Page 1

GE Oil & Gas

Mooney* FlowMax*

pressure reducing regulator

for natural gas pipelines

Page 2

2

Page 3

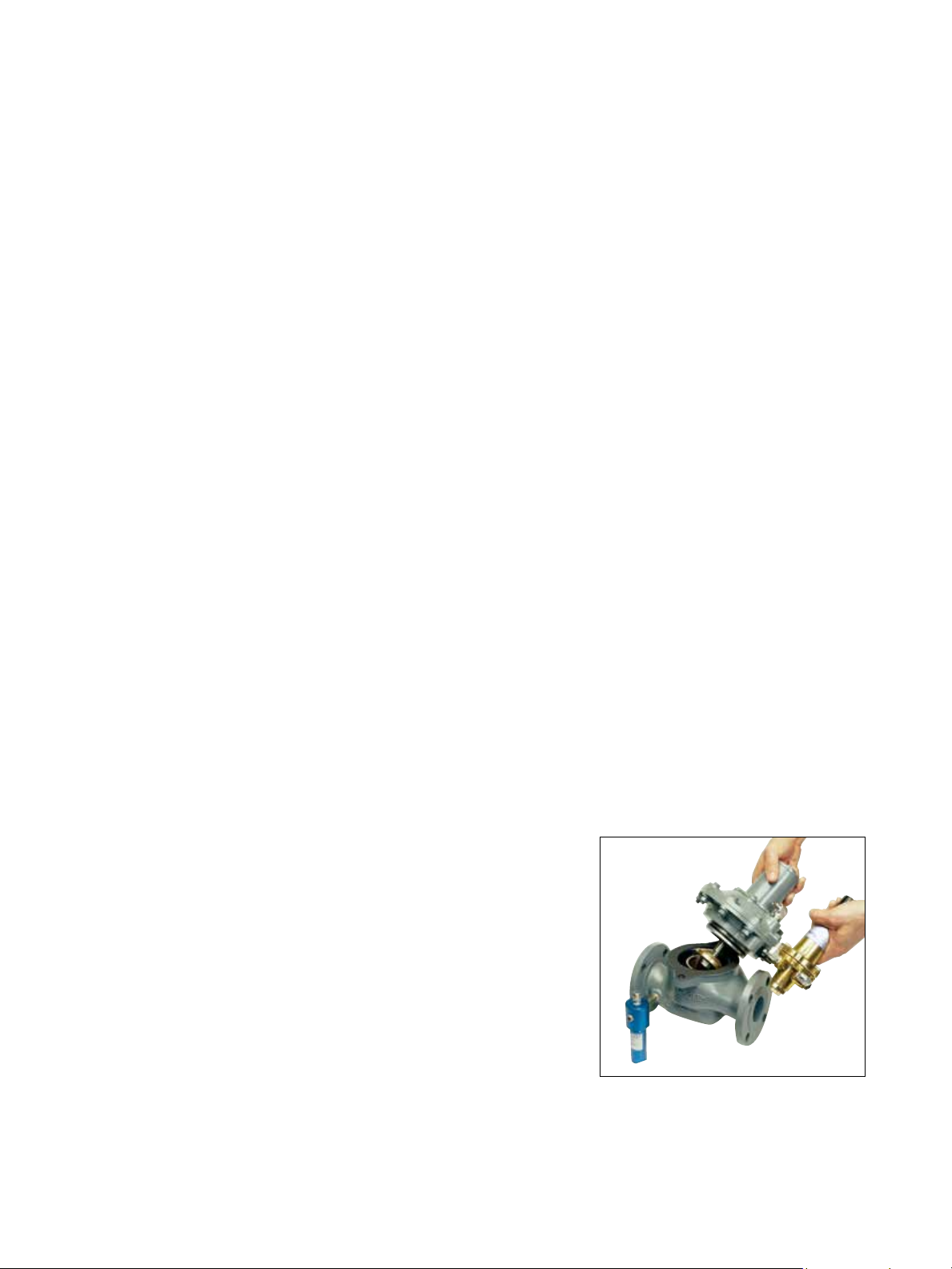

The Mooney FlowMax regulator is a pressure

reducing regulator that offers bubble tight shutoff at all pressure differentials and full capacity

at very low differential pressures. This innovative

GE Oil & Gas design compliments the Mooney

Flowgrid* regulator. The FlowMax regulator

maximizes capacity, speed of response, and

accuracy while incorporating many of the same

original maintenance and performance features

for which the Flowgrid regulator is renowned.

