable to each end of xture at mounting detail.

2. After xture is mounted:

a. Remove reector by turning reector fasteners quarter-turn.

Make connection to ballast leads per wiring diagram on ballast.

b.

c. Reinstall reector.

d. Peel protective covering from reector.

e. Install lamps.

Installing VH, HB, FH, NH, VP series xtures

1. EZ Leveling cable (see EZ Leveling cable attachment instructions below).

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered suciently for the purchaser’s purposes, the matter should be referred to

GE Lighting Solutions.

Components for Installing SS Series Fixtures

Reector/ballast cover must be installed to complete enclosure! Assemble reector part

RSFSS8-844UP-W only with BP-S082/ S081 Strip xture!

BR-S4-2LE-P-SS

Install socket/

socket bracket

assembly into

slots at end of

xture. Twist end

of tab with pliers

to insure locking

as shown.

BP-S054

If xture is run

across red iron,

use Bracket

Connector Kit for

alignment and

stiening.

BP-S009 or

BP-S067

If xture is run

with red iron,

use either a

slide-in connector

for alignment

proposes.

BP-S068

If xture is at the

end of a row, use

Tall End Plate

to cover end of

xture.

HW-F041

Attach alignment

clips to join

next reector if

required.

Page 2

MAINTENANCE

It will occasionally be necessary to clean the outside of the refractor to maintain the light

level. Frequency of cleaning will depend on the ambient dirt level and the minimum light

level which is acceptable to the user. The optional acrylic plastic lens should be washed

in a solution of warm water and any mild non-abrasive household detergent, rinsed

with clean water and wiped dry. Should the optical assembly become dirty on the inside,

wipe the reector and clean the inside of the lens in the above manner. Use of abrasive

cleansers will shorten the life of the optical assembly.

EZ Leveling Cable (Aircraft Cable) Hanging Directions (VH, HB, AL, SS, ES, FH,

SR, NH and EH Series)

