Page 1

TECHNICAL SERVICE GUIDE

GE Built-In Dishwasher with Stainless Steel Tall Tub

Models

GLD9312

GLD8312

GLD8110

08-MAN-DW-01

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing adequate backgroun ds of

electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal

injury and property damage. The manufacture or seller cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this product. If electrical power is required for

diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps clips, nuts, or washer used to complete a path to ground are removed for

service, they must be returned to their original position and properly fasten

ed.

Mabe Consumer & Industrial

Technical Service Guide

Copyright @2008

All rights reserved. This service guide may not be reproduced in whole or in part in any form without written

permission from the Mabe Canada.

2

Page 3

Table of Contents

Nomenclature ........................................................................................................................................... 4

Component Locator.................................................................................................................................. 9

Inside Door Panel after front panel has been removed ................................................................. 10

Bottom View ........................................................................................................................................10

Component Removal.............................................................................................................................. 12

Removing Upper Rack ........................................................................................................................ 12

Middle Spray Arm ............................................................................................................................... 12

Lower Spray Arm, Fine Filter, and Inlet Cover................................................................................. 12

Wash Pump Disassembly .................................................................................................................. 12

Drain Pump.......................................................................................................................................... 13

Fill Funnel............................................................................................................................................. 14

Door Panel ...........................................................................................................................................15

Troubleshooting...................................................................................................................................... 16

Service Mode ....................................................................................................................................... 16

Circulation Pump and Motor .............................................................................................................16

Temperature Sensor:.......................................................................................................................... 17

Drain Motor .........................................................................................................................................17

Water Valve and Flood Switch .......................................................................................................... 17

Control Module.................................................................................................................................... 18

Detergent/ Rinse Module................................................................................................................... 18

Active Vent........................................................................................................................................... 19

Schematic ................................................................................................................................................20

3

Page 4

Nomenclature

Model Number

*Note: The exterior colour, ll = Integrated, requires a panel kit

G L D 9 3 1 2 P 0 0 W W

Brand

G=GE

Size

L=Long Door

Product Type

D=Built-in

Platform

9 = Fully Integrated

Feather Pack

Number of Buttons

Model Year Designator

Engineering Model Suffix

Exterior Colour

WW = White on White

SS = Stainless Steel

BB = Black

4

Page 5

Serial Number

The model number and serial number are located inside the door jam.

The first two characters of the serial number identify

1 2 3 4 5 6 7 8 9

H

1 Date Code -Month -( Alpha)

2 Calendar Year Code (Alpha)

3 Model Class Code

4,5,6,7,8 Serial Number

9 Manufacturing Location

M 7 0 0 0 0 1 H

Column 1 Denotes the fiscal month of manufacture

Column 2 Denotes the fiscal year of manufacture (See Date of Manufacture Code Table below)

Column 3 Denotes the product being produced (regardless of Brand)

Columns 4 to 8 Model Class Code for Built-In dishwasher Products = 7 denotes the order of manufacture within a given

time period. The sequence will start with 00001 and progress until 99999 is reached or the fiscal

month has changed. The 5 digits need not be reset to the start of the numbering sequence each

month. This is left to the discretion of the factory.

Column 9 A letter, which will designate where the appliance was manufactured according to the following code:

H = Haier.

DATE OF MANUFACTURE CODE TABLE (For column 1 & 2)

A – Jan. A 2001, 2013

B – Feb. D 2002, 2014

F – Mar. F 2003, 2015

G – Apr. G 2004, XXXX

H – May. H – 1993 2005

L – June. L – 1994 2006

M – July. M – 1995 2007

R – Aug. R – 1996 2008

S – Sept. S – 1997 2009

T – Oct. T – 1998 2010

V – Nov. V – 1999 2011

Z – Dec. Z – 2000 2012

Example:

Using the example from the previous page. - HM700001H:

H = May

M = 2007

7 - Built-In Dishwasher

00001 = sequential production number

H = Haier

5

Page 6

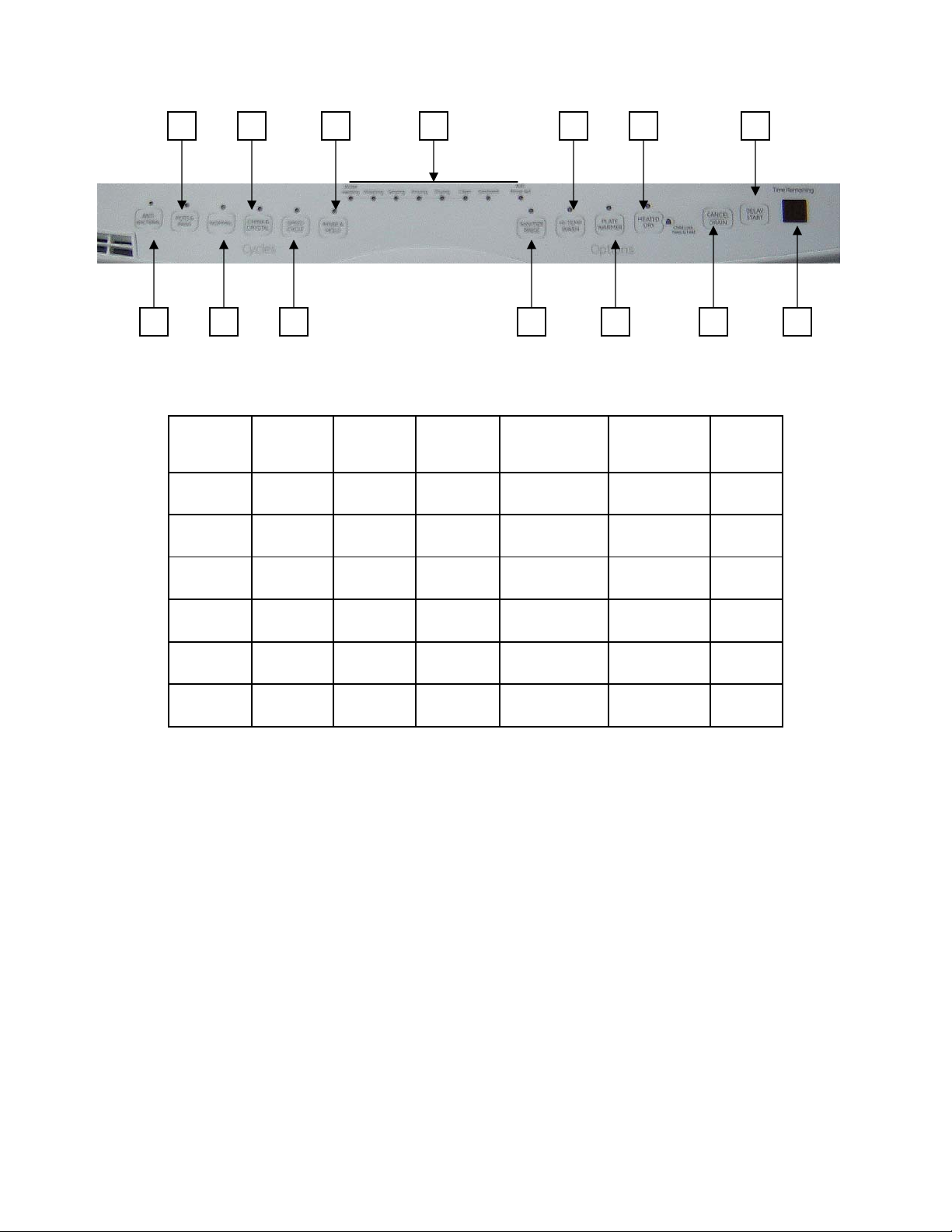

Control Features

2 4 1 13 7 9 11

1 3 5 6 8 10 12

Cycles

Cycle

Anti-

Bacterial

Pots &

Pans

Normal

Wash

China

Crystal

Speed

Wash

Rinse

Hold

NOTE: The sensor in the dishwasher monitors the soil level. Cycle time and/or water usage can vary

from the numbers above as the sensor adjusts the cycle for the best wash performance.

