Page 1

GE Healthcare

MAC™ 800

Resting ECG Analysis System

Software Version 1

Service Manual

2031504-159 Revision B

Page 2

© 2008 General Electric Company. All rights reserved.

CardioSoft, CASE, Hookup Advisor, MAC, Mactrode, MUSE, and 12SL are trademarks owned by GE Medical

Systems Information Technologies, a division of General Electric Company going to market as GE Healthcare.

All other marks are not owned by GE and are instead owned by their respective owners.

NOTE

This manual applies to the MAC™ 800 software version 1. Due to continuing product innovation, specifications

in this manual are subject to change without notice.

T-2 MAC™ 800 2031504-159B

15 August 2008

Page 3

Contents

1 Introduction

Manual Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Manual Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Equipment Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Responsibility of the Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Equipment Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Product Label Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Serial Number Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Service Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

2 Equipment Overview

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Detailed Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

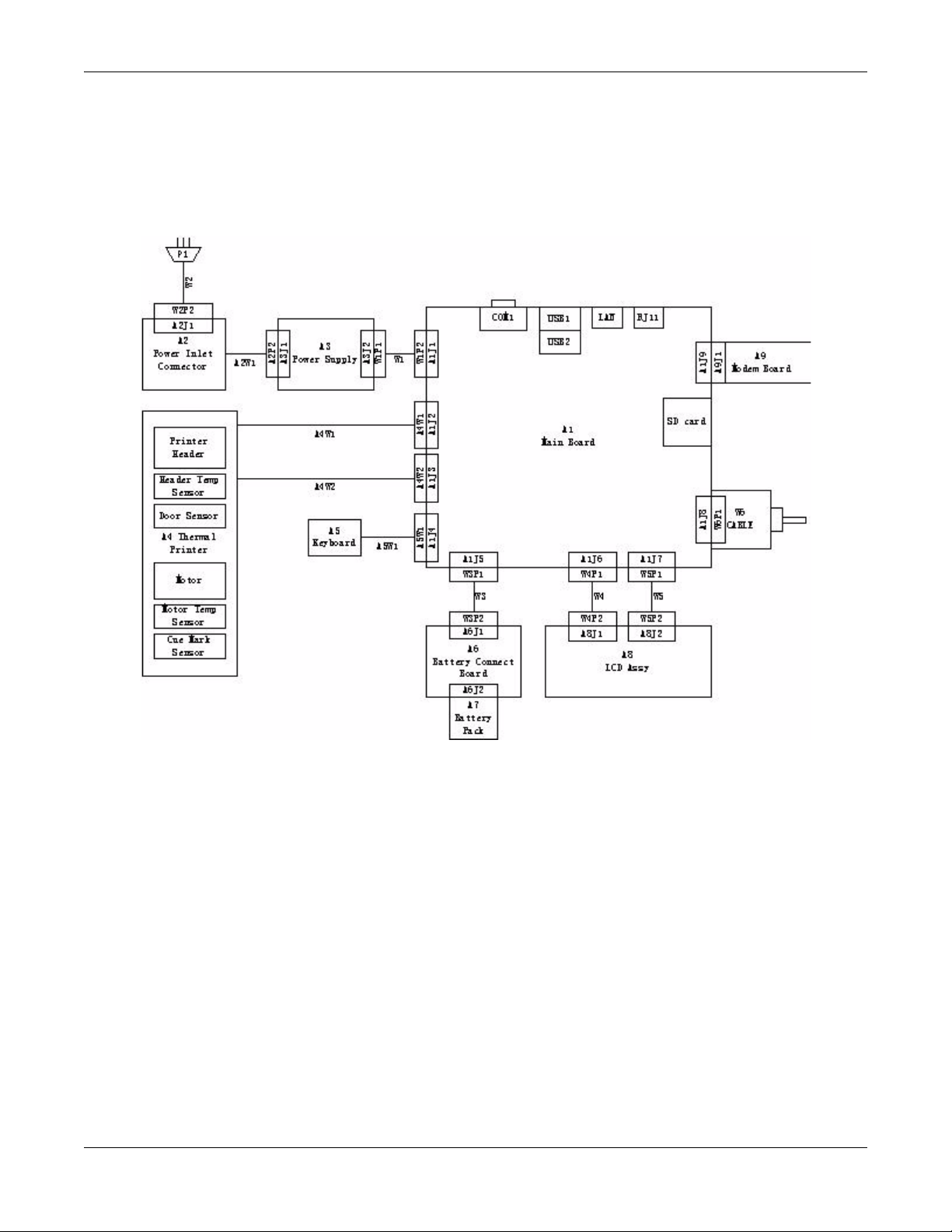

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Hardware/firmware Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Product Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

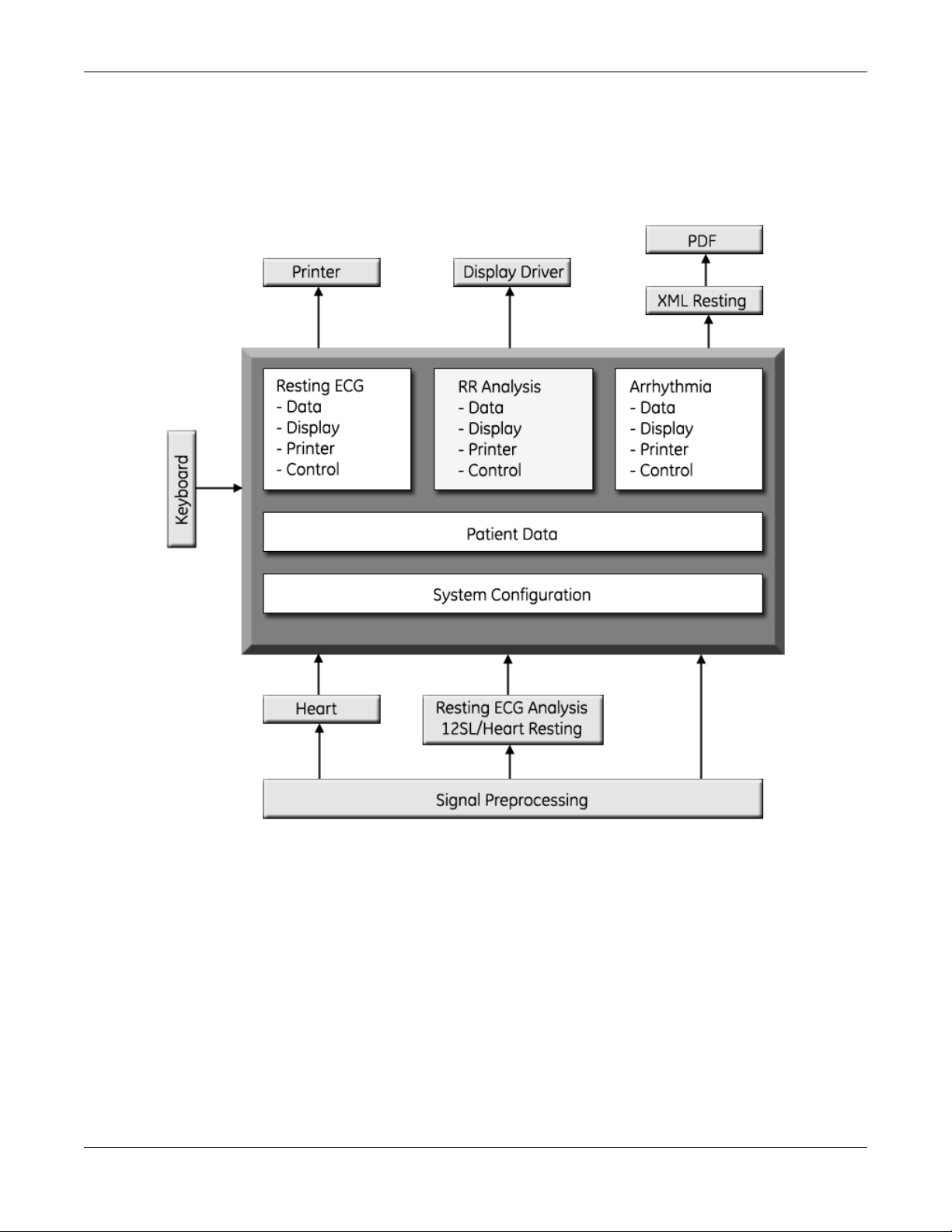

Layered Structure of application software. . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

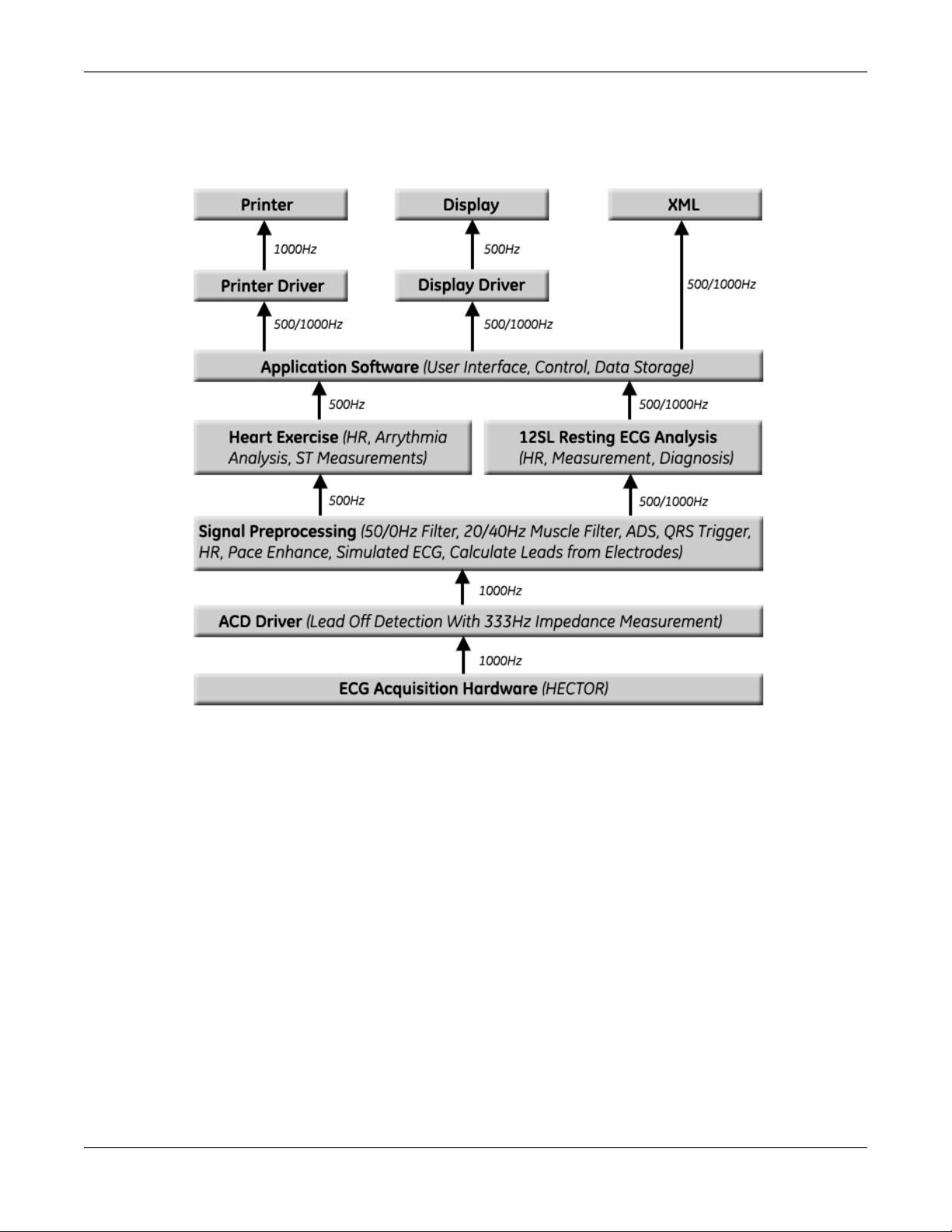

ECG Data Flow With Sampling Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

3 Troubleshooting

General Fault Isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Power-Up Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Poor Quality ECGs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Event Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting Up Event Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Exporting the Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Performing Diagnostic Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Accessing the System Diagnostics Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

2031504-159B MAC™ 800 1-i

Page 4

Speaker Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Acquisition Module Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Battery Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Writer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

RS232 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

LAN Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Modem Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

USB Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Patient Lead Wire Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Equipment Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

ECG Data Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Acquisition Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Printer Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Frequently Asked Questions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Save System Setups to SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Storing ECGs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Battery Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

MAC Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Location Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Patient Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Resting ECG Report Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Editing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Navigating the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Resting ECG Power Up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Arrhythmia Mode Power Up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Main Screen Power Up Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

