Page 1

GE

Measurement & Control Moisture

Optica™

Operator’s Manual

A40238752 Rev. G

December 2015

Page 2

Page 3

Optica™

General Eastern Dew Point Analyzer

Operator’s Manual

A40238752 Rev. G

December 2015

www.gemeasurement.com

©2015 General Electric Company. All rights reserved.

Technical content subject to change without notice.

Page 4

[no content intended for this page]

ii

Page 5

Contents

Chapter 1. Features and Capabilities

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Electronics Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Input/Output Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 The System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.1 System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.2 System Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.1 Dew Point Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.2 Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.3 Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.1 Hygrometer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.2 Hygrometer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5.3 Other Hygrometer Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 The PACER Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2. Installation

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Benchtop Optica Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.1 Mounting the Benchtop Optica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2.2 Using the Rack Mounting Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2.3 Wiring the Benchtop Optica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Wall-Mount Optica Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.1 Mounting the Wall-Mount Optica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.2 Wiring the Wall-Mount Optica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.4.1 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4.2 Alarm Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4.3 Serial Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Sensor Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.1 Sampling Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5.2 Ensuring Heat Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.3 High Dew Point Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.6 Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6.1 Model 1111H Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6.2 Model D-2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.6.3 Model 1211H Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.4 Model 1311DR Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6.5 Model 1311XR Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6.6 Model SIM-12H Heated Sensor and Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.6.7 Connecting the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Optica™ Operator’s Manual iii

Page 6

Contents

Chapter 3. Operation

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.2 Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

3.3 Operating the VGA Optica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.4 Operating the 4x40 Optica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.5 Network Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.6 Process Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.6.1 Actively Measuring Process Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.6.2 Manually Entering Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.6.3 Measuring at a Different Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.6.4 Scenario 1: Measurement Without Enabling the Process Pressure Feature . . . . . . . . . . . . . . . . . . . . . . . .31

3.6.5 Measuring Dew Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.6.6 Scenario 2: Measurement Requiring the Process Pressure Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.7 Status Line Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.7.1 Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.8 Sensor Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.9 Helpful Hints For Operating the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.9.1 Supercooled Dew Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.9.2 Contamination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.9.3 Mirror Flooding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.9.4 Sample Line Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

3.9.5 Pressure Effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Chapter 4. Programming the VGA Optica

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.2 Programming Fundamentals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.2.1 The Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.2.2 Data Entry Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.3 Units of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.4 User Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.5 Menu 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.5.1 Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.5.2 Pressure Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4.5.3 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.5.4 Automatic Cleaning and Balance Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

4.5.5 Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.5.6 Buzzer/Sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

4.5.7 Network Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4.5.8 Datalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

iv Optica™ Operator’s Manual

Page 7

Contents

4.6 Menu 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.6.2 Special . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6.3 User Equation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6.4 Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.6.5 Serial Output Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6.6 Set Time & Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.6.7 Restore Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.7 Saving Configuration Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Chapter 5. Programming the 4x40 Optica

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.2 Programming Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.3 Programmable Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.3.1 Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.3.2 Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

5.3.3 Serial Output Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3.4 Serial Output Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.3.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.3.6 Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.3.7 Pressure Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.3.8 Automatic Cleaning and Balance Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.3.9 Buzzer and Sounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.3.10 General Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.3.11 User Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.3.12 Set Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.3.13 Special . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.3.14 User Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.3.15 Factory Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Chapter 6. Network-Based Programming

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2 Programming Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 7. Maintenance

7.1 Minor Maintenance of Sensor Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.1.1 Cleaning and Balancing the Sensor Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.1.2 Procedure for Cleaning and Balancing the Sensor Mirror. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.2 Field Replacement of Sensor Mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.2.1 Replacing the Sensor Mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.3 Test and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Optica™ Operator’s Manual v

Page 8

Contents

7.4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

7.4.1 The Display Doesn’t Light Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

7.4.2 “Service” Appears on the STATUS Display Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

7.4.3 Incorrect Dew Point Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

7.4.4 “Balance” Remains on the Status Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

7.4.5 No Analog Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

7.4.6 No Serial Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Appendix A. Specifications

A.1 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

A.1.1 Accuracy [complete system at 25°C (77°F)] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

A.1.2 Measurement Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

A.1.3 Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

A.2 Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.2.1 Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.2.2 Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.2.3 Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.2.4 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.2.5 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.2.6 Operating Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

A.3 Physical (Bench Mount) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.3.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.3.2 Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.3.3 Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.3.4 Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.4 Physical (Wall Mount) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.4.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.4.2 Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.4.3 Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.4.4 Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

A.5 Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

A.5.1 T-100E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

A.5.2 PT-30A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

A.5.3 PT-300A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

A.6 European Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Appendix B. Humidity Equations and Conversion Chart

B.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

B.2 Vapor Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

B.3 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Appendix C. Configuring the Serial Interface

C.1 Wiring to a Personal Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

vi Optica™ Operator’s Manual

Page 9

Contents

Appendix D. Chilled Mirror Sensors

D.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

D.2 Depression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

D.3 Measurement Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

D.4 Comparing Optica Sensor Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Appendix E. Glossary

Appendix F. Automatic Balance (for earlier software versions)

F.1 Programming Automatic Balance for a VGA Optica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

F.2 Programming Automatic Balance for a 4x40 Optica. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix G. Communicating with the OPTICA Using Ethernet

G.1 Direct Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

G.2 Computer Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

G.2.1 Determining the Available Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

G.2.2 Retrieving the Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

G.2.3 Retrieving the Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

G.2.4 Retrieving Supported Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

G.2.5 Retrieving Labels and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

G.2.6 Retrieving Analog Output Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

G.2.7 Retrieving the Measured and Calculated Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

G.2.8 4X40 Optica Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Optica™ Operator’s Manual vii

Page 10

Contents

[no content intended for this page]

viii Optica™ Operator’s Manual

Page 11

Preface

Information Paragraphs

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not

essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information that emphasizes instructions that are essential to proper setup of

the equipment. Failure to follow these instructions carefully may cause unreliable performance.

CAUTION! This symbol indicates a risk of potential minor personal injury and/or severe damage to

the equipment, unless these instructions are followed carefully.

WARNING! This symbol indicates a risk of potential serious personal injury, unless these

instructions are followed carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national

codes, regulations, rules and laws related to safety and safe operating conditions are met for each

installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards,

regulations, or laws applicable to safety.

Working Area

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before

you perform maintenance procedures on the equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment.

Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Optica™ Operator’s Manual xi

Page 12

Preface

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control Solutions is an active participant in Europe’s Waste Electrical and Electronic Equipment

(WEEE) take-back initiative, directive 2012/19/EU.

The equipment that you bought has required the extraction and use of natural resources for its production. It may

contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural

resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the

materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional

waste administration.

Visit www.gemeasurement.com/environmental-health-safety-ehs

for take-back instructions and more information

about this initiative.

xii Optica™ Operator’s Manual

Page 13

Chapter 1. Features and Capabilities

Chapter 1. Features and Capabilities

1.1 Introduction

The GE Measurement & Control Optica is a multi-purpose chilled-mirror hygrometer, suitable for use in a wide variety

of applications. The Optica can function with any GE Measurement & Control chilled-mirror sensor to provide the

following measurement ranges (depending on the sensor selected):

• Dew/frost point from –80°C to +85°C (–112°F to +185°F)

• Relative humidity from 0.002% to 100%

• Moisture content from 500 ppb

to over 5.71 × 105 ppm

v

v

• Temperature from -100°C to +100°C (-212°F to +212°F)

The Optica also measures and displays gas pressure using a GE Sensing PT-30A or PT-300A pressure sensor, or a

user-supplied 4–20 mA or 0–5 VDC pressure sensor.

Note: If the pressure is known to be constant, a fixed pressure can be programmed, eliminating the need for a

pressure sensor.

Using the Optica, you can simultaneously measure and display dew point, temperature and pressure, with a wide

variety of units of measure. The Optica is Ethernet-ready, so you can access the unit using the Internet for remote

monitoring applications. You can use the data logging function to record and upload weeks of data.

