Page 1

Solar® SpO2 Module

with Masimo SET

Service Manual

2004407-001 Revision A

®

Page 2

127(Due to continuing product innovation, specifications in this manual are subject to change without

notice.

Listed below are GE Medical Systems Information Technologies trademarks. All other trademarks contained

herein are the property of their respective owners.

900 SC, ACCUSKETCH, AccuVision, APEX, AQUA-KNOT, ARCHIVIST, Autoseq, BABY MAC, C Qwik

Connect, CardioServ, CardioSmart, CardioSys, CardioWindow, CASE, CD TELEMETRY, CENTRA, CHART

GUARD, CINE 35, CORO, COROLAN, COROMETRICS, Corometrics Sensor Tip, CRG PLUS, DASH,

Digistore, Digital DATAQ, E for M, EAGLE, Event-Link, FMS 101B, FMS 111, HELLIGE, IMAGE STORE,

INTELLIMOTION, IQA, LASER SXP, MAC, MAC-LAB, MACTRODE, MANAGED USE, MARQUETTE,

MARQUETTE MAC, MARQUETTE MEDICAL SYSTEMS, MARQUETTE UNITY NETWORK, MARS,

MAX, MEDITEL, MEI, MEI in the circle logo, MEMOPORT, MEMOPORT C, MINISTORE, MINNOWS,

Monarch 8000, MULTI-LINK, MULTISCRIPTOR, MUSE, MUSE CV, Neo-Trak, NEUROSCRIPT,

OnlineABG, OXYMONITOR, Pres-R-Cuff, PRESSURE-SCRIBE, QMI, QS, Quantitative Medicine,

Quantitative Sentinel, RAC RAMS, RSVP, SAM, SEER, SILVERTRACE, SOLAR, SOLARVIEW, Spectra

400, Spectra-Overview, Spectra-Tel, ST GUARD, TRAM, TRAM-NET, TRAM-RAC, TRAMSCOPE, TRIM

KNOB, Trimline, UNION STATION, UNITY logo, UNITY NETWORK, Vari-X, Vari-X Cardiomatic,

VariCath, VARIDEX, VAS, and Vision Care Filter are trademarks of GE Medical Systems Information

Technologies registered in the United States Patent and Trademark Office.

12SL, 15SL, Access, AccuSpeak, ADVANTAGE, BAM, BODYTRODE, Cardiomatic, CardioSpeak, CD

TELEMETRY

Cumulus, Event-Link Nimbus, HI-RES, ICMMS, IMAGE VAULT, IMPACT.wf, INTER-LEAD, IQA,

LIFEWATCH, Managed Use, MARQUETTE PRISM, MARQUETTE

MicroSmart, MMS, MRT, MUSE CardioWindow, NST PRO, NAUTILUS, O

®

-LAN, CENTRALSCOPE, Corolation, EDIC, EK-Pro, Event-Link Cirrus, Event-Link

®

RESPONDER, MENTOR,

SENSOR, Octanet, OMRS, PHi-

2

Res, Premium, Prism, QUIK CONNECT V, QUICK CONNECT, QT Guard, SMART-PAC, SMARTLOOK,

Spiral Lok, Sweetheart, UNITY, Universal, Waterfall, and Walkmom are trademarks of GE Medical Systems

Information Technologies.

© GE Medical Systems Information Technologies, 2000. All rights reserved.

T-2 Masimo SET SpO2 Module Revision A

2004407-001 15 December 2000

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -4

Definitions of Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Equipment Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

2 Equipment Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Solar SpO

Solar 7000 Patient Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Solar 8000 Patient Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Solar 8000M Patient Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Tram-rac Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Insert Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Module with Masimo SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2

Revision A Solar SpO

2004407-001

with Masimo SET i

2

Page 4

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Recommended Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Recommended Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Cleaning Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Exterior Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Checkout Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Required Tools/ Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

SpO

Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

2

Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Required Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

AC Hi-Pot Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Test Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Required Tools/Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Current Leakage Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Patient (Source) Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Patient (Sink) Leakage Current Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

PM Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Repair Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

ii Solar SpO

2004407-001

with Masimo SET Revision A

2

Page 5

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Fault Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

First Things to Ask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

System OK LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

MS-3 Communications OK LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Isolated Power Supply OK LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Hardware Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Software Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

System Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Masimo MS-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Host Patient Monitor Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Power Condition and Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Isolated Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Patient Connector Flex Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

External Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

SpO

Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

2

Probe Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Host Patient Monitor Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Software Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

5 Parts Lists and Drawings . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Field Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Assembly Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Masimo SET SpO

Masimo SET SpO

Masimo SET SpO

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Solar SpO

Revision A Solar SpO

Module with Masimo SET 2001891-001A . . . . . . . . . . . . . . . . . . . . . . 5-5

2

2004407-001

MS-3 PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

2

Module Flex PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -4

2

Module PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

2

with Masimo SET iii

2

Page 6

iv Solar SpO

2004407-001

with Masimo SET Revision A

2

Page 7

1 Introduction

Revision A Solar SpO2 Module with Masimo SET 1-1

2004407-001

Page 8

For your notes

1-2 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 9

Manual Information

Revision History

Each page of the document has the document part number and revision

letter at the bottom of the page. The revision letter changes whenever

the document is updated.

Purpose

This manual provides technical information for maintaining the

equipment. Use it as a guide for maintenance and electrical repair of

parts considered field repairable.

Introduction: Manual Information

Revision Date Comment

A 15 December 2000 Initial release.

Intended Audience

Users of this manual are expected to have a background in electronics,

including analog and digital circuitry with RF and microprocessor

architectures. It is intended for service representatives and technical

personnel who maintain, troubleshoot, or repair this equipment.

Revision A Solar SpO2 Module with Masimo SET 1-3

2004407-001

Page 10

Introduction: Safety Information

Safety Information

Responsibility of the Manufacturer

GE Medical Systems Information Technologies is responsible for the

effects of safety, reliability, and performance only if:

n

assembly operations, extensions, readjustments, modifications, or

repairs are carried out by persons authorized by GE Medical Systems

Information Technologies, Inc;

n

the electrical installation of the relevant room complies with the

requirements of the appropriate regulations; and

n

the device is used in accordance with the instructions for use.

Intended Use

This device is intended for use under the direct supervision of a licensed

health care practitioner.

This device is not intended for home use.

Federal law restricts this device to be sold by or on the order of a

physician.

Contact GE Medical Systems Information Technologies for information

before connecting any devices to the equipment that are not

recommended in this manual.

Parts and accessories used must meet the requirements of the applicable

IEC 60601 series safety standards, and/or the system configuration must

meet the requirements of the IEC 60601 medical electrical systems

standard.

Periodically, and whenever the integrity of the device is in doubt, test all

functions.

The use of ACCESSORY equipment not complying with the equivalent

safety requirements of this equipment may lead to a reduced level of

safety of the resulting system. Consideration relating to the choice shall

include:

u

use of the accessory in the PATIENT VICINITY; and

u

evidence that the safety certification of the ACCESSORY has

been performed in accordance to the appropriate IEC 60601-1

and/or IEC 60601 harmonized national standard.

If the installation of the equipment, in the USA, uses 240V rather than

120V, the source must be a center-tapped, 240V, single-phase circuit.

1-4 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 11

Introduction: Safety Information

Definitions of Warnings, Cautions, and Notes

Warnings, cautions, and notes are used throughout this manual to

designate a degree or level of hazardous situations. Hazard is defined as

a source of potential injury to a person.