4 Maintenance

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Recommended Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Required Tools and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

High-Level FRU Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

FRU Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Preparing System for FRU Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Replacing the Patient Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Replacing Barcode Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Replacing the Battery Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Replacing the Top Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Replacing the Keypad Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Replacing the LCD Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Removing the Printer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

1-ii MAC™ 800 2031504-159B

Page 5

Reassembling the Printer Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Processing ECGs in Internal Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Saving System Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Removing the Mainboard Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Reassembling the Mainboard Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Replacing the Internal Modem (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Removing the Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Reassembling the Power Supply Assembly . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Replacing the Bottom Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Functional Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Operational Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Electrical Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Updating Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Conditioning the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

5 Parts Lists

Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Field Replaceable Units (FRUs). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

MAC 800 Upper Level Assembly Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

MAC 800 Upper Level Assembly Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

FRU Top Cover Assembly, PN 2039939-001 . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

FRU Printer Assembly, PN 2039941-001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

FRU Mainboard Assembly, PN 2039942-001 . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

FRU Power Supply Assembly, PN 2040052-001 . . . . . . . . . . . . . . . . . . . . . . . . .5-14

FRU Bottom Cover Assembly, PN 2039943-001 . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Model Data Matrix Barcode Scanner Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Keypads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-19

FRU Kits, PN 2039945-001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

A Technical Specifications

Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

B Electromagnetic Compatibility

Electromagnetic Compatibility (EMC) Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

2031504-159B MAC™ 800 1-iii

Page 6

Guidance and Manufacturer’s Declaration - Electromagnetic Emissions . . . . . . B-2

Guidance and Manufacturer’s Declaration - Electromagnetic Immunity . . . . . . . B-3

Guidance and Manufacturer's Declaration - Electromagnetic Immunity . . . . . . . B-3

Recommended Separation Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

EMC-Compliant Cables and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

C Supplies & Accessories

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Value Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Thermal Papers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Country-Specific Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

1-iv MAC™ 800 2031504-159B

Page 7

1 Introduction

2031504-159B MAC™ 800 1-1

Page 8

Introduction

Manual Information

Revision History

The document’s part number and revision appear at the bottom of each

page. The revision identifies the document’s update level. The revision

history of this document is summarized in the following table.

Revision Date Comment

Manual Purpose

Revision History, PN 2031504-159

A 1 July 2008 Initial release of document.

B 15 August 2008 Revised product specifications.

This manual supplies technical information for service representatives

and technical personnel so they can maintain the equipment to the

assembly level. Use it as a guide for maintenance and electrical repairs

considered field repairable. Where necessary, the manual identifies

additional sources of relevant information and/or technical assistance.

See the MAC™ 800 Resting ECG Analysis System Operator’s Manual

(2031504-182) for the instructions necessary to operate the equipment

safely in accordance with its function and intended use.

Intended Audience

This manual is intended for persons who use, maintain, or troubleshoot

this equipment.

Warnings, Cautions, and Notes

The terms danger, warning, and caution are used throughout this

manual to identify hazards—sources of potential injury to a person—and

to designate a degree or level or seriousness. Familiarize yourself with

their definitions and significance.

Term Definition

DANGER Indicates an imminent hazard which, if not avoided, will result in death or

serious injury.

WARNING Indicates a potential hazard or unsafe practice which, if not avoided, could

result in death or serious injury.

1-2 MAC™ 800 2031504-159B

Page 9

Term Definition

CAUTION Indicates a potential hazard or unsafe practice which, if not avoided, could

NOTE Provides application tips or other useful information to ensure that you get

Equipment Information

Failure on the part of the responsible individual, hospital, or institution

using this equipment to implement a satisfactory maintenance schedule

may cause undue equipment failure and possible health hazards.

To ensure patient safety, use only parts and accessories manufactured or

recommended by GE Healthcare.

Contact GE Healthcare for information before connecting any devices to

this equipment that are not recommended in this manual.

If the installation of this equipment, in the USA, will use 240 V rather

than 120 V, the source must be a center-tapped, 240 V, single-phase

circuit.

Introduction

result in minor personal injury or product/property damage.

the most from your equipment.

Safety Messages

Parts and accessories used must meet the requirements of the applicable

IEC 60601 series safety standards, and/or the system configuration must

meet the requirements of the IEC 60601-1-1 medical electrical systems

standard.

The use of accessory equipment not complying with the equivalent safety

requirements of this equipment may lead to a reduced level of safety of

the resulting system. Consideration relating to the choice shall include:

use of the accessory in the patient vicinity; and

evidence that the safety certification of the accessory has been

performed in accordance to the appropriate IEC 60601-1 and/or IEC

60601-1-1 harmonized national standard.

Additional safety messages may be found throughout this manual that

provide appropriate safe operation information.

DANGER

FLAMMABLE HAZARD — Do not use in the presence of

flammable anesthetics.

2031504-159B MAC™ 800 1-3

Page 10

Introduction

WARNING

USE APPROPRIATE POWER SOURCE — This is a

Class I device with protective earth equipment. The mains

plug must be connected to an appropriate power supply.

WARNING

PROPER GROUNDING — Operate the unit from its

battery if the integrity of the protective earth conductor is

in doubt.

CAUTION

AUTHORIZED SERVICE PERSONNEL ONLY — This

equipment contains no user serviceable parts. Refer

servicing to qualified service personnel.

CAUTION

USE ONLY ON ORDER BY PHYSICIAN — U.S.

Federal law restricts this device to the sale by or on the

order of a physician.

Responsibility of the Manufacturer

GE is responsible for the effects of safety, reliability, and performance

only if:

assembly operations, extensions, readjustments, modifications, or

repairs are carried out by persons authorized by GE,

the electrical installation of the relevant room complies with the

requirements of the appropriate regulations, and

the equipment is used in accordance with the instructions for use.

Equipment Symbols

See the MAC™ 800 Resting ECG Analysis System Operator’s Manual

(2031504-182) for information about the symbols used on this product

and its packaging.

Equipment Identification

Equipment can be identified via the product label and serial number

attached to the equipment. The following topics describe the components

of the product label and the serial number.

1-4 MAC™ 800 2031504-159B

Page 11

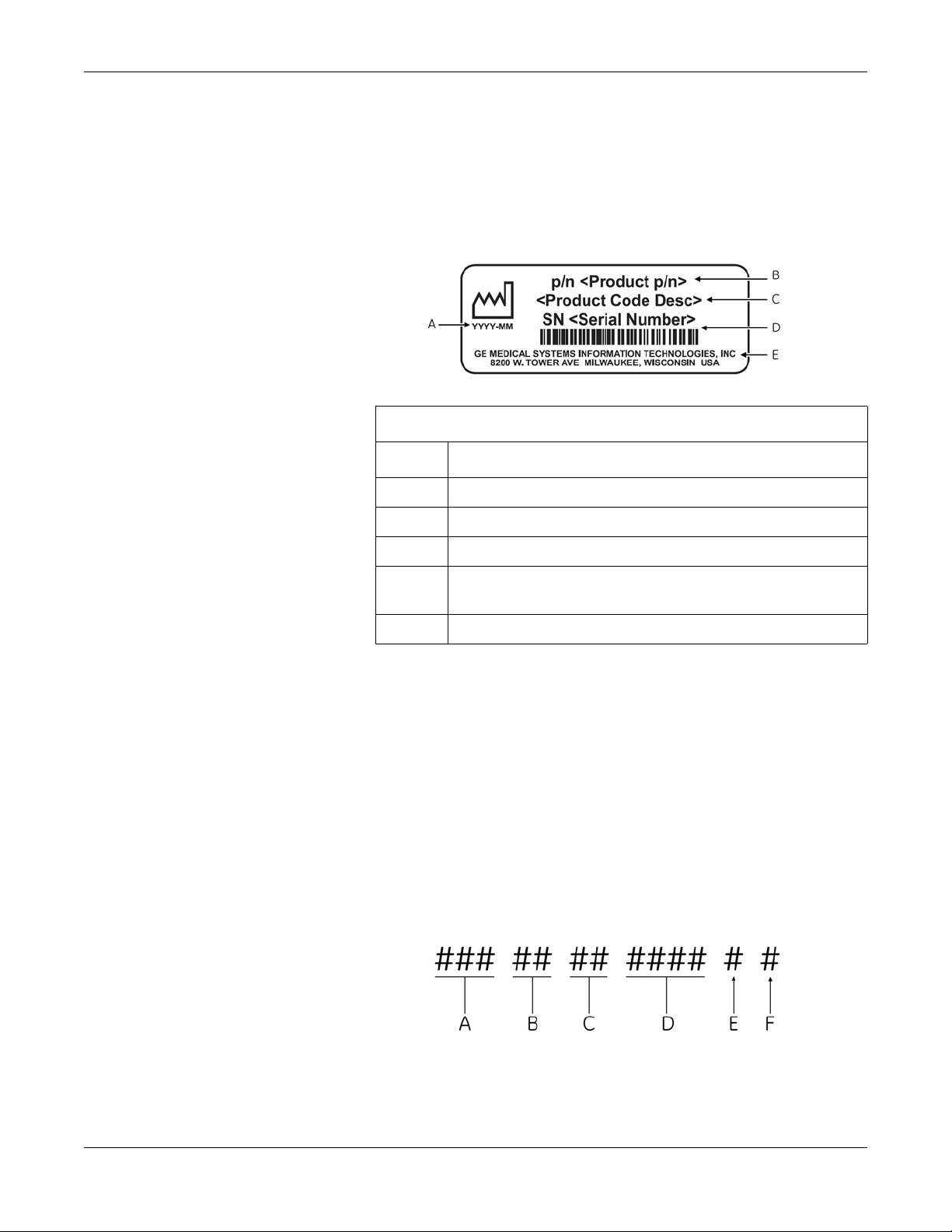

Product Label Format

Introduction

GE product labels provide the product’s part number, model description,

serial number, manufacture date, and manufacture site. The following

illustration shows the layout of a typical product label. A description of

the label components follows the illustration.

Product Label

Item Description

A Date of manufacture in YYYY-MM format

Serial Number Format

B Part number of product

C Product code description

D Serial number.

For more information, see “Serial Number Format” on page 1-5.

E Manufacture site

NOTE

Actual product label may differ from this representative example.

Every GE device is uniquely identified via serial number, which appears

on the product label (see “Product Label Format” on page 1-5). The

following illustration and table describe the serial number components.

2031504-159B MAC™ 800 1-5

Page 12

Introduction

Service Requirements

A The product code for MAC 800 systems is SDS.

B Year Manufactured (00-99). Examples:

07 = 2007

08 = 2008

C Fiscal Week Manufactured

D Production Sequence Number

E Manufacturing Site

F Miscellaneous Characteristic

Refer equipment servicing to GE-authorized service personnel only. Any

unauthorized attempt to repair equipment under warranty voids the

warranty.

It is the user’s responsibility to report the need for service to GE or to

one of their authorized agents.

1-6 MAC™ 800 2031504-159B

Page 13

2 Equipment Overview

2031504-159B MAC™ 800 2-1

Page 14

Equipment Overview

General Description

The MAC™ 800 is a 3- and 6-lead print, 12-channel display system with

a 7 inch (17.78 cm) diagonal display, active patient cable, battery

operation, and options for communication capabilities.