1. Anti-Bacterial - Use this cycle for all day-today soil types, including both normal and heavy

soils, giving you exceptional cleaning performance combined with reassuring sanitization.

2. Pots & Pans - Use this cycle for hard-to-clean, baked-on cookware and harder than normal

water conditions.

3. Normal - Use this cycle for loads with normal amounts of food soil. During the Main Wash,

the wash action will repeatedly pause for several seconds.

4. China & crystal - Use this cycle for china and crystal. This cycle uses a light wash and gentle

dry. During the heated dry, the heating element cycles on and off.

Max # of

Pre-wash

Cycles

Max # of

Wash

Cycle

2 1 4 42 110 150 160 10

2 1 4 38 104 140 150 10

2 1 4 23 99 120 130 10

1 1 1 30 52 130 135 10

0 1 1 19 120 130 10

0 0 1 12 12 / / /

Rinse

Cycles

Wash

Time

Min Max

Wash

Temperature

Min Max

Heated

Dry

Time

6

Page 7

5. Rinse & Hold - Use this rinse cycle for rinsing dishes, glasses and silverware that will not be

washed right away.

Options

6. Sanitize Rinse - Select this option to raise the water temperature in the final rinse to

approximately 160°F (71°C). The SANITIZE RINSE option adds heat and time to the cycle. This

high temperature rinse sanitizes your dishes and glassware in accordance with NSF/ANSI

standard 184 for residential dishwasher. Certified residential dishwashers are not intended

for licensed food establishments. ANTI-BACTERIAL WASH automatically uses this option.

SANITIZE RINSE is an option with the POTS & PANS and NORMAL cycles.

7. HI-TEMP WASH is an option with the POTS & PANS and NORMAL cycles. Always use HI-TEMP

WASH if you have hard water.

8. Plate Warmer- Use the PLATE WARMER option to warm serving dishes or dinner plates.

9. Heated Dry- Select this option to dry dishes with heat. HEATED DRY is an option with the

ANTI-BACTERIAL WASH, POTS & PANS, NORMAL and CHINA cycles.

Child Lock - Press & hold CHILD LOCK you can lock the controls to prevent any selections

from being made. Or you can lock the controls after you have started a cycle.

Children cannot accidentally start a dishwasher by touching pads with this option selected.

To unlock the dishwasher controls, press and hold the HEATED DRY pad for 3 seconds. To

lock the dishwasher, press and hold the HEATED DRY pay for 3 seconds. An indicator light

shows when CHILD LOCK is activated.

10. Drain Cancel ( GLD8110 GLD8312) Start Reset (GLD9312) - To change a cycle after washing

starts.

GLD8110-PLD8312 Series: Touch the DRAIN/CANCEL pad to cancel the cycle. Then the

water is pumped out if needed. This takes approximately 2 minutes.

GLD9312 Series: Open the door slowly to prevent splash-out. Touch the START/RESET pad to

cancel the cycle. If the START/RESET light is on, close the door until the water pumps out (this

takes approximately 2 minutes) and the light stops flashing.

When the light stops flashing, the dishwasher can be reprogrammed and restarted.

11. Delay Hours - You can delay the start of a wash cycle for up to 12 hours (GLD8110 GLD8312)

or 24 hours (GLD9312). Press the DELAY START pad to choose the number of hours you want

to delay the start of the cycle; then press START/RESET.

NOTE: To cancel the DELAY START selection before the cycle begins, press the DELAY START

pad until the display is blank

12. Time Remaining – A two digit display that shows the wash time left. This may reduce or

increase based on the readings of the Clean Sensor. It will display in minutes up to 99.

Between 100 and 120 Minutes it will show 2h (2 hours) and between 120 and 180 minutes it

will show 3h (3 hours)

7

Page 8

13. Status Indicators

Note: Status Indicators vary by model

The Status display tells you what is happening while the dishwasher is in operation and may flash,

indicating a malfunction. The lights will come ON indicating the sequence of the dishwasher

operation.