1.2 Electronics Enclosure

The Optica is available in two configurations:

• A benchtop model, with an optional rack-mount adapter available

• A wall-mount unit, housed in a Type 4 enclosure, suitable for industrial environments

See Chapter 2, “Installation” for details on how to mount the Optica.

Optica™ Operator’s Manual 1

Page 14

Chapter 1. Features and Capabilities

VGA Display Softkeys Alphanumeric Keypad

Power

On/Off

Switch

1.2.1 Front Panel

The Optica front panel is shown in Figure 1 below. The panel includes: a display, an alphanumeric keypad for data

entry, ENTER and TAB keys, and four softkeys to the right of the display screen.

Two display options are available:

• A high-resolution, full-color, liquid crystal display (LCD) with data graphing and on-screen programming

capability (referred to as the “VGA” unit). See Figure 1 below.

• A 4-line by 40-character alphanumeric display (referred to as the “4x40” unit).

Figure 1: Optica Benchtop Version with VGA Display

1.2.2 Input/Output Capability

Available inputs and outputs include the following:

• 4-wire Resistance Temperature Detector (RTD) input

• 4–20 mA and 0–5 VDC Pressure Sensor inputs

• Two simultaneous analog outputs, each with 4–20 mA and 0–5 VDC capability

• Two independent alarm relays (Form C, 5 Amp)

• Serial communications port

• Ethernet 10BaseT (on VGA Optica only)

The Optica uses the GE Measurement & Control patented Programmable Automatic Contaminant Error Reduction

PACER) system for automated self-cleaning and optics rebalancing. Detailed specifications for the Optica are given in

(

Appendix A, “Specifications”.

2 Optica™ Operator’s Manual

Page 15

Chapter 1. Features and Capabilities

1.3 The System

1.3.1 System Components

A complete Optica system consists of the following items:

• Electronic monitor • Temperature sensor (optional)

• Dew point sensor • Pressure sensor (optional)

• Interconnecting sensor cable • Maintenance kit

• AC line cord • User’s Manual

• Certification that the unit is traceable to the National Institute of Standards

and Technology (Certificate of Conformance)

1.3.2 System Planning

The Optica can be used for a wide variety of measurement applications, including the measurement of dew points of

gasses that are at pressures that exceed the measurement range of GE sensors. In this situation be sure to check

“Process Pressure” on page 30 for installation planning.

1.4 Sensors

The Optica can be configured with a chilled-mirror dew point sensor. The specific sensor is chosen according to the

expected dew point range and the environment in which the dew point is to be determined. In addition, the Optica can

be configured with a temperature and/or pressure sensor.

1.4.1 Dew Point Sensors

GE offers the following sensors for various applications:

• Model 1111H - Single-stage sensor

• Model 1211H - Two-stage sensor; high pressure and temperature

• Model D-2 - Two-stage sensor

• Model SIM-12H - Two-stage heated sensor

• Model 1311DR - Four-stage, liquid or air cooled sensor

• Model 1311XR - Five-stage, liquid cooled sensor

1.4.2 Temperature Sensor

• Model T-100E

1.4.3 Pressure Sensor

• Model PT-30A or PT-300A

Optica™ Operator’s Manual 3

Page 16

Chapter 1. Features and Capabilities

41.2°F

Dew Point Temperature

(Precision Thermometer)

LED

Regulation

Thermoelectric

Heat Pump Power

Gain

Optical Reference

1.5 Theory of Operation

Optical condensation hygrometry is a precise technique for determining the water vapor content in gases by directly

measuring dew point or frost temperatures. Using this technique, a metal mirror is cooled until it reaches a temperature

at which a thin layer of condensation begins to form on it. The dew layer is detected optically, and the mirror is held at

that temperature. The mirror temperature, measured with a platinum resistance thermometer, is an accurate indicator of

the dew or frost point. Because these hygrometers are so accurate, they are widely used as a standard in many of the

world’s metrology laboratories.

1.5.1 Hygrometer Function

Figure 2 below illustrates how GE Measurement & Control hygrometers detect and measure dew point. The

condensate mirror is illuminated with a solid state, infrared emitter (IR). A photodetector monitors the IR light

reflected from the mirror. The photodetector is fully illuminated when the mirror is clear of dew, and it receives less

light as dew forms. A separate LED and photodetector pair are used as a known reference to compensate for any

thermally induced changes in the optical components. The photodetectors are arranged in an electrical bridge circuit,

the output current of which is proportional to the light reflected from the mirror. The bridge output controls the

electrical current to the thermoelectric cooler.

A large bridge current develops when the mirror is dry, causing the mirror to cool toward the dew point. As dew begins

to form on the mirror, less light is reflected, and the bridge output decreases. This, in turn, causes a decrease in cooling

current. A rate feedback loop within the amplifier ensures critical response, causing the mirror to stabilize quickly at a

temperature that maintains a thin dew or frost layer on the mirror surface. A precision thermometer element embedded

within the mirror directly monitors this dew point temperature.

Figure 2: Chilled-Mirror Hygrometer Diagram

4 Optica™ Operator’s Manual

Page 17

Chapter 1. Features and Capabilities

1.5.2 Hygrometer Calibration

The Optica unit can be sent to the National Institute of Standards and Technology (NIST) in Gaithersburg, Maryland for

certification or to any National Standards lab for calibration against their primary humidity standards. A calibrated

instrument can then be used as a transfer standard in local laboratories to calibrate lower echelon instruments.

CAUTION! Field calibration of the Optica is not recommended.

Hygrometers used as calibration standards must have the following characteristics:

• The mirror thermometer must have suitable long-term accuracy (such as that obtained with a platinum

resistance thermometer).

1.5.3 Other Hygrometer Applications

Many GE Measurement & Control Chilled Mirror Hygrometers are used in industrial applications in addition to

metrology. The optical condensation hygrometer is not readily damaged or contaminated by industrial process gases

that can degrade other secondary measurement schemes such as saturated salt and polymer-based sensors. If the sensor

or sampling components should become contaminated with oils, salts, etc., they can be cleaned without harm to the

sensor or impairment to the system accuracy. The performance of the hygrometer can be checked at any time by

heating the mirror above the dew point, causing the dew deposit to evaporate, then reclosing the servoloop and

checking to see that the system cools and returns to the same dew point.

The GE optical condensation sensors cover a wide range of applications limited only by the heat pumping capabilities

of the thermoelectrically-cooled mirror.

At high dew points (up to 100°C), the sensor is limited by the thermal properties of the solid state optical components

as well as the thermoelectric heat pump capacity.

In a typical application measuring sub-ambient dew points, a two-stage thermoelectrically-cooled mirror can reach a

temperature approximately 65°C lower than an ambient (heat sink) temperature of +25°C. The thermoelectric cooler

pumps heat from the mirror into the heat sink. By reducing the temperature of the heat sink with a coolant such as

chilled water, or by applying the sensor in a low-temperature condition such as monitoring of a test chamber, even

lower dew points can be measured. In meteorological applications where the heat sink temperature is considerably

lower, frost points down to –75°C can be monitored.

Four- and five-stage sensors are available for measuring the lowest dew/frost points.

Optica™ Operator’s Manual 5

Page 18

Chapter 1. Features and Capabilities

Mirror Heats

Start of Cycle

End

Cooling Heating

Data is Sampled

and Held

(3 min)

Optical System

Automatically

Adjusts for

Correct

Reflectance

(5 sec)

Prevailing

Dew Point

Mirror Cools

and Coalesces

(30 sec)

Mirror Returns

To Dew Point

(60 sec)

To Dry State

(90 sec)

Before

PACER Cycle

After

PACER Cycle

1.6 The PACER Cycle

GE Measurement & Control has developed and patented a compensation technique called PACER (Programmable

Automatic Contaminant Error Reduction) that is very effective in reducing the Raoult Effect error associated with

soluble contaminants, particularly for near-ambient dew points. The Optica is equipped with the

AUTO balance as found on earlier models. The user can choose which self-cleaning and balancing routine to run

depending on the severity of the contamination.

