Page 1

GE Oil & Gas

Masoneilan* 12400 Series

Level Transmitter/Controller

Instruction Manual & Safety Guide

GE Data classification: Public

Page 2

Page 3

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 1

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFIC

REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION

AND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE PHILOSOPHIES VARY, GE

(GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES AND AFFILIATES) DOES NOT ATTEMPT TO

DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND REQUIREMENTS

CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING OF

THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENT IN

POTENTIALLY HAZARDOUS ENVIRONMENTS. THEREFORE, THESE INSTRUCTIONS SHOULD BE

INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY RULES AND REGULATIONS

APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER

EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT

NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH

INSTALLATION, OPERATION OR MAINTENANCE. SHOULD FURTHER INFORMATION BE DESIRED OR

SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED SUFFICIENTLY FOR THE

CUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR ARE STRICTLY

LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY OF THE

EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY GE REGARDING THE

EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE INSTRUCTIONS.

THESE INSTRUCTIONS CONTAIN PROPRIETARY INFORMATION OF GE, AND ARE FURNISHED TO THE

CUSTOMER/OPERATOR SOLELY TO ASSIST IN THE INSTALLATION, TESTING, OPERATION, AND/OR

MAINTENANCE OF THE EQUIPMENT DESCRIBED. THIS DOCUMENT SHALL NOT BE REPRODUCED IN

WHOLE OR IN PART NOR SHALL ITS CONTENTS BE DISCLOSED TO ANY THIRD PARTY WITHOUT THE

WRITTEN APPROVAL OF GE.

Page 4

2 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

Table of Contents

GENERAL ............................................................................................. 3

SPARE PARTS ............................................................................................. 3

AFTER SALES SUPPORT ............................................................................ 3

TRAINING ............................................................................................. 3

1. DESCRIPTION - OPERATION .............................................................. 4

1.1. P

RINCIPLE OF OPERATION ................................................................................ 4

1.2. SIGNAL PROCESSING .......................................................................................... 4

2. PROTECTION STANDARDS ................................................................ 5

2.1.

ATEX / IECEX CERTIFICATIONS ......................................................... 5

2.2.

FM / FMC CERTIFICATIONS ................................................................ 6

2.2.1. GENERAL REQUIREMENTS .............................................................................................. 6

2.2.2.

FLAMEPROOF AND DUST IGNITION PROOF REQUIREMENTS....................................... 6

2.2.3. I

NTRINSICALLY SAFE REQUIREMENTS ............................................................................ 6

2.2.4. D

ESCRIPTION OF EXPLOSION PROOF AND INTRINSIC SAFETY MARKING .................. 7

2.2.5. R

EPAIR................................................................................................................................ 8

2.2.6. ES-479

INTRINSICALLY SAFE INSTALLATION WIRING REQUIREMENTS .................... 9

2.2.7. N

OTES FOR INTRINSICALLY SAFE INSTALLATION........................................................10

3. MARKING – NUMBERING SYSTEM .................................................. 12

3.1. M

ARKING........................................................................................ 12

3.2. N

UMBERING SYSTEM ........................................................................ 12

4. INSTALLATION ................................................................................... 13

4.1. S

TORAGE AND CONDITIONS AT DELIVERY ........................................... 13

4.2. M

OUNTING ON SITE ......................................................................... 13

4.2.1. EXTERNAL MOUNTING ...................................................................................................13

4.2.2. I

NTERNAL MOUNTING ....................................................................................................14

5. CASE DESCRIPTION .......................................................................... 15

5.1. E

LECTRONIC COMPARTMENT ............................................................ 15

5.2. MECHANISM COMPARTMENT ............................................................ 15

5.3.

MTBF ............................................................................................ 15

5.4.

CONNECTION COMPARTMENT ........................................................... 15

5.4.1. ELECTRIC CIRCUIT ...........................................................................................................15

5.4.2. W

IRING AND CONNECTIONS ........................................................................................16

5.4.3. A

LLOWABLE SUPPLY VOLTAGES ...................................................................................16

5.4.4. M

AXIMUM POWER .........................................................................................................16

5.4.5. O

UTPUT SIGNAL AND LOAD RESISTANCE ...................................................................16

6. OPERATING THE INSTRUMENT ....................................................... 19

6.1. G

ENERAL PRINCIPLES ....................................................................... 19

6.1.1. THE LIQUID CRYSTAL DISPLAY (LCD) ...........................................................................19

6.1.2. P

USHBUTTONS ...............................................................................................................19

6.1.3. O

PERATING MODES ........................................................................................................19

6.1.4. P

USHBUTTONS MENUS DESCRIPTION .........................................................................20

7. COMMISSIONING .............................................................................. 22

7.1. INSTRUMENT COUPLING TO THE TORQUE TUBE ................................... 22

7.2. T

RANSMITTER CONFIGURATION ......................................................... 24

7.3. T

RANSMITTER CALIBRATION .............................................................. 25

7.3.3. CALIBRATION ON SITE WITH PROCESS FLUIDS .................................................30

7.3.4. C

ALIBRATION WITH MECHANICAL STOPS ........................................................31

7.4. CALIBRATION OF SPECIFIC GRAVITY METER ................................. 33

7.5. M

ECHANICAL STOPS SETTING .................................................... 34

7.6. T

ORQUE TUBE TEMPERATURE COMPENSATION ............................ 36

7.7. CONTROLLER FUNCTION (12410 MODEL ON LY) ......................... 38

8. SAFETY MANUAL FOR SIL APPLICATIONS ............................. 44

8.1. R

ELEVANT STANDARDS ............................................................. 44

8.2.

TERMS AND DEFINITIONS .......................................................... 44

8.3. SAFETY REQUIREMENTS ............................................................ 45

8.3.1. PROBABILITY OF FAILURES ON DEMAND (PFD) ..................................... 45

8.3.2. S

AFETY INTEGRITY OF THE HARDWARE ................................................. 45

8.4. SAFETY CHARACTERISTICS ......................................................... 45

8.4.1. ASSUMPTIONS .................................................................................. 45

8.4.2. S

AFETY INTEGRITY OF THE HARDWARE ................................................. 46

8.4.3. H

ARDWARE LOCK JUMPER ADJUSTMENT ............................................. 46

8.4.4. C

HARACTERISTICS ............................................................................. 47

8.5. SAFETY FUNCTION .................................................................... 47

8.6. P

ROOF TEST ............................................................................ 47

9. MAINTENANCE .......................................................................... 48

9.1. R

EMOVAL OF 12400 CASE FROM TORQUE TUBE ......................... 48

9.2. INSTALLATION OF 12400 CASE ON A TORQUE TUBE .................... 48

9.2.1. ON A 12200/300/400 SERIES TORQUE TUBE .................................. 48

9.2.2. ON

A 12120 OR 12800 SERIES TORQUE TUBE ................................... 49

9.3. REMOVAL OF 12400 CASE AND TORQUE TUBE S/A ...................... 50

9.4.

MOUNTING OF DLT CASE AND TORQUE TUBE S/A ......................... 51

9.5.

REVERSE INSTRUMENT CASE MOUNTING POSITION VERSUS TO

DISPLACER POSITION

(LEFT OR RIGHT) ........................................ 52

9.6. REPLACEMENT OF ELEC. AND MECH. COMPONENTS ..................... 52

10 TROUBLE SHOOTING ................................................................ 53

10.1. N

O SIGNAL ........................................................................... 53

10.2.

EXISTING SIGNAL BUT NOTHING ON LCD DISPLAY ...................... 53

10.3.

STEADY SIGNAL, NO CHANGE WHEN LEVEL VARIES ..................... 53

10.4.

OUTPUT SIGNAL DIFFERS FROM VALUE DISPLAYED ON LCD ........ 53

10.5. NO HART

®

COMMUNICATION ................................................ 54

10.6.

OUTPUT SIGNAL DOES NOT MATCH WITH THE LIQUID LEVEL

(LINEARITY ISSUE) .................................................................... 54

10.7. VIEW ERROR DIAGNOSTICS MESSAGES ...................................... 55

Appendix A

– NORMAL Menu / SETUP Menu ................... 60 to 61

Appendix B – BASIC SETUP Menu ...................................... 62 to 64

Appendix C – ADVANCED SETUP Menu ........................... 65 to 68

Appendix D – ENGINEERING UNIT Menu .......................... 69 to 71

Appendix E – 4-20mA GENERATOR Menu ........................ 72 to 73

Appendix F – VIEW DATA Menu ......................................... 74 to 75

Appendix G – FAILSAFE / VIEW ERROR Menus ................ 76 to 77

Page 5

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 3

IMPORTANT: SAFETY WARNING

Read these instructions carefully BEFORE this instrument is installed or maintained.