'$1*(5

indicates an imminent hazard which, if not avoided, will

result in death or serious i njury.

:$51,1*

indicates a potential hazard or unsafe practice which, if

not avoided, could result in death or serious injury.

&$87,21

indicates a potential hazard or unsafe practice which, if

not avoided, could result in minor personal injury or

product/property damage.

Equipment Symbols

127(provides application tips or other useful information to assure

that you get the most from your equipment.

The following symbols appear on the equipment.

ATTENTION: Consult accompanying documents before using the

equipment.

Revision A Solar SpO2 Module with Masimo SET 1-5

2004407-001

Page 12

Service Information

Service Requirements

n

n

n

n

n

Introduction: Service Information

Refer equipment servicing to GE Medical Systems Information

Technologies authoriz ed service personnel only.

Any unauthorized attempt to repair equipment under warranty voids

that warranty.

It is the user’s responsibility to report the need for service to GE

Medical Systems Information Technologies or to one of their

authorized agents.

Failure on the part of the responsible individual, hospital, or

institution using this equipment to implement a satisfactory

maintenance schedule may cause undue equipment failure and

possible health hazards.

Regular maintenance, irrespective of usage, is essential to ensure

that the equipment will always be functional when required.

Equipment Identification

Every GE Medical Systems Information Technologies device has a

unique serial number for identification. The serial number appears on

the product label on the base of each unit.

D 0 XX 0005 G XX

Month

Manufactured

A = January

B = February

C = March

D = April

E = May

F = June

G = July

H = August

J = September

K = October

L = November

M = December

Year

Manufactured

0= 2000

1= 2001

2= 2002

(and so on)

Product Code

Two-character

product descriptor

Product Sequence

Number

Manufacturing

number

(of total units

manufactured.)

Division

F = Cardiology

G = Monitoring

J = G.W. Labs

Device Characteristics

One or 2 letters that further

describe the unit, for example:

P = prototype not conforming to

marketing specification

R = refurbished equipment

S = special product documented

under Specials part numbers

U = upgraded unit

1-6 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 13

2 Equipment Overview

Revision A Solar S pO2 Module with Masimo S ET 2-1

2004407-001

Page 14

For your notes

2-2 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 15

Equipment Overview: System Components

System Components

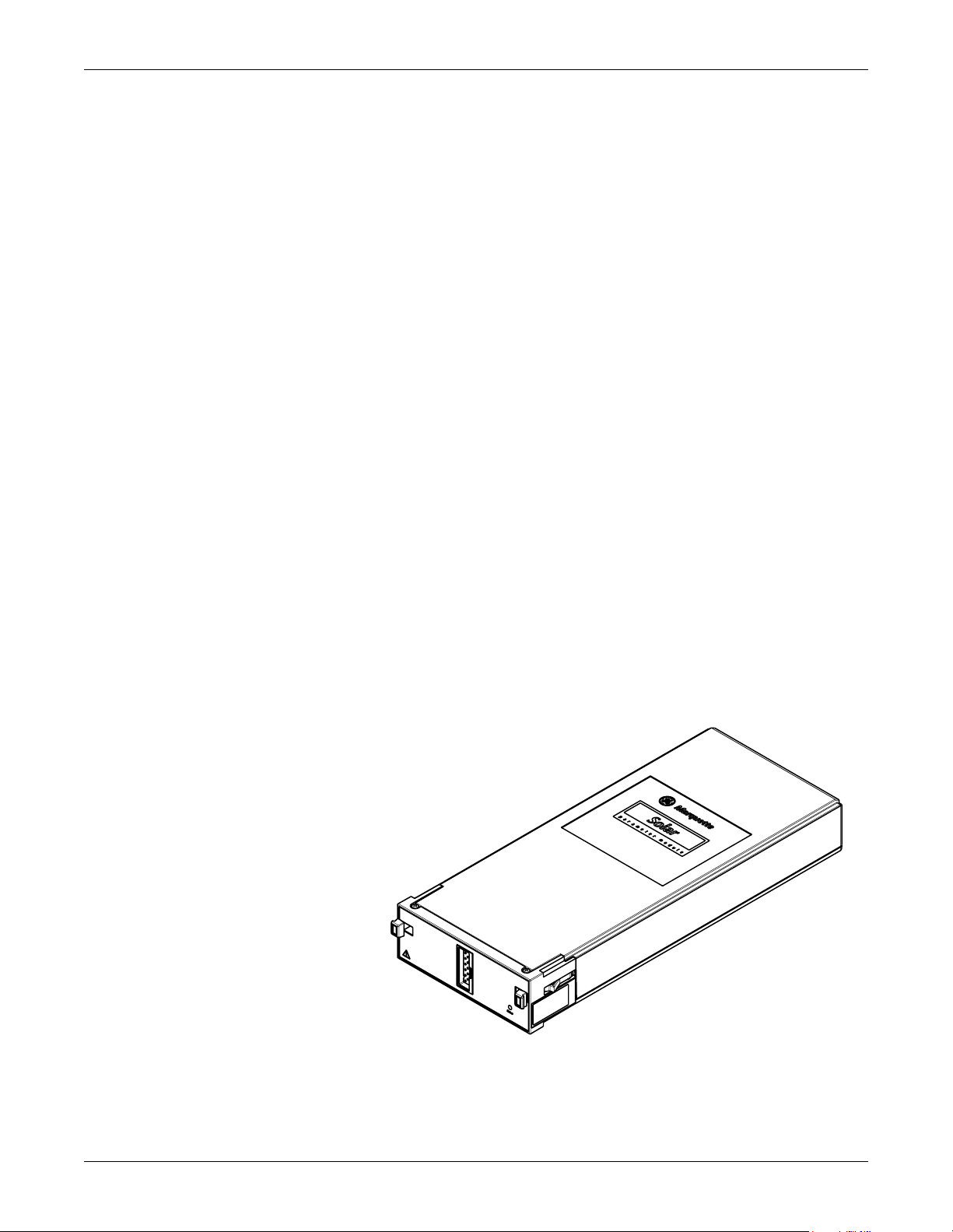

Solar SpO2 Module with Masimo SET

The Solar SpO2 module with Masimo SET, hereafter called the Masimo

module, and accessories is intended for continuous noninvasive

monitoring of functional oxygen saturation of arterial hemoglobin (SpO

and pulse rate (measured by an SpO

neonatal patients in hospitals and hospital-type environments. The

Masimo module provides all the necessary patient isolation. The Masimo

module is compatible with GE Medical Systems Information

Technologies Solar 7000, 8000, and 8000M modular products including

Tram-rac 4A. The device is housed in a standard single-high 7000 series

module enclosure.

The Masimo module uses spectrophotometric analysis to determine the

percent of oxygen saturation of hemoglobin in arterial bl ood also known

as pulse oximetry. When inserted into a Tram-rac 4A housing connected

to any Solar-based patient monitor, the module provides monitoring of

peripheral oxygen saturation and pulse rate for an adult, pediatric, or

neonatal patient.

sensor) for adult, pediatric, and

2

)

2

It uses Masimo LNOP cables. Other hardware functions include power

conditioning (soft-start live-insertion capability, short-circuit protection)

and isolation of the patient connected circuitry from earth ground.

Software may be updated using a laptop computer connected to any

compatible Solar based patient monitor.

