GE Masoneilan 4700P, Masoneilan 4800P, Masoneilan 4800E, Masoneilan 4700E Maintenance Manual

GE Oil & Gas

Masoneilan*

4700P/4700E & 4800P/4800E

Pneumatic and Electropneumatic Positioners

Maintenance Manual (Rev. C)

GE Data Classification: Public

© 2015 General Electric Company. All rights reserved.

2 | =GE Oil & Gas

About this Guide

The information in this manual is subject to change without prior notice.

The information contained in this manual, in whole or part, shall not be transcribed or

copied without GE Oil & Gas’ written permission.

In no case does this manual guarantee the merchantability of the positioner or the

software or its adaptability to a specific client needs.

Please report any errors or questions about the information in this manual to your

local supplier or visit www.geoilandgas.com/valves.

Disclaimer

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT

PROJECT-SPECIFIC REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/

OPERATOR'S NORMAL OPERATION AND MAINTENANCE PROCEDURES. SINCE

OPERATION AND MAINTENANCE PHILOSOPHIES VARY, GE (GENERAL ELECTRIC

COMPANY AND ITS SUBSIDIARIES AND AFFILIATES) DOES NOT ATTEMPT TO DICTATE

SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND REQUIREMENTS

CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL

UNDERSTANDING OF THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL

AND ELECTRICAL EQUIPMENT IN POTENTIALLY HAZARDOUS ENVIRONMENTS.

THEREFORE, THESE INSTRUCTIONS SHOULD BE INTERPRETED AND APPLIED IN

CONJUNCTION WITH THE SAFETY RULES AND REGULATIONS APPLICABLE AT THE

SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER EQUIPMENT

AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN

EQUIPMENT NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE MET IN

CONNECTION WITH INSTALLATION, OPERATION OR MAINTENANCE. SHOULD

FURTHER INFORMATION BE DESIRED OR SHOULD PARTICULAR PROBLEMS ARISE

WHICH ARE NOT COVERED SUFFICIENTLY FOR THE CUSTOMER/OPERATOR'S

PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR

ARE STRICTLY LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT

RELATING TO THE SUPPLY OF THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS

OR WARRANTIES BY GE REGARDING THE EQUIPMENT OR ITS USE ARE GIVEN OR

IMPLIED BY THE ISSUE OF THESE INSTRUCTIONS.

THESE INSTRUCTIONS ARE FURNISHED TO THE CUSTOMER/OPERATOR SOLELY TO

ASSIST IN THE INSTALLATION, TESTING, OPERATION, AND/OR MAINTENANCE OF

THE EQUIPMENT DESCRIBED. THIS DOCUMENT SHALL NOT BE REPRODUCED IN

WHOLE OR IN PART WITHOUT THE WRITTEN APPROVAL OF GE.

© 2015 General Electric Company. All rights reserved.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 3

Copyright

The complete design and manufacture is the intellectual property of GE Oil & Gas. All

information contained herein is believed to be accurate at the time of publication and

is subject to change without notice. All other trademarks and copyrights are

properties of their respective corporations.

Copyright 2015 by GE Oil & Gas. All rights reserved. PN 720014889-888- 0000 Rev. C

Document Changes

Version/Date Changes

B/08-2014 Added paragraph to first page of Calibration section about post-ship-

ment calibration.

C/04-2015 Added Disclaimer paragraph

and a new Figure 15.

This page intentionally left blank.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 5

© 2015 General Electric Company. All rights reserved

.

Safety Information .................................................................................... 11

Safety Symbols............................................................................................................................................. 11

4700P/4700E and 4800P/4800E Product Safety ......................................................................... 12

Introduction .............................................................................................. 15

General Description and Operation ................................................................................................... 15

Pilot ................................................................................................................................................................... 16

Direct Action ................................................................................................................................................. 16

Reverse Action ............................................................................................................................................. 16

Cam .................................................................................................................................................................. 16

Optional bypass valve (4700P, Direct Acting Model only) ........................................................ 16

Installation ................................................................................................ 19

Mounting and Orientation ..................................................................................................................... 19

Cover Removal............................................................................................................................................. 20

87/88 Actuator............................................................................................................................................. 22