Products certified for use in explosion proof (flameproof) or intrinsically safe installations MUST:

a) Be installed in accordance with EN/IEC 60079-14, EN/IEC 61241-14, EN/IEC 60079-17 standards and/or local and national codes for

hazardous area installations.

b) Only be used in situations which comply with the certification conditions stated in this manual and those stated in 400152322E ATEX

Instruction Manual.

c) Only be maintained by qualified personnel with adequate training on hazardous area instrumentation (see Instruction Manual

400152322E).

Taking the appropriate actions to ensure that site personnel who are performing installation, commissioning and

maintenance have been trained in proper site procedures for working with and around equipment, per Safe Site Work Practices,

are the end user's responsibility.

It is the end user's responsibility to:

• Verify material compatibility with the application

• Ensure proper use of fall protection when working at heights, per Safe Site Work Practices

• Ensure use of proper Personal Protective Equipment

• Take the appropriate actions to ensure that site personnel who are performing installation, commissioning and maintenance

have been trained in proper site procedures for working with and around equipment, per Safe Site Work Practices

Non-compliance with the rules and cautionary notes of this instruction may cause malfunction of the device or serious damage to it,

personnel or the surrounding equipment or site. Not intended for use in life support systems.

Items sold by GE are warranted to be free from defects in material and workmanship for a period of one year from the date of first use or

eighteen (18) months from the date of delivery, whichever occurs first, provided such items are used according to all relevant

recommendations and instructions from GE.

GE reserves the right to discontinue manufacture of any product or change product materials, design, or specifications without notice.

General

This manual provides installation, operation and maintenance instructions for the Masoneilan 12400 Series Digital Level

Transmitter/Controller from GE. It also includes a complete parts reference and a list of recommended spare parts.

Spare Parts

When performing maintenance, use GE’s Masoneilan spare parts only. Parts can be obtained through your local Masoneilan products

representative or the Spare Parts Department. When ordering parts, always include the Model and Serial Number of the unit being repaired.

After Market Support

GE offers aftermarket support for Masoneilan valves and instruments start-up, maintenance, and repair. Contact the nearest Masoneilan Sales

Office or Representative or After Sales Department.

Training

Regularly scheduled classes are conducted at GE’s Masoneilan facilities for training customer service and instrumentation personnel in the

operation, maintenance, and application of control valves and instruments. Arrangements for these classes can be made through your local

Masoneilan products sales contact.

Use of DANGER, WARNING, CAUTION, and NOTE.

These instructions contain DANGER, WARNING, CAUTION, and NOTE where necessary to alert you to safety

related or other important information.

DANGER - Hazards which result in severe personal injury or death.

WARNING - Hazards which could result in personal injury.

CAUTION - Hazards which could result in equipment or property damage.

NOTE - Alerts you to pertinent facts and conditions.

Although DANGER and WARNING hazards are related to personal injury, and the CAUTION hazards involve

equipment or property damage, it should be understood that operation of damaged equipment could, under

certain operational conditions, result in degraded process system performance which may lead to personal

injury or death. Therefore, comply fully with all DANGER, WARNING, and CAUTION notices.

Page 6

4 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

1. Description - Operation

The 12400 Series Digital Level Transmitter/Controller is a high performance, easy-to-set instrument based on a modular design

that permits quick, low-cost upgrades as new features are developed and as your needs change.

1.1. PRINCIPLE OF OPERATION

The Masoneilan 12400 Series instrument from GE is a 2-wire, loop powered, digital displacement level transmitter/controller

with HART

®

communication that uses field proven buoyancy and torque tube principles.

A change in liquid level varies the apparent weight of the displacer (130), which increases or decreases load on the torque tube

(136) by an amount directly proportional to the change in liquid level. The resulting rotation of the torque rod (138), seen in

Figure 1, modifies the magnetic field of a frictionless, non-contacting sensor (40). The signal generated by the sensor varies

current in the loop in proportion to the level in the vessel.

1.2 SIGNAL PROCESSING

The sensor analog signal is converted into an error-free digital signal for processing by the on board micro-controller. After

signal processing, the digital result is converted to analog output signals for use by configuration and options.

Transmitter model:

♦ The 4-20 mA analog output signal, available on the AO_1 terminal, is the level or interface measurement signal with HART®

communication.

Transmitter model with two (2) adjustable switches and second 4-20mA analog output:

♦ The two 4-20 mA analog output signals, available on the AO_1 and AO_2 terminals, are the level or interface measurement signal, with

HART communication (AO_1 only).

♦ DO_1 and DO_2 terminals are two independent isolated digital switch outputs. They are user-adjustable and polarity sensitive.

Controller model with two (2) adjustable switches and second 4-20mA analog output:

♦ The 4-20 mA analog output signal, available on AO_1 terminals, is the controller output signal generated by a PID algorithm based on

error between the local setpoint and the level process variable. HART communication is available on AO_1.

♦

The 4-20 mA analog output signal, available on the AO_2 terminals, is the level or interface measurement signal. No HART

communication.

♦ DO_1 and DO_2 terminals are two independent isolated digital switch outputs. They are user-adjustable and polarity sensitive.

The 12400 instrument enables retrofit of existing pneumatic or digital level instruments (see Section 9.2).

PARTS REFERENCES

40

Non contact Sensor

135

Torque arm

55

Magnet

136

Torque tube

130

Displacer

137

Torque tube housing

131

Displacer chamber

138

Torque rod

Figure 1 – Diagram of principle

IMPORTANT

Options described above are operable only if they have been ordered initially. You cannot add them later on

site (see numbering system Section 3.2).

Page 7

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 5

2. Protection standards

Installation in a hazardous atmosphere must be performed in accordance with the requirements specified in the applicable

standard for protection against explosion.

2.1. ATEX / IECEx CERTIFICATIONS

The 12400 Series Level Transmitter / Controller complies with the essential requirements of ATEX 94/9/EC European directive.

This instrument is certified for use in explosion proof (flameproof) or intrinsically safe installations with dust or gas from groups IIA, IIB and

IIC:

Category II 1 GD – zones 0, 1, 2, 20, 21 and 22 for protection mode "ia"

Category II 2 GD – zones 1, 2, 21 and 22 for protection mode "d".

The instrument also complies with the essential requirements of the modified EMC 2004/108/EC European directive for use

industrial environment.

It is the end user’s responsibility to ensure that products certified as explosion proof equipment or for use in intrinsically

safe installations MUST BE:

a) Installed, put into service, used and maintained in compliance with European and/or national and local regulations and

in accordance with the recommendations contained in the relevant standards concerning potentially explosive

atmospheres.

b) Used only in situations which comply with the certification conditions shown in this document and after verification of

their compatibility with the zone of intended use and the permitted maximum ambient temperature.

c) Installed and maintained only by personnel who have been trained and certified in installation, commissioning and

maintenance in proper site procedures for working with and around equipment, per Safe Site Work Practices.

Under certain operating conditions, use of a damaged instrument could cause a degradation of the performance of the

system, which may lead to personal injury or death, damage to the equipment and or other equipment, as well as the site.

Use only genuine replacement parts, provided by the manufacturer, to guarantee that the products comply with the

essential European Directives safety requirements mentioned above.

All actions related to installation, site commissioning and maintenance must be performed in accordance with

instructions provided in the ATEX instruction manual 400152322.

WARNING:

IMPROPER R

EPLACEMENT OR SUBSTITUTION OF ELECTRONIC COMPONENTS OR OF CERTAIN PARTS WHOSE

CHARACTERISTICS DO NOT MEET REQUIREMENTS OF THE APPLICABLE STANDARDS FOR EXPLOSION PROTECTION MAY

VOID THIS PROTECTION.

Page 8

6 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

2.2. FM / FMc CERTIFICATIONS

2.2.1. GENERAL REQUIREMENTS

! WARNING !

Failure to adhere to the requirements listed in this

manual may cause loss of life and property.

Installation and maintenance must be performed only by qualified personnel. Area Classification, Protection Type, Temperature Class,

Gas Group, and Ingress protection must conform to the data indicated on the label.

Wiring and conduit must conform to all local and national codes governing the installation. Wiring must be rated for at least 5ºC above

the highest expected ambient temperature.

Approved wire seals against ingress of water and dust are required and the NPT fittings must be sealed with tape or thread sealant in

order to meet the highest level of ingress protection.

Where the protection type depends on wiring glands, the glands must be certified for the type of protection required.

