Page 1

ORegen*

Waste Heat Recovery System

for GE and other OEM Gas Turbines

g g g

Increased production

g g g

Higher efficiency

g g g

Compliance with environmental regulations

c c c

Availability and Reliability

c c c

Life extension

Addressing environmental problems is becoming an important initiative

throughout the world. The reduction of CO

the path toward lowering the human contribution to climate change.

Many industrial processes generate waste energy that passes out of plant

stacks into the atmosphere and is lost.

Energy recovered from waste heat streams could supply part or all of the

electric power required by a plant, at no additional cost.

Therefore, heat recovery offers a great opportunity to conserve by

productively using this waste energy, to reduce overall plant energy

consumption and simultaneously decrease CO2emissions.

emissions is a key element in

2

Get more from your

Gas Turbines

* ORegen is a trademark of Nuovo Pignone S.p.A. and is available in select markets

a product of

ecomagination

SM

Layout of a plant equipped with the

ORegen waste heat recovery system

g

Page 2

Power generation with zero additional

emissions

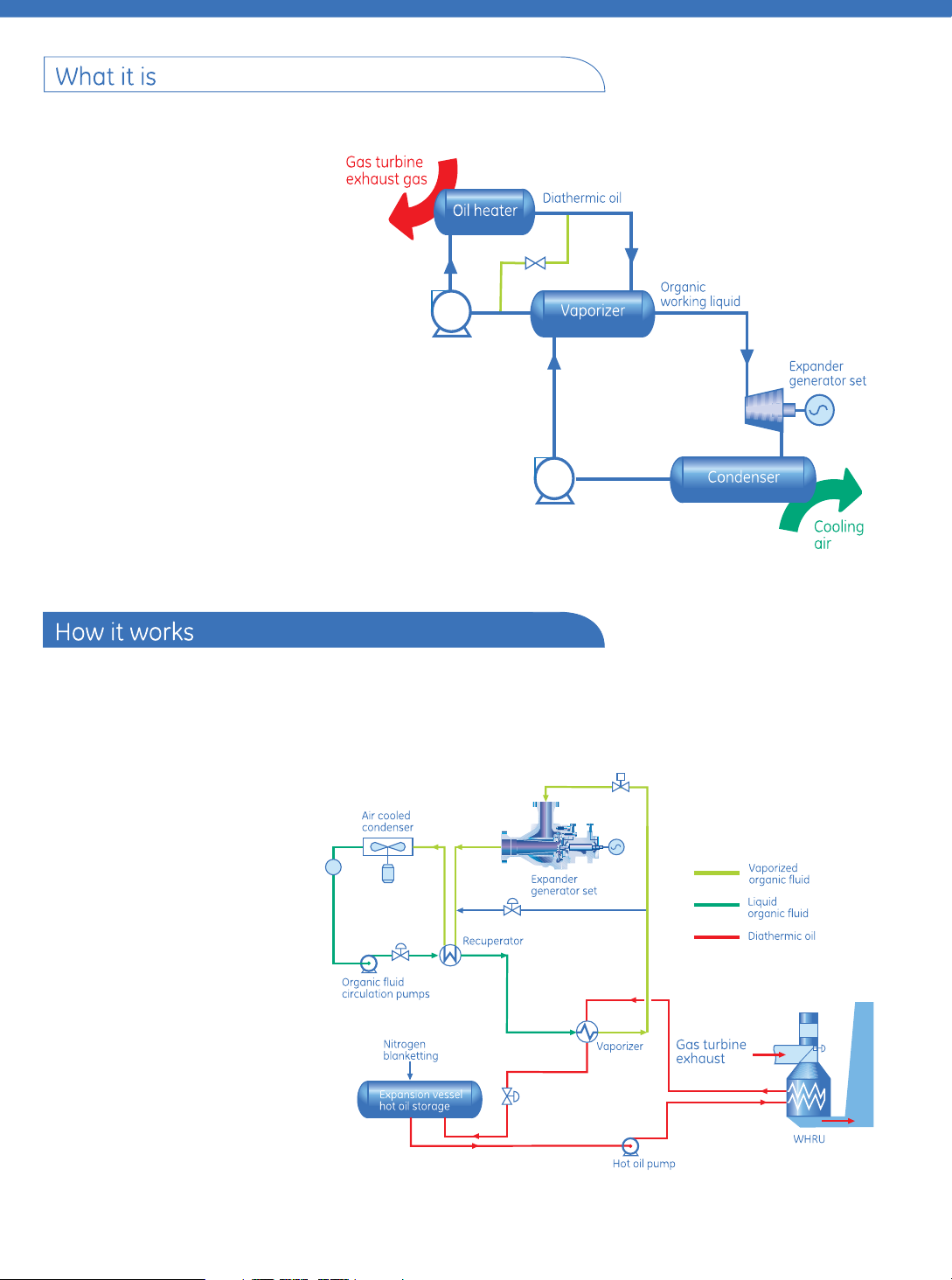

ORegen is a thermodynamic superheat

cycle that recovers waste heat from gas

turbine exhaust and converts it into

electric energy. The thermodynamic cycle

is based on an Organic Rankine Cycle

(ORC). Heat from the turbine exhaust is

transferred to a closed diathermic oil loop,

which is used to heat an organic fluid loop.

This lower temperature heat is then

converted into useful work that can

generate electricity. The ORC works with

a hydrocarbon fluid in place of water.

The system is similar to a conventional

steam bottoming cycle except for the

organic fluid that drives a turboexpander

that in turn drives the generator. The

diathermic oil and the organic fluid allow

low temperature heat sources to be

exploited efficiently to produce electricity

over a wide range of power output, from

a few MW up to 16 MW per unit.

Closed loop system

The organic working fluid is vaporized

and pressurized in the evaporator by

the application of heat taken from the

gas turbine exhaust stream. Then, the

vapor expands in the turboexpander

and is condensed using air-cooled

heat exchangers at ambient

conditions. The condensate is pumped

back to the evaporator, thus closing

the thermodynamic cycle. The