Mounting 4700P and 4700E on Series 87/88 Actuators ......................................................... 24

87U/88U Actuator....................................................................................................................................... 26

Mounting 4700P/4800P and 4700E/4800E on Series 87U/88U Actuators ..................... 26

Positioner Mounting and Orientation ................................................................................................ 28

Camflex II, Varimax, MiniTork II, Ball II, and HPBV ....................................................................... 28

Pneumatic Installation.............................................................................................................................. 31

Electrical Installation of 4700E/4800E .............................................................................................. 34

Hazardous Area Installations................................................................................................................ 35

Factory Mutual Approved Version ..................................................................................................... 36

CSA (Canadian Standards Association) Approved Version ................................................... 37

SIRA Approved Version ............................................................................................................................ 38

Split Range Operation............................................................................................................................... 43

Mounting Cam Coupling.......................................................................................................................... 44

Mounting Cam ............................................................................................................................................. 44

Lever S/A Orientation ............................................................................................................................... 44

Changing Lever S/A Orientation ......................................................................................................... 45

Calibration ................................................................................................. 47

General ............................................................................................................................................................ 47

Zero Adjustment.......................................................................................................................................... 48

Span Adjustment......................................................................................................................................... 48

Cam Lobe Change...................................................................................................................................... 49

Air to Open / Direct Acting Positioner ............................................................................................... 49

Air to Open / Reverse Acting Positioner .......................................................................................... 49

Contents

© 2015 General Electric Company. All rights reserved.

6 | =GE Oil & Gas

Air to Close / Direct Acting Positioner ............................................................................................... 50

Air to Close / Reverse Acting Positioner ........................................................................................... 50

Field Mounting and Complete Calibration, Rotary Actuators................................................. 51

Air to Open / Direct Acting Positioner ...............................................................................................51

Air to Open / Reverse Acting Positioner ........................................................................................... 51

Air to Close / Direct Acting Positioner ............................................................................................... 52

Air to Close / Reverse Acting Positioner ........................................................................................... 53

Field Mounting and Complete Calibration Reciprocating Valves using 87/88 .............. 54

Air to Open / Direct Acting Positioner ...............................................................................................54

Air to Open / Reverse Acting Positioner (4700P/4800P only) .................................................54

Air to Close / Direct Acting Positioner ............................................................................................... 55

Air to Close/Reverse Acting Positioner (4700P/4800P only) ................................................... 56

Damping Adjustment ...............................................................................................................................56

Positioner Action Change (4700P/4800P Only) ............................................................................. 57

From Air to Open / Direct to Air to Open/Reverse ...................................................................... 57

From Air to Open / Reverse to Air to Open/Direct ......................................................................57

From Air to Close / Direct to Air to Close/Reverse ......................................................................57

From Air to Close / Reverse to Air to Close/Direct ...................................................................... 57

Maintenance.................................................................................................................................................. 58

Pilot .................................................................................................................................................................... 58

Disassembly .................................................................................................................................................. 58

Reassembly ................................................................................................................................................... 58

Body................................................................................................................................................................... 59

Disassembly .................................................................................................................................................. 59

Reassembly ................................................................................................................................................... 60

Diaphragm .................................................................................................................................................... 60

I/P Module ...................................................................................................................................................... 60

Bypass Valve Option (4700P Only).......................................................................................................61

Assembly to Positioner ............................................................................................................................ 61

Disassembly .................................................................................................................................................. 62

Troubleshooting........................................................................................................................................... 63

Split Range Operation - 4700P/4800P ..............................................................................................64

Cam Lobe Selection and Lever Arm Orientation.......................................................................... 65

Parts Reference 4700P/4800P 3-15 and 6-30 Range................................................................ 68

Parts Reference 4700E/4800E .............................................................................................................. 71

Parts Reference............................................................................................................................................ 73

Specification Data....................................................................................................................................... 75

Specifications ............................................................................................ 75

Drawings .................................................................................................... 77

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 7

© 2015 General Electric Company. All rights reserved

.