The metal housing is in a standard die-casting alloy which is predominately aluminum. The housing can be stainless steel also.

Before powering the 12400:

1. Verify that the electronic cover screws are tightened. This maintains the ingress protection level and the integrity of the flameproof

enclosure.

2. If the Installation is Intrinsically Safe, check that the proper barriers are installed and the field wiring meets local and national codes for

an IS installation. Never install a device which was previously installed without an intrinsically safe barrier in an intrinsically safe system.

3. If the Installation is Non-Incendive, check that all the wiring meets local and national codes.

4. Verify that the markings on the label are consistent with the application.

2.2.2. FLAMEPROOF AND DUST IGNITION PROOF REQUIREMENTS

The ½” NPT fittings must enter the housing at least five full turns.

Conduit seals are required within 18” of the conduit for flameproof installation.

2.2.3. INTRINSICALLY SAFE REQUIREMENTS

Wiring must be in accordance with ES-749 (see Section 2.2.6) and must conform to national and local standards for intrinsically safe

installation.

Page 9

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 7

2.2.4. D

ESCRIPTION OF EXPLOSION PROOF AND INTRINSIC SAFETY MARKING

The label may not appear exactly as shown, but must contain the information listed below. Additional information NOT pertaining to FM

approval is allowed on the label.

SERIAL

xxx

WARNING:

POTENTIAL DANGER OF

ELECTROSTATIC

DISCHARGE

Protection

PERMANENTLY MARK

PROTECTION TYPE.

ONCE MARKED, IT CAN NOT

BE CHANGED

Protection

Protection

AO_1 40V 23mA; AO_2 30V 23mA; DO_1 & DO_2 30V 1A

Dresser Inc Masoneilan Operations

DPI 14110 Conde-Sur-Noireau, France

SUPPLY CONNECTION WIRING RATED 5oC ABOVE AMBIENT

HOUSING CONDUIT ENTRY ½ INCH NPT

INGRESS PROTECTION TYPE 4X-6P

OPERATING TEMPERATURE LIMITS -40oC TO 80oC

Page 10

8 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

2.2.5. REPAIR

WARNING: EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR USE AND CAUSE DAMAGE TO

PERSONNEL, THE EQUIPMENT, OTHER EQUIPMENT AND THE SITE IN A HAZARDOUS LOCATION.

Only qualified service personnel are permitted to make repairs.

Replace ONLY with genuine Masoneilan parts from GE.

Only Masoneilan parts from GE are permitted. This includes not only the major assemblies but also mounting screws and “O” rings. No

substitutions with non-Masoneilan parts are permitted.

The following summary assures the safe operation of the 12400.

For ambient temperature greater than 70 °C, the user must choose a cable entry and a cable compatible with:

Ambient Temperature

Cable Temperature

75 °C

80 °C

80 °C

85 °C

The cable entry and the cable must be compatible with the minimum temperature of -40 °C as indicated on the marking plate.

The cable entry must have an ingress protection level at least equal to type 4X – 6P.

The joints (three pushbuttons, covers thread and O-ring) are greased with one of the following acceptable greases:

Grease Type

Manufacturer

GRAPHENE 702

ORAPI

MOLYKOTE111 COMPOUND

MOLYKOTE®

MULTILUB

MOLYKOTE®

GRIPCOTT NF

MOLYDAL

It is the user’s responsibility to check the gaskets once a year and in the event of damage to replace the defective parts with

manufacturer's replacement parts only.

For use in dusty hazardous areas, the user must maintain the enclosure to avoid the deposits of dusts, the maximum thickness must be

<5 mm. For safe operation, this can be done only if the local conditions around the device are free of potentially explosive atmosphere.

The user must check the temperature increase on the 12400 head coming from the mechanical part in contact with the 12400 housing or

through the process thermal radiation and ensure it is less or equal than the temperature classification allowed. This must be done in

conformance with EN/IEC 60079-14 and / or national and local regulations applicable for explosible atmospheres.

The user may clean the device, mainly the plastic label, with a wet rag to avoid any electrostatic spark. For safe operation, this can be

done only if the local conditions around the device are free of potentially explosive atmosphere.

Page 11

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 9

2.2.6. ES-479

INTRINSICALLY SAFE INSTALLATION WIRING REQUIREMENTS

Each intrinsically safe cable must include a grounded shield or be run in a separate metal conduit.

3

1

2

4

VOLTAGE SUPPLY

FROM CONTROL SYSTEM

30V MAXI

1 to 5 Volts or 4-20mA

LEVEL FEEDBACK

to Control System

12400 LEVEL TRANSMITTER /

CONTROLER

PRIMARY OUT

4-20mA

SECONDARY OUT

4-20mA

SW1 / SW2

OUT

+

-

+

-

+

-

3

1

2

4

250 Ω

3

1

2

4

VOLTAGE SUPPLY

FROM CONTROL SYSTEM

30V MAXI

VOLTAGE SUPPLY

FROM CONTROL SYSTEM

30V MAXI

DI to CONTROL SYSTEM

OPTIONAL

SOLENOID

LOAD

1 to 5 Volts or 4-20mA

LEVEL FEEDBACK

to Control System

VALVE

POSITIONER

-

+

3

1

2

4

250 Ω

Note 7

Note 4

Note 6

Note 7

Note 7

Note 7

Note 5

Barrier with internal or external sense resistor.

Barrier with 4-20 mA retransmit.

See Note 3

Note 5

Note 6

Barrier with internal or external sense resistor.

See Note 4

Barrier type

See Note 5

Barrier type

See Note 6

4-20 mA SETPOINT

FROM CONTROL SYSTEM

With or

Without local

Solenoid

HAZARDOUS LOCATION

SEE NOTES 1 & 2

NON-HAZARDOUS LOCATION - UNSPECIFIED EXCEPT THAT

BARRIERS MUST NOT BE SUPPLIED FROM NOR CONTAIN

UNDER NORMAL OR ABNORMAL CONDITIONSA SOURCE OF

POTENTIAL WITH RESPECT TO EARTH IN EXCESS OF 250

VOLTS RMS OR 250 VOLTS DC.

The Optional 4-20 mA

secondary output from 12400

must not be connected in an

Intrinsic Safe Installation which

requires FM or CSA approval.

See Note4.

Page 12

10 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

2.2.7. NOTES FOR INTRINSICALLY SAFE INSTALLATION

Note 1: HAZARDOUS LOCATION

Refer to the device label for the description of the environment in which the device may be installed.

For Div 1 areas the barriers are always required. For Div 2 areas the barriers are not required as long as Div 2 wiring practices

comply with the local electrical code and the supply voltages are normally less than 30 Volts.

Note 2: FIELD WIRING

Intrinsically Safe wiring must be made with grounded shielded cable or installed in grounded metal conduit. The electrical

circuit in the hazardous area must be capable of withstanding an A.C. test voltage of 500 Volts R.M.S. to earth or frame of the

apparatus for one minute. Installation must be in accordance with GE’s guidelines. The installation including the barrier

earthing requirements must comply with the installation requirements of the country of use.

Factory Mutual requirements (USA): ANSI/ISA RP12.6 (Installation of Intrinsically Safe Systems for Hazardous (Classified)

Locations) and the National Electrical Code, ANSI/NFPA 70. Division 2 installations must be installed per the National Electrical

Code, ANSI/NFPA 70. See also, note 4.

CSA requirements (Canada): Canadian Electrical Code Part 1. Division 2 installations must be installed per the Canadian

Electrical Code Division 2 Wiring Methods. See also note 4.

Note 3: PRIMARY OUT (+) and (-) 4-20 mA Terminals

These terminals are the main loop power of the 12400 and provide a 4 to 20mA signal related to the level measurement or the

embedded controller output for level control process. A transmitter type barrier with 250 Ohm series resistance (internal or

external) is used for this connection; for example, MTL 788 or 788R. For controller application, an active barrier with 4-20mA

retransmit can be used to drive a valve positioner.

Entity Parameters: Vmax= 30 VDC; Imax=125 mA; Ci=2 nF; Li=500 μH; Pmax=900 mW

Note 4: SECONDARY OUT (+) and (-) 4-20 mA Terminals

These terminals provide an additional 4 to 20 mA signal related to the level measurement. Use a transmitter type barrier with

250 Ohm series resistance (internal or external) for this connection; for example, MTL 788 or 788R.

Entity Parameters: Vmax=30 VDC; Imax=125 mA; Ci = 9 nF; Li=500 μH; Pmax=900 mW.

NOTE: The secondary out must not be connected in an Intrinsic Safe installation which requires FM or CSA approval.