Product Features

Top-entry design for ease of maintenance

One actuator for all pressure control ranges

Oversized balanced diaphragm provides

shut off force

Full portal designs for ultra high capacity

Guiding piston

Positive bubble tight shut-off at all

pressure differentials

Control range - 5 i.w.c. to 247 psig

(12 mbar to 17 bar)

Full open differential - as low as 3 psig (0.21 bar)

Quick acting two-path pilot control system

Low-volume casing (actuator)

Lightweight and compact design

Reversible plug seal

Designed for a range of applications

District regulator

Monitor, first stage, or second stage regulator

Industrial service regulator

Boiler/burner fuel gas regulator

3

Page 4

Designed for bubble tight shut-off at all

pressures and full capacity at very low

differential pressures.

Pressure Reducing Valve

When the downstream pressure is greater than

the set point of the pilot, the pilot is closed, resulting in equal pressure above and below the main

diaphragm. With a balancing diaphragm area

slightly larger than the seat area, the resulting

closing force, along with the force of the main

spring, forces the plug against the seat.

With an increase in demand, the outlet pressure

will begin to drop and decrease the pressure

above the main diaphragm. The drop of the outlet

pressure below the pilot set point will cause the

pilot to open. As the pilot opens, pressure increases underneath the main diaphragm faster than

pressure can bleed through the internal restrictor.

The imbalance in pressure on the main diaphragm

overcomes the spring force and the additional

closing force from the balancing diaphragm,

causing the plug to rise off the seat and satisfy

the flow demand.

Once the flow demand is satisfied and the downstream pressure begins to increase, the pressure

above the main diaphragm and in the pilot sense

cavity rises.

This causes the pilot to close. The pressure below

the main diaphragm bleeds through the internal restrictor until pressure equalizes above and

below the main diaphragm. The forces of the main

spring and the over-sized balancing diaphragm

then close the plug on the seat.

Back Pressure Valve

In a back pressure relief application (BPV) the valve

functions to maintain upstream pressure at the

pilot set point. The sense line for the control pilot is

located upstream of the regulator. The extra sense

port on the actuator is plugged for BPV pilot

configuration. The action of the pilot is the reverse

of a pressure reducing pilot, such that the pilot

opens when the upstream pressure increases

above its set point. The pilot will close when the

upstream pressure is less than its set point.

Plug

BPV Pilot Sense

Pilot Supply

4

PRV Pilot Sense

Pilot Loading

for BPV

Balancing Diaphragm

Regulator Sense Line

Internal Restrictor

Inlet Pressure

Loading Pressure Outlet Pressure

Page 5

Spring Color Series 20*

Pilot

Outlet Presure

Range

White 20L 5-15 i. w. c.

(12 mbar - 37 mbar)

Brown 20L 10-40 i. w. c.

(25 mbar - 100 mbar)

Yellow 20L 1-3 psig

(0.02 bar - 0.21 bar)

Orange 20L 2-5 psig

(0.14 bar - 0.34 bar)

Gray 20L 4-8 psig

(0.28 bar - 0.55 bar)

Spring Color Series 20

Pilot

Red 20 3-12 psig

Cadmium 20 10-40 psig

Blue 20 25-90 psig

Purple 20 60-200 psig

Black 20 100-260 psig

Outlet Presure

Range

(0.21 bar - 0.83 bar)

(0.69 bar - 3 bar)

(2 bar - 6 bar)

(4 bar - 14 bar)

(7 bar - 18 bar)

Specifications

Body Size 2” (DN 50) 3” (DN 80) 4” (DN 100) 6” (DN 150)

End Connection

Minimum Differential

(fully open)

Maximum Inlet Pressure

Maximum Outlet Pressure

Maximum Casing Pressure

Outlet Pressures

Series 20 Pilot

Series 20L Pilot

Maximum Differential

Pressure

Temperature

Emergency Temperature

100% Capacity

Cg

C

1

C

v

50% Capacity

Cg

C1

C

v

Face to Face Dimensions

NPT

CL 150 RF & CL 150 FF

Weight

NPT

CL 150 RF & CL 150 FF

NPT

ANSI CL 150 RF

CL 150 FF***

3 psig (0.21 bar) 4 psig (0.28 bar) 4 psig (0.28 bar) 4 psig (0.28 bar)

250 psig (17 bar) 250 psig (17 bar) 250 psig (17 bar) 250 psig (17 bar)