PACER cycle, diagrammed in Figure 3 below, begins with a coalescence period, during which the mirror is cooled

The

well below the dew point of the sample gas, condensing out a large amount of water.

PACER cycle as well as

This excess water easily dissolves any water-soluble contaminants. The mirror is then heated. During the heating

phase, the large puddles of water gradually evaporate, carrying increasingly heavy concentrations of salts as the

puddles become smaller. Finally, when all the puddles have evaporated, dry “islands” of crystallized salt are left on the

mirror. The area between the islands (80-85% of the mirror surface) is now clean and shiny, whereas before the

cycle it may have been completely covered. The total amount of contamination has not been reduced, but instead,

redistributed as shown in Figure 4 below, with more clean mirror surface available for dew formation. The reflected

light signal is then electronically balanced against the reference.

Figure 3: A Typical PACER Cycle

PACER

Figure 4: Results of the PACER Cycle

6 Optica™ Operator’s Manual

Page 19

Chapter 2. Installation

Dimensions =

*Add .75” (19 mm)

6.5*

13.5

13

(330)

(343)

(165)

inches

(mm)

for Feet

Chapter 2. Installation

2.1 Introduction

This chapter explains the installation of the benchtop and wall-mount versions of the Optica, the various sensors used

with the system and the I/O and power wiring. To install your Optica, refer to the instructions and drawings for your

specific configuration:

• Benchtop - see “Benchtop Optica Installation” on page 7

• Wall-Mount - see “Wall-Mount Optica Installation” on page 12

WARNING! To ensure the safe operation of this unit, you must install and operate the Optica as

described in this manual. In addition, be sure to follow all applicable safety codes and regulations for

installing electrical equipment in your area.

2.2 Benchtop Optica Installation

2.2.1 Mounting the Benchtop Optica

The Optica benchtop dimensions are shown in Figure 5 below. Two feet on the bottom of the case can be unfolded to

raise up the front for easier viewing, if desired.

Figure 5: Optica Benchtop Dimensions

Optica™ Operator’s Manual 7

Page 20

Chapter 2. Installation

2.2.2 Using the Rack Mounting Option

There is an optional kit for mounting the benchtop unit in a standard 19-inch rack (see Figure 6 below, Figure 7 on

page 9, and Figure 8 on page 10). The two brackets are attached to the front panel using four #8 screws. The Optica is

mounted to the brackets using the eight mounting holes located just in front of and behind the unit’s feet.

Figure 6: Optica Rack-Mount Adapter

8 Optica™ Operator’s Manual

Page 21

2.2.2 Using the Rack Mounting Option (cont.)

1.32

(33.5)

1.11

(28.2)

6.52

(165.6)

2.69

(68.3)

3.91

(99.3)

19.00 (482.6)

14.62 (371.3)

12.53 (318.3)

0.50 (12.7)

2.19 (55.6)

1.32

(33.5)

2.88

(73.2)

2.38

(60.5)

8.75

(222.3)

4.00

(101.6)

3.00

(76.2)

2.74 (69.6)

3.23 (82.0)

18.25 (463.6)

13.53 (343.7)

7.07 (179.6)

0.59 (15.0)

0.09

(2.3)

FH-032-8

4 places

0.38

(9.7)

Note: Dimensions are in inches (millimeters).

Chapter 2. Installation

Optica™ Operator’s Manual 9

Figure 7: Optica Rack-Mount Adapter - Front Panel

Page 22

Chapter 2. Installation

Note: Dimensions are in inches (millimeters).

0.66 (16.8)

0.75 (19.1)

1.44

(36.6)

11.00 (279.4)

1.50

(38.1)

1.13 (28.7)

1.00 (25.4)

1.09 (27.7)

0.55 (14.0)

3.91

(99.3)

5.86

(148.8)

6.00

(152.4)

0.98 (24.9)

3.19 (81.0)

1.82

(46.2)

0.59 (15.0)

0.80 (20.3) 3.03 (77.0)

1.00 (25.4)

1.00 (25.4)

12.41 (315.2)

1.04

(26.4)

2.2.2 Using the Rack Mounting Option (cont.)

Figure 8: Optica Rack-Mount Adapter - Bracket

10 Optica™ Operator’s Manual

Page 23

Chapter 2. Installation

*Note: Depending on the model revision, the LAN connector is located in one of two places.

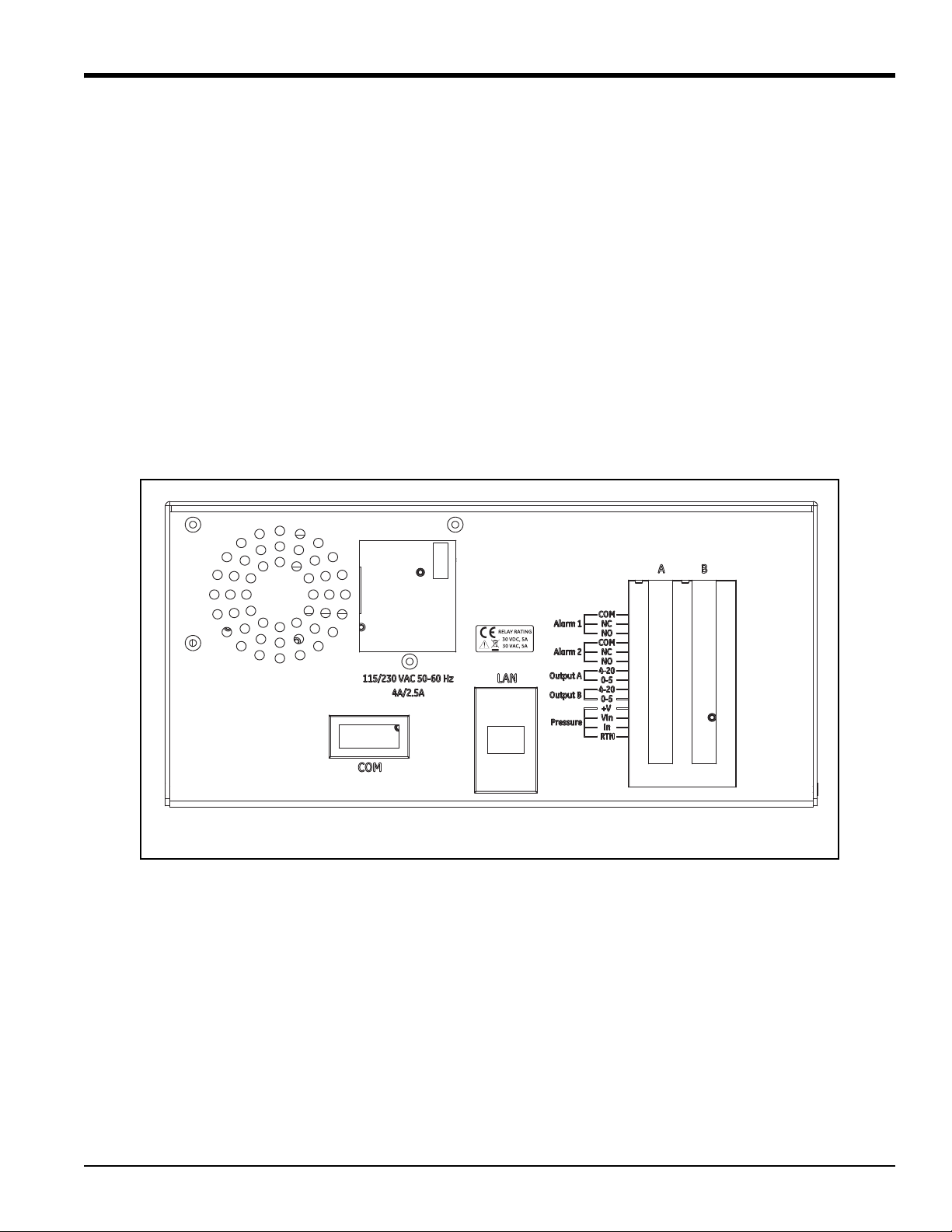

2.2.3 Wiring the Benchtop Optica

2.2.3a Input Power

The Optica operates with input power from 100 to 120 VAC at 4 amps, or from 200 to 240 VAC at 2.5 amps. It is

designed for a nominal 100, 115 or 230 VAC source. A switch on the rear panel selects the appropriate voltage range

(see Figure 9 below).