WASHING On during pre-wash and main wash periods

RINSING On during rinse periods

DRYING On during dry periods.

SANITIZED On when cycle has met Sanitization requirements

CLEAN On when a wash cycle is complete and Options are complete.

ADD RINSE AID On when the rinse aid is empty

WATER HEATING On when the dishwasher is heating the water

8

Page 9

Component Locator

1. Upper Spray . 7. Split Folding Utility Shelf (4)

2. Top Rack Track 8. Adjustable Top Rack

3. Water Inlet Opening. (in tub wall). 9. Middle Spray Arm

4. Lower Spray Arm 10. Removable Silverware Basket

5. Bottom Rack 11. Overfill Protection Float

6. Vent System 12. Heating Element

13. Detergent and Rinse Aid Dispenser

9

Page 10

Vent

Assembly

Vent Wax

Motor

Dispenser

Assembly

Inside Door Panel after front panel has been removed

Latch

Assembly

Interlock

Switch

Control

Board

Fill Solenoid

Electrical

Junction Box

Schematic is located behind the bottom kick plate

10

Page 11

Bottom View

Fill

Valve

Thermal

Safety

Wash

Motor

Wash

Sump

Float

Switch

Clean

Sensor

Drain

Motor

Temperature

Sensor

Heating

Element

11

Page 12

Component Removal

Removing Upper Rack

1. Pull tab out and remove the end cap

2. Pull the rack straight out and off the rails.

3. Replace the end caps.

4. Push the rails all the way back into the

dishwasher and pull upper rack all the way

out

Tab

Middle Spray Arm

Check holes in spray arm on for bits of foreign

matter.

Check spray arms for rotation

REMOVAL AND REPLACEMENT

1. Pull upper rack all the way out

2. Unscrew the plastic collar holding the spray

arm to the upper rack

.

Lower Spray Arm, Fine Filter, and Inlet Cover

Check the holes in the arm for bits of foreign

matter. Also check the spray wash arm for

rotation. Clean the fine filter screen if soil is

present.

The lower spray wash arm can be removed by

gently lifting and rotating it counter clockwise.

Wash Pump Disassembly

1. Remove the lower spray arm

2. Remove the 3 screws holding the hub.

3. Detach the water conduit from the tub

assembly.

4. Lift the water conduit and hub straight up to

remove from the pump.

Holding Clips

Water

Conduit

3 screws

.

Collar

12

Page 13

Wash Pump Disassembly con’t

5. Remove 2 screws holding the fine filter

assembly and lift to remove.

Press on

Nut

2 screws

6. Remove the 1 screw holding the coarse filter.

Lift out the coarse filter.

7. Remove the 2 screws holding the inlet

protector.

Screw

3. Remove the pulveriser blade, screen, spring and

washers.

Order of pulveriser components

4. Tip dishwasher on its back. Remove the one

Philips head screw that holds the motor in

place. It is located behind the cardboard shield.

Philips head

screw

Wash Motor

1. Disassemble the wash pump (see procedure)

2. Remove the press on nut to disassemble the

pulveriser

5. Disconnect the motor connector and rotate the

2 Screws

13

motor clockwise until it disengages from the

sump.

Note: Before removing the wash motor, remove the

water from the sump with a syringe

Drain Pump

1. Disconnect the pump connector

2. Press the tab and rotate the pump assembly

counter clockwise to remove.

Page 14

Tab

Fill Funnel

The top section of the fill funnel separates from the

main body. The fill funnel body is held in place by a

nut (located on the inside of the dishwasher).

Rotate the nut counter clockwise to remove the

main body. There is an O-ring seal between the fill

funnel and dishwasher tub. Make certain the O-ring

is fully seated when reinstalling.

Heating Element

The heating element nuts are located on the

underside of the washer, near the door. Ample

force is required to remove the nuts.

Removing the dishwasher from installation

may be required.