Note 5: SW1 & 2 (+) and (-) Terminals

There are two independent isolated solid state switch contact outputs on the 12400. They are labelled SW#1 and SW#2. The

switches are polarity sensitive – that is, conventional current flows into the plus terminal. Examples of suitable barriers are MTL

707, MTL 787 and MTL 787S.

Entity parameters are: Vmax=30 VDC; Imax=125 mA; Ci = 4.5 nF; Li=10 μH; Pmax=900 mW.

Note 6: Controller mode

The barrier is a Controller Output Type; for example, MTL 728. This barrier can be driven by an active barrier with 4-20mA

retransmit or by the control system.

Entity Parameters: The optional device may be an I/P type 8000 series or a valve positioner type SVI II AP.

Note 7: Entity Requirement

Cable capacitance and inductance plus the I.S. apparatus unprotected capacitance (Ci) and inductance (Li) must not exceed

the allowed capacitance (Ca) and inductance (La) indicated on the associated apparatus. If the optional HART

®

handheld

Communicator (type DPI 620) is used on the Hazardous Area side of the barrier, then the capacity and inductance of the

communicator must be added and the communicator must be agency approved for use in the hazardous area. Also, the

current output of the Hand Held Communicator must be included in the current output of the associated equipment.

Page 13

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 11

Note 8: Barrier type

The barriers may be active or passive and from any certified manufacturer for FMRC and CSA as long as the barriers comply

with the listed entity parameters.

Note 9: Use in dust atmosphere

Dust-tight conduit seal must be used when installed in dust hazard environments.

Note 10: Multiple protection approvals

A device which has previously been installed without an approved IS barrier must NEVER be used subsequently in an

intrinsically safe system. Installing the device without a barrier can permanently damage the safety related components in the

device making the device unsuitable for use in an intrinsically system.

Page 14

12 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

3. Marking – Numbering System

3.1. MARKING

The firm plate (124) is applied on the top of the mechanical

compartment housing.

The following data are indicated: manufacturer contact details,

serial number, year of manufacturing and instrument electric

characteristics.

ATEX marking is described in 400152322 ATEX instruction

manual which is supplied with every 12400.

Figure 2 - Marking

3.2. NUMBERING SYSTEM

Note: only the Transmitter function is SIL certified.

12 4 a b

C d

Model Action Mounting Hazardous Protection Housing Material

4 – HART

®

communication protocol,

LCD display and pushbuttons, SIL Certified

1 – Controller with

adjustable switches

and second 4-20mA

analogue output

signal:

AO_1, AO_2,

DO_1, DO_2

2 – Transmitter: AO_1

3 – Transmitter with

adjustable switches

and second 4-20mA

analogue output

signal:

AO_1, AO_2,

DO_1, DO_2

0 – Top and bottom,

Screwed, BW or SW

1 – Top and bottom, Flanged

2 – Side and side, Flanged

3 – Top vessel, Flanged

4 – Side vessel, Flanged

5 – Top and side,

Screwed, BW or SW

6 – Side and bottom,

Screwed, BW or SW

7 – Side and bottom, Flanged

8 – Top and side, Flanged

9 – Side and side,

Screwed, BW or SW

1 – FM & FMc (ex CSA)

Intrinsically Safe,

Explosion proof, nL and

Nema 4X-6P

2 – JIS,

Explosion proof

3 – Rosteknadzor,

Intrinsically Safe,

Explosion proof, nL

and IP 66/67

4 – Inmetro,

Intrinsically Safe,

Explosion proof, nL

5 – ATEX & IECEx

Intrinsically Safe,

Explosion proof, nL

and IP 66/67

6 – Other approvals

(based on ATEX/IEC

approvals)

7 – Other approvals

(not based on

ATEX/IEC approvals)

1 – Aluminum with

epoxy painting

2 – 316L Stainless

steel

Page 15

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 13

4. Installation

4.1. STORAGE AND CONDITION AT DELIVERY

Level instruments have been carefully packed in our premises to

prevent them from damage during handling and transportation.

Units must be stored in an area where temperatures are

between -50 °C and +93 °C.

Units are factory dry calibrated (simulation by weight) to the

service specific gravity specified by the customer.

When service specific gravity has not been specified, units are

factory dry calibrated to a specific gravity of 1.

Recalibration is recommended when the actual specific gravity

differs from calibration specific gravity.

Recalibration is needed when verification of instrument

performance is made with liquid in the displacer chamber.

4.2. MOUNTING ON SITE

Unpack the unit carefully and record the serial number for future

reference. Remove the shipping stud that secures the displacer in

the chamber.

Whenever possible, locate the instrument at some easily

accessible, well-lighted place on the vessel. The location must

have ambient temperature at the instrument case within the

range of -50 °C to +80 °C (unless limitations due to hazardous

area approvals – see Section 2).

NOTE: Do not remove instrument cover until the unit has been

installed and is ready for calibration.

The codes shown on numbering system indicate the instrument

designation as a function of various installation modes, displacer

chamber connections, and environmental standard or protection

of the case against explosion. Figures 3 and 6 show the various

ways of installing the displacer chamber.

4.2.1. EXTERNAL MOUNTING

(Chamber Type Model, Figures 3 & 4)

Install the instrument in a vertical position on the side of the tank

or vessel, so that the mid-range mark on the chamber is at

normal level. The mid-range is marked on the chamber.

The equalizing lines between chamber and vessel must be the

same size as the chamber connections. Install a block valve in

each line.

The use of a drain connection is recommended as shown in

Figure 3.

CAUTION: The displacer is always immobilized in the displacer

chamber to avoid any internal damage during transportation.

During the level installation, the displacer has to be unlocked by

unscrewing the M6 stern at the drain.

Type 12405 (Screwed NPT, BW, SW) Type 12406 (Screwed NPT, BW, SW)

Type 1240

8 (Flanged) Type 12407 (Flanged)

Figure 4

Type 12400 (Screwed NPT, BW, SW) Type 12409 (Screwed NPT, BW, SW)

Type 1240

1 (Flanged) Type 12402 (Flanged)

MID

RANGE

MID

RANGE

MID

RANGE

MID

RANGE

Page 16

14 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

4.2.2. INTERNAL MOUNTING

An internally mounted 12400 Series instrument has no displacer chamber and the mechanism chamber bolts directly to the

vessel nozzle flange.

a. Type 12403 Top Flange Mounted Instrument (Figure 5)

There are two mounting possibilities:

1. Overhead space necessary for mounting the instrument is

sufficient:

♦ Attach the displacer to the torque tube before bolting the

chamber flange to the nozzle flange on the vessel.

2. Overhead space is insufficient: in this case, install a detachable

hanger extension. Before attaching the extension:

♦ Lower the displacer partway into the tank.

♦ Fasten and pin the extension to the displacer.

♦ Hook the displacer to the torque arm and lower the entire unit

into position. When the extension consists of several

detachable elements, repeat this operation for each element

and the lower the displacer progressively into the tank.

♦ Mount the instrument and bolt the mechanism chamber onto

the nozzle flange.

b. Type 12404 side flange mounted Instrument (Figure 6)

When the instrument is side flange mounted, provide enough clearance to permit attachment of the displacer after the

chamber flange is bolted in place. To attach the displacer:

♦ Reach into the end of the protective case and depress the torque arm.

♦ Bring the displacer hanger up through the hole in the bottom of the case and slip the displacer hanger over the

torque arm pin.

♦ Lower the displacer until the pin engages the top of the slot in the hanger.

4.2.2.1. Guide brackets for type 12404 (Figure 6)

If the liquid is in motion, provide brackets as shown in Figure 6 to guide the lower end of the displacer. The diameter of the

hole must be 25 to 35 mm (1” to 1 1/2”) larger than the diameter of the displacer for ranges to 1.8 m (6’), and 50 to 70 mm

(2” to 3”) larger for greater ranges.

Place the brackets at 50 to 70 mm (2” to 3”) from each end of the displacer. Locate the centerline of the hole so that the

displacer hangs freely.

4.2.2.2. Stilling well for type 12403 (Figure 5)

If the liquid is turbulent, provide a stilling well.

Make the well from tubing or pipe of a suitable diameter to allow

sufficient clearance between displacer and pipe. Mount it so that

it extends at least 75 mm (3”) below a free hanging displacer.

Provide a hole at the top of the stilling well to equalize pressure

between well and vessel.

4.2.2.3. Instrument case mounting (Figure 7)

The standard case mounting is left handed — the case is to the

left of the displacer. Right hand mounting is optional. To reverse

instrument case mounting, refer to Section 9 - Maintenance.