The Masimo module shown below monitors pulse oximetry.

Revision A Solar S pO2 Module with Masimo S ET 2-3

2004407-001

Page 16

Equipment Overview: System Components

Solar 7000 Patient Monitor

One Solar based patient monitor used with the Masimo module is the

Solar 7000 patient monitor (software version 3C, 4B, or later). It is an

intelligent terminal, containing the display, all of the user controls, and

processors to communicate with patient monitor peripherals and analyze

patient data. It is capable of displaying up to six or eight different

waveforms at one time. System software may be updated by a laptop

computer at the monitor or through the Unity Network using a central

station.

Solar 7000

Patient Monitor

Solar 8000 Patient Monitor

The Solar 8000 patient monitor system (software version 3C, 4B, or

later) consists of a Solar 8000 processing unit with a compatible display.

The processing unit provides the user controls, processors to

communicate with patient monitor peripherals, and analyzes patient

data. It is capable of displaying up to six or eight different waveforms at

one time on the compatible 12, 15, 17, or 19-inch display. System

software may be updated using a laptop computer conne cted to t he Solar

8000 processing unit or through the Unity Network using a central

station.

2-4 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 17

Equipment Overview: System Components

Solar 8000M Patient Monitor

The Solar 8000M patient monitor (software version 1A or later) consists

of a Solar 8000M processing unit with compatible display.

The processing unit is the center of the Solar 8000M Patient Monitoring

system. It provides the user con trols, t he processors t o communicate with

various patient monitoring modules, and it analyzes patient data. It can

display up to eight di fferent waveforms at one time. System software

may be updated using a laptop computer connected to the Solar 8000M

processing unit or from a central station on the Unity Network.

Tram-rac Housing

The Tram-rac housing (remote acquisition case) acquires patient data for

the patient monitor. The Tram-rac Housing Service Manual has more

information.

Only compatible Solar based monitors and the Tram-rac 4A (software

version 6C or later) housing support the Masimo module.

Shown below is a Tram-rac 4A housing.

Revision A Solar S pO2 Module with Masimo S ET 2-5

2004407-001

Page 18

Equipment Overview: Technical Specifications

Technical Specifi ca ti ons

127(

Nellcor, GE Medical Systems Information Technologies, and Masimo

pulse oximetry is calibrated to display functional saturation.

Ohmeda pulse oximetry is calibrated to display fractional saturation.

Item Description

Display Messages ARTIFACT DETECTED, LOW QUALITY, PROBE IS OFF

Measurement Range

Saturation

Pulse Rate

Perfusion

Performance Specifications

THE PATIENT, PROBE OR MODULE MALFUNCTION,

POOR SIGNAL QUALITY DETECTED, PULSE SEARCH

1 to 100% SpO

25 to 240 bpm

0.02 to 20%

2

Accuracy

Saturation, no motion

Saturation, motion

Pulse Rate, no motion

Pulse Rate, motion

Item Description

Maximum Power Consumption

(non-isolated)

Item Description

Operating Conditions

Temperature

Relative Humidity

SpO

over the range 70 to 100%, below 69% is unspecified

2

±2 digits for adults and pediatrics, ±3 digits for neonates

SpO

over the range 70 to 100%, below 69% is unspecified

2

±3 digits for adults, pediatrics, and neonates

25 to 240 bpm, ±3 bpm

25 to 240 bpm, ±5 bpm

Power Requirements

+16.5V, 150mA

+5V, 150mA

Environmental Specifications

0°C to 40°C (32°F to 104°F)

15 to 90% (non-condensing)

Storage Conditions

Temperature

Relative Humidity

Altitude -305 to 1830m (-1000 to 6,000ft.)

Atmospheric Pressure 645 to 795mmHg (860 to 1060hPa)

2-6 Solar SpO2 Module with Masimo SET Revision A

2004407-001

–40°C to +70°C (–40°F to +140°F)

0 to 95% (non-condensing)

Page 19

Equipment Overview: Technical Specifications

Alarm Specifications

Item Description

Alarm Limit Range SpO2: 1% to 105%

Pules: 40 BPM to 235 BPM

Type Audible

Visual

Physical Specifications

Item Description

Height 4.0 cm (1.6 in)

Width 11.4 cm (4.5 in)

Depth 28.6 cm (11.25 in)

Weight 0.50 Kg (1.11 lb)

Cooling Method Natural convection

Heat Dissipation 8.75Btu/Hr (2.5W), maximum

Certification UL 2601-1 Classified.

UL Classified for CAN/CSA C22.2 No. 601.1.

CE Marking for the 93/42/EEC medical Device Directive.

IEC 60601-1 Certified.

Warranty One year (accessories may differ)

Revision A Solar S pO2 Module with Masimo S ET 2-7

2004407-001

Page 20

Insert Module

Equipment Overview: Insert Module

1. Insert the module in one of the bottom two slots of a Tram-rac 4A

housing.

TRAMSCOPE 12

MARQUETTE

2. Connect the patient cable assembly to the SpO

connector on the

2

module.

Make sure the following eve nts tak e pl ace .

u

The front panel LED of the module illuminates steady green

after all self-tests of the processor are complete.

u

The module identifies itself on the monitor screen with a patient

parameter box.

127(

The module will not identify itself on the monitor if the patient cable

assembly is not connected.

127(

When used with a powered Tram-rac, the patient isolated circuitry

voltage is enabled by the host monitor as indicated by the PWR LED.

3. If the module does not identify itself on the screen and the patient

cable assembly is connected, refer to chapter 4, Troubleshooting.

Otherwise, go to chapter 3, Maintenance and perform the Checkout

Procedures and Safet y Tests.

2-8 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 21

3 Maintenance

Revision A Solar SpO2 Module with Masimo SET 3-1

2004407-001

Page 22

For your notes

3-2 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 23

Maintenance: Maintenance Schedule

Maintenance Schedule

Recommended Maintenance

A regular equipment maintenance program helps prevent unnecessary

equipment failures and also reduces possible health hazards. This

chapter contains instructions for the following recommended

maintenance:

n

Inspecting and cleaning the module

n

Checkout procedure to verify the unit is working properly

n

Leakage tests to verify the equipment does not propose a safety

hazard

Recommended Frequency

To help you establish a systematic maintenance routine, GE Medical

Systems

maintenance procedures presented in this chapter

Information Technologies

recommends that you perform all

Safety Tests

n

upon receipt of the module,

n

every twelve months thereafter,

n

each time a circuit board is removed or replaced, and

n

record the results on the Repair Log included at the end of this

chapter.

It is recommended that all safety tests be performed if a unit has been

opened for any reason or repaired. Listed below are the safety tests

recommended.

n

All leakage tests described in this chapter,

n

All hi-pot tests described in this chapter,

:$51,1*

Failure to implement a satisfactory maintenance

schedule may cause undue equipment failure and

possible health hazards. Unless you have an Equipment

Maintenance Contract, GE Medical Systems Information

Technologies does not in any manner assume the

responsibility for performing the recommended

maintenance procedures. The sole responsibility rests

with the individual or institution using the equipment.

GE Medical Systems Information Technologies service

personnel may, at their discretion, follow the procedures

provided in this manual as a guide during visits to the

equipment site.