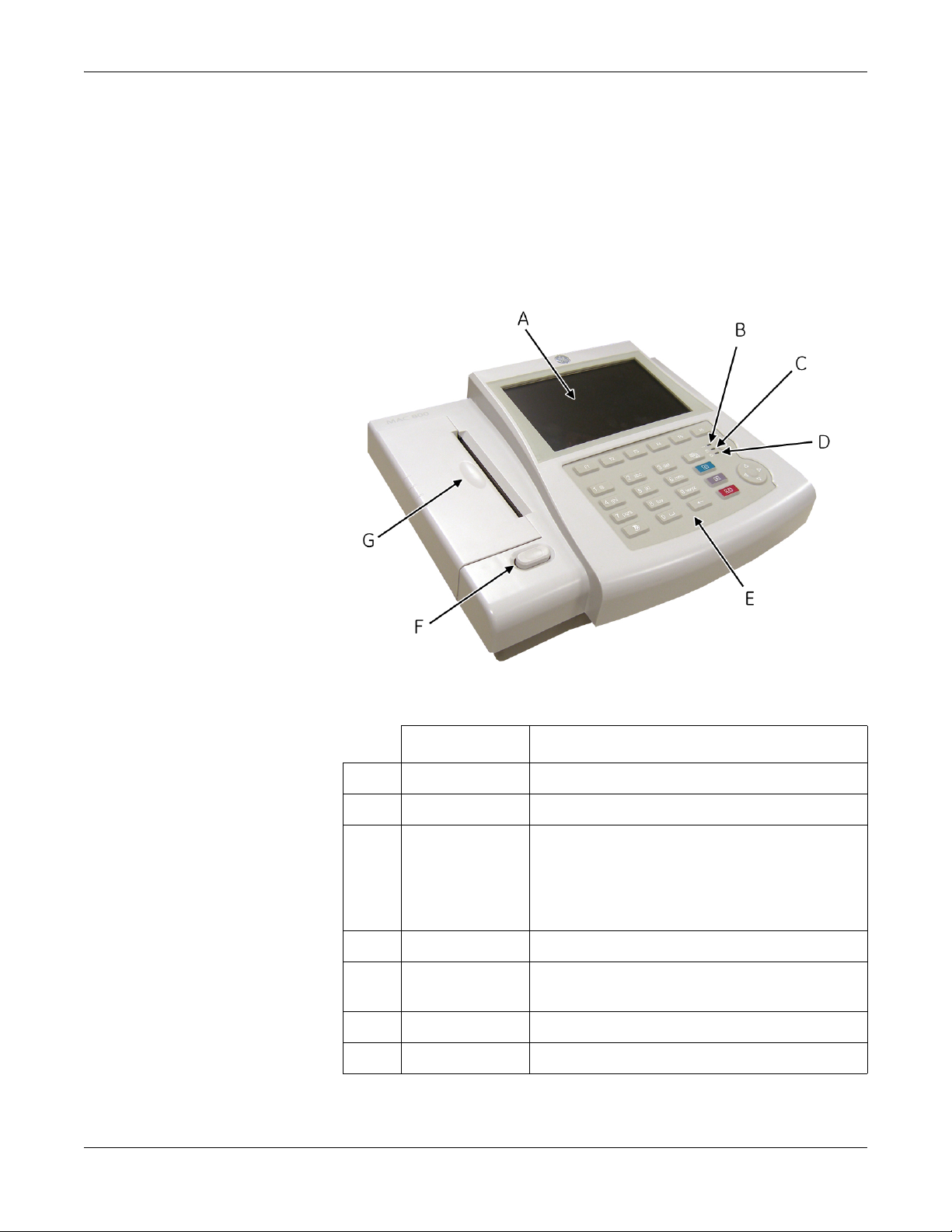

Front View

Name Description

A Screen Displays waveform and text data.

B AC LED Indicates when the unit is connected to AC power.

C Battery LED Indicates current battery status.

Solid indicates the battery is charging.

Flashing indicates the battery is low.

Off indicates the battery is fully-charged or is

discharging but not at a low state.

D Power LED Indicates when the unit is powered on.

E Keypad Controls the system or enters data. See “Keypad” on

page 2-4 for more information.

F Writer Door Button Opens printer door.

G Writer Prints reports.

2-2 MAC™ 800 2031504-159B

Page 15

Side View

Equipment Overview

Name Description

A ECG signal input connector Connects the patient cable to the device.

Back View

B Secure digital (SD) card

slot

Houses the secure digital (SD) card for external

storage.

Name Description

A Modem port Standard RJ-11 jack for connecting the modem to

a telephone line.

2031504-159B MAC™ 800 2-3

Page 16

Equipment Overview

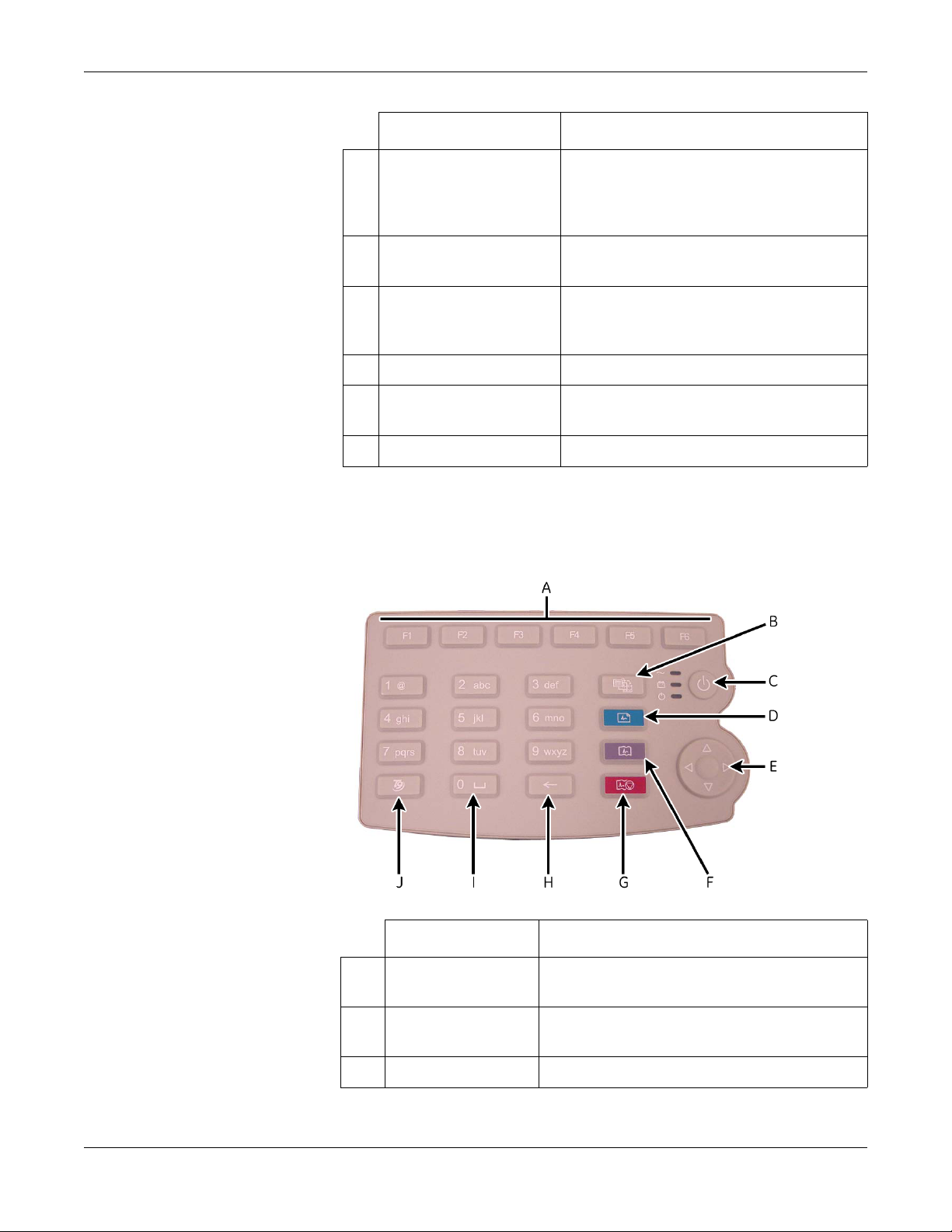

Keypad

Name Description

B LAN port Standard RJ-45 jack for connecting the device to a

LAN. LEDs on the port indicate status.

Solid green indicates a good connection.

Flashing amber indicates network traffic.

C USB port Universal Serial Bus port used to connect external

devices, such as the optional barcode reader.

D COMM port Serial port for data communication. Use a serial

cable to connect the unit to a CASE/Cardiosoft or

MUSE system.

E Main AC power connector Connects the unit to an AC power outlet.

F Equipotential grounding lug Grounded connector for attaching non-grounded

peripheral devices to ensure equipotentiality.

G Carry handle Retractable handle for carrying the unit.

The English keypad is shown in the following illustration.

Name Description

A Function Keys

(F1 through F6)

Selects menu options on the screen.

B Leads key Changes the leads when the screen is being used to

display waveforms.

C Power Button Turns the unit on and off.

2-4 MAC™ 800 2031504-159B

Page 17

Equipment Overview

Name Description

D ECG key Acquires a resting ECG and prints a 10-second report

in Arrhythmia mode.

E Trimpad The arrows move the cursor left, right, up, or down.

The center button moves the focus within a window or

selects the currently active item.

F Rhythm key Prints a continuous, real-time rhythm ECG strip. Press

the Stop key to stop the rhythm strip from printing.

G Stop key Stops the writer from printing.

H Backspace Key Deletes characters.

I Space Key Adds a space between typed characters.

J T9 key Switches between different input methods. For more

information on using the T9 key, refer to the MAC™

800 Operator’s Manual.

2031504-159B MAC™ 800 2-5

Page 18

Equipment Overview

Detailed Description

Block Diagram

2-6 MAC™ 800 2031504-159B

Page 19

System Architecture

Overview

Equipment Overview

2031504-159B MAC™ 800 2-7

Page 20

Equipment Overview

Hardware/firmware Architecture

The MAC 800 hardware and firmware subsystems include the following:

Hardware Subsystems Firmware Subsystems

Product Interfaces

CPU core

Display

Keyboard

ECG Acquisition subsystem

Thermal printer

Power supply

Housing

CE BSP (Board-Support-Package)

Printer API

Printer SW (Firmware for the Printer)

Acquisition API

Acquisition SW (Firmware for the Printer)

The MAC 800 system offers the following interfaces for connecting to

external devices for data communication, software updates, and the

control of workload devices:

RS232 port (1)

Connects to external systems, like MUSE or Cardiosoft.

RJ-45 port (1)

Connects to networks via 100baseT ethernet connector via an

external medical isolator.

USB connector(2)

Connects to USB-capable devices, such as optional barcode reader or

external USB keyboard.

Secure Digital (SD) Card slot

Interfaces with a Secure Digital card, which is used to store ECGs, to

flash the device with software updates, and to connect memory /

future IO extensions.

RJ-11 port (1)

Connects an internal medical grade Analog Modem (optional) to a

phone line.

2-8 MAC™ 800 2031504-159B

Page 21

Software Architecture

Layered Structure of application software

Equipment Overview

2031504-159B MAC™ 800 2-9

Page 22

Equipment Overview

ECG Data Flow With Sampling Rates

2-10 MAC™ 800 2031504-159B

Page 23

3 Troubleshooting

2031504-159B MAC™ 800 3-1

Page 24

Troubleshooting

General Fault Isolation

Power-Up Self-Test

See the MAC™ 800 Operator’s Manual, Chapter 2, “Equipment

Overview: Getting Started” to verify operation.

On power-up, the system automatically runs an internal self-test. If all

circuit tests pass, you will see the start-up screen.

Poor Quality ECGs

The next screen that appears after the start-up screen depends on the

Power Up mode selected in System Configuration. The Resting ECG

mode is the default Power Up mode.

If the equipment is not working properly, ask the following questions.

Is the unit turned on?

Have there been any changes in the use, location, or environment of

the equipment that could cause the failure?

Has the equipment hardware or software been modified since last

use?

Is operator error the cause of the problem?

Try to repeat the scenario exactly and compare that to the proper

operation of the equipment described in the manual.

Is the battery installed?

When connected to the AC wall outlet, does the green AC power light

glow?

Poor quality ECGs can be caused by factors in the environment,

inadequate patient preparation, hardware failures related to the

acquisition module, lead wires, cables, or problems in the unit.

3-2 MAC™ 800 2031504-159B

Page 25

Visual Inspection

Troubleshooting

A thorough visual inspection of the equipment can save time. Small

things—disconnected cables, foreign debris on circuit boards, missing

hardware, loose components—can frequently cause symptoms and

equipment failures that may appear to be unrelated and difficult to

track.

NOTE

Take the time to make all the recommended visual checks before

starting any detailed troubleshooting procedures

If the area is… Look for…

I/O Connectors and Cables

AC power cord

Interface cables

Circuit boards

Fraying or other damage

Bent prongs or pins

Cracked housing

Loose screws in plugs

Excessive tension or wear

Loose connection

Strain reliefs out of place

Moisture, dust, or debris (top and bottom)

Loose or missing components

Burn damage or smell of over-heated components

Socketed components not firmly seated

PCB not seated properly in edge connectors

Solder problems: cracks, splashes on board, incomplete

feedthrough, prior modifications or repairs

Ground wires/Wiring

Loose wires or ground strap connections

Faulty wiring

Wires pinched or in vulnerable position

Fasteners Loose or missing screws or other hardware, especially

fasteners used as connections to ground planes on PCBs

Power source

Faulty wiring, especially AC outlet

Circuit not dedicated to system

NOTE

Power source problems can cause static discharge,

reading problems, and discharge.