Figure 5 Figure 6

Type 12403 Type 12404

Left mounting

(top view)

Right mounting

(top view)

Figure 7

Page 17

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 15

5. Case description

The purpose of this section is to describe the various instrument sub-assemblies to facilitate their use and maintenance.

See figures 8 to 13.

5.1. ELECTRONIC COMPARTMENT

The electronics compartment, located at the front of the instrument, can be accessed by removing the main cover (281). This

main cover is equipped with a glass (251) and three explosion proof pushbuttons (260).

The cover (281) is fully screwed on to the case (2) and sealed with an O-ring (109). It may be necessary to unscrew the cover

by less than a turn to align the window and LCD display and to install the safety screw (110). The cover (255) protects the

pushbuttons.

The sensor S/A (40) and its seal (111) are secured by two screws (112), located in the upper part of the electronics compartment.

The microprocessor, the display and the three pushbuttons are mounted on the resin potted electronic board which makes

the main electronic module (200). This subassembly is inserted into the case with the display facing the top of the case. It is

assembled by four screws (201).

5.2. MECHANISM COMPARTMENT

The mechanism compartment (Figures 12 & 13) on the back of the case has an opening on the right side (operator facing

instrument), which is closed by a threaded cover (107) and a gasket (108). A second opening at the bottom, closed by a

special 3/4” NPT plug (190), allows access to the mechanical flexure (59), which is part of the beam.

The mechanism (50) is completely factory assembled and calibrated before being installed into the mechanism

compartment. The pivot (51) is positioned toward the back of the case through two pins (52-53) and fastened by two screws

(113).

Two set screws (114) are located in tapped holes in the side of the case. The holes are covered by two plugs (115).

5.3. MTBF

The MTBF (Mean Time Between Failure) of 12400 Series instrument is 55.7 years, according to MIL-STD-HDBK-217F

Specification.

5.4. CONNECTION COMPARTMENT

Located on the left side, the connection compartment is closed by a threaded cover (104) with O-ring gasket (105) and locked

by a safety screw (106). It is equipped with a terminal board (90) mounted with a screw (92).

To mount the safety screw (106), the cover must be fully screwed on the case and then unscrewed by less than a turn.

5.4.1. ELECTRIC CIRCUIT

Both the terminal strip and the ground terminal are located in connection compartment (Figures 8 and 9). Connections are

done with four flat handle terminal blocks (90) or a terminal board connector (90A) (Japan) and included ground connection

(96). Follow strip rules to prevent from any short circuit and comply with local and national standards for hazardous area installations.

A 1/2” NPT (or M20) conduit connection is provided in the lower part of the junction box for connecting the supply leads via a

supplied stuffing box with an integrated cable clamp device or any cable gland with cable clamp device suitable for the

considered hazardous area.

DANGER:

FOR ANY ACTION ON 12400 SERIES INSTRUMENT, DO NOT REMOVE EITHER COVER PRIOR TO READING

400152322 ATEX INSTRUCTION MANUAL.

Page 18

16 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

5.4.2.

WIRING AND CONNECTIONS

All wiring and connections must be done in accordance with EN/IEC 60079-14, EN/IEC 61241-14 and/or local and national codes

for hazardous area installations.

5.4.3.

ALLOWABLE SUPPLY VOLTAGES

Electrical connections on terminal board must respect polarity + and –, as well as maximum allowable supply voltages given

below. Connect the instrument to the ground using the ground terminals internally and externally to the case.

Supply Voltage

U (VDC)

AO_1 AO_2 DO_1/DO_2

MIN MAX MIN MAX MIN MAX

Explosion proof

10 V

40 V

10 V

30 V

0.5 V

30 V

Intrinsic Safety

10 V 30 V 10 V 30 V 0.5 V 30 V

5.4.4.

MAXIMUM POWER

3 W into 12400 case

5.4.5.

OUTPUT SIGNAL AND LOAD RESISTANCE

♦ AO_1 and AO_2

Response (scan) time: <60ms

Power interruption without causing reset: <100ms

Power-Up time: < 1s

Compliance with NAMUR NE-43 specification

standard level measurement: 3.8mA to 20.5mA

Low or high failsafe signals (severe fault): < 3.6mA or > 21mA

♦ Maximum load resistance

For AO_1 and AO_2: R max (Ω) = U (V) – 10 (V)

Imax (A)

♦ DO_1 and DO_2

There are two independent isolated output switches with open collectors. 1A maximum output signal. A load resistance must

be used in series to limit maximum current. 30 VDC across switch terminals and 1 A cannot exist simultaneously; doing so will

result in failure of the digital output circuit.

Figure 8 – Terminal board

Standard version with clamp (Ref. #90)

Figure 9 - Terminal board

Japanese version with screws (Ref. #90A)

R

load

U

Figure 10

Page 19

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 17

Figure 11

Case External side view of case

Terminals for

local HART

®

communication

Figure 12

Front view

Cross-section back view

90 or 90A

90 or 90A

Page 20

18 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

● Recommended spare parts ■ Spare parts available

1) These 3 rings are part of a kit.

PARTS REFERENCE

Ref N° Qty Parts Name Ref N° Qty Parts Name Ref N° Qty Parts Name

2

1

Case

■ 97

1

C M4-10 screw

■ 190

1

Plug S/A

40

1

Sensor S/A

■ 98

1

Lockwasher

191 1 Plug

50

1

Mechanism S/A

■ 99

1

Flat washer

192 1 Sponge cord

51

1

Pivot

■ 100

1

Clamp

200

1

Main electronic module

52

1

Pin

■ 101

1

C M5-12 screw

■ 201

4

CHC M4-25 screw

53

1

Special pin

■ 102

1

Lockwasher

241

1

Bias S/A

54

1

Beam

■ 103

1

Cap

242 1 Spring arm

55

1

Magnet

■ 104

1

Junction box cover

243 1 pin

56

2

“U” lamella

■ ●

1

O-ring (1)

244 2 Lateral screw

57

4

Flange, lamella

■ 106

1

CHC M4-16 screw

■ 281

1

Main cover S/A

58

8

CHC M4-8 screw

■ 107

1

Visit plug

280 1 Main cover

59

1

Flexible lamella

■ ●

1

O-ring (1)

250 1 Glass O-ring

60

2

CHC M3-8 screw

■ ●

1

O-ring (1)

251 1 Glass

62

1

CHC M3-8 screw

■ 110

1

CHC M4-16 screw

252 1 Clamp, spring

63

1

Flange, lamella

■ 111

1

O-ring, sensor housing

253 4 CHC M4x0.7x10 screw

270

1

Bell

■ 112

2

CHC M3-8 screw

■ 255

1

Cover, pushbuttons

271

1

HC M3-6 screw, bell

■ 113

2

CHC M4-20 screw

■ 256

1

Gasket cover, pushbuttons

70

1

Coupling lamella S/A

■ 114

2

Adjusting screw

■ 257

1

Screw captive panel

71

1

Coupling lamella

■ 115

2

1/8” NPT plug

■ 258

1

Pivot pin, pushbuttons cover

72

1

Pin

■ 75

1

Coupling S/A

■ 259

2

Circlip

73

1

Washer, coupling lamella

116

1

Coupling

260 3 Push Button

90

1

Standard terminal board S/A

117

1

Flange, coupling lamella

261 3 Spring compression

90A

1

Japan terminal board S/A

118

2

CHC M3-8 screw

262 3 Washer, retaining spring

■ 92

1

CHC M3-8 screw

■ 119

2

HC M3-6 screw

263 3 O-ring, pushbuttons

■ 93

1

Flat washer

■ ●

1

O-ring

264 3 Circlip

■ 94

1

Lockwasher

■ 121

4

CHC M6 screw

■ 290

1

Cable protector

■ 95

1

Flat washer

■ 122

4

Lockwasher

■ 291

1

Screw

■ 96

1

Clamp

124

1

Serial plate

Figure 13 – Cross Section of 12400 Series Digital Level Transmitter/Controller

Page 21

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 19

6. Operating the instrument

6.1. GENERAL PRINCIPLES

All digital settings of the 12400 instrument are made by means of three pushbuttons and a liquid crystal display on the front

of the instrument, or using HART

communication handheld terminals or GE’s Masoneilan software: ValVue*, ValVue AMS*

Snap-on and ValVue PRM

*

. Instrument settings can also be performed with any software compliant with FDT/DTM protocol.

The codes or values displayed by the LCD can be seen through a window on the main cover. Access to the three pushbuttons

is obtained by opening the cover (255). It is not necessary to open the main cover for calibration or adjustment of the

instrument. Except for maintenance and out of hazardous area, the cover must remain closed.