WARNING

Unit will fall if not installed properly

• Follow installation instructions

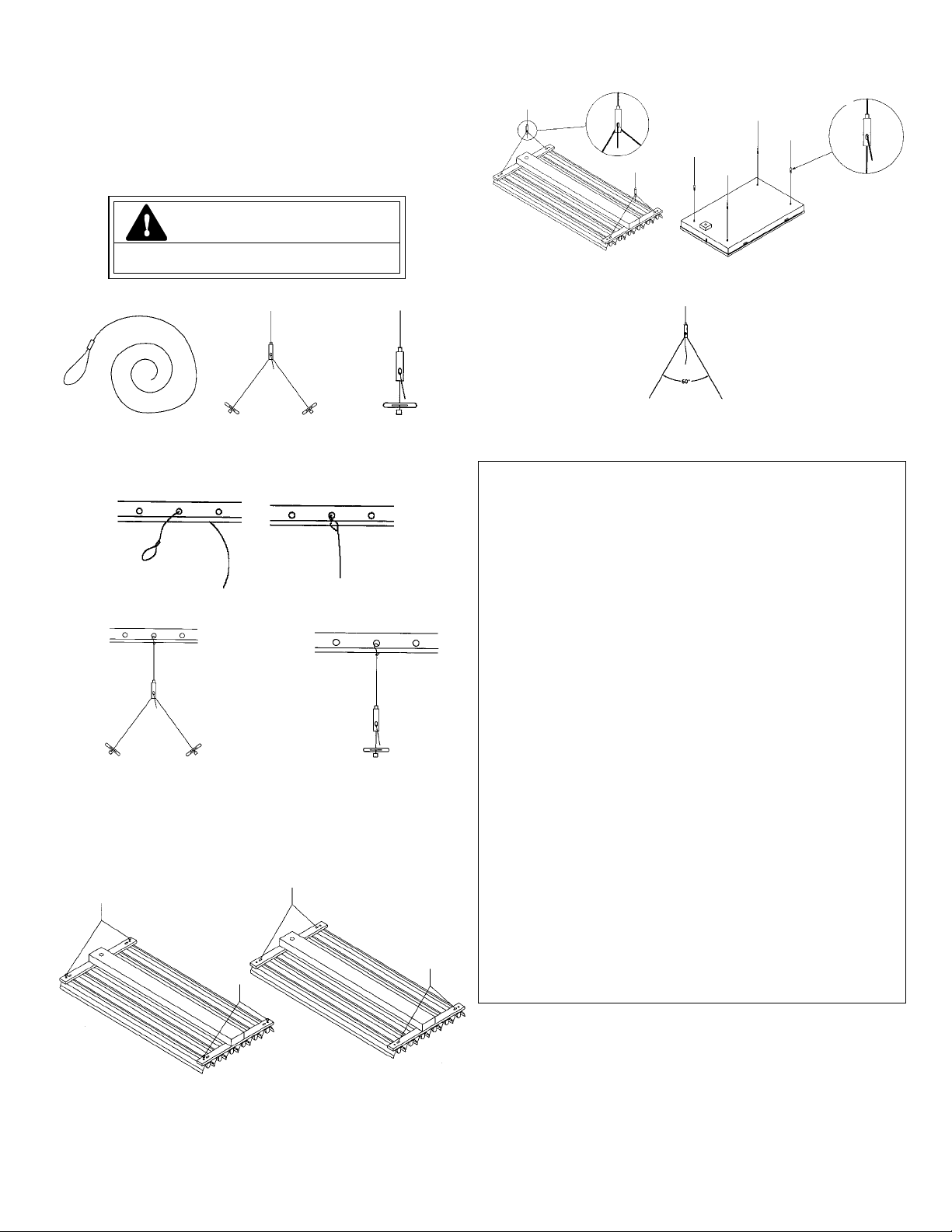

1. Parts included:

5. To readjust the wire height of the xture, pull the wire while pressing the

button of the top of adjuster.

6. Double Toggle Y-Fit – The angle between the legs should not exceed

60 deg.

15’ Aircraft cable

with Loop

2. Thread the tail of the adjustable wire rope around (or through) the pole

or other structure that the xture will be attached to. Pass the tail of the loop

and pull tight.

3. Insert the wire rope into the adjuster.

15” Y Toggle

(Type 1)

(Type 1)

4. If the xture is equipped with threaded inserts on support arm, thread

eyebolt until fully seated. Then insert Aircraft wire hanger end into eyebolt.

If xture does not have threaded insert, Insert the aircraft hangers into

mounting slots of the xture. Draw the toggle plate back from the end stop

and align down the length of the wire rope. Push the end stop plate through

the hole. When the toggle plate has cleared the hole, pull back on the

cable, or simply let the weight of the object settle onto the toggle.

15” straight Toggle

(Type 2)

(Type 2)

7. Caution: To be used only on xtures weighing less then 44 lbs when 2

Aircraft cable Loops per xture are used.

EZ Leveling Cable (Aircraft Cable) Application Recommendations:

Environment – Aircraft Cable Hanger may be used only in dry locations. Stainless steel

Aircraft Cable Hanger may be used in certain indoor corrosive environments such as

properly ventilated swimming pool arenas.

Load – Do not exceed the Safe Working Load (SWL) of any Aircraft Cable Hanger

product.

No Lifting – Do not use for lifting, such as in a crane or pulley situation.

No Movement – Aircraft Cable Hanger are to be used to suspend stationary loads only. Do

not use to suspend moving surfaces or surfaces likely to be subject to movement.

No Joining – Aircraft Cable Hanger must not be spliced together using a Aircraft Cable

Hanger, or any other joining device. An Aircraft Cable Hanger assembly must comprise

one length of cable and one Aircraft Cable Hanger fastener only. If a longer length is

needed, do not attempt to join two assemblies together.

Limitations Of Use – All Aircraft Cable Hangers, accessories and other Aircraft Cable

Hanger products must only be used for the purposes of suspending electrical and

mechanical services and are not to be used for any other purpose.

Painting – If painting, ensure that covering is applied to the Aircraft Cable Hanger fastener

before painting. Do not move the Aircraft Cable Hanger fastener on the cable after

painting.

Building Codes – Compliance with local codes and where applicable national codes, is the

buyer and or installers responsibility.

Lubricants – Do not apply oil or any other lubricant to any part of the assembly.