Keyboard

Cuts or cracks in the keyboard membrane

Unreadable labels

LCD display filter Scratches or cracks in the display filter (transparent part of

keyboard bezel) that impair viewing

Battery pack

SD card

2031504-159B MAC™ 800 3-3

Cracks, swells, or leaks in the battery casing

Dirt, scratches, or debris on contacts

Cracks

Dirt, scratches, or debris on contacts

Page 26

Troubleshooting

Event Logging

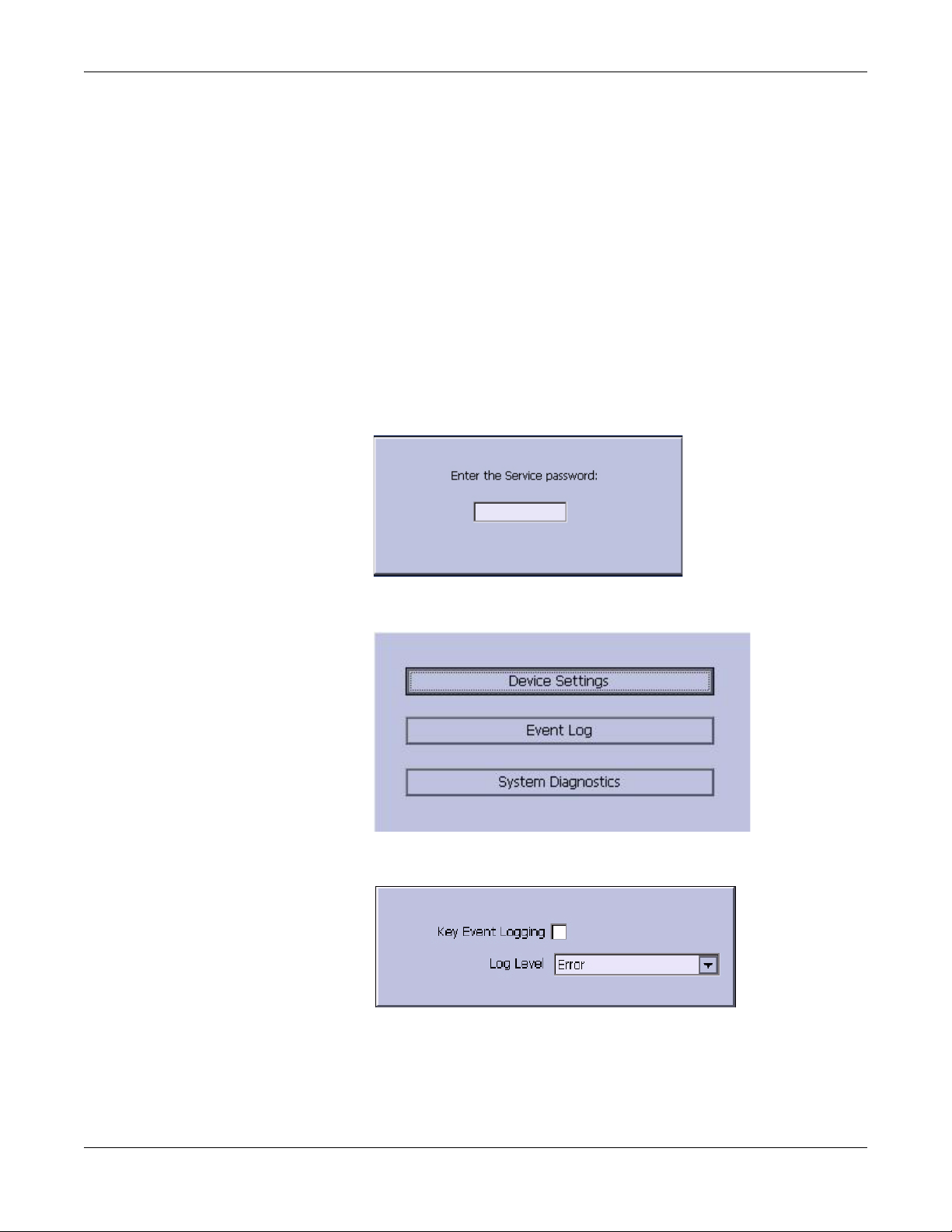

Setting Up Event Logging

The MAC 800 system can be set up to create an XML-format Event Log

that contains system errors, warnings, and informational messages. Use

the following procedure to configure the level of severity of messages

written to the Event Log.

1. Power on the MAC 800 system by pressing the Power button.

2. From the Main Menu, press F4 to select System Configuration.

3. Press F6 (More) > F6 (More) > F5 (Service Setup).

The following window prompts you to enter the Service password.

4. Type 7763 and press F6 to select OK to open the Service Setup menu.

5. Move the focus to the Event Log button and press the Enter key.

6. Do one of the following:

To enable event logging, check the Key Event Logging check box.

To disable event logging, clear the Key Event Logging check box.

3-4 MAC™ 800 2031504-159B

Page 27

7. Select a level of severity to log from the Log Level list:

8. Press F6 to select Save.

Exporting the Event Log

1. Repeat step 1 through step 5 in “Setting Up Event Logging” on

2. Insert an SD card (gold contacts down) into the SD card slot as

Troubleshooting

Select None to log nothing to the Event Log.

Select Error to log only errors to the Event Log.

Select Warning to log errors and warnings to the Event Log.

Select Information to log errors, warnings, and information

messages to the Event Log.

page 3-4.

shown in the following illustration.

3. Press F1 to select Export Log Files.

The current Event Log file, log_0.log, is copied to a log directory on

the SD card.

NOTE

To access the log file, insert the SD card into an SD card reader

connected to a computer with a Windows operating system and open

the log file with a text editor like Notepad or WordPad. If the Event

Log is requested by GE Service for troubleshooting an issue, the file

can be sent as an email attachment.

Performing Diagnostic Tests

Diagnostic tests can be used to verify that the MAC™ 800 operates

properly. The tests check the operation of the display screen, speaker,

keyboard, thermal writer, battery, and communications. They are useful

tools for troubleshooting problems and can be useful as a part of system

checkout procedures.

2031504-159B MAC™ 800 3-5

Page 28

Troubleshooting

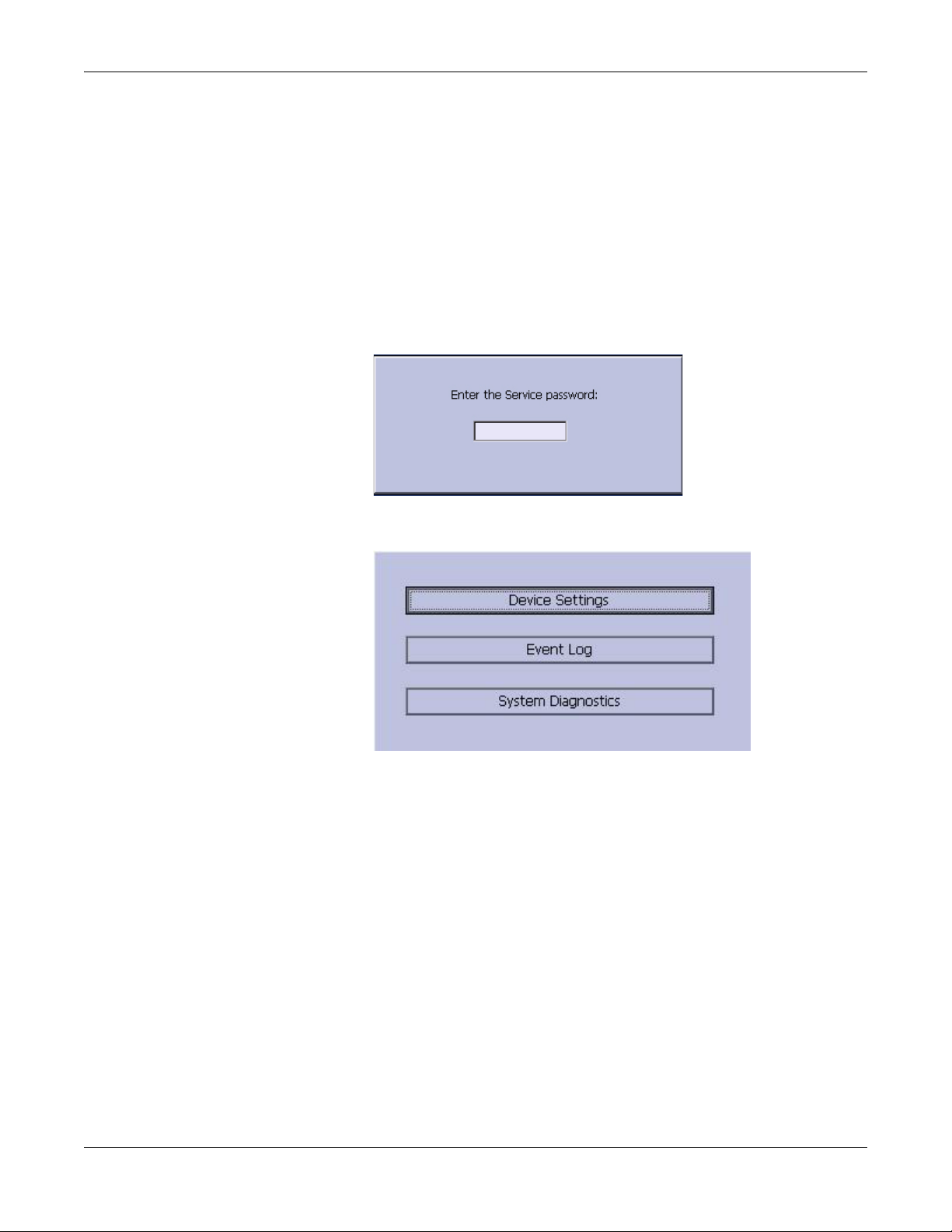

Accessing the System Diagnostics Function

The System Diagnostics menu can be used to perform functional

diagnostic tests. Use the following procedure to access the System

Diagnostics menu.

1. Power on the MAC 800 system by pressing the Power button.

2. From the Main Menu, press F4 to select System Configuration.

3. Press F6 (More) > F6 (More) > F5 (Service Setup).

The following window prompts you to enter the Service password.

4. Type 7763 and press F6 to select OK to open the Service Setup menu.

5. Move the focus to the System Diagnostics button and press the Enter

key to open the Diagnostic Tests window.

3-6 MAC™ 800 2031504-159B

Page 29

Display Test

Troubleshooting

The following sections describe how to perform the specific diagnostic

tests. Proceed to the appropriate section for the test you need to perform.

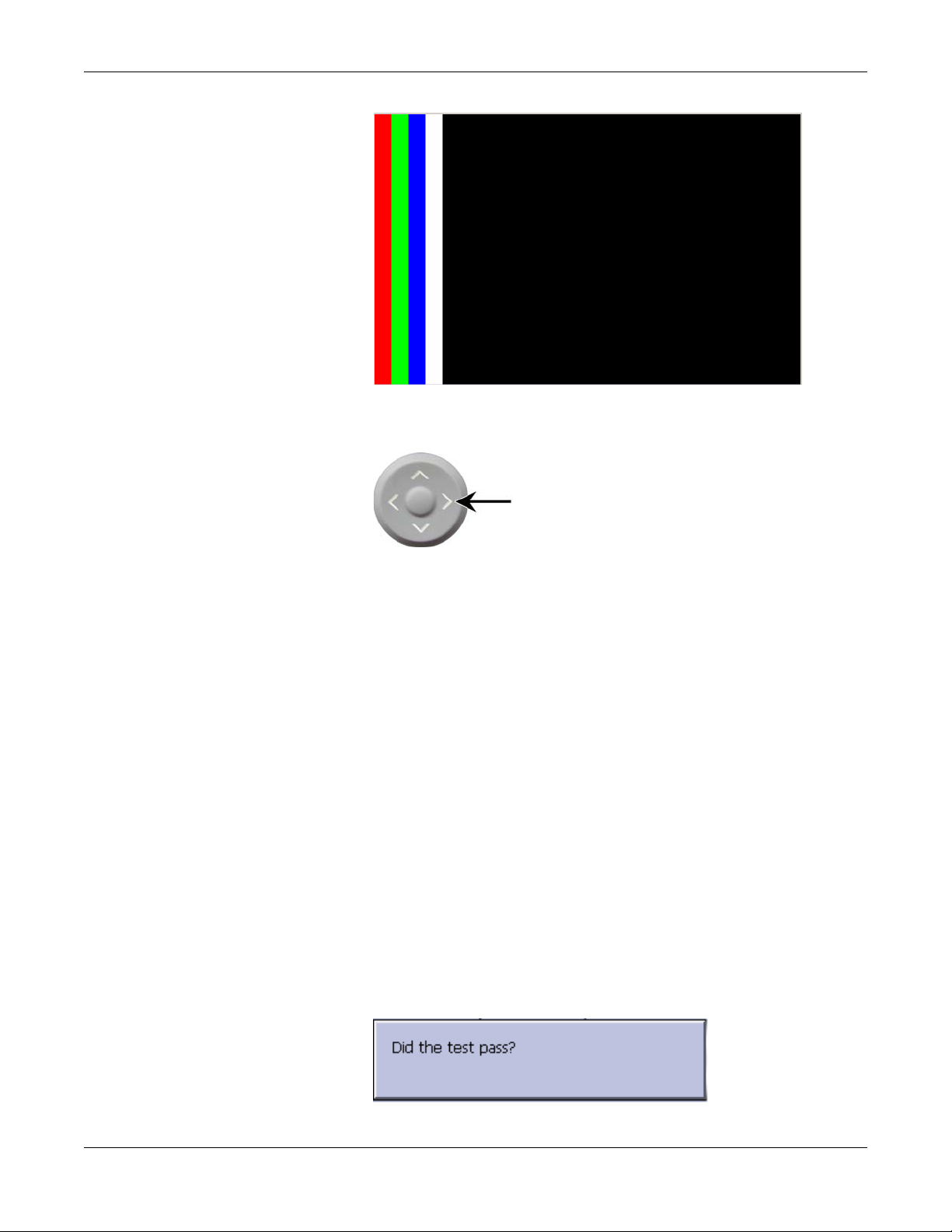

The Display Test can be used to determine if the display pixels are

working properly.