Figures

1 Model 4700P/4700E and 4800P/4800E Positioner Numbering ..........15

2 Cover Removal............................................................................................................20

3 Rotary..............................................................................................................................21

4 Reciprocating .............................................................................................................21

5 87/88 Actuator............................................................................................................23

6 87/88 Actuator: Bracket Mounting Travel Settings....................................25

7 87U/88U Actuator .....................................................................................................27

8 Camflex II and Varimax...........................................................................................29

9 Ball II and MiniTork II.................................................................................................29

10 High Performance Butterfly Valve .....................................................................30

11 Pneumatic Installation.............................................................................................33

12 Electrical Connections .............................................................................................35

13 FM Installation.............................................................................................................40

14 CSA Installation...........................................................................................................41

15 ATEX Installation.........................................................................................................42

16 Split Range ....................................................................................................................43

17 Lobe Identification.....................................................................................................44

18 Pilot Subassembly......................................................................................................62

19 4700P/4800P 3-15 and 6-30 Ranges...............................................................68

20 4700E/4800E................................................................................................................71

21 Bypass Option (4700 Only).....................................................................................74

22 Positioner and Cast Body Assembly .................................................................77

This page intentionally left blank.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 9

© 2015 General Electric Company. All rights reserved

.

Tables

1 Mounting Parts Reference 87/88 .................................................................. 22

2 Mounting Parts Reference 87U/88U............................................................ 26

3 Mounting Parts Reference................................................................................ 28

4 Split Range Operation......................................................................................... 64

5 Parts Reference 4700P/4800P 3-15 and 6-30 Range ......................... 69

6 Parts Reference 4700E/4800E........................................................................ 72

7 Specification Data................................................................................................ 75

This page intentionally left blank.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 11

© 2015 General Electric Company. All rights reserved

.

This section provides safety information and defines the documentation safety symbols.

Read this entire section befor

e installation and operation.

Safety Symbols

4700/4800 instructions contain WARNINGS, CAUTIONS labels and Notes, where necessary, to

alert you to safety related or other important information. Total compliance with all WARNING,

and CAUTION notices is required for safe operation.

Indicates a potentially hazardous situation, which if not avoided

could result in serious injury or death.

CAUTION

WARNING

Safety Information

© 2015 General Electric Company. All rights reserved.

12 | =GE Oil & Gas

4700P/4700E and 4800P/4800E Product Safety

The 4700/4800 are intended for use with industrial compressed air or, natural gas systems only.

NOTE Installations using natural gas are Zone 0 or Div 1 installations.

Ensure that an adequate pressure relief provision is installed when the application of system

supply pressure could cause peripheral equipment to malfunction. Installation must be in accordance with local and national compressed air and instrumentation codes.

General installation, maintenance or replacement

Products must be installed in compliance with all local and national codes

and standards by qualified personnel using safe site work practices.

Personal Protective Equipment (PPE) must be used per safe site work

practices.

Ensure proper use of fall protection when working at heights, per safe site

work practices. Use appropriate safety equipment and practices to prevent

the dropping of tools or equipment during installation.

All surrounding pipe lines must be thoroughly flushed to ensure all entrained

debris has been removed from the system.

Indicates a situation, which if not avoided could result in property or data damage.

Indicates important facts and conditions.

CAUTION

NOTE

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 13

© 2015 General Electric Company. All rights reserved

.

Hazardous Area Installation

Products certified as explosion proof or flame proof equipment or for use in intrinsically safe installations MUST BE:

Installed, put into service, used and maintained in compliance with national

and local regulations and in accordance with the recommendations

contained in the relevant standards concerning potentially explosive

atmospheres.

Used only in situations that comply with the certification conditions shown in

this document and after verification of their compatibility with the zone of

intended use and the permitted maximum ambient temperature.

Installed, put into service and maintained by qualified and competent

professionals who have undergone suitable training for instrumentation

used in areas with potentially explosive atmospheres.

WARNING Before using these products with fluids/compressed gases other

than air or for non-industrial applications, consult the factory or

local representative. This product is not intended for use in life

support systems.

WARNING Under certain operating conditions, the use of damaged

instruments could cause a degradation of the performance of the

system, which can lead to personal injury or death.

Installation in poorly ventilated confined areas, with any potential

of gases other than oxygen being present, can lead to a risk of

personnel asphyxiation.

Use only genuine replacement parts which are provided by the manufacturer, to guarantee that

the products comply with the essential safety requirements of the European Directives.