• The 115 VAC setting operates over a range of 100 to 120 VAC

• The 230 VAC setting operates over a range of 200 to 240 VAC

The Optica’s voltage and frequency rating are listed on the rear panel.

2.2.3b Sensors

Connect the dew point sensor cable to the 25-pin connector in Slot B on the Optica’s rear panel (see Figure 9 below).

Connect the optional temperature sensor cable to the 9-pin connector in

sensor and other I/O wiring connects to the terminal block in

Slot A.

Slot B on the rear panel. The optional pressure

Figure 9: Optica Benchtop Rear Panel

Optica™ Operator’s Manual 11

Page 24

Chapter 2. Installation

Dimensions =

6.5

13.7

(348)

(165)

inches

(mm)

16.725

(425)

Use the two mounting holes

to secure the enclosure to

the chosen wall, using 1/4”

fasteners of the appropriate

type for the wall material. Be

sure that the mounting holes

are located on a vertical line

on the wall.

below unit for cabling.

Allow adequate space

17.43"

(443 mm)

Ø.261 (6.63 mm)

2 places

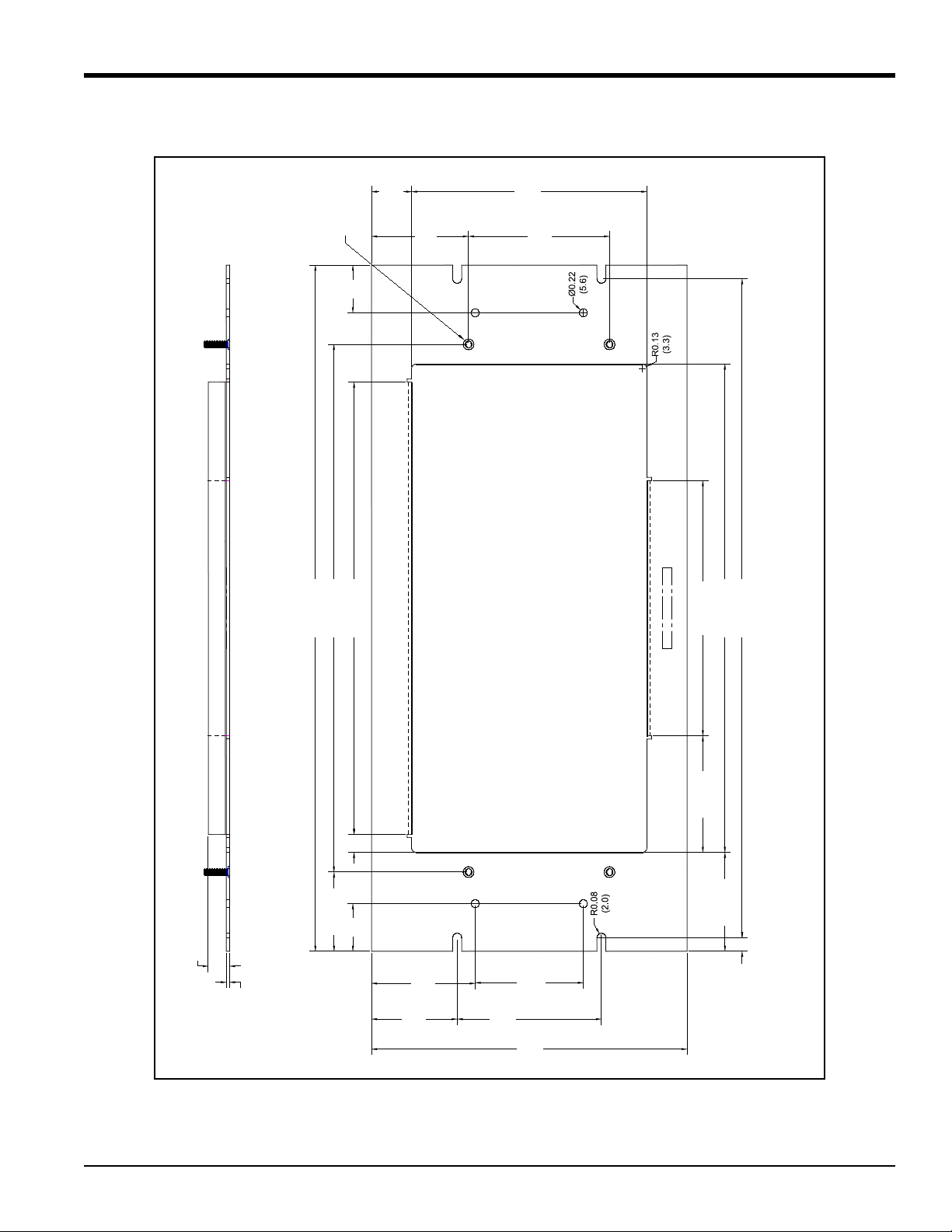

2.3 Wall-Mount Optica Installation

The Optica Wall-Mount unit is designed to mount on a flat, vertical surface, such as a wall or panel. To mount the

wall-mount version, see Figure 10 and Figure 11 below.