250 psig (17 bar) 250 psig (17 bar) 250 psig (17 bar) 250 psig (17 bar)

250 psig (17 bar) 250 psig (17 bar) 250 psig (17 bar) 250 psig (17 bar)

3-246 psig

(0.21-17 bar)

5 i.w.c.-8 psig

(12.5 mbar-0.55 bar)

250 psid (17 bar) 250 psid (17 bar) 250 psid (17 bar) 250 psid (17 bar)

-20°F to 150°F

(-29°C to 66°C)

-40°F to 175°F

(-40°C to 79°C)

2,250

35

64

1,200

31**

39**

10.50 (267 mm)

10.00 (254 mm)

31 lbs (14 kg)

36 lbs (16 kg)

ANSI CL 150 RF

CL 150 FF***

3-246 psig

(0.21-17 bar)

5 i.w.c.-8 psig

(12.5 mbar-0.55 bar)

-20°F to 150°F

(-29°C to 66°C)

-40°F to 175°F

(-40°C to 79°C)

4,200

37

114

2,100

32**

66**

N/A

11.75 (298 mm)

N/A

59 lbs (27 kg)

ANSI CL 150 RF

CL 150 FF***

3-246 psig

(0.21-17 bar)

5 i.w.c.-8 psig

(12.5 mbar-0.55 bar)

-20°F to 150°F

(-29°C to 66°C)

-40°F to 175°F

(-40°C to 79°C)

7,500

35

212

3,800

31**

123**

N/A

13.88 (353 mm)

N/A

103 lbs (47 kg)

ANSI CL 150 RF

CL 150 FF***

3-246 psig

(0.21-17 bar)

5 i.w.c.-8 psig

(12.5 mbar-0.55 bar)

-20°F to 150°F

(-29°C to 66°C)

-40°F to 175°F

(-40°C to 79°C)

14,500

37

393

7,200

31

231

N/A

17.75 (451 mm)

N/A

190 lbs (86 kg)

** Estimated

*** CL150 FF mates with 125 FF cast iron pipe.

5

Page 6

Flow Capacity Charts

(MSCFH)

Inlet

Pressure

psig (bar)

3 (0.21) 0.25 (0.02)

5 (0.34)

10 (0.69)

15 (1.0)

25 (1.7)

30 (2.1)

40 (2.8)

50 (3.4)

Outlet

Pressure

psig (bar)

1 (0.07)

0.25 (0.02)

1 (0.07)

3 (0.21)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

2”

(50 DN)3”(80 DN)4”(100 DN)6”(150 DN)

32

28

43

40

30

63

62

57

50

80

79

76

72

56

97

96

94

91

80

61

130

130

126

124

118

108

94

159

159

159

156

151

145

136

106

188

188

188

188

183

179

172

153

117

57

50

76

71

53

114

111

101

89

146

144

138

130

99

177

175

170

164

143

108

243

243

230

226

214

195

167

297

297

297

285

276

263

246

189

351

351

351

351

335

325

312

274

208

107

93

142

133

99

210

205

189

166

268

265

254

240

185

323

320

312

303

266

203

433

433

420

414

393

361

312

530

530

530

518

505

484

454

353

627

627

627

627

610

595

575

509

389

197

171

263

245

181

393

382

350

307

505

498

475

448

342

610

604

587

567

495

373

837

837

795

782

738

673

578

1025

1025

1025

984

952

908

848

651

1212

1212

1212

1212

1156

1123

1078

946

717

Inlet

Pressure

psig (bar)

60 (4.1)

70 (4.8)

80 (5.5)

100 (6.9)

Outlet

Pressure

psig (bar)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

2”

(50 DN)3”(80 DN)4”(100 DN)6”(150 DN)

217

217

217

217

217

210

206

191

168

127

246

246

246

246

246

246

238

227

209

181

136

275

275

275

275

275

275

269

260

246

225

194

145

333

333

333

333

333

333

333

324

314

301

282

255

405

405

405

405

405

385

375

346

300

225

459

459

459

459

459

459

434

411

376

324

242

514

514

514

514

514

514

492

473

445

405

347

257

622

622

622

622

622

622

622

592

572

544

507

457

724

724

724

724

724

701

686

638

558

422

820

820

820

820

820

820

792

756

696

604

453

917

917

917

917

917

917

896

867

820

751

647

482

1111

1111

1111

1111

1111

1111

1111

1079

1048

1002

938

850

1399

399

1399

1399

1399

1328

1293

1193

1036

778

1586

1586

1586

1586

1586

1586

1499

1419

1298

1119

834

1773

1773

1773

1773

1773

1773

1700

1633

1536

1397

1197

887

2148

2148

2148

2148

2148

2148

2148

2044

1974

1878

1749

1576

NOTE: High differentials may result in high outlet piping velocities. Swaging up outlet piping is required.