Round Duct / Pipes – When wrapping around duct or other round pipes, do not exceed an

angle of 60 degrees between the top of the pipe and the Aircraft Cable Hanger.

Not For Re-Use – Aircraft Cable Hangers are designed for permanent installations, not

for re-use.

Y-Fit Installation Angle – Arms on Y-t hangers not to be installed at angles greater than

60 degrees.

Failure to observe these usage instructions may result in product malfunction, resulting in

property damage and bodily injury.

Page 3

GE

INSTRUCTIONS

g

Lighting Solutions

Luminaire UltraStar

Luminaire uorescent T5/T8

Série VH Série HB Série AL Série SS Série ES

Série FH Série SR Série NH Série EH Série VP

GEH-5983

®

LIRE ATTENTIVEMENT AVANT D’INSTALLER

AVERTISSEMENT

Risque d’électrocution

• Couper l’alimentation électrique avant toute réparation

– Voir les instructions

AVERTISSEMENT

Danger de rebords coupants

• Porter des gants durant l’installation

GÉNÉRALITÉS

Ce luminaire a été conçu pour une utilisation à l’intérieur uniquement . Il doit être

installé et entretenu conformément aux instructions suivantes. Si cet équipement peut

être installé dans un endroit humide ou mouillé, une indication en ce sens apparaît sur

l’étiquette. Toute pièce endommagée durant ou après l’assemblage et l’installation doit

être remplacée.

DÉBALLAGE

Ce luminaire a été soigneusement emballé pour qu’aucune pièce ne subisse de

dommages durant le transport . Procédez à une inspection pour vous en assurer. Aucune

pièce endommagée ne doit être installée.

Attention : Les pièces en tôles peuvent avoir des rebords coupants susceptibles de causer

des blessures. Le fabricant recommande de faire attention durant l’installation et de

porter des gants dans la mesure du possible. Avant de mettre l’appareil d’éclairage sous

tension, enlevez les pellicules protectrices sur les lentilles.

CÂBLAGE

Toutes les connexions doivent être conformes aux normes électriques nationales et à

la réglementation locale en vigueur (code électrique du Canada et réglementation

locale applicable). Assurez-vous que la tension électrique indiquée sur l’étiquette du

ballast correspond à la tension de l’alimentation électrique locale. Utilisez des câbles

d’alimentation électrique conçus pour supporter au moins 90º C.

INSTALLATION DU LUMINAIRE (séries VH, HB, AL, SS, ES, FH, SR, NH, VP et EH)

AVERTISSEMENT

L’appareil tombera au sol s’il est mal installé

• Suivez les instructions d’installation

Installation d’un luminaire de série SR, ES, SS ou AL

1. Câbles EZ Leveling (voir les instructions de xation des câbles EZ Leveling ci-après).

a. Pour installer le luminaire, il faut quatre câbles droits EZ Leveling.

b. Installez les câbles EZ Leveling sur les extrémités du luminaire, aux points de

montage.

2. Après le montage du luminaire :

a. Enlevez le réecteur en tournant les xations de ce dernier sur un quart de tour.

Connectez les conducteurs du ballast conformément au schéma de câblage aché sur

b.

le ballast.

c. Réinstallez le réecteur.

d. Décollez la pellicule protectrice sur le réecteur.

e. Installez les lampes.

Installation d’un luminaire de série VH, HB, FH, NH ou VP

1. Câbles EZ Leveling (voir les instructions de xation des câbles EZ Leveling ci-après).

a. Le luminaire peut être installé avec des câbles droits EZ Leveling ou avec des

câbles à bascule en Y EZ Leveling.

b. Installez les câbles EZ Leveling sur les extrémités du luminaire, aux points de

montage.

2. Accrochage des crochets en S

Le luminaire peut être installé avec des crochets en S (non inclus) sur les points de

montage situés aux extrémités supérieures du luminaire

3. Les luminaires de série NH ont des xations vissées intégrées et des boulons à œillets

inclus. Pour monter ces luminaires, il sut de xer les câbles EZ Leveling dans les

œillets.

4. Les luminaires de série VP sont livrés avec des xations de montage. Pour monter ces

luminaires, il sut d’installer les câbles EZ Leveling dans les xations de montage.