2.3.1 Mounting the Wall-Mount Optica

Figure 10: Optica Wall-Mount Unit Dimensions

Figure 11: Optica Wall-Mount Unit Mounting Hole Locations

12 Optica™ Operator’s Manual

Page 25

Chapter 2. Installation

I/O Terminal Blocks

Ethernet LAN Connector

I/O Cable Gland

Serial Port

Temperature Sensor

Dew Point Sensor

AC Wiring Terminal Blocks

AC Power Input Gland

DEW POINT

Gland for

I/O Wiring

INPUT

LAN

COM

Optional Ethernet

LAN Connector

Serial Port

Dew Point Sensor

Gland for

AC Power

Wiring

4 ASB 250V TYPE T

115/230 VAC 50-60 Hz

AC LINE

TEMP

Temperature Sensor

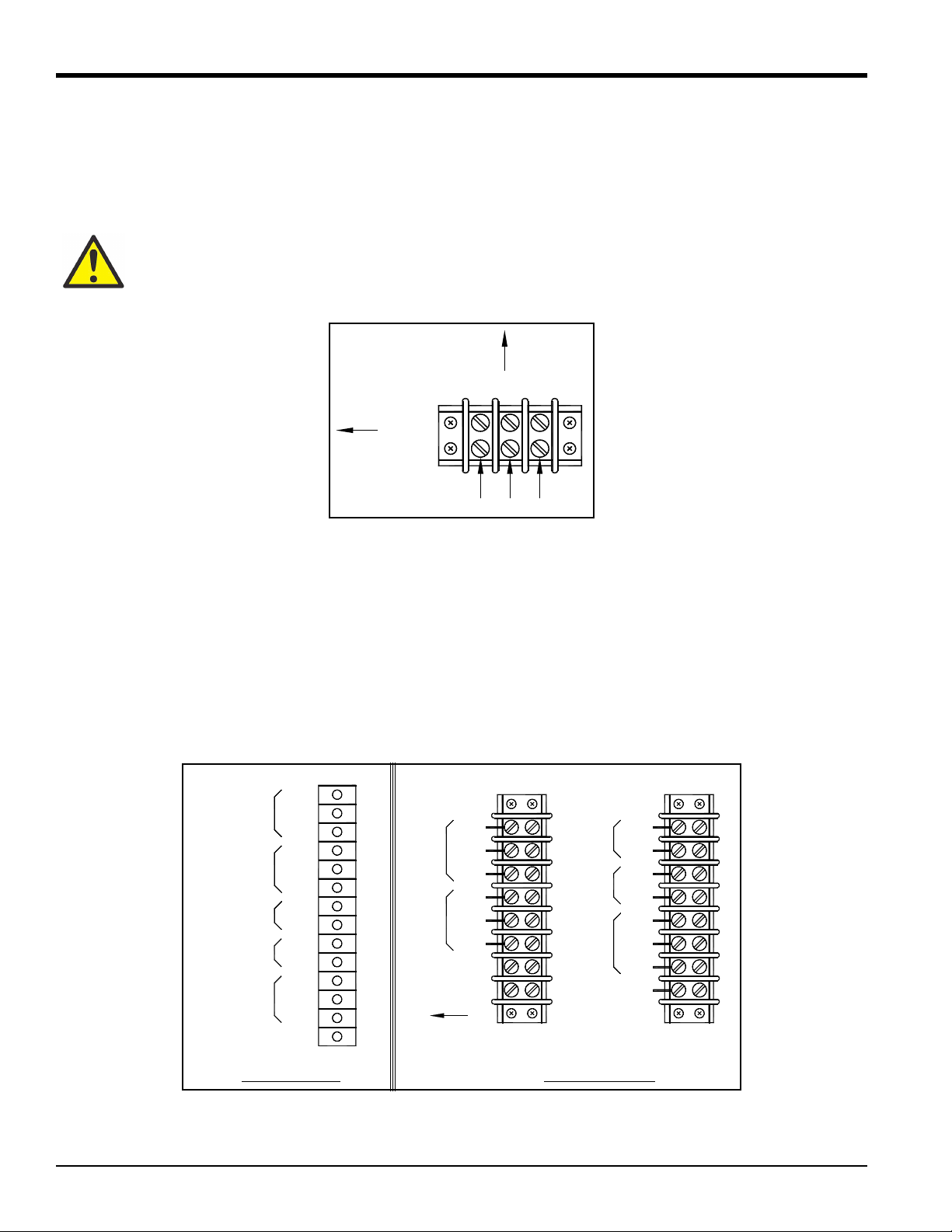

2.3.2 Wiring the Wall-Mount Optica

All connections to the wall-mount unit are made through the panel at the bottom of the case as shown in Figure 12 and

Figure 13below. Any I/O cabling is brought into the unit through a gland at the lower left of the case and connects to

the terminal blocks on the left side of the case. Wiring for these connections is shown in Figure 15 on page 14. The

dew point sensor and temperature sensor cable connectors are located near the center of this panel.

Optica™ Operator’s Manual 13

Figure 12: Wall-Mount Wiring Entrance Locations

Figure 13: Wall-Mount Bottom Panel (viewed from bottom of Case)

Page 26

Chapter 2. Installation

Front of Case

Top

L

Case

NG

of

AL2 NC

OUT A

0-5

PRESSURE

I in

Benchtop Unit

RTN

4-20

OUT B

0-5

V in

+V

Case

of

Front

NO

ALARM 1

ALARM 2

NC

COM

4-20

NC

NO

NO

COM

Slot A

COM

NO

COM

AL1 NC

+V

Wall-Mount Unit

PRES

I in

RTN

V in

Top

OUT B

OUT A

4-20

4-20

0-5

0-5

2.3.2a Input Power

Power wiring enters the case through a gland fitting at the lower right of the unit and connects to a screw terminal block

mounted on the right side of the case. Wiring of this terminal block is shown in Figure 14 below. The voltage and

frequency rating and tolerances, as well as fusing data, are listed on the bottom of the unit.

WARNING! There is a potential shock hazard at this location. Disconnect and lock out the main

power prior to any service procedures.

Figure 14: Wall-Mount AC Power Wiring

2.4 Output Wiring

The benchtop Optica outputs are connected to removable terminal blocks on the rear panel. Figure 9 on page 11 shows

the location of the benchtop unit terminal blocks and Figure 15 below shows the

The Wall-Mount Optica input/output terminal blocks are located inside the front door as shown in Figure 12 on

page 13. Cabling is brought in through the gland on the bottom of the unit and wired to the terminal blocks shown in

Figure 15 below.

Note: Output programming is described in Chapters 4, 5 and 6.

14 Optica™ Operator’s Manual

Figure 15: Benchtop and Wall-Mount Input/Output Terminal Blocks

Slot A connections.

Page 27

Chapter 2. Installation

V

out

T

actualTlower

–()

T

upperTlower

–()

----------------------------------------

5×=

23 0–()

100 0–()

---------------------

5× 1.15V=

I

out

mA()

T

actualTlower

–()

T

upperTlower

–()

----------------------------------------

20 4–()× 4+=

23 0–()

100 0–()

---------------------

16()× 4+ 7.68mA=

2.4.1 Analog Outputs

Note: When the Optica is being programmed, the analog outputs provide 4–20 mA and 0–5 VDC signals representing

the designated parameters.

• For 4–20mA output, connect to terminals labelled 4–20 (+) and RTN (–).

Note: The maximum load allowed for current output is 500 Ohms.

• For 0–5 VDC output, connect to terminals labelled 0–5 (+) and RTN (–).

Note: The maximum current allowed for voltage output is 5 mA.

Example:

Assume a temperature output, scaled to range from 0°C (T

of 23°C (T

actual

):

The voltage output is calculated by:

yielding an output voltage of 1.15V.

The current output is calculated by:

yielding an output current of 7.68 mA.

) to 100°C (T

lower

), with a measured actual temperature

upper

Optica™ Operator’s Manual 15

Page 28

Chapter 2. Installation

V

out

T

actualTlower

–()

T

upperTlower

–()

----------------------------------------

51–()× 1+=

23 0–()

100 0–()

---------------------

4× 1+ 1.92V=

2.4.1a Additional Voltage Outputs

It is possible to use either analog current output as an additional voltage output by connecting a precision resistor from

the current output to its return. A voltage will be produced equal to the output current times the load resistance. To

produce a voltage output range of 1 to 5 volts, connect a 250 ohm resistor (0.1% tolerance recommended).

Using a 250 ohm resistor, the voltage output is calculated by:

yielding an output voltage of 1.92V for this example.

2.4.2 Alarm Outputs

Each alarm output connects to the contacts of a 5-Amp, Form C (SPDT) relay.

Make connections as follows:

• For normally open contacts, connect to NO and COM.

• For normally closed contacts, connect to NC and COM.

Any available parameter can be used to control an alarm relay by programming the parameter name and its threshold

values. An alarm can also be programmed to monitor the state of the Control,

Chapter 4, 5 or 6 for programming instructions.

Both Upper and Lower threshold values are programmed for each parameter. These values designate an alarm band.

How they are used depends on the programmed alarm type. Details are shown in “Inner Band Alarm” on page 17 and

“Outer Band Alarm” on page 17.