6

Page 7

Flow Capacity Charts

(MSCFH)

Inlet

Pressure

psig (bar)

125 (8.6)

150 (10.3)

175 (12)

Outlet

Pressure

psig (bar)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

100 (6.9)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

100 (6.9)

125 (8.6)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

100 (6.9)

125 (8.6)

150 (10.3)

2”

(50 DN)3”(80 DN)4”(100 DN)6”(150 DN)

406

406

406

406

406

406

406

406

394

385

372

356

268

478

478

478

478

478

478

478

478

478

464

455

444

386

295

551

551

551

551

551

551

551

551

551

551

535

526

484

423

320

758

758

758

758

758

758

758

758

721

701

675

642

477

893

893

893

893

893

893

893

893

893

849

930

805

693

525

1029

1029

1029

1029

1029

1029

1029

1029

1029

1029

978

958

873

757

568

1353

1353

1353

1353

1353

1353

1353

1353

1314

1283

1242

1186

893

1595

1595

1595

1595

1595

1595

1595

1595

1595

1548

1518

1479

1287

983

1837

1837

1837

1837

1837

1837

1837

1837

1837

1837

1783

1752

1613

1410

1065

2616

2616

2616

2616

2616

2616

2616

2616

2488

2419

2330

2217

1648

3084

3084

3084

3084

3084

3084

3084

2932

2864

2780

2392

1812

3552

3552

3552

3552

3552

3376

3309

3014

2615

1961

Inlet

Pressure

psig (bar)

200 (14)

—

—

225 (16)

—

—

—

—

—

250 (17)

Outlet

Pressure

psig (bar)

0.25 (0.02)

1 (0.07)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

100 (6.9)

125 (8.6)

150 (10.3)

175 (12)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

100 (6.9)

125 (8.6)

150 (10.3)

175 (12)

200 (14)

3 (0.21)

5 (0.34)

10 (0.69)

15 (1.0)

20 (1.4)

30 (2.1)

40 (2.8)

50 (3.4)

60 (4.1)

70 (4.8)

100 (6.9)

125 (8.6)

150 (10.3)

175 (12)

200 (14)

225 (16)

2”

(50 DN)3”(80 DN)4”(100 DN)6”(150 DN)

2079

2079

2079

2079

2079

2079

2079

2079

2079

2017

1908

1757

1523

1142

2321

2321

2321

2321

2321

2321

2321

2188

2069

1892

1629

1214

2563

2563

2563

2563

2563

2563

2563

2563

2458

2361

2220

2019

1729

1282

—

—

4020

4020

4020

4020

4020

4020

4020

3820

3582

3276

2821

2010

—

—

—

4488

4488

4488

4488

4488

4488

4488

4120

3872

3520

3013

2232

—

—

4956

4956

4956

4956

4956

4956

4956

4642

4433

4145

3749

3194

2355

624

624

624

624

624

624

624

624

624

624

624

605

573

527

457

343

696

696

696

696

696

696

696

696

696

696

656

621

568

489

364

769

769

769

769

769

769

769

769

769

769

737

708

666

606

519

385

1164

1164

1164

1164

1164

1164

1164

1164

1164

1164

1106

1038

949

817

609

1300

1300

1300

1300

1300

1300

1300

1300

1300

1300

1194

1122

1019

873

646

1435

1435

1435

1435

1435

1435

1435

1435

1345

1345

1284

1201

1086

925

682

—

—

—

—

—

—

—

—

—

—

—

—

NOTE: High differentials may result in high outlet piping velocities. Swagging up outlet piping is required.

7

Page 8

GE Oil & Gas

2822 S. 1030 West

Salt Lake City, UT 84119

T: +1 801.487.2225

F: +1 801.487.2587

E: mooney.inquiries@ge.com

Visit us online at:www.ge.com/energy

©2014 General Electric Company

All Rights Reserved

*Trademark of General Electric Company

GEA19188_Mooney FlowMax Regulator

6.14

Loading...

Loading...