Revision A Solar SpO2 Module with Masimo SET 3-3

2004407-001

Page 24

Maintenance: Inspection and Cleaning

Inspection and Cleaning

Visual Inspection

Remove module before making an inspection or cleaning the module.

n

Check the case for cracks or other damage.

n

Regularly inspect cables for fraying or other damage.

n

Inspect all plugs, cables, and connectors for bent prongs or pins.

n

Verify that all cables and connectors are securely seated. Note that

replacement of components should be performed only by qualified

service personnel.

Cleaning Precautions

Recommended cleaning supplies:

n

ammonia (diluted), or

n

Cidex solution, or

n

sodium hypochlorite bleach (diluted), or

n

mild soap (diluted), and

n

lint-free cloth, and

n

dust remover (compressed air)

Exterior Cleaning

To avoid damage to the equipment surfaces, do not use the following

cleaning agents:

n

organic solvents,

n

ammonia based solutions,

n

acetone solution,

n

alcohol based cleaning agents,

n

Bentadine solution,

n

a wax containing a cleaning substance, or

n

abrasive cleaning agents.

Clean the exterior surfaces with a clean, lint-free cloth and one of the

cleaning solutions listed above.

n

Wring the excess water from the cloth. Do not drip any liquid into

open vents, plugs, or connectors.

n

Dry the surfaces with a clean cloth or paper towel.

3-4 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 25

Maintenance: Checkout Procedure

Checkout Procedure

General

This procedure tests the functions of the module. The checkout

procedures consist of the SpO

These procedures are based on the assumption that the modu le under

test is used with known good cables and known good test equipment. It

also assumes that you are at least somewhat familiar with the operation

of all devices required for the procedures. For more information

concerning the operation of these components, consult the appropriate

operator’s manuals.

Required Tools/Equipment

The following lists the test equipment, adapters, and cables necessary to

complete the checkout procedures.

n

Compatible Solar monitor and a Tram-rac 4A housing to power the

module.

n

Simulators and cables listed below provide waveforms and patient

vital signs.

tests.

2

Required Simulators and Cables

Item

SpO

Simulator 408610-001 or equivalent

2

Simulator Cable 2006011-001 or equivalent

SpO

2

n

Any patient cable or leadwire set that you would usually use on

patients.

Manufacturer and

Part Number/Model

Revision A Solar SpO2 Module with Masimo SET 3-5

2004407-001

Page 26

Preparation

Maintenance: Checkout Procedure

1. Install the module in a Tram-rac 4A housing.

TRAMSCOPE 12

MARQUETTE

2. Apply power to the monitor by turning the rear panel power switch to

the ON position.

3. Turn the display ON by pressing the DISPLAY ON/OFF or

POWER key on the front panel of the monitor.

SpO2 Test

4. Ensure that the power indicator of the monitor is on.

5. Ensure that the power indicator of the module is illuminated green.

127(

Do not connect the simulator to an AC power supply for these tests.

Operate the simulator on b attery power.

1. Turn the SpO

simulator power switch OFF.

2

2. Connect the simulator cable to the module.

3. Set the simulator as follows:

127(

Use the white-colored values on the simulator.

u

Set the MODE to NELLCOR.

u

Set the SpO2% to 99.

u

Set the PRR to 70 beats/minute.

u

Turn the power ON.

4. Verify the following are displayed at the monitor: (It might be

necessary to turn the SpO

parameter on.)

2

u

A waveform with an SpO2 label.

u

An SpO2% reading between 97 - 100%.

u

A PRR reading between 67 and 72 beats per minute.

3-6 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 27

Maintenance: Checkout Procedure

5. Test the accuracy of these SpO

% settings.

2

SpO

Settings

2

Simulator Setting Displayed Value

99% 96 - 100%

90.6% 87 - 94%

80.3% 77 - 83%

6. Test the accuracy of these PPR settings.

PPR Settings

Simulator Setting Displayed Value

70 67 – 73

100 97 – 103

7. Return the simulator to these conditions:

u

Set the SpO2% to 99.

u

Set the PPR to 70 beats/minute.

8. Set these alarms on the monitor:

u

Set SpO2% LO to 90.

u

Set PPR HI to 90.

9. Set PPR on the simulator to 100.

10. Make sure the PPR value on the monitor flashes, and it sounds an

alarm.

11. Return PPR on the simulator to 70.

12. Set SpO

% on the simulator to 80.3.

2

13. Make sure the SpO2% value on the monitor flashes, and it sounds an

alarm.

14. Disconnect the simulator cable from the module.

Revision A Solar SpO2 Module with Masimo SET 3-7

2004407-001

Page 28

Maintenance: Electrical Safety Tests

Electrical Safety Tests

Electrical safety tests provide a method of determining if potential

electrical safety hazards to the patient or operator of the device exist.

Recommendations

GE Medical Systems Information Technologies recommends electrical

safety tests be performed:

n

upon receipt of the module,

n

every twelve months thereafter, and

n

each time the module is opened or repaired.

Record the date and results on the Repair Log included at the end of this

chapter.

Required Tests

Test Conditions

To help you establish a systematic maintenance routine, GE Medical

Systems Information Technologies recommends that you perform all

safety tests presented in this chapter.

These instructions are intended for every module in the system. The

Tram-rac housing should remain connected to the host during the safety

tests. Listed below are the safety tests.

n

Hi-Pot Tests

These tests are mandatory when a module is opened or repaired.

n

Leakage Current Tests

These tests are performed after the hi-pot tests.

If a module under test fails the leakage tests, call Tech Support for

assistance. (Refer to “How to Reach Us” in front of this manual.)

All electrical safety tests may be performed under normal ambient

temperature, humidity, and pressure conditions with the module

inserted in a Tram-rac 4A.

3-8 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 29

AC Hi-Pot Test

Test Frequency

Maintenance: Electrical Safety Tests

Hi-pot (high-potential) tests protect the patient from possible electrical

safety hazards. They are recommended for any repaired patientconnected devices to ensure patient isolation after the repair.

This test is requ ired each time the module is op ened or repaired.

:$51,1*

Failure to perform hi-pot tests may cause undue

equipment failure and possible health hazards. GE

Medical Systems Information Technologies does not in

any manner, unless an Equipment Maintenance

Contract exists, assume the responsibility for performing

this recommended health test. The sole responsibility

rests with the individual or institution using the

equipment.

Required Tools/Equipment

Procedures

Equipment required to perform the test is listed below. Equivalent

equipment may be substituted.

Required Tools/Equipment

Item

AC Hi-Pot Generator 0 - 5000 Vac

Masimo Test Body Cable Assembly 2006036-001

:$51,1*

Shock hazard. DO NOT perform this test on any of the

other connectors.

1. Install the Masimo test body in the SpO

Specifications or

Part Number

connector of the module.

2

2. Connect the hi-pot generator output lead to the exposed lead of the

test body and connect the hi-pot return to any connector shell on the

back of the Tram-rac.

3. Set the HIGH VOLTAGE switch to ON.

4. Slowly increase output voltage to 4000 volts.

Revision A Solar SpO2 Module with Masimo SET 3-9

2004407-001

Page 30

Current Leakage Tests

Preparation

Maintenance: Electrical Safety Tests

5. Wait for 60 seconds. There should be no indication of breakdown

(warning lamp or buzzer).

6. Turn off the hi-pot tester and disconnect the leads.

7. If your module fails this test, contact GE Medical Systems

Information Technologies Tech Support.