PACER Balance, or Service indicators. See

16 Optica™ Operator’s Manual

Page 29

Chapter 2. Installation

UPPER edge of band

LOWER edge of band

Parameter

Alarm

Deactivated

Alarm

Deactivated

Alarm

Activated

“NC” Contacts

Closed

“NC” Contacts

Closed

Alarm

Activated

“NO” Contacts

Closed

“NO”

Closed

Contacts

“NO” Contacts

UPPER edge of band

LOWER edge of band

Parameter

Closed

Alarm

Deactivated

Alarm

Deactivated

Alarm

Activated

“NC” Contacts

Closed

“NC” Contacts

Closed

“NC” Contacts

UPPER edge of band

LOWER edge of band

Parameter

Closed

Alarm

Activated

Alarm

Activated

Alarm

Deactivated

“NO” Contacts

Closed

“NO” Contacts

Closed

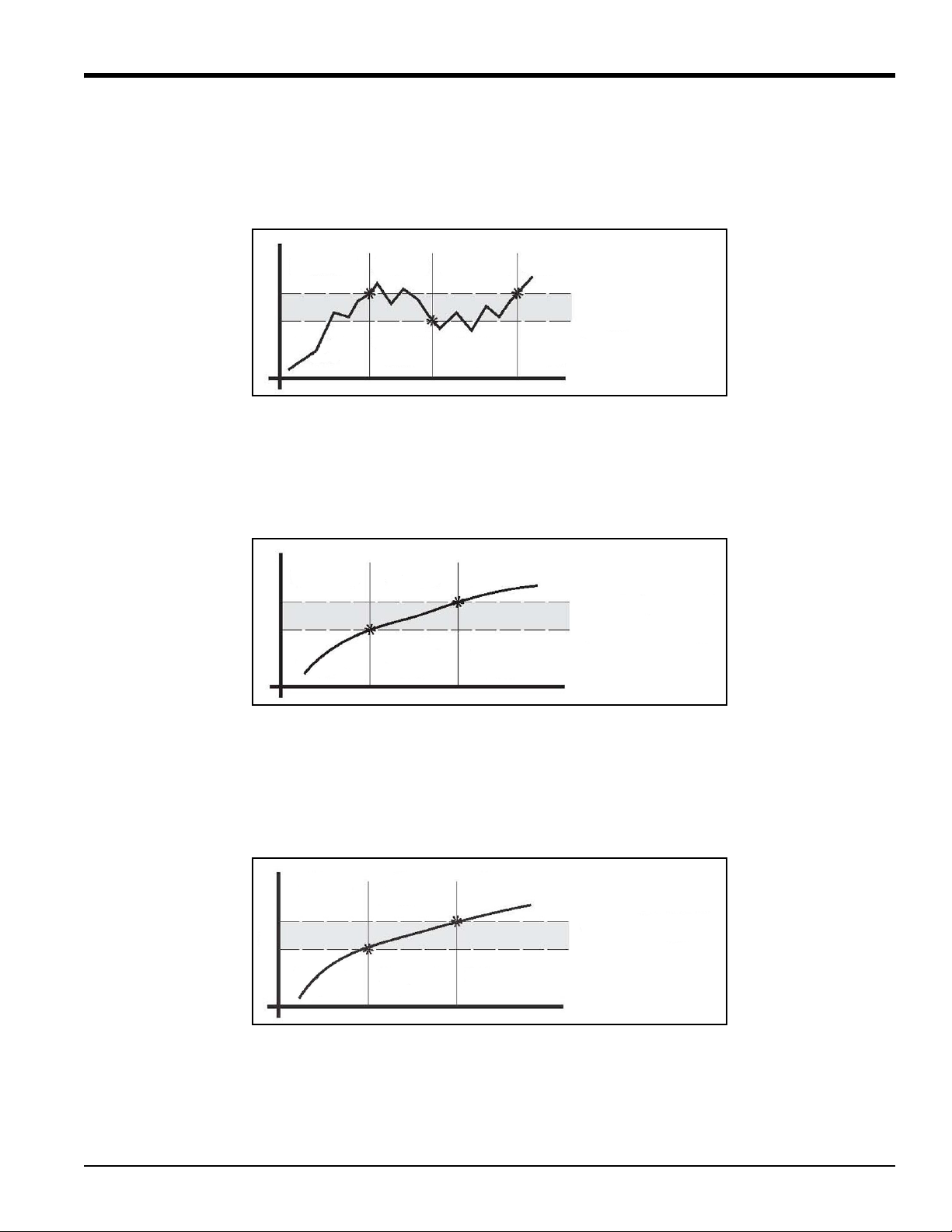

2.4.2a Set Point Alarm

For the Set Point alarm type, the alarm band provides hysteresis to prevent frequent operation of the alarm relay when

the parameter is near the specified value. The relay is

deactivated when the parameter goes below the lower limit.

activated when the parameter exceeds the upper limit, and

Figure 16: Set Point Alarm

2.4.2b Inner Band Alarm

For the Inner Band alarm type, the alarm relay activates whenever the parameter value is between the lower and upper

limits.

Figure 17: Inner Band Alarm

2.4.2c Outer Band Alarm

For the Outer Band alarm, the alarm relay activates whenever the parameter value is greater than the upper limit or

less than the lower limit.

Figure 18: Outer Band Alarm

Optica™ Operator’s Manual 17

Page 30

Chapter 2. Installation

2.4.3 Serial Output

The Serial Output connector is located at the lower left of the rear panel of the bench-mount unit, and the bottom panel

of the wall-mount unit. The output provides RS-232 serial communications between the unit and a terminal or a PC

running in terminal emulation mode.

The connector is a standard 9-pin D connector. For connection to another serial device, the cable is wired as shown in

Table 1 below. For a basic interface without handshaking, only pins 2, 3 and 5 (RX, TX and GND) on the Optica

connector are needed. Pin connections are given for both 25-pin and 9-pin devices.

Table 1: Serial Output Wiring Connections

Optica Connector 25-Pin Device 9-Pin Device

Pin Connection Pin Connection Pin Connection

2(RX)3(TX)3(TX)

3 (TX) 2 (RX) 2 (RX)

4 (DTE) 6 (DSR) 6 (DSR)

5 (GND) 7 (GND) 5 (GND)

6 (DSR) 20 (DTE) 4 (DTE)

7 (RTS) 4 (CTS) 8 (CTS)

8 (CTS) 5 (RTS) 7 (RTS)

The baud rate, format of the data, number of stop bits, number of data bits, and parity can all be programmed using the

menus.

18 Optica™ Operator’s Manual

Page 31

Chapter 2. Installation

2.5 Sensor Information

GE Measurement & Control produces a variety of sensors compatible with the Optica, ranging from one to five stages

of thermoelectric cooling. A comparison chart listing specifications of each sensor is given in Appendix D. “Chilled

Mirror Sensors“. The following sections provide information on installing the following GE dew point sensors:

• Model 1111H — Single-stage sensor

• Model 1211H — Two-stage sensor; for high pressure and temp.

• Model D-2 — Two-stage sensor

• Model SIM-12H — Two-stage heated sensor

• Model 1311DR — Four-stage heated sensor

• Model 1311XR — Five-stage water-cooled sensor

When selecting a location for installing a sensor, consider the following criteria:

• Locate the sensor as close as is practical to the source of the gas to be measured, to keep the sampling lines as

short as possible. This minimizes the system response time and reduces the error rate at low frost points due to

sample line outgassing.

• Choose a sensor location that provides access to the dewpoint sample cavity cover, to facilitate periodic mirror

cleaning.

CAUTION! Never place the sensor in a location where temperatures rise above the maximum rated

temperature for the device. See Appendix D. “Chilled Mirror Sensors“ for complete sensor

specifications.

2.5.1 Sampling Lines

Keep the length of sample tubing between the source and the sensor short, for quick response and highest accuracy. All

sampling line compression fittings provided with the sensor are for ¼-inch diameter tubing, unless otherwise specified

at the time of order. The material used for the inlet lines can have an important effect on the validity of the readings. Do

not use rubber hose or plastic tubing such as PVC or Tygon, because of their hygroscopic nature.

When measuring frost points below –30°C, sample gas leaving the sensor outlet should be vented through an additional

line three to six feet long, since backflow of ambient moisture into the sensor can take place even under positive

pressure. Use stainless steel tubing and fittings, and ensure that all plumbing is completely free from leaks.