6.1.1.

THE LIQUID CRYSTAL DISPLAY (LCD)

The LCD displays simultaneously two lines of nine ASCII characters and one line of seven digital characters.

The display is also used to configure, calibrate and diagnose the 12400 instrument.

For ease of operations, values, codes or short names appear on the display. The various parameters are listed in the menus

(see Appendixes A, B, C, D, E, F and G).

6.1.2.

PUSHBUTTONS

Three pushbuttons (260) are located behind the cover (255) on the front of the instrument.

♦ The left button is marked with a star , the middle button with the sign –, and the right one with the sign +.

♦ means enter the function, accept or save to memory. It may be understood as "YES".

♦ + or – means vertical movement in the program structure. It may be understood by "NO" or "NEXT" or "PREVIOUS".

NOTE:

♦ Do not over push on the buttons. Press a button at least one second to perform the action.

♦ Accidental pushing of any of the buttons will not cause any malfunction.

After using the buttons, check instrument is in back to NORMAL mode, which displays in sequence the current signal and the

level of liquid. Close the cover (255).

6.1.3. OPERATING MODES

The instrument can operate under three modes with associated menus:

♦ NORMAL Mode: It is the normal operating mode. As a level transmitter, the 4-20 mA output signal (AO_1) is proportional

to the level in the tank. As a level controller, the 4-20 mA output signal (AO_1) is the controller output. The local digital

display alternately displays loop current and level expressed in the unit (% or engineering unit) shown in the low left

corner of the screen. Reading of the instrument database is possible.

♦ SETUP Mode: Mode to set parameters of the instrument (configuration, calibration or diagnostic) or to read data. The

output current is not proportional to the tank level.

♦ FAILSAFE Mode: The instrument automatically sets to the failsafe mode when a severe error has occurred. The output

current is set to the value entered in the ADVANCED SETUP Menu.

Page 22

20 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

6.1.4. PUSHBUTTONS MENUS DESCRIPTION AND HOW TO USE THEM

Seven Appendixes (A, B, C, D, E, F and G) detail the communication paths inside each menu and give descriptions and

explanations of each function.

♦ NORMAL Menu (see Appendix A).

♦ SETUP Menu (see Appendix A).

♦ BASIC SETUP Menu (see Appendix B).

♦ ADVANCED SETUP Menu (see Appendix C).

♦ ENGINEERING UNIT Menu (see Appendix D).

♦ FILTERING Menu (see Appendix D).

♦ 4-20mA GENERATION Menu (see Appendix E).

♦ AUTOMATIC TUNING Menu (see Appendix E).

♦ VIEW DATA Menu (see Appendix F).

♦ FAILSAFE Menu (see Appendix G).

♦ VIEW ERROR Menu (see Appendix G).

6.1.4.1. NORMAL Menu (Appendix A)

To enter NORMAL Menu from normal operating mode, press any button.

NORMAL menu allows to:

♦ Enter SETUP menu in order to set all instrument parameters.

♦ Access VIEW DATA menu (Appendix F) where the user can READ ONLY all current configuration, calibration and diagnostics

data saved in the instrument.

♦ View all faults which have occurred since the last fault clear with VIEW ERROR menu (Appendix G).

♦ Clear all faults with CLEAR FAULT function (Appendix G).

♦ Come back to normal operating mode: display in sequence of level variable and output current.

6.1.4.2. SETUP Menu (Appendix A)

SETUP menu allows to:

♦ Enter BASIC SETUP menu (Appendix B) to set all basic configuration and calibration parameters for a quick commissioning.

♦ Enter ADVANCED SETUP menu (Appendix C) to set all advanced configuration and calibration parameters for complete

management of process constraints and user practices.

♦ Come back to NORMAL menu.

♦ Access VIEW DATA menu (Appendix F) where the user can READ ONLY all current configuration, calibration and diagnostics

data saved in the instrument.

♦ View all faults which have occurred since the last fault clear with VIEW ERROR menu (Appendix G).

♦ Clear all faults with CLEAR FAULT function (Appendix G).

6.1.4.3. ENGINEERING UNIT Menu (Appendix D)

This menu allows the user to:

♦ Define the desired engineering unit for the level variable (%, cm, cm

3

…).

♦ Define the lower and higher level values (zero and span) expressed in engineering unit.

6.1.4.4. FILTERI

NG Menu (Appendix D)

This menu allows the setting of the two filterings available in the instrument:

♦ Damping adjustment (analog filtering).

♦ Smart filtering parameters tuning.

Page 23

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 21

6.1.4.5. 4-20mA GENERATOR Menu (Appendix E)

This menu enables generation of a loop current to a defined value independently of true level measurement. This function is of

help to set another instrument (such a positioner) in series in the loop, by generating the required output current.

6.1.4.6. AUTOMATIC TUNING Menu (Appendix E)

This menu enables to automatic tuning of the smart filtering parameters.

6.1.4.7. FAILSAFE Menu (Appendix G)

This menu is available only when the instrument failed and went to FAILSAFE mode. Then, the output signal is locked in low or

high failsafe value (see Advanced Setup menu).

This menu allows the user to:

♦ Enter SETUP menu to change any parameter.

♦ Come back to normal operating mode: display in sequence of level variable and output current.

♦ Perform a reset of the instrument.

♦ Access VIEW DATA menu (Appendix F) where the user can READ ONLY all current configuration, calibration and diagnostics

data saved in the instrument.

♦ View all faults which have occurred since the last fault clear with VIEW ERROR menu (Appendix G).

♦ Clear all faults with CLEAR FAULT function (Appendix G).

Page 24

22 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

7. Commissioning

This section is based on the following assumptions:

♦

12400 head has previously been mounted on a torque tube without coupling adjustment.

♦

Torque arm is mounted according to site requirements, if calibration has previously been done at workshop.

♦

Instrument is powered.

The steps described in the following pages for instrument settings and checking are done with the three pushbuttons and the

LCD display.

To perform 12400 commissioning through HART communication ValVue* software or handheld terminal, consult related

instruction manuals. Setting and calibration procedures are similar as based on the same philosophy.

Perform the following actions in the order given. They are also used for maintenance purposes. Several calibration procedures

are provided to cover available solutions at workshop and on site.

7.1. INSTRUMENT COUPLING TO THE TORQUE TUBE

NOTE: It is necessary to know the mounting direction (right or left) in order to correctly adjust the torque arm. See figures 7 and

23.

a. Remove the screw (106), the covers (104 & 107) of the connection and mechanism compartments, and the plug (190)

located at the bottom of the instrument.

b. Required level of liquid for coupling:

b1. At workshop with weights:

Coupling between torque tube and mechanism is achieved by simulating a half level of a 1.4 specific gravity liquid with

weights. Attach to the torque arm a weight equivalent to that of a displacer half immersed in a 1.4 specific gravity liquid

according to the following calculation:

b2. On site with the process liquid(s):

Two situations may occur:

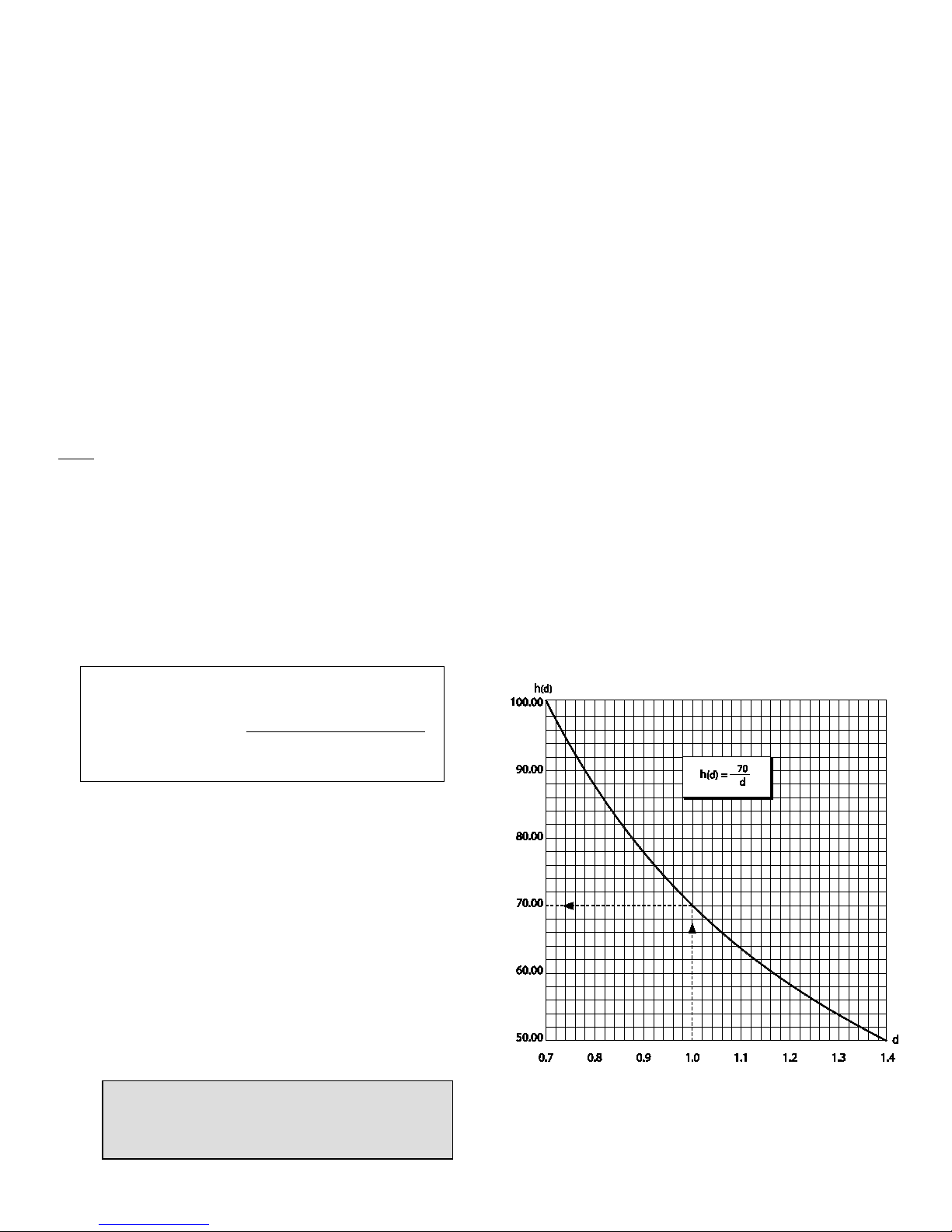

•

If the specific gravity (or the difference of the density in case

of an interface service) of the available liquid is between 0.7

and 1.4:

Simulate half level h (1.4) of a 1.4 specific gravity liquid with a

calculated value h (d) of the available liquid (refer to chart

Figure 14).

• If the specific gravity (d3) (or the difference of the density in

case of an interface service) of the available liquid is below

0.7:

Perform the coupling at high level in liquid service

(immersed displacer) or at high level of the highest spec

gravity liquid in interface application.

Figure 14

Curve of Half Level Simulation in a Liquid with S.G.

between 0.7 and 1.4

CAUTION: In this situation, the instrument must

be used for specific gravities (or the difference

of SG) ranging from 0.15 to 2xd3.

Simulated weight =

Actual displacer weight –

i.e. 1362 – 907 x 1.4 / 2 = 727.1 g for a standard displacer

(Actual volume displacer X 1.4)

2

Page 25

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 23

c. Enter the BASIC SETUP menu to display [COUPLNG:%].

d. Look through the side orifice and verify that the screw (62) coupling end of the beam (54) is loose and that the spring arm

(242) is disengaged from the pin (243). Through the 3/4 ” NPT hole at the bottom of the case, push the flexure (59) from

left to right with your finger to verify it is possible to move the beam (54). The value displayed should vary accordingly. Pin

(72) must rotate freely inside the coupling end of the beam.

e. Look at the mechanism through the lateral orifice, and index the oval hole of the flexure towards the special conical

ended pin (53) by bending the flexure (59) toward the case front (see Figure 15). The value read on the LCD must be

between –5% and +5%.

NOTE: Check there is no oscillation of the weight used to simulate the displacer.

f. While holding the flexure (59) in that position, slightly but firmly tighten the screw (62) using a 2.5 mm Allen wrench.

g. Bias (spring arm function) setting

g1. Index again the flexure (59) on the conical ended pin (53).

g2. Move the spring arm (242) below the pin (243) on the beam. The pin has a groove to position correctly the spring.

Check the spring arm is locating inside the pin groove.

g3. Relax the flexible lamella, check the weight stability and control the value on the LCD is always inside +/-5%.

53

59

243

242

72

62

54

CAUTION:

Do not over tighten. This can damage the instrument.

Figure 15

Indexing for coupling adjustment

Page 26

24 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

7.2. TRANSMITTER CONFIGURATION

Always perform or check instrument configuration before any calibration procedure. Configuration defines 12400 operating

mode, validates various features or sub-menus activation and impacts instrument internal diagnostics.

Check the following key features before initiating any calibration procedure:

♦ Measurement function: LEVEL or INTERFACE.

For special applications, it might be of interest to set the instrument in interface mode even for a level measurement. In this

case low specific gravity is set at 0.

♦ Mounting position of the instrument head versus displacer: LEFT or RIGHT.

An incorrect configuration causes calibration errors that my impact instrument operating and advanced diagnostics

capabilities.

♦ Loop current action: DIRECT or REVERSE.

This function both applies on AO_1 and AO_2 (main and second 4-20 mA output signals).

♦ See Appendixes A to G which describe operating and setting menus.

CAUTION:

In case of failsafe signal use ([FAIL LOW] or [FAIL HIGH]), check that loop current v

ariations are in line with

process and safety rules implemented into the Distributed Control System.

Page 27

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 25

CAUTION: If a new calibration is performed, the

parameters of the reduced range [R SPAN:%] and/or zero

shift function [Z SHIFT:%] are automatically set to zero.

In interface service, if the [LSG SERV] and/or [HSG SERV]

are modified, an automatic calculation is performed to set

a new value in [Z SHIFT:%].

CAUTION: In interface service, if the [LSG SERV] and/or [HSG SERV] are modified, an automatic

calculation is performed to set a new value in [Z SHIFT:%].

7.3. TRANSMITTER CALIBRATION

7.3.1. OPERATING RULES AND CALIBRATION PRINCIPLE

The purpose of this chapter is to detail internal device operating rules to understand names of functions and describe actions

generated by the embedded firmware during calibration. Advanced settings are also described to answer user constraints. In

some cases, the user can avoid doing a new calibration following a process change or can enable a level measurement on a

specific range different than the standard one.

♦ Specific Gravity of Calibration:

Specific Gravity of Calibration is unique in level service and double in interface service. If Specific Gravity of Calibration is

unknown (enter 1.0 in level service, and 1.0 and 0.001 in interface service as default values) or known without accuracy,

calibration is still possible. However, automatic setting of the Specific Gravity of Service will not be correctly performed or may

generate measurement errors.

The Specific Gravity of Calibration is that of the liquid used (or simulated by weights) for zero and span calibration in the BASIC

SETUP menu. Modify it only if zero and span calibration are performed again for a liquid of different specific gravity. See Section

7.3.3.

♦ Specific Gravity of Service:

Specific Gravity of Service is unique in level service and double in interface service.

The Specific Gravity of Service is the one used for the function [SG SERV] in the BASIC SETUP menu. Its value is identical to that

of [SG CALIB] just after calibration. If the specific gravity of the process liquid is different, simply modify the value of [SG SERV]

without performing a new calibration.

♦ Reduced Span and/or zero shift:

For an application where the level change is smaller than

the displacer height, it is possible to obtain the full signal

range for this reduced level range thanks to Reduced Span

and Zero Shift functions.

Example: To modify a calibration so that 0 % corresponds to

a displacer immersed to 1/4 of its height (25%), and 100%

corresponds to a displacer immersed to 4/5 of its height

(80 %), adjust zero shift to 25 % and span reduction to 45 %.

See schematic on Figure 16.

[ZERO]: Corresponds to the low level reference; usually to the displacer not immersed in level application or to the displacer

fully immersed in lower specific gravity in an interface application.

[SPAN]: Corresponds to the high level reference; usually to the displacer fully immersed in level application or fully

immersed in higher specific gravity in an interface application.

Figure 16

Schematic example of reduced range

Page 28

26 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

♦ Calibration of transmitter for level application:

The electronic circuit is calibrated towards two reference levels (REF L and REF H). See schematic below.

REF L corresponds to the displacer completely out of liquid.

REF H corresponds to the displacer fully immersed in the liquid of Specific Gravity used for calibration [SG CALIB].

The loop current corresponding to REF L may be set through [MA LO:mA] via [VAR SET]; it is generally 4mA.

The current corresponding to REF H may be set through [MA HI:mA] via [VAR SET]; it is generally 20mA.

The value of [MA HI:mA] must always be higher than the value of [MA LO:mA].

