Page 1

Technical

Publication

Part Number FC091194

Revision 02

GE Medical Systems

GE Medical Systems

Vivid 7 / Vivid 7 PRO Service Manual

Copyright© 2002 General Electric Co.

All rights reserved

Page 2

Page 3

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

IMPORTANT PRECAUTIONS

LANGUAGE

• THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

• IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A

LANGUAGE OTHER THAN ENGLISH, IT IS THE CUSTOMER’S

RESPONSIBILITY TO PROVIDE TRANSLATION SERVICES.

WARNING

AVERTISSEMENT

• DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS

SERVICE MANUAL HAS BEEN CONSULTED AND IS

UNDERSTOOD.

• FAILURE TO HEED THIS WARNING MAY RESULT IN INJURY TO

THE SERVICE PROVIDER, OPERATOR OR PATIENT FROM

ELECTRIC SHOCK, MECHANICAL OR OTHER HAZARDS.

• CE MANUEL DE MAINTENANCE N’EST DISPONIBLE QU’EN

ANGLAIS.

• SI LE TECHNICIEN DU CLIENT A BESOIN DE CE MANUEL DANS

UNE AUTRE LANGUE QUE L’ANGLAIS, C’EST AU CLIENT QU’IL

INCOMBE DE LE FAIRE TRADUIRE.

• NE PAS TENTER D’INTERVENTION SUR LES ÉQUIPEMENTS

TANT QUE LE MANUEL SERVICE N’A PAS ÉTÉ CONSULTÉ ET

COMPRIS.

• LE NON-RESPECT DE CET AVERTISSEMENT PEUT ENTRAÎNER

CHEZ LE TECHNICIEN, L’OPÉRATEUR OU LE PATIENT DES

BLESSURES DUES À DES DANGERS ÉLECTRIQUES,

MÉCANIQUES OU AUTRES.

WARNUNG

• DIESES KUNDENDIENST-HANDBUCH EXISTIERT NUR IN

ENGLISCHER SPRACHE.

• FALLS EIN FREMDER KUNDENDIENST EINE ANDERE SPRACHE

BENÖTIGT, IST ES AUFGABE DES KUNDEN FÜR EINE

ENTSPRECHENDE ÜBERSETZUNG ZU SORGEN.

• VERSUCHEN SIE NICHT, DAS GERÄT ZU REPARIEREN, BEVOR

DIESES KUNDENDIENST-HANDBUCH NICHT ZU RATE

GEZOGEN UND VERSTANDEN WURDE.

• WIRD DIESE WARNUNG NICHT BEACHTET, SO KANN ES ZU

VERLETZUNGEN DES KUNDENDIENSTTECHNIKERS, DES

BEDIENERS ODER DES PATIENTEN DURCH ELEKTRISCHE

SCHLÄGE, MECHANISCHE ODER SONSTIGE GEFAHREN

KOMMEN.

- iii

Page 4

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

• ESTE MANUAL DE SERVICIO SÓLO EXISTE EN INGLÉS.

• SI ALGÚN PROVEEDOR DE SERVICIOS AJENO A GEMS

SOLICITA UN IDIOMA QUE NO SEA EL INGLÉS, ES

RESPONSABILIDAD DEL CLIENTE OFRECER UN SERVICIO DE

TRADUCCIÓN.

AVISO

• NO SE DEBERÁ DAR SERVICIO TÉCNICO AL EQUIPO, SIN

HABER CONSULTADO Y COMPRENDIDO ESTE MANUAL DE

SERVICIO.

• LA NO OBSERVANCIA DEL PRESENTE AVISO PUEDE DAR

LUGAR A QUE EL PROVEEDOR DE SERVICIOS, EL OPERADOR

O EL PACIENTE SUFRAN LESIONES PROVOCADAS POR

CAUSAS ELÉCTRICAS, MECÁNICAS O DE OTRA NATURALEZA.

• ESTE MANUAL DE ASSISTÊNCIA TÉCNICA SÓ SE ENCONTRA

DISPONÍVEL EM INGLÊS.

• SE QUALQUER OUTRO SERVIÇO DE ASSISTÊNCIA TÉCNICA,

QUE NÃO A GEMS, SOLICITAR ESTES MANUAIS NOUTRO

IDIOMA, É DA RESPONSABILIDADE DO CLIENTE FORNECER

ATENÇÃO

OS SERVIÇOS DE TRADUÇÃO.

• NÃO TENTE REPARAR O EQUIPAMENTO SEM TER

CONSULTADO E COMPREENDIDO ESTE MANUAL DE

ASSISTÊNCIA TÉCNICA.

• O NÃO CUMPRIMENTO DESTE AVISO PODE POR EM PERIGO A

SEGURANÇA DO TÉCNICO, OPERADOR OU PACIENTE DEVIDO

A‘ CHOQUES ELÉTRICOS, MECÂNICOS OU OUTROS.

• IL PRESENTE MANUALE DI MANUTENZIONE È DISPONIBILE

SOLTANTO IN INGLESE.

• SE UN ADDETTO ALLA MANUTENZIONE ESTERNO ALLA GEMS

RICHIEDE IL MANUALE IN UNA LINGUA DIVERSA, IL CLIENTE È

TENUTO A PROVVEDERE DIRETTAMENTE ALLA TRADUZIONE.

• SI PROCEDA ALLA MANUTENZIONE DELL’APPARECCHIATURA

AVVERTENZA

SOLO DOPO AVER CONSULTATO IL PRESENTE MANUALE ED

AVERNE COMPRESO IL CONTENUTO.

• NON TENERE CONTO DELLA PRESENTE AVVERTENZA

POTREBBE FAR COMPIERE OPERAZIONI DA CUI DERIVINO

LESIONI ALL’ADDETTO ALLA MANUTENZIONE,

ALL’UTILIZZATORE ED AL PAZIENTE PER FOLGORAZIONE

ELETTRICA, PER URTI MECCANICI OD ALTRI RISCHI.

iv -

Page 5

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

DAMAGE IN TRANSPORTATION

(For USA Only)

All packages should be closely examined at time of delivery. If damage is apparent

write “Damage In Shipment” on ALL copies of the freight or express bill BEFORE

delivery is accepted or “signed for” by a GE representative or hospital receiving

agent. Whether noted or concealed, damage MUST be reported to the carrier

immediately upon discovery, or in any event, within 14 days after receipt, and the

contents and containers held for inspection by the carrier. A transportation

company will not pay a claim for damage if an inspection is not requested within

this 14 day period.

For USA Only:

Call Traffic and Transportation, Milwaukee, WI (262) 785-5052 or 8*323 5052

immediately after damage is found. At this time be ready to supply name of carrier,

delivery date, consignee name, freight or express bill number, item damaged and

extent of damage.

For USA Only:

Complete instructions regarding claim procedure are found in Section S of the

Policy And Procedures Bulletins.

14 July 1993

- v

Page 6

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CERTIFIED ELECTRICAL CONTRACTOR STATEMENT

(For USA Only)

All electrical Installations that are preliminary to positioning of the equipment at the

site prepared for the equipment shall be performed by licensed electrical

contractors. Other connections between pieces of electrical equipment,

calibrations and testing shall be performed by qualified GE Medical personnel. In

performing all electrical work on these products, GE will use its own specially

trained field engineers. All of GE’s electrical work on these products will comply

with the requirements of the applicable electrical codes.

The purchaser of GE equipment shall only utilize qualified personnel (i.e., GE’s

field engineers, personnel of third-party service companies with equivalent training,

or licensed electricians) to perform electrical servicing on the equipment.

OMISSIONS & ERRORS

If there are any omissions, errors or suggestions for improving this documentation,

please contact the GE Medical Systems Global Documentation Group with specific

information listing the system type, manual title, part number, revision number,

page number and suggestion details. E-mail the information to :

UltrasoundDocError@med.ge.com

GE Medical Systems employees should use the Customer Quality Assurance

(CQA) System to report all documentation omissions, errors or suggestions.