5. Après le montage du luminaire, accédez au ballast an de procéder aux connexions

électriques. Procédez comme suit :

a. Séries SR, ES, SS et AL : Enlevez le réecteur/couvercle du ballast en tournant les

xations sur un quart de tour.

b. Séries HB et NH : Enlevez le couvercle supérieur du ballast et ouvrant la fermeture

pression.

c. Séries FH et VH : Branchez le connecteur directement sur la che de raccordement

modulaire, sur le côté du canal du ballast.

d. Série VP : Enlevez les clips sur le réecteur.

6. Connectez les conducteurs du ballast conformément au schéma de câblage aché

sur le ballast.

7. Réinstallez le réecteur/couvercle de ballast.

8. Décollez la pellicule protectrice sur le réecteur (réecteurs avec nition Miro).

9. Installez les lampes.

LAMPE

ATTENTION

Risque de brûlure

• Laissez refroidir la lampe et l’appareil d’éclairage avant

de les toucher

Utilisez uniquement des lampes conformes aux exigences de la plaque signalétique.

Respectez les recommandations du fabricant de la lampe, ainsi que les restrictions

s’appliquant à l’utilisation de la lampe, notamment sur le type de ballast, la position de

brûlage, etc.

Installation d’un faisceau de câblage modulaire (composant optionnel)

Insérez le faisceau de câblage avec che modulaire dans le réceptacle à l’extrémité du

luminaire, puis reliez le l sur le support de câble à la source d’alimentation électrique

locale.

Composants pour l’installation d’un luminaire de série SS

Le réecteur/couvercle de ballast doit être installé de façon à bien fermer

l’ensemble! Le réecteur RSFSS8-844UP-W doit être assemblé uniquement

avec une bande de xation BP-S082/S081!

Ces instructions n’ont pas pour destination de couvrir tous les détails ou variantes de l’équipement, ni de répondre à toutes les éventualités que vous pourriez rencontrer pendant

l’installation, le fonctionnement ou l’entretien. Si vous souhaitez des informations complémentaires, ou si vous rencontrez un problème particulier qui ne soit pas adressé de votre point

de vue d’acheteur, le sujet doit être remonté jusqu’à la société GE Lighting Solutions

Page 4

5. Pour réajuster la hauteur de câble du luminaire, tirez le câble tout en appuyant sur le

bouton en haut du dispositif de réglage.

BR-S4-2LE-P-SS

Installez la douille ou

le support dans les

fentes aux extrémités

du luminaire. Pliez

l’extrémité des pattes

avec une pince pour

vous assurer qu’elles

sont bien bloquées

(voir illustration).

ENTRETIEN

Il sera périodiquement nécessaire de nettoyer l’extérieur du réfracteur pour préserver

la qualité de l’éclairage. La fréquence des nettoyages dépendra du degré de saleté de

l’air ambiant et du niveau minimum d’éclairage acceptable pour l’utilisateur. La lentille

optionnelle en plastique acrylique doit être lavée dans une solution d’eau chaude et de

détergent domestique doux, non abrasif, puis rincée avec de l’eau propre et essuyée. Si

l’intérieur de l’assemblage optique est sale, essuyez le réecteur et nettoyez l’intérieur

de la lentille de la manière ci-dessus. L’utilisation de nettoyants abrasifs raccourcira la

longévité de l’assemblage optique.

Câble EZ Leveling (câble d’aviation), instructions d’installation (séries VH,

HB, AL, SS, ES, FH, SR, NH et EH)

BP-S054

Si l’appareil d’éclairage

est installé dans du fer

rouge, utilisez le kit de

connexion de douille

pour aligner et serrer.

BP-S009 or

BP-S067

Si l’appareil

d’éclairage est

installé avec du fer

rouge, utilisez un

connecteur à coulisse

pour procéder à

l’alignement.

BP-S068

Si l’appareil

d’éclairage est

au bout d’une

rangée, utilisez

la grande plaque

d’extrémité pour

couvrir l’extrémité du

luminaire

HW-F041

Installez les clips

d’alignement pour

joindre le réecteur

suivant si nécessaire.