The leakage current tests are safety tests to ensure that the equipment

poses no electrical safety hazards. It is recommended after performing

the hi-pot tests.

127(

These procedures test the integrity of this modu le only, not the entire

system.

:$51,1*

Failure to perform leakage tests may cause undue

equipment failure and possible health hazards. GE

Medical Systems Information Technologies does not in

any manner, unless an Equipment Maintenance

Contract exists, assume the responsibility for performing

this recommended health test. The sole responsibility

rests with the individual or institution using the

equipment.

The module must be installed in a Tram-rac 4A housing. Equipment and

tools are listed be low .

Required Tools/Equipment

Item

Leakage Current Tester Equivalent to the circuits shown below

Digital Multimeter (DMM) 0 - 200 AC millivolts

Masimo Test Body Cable Assembly 2006036-001

Specifications or

Part Number

3-10 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 31

Maintenance: Electrical Safety Tests

Use the table below to determine the maximum allowable leakage

currents. For international leakage limits, refer to the internal standards

agencies of the particular country.

Maximum Allowable Leakage Currents

Test Maximum Current

Patient (Source) leakage current

Ground closed, normal & reverse polarity

Patient (Source) leakage current

Ground open, normal & reverse polarity

Patient (Sink) leakage current

Ground closed, normal & reverse polarity

Patient (Source) Leakage Current Test

This test checks leakage current from the patient cable connector of the

module to ground.

1. Prepare the sy stem according to instructio ns on page 3-6.

2. Configure the leakage tester like the circuit shown below.

LEAKAGE TESTER

HIGH

LOW

GND

POWER CORD

Measuring

Device

V*

1K

0.15µF

10

NORM

RVS

GND

10 µA

50 µA

50 µA

POWER CORD

UNIT

UNDER

TEST

TEST BODY

1-mV meter reading = 1-µA leakage current

3. Connect the host power cord to the power outlet on the leakage

tester.

4. With the power switch of the leakage tester off, connect the power

cord of the leakage tester to a correctly wired and properly grounded

ac power outlet.

5. Set leakage tester switches as follows:

u

Set the GND switch to GND OPEN.

u

Set the polarity switch to NORM/FORWARD.

u

Set the power switch to OFF.

6. Set the leakage tester power switch to ON.

Revision A Solar SpO2 Module with Masimo SET 3-11

2004407-001

Page 32

Maintenance: Electrical Safety Tests

7. Set the host rear panel power switch to ON.

8. Read the leakage current indicated on the measuring device.

9. Change the leakage tester polarity switch to the REVERSE position.

10. Read the leakage current indicated on the measuring device.

127(

If either reading is greater than 50 µA, the module fails this test.

Contact GE Medical Systems Information Technologies Tech

Support.

11. Change the GND switch to the CLOSED position.

12. Read the leakage current indicated on the measuring device.

13. Change the leakage tester polarity switch to the REVERSE position.

14. Read the leakage current indicated on the measuring device.

15. Set the power switch of the leakage tester to OFF.

If either reading is greater than 10 µA, the module fails this test.

Contact GE Medical Systems Information Technologies Tech

Support.

127(

The AAMI and IEC single fault condition (ground open) limit is

50 µA, whereas the normal condition (ground closed) limit is 10 µA.

Patient (Sink) Leakage Current Test

This tests the patient cable leakage current from a 115 or 220V ac source

into the SpO

1. Prepare the sy stem according to instructio ns on page 3-6.

2. Configure the leakage tester like the circuit shown below.

LEAKAGE TESTER

HIGH

LOW

GND

POWER CORD

Measuring

Device

V*

connector of the module.

2

NORM

RVS

120K

0.15µF

1K

10

GND

POWER CORD

(Keep cable length

short as possible.)

TEST BODY

UNIT

UNDER

TEST

1-mV meter reading = 1-µA leakage current

3. On the leakage tester, leave the GND switch set to CLOSED and set

the polarity switch to NORM/FORWARD.

3-12 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 33

Completion

Maintenance: PM Form

:$51,1*

Shock hazard. The following step causes high voltage at

the test body. Do not touch the test body.

4. Set power switch on the leakag e tester to ON.

5. Read leakage current indicated on measuring device.

6. Change the leakage tester polarity switch to the REVERSE position.

7. Read the leakage current indicated on the measuring device.

8. Set the power switch on the leakage tester to OFF.

If either reading is greater than 50 µA, the module fails this test.

Contact GE Medical Systems Information Technologies Tech

Support.

1. Disconnect all test equipment from the module.

2. Disconnect the host power cord from leakage tester.

PM Form

3. Disconnect the tester from the power outlet.

Due to continuing product innovation and because specifications in this

manual are subject to change without notice, a PM form is not included

with this manual. For the latest PM form regarding this product, contact

a GE Medical Systems Information Technologies service representative.

On the following pages is a repair log to record the repair history of this

product.

Revision A Solar SpO2 Module with Masimo SET 3-13

2004407-001

Page 34

Repair Log

Unit Serial N umber:

Institution Name:

Date Maintenance/Repair Technician

Maintenance: Repair Log

3-14 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 35

Maintenance: Repair Log

Revision A Solar SpO2 Module with Masimo SET 3-15

2004407-001

Page 36

Maintenance: Repair Log

3-16 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 37

4 Troubleshooting

Revision A Solar SpO2 Module with Masimo SET 4-1

2004407-001

Page 38

For your notes

4-2 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 39

Troubleshooting: General Fault Isolation

General Fault Isolation

First Things to Ask

If the unit is not work ing properly ask these basic questions.

u

Is the module seated correctly?

u

Is the monitor and Tram-rac housing power cord connected?

u

Is the monitor turned ON at the rear of the monitor?

u

Is the display LED illuminated? Are all the communication

cables firmly connected?

u

Were there any changes in the use, location, or environment of

the equipment that could cause the failure?

u

Has the unit been modified in any way, either in software or

hardware?

Is operator error the cause of the problem? Try to repeat the use r’s

scenario exactly and compare that to the pr oper operation of the

equipment. Check the operator’s manual as necessary.

Visual Inspection

A thorough visual inspection of the equipment can save time. Small

things—disconnected cables, foreign debris on circuit boards, missing

hardware, loose components—can frequently cause symptoms and

equipment failures that may appear to be unrelated and difficult to

track.

Take the time to make all the recommended visual checks (refer to the

visual inspection chart on the next page) before starting any detailed

troubleshooting procedures.

Revision A Solar SpO2 Module with Masimo SET 4-3

2004407-001

Page 40

Area Look for the following problems:

I/O Connectors and Cables

Troubleshooting: General Fault Isolation

Visual Inspection List

n

Fraying or other damage

n

Bent prongs or pins

n

Cracked housing

n

Loose screws in plugs

Interface Cables

Circuit Boards

Note: If module is opened,

perform Electrical Safety Tests

in chapter 3, Maintenance.

Ground Wires/Wiring

Mounting Hardware

Power Source

n

Excessive tension or wear

n

Loose connection

n

Strain reliefs out of place

n

Moisture, dust, or debris (top and bottom)

n

Loose or missing components

n

Burn damage or smell of over-heated components

n

Socketed components not firmly seated

n

Solder problems: cracks, splashes on board, incomplete feedthrough, prior

modifications or repairs

n

Loose wires

n

Faulty wiring

n

Wires pinched or in vulnerable position

n

Loose or missing screws or other hardware

n

Faulty connection between PCBs

n

Power source problems may cause static discharge, resetting problems, and

noise.)