vi -

Page 7

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

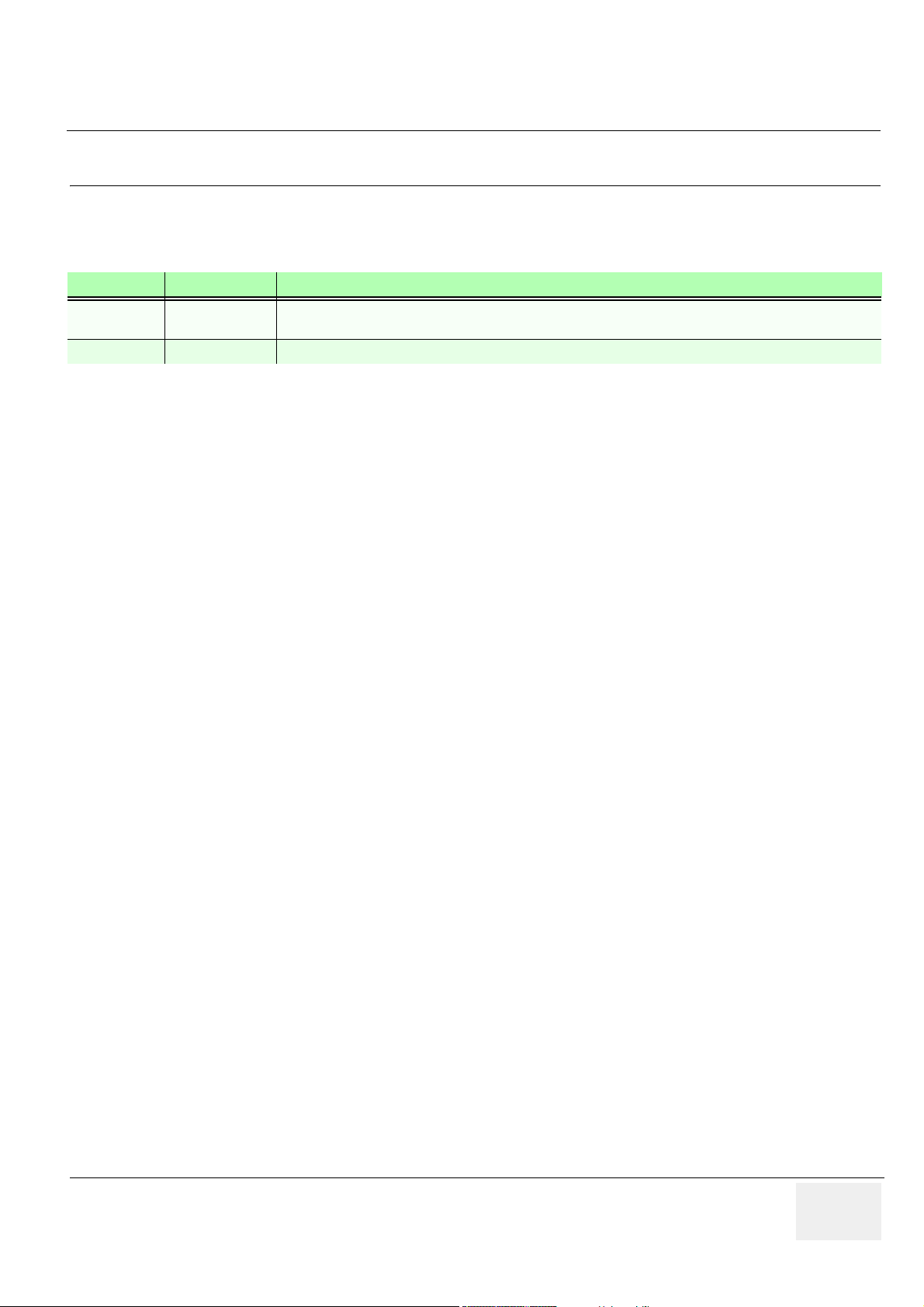

Revision History

REVISION DATE REASON FOR CHANGE

01

02

11. JUN. 2002

30. AUG. 2002 Updated per BT02-M4 release. Included description for BEP-2.

Covers both Vivid 7 and Vivid 7 PRO

Replaces Vivid 7 Service Manual, Part Number FB091202

- vii

Page 8

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

List of Effected Pages

Pages Revision Pages Revision Pages Revision

Title Page 02 4-1 to 4-66 02 9-1 to 9-37 02

Warnings

iii to vi

Rev History/LOEP

vii to viii

1-1 to 1-40 02 7-1 to 7-70 02

2-1 to 2-12 02 8-1 to 8-56 02

3-1 to 3-58 02

02 5-1 to 5-104 02 10-1 to 10-26 02

02 6-1 to 6-8 02 Back Cover N/A

viii -

Page 9

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Table of Contents

CHAPTER 1

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Purpose of Chapter 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Purpose of Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Typical Users of the Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Vivid 7 / Vivid 7 PRO Models Covered by this Manual . . . . . . . . . . . . . . . . 1 - 2

Purpose of Operator Manual(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Important Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Conventions Used in Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Standard Hazard Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Product Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

Human Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 12

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

Labels Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14

Dangerous Procedure Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 36

Lockout/Tagout Requirements (For USA Only) . . . . . . . . . . . . . . . . . . . . . . 1 - 36

EMC, EMI, and ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 37

Electromagnetic Compatibility (EMC) and Interference (EMI) . . . . . . . . . . . 1 - 37

CE Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 37

Electrostatic Discharge (ESD) Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 37

Customer Assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 38

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 38

System Manufacture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 39

Table of Contents ix

Page 10

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 2

Pre-Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Purpose of Chapter 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

General Console Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Console Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

EMI Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Probes Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Time and Manpower Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Facility Needs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Purchaser Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Required Facility Needs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

Desirable Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Minimal Floor Plan Suggestion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Networking Pre-installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

x Table of Contents

Page 11

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 3

Installation

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Purpose of Chapter 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Installation Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Average Installation Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Installation Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Receiving and Unpacking the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Receiving Vivid 7 / Vivid 7 PRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Unpacking Vivid 7 / Vivid 7 PRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Transportation Box Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Preparing for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

EMI Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Connect Footswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Connect Telephone Line to Modem Connector . . . . . . . . . . . . . . . . . . . . . 3 - 10

Connect ECG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Connect Phono . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Connect Pulse Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Connect Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Probe Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Power ON/Boot Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

Power Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 17

Switching OFF the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 17

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 21

Vivid 7 / Vivid 7 PRO Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Service Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 28

Optional Peripherals/Peripheral Connection . . . . . . . . . . . . . . . . . . . . . . . . 3 - 32

Available Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 32

Video Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 32

Table of Contents xi

Page 12

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Software Options Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 33

Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 35

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 35

Physical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 35

Connectivity Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 37

Installation Paperwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 56

User Manual(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 56

Complete the Post Delivery Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 56

Post Delivery Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 57

xii Table of Contents

Page 13

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 4

Functional Checks

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Purpose of Chapter 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Special Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

General Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Power ON/ Boot Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Power Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Using Removable Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Labeling Removable Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

Formatting Removable Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Verifying Removable Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Archiving and Loading Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 12

Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Basic Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 16

2D Mode (B mode) Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 17

M Mode Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 24

Color Mode Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 28

Doppler Mode Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 34

Tissue Velocity Imaging (TVI) Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 40

Contrast Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 46

Stress Echo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 46

Measurements and Multi Image Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 47

Multi Image Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 49

Probe/Connectors Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 50

ECG Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 51

Cineloop Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 52

Backend Processor Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 56

Peripheral Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 57

Mechanical Functions Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 61

Application Turnover Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 63

Software Configuration Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 63

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 64

Power Supply Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 64

Power Supply Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 64

Table of Contents xiii

Page 14

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Site Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 65

xiv Table of Contents

Page 15

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 5

Components and Functions (Theory)

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Purpose of Chapter 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Front End Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Front End Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Phased and Linear Array Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Transmitter Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Mid Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Major Sub-Systems in Vivid 7 / Vivid 7 PRO . . . . . . . . . . . . . . . . . . . . . . . 5 - 11

Front End Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 12

Mid Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 13

Back End Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

Signal Flow and Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

Location of the Back End Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

BEP-1 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 15

BEP-1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 16

BEP-2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 17

BEP-2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 18

PCVIC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 19

UPS Battery Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 19

Internal Storage Devices: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 20

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 20

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 22

Patient I/O (Physio) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 23

Internal I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 24

Location in the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 26

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 26

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 26

Jumpers and Dip-switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 26

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 27

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 29

Table of Contents xv

Page 16

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Top Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 31

Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 32

On-board Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 32

External Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 32

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 33

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 34

Overall AC Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 34

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

AC Power Distribution Box (PWB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

DC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 37

TX Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 41

Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 44

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 44

Relay Board, RLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 45

Transmitter Board, TX128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 47

Receiver Board, RX-128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 50

Beamformer Board(s), BF-64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 53

Front End Controller Board, FEC-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 56

Transducer Bus Boards, XD BUS Boards . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 61

RF & Tissue Processor Board, RFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 62

Spectrum Doppler Processor Board, SDP . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 66

Image Port 2 Board, IMP2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 70

Backend Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 74

Patient I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 78

Internal I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 79

External I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 87

Interconnect Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 90

Motherboard (Back Plane) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 92

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 93

Video Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 95

PAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 95

NTSC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 95

System Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 95

Board Rack Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 96

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 96

Location in the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 96

xvi Table of Contents

Page 17

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Top Console Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 97

General Description Vivid 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 97

Transportation of Vivid 7 / Vivid 7 PRO . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 97

Location in the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 98

General Description Vivid 7 PRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 100

Location in the Unit Vivid 7 PRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 100

Common Service Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 101

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 101

iLinq Interactive Platform Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 101

Global Service User Interface (GSUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 102

Table of Contents xvii

Page 18

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 6

Service Adjustments

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Purpose of Chapter 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Power Supply Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Monitor Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Cautions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Access to Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Adjustment Procedure(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Front End Alignment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

When to do a Front End Alignment Procedure . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Direction Lock and Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Front Caster Brakes Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Direction Lock Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Rear Brakes Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

xviii Table of Contents

Page 19

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 7

Diagnostics/Troubleshooting

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Purpose of Chapter 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Service Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Special Service Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Diagnostic Procedure Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Common Service Diagnostic Interface (Ultrasound Interface) . . . . . . . . . . 7 - 4

Service Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 5

Description of Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 6

Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 7

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 17

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 23

Image Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 28

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 29

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 31

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 32

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 42

PM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 43

Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 43

Exit From Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 43

Common Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 44

Common Diagnostics - Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 45

PC (Backend Processor) Diagnostics, Non-Interactive Tests . . . . . . . . . . 7 - 47

PC (Backend Processor) Diagnostics, Interactive Tests . . . . . . . . . . . . . . 7 - 53

Acquisition Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 59

System Test Diagnostics Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 59

Start System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 59

Beamformer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 60

System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 61

Beamformer Calibration (Front End Alignment) . . . . . . . . . . . . . . . . . . . . . 7 - 65

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 67

Console Troubleshooting Trees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 67

Table of Contents xix

Page 20

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 8

Replacement Procedures

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Purpose of Chapter 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Plastic Parts Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Overview of Covers and Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Side Covers Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 3

Front Cover Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 5

Filter Cover Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 6

Filter Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 7

Lower Rear Cover Replacements Procedure . . . . . . . . . . . . . . . . . . . . . . . 8 - 8

SW Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Customer Provided Prerequisite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Tools Provided With Unit or After a Software Upgrade . . . . . . . . . . . . . . . . 8 - 10

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 11

Prepare MO Disks for Image Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 12

Move Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 13

Prepare MO Disk for Patient Archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 15

Backup of Patient Database and User Presets . . . . . . . . . . . . . . . . . . . . . . 8 - 16

Recording of SW Option Keys, TCP/IP and Service Settings . . . . . . . . . . . 8 - 18