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

2. Select the Display Test button.

The following window opens.

3. Select the Start Test button.

The following window opens.

2031504-159B MAC™ 800 3-7

Page 30

Troubleshooting

4. Press the right arrow key on the Trimpad repeatedly to move the

color bars horizontally across the screen.

5. Verify that the color band pattern (red, green, blue, white) scrolls

across the screen.

Pass the test if the pattern is replicated without discoloration.

6. Press the F1 key to switch to horizontal color bars.

7. Press the down arrow key on the Trimpad repeatedly.

8. Verify that the color band pattern (red, green, blue, white) scrolls

down the screen.

Pass the test if the pattern is replicated without discoloration.

9. Press the F1 key to switch to cycle through the solid color pane (red,

green, blue, white).

For each pane, check for black pixels. Pass the test if no more than

four black pixels are observed on any single color pane.

NOTE

A black pixel observed on one pane will probably be observed on

every pane.

10. Press Enter when the test is complete.

The following window opens.

3-8 MAC™ 800 2031504-159B

Page 31

Speaker Test

Troubleshooting

11. Select Pass or Fail:

If the test passed, press F4 to select Yes.

If the test failed, press F5 to select No.

Replace the display assembly as described in “Replacing the LCD

Assembly” on page 4-11.

The Speaker Test can be used to determine if the speaker is working

properly.

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

2. Select the Speaker Test button.

3. Listen for a brief audible tone coming from the speaker.

The following window opens.

Keyboard Test

4. Select Pass or Fail:

If you heard an audible tone, press F4 to select Yes.

If you did not hear an audible tone, press F5 to select No.

Replace the mainboard assembly as described in “Replacing the

Mainboard Assembly” on page 4-15.

The Keyboard Test can be used to determine if the keyboard is working

properly.

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

2. Select the Keyboard Test button.

The following window opens.

2031504-159B MAC™ 800 3-9

Page 32

Troubleshooting

3. Press each key on the keyboard and verify the value appears in the

corresponding representation of that key on the screen.

A key passes the test if its value appears on the screen when the

corresponding key is pressed.

4. To test for “sticky keys”, continue to press keys and verify that the

screen representation of the key is refreshing with each subsequent

key press.

5. Press F1 > Stop when the test is complete.

6. Select Pass or Fail:

Acquisition Module Test

The Acquisition Module Test can be used to determine if the acquisition

board is working properly.

1. Open the Diagnostic Tests window as described in “Accessing the

A key passes if the key on the screen refreshing with each repeated

key press.

The following window opens.

If every key passes the tests, press F4 to select Yes.

If any key fails a test, press F5 to select No.

Replace the keyboard assembly as described in “Replacing the

Keypad Assembly” on page 4-10.

System Diagnostics Function” on page 3-6.

2. Select the Acquisition Module Test button.

The following window opens.

3-10 MAC™ 800 2031504-159B

Page 33

Battery Test

Troubleshooting

Passed

1

3. Note the test result and press F6 to select Cancel.

If the result of the Acquisition Module Test Result is Failed, replace

the mainboard assembly as described in “Replacing the Mainboard

Assembly” on page 4-15.

The Battery Test can be used to determine the status of the Lithium-Ion

battery.

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

Writer Test

2. Select the Battery Test button.

The following window opens.

3. Note the battery status information and press F6 to select Cancel

and close the Battery Status window.

If the Battery Status was Failed, replace the battery as described in

“Replacing the Battery Assembly” on page 4-7.

The Writer Test can be used to determine if the writer is working

properly.

NOTE

Before performing the Writer Test, be sure that the correct thermal

paper is properly loaded in the writer tray. Refer to the MAC 800

Resting ECG Analysis System Operator’s Manual for instructions on

loading paper.

2031504-159B MAC™ 800 3-11

Page 34

Troubleshooting

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

2. Select the Writer Test button.

The following window opens.

3. Perform the 50mm/s Speed Test.

a. Select the 50mm/s Speed Test button.

The writer prints the 50 mm/s speed test report.

b. When one page of the report has printed, press the Stop button.

The following window opens.

c. Examine the printed report.

The 50mm/s speed test passes if one cycle of the square wave

spans 50 mm on paper, measured from corner to corner of wave,

with allowable tolerance of 1.0 mm. If that criteria is not met, the

text fails.

d. Do one of the following:

If the test passed, press F4 to select Yes.

If the test failed, press F5 to select No.

4. Repeat the previous step for the other speed tests.

The pass-fail criteria for each of the remaining tests is as follows:

25mm/s Speed Test - If one cycle of the square wave spans 25

mm on paper, measured from corner to corner of wave, with

allowable tolerance of 0.5 mm, the test passes. If this criteria is

not met, the test fails.

5mm/s Speed Test - If one cycle of the square wave spans 5 mm

on paper, measured from corner to corner of wave, with allowable

tolerance of 0.25 mm, the test passes. If this criteria is not met,

the test fails.

3-12 MAC™ 800 2031504-159B

Page 35

Troubleshooting

5. Perform the Print Head Test.

a. Select the Print Head Test button.

The writer prints a 1-page print head test report.

b. Verify that there are no gaps in any of the lines printed.

Up to 5 mm of blank paper is allowable at the top and bottom of

the page.

When the page is done printing, the following window opens.

c. Do one of the following:

If there are no gaps in the lines on the printed report, press

F4 to select Yes.

If there are gaps in the lines on the printed report, press F5

to select No.

Replace the printer as described in “Replacing the Printer

Assembly” on page 4-12.

6. When all writer tests have been performed, press F6 to select Cancel

and close the window.

RS232 Test

The RS232 Test can be used to determine if the comm ports are working

properly.

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6

2. Use a paper clip to short pins 2 and 3 in the COM port.

3. Select the RS232 Test button.

The following window opens.

2031504-159B MAC™ 800 3-13

Page 36

Troubleshooting

4. Perform the COM Port Loop Back test on COM 1.

a. With the focus on COM 1, press the Enter key.

The results of the COM Loop Back Test are displayed.

b. Note the results of the test.

If either test failed, replace the mainboard assembly as described

in “Replacing the Mainboard Assembly” on page 4-15.

5. When the test is complete, press F6 to Cancel and close the results

window.

LAN Test

The LAN Test can be used to test network connectivity.

1. Connect the MAC 800 device to an active LAN.

Ensure that the LAN is an active network. If you connect to an

inactive network tap, the test result may be a false negative.

2. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

3. Select the LAN Test button.

The following window opens.

4. Press the Enter key to select the Test Network Connectivity button.

The Checking connectivity. Please wait. message is displayed. Then,

the results of test are displayed.

If the System Connected to Network message is displayed in the

window, the test passes.

3-14 MAC™ 800 2031504-159B

Page 37

Modem Test

Troubleshooting

If the Network Unavailable message is displayed in the window

and you are sure the device is connected to an active network, the

test fails.

Replace the mainboard assembly as described in “Replacing the

Mainboard Assembly” on page 4-15.

5. When the test is complete, press F6 to Cancel and close the results

window.

The Modem Test can be used to test the internal modem.

1. Connect the MAC 800 device to an active analog phone line.

Ensure that the phone line is active. If you connect to an

inactive phone line, the test result may be a false negative.

2. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

3. Select the Modem Test button.

USB Test

The following window opens.

4. With the focus on the Internal Modem Test button press the Enter

key.

The Test in Progress. Please wait message is displayed.

Then the results of the test are displayed.

If the Passed message is displayed in the window, the test passes.

If the Failed message is displayed in the window, the test fails.

Replace the internal modem as described in “Replacing the

Internal Modem (option)” on page 4-18.

The USB Test can be used to test the USB port.

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

2. Connect a USB keyboard to the USB port of the MAC 800 back panel.

3. Select the USB Test button.

The following window opens.

2031504-159B MAC™ 800 3-15

Page 38

Troubleshooting

4. Press any key on the USB keyboard and verify pass or fail:

If the character that appears in the Character Input field

matches the key you pressed, the test passed.

If the character does not match or no character appears in the

Character Input field, the test fails.

5. When the test is complete, press F6 to Cancel.

The following window opens.

Patient Lead Wire Test

6. Do one of the following:

If the test passed, press F4 to select Yes.

If the test failed, press F5 to select No.

Replace the mainboard assembly as described in “Replacing the

Mainboard Assembly” on page 4-15.

Test the patient leadwires as described in this section.

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

2. Connect a patient cable with lead wires to the MAC 800 patient cable

connector.

3. Connect all leads to a patient simulator or shorting bar.

4. Select the Patient Lead Wire Check button.

The window shown below opens.

3-16 MAC™ 800 2031504-159B

Page 39

Troubleshooting

5. Press the Enter key to select the Start Test button.

For each lead wire, the test results are displayed.

If the Connected message is displayed, the lead wire passes the

test.

If the Disconnected message is displayed, the lead wire fails the

test.

6. Press F6 (Cancel) when the test is complete.

7. Replace every lead wire that failed the test.

8. Repeat the test.

If the lead wire still fails the test, replace the mainboard assembly as

described in “Replacing the Mainboard Assembly” on page 4-15.

Equipment Problems

ECG Data Noise

If the acquired ECG data displays unacceptable noise levels:

When troubleshooting noise or signal quality, be sure the problem

is not being caused by poor skin preparation, or placement and

condition of electrodes.

Careful skin preparation is the key to an interference-free ECG.

Signal quality is indicated using Hookup Advisor. Hookup Advisor

can be turned on or off in the ECG menu. Select Main Menu > System

Configuration > Resting ECG Setup > Page Down.

Check for defective or date-expired electrodes.

Check for defective, broken, or disconnected leadwires.

Run the Acquisition Module Tests in the Diagnostic menu and make

sure all lead wires pass the noise test.

Refer to “Acquisition Module Test” on page 3-10.

2031504-159B MAC™ 800 3-17

Page 40

Troubleshooting

Error Codes

No action is necessary for isolated error occurrences. However if the unit

is malfunctioning and any of the following error messages are repeating

and unrecoverable, replace the FRUs in the order as listed.

Acquisition Error Codes

If you repeatedly receive any of the following acquisition error codes,

replace the mainboard assembly as described in “Replacing the

Mainboard Assembly” on page 4-15.

Acquisition Error -1 General acquisition error

Acquisition Error Codes

Error Code Cause

Printer Error Codes

Acquisition Error 3 Sequence number error in 100ms ECG Packet

Acquisition Error 9 Acquisition self test error

If you repeatedly receive any of the following printer error codes, replace

the printer assembly as described in “Replacing the Printer Assembly” on

page 4-12.

Printer Error Codes

Error Codes Cause

Printer Internal Error 2 Printhead temperature is too hot or too cold to print

Printer Internal Error 3 Printer driver could not be opened

Printer Internal Error 4 Printer driver communication error

Printer Internal Error 5 Printer driver timeout error

Printer Internal Error 6 Printer driver miscellaneous error

Printer Internal Error 7 Undefined printer status was received

3-18 MAC™ 800 2031504-159B

Page 41

Frequently Asked Questions

Maintenance

NOTE

See the MAC™ 800 Operator’s Manual for complete System

Configuration information.

Save System Setups to SD Card

Q: How do I save changes I have made to the System Configuration?

A: Perform the following steps:

1. Insert the SD card into the SD card slot in right side as shown.

Troubleshooting

2. Push the SD card into the slot to seat it in place.

3. From the Main Menu, press F4 to select System Configuration.

4. Press F6 (More) > F6 (More) > F3 to select Export Setup.

5. Highlight the setup file you want to save to SD card from the list on

left side of the window.