:$51,1*

Solder multilayer and surface mount PCB assemblies at

your own risk! Improper repair methods can damage the

PCB assemblies even further. Only qualified service

personnel with the proper laboratory equipment should

attempt to repair PCB assemblies.

4-4 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 41

Troubleshooting: Troubleshooting Procedure

Yes No

Yes No

Yes No

Troubleshooting Procedure

To use this troubleshooting procedure, read through the steps in the

table until you find a similar problem to the one you are having. Do not

perform any invasive procedures listed in this procedures unless you are

a trained field or bio-medical engineer.

:$51,1*

This procedure is intended for use by service personnel

with advanced troubleshooting skills. The consequences

of the following steps may cause loss of patient data and

disruption of the entire Unity Network.

Troubleshooting Chart

Is LED on front panel

green?

Is patient data displayed at

the monitor?

This problem has many sources, so try one or more of the following solutions.

1. Verify Tram-rac 4A housing is functional.

n

Verify Tram-rac power LED is ON.

n

Check for a loose or faulty cable from the patient monitor to the Tram-rac housing.

n

Power cycle Tram-rac 4A housing if it has an external power supply.

n

Swap Tram-rac 4A housing with a known good one.

2. If module LED is off or PROBE OR MODULE MALFUNCTION displays on the screen, there is a

hardware problem with the module.

n

Reseat Solar SpO2 module in the Tram-rac 4A housing.

n

Remove the sensor from the module, then reseat the Masimo module in the Tram-rac housing.

n

Verify Tram-rac housing is a Tram-rac 4A housing and turned ON.

n

Verify the host is a Solar-based monitor and turned ON.

n

Verify Solar-based monitor is running V2A or later software.

n

Verify Solar-based monitor is not resetting itself.

n

Swap module with a known good one.

Try one of the following solutions.

1. Verify correct patient or simulator leadwire connections to module.

2. Contact GE Medical Systems Information Technologies Tech Support.

Is the parameter box

displayed at the monitor?

End This is the extent of troubleshooting steps.

Revision A Solar SpO2 Module with Masimo SET 4-5

Verify that the patient cable is connected.

2004407-001

Page 42

Troubleshooting: Troubleshooting Procedure

System OK LED

The system LED, DS1, is red and is located inside the module. This LED

indicates whether the software is operating normally. The status of the

LED toggles each time the module completes transmitting a packet to

the host patient monitor.

MS-3 Communications OK LED

The MS-3 communications LED, DS2, is yellow and is located inside the

module. This LED indicates whether communications between the

Masimo MS-3 analyzer and the system processor are operating normally.

The LED toggles if a complete data packet is received from the Masimo

MS-3 analyzer pcb.

Isolated Power Supply OK LED

The isolated power supp ly LED, D S3, is gre en an d is lo cated on t he front

panel of the module. This LED indicates whether the isolated power

supply is operating normally. The LED is illuminated if power is applied

to the Masimo MS-3 analyzer pcb.

4-6 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 43

Troubleshooting: Theory of Operation

Theory of Operation

Hardware Functions

The Masimo SET SpO2 Module, hereafter referred to as the Masimo

module, provides all the hardware necessary to communicate with a host

patient monitor and continuously monitor the functional oxygen

saturation of arterial hemoglobin (SpO

features include the following items:

n

n

n

n

n

Software Functions

) and pulse rate. The hardware

2

Bedside communications using the Synchronous Serial Shift Register

Interface protocol.

Masimo MS-3 analyzer communications and control

Input power conditioning and soft-start current limiting

Code download - from host or BDM

4000 Volt patient isolation

System Processor

The Masimo module PCB performs the communications with the Masimo

MS-3 Analyzer PCB and host bedside communications. The device

performs the following functions under software control:

n

Bedside communications and error detection

n

Masimo MS-3 Analyzer communications and control

n

SpO2 value calculation

n

Respiration rate calculation

n

Error detection and alarm indication

n

Initialization and self test

The system processor uses external memory for operation. There is a

512K x 8 static RAM for temporary data storage.

127(The static RAM is not battery bac ked-up, therefore this device is

not a transportable patient monitor such as the TRAM module.

The static RAM is also used as temporary storage of Masimo MS-3

program code during program download of the MS-3 software. The

program code is stored in a 128K x 8 sectored FLASH EPROM. This

device can be erased on an individual sector basis. The first sector of

FLASH is used for storing the BOOT code. This insures that even if a

download of code fails the module still attempts another download of

code. The other seven sectors of FL ASH store the MAIN code. The MAIN

code operates during normal operation of the module. This code can be

updated using the host patient monitor.