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 24

FRU Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

AC Transformer Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 31

AC Power Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 34

DC Power Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 36

TX Power Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 38

Rear Casters Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 40

Front Casters Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 45

Front Bumper Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 50

Brake Pedal Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 51

Direction Lock Pedal Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . 8 - 52

Brake Pedal and Direction Lock Assembly Replacement Procedures . . . . . 8 - 53

Power Supply Battery Pack Replacement Procedure . . . . . . . . . . . . . . . . . 8 - 54

xx Table of Contents

Page 21

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 9

Renewal Parts

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Purpose of Chapter 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

List of Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

Parts List Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Plastic Parts, Console, Top and Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 4

Plastic Parts, Airduct Cover and Cover Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 5

Plastic Parts, Covers and Bumpers, Left, Right and Rear . . . . . . . . . . . . . . . . . . . 9 - 6

Control Panel Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 7

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 8

Input /Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 9

PCB Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 10

Mechanical Parts, Rack, Casters and Frogleg . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 12

Brake Assembly and Console Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 13

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 14

Electrical Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 23

Backend Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 24

Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 25

Printers On Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 25

Network Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 25

Video Cassette Recorder (VCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 25

Footswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 26

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 27

Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 28

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 29

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 30

Table of Contents xxi

Page 22

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 31

Parts Lists for Bumper Kit, Frogleg (Vivid 7 ONLY) . . . . . . . . . . . . . . . . . . . 9 - 32

Parts Lists for Column Cover Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 33

Accessory Box, Vivid 7 / Vivid 7 PRO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 34

Accessory Box, SERVICE V7, US. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 36

Packing Parts for Reshipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 37

xxii Table of Contents

Page 23

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

CHAPTER 10

Periodic Maintenance

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Purpose of Chapter 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Why do Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Keeping Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Quality Assurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Periodic Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

How often should PMs be performed? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

Special Tools, Supplies and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 4

System Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 5

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 5

Functional Checks (See Also Chapter 4) . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 7

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 7

Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

Optional Diagnostic Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

Probe Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

Using a Phantom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

Safety Test Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

GEMS Leakage Current Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 11

Outlet Test - Wiring Arrangement - USA & Canada . . . . . . . . . . . . . . . . . . 10 - 12

Grounding Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 12

Chassis Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 14

Isolated Patient Lead (Source) Leakage–Lead to Ground . . . . . . . . . . . . . 10 - 16

Isolated Patient Lead (Source) Leakage–Lead to Lead . . . . . . . . . . . . . . . 10 - 17

Isolated Patient Lead (Sink) Leakage-Isolation Test . . . . . . . . . . . . . . . . . 10 - 18

Probe Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 20

When There's Too Much Leakage Current... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 23

IndeX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index - 1

Table of Contents xxiii

Page 24

GE MEDICAL SYSTEMS

D

IRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

This page was intentionally left blank.

xxiv Table of Contents

Page 25

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Chapter 1

Introduction

Section 1-1

Overview

1-1-1 Purpose of Chapter 1

This chapter describes important issues related to safely servicing this ultrasound machine. The service

provider must read and understand all the information presented here before installing or servicing a

unit.

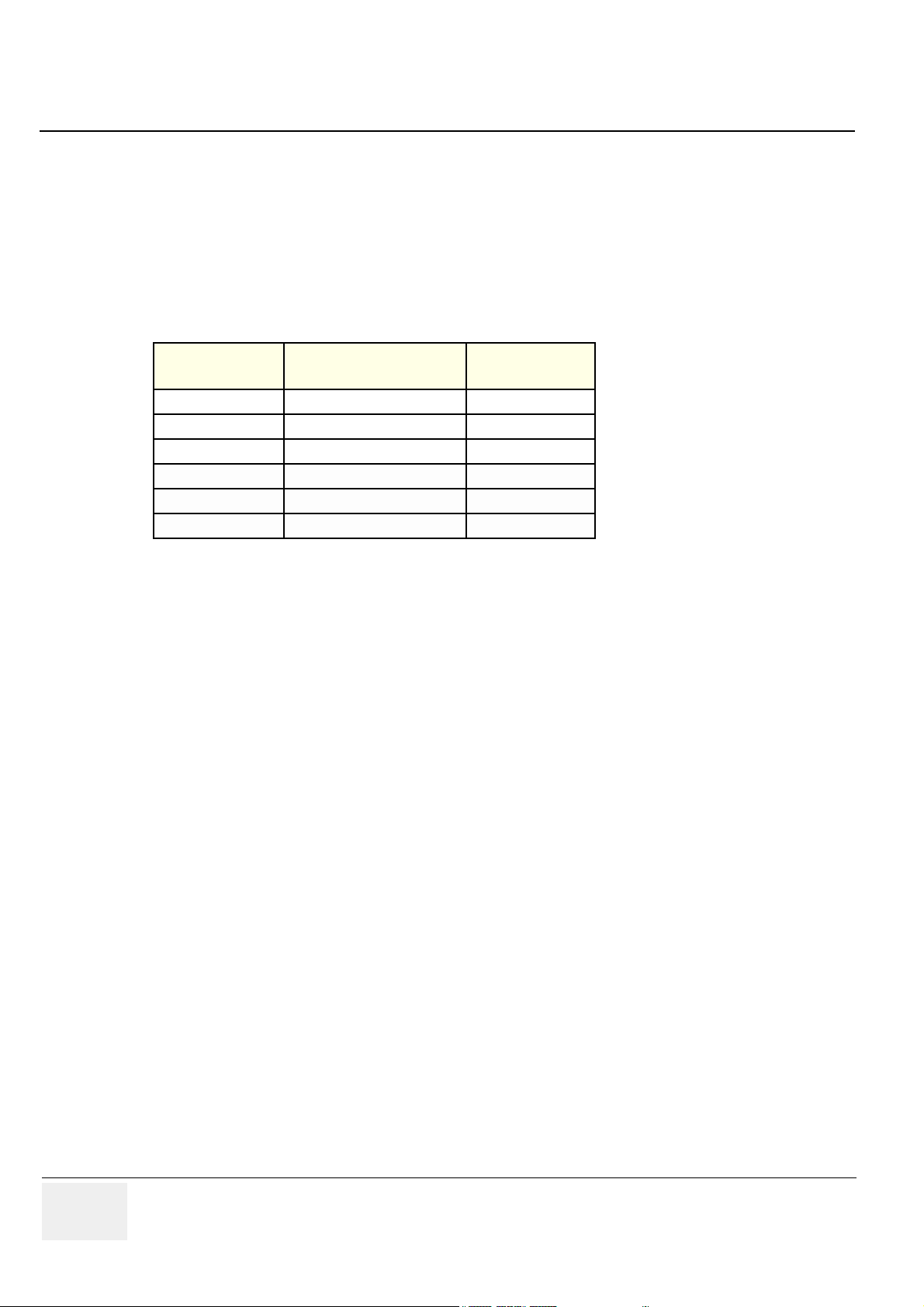

Table 1-1 Contents in Chapter 1

Section Description Page Number

1-1 Overview 1-1

1-2 Important Conventions 1-8

1-3 Safety Considerations 1-12

1-4 EMC, EMI, and ESD 1-37

1-5 Customer Assistance 1-38

1-1-2 Purpose of Service Manual

This Service Manual provides installation and service information for the Vivid 7 / Vivid 7 PRO

Ultrasound Scanning unit and contains the following chapters:

1.) Chapter 1 - Introduction: Contains a content summary and warnings.

2.) Chapter 2 - Pre-Installation: Contains any pre-installation requirements for the Vivid 7 / Vivid

7 PRO.

3.) Chapter 3 - Installation: Contains installation procedure with installation checklist.

4.) Chapter 4 - Functional Checks: Contains functional checks that must be performed as part

of the installation, or as required during servicing and periodic maintenance.

5.) Chapter 5 - Components and Functions (Theory): Contains block diagrams and functional

explanations of the electronics.

6.) Chapter 6 - Service Adjustments: Contains instructions on how to make any available

adjustments to the Vivid 7 / Vivid 7 PRO.

7.) Chapter 7 - Diagnostics/Troubleshooting: Provides procedures for running and diagnostic

or related routines for the Vivid 7 / Vivid 7 PRO.

8.) Chapter 8 - Replacement Procedures: Provides disassembly procedures and reassembly

procedures for all changeable FRU.

9.) Chapter 9 - Renewal Parts: Contains a complete list of replacement parts for Vivid 7 / Vivid 7

PRO.

10.)Chapter 10 - Periodic Maintenance: Provides periodic maintenance procedures for Vivid 7 /

Vivid 7 PRO.

Chapter 1 - Introduction 1 - 1

Page 26

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-1-3 Typical Users of the Service Manual

• Service Personnel (installation, maintenance, etc.).