6. Press F1 to select Export.

The following window opens.

2031504-159B MAC™ 800 3-19

Page 42

Troubleshooting

Storing ECGs

7. Press F6 to select OK.

8. Eject the SD card by pushing it in once.

Store it in a secure location.

Q: Why won't any of the ECGs I perform save to the SD card?

A: Check the following:

Is the SD card fully inserted into the drive?

Are you using 128 MB or greater SD cards?

Is the SD card write-protected?

Have you tried a new SD card?

Is your system set up to automatically save records?

If your system is not set up to automatically save records, did you

press Store?

Cleaning

Q: Should I clean the MAC 800?

A: Clean the exterior surfaces of all the equipment and peripheral

devices monthly, or more frequently if needed.

Use a clean, soft cloth and a mild dish-washer detergent diluted in

water.

Wring the excess water from the cloth.

Do NOT drip water or any liquid on the writer assembly, and avoid

contact with open vents, plugs, and connectors.

Dry the surfaces with a clean cloth or paper towel

Refer to the MAC™ 800 Operator’s Manual for details on cleaning the

MAC 800 system.

3-20 MAC™ 800 2031504-159B

Page 43

Battery Capacity

MAC Address

Troubleshooting

Q: What is the capacity of the battery?

A: We recommend that the MAC 800 be connected to AC power through

a wall outlet whenever it is not in use. However, if operating the device

without AC power, be aware that a fully-charged battery is capable of

printing approximately 1000 single page reports or 2 hours of continuous

operation (without printing).

Q: I need to provide the MAC address of the device to the network

administrator to enable the LAN communication option. How do I obtain

the MAC address?

A: Follow these steps to obtain the MAC address:

1. Open the Diagnostic Tests window as described in “Accessing the

System Diagnostics Function” on page 3-6.

2. Move the focus to the Service Report button and press the Enter key

to select.

Calibration

3. Find the MAC address on the printed service report.

Q: How do I calibrate the MAC 800 system?

A: When it becomes necessary, you can calibrate the MAC 800 system

using the following method:

1. Using a standardizing waveform generator, produce a 1.00 ± 0.01

-mV pulse signal with a rise-time no greater than 5ms and a width

no greater than 100ms.

2. Connect the pulse signal to all available channels and set the gain to

10 mm/mV.

3. Verify the display pulses have an amplitude within ± 5% of the

amplitude obtained when the 1.00 ± 0.01 -mV signal is applied.

4. Repeat the test for all fixed gain settings to verify the

standardization pulse correctly reflects the gain setting.

NOTE

The error must be less than ±5% of the expected value or 0.5mm,

whichever is greater.

5. Verify that the standardization signal appears on all channels.

2031504-159B MAC™ 800 3-21

Page 44

Troubleshooting

System Setup

Location Number

Q: When entering patient data, how do I get the Location field to

automatically populate with the same number?

A: The Location number can be set in Basic Setup to save you from

entering it for each test.

1. From the Main Menu, press F4 to select System Configuration.

2. Press F1 to select Basic Setup.

3. Move the focus to the Location field.

4. Type the desired Location number.

5. Press F6 to select Save.

6. Press F5 to select Main Menu.

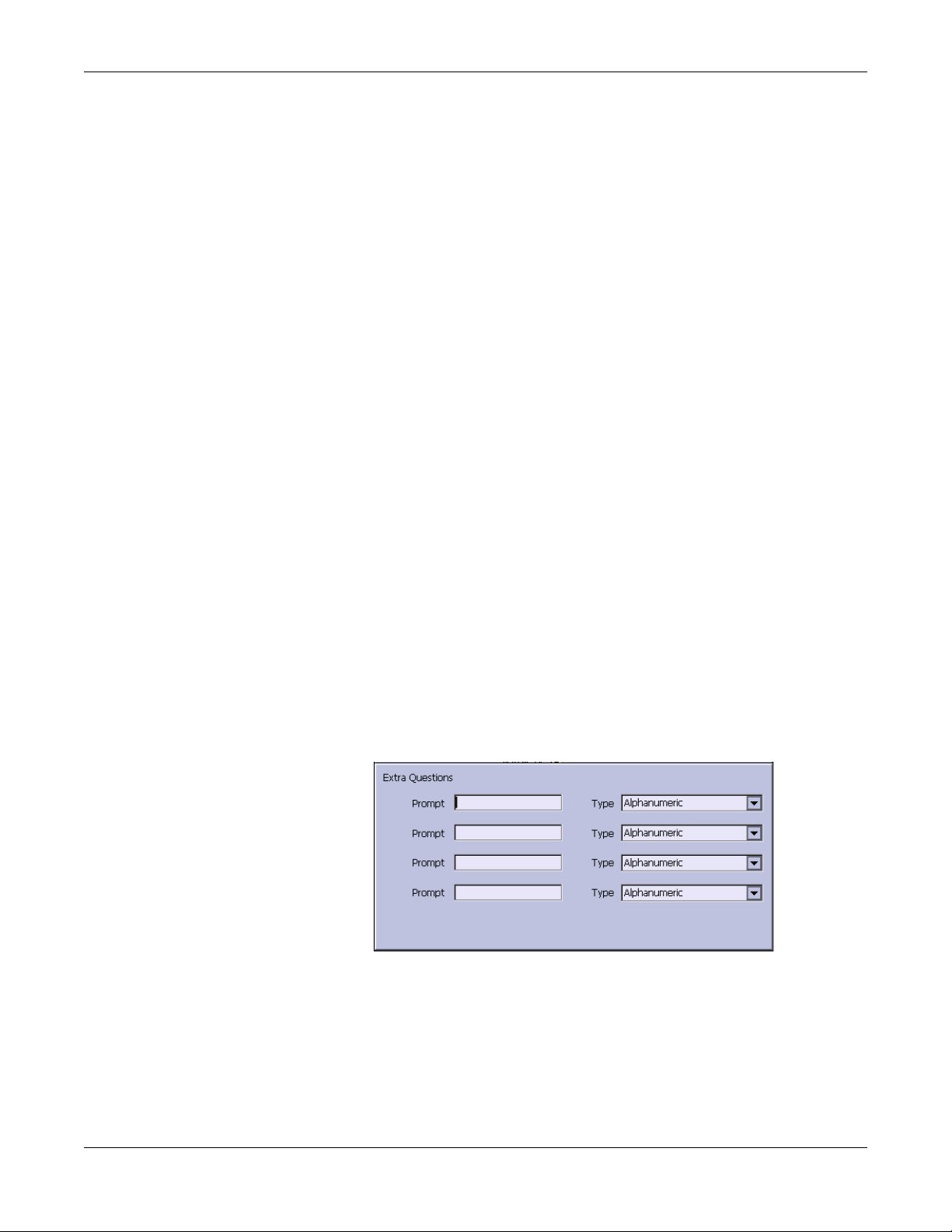

Patient Questions

Q: How do I change which questions I see when I am entering the

patient data?

A: The patient questions you see on the Patient Data window when

starting a test were set up in Patient Setup.

1. From the Main Menu, press F4 to select System Configuration.

2. Press F6 (More) > F4 (Patient Setup) > F4 to select Page Down.

3. Move the focus to the Extra Questions... button and press Enter to

open the Extra Questions window.

4. For each extra question you wish to ask in the Patient Data window,

type the Prompt and select the type of question from the Type list

(Alphanumeric, Numeric, Yes/No/Unknown).

5. Press F6 to select Save in the Extra Questions window.

6. Press F6 to select Save in the Test Information Setup window.

7. Return to the Main Menu.

3-22 MAC™ 800 2031504-159B

Page 45

Passwords

Serial Number

Troubleshooting

Q: The system was set up for High Security Mode and I forgot my

password. How do I access the system?

A: Use the following steps:

1. Contact GE Tech Support and provide the serial number of the

device you want to access.

They will generate a temporary, device-specific name and password

that can only be used for 24 hours.

2. Log into the system with the password provided by GE Tech Support.

3. Immediately after logging into the system, verify your MAC 800 user

name and password. Record this information and store in a secure

location for future reference.

Q: When the mainboard is replaced, how do I reenter the serial number

to the new mainboard?

A: Use the following steps:

1. From the Main Menu, select F4 (System Configuration) > F6 (More)

2. Type 7763 and press Enter.

3. Move the focus to Device Settings and press Enter.

4. Enter the unit’s serial number and press Enter.

Clinical

Resting ECG Report Format

Q: How do I change the way an ECG looks (format) when it prints out?

> F6 (More) > F5 (Service).

The system prompts for the service password.

The service window opens.

The Device Settings window opens.

The unit’s serial number is located on the product label on the bottom

of the device.

A: Do the following.

1. From the Main Menu, press F4 to select System Configuration.

2. Press F2 to select Resting ECG Setup.

3. Press F4 (Page Down) three times.

2031504-159B MAC™ 800 3-23

Page 46

Troubleshooting

4. Select which type of ECG report you want to change from 10s ECG

5. Select the number of copies you want from Report Copies list.

6. If you want the MAC 800 or 12SL Interpretation included on the

7. If you do not want the MAC 800 interpretation to print on the ECG,

8. Press F6 to save the setup.

Editing

Q: Can you edit the interpretation at the MAC 800, and then transmit

the edited record to the MUSE system as an unconfirmed record?

A: MAC 800 does not support edit interpretation.

Navigating the User Interface

Report Format list:

ECG, check the Print Interpretation check box.

clear the Print Interpretation check box.

Q: How do I navigate from the startup screen to the Main Menu?

A: The MAC 800 system can be configured in a number of different

ways. Some of these configuration choices determine the actions that

need to be performed in order to proceed from the power up display to the

Main Menu.

There are three configurations that determine the initial window that

appears at power up and what actions the user will need to perform to

navigate to the Main Menu.

Power Up mode currently selected in Basic Setup:

High Security mode enabled in Basic Setup:

USB Barcode Reader support option activated - yes or no.

3-24 MAC™ 800 2031504-159B

Page 47

Troubleshooting

The various steps in this section describe how to navigate from the power

up screen to the Main Menu for the various system configurations.

Use the steps that apply to your system configuration settings.

If your system is configured to power up in the Resting ECG mode,

go to “Resting ECG Power Up Mode” on page 3-25.

If your system is configured to power up in the Arrhythmia mode,

go to “Arrhythmia Mode Power Up Mode” on page 3-26.

If your system is configured to power up in the Main Screen mode,

go to “Main Screen Power Up Mode” on page 3-26.

Resting ECG Power Up Mode

These steps describe how to navigate to the Main Menu after powering

on the MAC 800 system when Resting ECG is selected for Power Up

mode in Basic Setup.

NOTE

1. If the High Security Mode is enabled, proceed with step a through

2. Press F5 to select Cancel.

3. Press F6 to select More.

To perform system setup functions, log in as a user who is assigned

setup editing privileges.

step d when prompted for a User ID and Password; if the password

prompt does not appear, go to step 2.

a. Type your user ID in the User ID field.

b. Press the Enter key or press the down arrow key on the

trimpad to move the focus to the Password field.

c. Type your password in the Password field.

d. Press the F5 key to select Login.

4. Press F5 to select Main Menu.

2031504-159B MAC™ 800 3-25

Page 48

Troubleshooting

Arrhythmia Mode Power Up Mode

These steps describe how to navigate to the Main Menu after powering

on the MAC 800 system when Arrhythmia is selected for Power Up mode

in Basic Setup.

NOTE

To perform system setup functions, log in as a user who is assigned

setup editing privileges.

1. If the High Security Mode is enabled, proceed with step a through

step d when prompted for a User ID and Password; if the password

prompt does not appear, go to step 2.

a. Type your user ID in the User ID field.

b. Press the Enter key or press the down arrow key on the

c. Type your password in the Password field.

d. Press the F5 key to select Login.

trimpad to move the focus to the Password field.

If the barcode reader option is enabled, a window opens

prompting you to scan the patient barcode.

2. Press F6 to select Cancel.

3. Press F5 to select Cancel.

4. Press F6 to select More.

5. Press F5 to select Main Menu.

Main Screen Power Up Mode

These steps describe how to navigate to the Main Menu after powering

on the MAC 800 system when Main Screen is selected for Power up mode

in Basic Setup.

NOTE

1. If the High Security Mode is enabled, proceed with step a through

NOTE

If the barcode prompt does not appear, go to step 3.

To perform system setup functions, log in as a user who is assigned

setup editing privileges.

step d when prompted for a User ID and Password; if the password

prompt does not appear, go to step 2.

a. Type your user ID in the User ID field.

b. Press the Enter key or press the down arrow key on the

trimpad to move the focus to the Password field.

c. Type your password in the Password field.

d. Press the F5 key to select Login.