At dew/frost points above –20°C, tubing material is not as critical. Copper, PTFE, polypropylene, aluminum or brass

tubing and fittings may be used. The sampling system should allow for periodic cleaning. It may be helpful to install a

tee and closing valve on the inlet side, to permit the sensor to be shut off while the sampling lines are flushed. At very

low humidities, even a trace amount of contamination can alter measured frost point, so cleanliness is particularly

important.

Optica™ Operator’s Manual 19

Page 32

Chapter 2. Installation

2.5.2 Ensuring Heat Transfer

Be sure the sensor has an adequate heat sink when operating in hot environments. The sensor must never be allowed to

reach a temperature above its rated limit. It is not sufficient merely to ensure that the sensor is in an environment whose

temperature is below the rated limit; a means must be supplied to remove heat from the sensor.

When the Model 1111H or D-2 sensors are used at ambient temperatures of 20° to 24°C, full rated depression can be

achieved by mounting the sensor on a smooth, thermally conductive surface (such as metal), which tends to remain at

the ambient temperature.

If possible, do not operate the sensor continuously at or near full depression. Doing so may decrease the anticipated life

of the thermoelectric heat pump.

2.5.3 High Dew Point Measurements

2.5.3a Using Heated Sensors

When measuring dew points at or above the ambient temperature, the sensor must be heated to a temperature of at least

5 to 10°C above the highest anticipated dew point (but not higher than the sensor temperature rating). Some sensors can

be mounted on a liquid heat exchanger, or a temperature-controlled electric hot plate, or installed in a heated enclosure.

GE recommends closed-loop active control of the elevated sensor body temperature.

The sensor base should be coated with zinc-oxide-filled silicone thermal grease and securely anchored to the heat sink

with suitable fasteners. Allow ½ hour for the sensor to reach thermal equilibrium after adjusting the temperature of the

heat sink.

The GE

SIM-12H high temperature sensor is designed for high-temperature applications. It measures dew points above

ambient temperature without condensation problems.

2.5.3b Sample Lines for High Dew Point Measurements

Sampling lines carrying gas to the sensor must be heated and insulated when the dew point of the gas is above the

sample line’s ambient temperature. The simplest way to achieve this is to use heater tape (either thermostatically

controlled, or continuously operating, and sized to provide the required temperature rise). At high temperatures, use

stainless steel tubing with adequate insulation to avoid hot and cold sections in the line and to avoid water absorption/

desorption cycling as the heater is thermostatically controlled. Heated sampling lines (HSL) are available from GE.

20 Optica™ Operator’s Manual

Page 33

Chapter 2. Installation

2.5.3c Filter Requirements

If the gas to be monitored is free from particulates and hydrocarbon liquids or vapor, filtering is not necessary.

However, most sample gas streams contain some particulates, and using a filter reduces the need for frequent mirror

cleaning. On the other hand, filtering tends to slow the system’s response, particularly at low frost points.

The Series 912 filters manufactured by Balston Company (or equivalent) are effective for most applications. For

particulates and liquid hydrocarbons, use a Balston Typ e DX filter element.

To filter out very fine particles, the Type DX filter can be followed by a Ty pe B X filter. A Type CI filter can be used to

remove hydrocarbon vapors.

If the sample gas is heavily and routinely contaminated, we recommend using a quick-change filter element. Avoid

using glass wool, cellulose, and other hygroscopic materials as a filter medium.

2.5.3d Flow Rate

It is important to have adequate flow through the sensor. Too little flow can slow the response (particularly at very low

frost points). Too much flow can cause instability of the control system at high dew points and can reduce the

depression capability of the thermoelectric cooler at very low dew points. Too much flow also accelerates the rate of

system contamination. A flow rate of 2 to 2.5 ft

cases, flow rates between 0.2 and 5 ft

3

/h (0.1 and 2.5 liter/min) may be used.

3

/h (a little over 1 liter/min) is ideal for most applications. In many

Optica™ Operator’s Manual 21

Page 34

Chapter 2. Installation

2.6 Sensor Installation

This section provides installation details for the GE Measurement & Control line of chilled-mirror humidity sensors.

2.6.1 Model 1111H Sensor

The Model 1111H is an open-type sensor (see Figure 19 below). It can be threaded into standard pipe fittings or

mounted in a type 0111D pressure boss, which encloses it and adapts it for ¼-inch compression fittings. When

installing the sensor in the pressure boss, remove the black aluminum sensor cover.

For maximum thermal conductivity, the base of the Model 0111D pressure boss should be coated with heat-conducting

grease. When so installed on a surface suitable for dissipating heat, the sensor will achieve its maximum rated

depression. See the Chilled Mirror Sensor Comparison Chart in Appendix D. “Chilled Mirror Sensors“.

Figure 19: Model 1111H Sensor

2.6.2 Model D-2 Sensor

The Model D-2 is a general purpose, two-stage sensor with 65°C (117°F) of depression capability. It features wetted

parts of stainless steel and glass, for durability in demanding industrial applications. The Model D-2 can be used as a

benchtop sensor, mounted to a heat sink, or mounted to a cooling fan for maximum operating range. Advanced features

include field-replaceable optics and cooler assemblies, and auxiliary visible light optics with a viewing window for

inspecting the mirror during operation (see Figure 20 below).

For maximum thermal conductivity, the base of the Model D-2 sensor should be coated with heat-conducting grease.

When so installed on a surface suitable for dissipating heat, the sensor will achieve its maximum rated depression. See

the Chilled Mirror Sensor Comparison Chart in Appendix D. “Chilled Mirror Sensors“.

Figure 20: Model D-2 Sensor

22 Optica™ Operator’s Manual

Page 35

Chapter 2. Installation

2.6.3 Model 1211H Sensor

The Model 1211H is a two-stage sensor with 65°C (117°F) of depression capability. It features wetted parts of stainless

steel and may be used at higher temperature and pressure than the D2 sensor. The Model 1211H can be used as a

benchtop sensor, mounted to a heat sink. Features include a field-replaceable mirror, optics and cooler assembly. See

the Chilled Mirror Sensor Comparison Chart in Appendix D. “Chilled Mirror Sensors“.

2.6.4 Model 1311DR Sensor

The 1311DR is a stainless steel, liquid cooled, four-stage sensor suitable for measuring dew points between

–75°C and +25°C.

Mount the 1311DR sensor so that the air inlet and exhaust openings are free from obstruction (see Figure 21 below). If

the sensor is liquid cooled, vertical wall mounting is recommended, observing the “UP” arrow on the case. This

ensures that condensation forming on cold portions of the 1311DR will drain from the enclosure.

At room temperatures (25°C) with air cooling, dew points from –65°C to +25°C can be measured. When operating it

without liquid cooling, switch on the built-in fan. For lower frost point measurements, a chilled-water coolant loop can

be used for cooling. Make sure the fan switch is off when using liquid cooling.

Sample flow rates from 0.5 to 5 SCFH (0.25 to 2.5 L/min) should be used.

CAUTION! If it can be avoided, do not operate the sensor continuously at or near full depression.

Doing so may decrease the life of the thermoelectric heat pump.

Liquid cooling is required for measuring frost points below –65°C (at 25°C ambient), and may be used to create faster

response at higher dew point temperatures. If a recirculating chiller is used, it should have a capacity of at least

300 watts at the coolant temperature. Switch the internal fan ON if air cooling is used; leave it OFF for liquid cooling.

Install the gas sampling lines according to the instructions listed in “Sampling Lines” on page 19.