• Hospital’s Service Personnel

• Architectural Planners/Installation Planners (some parts of Chapter 2, Pre-Installation)

1-1-4 Vivid 7 / Vivid 7 PRO Models Covered by this Manual

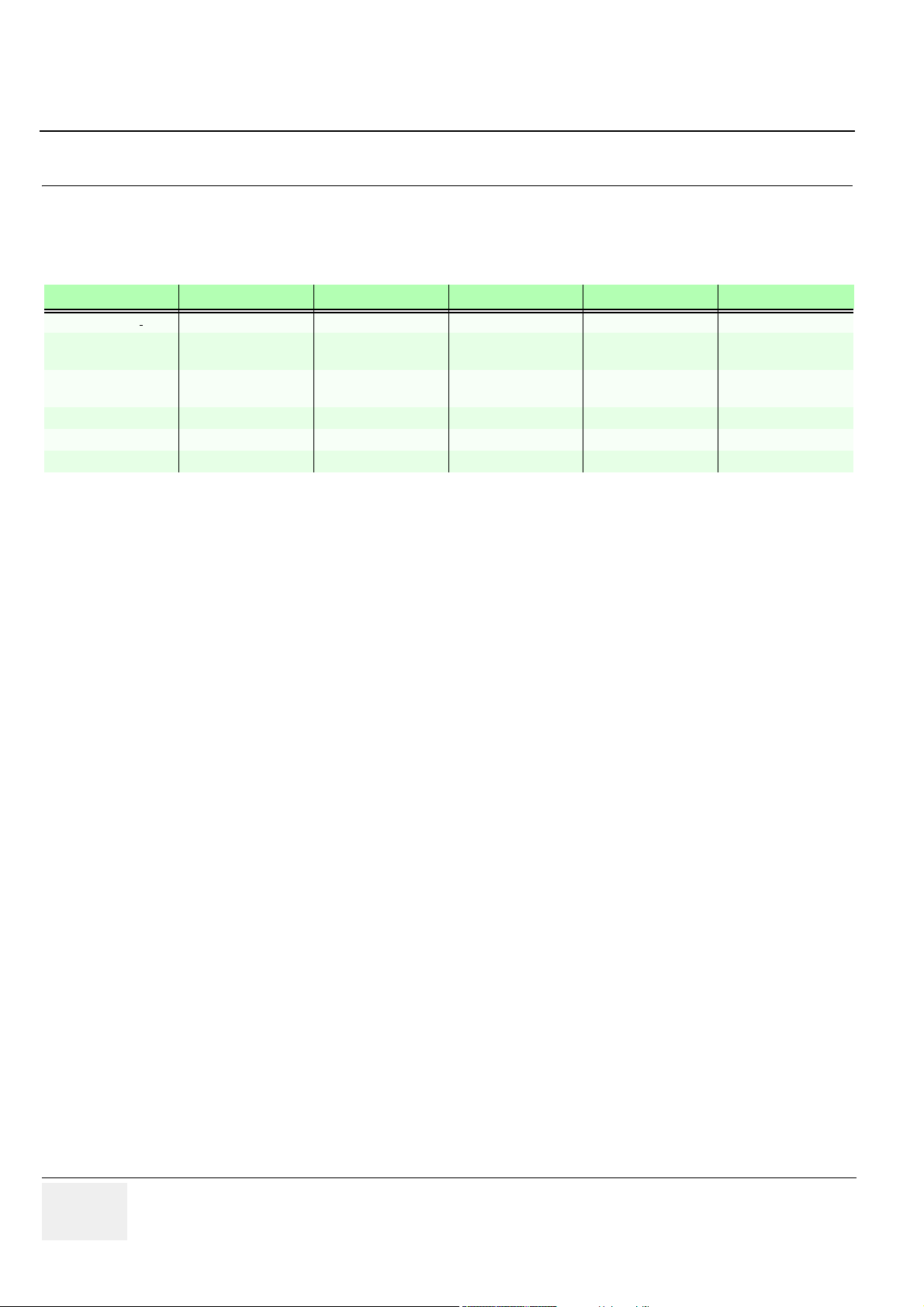

Table 1-2 Vivid 7 / Vivid 7 PRO Models Covered in this Manual

GE VINGMED

PART NUMBER

FB000030 VIVID 7 (BT ’01) 230 VAC

FC000060 VIVID 7 (BT ’01) 100 - 120 VAC

FC000180 VIVID 7 PRO (BT ’02) 220 - 240 VAC

FC000190 VIVID 7 PRO (BT ’02) 100 - 120 VAC

FC000200 VIVID 7 (BT ’02) 220 - 240 VAC

FC000210 VIVID 7 (BT ’02) 100 - 120 VAC

DESCRIPTION VOLTAGE

1-1-4-1 Overview

• Vivid 7 / Vivid 7 PRO is a phased and linear array ultrasound imaging scanner. It also has provisions

for analog input sources like ECG and phono, and a Doppler probe may be connected and used too.

• The unit can be used for:

- 2D Black and White imaging

-2D Color Flow

- M-Mode Black and White imaging

- Color M-Mode

- Doppler

- a number of combinations of the above

• Vivid 7 / Vivid 7 PRO is a digital beam forming unit and can handle up to 192 element linear probes

by use of multiplexing.

• Signal flow from the Probe Connector Panel to the Front End, then to the Mid Processors and

Backend Processor and finally to the monitor and peripherals.

• System configuration is stored on a hard disk and all necessary software is loaded from the hard

disk on power up.

1 - 2 -

Page 27

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

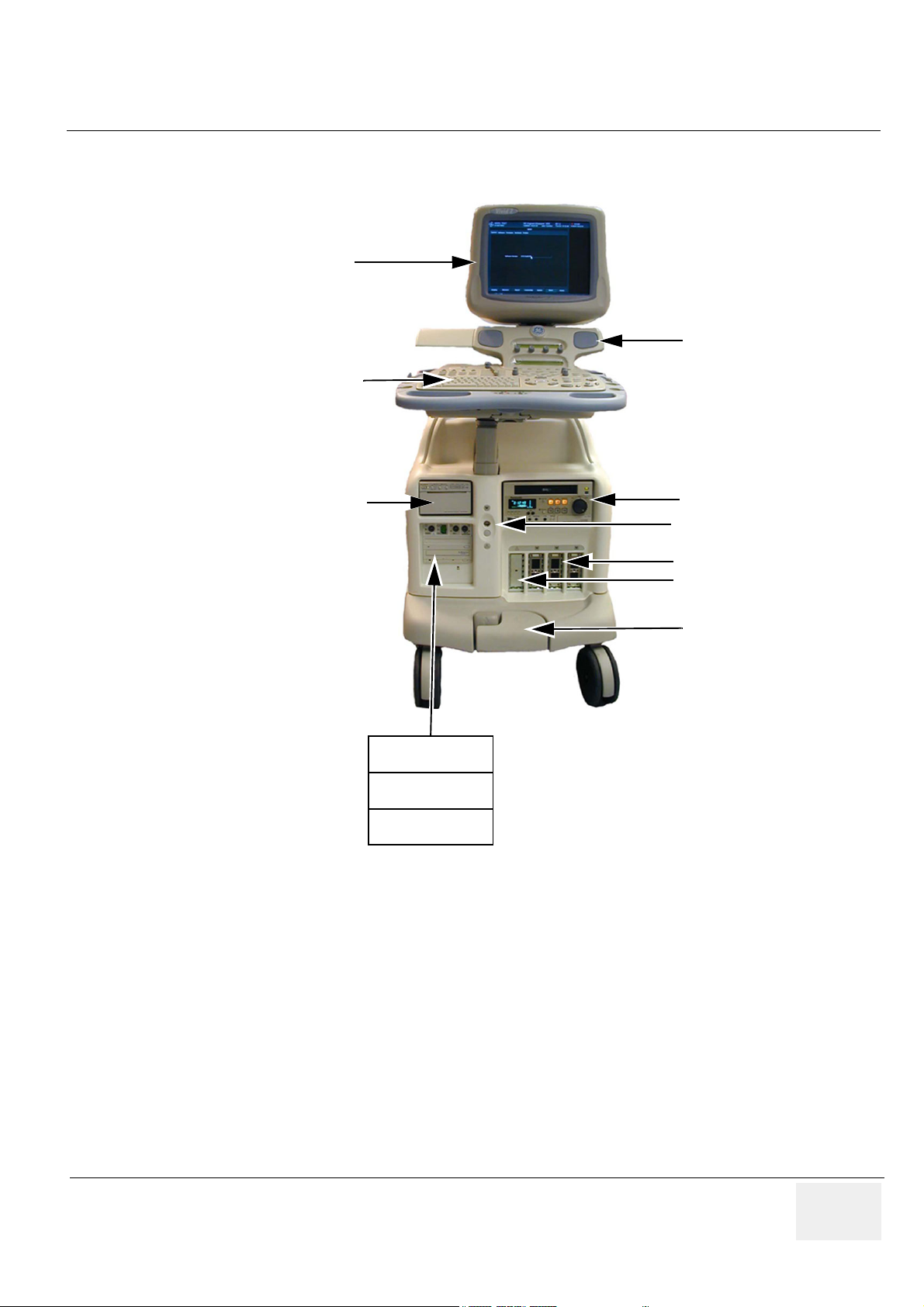

1-1-4-1 Overview (cont’d)