3-26 MAC™ 800 2031504-159B

Page 49

Troubleshooting

The Main Menu is displayed.

2. If the system is configured for Main Screen Power up mode and does

not have the High Security Mode enabled, the Main Menu appears

after powering up the system. No further keys need be pressed in

order to display the Main Menu.

2031504-159B MAC™ 800 3-27

Page 50

Troubleshooting

3-28 MAC™ 800 2031504-159B

Page 51

4 Maintenance

2031504-159B MAC™ 800 4-1

Page 52

Maintenance

Introduction

Recommended Maintenance

Regular maintenance, irrespective of usage, is essential to ensure that

the equipment will always be functional when required. See the MAC

800 Resting ECG Analysis System Operator’s Manual for cleaning

procedures. GE recommends that electrical safety checks be performed

annually.

WARNING

MAINTENANCE RESPONSIBILITIES — Failure on the

part of all responsible individuals, hospitals or

institutions employing the use of this device to implement

the recommended maintenance schedule may cause

equipment failure and possible health hazards. The

manufacturer does not, in any manner, assume the

responsibility for performing the recommended

maintenance schedule, unless an Equipment

Maintenance Agreement exists.

The sole responsibility for performing the recommended

maintenance schedule rests with the individuals,

hospitals, or institutions utilizing the device.

Required Tools and Supplies

The following list identifies the tools required to perform the procedures

described in this chapter.

ECG simulator

Phillips #1 screwdriver

Hexagonal screw drivers

Current leakage tester

Anti-static wrist strap

MAC™ 800 Service Manual

MAC™ 800 Operator’s Manual

NOTE

Always use an anti-static wrist strap while opening the MAC 800

unit to avoid possible damage due to static electricity.

4-2 MAC™ 800 2031504-159B

Page 53

High-Level FRU Identification

Top Cover Assembly

Bottom Assembly

Maintenance

Battery

LCD Assembly

2031504-159B MAC™ 800 4-3

Page 54

Maintenance

Mainboard (A) and

Internal Modem (B, option)

Power Supply Assembly

Writer Assembly

Keypad Assembly

Barcode Reader (option)

4-4 MAC™ 800 2031504-159B

Page 55

Patient Cable

Serial Cable

FRU Replacement Procedures

Maintenance

Preparing System for FRU Replacement

Prior to performing any disassembly procedures, perform these steps.

NOTE

Take strict precautions against electrostatic discharge damage

while replacing field replaceable units.

1. Power off the system.

2. Disconnect the unit from the AC wall outlet.

3. Disconnect the power cord from the back panel connector.

4. Disconnect the patient cable from the unit as described in “Replacing

the Patient Cable” on page 4-5.

5. Remove the battery as described in “Replacing the Battery

Assembly” on page 4-7.

Replacing the Patient Cable

1. Disconnect the system from AC power.

2. Disconnect the patient cable from the MAC 800 side panel connector

as shown in the following illustration.

2031504-159B MAC™ 800 4-5

Page 56

Maintenance

3. Connect the new patient cable to the side panel connector.

4. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

Replacing Barcode Reader

1. Power off the system and disconnect from AC power.

2. Disconnect the barcode reader from the USB connector on the

MAC 800 rear panel as shown in the following illustration.

3. If only the cable is to be replaced, disconnect the cable from the

barcode reader using the following instructions.

a. Insert an Allen wrench (or straightened paper clip) in the

small hole in the base of the barcode reader.

4-6 MAC™ 800 2031504-159B

Page 57

Maintenance

b. While pushing the tool into the hole, pull the cable to remove it

from the base of the barcode reader.

4. With a new cable, reverse the disassembly procedures to reassemble.

Insert USB connector with (the USB symbol) facing down.

5. Configure the new barcode reader as described in the MAC™ 800

Operator’s Manual.

6. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

Replacing the Battery Assembly

1. Disconnect the system from AC power.

2. Turn the unit over.

3. Press the battery release tab (A) and raise the battery from its

compartment to remove it.

4. Insert the new battery by reversing the steps for removal.

5. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

2031504-159B MAC™ 800 4-7

Page 58

Maintenance

Replacing the Top Cover Assembly

1. Disconnect the system from AC power.

2. Remove the battery assembly as described in “Replacing the Battery

Assembly” on page 4-7

3. Remove the six screws from the bottom of the device.

4. Turn the unit right side up.

5. Press the printer button.

6. Open the printer door.

7. Lift the top assembly approximately 1 inch at the back panel side.

4-8 MAC™ 800 2031504-159B

Page 59

Maintenance

8. Pull up the lock-release tab on mainboard keypad connector.

9. Disconnect the keypad cable as shown.

2031504-159B MAC™ 800 4-9

Page 60

Maintenance

10. Remove the eight screws from the bottom of the top cover assembly.

11. Separate the keypad from the top cover assembly.

12. Reassemble a new top cover assembly by reversing the steps for

removal.

13. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

Replacing the Keypad Assembly

1. Perform step 1 to step 11 as described in “Replacing the Top Cover

Assembly” on page 4-8.

2. Reassemble a new keypad assembly by reversing the steps for

removal.

3. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

4-10 MAC™ 800 2031504-159B

Page 61

Replacing the LCD Assembly

1. Disconnect the system from AC power.

2. Remove the battery assembly as described in “Replacing the Battery

Assembly” on page 4-7.

3. Remove the top cover assembly as described in “Replacing the Top

Cover Assembly” on page 4-8.

4. Remove the two screws that hold the LCD assembly in place.

Maintenance

5. Push the LCD assembly forward to away from the rear panel.

2031504-159B MAC™ 800 4-11

Page 62

Maintenance

6. Disconnect the inverter cable from the mainboard.

7. Disconnect the LCD cable from the mainboard.

8. Lift the LCD ASSY out of the BOTTOM ASSY.

9. Reassemble a new LCD ASSY by reversing the steps for removal.

10. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

Replacing the Printer Assembly

Removing the Printer Assembly

1. Disconnect the system from AC power.

2. Remove the battery assembly as described in “Replacing the Battery

Assembly” on page 4-7.

3. Remove the top cover assembly as described in “Replacing the Top

Cover Assembly” on page 4-8.

4. Remove the LCD Assembly as described in “Replacing the LCD

Assembly” on page 4-11.

4-12 MAC™ 800 2031504-159B

Page 63

Maintenance

5. Remove the printer door from the bottom cover assembly as shown.

6. Disconnect the printer cable from the mainboard.

7. Remove the two screws from the printer mounting base as shown.

2031504-159B MAC™ 800 4-13

Page 64

Maintenance

8. Remove the printer motor from the printer mounting base.

Reassembling the Printer Assembly

1. Replace a new printer motor on the bottom assembly as shown.

2. Replace the two mounting screws.

3. Reconnect the printer cable to the mainboard.

4. Replace the printer door.

5. Reassemble the LCD assembly.

6. Reassemble the top cover assembly.

7. Reassemble the battery assembly.

8. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

4-14 MAC™ 800 2031504-159B

Page 65

Replacing the Mainboard Assembly

Processing ECGs in Internal Storage

If the system has the internal storage option, process any ECGs

remaining in storage by transmitting to your archival system and/or

print them to ensure you have a printed record before proceeding with

the mainboard replacement.

Saving System Configuration Settings

1. Store the System Configuration settings to an SD card.

a. Insert SD card in the SD card slot.

b. From the Main Menu, press F4 to select System Configuration.

c. Press F6 (More) > F6 (More) > F3 to select Export Setup.

d. Highlight the system setup file you want to export to the SD

card.

Maintenance

e. Press F1 to select Export.

f. When the Configuration was successfully exported message is

displayed, press F6 to select OK.

g. Remove the SD card and store in a secure location.

2. Print the System Setup Report if you feel you may need it for

additional reference after the FRU replacement procedure.

a. From the Main Menu, press F4 to select System Configuration.

b. Press F6 (More) > F3 to select Print Setup Report.

c. Move the focus to the Complete Setup button and press Enter.

d. Save the printed setup report in a secure location. It can be used

as a reference if System Setup needs to be restored manually.

Removing the Mainboard Assembly

1. Disconnect the system from AC power.

2. Remove the battery assembly as described in “Replacing the Battery

Assembly” on page 4-7.

3. Remove the top cover assembly as described in “Replacing the Top

Cover Assembly” on page 4-8.

4. Remove the LCD assembly as described in “Replacing the LCD

Assembly” on page 4-11.

5. Disconnect the printer cable from the mainboard.

2031504-159B MAC™ 800 4-15

Page 66

Maintenance

6. Remove the 10 screws that hold the mainboard in place.

7. Lift the mainboard assembly approximately 1.5 inch.

8. Disconnect the battery cable from the bottom side of mainboard.

4-16 MAC™ 800 2031504-159B

Page 67

9. Disconnect the AD-DC cable from the bottom side of mainboard.

Reassembling the Mainboard Assembly

1. Reconnect the AC/DC cable to the bottom of the new mainboard.

2. Reconnect the battery cable to the bottom of the new mainboard.

Maintenance

3. Replace the new mainboard assembly on bottom cover assembly as

shown.