Figure 21: Model 1311DR Sensor

Optica™ Operator’s Manual 23

Page 36

Chapter 2. Installation

2.6.5 Model 1311XR Sensor

The 1311XR is a stainless steel, water cooled, five-stage sensor (see Figure 22 below) that can measure frost points as

low as –80°C. The sample gas flow rate should be between 1 and 5 ft

3

/h. The maximum permissible coolant

temperature is +50°C; the minimum is –10°C. A minimum coolant flow rate of 0.1 gallons per minute must be

maintained for most dew point measurements. If the fourth stage power supply control is set below –65°C, the

minimum coolant flow rate is 0.25 gal/min. The coolant temperature affects the maximum dew/frost point depression.

For frost points of –80°C, coolant temperature should be below 20°C.

Figure 22: Model 1311XR Sensor

2.6.5a Electrical Connections

All the electrical connectors on the Model 1311XR dew/frost point sensor are unique. The cables supplied with the

sensor can only interconnect the system in one way. Connect the cables as follows:

1. Plug the instrument into a 115/230 VAC power outlet.

2. Connect the 37-pin round black connector on the back of the instrument to the 19-pin military-style connector

on the back of the 1311XR sensor.

3. Connect the 17-pin military style connector on the back of the 1311XR sensor to the 24-pin round connector on

the back of the heat pump controller module.

4. Connect the 9-pin round connector on the back of the heat pump controller module to the 8-pin rectangular

connector on the back of the fourth stage heat pump power supply.

5. Plug the heat pump power supply into a 115/230 VAC outlet.

2.6.5b Coolant

Connect the two 3/8-inch brass compression fittings on the back of the 1311XR sensor to the coolant lines. Do not run

the instrument without sufficient coolant flow.

Suitable coolants include water, glycol and other noncorrosive liquids. The coolant can be recirculated liquid or tap

water that is cooled or chilled. If a recirculating chiller is used, it should have a capacity of at least 600 watts at the

coolant temperature.

2.6.5c Sample Gas Fittings

The 1311XR sensor has 1/4” stainless steel compression fittings for sample gas inlet and outlet at the back of the sensor

chassis.

24 Optica™ Operator’s Manual

Page 37

Chapter 2. Installation

2.6.5d Heat Pump Controller Settings

The 1311XR’s heat pump controller module has the following settings:

Table 2: Model 1311XR Heat Pump Controller Settings

Setting Function

AUTO When set to AUTO, the system operates fully automatically, controlling the heat pump in

response to any dew/frost point within its operating range. In AUTO mode, the controller

senses the current supplied by the Optica to the top two stages of the thermoelectric

coolers. The controller switches on the fourth stage power supply, as required to

maintain the mirror temperature at the dew/frost point.

The AUTO setting is recommended for most applications.

Below –55°C If the frost point is known to be below –55°C, the switch can be set to this position to

provide slightly faster response than the AUTO setting. However, depression is limited at

this setting. If frost points approaching –80°C are to be measured, use the AUTO setting.

–65°C to –10°C If the dew/frost point is known to be between –65°C and –10°C, the switch can be set to

this position to reduce overshoot and settling time.

Above –25°C If the dew/frost point is known to be above –25°C, the switch can be set to this position to

reduce overshoot and settling time.

Note: The third-stage power indicator may blink in any setting. This is normal.

2.6.5e Fourth-Stage Power Supply Control Knob

The control knob on the 1311XR’s fourth-stage power supply sets the power consumption limit and the coolant

requirement when measuring dew/frost points using the

AUTO or BELOW –55°C settings. Set this knob to the lowest

anticipated dew/frost point.

If the control is set lower than necessary, the system dissipates excess power and requires additional cooling to remove

the extra heat generated. If the setting is too high, the system may not be able to reach the true dew/frost point.

To allow the 1311XR sensor to act as a turnkey system (whereby it will cover its entire range automatically), set the

switch to

AUTO and the power supply control knob to the –80°C position.

2.6.5f Heat Pump Controller Error Indicators

The heat pump controller module has two overheat indicators connected to thermal shutdown switches. If either

indicator comes on, check for and correct any problems before continuing operation. Check the cable connections,

coolant flow and coolant temperature.

2.6.5g Purging the Sensor

CAUTION! The 1311XR must be purged after each use, either with the sample gas after measuring

it, or with another dry gas source. Otherwise, condensation inside the sensor housing may cause

corrosion and eventual failure of the thermoelectric coolers.

For extremely dry gas measurements, the 1311XR sensor enclosure must be purged with a gas having a frost point

lower than –20°C. For intermediate temperatures, any gas having a frost point at least as low as the sample gas can be

used.The sample gas outflow from the sensor can be used for this purpose, if it is suitable (non-explosive, non-lethal,

etc.). Introduce the purge gas to the enclosure via the purge fitting on the rear of the sensor. The simplest method for

purging is to run the sample gas outflow through the U-tube supplied with the sensor.

Optica™ Operator’s Manual 25

Page 38

Chapter 2. Installation

2.6.6 Model SIM-12H Heated Sensor and Components

The SIM-12H heated sensor module is suitable for measuring dew/frost points between –10°C and +85°C. It contains

precision heating, as well as cooling, capability. Three separate heaters are located in the sensor walls, 120 degrees

apart. Three temperature sensors measure the body temperature at those points, and three control circuits precisely

adjust the temperature of each heater. Any detected temperature gradient across the sensor cavity is immediately

eliminated, resulting in very even control. All three heaters are controlled by the temperature set by the front panel

selector knob. The sensor is a two-stage unit, providing 65°C of depression capability, and 60°C actual measurement

range.

2.6.6a Type SIM-HFT Heated Filter Module

The SIM-HFT heated filter module allows the sample gas to be purged of particulate contaminants prior to entering the

sensor. The incoming gas is first passed through a 90-micron prefilter, then a 15-micron final filter. All parts in contact

with the sample are heated to a constant 105°C, eliminating any possibility of condensation. The sintered filters are

easily removed for cleaning or replacing if required.

2.6.6b Type SIM-HFM Heated Flow Meter

The SIM-HFM heated flow meter module allows the sample gas flow rate to be both measured and controlled at a rate

that is optimum for the sensor. A metering valve mounted on the front panel allows control over a range of 0 to 2 ft

All parts in contact with the sample gas are heated to a constant 105°C, so that no condensation occurs. The flow meter

is normally mounted downstream from the heated sensor.

3

/h.

2.6.6c Type SIM-HSL Heated Sampling Line

The SIM-HSL heated sampling line is self-regulated at a temperature high enough to ensure that no condensation

occurs. The line is made of ¼-inch outside diameter PTFE, with stainless steel fittings.

2.6.6d Type SIM-MPL Mounting Plate

The SIM-MPL mounting plate is designed to accept one, two or three heated modules: the heated sensor, the heated

filter, and the heated flow meter. The mounting plate provides a convenient method of wall-mounting the entire heated

sampling system. When ordered with one or more modules, the factory performs all mounting, plumbing and wiring

work, thus providing a complete system ready for installation.

2.6.7 Connecting the Sensors

Dew point, temperature and pressure sensors provided by GE for the Optica monitor are pre-wired with connectors

installed. Plug these connectors into their corresponding sockets as shown in Figure 9 on page 11 for the benchtop unit,

or Figure 12 on page 13 for the wall-mount unit.

26 Optica™ Operator’s Manual

Page 39

Chapter 3. Operation

Chapter 3. Operation

3.1 Introduction

Operating instructions fall into three categories:

• Normal Operation - Using the unit’s controls.

• Setup and Programming - Customizing the unit for specialized applications (not required for many

conventional applications).

Note: The unit is shipped pre-programmed to meet typical requirements. The factory default settings are listed in

Table 4 on page 35. Complete programming instructions are given in Chapters 4, 5, and 6.

• Maintenance - Manually testing the unit’s cooling capacity, cleaning the mirror, and other operations that might

be required on a regular basis, or when a problem is suspected, depending on the application. Details are given

in Chapter 7. “Maintenance“.

3.2 Normal Operation

Normal operation of the Optica is very simple. To turn the unit on, check that the main power switch on the rear of the