Monitor

Upper Panel With

Stereo Loudspeakers

Control Panel

B/w Video Printer

Figure 1-1 Vivid 7 / Vivid 7 PRO Major Components

VCR

Doppler (PEDOF) connector

Probe Connectors

Parking Slot

Brake Pedals

Patient I/O

MO Disk

CD-R Drive

Chapter 1 - Introduction 1 - 3

Page 28

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

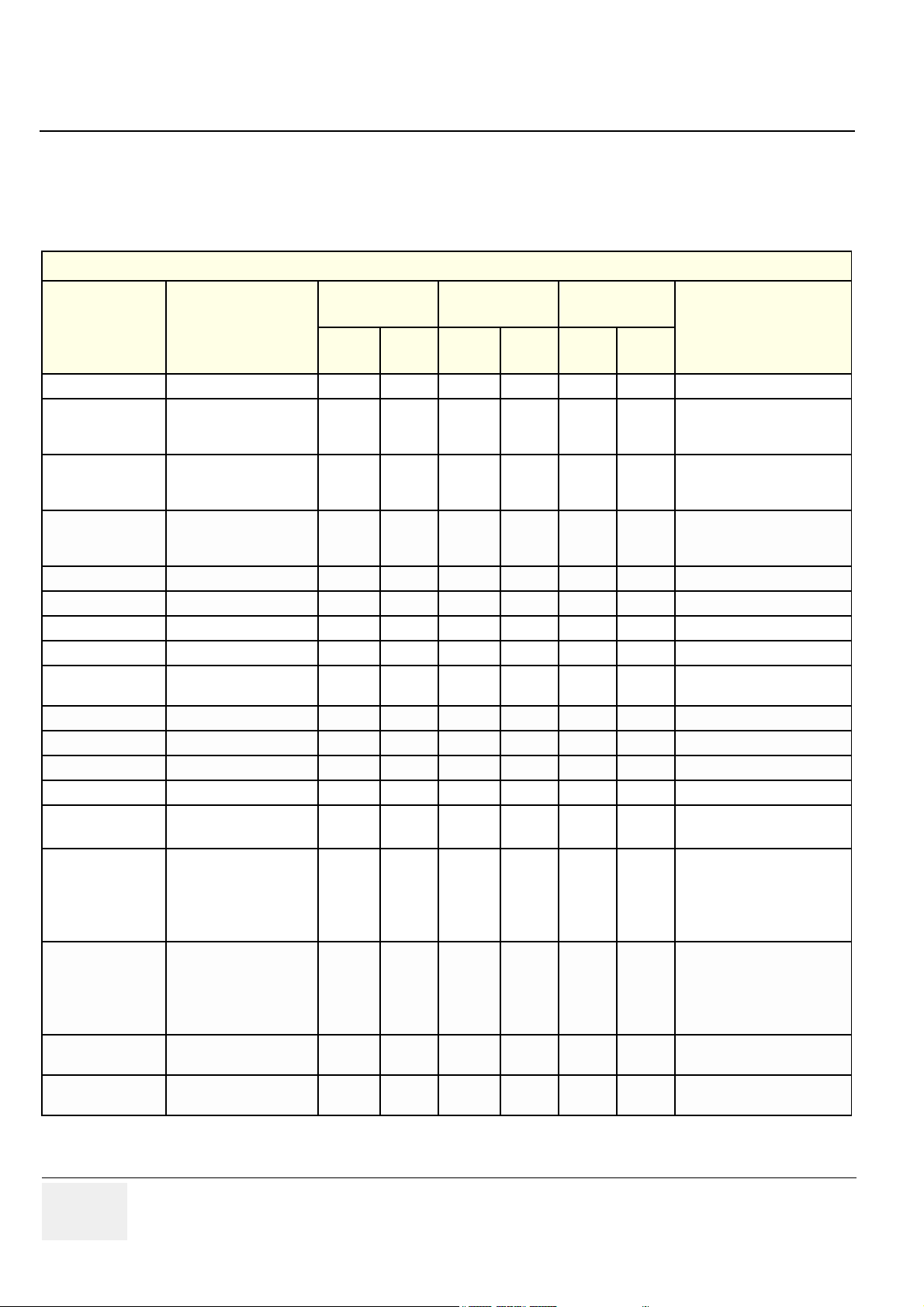

1-1-4-2 History - Hardware/Software Versions

Use Table 1-3 to verify the correct/needed revision on each card in the Card Rack.

Table 1-3 Required Revisions for Cards and Modules

Card Rack

BT’01

(sw. 1.0)

Func.

Part Number Name

FA200985 Motherboard - 02 - 02 - 02

FB200060 RLY-3 05 06 05 06 05 06

FB200170 TX128-2. A B A B A B

FC200022 TX128-3 - - - - 01 01

FB200831 RX128-3B 01 A 01 A,B 01 A,B

FB200158 XDBUS-2 - 02 - 02 - 02 2x used

FB200900 BF64 - B - C - C/D/E 2x used

FB200165 FEC-II - 03 - 03, 04 - 03, 04

FB200140 RFT1 F B,C F B,C F B, C, D

FB200865 SDP 01 02 01 02 01 02

FB200991 IMP-2B A A A A,B A A,B

FA200945 Power, DC - 02 - 02 - 02

FB200574 Power, TX (TXPS) - 03 - 03 - 03

Rev.

MCD

BT’01

(sw. 1.0 / 1.1 / 1.2)

Func.

Rev.

MCD

BT’02

(sw. 2.0 / 2.1)

Func.

Rev.

MCD

Comments

MCD rev. 07 includes a

noisefix for use of PAMPTE

probe.

For Vivid 7 produced before

June 3, 2002 and for Vivid 7

Replacement for FB200170

used on Vivid 7 produced after

June 3, 2002

Both MCD rev. B, C and D may

be used.

PRO

FB200724 AC Controller - 06 - 06/07 - 08

FC200079 AC Power 100-120V - 01 - 01 - 01

FC200081 AC Power 220-240V - 01 - 01 - 01

FB200198 External I/O Complete 08 08 08, 09, 10

FB200197

Internal I/O Board

Complete

05 06 05 06 05 06

08, 09, 1008, 09, 1008, 09,

1 - 4 -

Covers both 100-120 VAC and

220-240 VAC

AC Power supply for 100-120

VAC

Used as replacement for AC

Controller, FB200724 on 100120 VAC units

AC Power supply for 220-240

VAC

Used as replacement for AC

Controller, FB200724 on 220240 VAC units.