Revision A Solar SpO2 Module with Masimo SET 4-7

2004407-001

Page 44

Troubleshooting: Theory of Operation

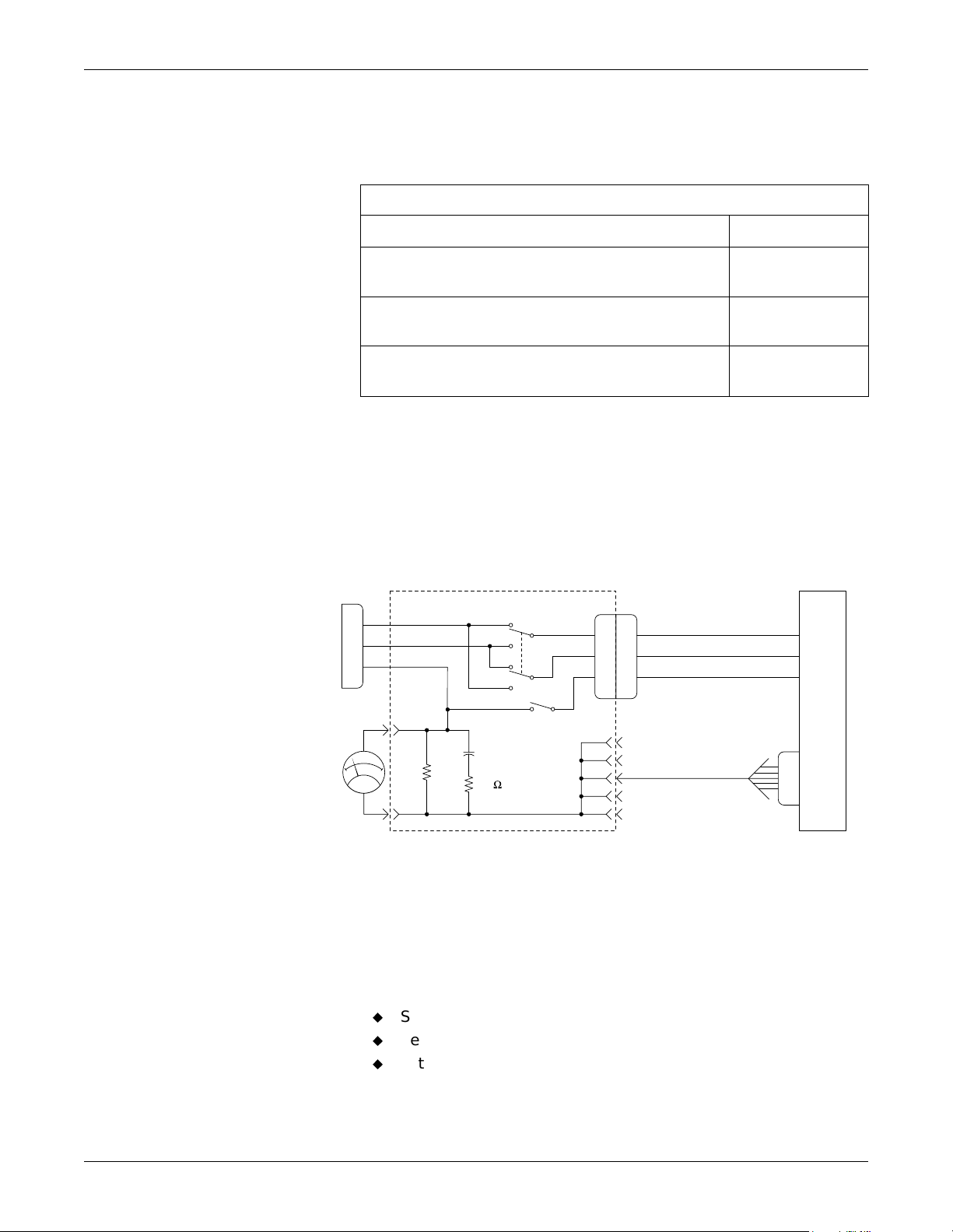

Below is the overall block di agram for the Masimo module.

Power Status LED

Masimo SET SpO2 Module PCB

FLASH

Program

Memory

SRAM

Data

Memory

Serial Shift Register Interface Signals

Module Communications Processor

Bendix Connector

+5V

+16.75V

Supports serial shift register interface to Tram-rac 4A

Power Condition

and Soft Start

Isolated Switching Power Supply

Communication

Processor

MC68332

+5V

Soft Starte d

+16.75V

Soft Starte d

Power Supply Enable

Power

Supply

Primary

4000 VAC Isolation Barrier

Tx

Opto

Rx

Opto

Reset

Opto

Feedback

Opto

Power

Supply

Isolated

Secondary

Masimo MS-3 Board

FLASH

Program

Memory

DSP

SRAM

Data

Memory

J3 J1

+5V

ISO

+15V ISO

-15V ISO

LED Drive / Sensor ID

Detector Signal

Instrument

(Flex) Cable

Adapter Signal

Masimo

Sensor

Connector

Receptacle

Masimo MS-3

The principles of operation of the Masimo MS-3 pulse oximeter is that

oxyhemoglobin and deoxyhemoglobin differ in their absorption of red and

infrared light (spectrophotometry), the volume of arterial blood in tissue

(and hence, light absorption by that blood) changes during the pulse

(plethysmography), and that arterio-venous shunting is highly variable

and that fluctuating absorbance by venous blood is a major component of

noise during the pulse. Because oxyhemoglobin and deoxyhemoglobin

differ in light absorption, the amount of red and infrared light absorbed

by the blood is related t o hemoglobin oxygen saturati on. The Masimo

MS-3 pulse oximeter decomposes the red and infrared pulsatile

absorbance signal into an arterial signal plus a noise component and

calculates the ratio of the arterial signals without noise. The ratio of the

two arterial pulse-added absorbance signals and its value is used to find

the SpO

MS-3’s software.

4-8 Solar SpO2 Module with Masimo SET Revision A

saturation in an empirically derived equation into the Masimo

2

2004407-001

Page 45

Troubleshooting: Theory of Operation

Host Patient Monitor Communications

The Masimo module communicates with the host patient monitor using

the synchronous Serial Shi f t Register Interface Signals. The

communication processor performs this function, operating in slave mode

it receives clock and enable signals from the host patient monitor.

All integrated circuits with signals connected to the backplane are

powered directly from the backplane +5 volts not the soft-started power

supplies. This is so the signals won’t load down the synchronous Serial

Shift Register Interface S ignals upon insertion of the module.

Power Condition and Soft Start

The Masimo module receives power from the host Tram- rac. The module

is designed for insertion into a live Tram-rac. All the power supply pins

incorporate soft-start circuitry to limit inrush currents. This module uses

the +5V and +16.5V power supplies from the host patient monitor.

Isolated Power Supply

The Masimo module uses an isolated power supply to power the Masimo

MS-3 board. The power supply is designed to provide 4000 volts of

patient isolation from the host patient monitor. The isolated power

supply generates +5V, +15V, and -15V and is controlled by the system

processor.

The system processor moni tors signal PS_FAULT whic h indicates a fault

condition with the power supply. If this signal is active (logic high) for

more than 200ms, the system processor shuts down the isolated power

supply. The system processor does not monitor this line for the first

100ms after the power supply is enabled allowing the isolated power

supply time to stabilize.

Patient Connector Flex Circuit

The flex circuit a ssemb ly p r ovide s t he conn ectio n fro m t he Masi mo MS-3

analyzer to the patient receptacle on the front panel of the module. The

Masimo Flex PCB includes a ferrite core to reduce electromagnetic

emissions/susceptibility and a shield around the front panel connector to

reduce susceptibility to external interference.

Revision A Solar SpO2 Module with Masimo SET 4-9

2004407-001

Page 46

Troubleshooting: External Connectors

External Connectors

Pin-by-pin descriptions and the signal names for each connector on the

front panel of the module are described in this section.

SpO2 Signals

The SpO2 patient cable attaches to the fron t panel 11-pin Blue Nicolay

SpO

Signal Name Pin Type Description

Detector Anode 1 I Detector Anode

Detector Cathode 2 I Detector Cathode

connector.

2

SpO

Connector

2

NC 3 X No connection

NC 4 X No connection

IR LED Cathode 5 O IR LED Cathode/Red LED Anode

Outer Shield 6 O Outer shield of patient cable

Inner Shield 7 O Inner shield (shield around detector wires of

patient cable)

NC 8 X No connection

NC 9 X No connection

RED LED

Cathode

Outer Shield 11 O Outer shield of patient cable

10 O Red LED Cathode/IR LED Anode

1

7

2

8

3

9

4

10

5

11

6

Front View

of Module

4-10 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 47

Troubleshooting: External Connectors

Probe Schematic Diagram

The schematic diagram of the Nellcor probe sensor is presented below.

RED_LED CATHODE

10

IR_LED CATHODE

5

NC

3

NC

4

DETECTOR ANODE

1

DETECTOR CATHODE

2

INNER SHIELD

7

NC

8

NC

9

ISOGND

11

FSHIELD

6

Host Patient Monitor Connector

The Masimo module uses a 2 x 15 pin female Bendix connector with

bristle brush pins to mate with the Tram-rac housing. The following

table lists signal names, input pins, type, and descriptions. Signals with

an asterisk (*) indicate a low signal.

151413121110987654321

B

151413121110987654321

A

Revision A Solar SpO2 Module with Masimo SET 4-11

2004407-001

Page 48

Troubleshooting: External Connectors

Signal Name Pin Type Description

GND A1 I +16.5 volt power supply return

WF_A B1 O Not Used

MOD_EN_B A2 I Not Used

MOD_EN_A B2 I MODULE CHANNEL A ENABLE: This signal is the

enable for this module. This signal is asserted high to

enable the module to communicate via the synchronous

serial shift register interface.