Changes to specifications, structure, and components used may not lead to the revision of this

manual unless such changes affect the function and performance of the product.

This page intentionally left blank.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 15

© 2015 General Electric Company. All rights reserved

.

General Description and Operation

The 4700P/4700E and 4800P/4800E positioners function to make a valve stroke proportional to

a pneumatic or electrical control signal from a controller, or to modify the natural flow characteristic of the valve itself through the use of a characterized cam. They can be configured to provide split-ranging of valves and may be used with supplemental air supplies to achieve greater

valve pressure drop. The 4700P/4800P pneumatic positioner can also be configured to reverse

valve response to a control signal (i.e. control signal can either open or close valve). The 4700E/

4800E electropneumatic positioner is not available with reverse action.

The Model 4700P/4700E and 4800P/4800E pneumatic positioner design is based on the

force-balance principle: the signal pressure exerted on a diaphragm is opposed by a feedback

spring. In the balanced state, when the pneumatic signal varies, the diaphragm assembly moves.

This movement is followed by the pilot plug which is opposed by the pilot spring.

Movement of the pilot plug alternately connects the output circuit to the supply circuit or the exhaust port, thus modifying air pressure to the actuator. The cam transmits valve plug movement

to the feedback spring. The valve plug continues to move until the spring force exactly balances

the force of the instrument signal on the diaphragm. In the new balanced state, the valve plug is

positioned in a programmed relationship to the instrument signal.

Figure 1 Model 4700P/4700E and 4800P/4800E Positioner Numbering System

Introduction

© 2015 General Electric Company. All rights reserved.

16 | =GE Oil & Gas

Pilot

The pilot is essentially a three-way sliding valve. The plug regulates supply air flow to and from

the actuator to the exhaust port. The position of this plug, governed by the diaphragm, determines the output pressure of the positioner. The 4700P/4800P pneumatic positioner action may

be reversed by interchanging the supply and exhaust connections and changing cam lobe and

lever arm orientation.

Direct Action

Increasing instrument signal pressure produces an increase in output pressure.

Reverse Action

Increasing instrument signal pressure produces a decrease in output pressure.

Cam

The cam is the intermediate element in the feedback mechanism between the actuator and the

feedback spring. Its profile determines the relationship between the valve plug position and the

control signal. Linear, Split Linear, or Percentage Control characteristics are available by selection

of proper lobe on cams supplied for Camflex II, Varimax, 87/88, and 87U/88U, actuators. Cams

supplied on Ball and Butterfly valves maintain the inherent valve characteristic. Custom characteristics are available on special order.

Optional bypass valve (4700P, Direct Acting Model only)

During normal operation, the instrument signal is applied directly to the positioner diaphragm

and the regulated supply pressure flows through the pilot valve to or from the actuator.

The bypass valve module permits the positioner to be isolated for maintenance while operating

the valve directly with the instrument signal. By turning the nylon bypass valve to the bypass position (the raised arrow on the bypass valve aligned with the word Bypass on the face positioner

body indicates this position), the normal positioner output pressure to the actuator is blocked

and the instrument signal is applied both to the positioner diaphragm and the actuator. The bypass valve does not block supply pressure to the pilot. Therefore, the supply line should be shut

off before disassembling the positioner.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 17

© 2015 General Electric Company. All rights reserved

.

WARNING When a valve (because of high pressure drop) uses a supply

pressure higher than 20 psig, the 3-15 psig instrument signal may

not be sufficient to operate the valve when the positioner is

bypassed. Moreover, if the positioner with a high supply pressure

is bypassed suddenly, the high pressure in the actuator may

damage the diaphragm and/or the control instrument. Therefore,

the bypass valve should be used only if the positioner supply

pressure is 20 psig (140 kPa or 1, 4 bar), or at most 35 psig (240

kPa, or 2, 4 bar), or if the controller is capable of operating the

valve directly. When bypassing a positioner, ensure that the

controller output is equal to supply required to operate valve.

This page intentionally left blank.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 19

© 2015 General Electric Company. All rights reserved

.