10

Page 29

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

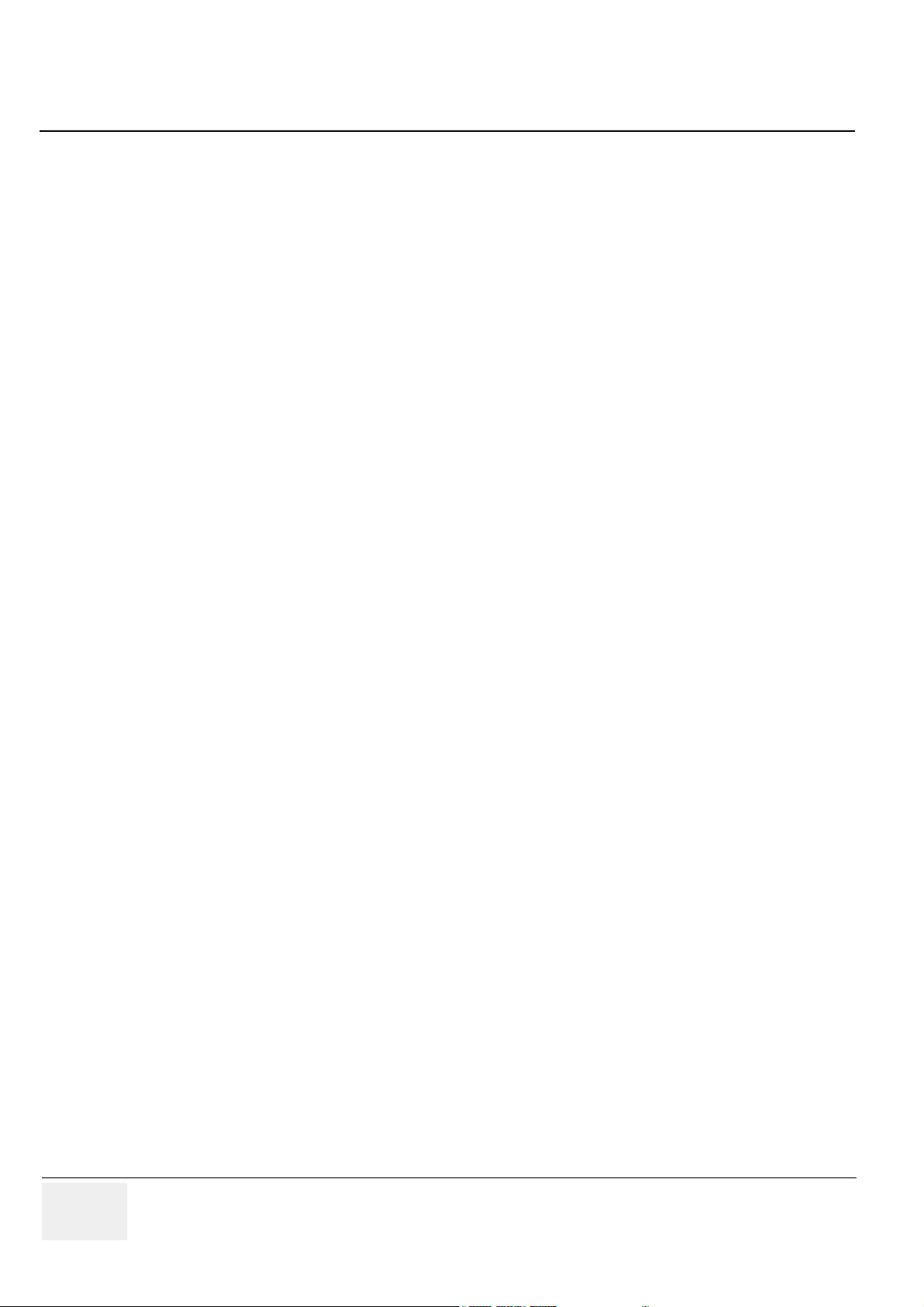

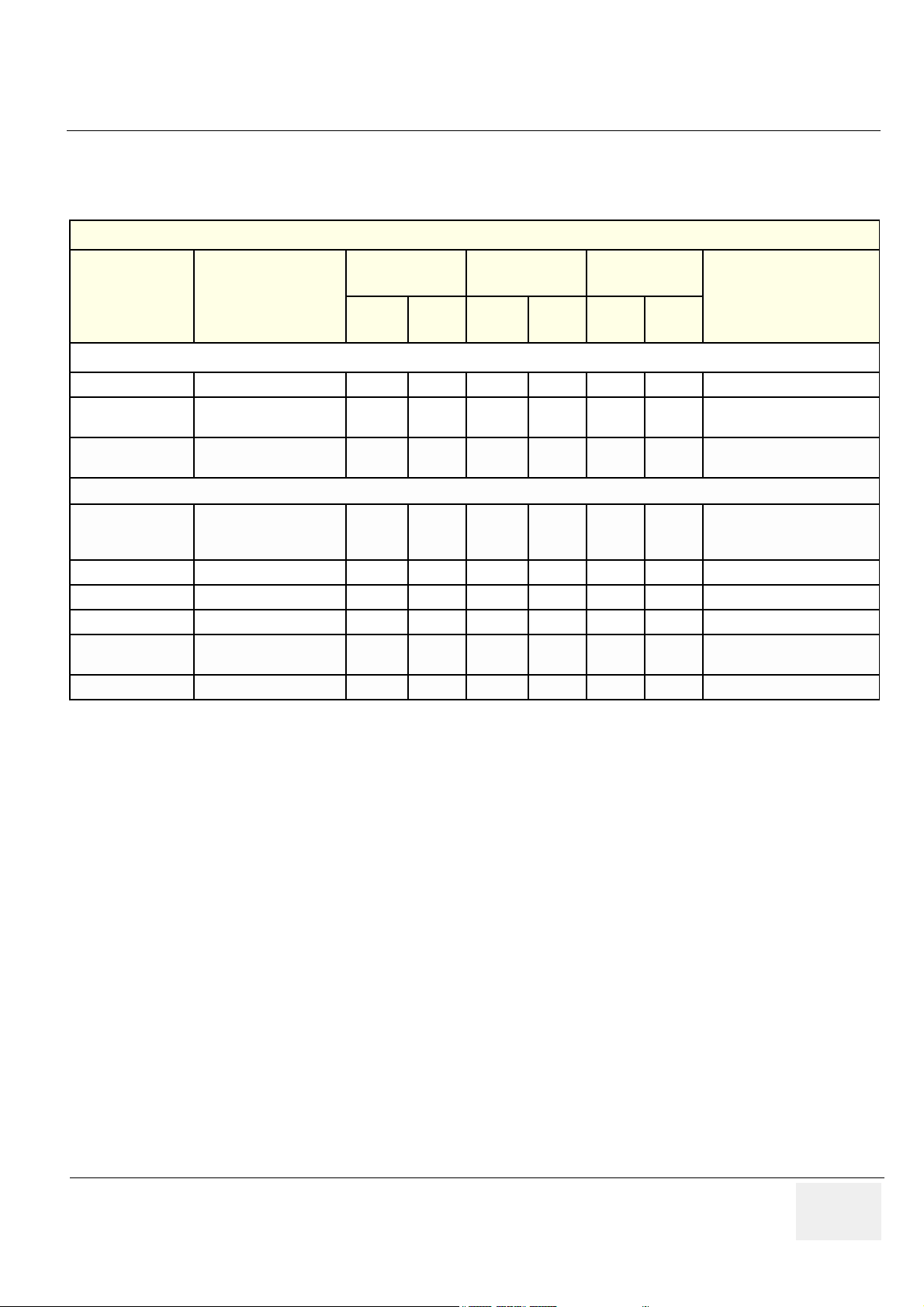

1-1-4-2 History - Hardware/Software Versions (cont’d)

Table 1-4 Required Revisions for Cards and Modules

Backend Rack

Part Number Name

BT’01

(sw. 1.0)

Func.

Rev.

MCD

BT’01

(sw. 1.0 / 1.1 / 1.2)

Func.

Rev.

MCD

BT’02

(sw. 2.0 / 2.1)

Func.

Rev.

MCD

Comments

BACKEND PROCESSOR Used in Production Before September 2002

FB200480 BACKEND PROCESSOR - 02 - 02 - 02

FA200801

2266548-5

PATIENT I/O MODULE II

(COMPL)

Battery For Backend

Processor UPS

-E-E-E

- N/A - N/A - N/A

MCD revision F, G, H or I may

also be used

BACKEND PROCESSOR - II Used in Production After September 2002

2348186

2348186-20 POWER SUPPLY - - - - - -

2348186-21 CD RW DRIVE - - - - - -

2348186-22 PATIENT IO MODULE - - - - - - Same as FA200801(?)