The level indication corresponding to REF L is set through function [LRV] via [VAR SET]; it is expressed in the unit set through

[UNIT] function; if UNIT is "%", [LRV] must be 0.00%.

The level indication corresponding to REF H is set through function [URV] via [VAR SET]; it is expressed in the unit set through

[UNIT] function; if UNIT is "%", [URV] must be 100.00%.

Page 29

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 27

♦ Calibration of transmitter for interface application:

The level transmitter is used to measure the interface level of two immiscible liquids of different specific gravities. The displacer

must always be fully immersed.

The electronic circuit is calibrated towards two reference levels (REF L and REF H). See schematic below.

REF L corresponds to the displacer completely immersed in the liquid of Lower Specific Gravity used for calibration [LSG

CALIB].

REF H corresponds to the displacer fully immersed in the liquid of Higher Specific Gravity used for calibration [HSG CALIB].

The loop current corresponding to REF L may be set through [MA LO:mA] via [VAR SET]; it is generally 4mA.

The current corresponding to REF H may be set through [MA HI:mA] via [VAR SET]; it is generally 20mA.

The value of [MA HI:mA] must always be higher than the value of [MA LO:mA].

The level indication corresponding to REF L is set through function [LRV] via [VAR SET]; it is expressed in the unit set through

[UNIT] function; if UNIT is "%", [LRV] must be 0.00%.

The level indication corresponding to REF H is set through function [URV] via [VAR SET]; it is expressed in the unit set through

[UNIT] function; if UNIT is "%", [URV] must be 100.00%.

Page 30

28 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

Standard displacer characteristics S.I Units English Units

Displacer weight 1362 g 3 lbs

Displacer volume 907 cm

3

55.34 in3

Fluid specific gravity

CAUTION: During the dry calibration without mechanism chamber, DO NOT ATTACH SPECIAL INTERFACE

DISPLACER (OR ITS EQUIVALENT EFFECTIVE WEIGHT) on the torque arm. Indeed, these displacers being

heavier than those for liquid level service and no mechanical stop being available without of mechanism

chamber, the torque tube and/or the instrument mechanism would be damaged.

7.3.2. CALIBRATION AT WORKSHOP WITH WEIGHTS

a. From [BAS SETUP] menu, enter the [CALIB Z S] sub-menu.

b. Enter specific gravity of calibration in level application [SG CALIB] or the low and high specific gravities in interface

application [LSG CALIB] and [HSG CALIB].

Actual volume and weight of the displacer can be read using HART communication (if data have been previously saved into

the 12400 instrument memory). Otherwise actual volume of the displacer is marked on the firm plate and displacer weight

can be measured by weighting of it.

c. Low Level [ZERO]

c1. Liquid application:

Attach to the torque arm a set of weights equivalent to the true displacer weight (i.e. 1362 g for a standard displacer) to

simulate the low level.

c2. Interface application:

Attach to the torque arm a set of weights equivalent to the displacer weight completely immersed in the liquid of Lower

Specific Gravity used for calibration [LSG CALIB] using the following formula:

c3. Enter and validate the [ZERO]: the [LEVEL:%] value indicated on the display must equal to 0.0%. If not, restart the

procedure until very close to this value. See Appendix B.

Displacer Apparent Weight for REF B =

Displacer Actual Weight - (Displacer Actual Volume X [LSG CALIB])

Page 31

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 29

d. High Level [SPAN]

d1. Liquid application:

Attach to the torque arm a set of weights equivalent to the apparent weight of the displacer fully immersed in the

calibration fluid with Specific Gravity of Calibration [SG CALIB], i.e.:

d2. Interface application

Attach to the torque arm a set of weights equivalent to the displacer weight completely immersed in the liquid of

Higher Specific Gravity used for calibration [HSG CALIB] using the following formula:

d3. Enter and validate the [SPAN]: the [LEVEL:%] value indicated on the display must equal 100.0%. If not, restart the

procedure until very close to this value. See Appendix B.

e. Press the * button when [SAVE] is displayed to validate the [ZERO] and [SPAN] settings.

Displacer Apparent Weight for REF H =

Displacer Actual Weight - (Displacer Actual Volume X [SG CALIB])

i.e. 1362 – 907 x 1 = 455 g for a standard displacer and water

Displacer Apparent Weight for REF H =

Displacer Actual Weight - (Displacer Actual Volume X [HSG CALIB])

Page 32

30 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

7.3.3. CALIBRATION ON SITE WITH PROCESS FLUIDS

a. From [BAS SETUP] menu, enter the [CALIB Z S] sub-menu.

b. Enter specific gravity of calibration for level application [SG CALIB] or the low and high specific gravities for interface

application [LSG CALIB] and [HSG CALIB].

c. Take all necessary actions to enable level variations into the displacer chamber: open/close isolation valves, vent, purge

…

d. Empty and fill the displacer chamber with fluid(s) of service to get level variations.

e. Wait for a few seconds until the displacer stabilizes to validate and save the values displayed on the LCD after each level

variation.

f. Low Level [ZERO]

f1. Liquid application:

Empty the displacer chamber.

f2. Interface application:

Fully immerse the displacer in the liquid of Lower Specific Gravity used for calibration [LSG CALIB].

f3. Enter and validate the [ZERO]: the [LEVEL:%] value indicated on the display must equal to 0.0%. If not, restart the

procedure until very close to this value. See Appendix B.

g. High Level [SPAN]

g1. Liquid application:

Fully immerse the displacer in the liquid of Specific Gravity used for calibration [SG CALIB].

g2. Interface application:

Fully immerse the displacer in the liquid of Higher Specific Gravity used for calibration [HSG CALIB].

g3. Enter and validate the [SPAN]: the [LEVEL:%] value indicated on the display must be equal 100.0%. If not, restart the

procedure until very close to this value. See Appendix B

h. Press the * button when [SAVE] is displayed to validate the [ZERO] and [SPAN] settings.

Page 33

® 2014 General Electric Company. All rights reserved. Masoneilan 12400 Series Transmitter/Controller Instruction Manual | 31

7.3.4. CALIBRATION WITH MECHANICAL STOPS

This calibration procedure is very useful on site and for interface application when there is no capability to make level

variations into the tank.

a. Open the access plug (107) on the right side of the case to look at the simulation mechanism. Remove plug (190) and the

two 1/8” NPT plugs (115). Use a 5 mm Hex wrench.

b. Simulate level variations by moving the flexure (59) in the direction of the torque tube until the flexure touches the

adjusting screw post (114).

c. While maintaining contact, slide the flexure left or right along the surface of the screw post (figure 17) to simulate low and

high level values of the process fluid(s).

d. Enter [BAS SETUP] menu and the [CALIB Z S] sub-menu.

e. Enter specific gravity of calibration in level application [SG CALIB] or the low and high specific gravities in interface

application [LSG CALIB] and [HSG CALIB].

f. Low Level [ZERO]

f1. Liquid application:

Move the flexure (59) against the adjusting screw shoulder (114), which corresponds to the low level (opposite side to

the displacer). Wait for a few seconds until the displacer stabilizes.

f2. Interface application:

Move the flexure (59) against the adjusting screw shoulder (114), which corresponds to the lowest specific gravity fluid

of calibration [LSG CALIB] (opposite side to the displacer). Wait for a few seconds until the displacer stabilizes.

f3. Enter and validate the [ZERO]: the [LEVEL:%] value indicated on the display must equal 0.0%. If not, restart the

procedure until very close to this value. See Appendix B.

CAUTION:

This procedure is only possible if mechanical stops (adjusting screws) have been previosuly adjusted upon process fluids.

See mechanical stops setting Section 7.5.

Figure 17

Calibration with adjusting screws

Page 34

32 | GE Oil & Gas ® 2014 General Electric Company. All rights reserved.

g. High Level [SPAN]

g1. Liquid application:

Move the flexure (59) against the adjusting screw shoulder (114), which corresponds to the high level of calibration

fluid [SG CALIB] (on displacer side). Wait for a few seconds until the displacer stabilizes.

g2. Interface application:

Move the flexure (59) against the adjusting screw shoulder (114), which corresponds to the high level of highest specific

gravity fluid of calibration [HSG CALIB] (on displacer side). Wait for a few seconds until the displacer stabilizes.

g3. Enter and validate the [SPAN]: the [LEVEL:%] value indicated on the display must equal 100.0%. If not, restart the

procedure until very close to this value. See Appendix B.

h. Press the * button when [SAVE] is displayed to validate the [ZERO] and [SPAN] settings.

i. Reinstall all plugs (107), (190), and (115).

Page 35