4. Replace the 10 screws that were removed in step 6 on page 4-16.

5. Reconnect the printer cable to the new mainboard.

6. Reassemble the LCD assembly.

7. Reassemble the top cover assembly.

8. Reassemble the battery assembly.

9. Connect the power cord to AC power.

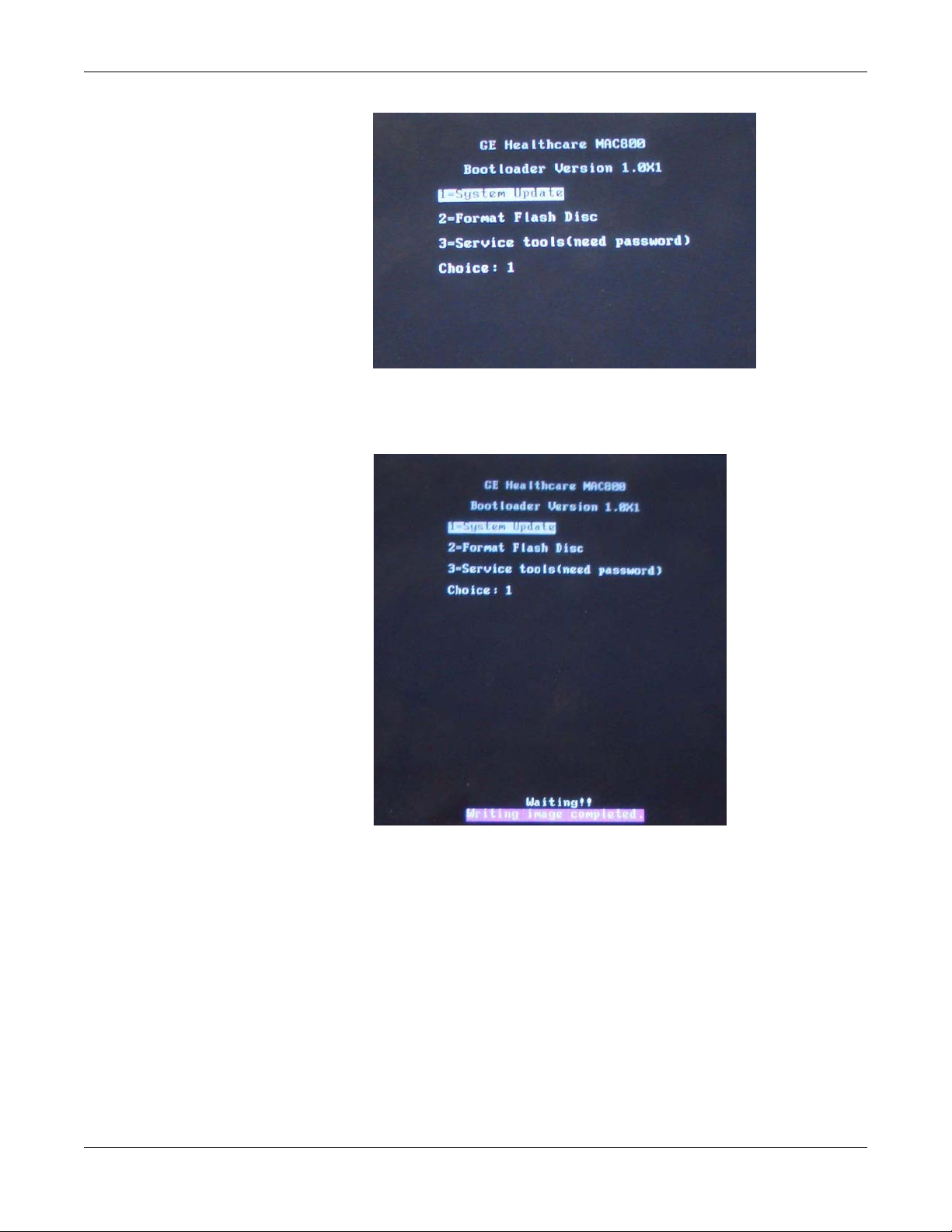

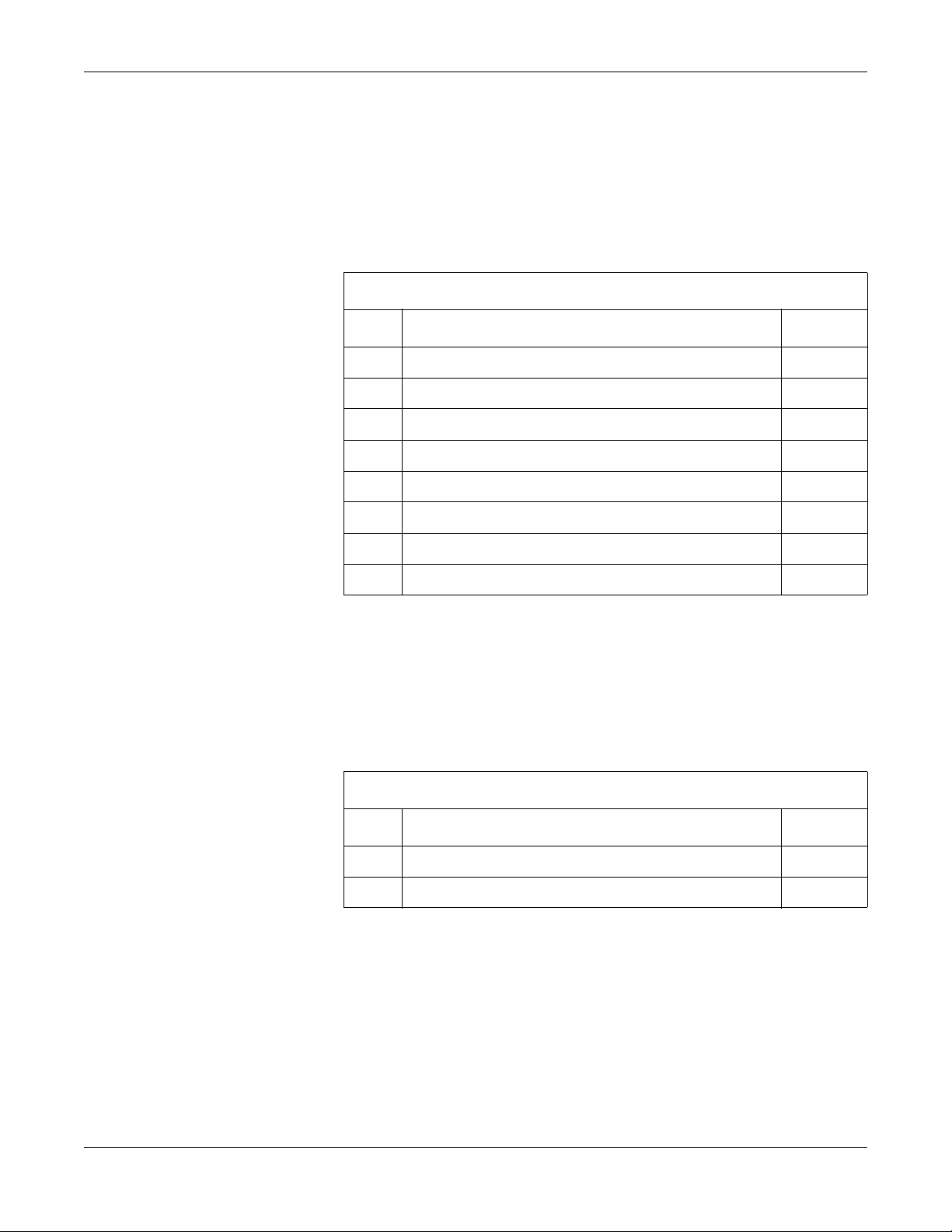

10. Install the software from the SD card that shipped with the

mainboard and activate the options.

2031504-159B MAC™ 800 4-17

Page 68

Maintenance

11. Restore system setups that were saved to the SD card.

12. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

Replacing the Internal Modem (option)

1. Disconnect the system from AC power.

2. Remove the battery assembly as described in “Replacing the Battery

Assembly” on page 4-7.

3. Remove the top cover assembly as described in “Replacing the Top

Cover Assembly” on page 4-8.

4. Remove the lcd assembly as described in “Replacing the LCD

Assembly” on page 4-11.

5. Remove the internal modem from its socket.

6. Reassemble the internal modem by reversing the steps for removal.

Take care to align the contact pins with the sockets and align the

hole with the plastic pin before pushing it into the sockets.

7. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

Replacing the Power Supply Assembly

Removing the Power Supply Assembly

1. Disconnect the system from AC power.

2. Remove the battery assembly as described in “Replacing the Battery

Assembly” on page 4-7.

3. Remove the top cover assembly as described in “Replacing the Top

Cover Assembly” on page 4-8.

4. Remove the LCD assembly as described in “Replacing the LCD

Assembly” on page 4-11.

5. Remove the mainboard assembly as described in “Removing the

Mainboard Assembly” on page 4-15.

6. Remove the six M3X8 screws from the shield plate as shown in the

following illustration.

4-18 MAC™ 800 2031504-159B

Page 69

Maintenance

7. Remove the two M3X12 flat screws from the shield plate as shown in

the following illustration.

8. Remove the four hexagon screws from the shield plate as shown in

the following illustration.

2031504-159B MAC™ 800 4-19

Page 70

Maintenance

9. Remove the shield plate from the bottom cover assembly.

10. Remove the four hexagon screws of AC/DC as shown in the following

illustration.

11. Lift the AC/DC and disconnect the AC inlet cable as shown in the

following illustration.

4-20 MAC™ 800 2031504-159B

Page 71

Reassembling the Power Supply Assembly

1. Connect the AC inlet cable to the new AC/DC.

2. Place the new AC/DC in the bottom cover assembly.

3. Replace the four hexagon screws.

4. Route the AC/DC cable for mainboard as shown.

Maintenance

5. Replace the shield plate.

6. Replace the six M3X8 screws, two M3X12 flat screws, and four

hexagon screws on the shield plate.

7. Reassemble the mainboard assembly.

8. Reassemble the printer assembly.

9. Reassemble the LCD assembly.

10. Reassemble the top cover assembly.

11. Reassemble the battery assembly.

12. Perform the applicable checkout procedures.

Refer to “Functional Checkout” on page 4-23.

Replacing the Bottom Cover Assembly

1. Disconnect the system from AC power.

2. Remove the battery assembly as described in “Replacing the Battery

Assembly” on page 4-7.

3. Remove the top cover assembly as described in “Replacing the Top

Cover Assembly” on page 4-8.

4. Remove the LCD assembly as described in “Replacing the LCD

Assembly” on page 4-11.

2031504-159B MAC™ 800 4-21

Page 72

Maintenance

5. Remove the printer assembly as described in “Removing the Printer

Assembly” on page 4-12.

6. Remove the mainboard assembly as described in “Removing the

Mainboard Assembly” on page 4-15.

7. Remove the power supply assembly as described in “Replacing the

Power Supply Assembly” on page 4-18.

8. Replace the new bottom cover assembly.

9. Reassemble the power supply assembly.

10. Reassemble the mainboard assembly.

11. Reassemble the printer assembly.

12. Reassemble the LCD assembly.

13. Reassemble the top cover assembly.

14. Reassemble the battery assembly.

15. Perform the applicable checkout procedures.

Replacing the Fuse

Refer to “Functional Checkout” on page 4-23.

1. Disconnect the system from AC power.

2. Using a screw driver, take out the fuse holder from the AC inlet as

shown in the following illustration.

3. Replace two new fuse in the fuse holder.

4-22 MAC™ 800 2031504-159B

Page 73

4. Reassemble the fuse holder into AC inlet.

Functional Checkout

The checkout procedures apply to all MAC 800 systems.

NOTE

The FRU checkout procedure for any listed FRU also applies to its

internal PCBs and components.

Maintenance

Perform the applicable product or product configuration dependant

procedures when an asterisk (*) is listed.

FRU replacement procedures are contained within this chapter of

the manual.

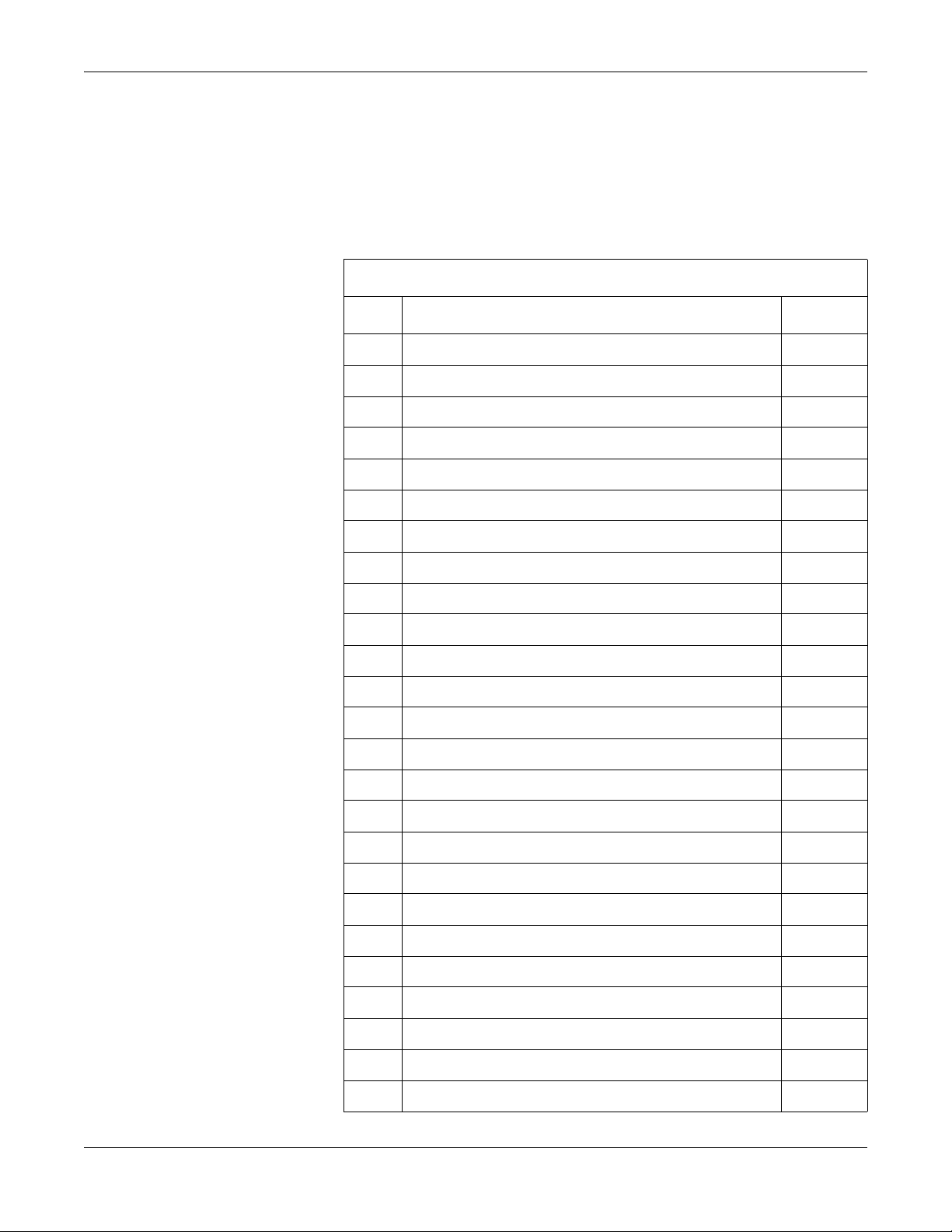

Basic System FRU Repairs

FRU Description Visual Inspection

Patient Cable 1, 2, 7 1, 2, 3

Keypad Assembly 3, 6, 7 1, 2, 3, 7

Top Cover Assembly 6, 7 1, 2, 3, 14

LCD Assembly 3, 6, 7 1, 2, 3, 6

Printer Assembly 6, 7 1, 2, 3, 8

Mainboard Assembly 6, 7 1, 2, 3, 4, 5, 6, 7, 8, 9, 10,