AGND A3 I Not Used

WF_B B3 O Not Used

SNYC_ECG A4 I Not Used

+16.5V B4 I +16.5 volt power supply

MOD_DATA_CLK* A5 I MODULE DATA CLOCK*: This signal is the 7000-series

module data clock used in the synchronous serial shift

register interface. The falling edge is used to shift data

both into and out of the module.

PWRBUS B5 I/O Not Used

MOD_DATA_IN* A6 I MODULE LOAD, MODULE DATA IN: The module load

function is used in the synchronous serial shift register

interface to pre-load the module’s output shift register

prior to transferring data out of the module to the Tram-

rac. When this interface is used, active-low binary input

data is transferred to the module’s input serial shift

register on this signal with the falling edge of the module

data clock signal.

WF_OUT1 B6 I/O Not Used

MOD_DATA_OUT* A7 O MODULE DATA OUT*: When the 7000-series

synchronous serial shift register interface is used,

active-low binary output data is transferred from the

module’s output shift register on this signal with the

falling edge of the module data clock signal.

WF_OUT2 B7 I/O Not Used

MOD_DATA_LAT* A8 I MODULE DATA LATCH*: This signal is the 7000-series

module data latch strobe used in the synchronous serial

shift register interface. After 8 data bits of input data

have been shifted into the module using the module

data clock signal, this signal strobes the input data into

the modules latch.

WF_OUT3 B8 I/O Not Used

AGND A9 I Not Used

4-12 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 49

Troubleshooting: External Connectors

Signal Name Pin Type Description

123KHZ B9 I Not Used

CALIBRATE* A10 I Not Used

WF_OUT5 B10 O Not Used

Software Updates

GND A11,

B11

TN_ENA* A12 O TRAMNET ENABLE*: When high this signal identifies

+5 B12 I +5V DIGITAL POWER: +5V power supply to the module

+15V A13,

B13

-15V A14,

B14

AGND A15,

B15

Two types of downloading procedures are available for the Masimo

module. Software may be downloaded from a programmed software

diskette using a patient monitor by either of the following two ways:

I GROUND: These pins are the logic reference and the

+5V power supply return lines.

the device’s communication protocol as the

synchronous serial shift register interface. When low this

signal identifies the device’s communication protocol as

Tramnet.

for the device digital circuitry.

I Not Used

I Not Used

I Not Used

n

from a laptop personal computer or terminal, or

n

across the Unity Network from a central station.

These procedures are explained in detail in the software upgrade kit.

Contact your GE Medical Systems Information Technologies service

representative for information.

Revision A Solar SpO2 Module with Masimo SET 4-13

2004407-001

Page 50

For your notes

Troubleshooting: External Connectors

4-14 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 51

5 Parts Lists and Drawings

Revision A Solar SpO2 Module with Masimo SET 5-1

2004407-001

Page 52

For your notes

5-2 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 53

Ordering Parts

General

The parts lists and assembly drawings in this chapter supply enough

detail for you to order parts for the assemblies considered field

serviceable. If you require additional information or troubleshooting

assistance, contact Tech Support.

To order parts, contact Service Parts at the address or telephone number

listed on the “How to Reach Us...,” page found at th e front of th is manual.

Field Replaceable Units

The tables below list the most commonly replaced assemblies ordered in

the service spare circuit board kits.

Parts Lists and Drawings: Ordering Parts

Field Replaceable Units

Item Part Number

Masimo SET SpO

Masimo SET SpO2 Module Flex PCB 2001861-001

Masimo SET SpO

The following is a list of all accessories available for the Masimo SET

SpO2 Module.

Cable Assy Patient Adapter Masimo SpO2 12 FT 2002592-001

Cable Assy Patient Adapter Masimo SpO2 8 FT 2002592-002

Kit Samples Masimo Adult/Pediatric Sensors 2002797-001

Masimo LNOP Adt Adult Sensor N/A

Masimo LNOP Pdt Pediatric Sensor N/A

Kit Samples Masimo Neonatal Sensors 2002798-001

Module PCB 2001857-001

2

MS-3 PCB 2002271-001

2

Accessories

Description Part Number

Masimo LNOP Neo Neonatal Sensor N/A

Masimo LNOP NeoPt Neonatal Sensor N/A

Masimo LNOP DC1P Reusable Finger Sensor Pediatric 2002799-001

Masimo LNOP DC1 Reusable Finger Sensor Adult 2002800-001

Revision A Solar SpO2 Module with Masimo SET 5-3

2004407-001

Page 54

Parts Lists and Drawings: Disassembly Procedures

Disassembly Procedures

Refer to the exploded vi ew that f ollows the se procedu res f or part lo cation.

Assembly Housing

1. Remove 2 screws from the module top and 2 screws from t he module

bottom.

2. Slide the housing away from the bezel.

Masimo SET SpO2 MS-3 PCB

1. Remove the assembly housing according to the steps above.

2. Remove 3 screws from the MS-3 PCB and pull the PCB up and away

from the spacers.

3. Disconnect the Masimo module flex PCB from the MS-3 PCB and

remove the MS-3 PCB.

Masimo SET SpO2 Module Flex PCB

1. Remove the assembly housing and the Masimo module MS-3 PCB

according to the steps above.

2. Disconnect ends of the flex assembly an d remove.

Masimo SET SpO2 Module PCB

When the assembly housing, the MS-3 PCB, and the flex PCB are

removed according to the steps above, the Masimo module PCB is loose

and can be removed.

Reassembly

Reverse the above st eps to reassemble the Masimo module.

Testing

Perform the Electrical Safety Tests described in chapter 3, Maintenance.

5-4 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 55

Parts Lists and Drawings: Solar SpO2 Module with Masimo SET 2001891-001A

Solar SpO2 Module with Masimo SET 2001891-001A

Find

Number

1 2001857-001 PCB MASIMO SET SPO2 MODULE 1

2 2001861-001 PCB FLEX MASMO SET SPO2 MODULE 1

4 2002271-001 PCB MS-3 MASIMO SET SPO2 1

5 2002326-001 SPACER 5.5MM HEX M3 F/F 20.1LG NYLON 3

6 45209-411 SCREW PH M3 X 8MM 6

7 404525-008 LABEL BLANK 1.2IN X .6IN 1

8 406019-001 LATCH SPRING TRAM 2

9 406037-001 LATCH PIN TRAM 2

10 410124-020 MDL FR BEZEL NICOLAY SGL 11P 1

11 410337-001 LATCH MODULE 2

12 412669-001 ASSY MODULE HOUSING 1

13 414536-001 ADAPTER CONN NICOLAY 11P 1

14 2004668-001 LABEL MODULE COVER SOLAR 1

Item Number Item Description Qty

15 4521-304 NUT,ESNA,4-40, 3

16 4551-312 SPRING COMPRESSION .50 LG 2

17 4760-014 SCREW PH 2-56X3/16 COATED 4

18 404525-001 LABEL BLANK 2 X 3/4 1

19 4550-014 WASH NYL .28 OD .12 ID .03THK 3

24 2004407-001 MNL SVCE MASIMO SET SPO2 MODULE ENG .25

Revision A Solar SpO2 Module with Masimo SET 5-5

2004407-001

Page 56

Parts Lists and Drawings: Solar SpO2 Module with Masimo SET 2001891-001A

Schematic Diagram

5-6 Solar SpO2 Module with Masimo SET Revision A

2004407-001

Page 57

Page 58

Loading...

Loading...