AVERTISSEMENT

L’appareil tombera au sol s’il est mal installé

• Suivez les instructions d’installation

1. Pièces incluses :

Câble d’aviation de 15 pieds

(4,5 mètres) avec boucle

2. Vissez la queue du câble métallique réglable autour (ou au travers) du poteau ou

de toute autre structure à laquelle sera le luminaire sera xé. Enlez la queue de la

boucle et tirez pour bien serrer.

3. Insérez le câble métallique dans le dispositif de réglage.

Bascule Y de 15 po

(6 cm) (type 1)

(Type 1)

4. Si le luminaire est doté de xations vissées sur le bras de support , vissez les boulons

à œillet jusqu’au fond. Insérez ensuite l’extrémité du dispositif de suspension dans

l’œillet. Si le luminaire n’a pas de xation vissée, insérez les crochets du dispositif

de suspension dans les fentes de montage du luminaire. Tirez la plaque de bascule

vers l’arrière depuis la butée d’extrémité et alignez-la sur le long du câble métallique.

Poussez la plaque de butée dans le trou. Lorsque la plaque de bascule est passée

dans le trou, tirez le câble vers l’arrière ou laissez simplement le poids de l’objet se

stabiliser sur la bascule.

Bascule droite de 15 po

(6 cm) (type 2)

(Type 2)

6. Double bascule en Y : L’angle entre les pattes ne doit pas dépasser 60 degrés.

7. Mise en garde : Lorsque 2 boucles de câble d’aviation sont utilisées par luminaire, le

luminaire ne doit pas peser plus de 20 kg (44 lb).

Recommandation d’application concernant les câbles EZ Leveling

(câbles d’aviation) :

Environnement : Le dispositif de suspension avec câble d’aviation peut être utilisé

uniquement dans un endroit sec. Le dispositif de suspension en acier inoxydable peut

être utilisé dans certains environnements intérieurs corrosifs, notamment autour

d’une piscine intérieure dont l’air est susamment ventilé.

Charge : Ne dépassez pas la charge de travail autorisé du dispositif de suspension

avec câble d’aviation.

Aucun levage : N’utilisez pas ces câbles pour des opérations de levage, notamment

sur une grue ou un palan.

Aucun mouvement : Les dispositifs de suspension avec câble d’aviation doivent être

utilisés uniquement pour suspendre des charges stationnaires. Ne les utilisez pas

pour suspendre des objets mobiles ou susceptibles de bouger.

Aucun joint : Les dispositifs de suspension ne doivent pas être constitués de plusieurs

sections de câble d’aviation épissées et réunies. Un dispositif de suspension ne doit se

composer que d’une section de câble d’aviation et d’une attache spéciale. Si un câble

plus long est nécessaire, ne tentez pas de joindre deux sections bout à bout.

Restrictions d’utilisation : Tous les dispositifs de suspension avec câble d’aviation, les

accessoires et les produits connexes ne doivent être utilisés que pour suspendre des

équipements électriques et mécaniques, jamais à d’autres ns.

Peinture : Si de la peinture est appliquée, assurez-vous qu’un revêtement est enduit

sur le dispositif de suspension avant de peindre. Après l’application de la peinture, le

dispositif de suspension ne doit plus être déplacé sur le câble.

Codes de construction – L’acheteur et/ou l’installateur sont responsables du respect

des normes de construction nationales et locales.

Lubriants : Il ne faut jamais appliquer d’hui ni d’autre lubriant sur aucune partie de

l’assemblage.

Conduits/tuyaux ronds : Si un dispositif est installé autour d’un conduit ou tuyau rond,

il ne faut jamais dépasser un angle de 60 degrés entre le haut du tuyau et le dispositif

de suspension.

Réutilisation interdite : Les dispositifs de suspension avec câble d’aviation sont conçus

pour une installation permanente et ne doivent pas être réutilisés.

Angle d’installation des Y : les bras des dispositifs de suspension en Y ne doivent pas

être installés avec un angle supérieur à 60 degrés.

Le non-respect de ces instructions d’utilisation peut causer un mauvais fonctionnement

du produit, ainsi que des dommages matériels et des blessures.

g

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

1 6 9 4 3 5 3 3- - -- 8 8 8

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

35-201578-175 (1/10)

Loading...

Loading...