2348186-24

2348186-25 FAN - - - - - -

BACKEND

PROCESSOR-II

WITHOUT MO DRIVE

MOD DRIVE 9.0G

CAPACITY SCSI

- - - - - -

- - - - - -

Chapter 1 - Introduction 1 - 5

Page 30

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

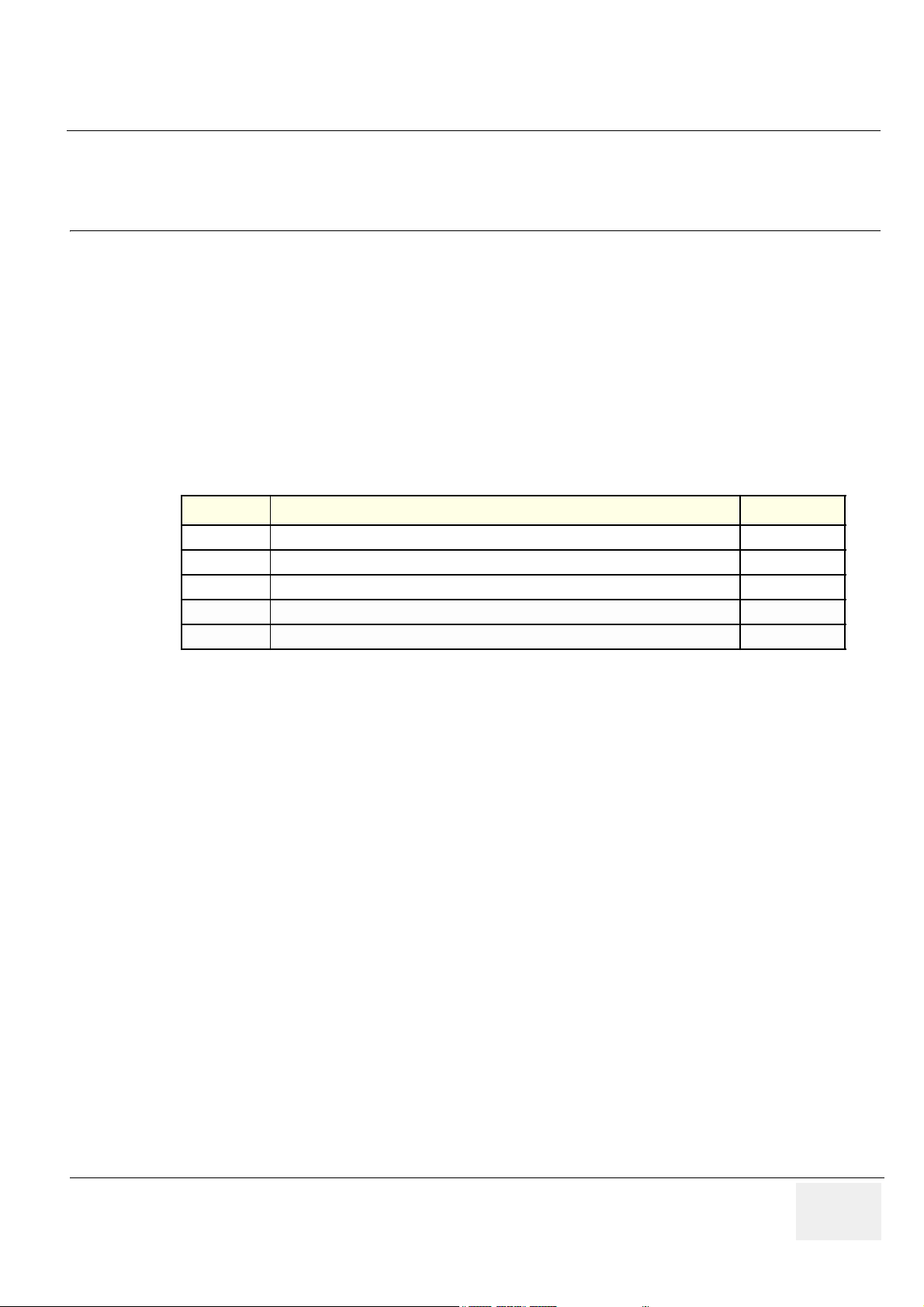

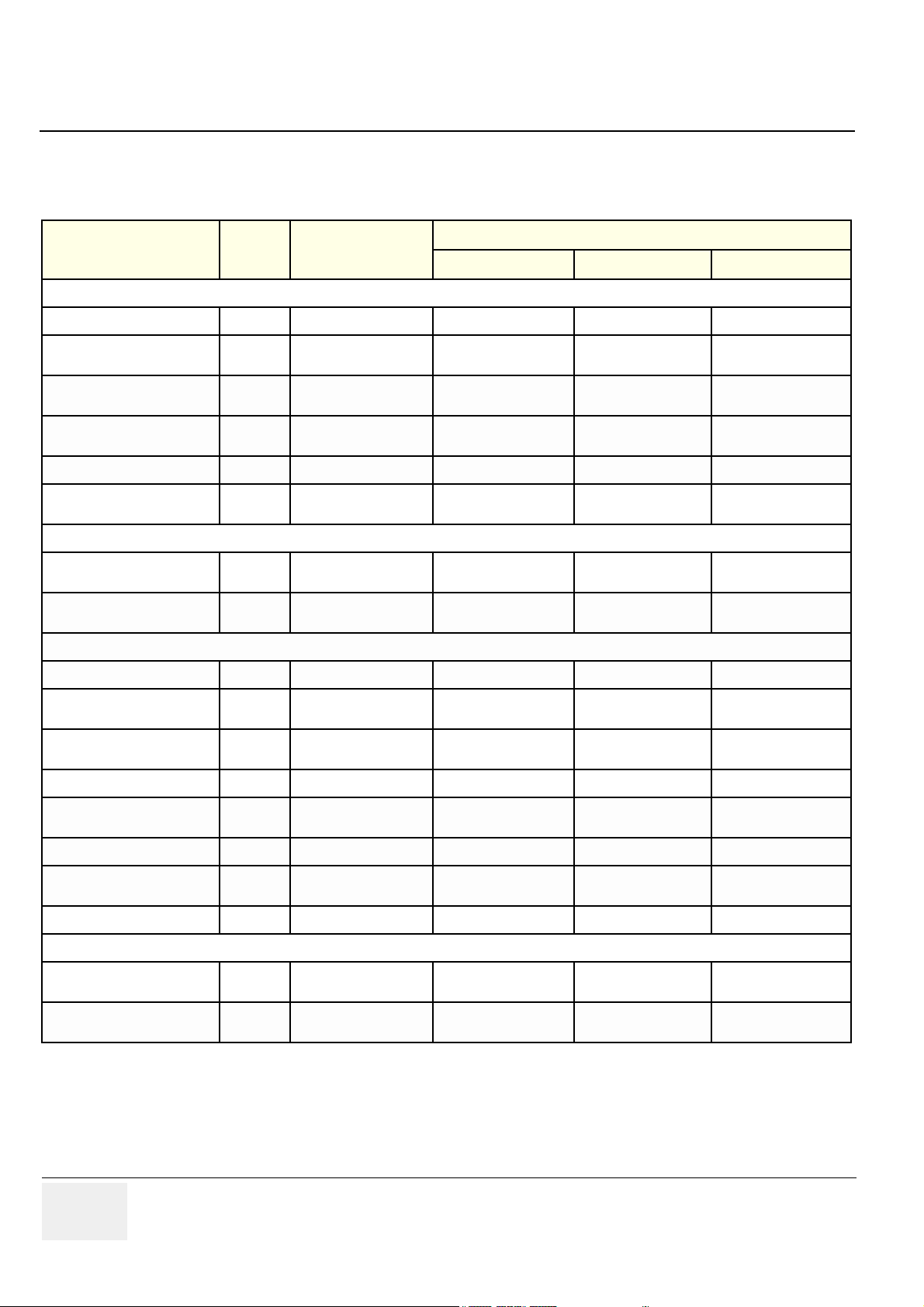

1-1-4-3 History - Supported Probes

Table 1-5 Supported Probes and SW Versions

PROBES

Sector

3S (Probe, Sector 3S)

3S, Comfort Scan Probe

M3s (Probe, AMA Sector M3s)

5S (Probe, Sector 5S)

7S (Probe, Sector 7S)

10S (Probe, Sector 10S)

PAMPTE

6T (Probe, TEE 6T)

8T (Probe, TEE 8T)

Linear & Convex & Others

7L (Probe, Linear 7L)

10L (Probe, Linear 10L)

12L (Probe, Linear 12L)

M12L

3.5 C (Probe, Convex 3C)

PART

SUPPORTED MODELS & SW VERSION

NUMBER

2252157 3S PROBE, L500 BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

2323337

2295649

2290751

2263669 7S PROBE BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

2298589

KN100022

KN100023

2294521 7L PROBE TYPE (EXP) BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

2294523

2295377

2294511 M12L MIH PROBE ----------- BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

2296158

NAME

3S COMFORTSCAN

PROBE

2295649 M3S AMA

SECT.

5S SECTOR

TRANSDUCER

10 S SECTOR

TRANSDUCER

KN100022 6T TEE

PROBE

KN100023 8T PED.TEE

PROBE

10L PROBE TYPE

(EXP)

12L PROBE TYPE

(EXP)

3.5C CONVEX

TRANSDUCER

BT-01, V7 BT-02, V7 BT-02, V7 PRO

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x -----------

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

5C (Probe, Convex 5C)

i13L

E8C

Pencil

P2D Pencil Probe

P6D Pencil Probe

2294516 5C PROBE TYPE (EXP) BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

KW100011

2294641 E8C PROBE ----------- BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

TE100024

TQ100002

KW011 I13L

INTRAOP.PROBE

TE100024 PENCIL

PROBE 2D

TQ100002 PENCIL

PROBE 6D

1 - 6 -

----------- BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

BT-01 SW ver. 1.x.x BT-02 SW VER. 2.x.x BT-02 SW VER. 2.x.x

Page 31

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-1-4-4 How to Turn the Scanner ON and OFF

Please refer to Chapter 4, section 4-2-1 - Power ON/ Boot Up, for a detailed description of how to turn

the scanner ON and to Chapter 4, section 4-2-2 - Power Shut Down for a detailed description of how to

turn the scanner OFF.

1-1-4-5 How to Check for Hardware/Software Version, Installed Options

• Please refer to "History - Hardware/Software Versions" on page 1-4 to check the hardware versions

on the boards

• Please refer to "Software Configuration Checks" on page 4-63 to check the software versions on

local software on the boards.

• Please refer to "Functional Checks" on page 4-14 to check for installed options.

1-1-5 Purpose of Operator Manual(s)

The Operator Manual(s) should be fully read and understood before operating the Vivid 7 / Vivid 7 PRO

and also kept near the unit for quick reference.

Chapter 1 - Introduction 1 - 7

Page 32

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Section 1-2

Important Conventions

1-2-1 Conventions Used in Book

1-2-1-1 Model Designations.

This manual covers the Vivid 7 / Vivid 7 PRO scanners listed in Ta b le 1 -2 .

1-2-1-2 Icons.

Pictures, or icons, are used wherever they will reinforce the printed message. The icons, labels and

conventions used on the product and in the service information are described in this chapter.

1-2-1-3 Safety Precaution Messages.

Various levels of safety precaution messages may be found on the equipment and in the service

information. The different levels of concern are identified by a flag word that precedes the precautionary

message. Known or potential hazards are labeled in one of three ways:

DANGER

Danger is used to indicate the presence of a hazard that will cause severe

personal injury or death if the instructions are ignored.

WARNINGWARNING

CAUTION

NOTICE

NOTE: Notes are used to provide important information about an item or a procedure.

Warning is used to indicate the presence of a hazard that can cause severe personal

injury and property damage if instructions are ignored.

Caution is used to indicate the presence of a hazard that will or can cause minor personal injury

and property damage if instructions are ignored. Equipment Damage Possible.

Notice is used when a hazard is present that can cause property damage but has absolutely no

personal injury risk.

Example: Disk drive will crash.

Be sure to read the notes; the information contained in a note can often save you time or effort.

1 - 8 Section 1-2 - Important Conventions

Page 33

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-2-2 Standard Hazard Icons

Important information will always be preceded by the exclamation point contained within a

triangle, as seen throughout this chapter. In addition to text, several different graphical icons (symbols)

may be used to make you aware of specific types of hazards that could possibly cause harm.

Table 1-6 Standard Hazard Icons

ELECTRICAL MECHANICAL RADIATION

LASER HEAT PINCH

LASER

LIGHT

Some others make you aware of specific procedures that should be followed.

Table 1-7 Standard Icons that indicates that a special procedure is to be used

AVOID STATIC ELECTRICITY TAG AND LOCK OUT WEAR EYE PROTECTION

TAG

&

LOCKOUT

Date

Signed

Chapter 1 - Introduction 1 - 9

Page 34

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-2-3 Product Icons

The following table describes the purpose and location of safety labels and other important information

provided on the equipment.

Table 1-8 Product Icons

LABEL/SYMBOL PURPOSE/MEANING LOCATION

Manufacturer's name and address

Identification and Rating Plate

Date of manufacture

Model and serial numbers

Electrical ratings

Rear of console near power inlet

Type/Class Label

IP Code (IPX8/IP68)

Device Listing/Certification Labels

CAUTION - This unit weighs...Special

care must be used to avoid..."

Used to indicate the degree of safety or

protection.

Indicates the degree of protection

provided by the enclosure per IEC 529.

IPX8 indicates drip proof and may be

used in an Operating Theater.

The footswitch delivered with Vivid 7 /

Vivid 7 PRO is IP68 rated.

Equipment Type BF (man in the box

symbol) IEC 878-02-03 indicates B

Type equipment having a floating

applied part.

Equipment Type CF (heart in the box

symbol) IEC 878-02-05 indicates

equipment having a floating applied part

having a degree of protection suitable

for direct cardiac contact.

Laboratory logo or labels denoting

conformance with industry safety

standards such as UL or IEC.

This precaution is intended to prevent

injury that may result if one person

attempt to move the unit considerable

distances or on an incline due to the

weight of the unit.

Footswitch

Probe connectors including Doppler

probe connector

ECG connector and surgical probes

Rear of console

On the console where easily seen

during transport

"DANGER - Risk of explosion used in..."

The system is not designed for use with

flammable anesthetic gases.

“CAUTION” The equilateral triangle is

usually used in combination with other

symbols to advise or warn the user.

1 - 10 Section 1-2 - Important Conventions

Rear of console

Various

Page 35

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Table 1-8 Product Icons (continued)

LABEL/SYMBOL PURPOSE/MEANING LOCATION

“ATTENTION - Consult accompanying

documents” is intended to alert the user

to refer to the operator manual or other

instructions when complete information

cannot be provided on the label.

“CAUTION - Dangerous voltage” (the

lightning flash with arrowhead in

equilateral triangle) is used to indicate

electric shock hazards.

Various

Various

“Mains OFF” Indicates the power off

position of the mains power switch.

“OFF/Standby” Indicates the power off/

standby position of the power switch.

CAUTION

This Power Switch DOES NOT

ISOLATE Mains Supply

“Mains ON” Indicates the Power ON

position of the mains power switch.

“ON” Indicates the power on position of

the power switch.

CAUTION

The Power Switch on the Front Panel

DOES NOT ISOLATE Mains Supply

“Protective Earth” Indicates the

protective earth (grounding) terminal.

“Equipotentiality” Indicates the terminal

to be used for connecting equipotential

conductors when interconnecting

(grounding) with other equipment.

Rear of system adjacent to mains switch

Adjacent to On/Off (Standby) Switch

Used several places inside the scanner.