Mounting and Orientation

The valve is installed in the pipeline to operate in one of two ways:

Air to Open Air to Close

Close on air failure Open on air failure

(Reverse Action) (Direct Action)

The choice depends on the desired air failure action. This subject is dealt with in separate actuator instructions. The positioner can operate either by direct action (increasing instrument signal

produces an increase in output pressure) or reverse action (increasing instrument signal produces a decrease in output pressure). See Figure 3 and Figure 4.

The 4700E/4800E is not available w

ith reverse action, hence

if the application demands reverse action, a 4700P/4800P

with an external I/P Transducer is required.

NOTE

Installation

When installing a positioner on a valve, it is necessary to

choose the proper valve action and positioner action. It is

absolutely necessary to place valve travel at the point

corresponding to the low end of the signal range when

removing or installing a cam. At this point, feedback spring

compression is at lowest value and will facilitate cam

removal or installation. Prior to performing any work, read

and understand “General Description and Operation” on

page 15 and “Mounting and Orientation” on page 19. Define

the scope of work to be performed and find the appropriate

s

ection that should be followed.

© 2015 General Electric Company. All rights reserved.

20 | =GE Oil & Gas

The 4700 series positioners have the same mounting and link-age attachment dimensions as

the 4600, 4600A, 4600B and 4700B series positioners but have a different layout of pneumatic

connections. They can replace the older models if operational requirements are identical and

pneumatic connections are changed. The mounting details in this instruction cover only the

more widely used valves and actuators.

Cover Removal

The snap-on cover must be removed to access the zero and span adjustments and to mount the

positioner on the valve.

To remove the cover (Figure 2), press the latch bar inward as shown in the figure below, pull cover

away from body until latch tab is clear, then pull along body axis to free the two top locking tabs.

Figure 2 Cover Removal

CAUTION

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 21

© 2015 General Electric Company. All rights reserved

.

Figure 3 Rotary

Figure 4 Reciprocating

For 4700P/4800P model only, positioner action can be reversed by simply engaging the proper

lobe on the cam and reversing the follower arm (numbers 1 and 2 above), and the supply and

exhaust ports (number 3 above).