heating and cooling sources are not in

direct contact with the working fluid,

nor with the expander. For higher

temperature applications, a high

temperature thermal oil is used as

the heat carrier and a regenerator is

added to further improve the cycle

performance.

The selection of the working fluid is

key in a Rankine Cycle.

The features are:

• Low freezing point and high

temperature stability

• High heat of vaporization and

density

• Low environmental impact

• No additional EHS considerations

• Readily available at low cost

Page 3

ORegen vs Steam Cycle

Features

ORegen Standard Steam

Combined Cycle

Water free *** *

Low maintenance *** *

Power flexibility *** *

Low investment ** *

Plant simplicity *** *

Reduced footprint *** *

No replenishment of working fluid *** *

Unmanned capability *** *

Additional output ** ***

Expected ORegen Power Output

for Mechanical Drive and Power Generation Gas Turbines

Gas Gas Turbine Exhaust Exhaust Gas Turbine ORegen Gross System

Turbine Power Flow Temp Efficiency Output Efficiency

Model (KW) (Kg/sec) (°C) (%) (MWe) (%)

PGT25 (*) 23,261 68.9 525 37.7 6.9 48.9

PGT25+ (*) 31,364 84.3 500 41.1 7.9 51.5

PGT25+ G4 (*) 33,973 89.0 510 41.1 8.6 51.5

MS5001 (*) 26,830 125.2 483 28.4 11.3 40.4

MS5002C (*) 28,340 124.3 517 28.8 12.4 41.4

MS5002D (*) 32,580 141.4 509 29.4 13.8 41.9

MS6001B (*) 43,530 145.0 544 33.3 15.6 45.2

LM6000 (**) 43,397 125.6 454 41.7 9.7 51.1

Reference data @ISO Conditions, 100% GT Turbine load, one to one configuration

(*) Values at gas turbine shaft

(**) Values at generator terminals for LM6000PC coupled to 60 Hz generator

Scope of Supply

The basic scope of supply includes the following:

• Organic fluid system

• Diathermic oil system

• Boilers and heat exchangers

• Turboexpander genset

• Piping and BOP components

• Air or water cooler

Waste Heat Recovery Unit

Organic Fluid System

Page 4

g

GE imagination at work

GE Oil & Gas

Global Headquarters

Via Felice Matteucci, 2

50127 Florence, Italy

T +39 055 423 211

F +39 055 423 2800

Nuovo Pignone S.p.A.

Nuovo Pignone S.r.l.

E customer.service.center@ge.com

www.ge.com/oilandgas

GE, the GE Monogram,

and imagination at work

are registered trademarks of

the General Electric Company.

COMK/MARK 839/II - Designed by: Studio Tre Fasi

Printed by: Sagraf - 12-2011

©2011 General Electric Company

All Rights Reserved

Loading...

Loading...