Rear of console

Chapter 1 - Introduction 1 - 11

Page 36

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Section 1-3

Safety Considerations

1-3-1 Introduction

The following safety precautions must be observed during all phases of operation, service and repair of

this equipment. Failure to comply with these precautions or with specific warnings elsewhere in this

manual, violates safety standards of design, manufacture and intended use of the equipment.

1-3-2 Human Safety

Operating personnel must not remove the system covers.

Servicing should be performed by authorized personnel only.

Only personnel who have participated in a Vivid 7 / Vivid 7 PRO Training Seminar are authorized to

service the equipment.

1-3-3 Mechanical Safety

WARNINGWARNING

WARNINGWARNING

WARNINGWARNING

CAUTION

CAUTION

CAUTION

WHEN THE UNIT IS RAISED FOR A REPAIR OR MOVED ALONG ANY INCLINE, USE

EXTREME CAUTION SINCE IT MAY BECOME UNSTABLE AND TIP OVER.

ULTRASOUND PROBES ARE HIGHLY SENSITIVE MEDICAL INSTRUMENTS THAT CAN

EASILY BE DAMAGED BY IMPROPER HANDLING. USE CARE WHEN HANDLING AND

PROTECT FROM DAMAGE WHEN NOT IN USE. DO NOT USE A DAMAGED OR

DEFECTIVE PROBE. FAILURE TO FOLLOW THESE PRECAUTIONS CAN RESULT IN

SERIOUS INJURY AND EQUIPMENT DAMAGE.

NEVER USE A PROBE THAT HAS FALLEN TO THE FLOOR. EVEN IF IT LOOKS OK, IT

MAY BE DAMAGED.

Ensure that nobody touch the console arm/frogleg when moving the keyboard console.

Do not move the unit if the keyboard console is in unlocked position.

Always lock the Control Console in its parking (locked) position before moving the scanner

around.

WARNINGWARNING

WHEN THE TOP CONSOLE IS IN ITS LOCKED POSITION, THE GAS SPRING IS

COMPRESSED AND STORES MECHANICAL ENERGY. DURING NORMAL OPERATION

THE TOP CONSOLE, THE WEIGHT OF THE MONITOR AND THE MECHANICAL FORCE

OF THE GAS SPRING ARE IN BALANCE. TAKE CARE IF/WHEN YOU ACTIVATE THIS

GAS SPRING. PERSONAL INJURY CAN OCCUR AFTER THE PANEL IS REMOVED AND

THE SPRING PRESSURE IS RELEASED. TAKE CARE WHEN YOU REPAIR THE

ELEVATION ASSEMBLY.

1 - 12 Section 1-3 - Safety Considerations

Page 37

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-3 Mechanical Safety (cont’d)

CAUTION

VIVID 7 / VIVID 7 PRO weighs 190 kg (419 lbs) or more, depending on installed peripherals, when

ready for use. Care must be used when moving it or replacing its parts. Failure to follow the

precautions listed below could result in injury, uncontrolled motion and costly damage.

CAUTION

-

Do not transport Vivid 7 / Vivid 7 PRO in a vehicle without locking the casters (wheels).

ALWAYS:

- Be sure the pathway is clear.

- Use slow, careful motions.

- Use two people when moving on inclines or lifting more than 23 kg (50 lbs).

NOTE: Special care should be taken when transporting the unit in a vehicle:

• Lock keyboard in place.

• Eject Magneto Optical disk from the MO Drive (if installed).

• Eject CD from CD drive.

• Secure the unit in an upright position.

• Lock the casters (wheels) (brake)

• DO NOT use the Control Panel as an anchor point.

• Place the probes in their carrying case.

CAUTION

Keep the heat venting holes on the monitor unobstructed to avoid overheating of the monitor.

1-3-4 Electrical Safety

1-3-4-1 Safe Practices

Follow these guidelines to minimize shock hazards whenever you are using the scanner;

• The equipment chassis must be connected to an electrical ground.

• The unit is equipped with a three-conductor AC power cable. This must be plugged into an approved

electrical outlet with safety ground.

• The power outlet used for this equipment should not be shared with other types of equipment.

• Both the system power cable and the power connector must meet international electrical standards.

1-3-4-2 Probes

Follow these guidelines before connecting a probe to the scanner;

• Inspect the probe prior to each use for damage or degradation to the;

- housing

- cable strain relief

-lens

- seal

• Do not use a damaged or defective probe.

Chapter 1 - Introduction 1 - 13

Page 38

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

• Never immerse the probe connector or adapter into any liquid.

1-3-5 Labels Locations

1-3-5-1 Labels on Front of Monitor and Control Panel

Table 1-9 Labels on Front of Monitor and Control Panel

DESCRIPTION ILLUSTRATION

Label, Vivid 7 (Monitor) - BT’01

Label, Vivid 7 (Monitor) - BT’02

Label, Vivid 7 PRO (Monitor) - BT’02

Label, GE Logo

1 - 14 Section 1-3 - Safety Considerations

Page 39

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Table 1-9 Labels on Front of Monitor and Control Panel (continued)

DESCRIPTION ILLUSTRATION

Label, On/Off Switch

(Two versions of the label have been

used, the one to the right is the latest

version.)

OR

ON/OFF:

press once

FC314104 03

Label position

Chapter 1 - Introduction 1 - 15

Page 40

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-2 Labels on Front Handle

Table 1-10 Labels on Front Handle

DESCRIPTION ILLUSTRATION

Label, Front Handle

(Three versions of the label have been

used.

The lower one is the latest version)

OR

OR

OR

1 - 16 Section 1-3 - Safety Considerations

Page 41

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-3 Labels Near Connectors on Front

Table 1-11 Labels Near Connectors on Front

DESCRIPTION ILLUSTRATION

Label, Probe Connector

(The Label, “Probe Connector” consists

of three labels, named;

- “Main Label Part”,

- “Heart Symbol” and

- “See Manual symbol”.)

Label, Patient I/O Module II

Label CD ROM

(introduced April 2002)

Chapter 1 - Introduction 1 - 17

Page 42

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-4 Label on External I/O

Table 1-12 Label, External I/O

DESCRIPTION ILLUSTRATION

Label, External. I/O

1 - 18 Section 1-3 - Safety Considerations

Page 43

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-5 Labels at AC Mains Inlet and Circuit Breaker

Table 1-13 Labels at AC Mains Inlet and Circuit Breaker (used before May 2002)

DESCRIPTION ILLUSTRATION

Label, Warning

System: P/N, Pwr.rating

Label,

Label, System: S/N

or

Ground (GND) Label. (Used on 230 VAC Systems and some 100-120 VAC Systems.) l

or

Label, GND-symbol

Chapter 1 - Introduction 1 - 19

Page 44

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Table 1-13 Labels at AC Mains Inlet and Circuit Breaker (used before May 2002) (continued)

DESCRIPTION ILLUSTRATION

l

Hospital Grade Ground

Label, GND-symbol., Hospital Grade

(GND) Label. (Used on some

100-120 VAC Systems)

Table 1-14 Labels at AC Mains Inlet and Circuit Breaker (used after May 2002)

DESCRIPTION ILLUSTRATION

Label, AC Controller

1 - 20 Section 1-3 - Safety Considerations

Page 45

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-6 Label on Rear Cover

Table 1-15 Label on Rear Cover

DESCRIPTION ILLUSTRATION

l

Label, General Info

(Located on rear of system)

Label used for Vivid 7 before 2 May 2002

Label, General Info

(Located on rear of system)

Label used for Vivid 7 after 2 May 2002

Chapter 1 - Introduction 1 - 21

Page 46

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Table 1-15 Label on Rear Cover (continued)

DESCRIPTION ILLUSTRATION

Label, General Info

(Located on rear of system)

Label used for Vivid 7 to China

Label, General Info

(Located on rear of system)

Label used for Vivid 7 PRO

1 - 22 Section 1-3 - Safety Considerations

Page 47

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

Table 1-15 Label on Rear Cover (continued)

DESCRIPTION ILLUSTRATION

Label, General Info

(Located on rear of system)

Label used for Vivid 7 PRO to China

Chapter 1 - Introduction 1 - 23

Page 48

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-7 Labels on Internal I/O (Inside Scanner)

Label on Front End Card Cage Side of Internal I/O

Figure 1-2 Labels on Internal I/O (Inside Scanner), Front End Card Cage Side of Internal I/O

1 - 24 Section 1-3 - Safety Considerations

Page 49

GE MEDICAL SYSTEMS

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-8 Labels on Internal I/O (Inside Scanner)

Label on Backend Processor Side of Internal I/O

Figure 1-3 Labels on Internal I/O (Inside Scanner), Backend Processor Side of Internal I/O

Chapter 1 - Introduction 1 - 25

Page 50

GE MEDICAL SYSTEMS

Rack

V

4

n

DIRECTION FC091194, REVISION 02 VIVID 7 / VIVID 7 PRO SERVICE MANUAL

1-3-5-9 Label, Internal Connections (Int.Conn.) - Part 1, Left Part of Label

Located on the outside of the Front End Card Rack’s cover (inside unit).Different versions of the label

has been used since production start. The label shown here, is the latest version.

AC

Cable and Connector num bering and nam ing system u sed:

IIO= Internal IO m odule

EIO= External IO m odule

BEP = B acken d Processor

FEP = Frontend P rocessor

ACP = AC contro ller m o dule

ACD = AC distribution box

ACT = AC iso lation transform er m odule

BEPIO= IO m odule on the BEP

A xx : connectors on IIO with other connections than the BEP

B xx : connectors on IIO that are connected to BEP

C xx : connectors on BEP, except for the BEPIO

D xx : connectors on BEPIO

E xx : connector on the BEP pow er supply

Fxx : connectors on ACP

G xx : connectors on FEP

H xx :external accesable connectors (D oppler probe)

K xx : connectors on MODEM

M xx : connectors on ACT

N xx : connectors on ACD

Lxx : connectors on EIO