* Option 4700P only

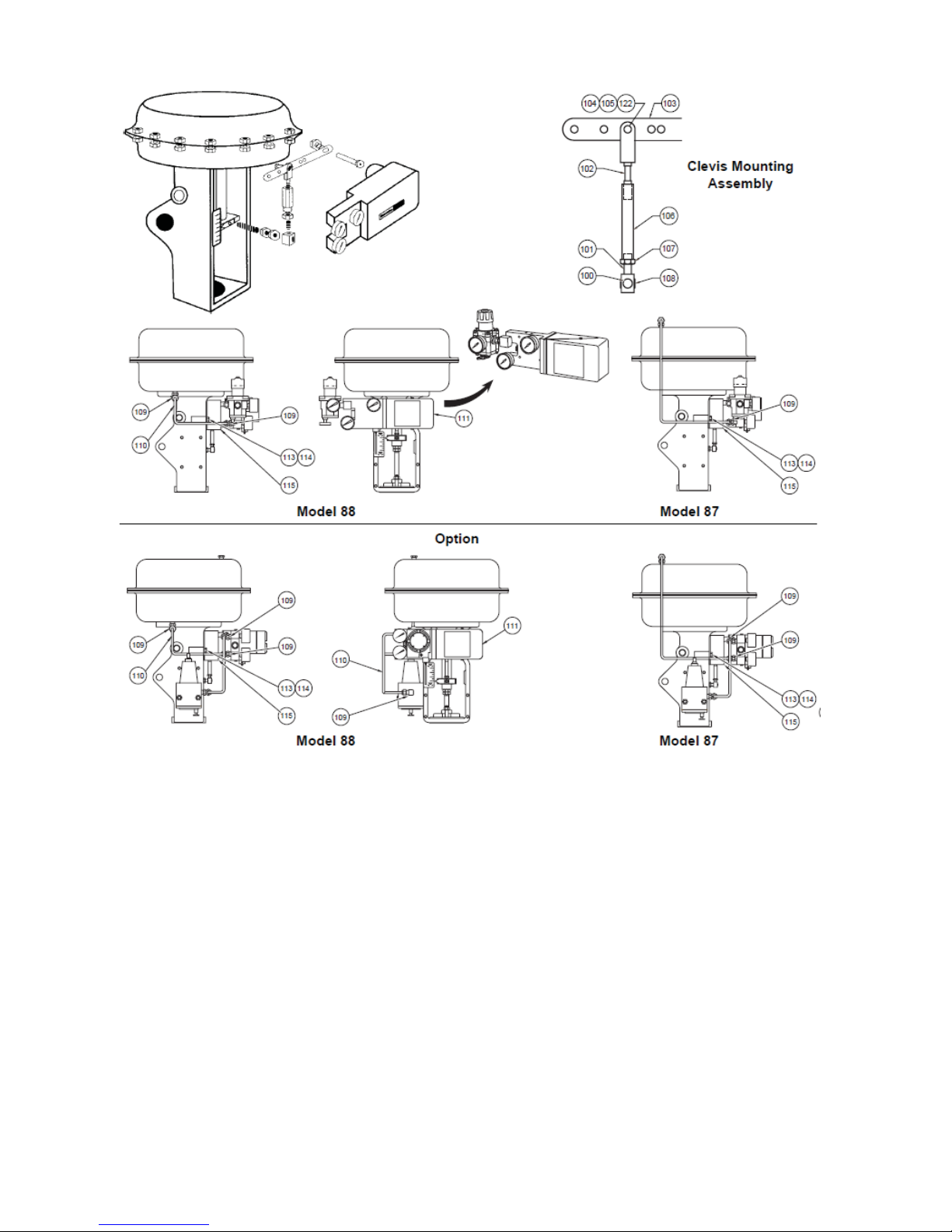

Table 1: Mounting Parts Reference 87/88

Ref.

No.

Description Ref.

No.

Description Ref.

No.

Description

100 Clamp Rod 110 Tubing 29 Screw,.312-18 x 1.25

101 Turnbuckle Screw 111 Positioner 30 Washer, Shakeproof

102 Clevis 112 Male Connector 37 Ring, Retaining

103 Back Lever 113 Cap Screw 38 Cap Screw

104 Clevis Pin 114 Lockwasher 39 Lockwasher

105 Retaining Clip 115 Mounting Bracket 40 Washer,.531 ID

106 Turnbuckle 122 Washer 41 Post Hub

107 Locknut 26 Cam 42 Input Shaft

108 Locknut 27 Washer 135 Instruction Plate

109 Elbow 28 Pan Head Screw

© 2015 General Electric Company. All rights reserved.

22 | =GE Oil & Gas

87/88 Actuator

Ref. Nos 109, 110, and 112 are not included in the mounting kit.

Masoneilan 4700P/E & 4800P/E Positioners Manual =| 23

© 2015 General Electric Company. All rights reserved

.

Figure 5 87/88 Actuator

© 2015 General Electric Company. All rights reserved.

24 | =GE Oil & Gas

Mounting 4700P and 4700E on Series 87/88 Actuators

1. Using screws (113) and lockwashers (114), mount bracket (115) on actuator with

opening located to the right side of the bracket (Figure 5).

2. Install input shaft (42) in post hub with a washer (40) on each side of the hub and

r

etaining ring (37) on cam end.

3. Mount back lever (103) to input shaft using screw (38) and lockwasher (39).

4. Install clevis (102), clevis pin (104), washer (122),

and retaining clip (105) in the

proper location on the back lever. Location is based on valve stroke required.

5. Check Figure 6 for proper mounting location for positioner on bracket.

6. Mount positioner on bracket using socket head screws (29) and lockwashers (30).

NOTE Back lever must be behind bracket.

7. Mount cam (26) on input shaft using washer (27) and screw (28) with desired lobe

ag

ainst cam follower. (Do not mount cam if positioner is reverse action).

8. Connect turnbuckle (106), locknut (107), turnbuckle screw (101), locknut (108), and

clamp r

od (100).

Model Travel (mm) Travel (in.) Hole Location

4700 20.3 .8 A

4700 25.4 1.0 B

4700/4800 38.1 1.5 C

4700/4800 50.8 2.0 D

4700/4800 63.5 2.5 E

NOTE Strokes shorter than 20.3 mm (0.8"), require a special mounting

kit. Consult with the factory for information.

Loading...

Loading...