14

Page 15

Door Panel

The door panel covers the main control board,

detergent cup, vent, wax motor, louver, and

door-interlock switch. The outer door panel is

held in place by 14 screws (7 Phillips head

screws per side)

NOTE: Ribbon cable(s) connect the keypad

membrane (2-digit display on some models)

to the control circuit board. Due to the ribbon

length, care much be taken when removing

the door panel to ensure that the ribbon

cable(s) are not damaged.

Membrane Keypad

The door panel must be removed to access

the membrane keypad (see Door Panel).

When removing the membrane keypad, peel

the keypad from right to left.

On models with an LED display, the display is

held in place with a plastic clip.

NOTE: When replacing the keypad membrane,

always run the Service Mode to calibrate the

keypad membrane to the control board.

Control Module

The door panel must be removed to access

the control module (see Door Panel). The main

control is considered a “smart” control,

capable of learning the water temperature

and turbidity characteristics of the home.

It is normal if the cycle times vary over a

period of time from the factory default

settings due to temperature and water

quality.

The control module is held in place by two

screws that secures the module to the right

side of the inner door panel.

15

Page 16

Troubleshooting

Service Mode

To enter service mode, ensure door is closed

and press the following keys.

High Temp Wash. – Heat Dry - High Temp

Wash

If followed correctly Dishwasher will enter into

SERVICE MODE

All LED will illuminate indicating that they are

functioning properly

Has no diagnostics

Press Pots& Pans to activate

Water Solenoid Valve

Press Normal to activate Wash

Motor

Press China & Crystal to

activate Detergent Dispenser

Press Speed Cycle to activate

Heater and Wash Motor

Press Sanitize Darin Pump will

run for two min.

Circulation Pump and Motor

The Dishwasher must be removed from its

installation to gain access to the circulation

pump and motor. The circulation pump can

be activated using Test Mode. Refer to

schematic or strip circuit for motor resistance

value.

It is important to remember the motor does

not start immediately when the dishwasher

cycle has started. If the motor hums, but will

not start, make certain the pump impeller is

free from obstruction and the motor shaft can

turn freely.

The terminals on the induction motor are

labelled L1 and N. The motor is thermally

protected (internally) through the L1 side. The

wiring connector is blue to match the wire

leading to the motor. It is designed to go only

one way on the terminals. Make certain the

connector is fully seated when installing.

Heating Element

The heating element can be activated using

Service Mode.

The dual-wattage heating element produces

850 watts during wash, to help heat the

water, and an effective wattage due to

cycling of 541 watts during the dry cycle.

Water inlet temperature must be at least

120’F for proper drying. If the problem is that

the dishes are not drying correctly, don’t

overlook the rinse agent. A rinse agent will

improve the water sheeting action and drying

performance. It is normal for the stainless

steel tub and inner door panel to retain water

droplets even though the dishes are dry.

16

Page 17

Clean Sensor

The clean sensor measures the amount of

suspended particles in the wash water in the

sump. The control sends the turbidity sensor a

pulse with modulated 5 volt signal for

calibration and usage during operation

Red

White

Blue

Temperature Sensor:

The dishwasher uses a thermocouple to

measure water temperature. The sensor has a

negative temperature coefficient - as the

temperature rises, the sensor resistance

decreases. At room temperature (25 Degrees

Celsius), the temperature sensor will have a

resistance of 11 K and at 60 degrees Celsius,

the temperature sensor resistance will be 2.8

K

Drain Motor

Drainage system consists of the following

components:

Drain motor

Drain hose (one way check valve)

Water Valve and Flood Switch

The water valve is a 120 VAC solenoid valve

that is switched on/off by the control module.

The flood switch acts as a safety switch ONLY

and does not control normal operation of the

water valve. The flood switch opens the L1

side of the water valve circuit.

The switch is normally open. The weight of the

flood switch float holds the switch closed. The

flood switch will not stop the flow of water if

the valve sticks open from a mechanical

failure.

The water valve can be replaced with the

dishwasher installed.

WARNING: Disconnect power to dishwasher

before servicing water valve and flood switch.

The flood switch is held in place by 2 Phillips

head screws.

Water Valve Test

Attempt to activate water valve using Service

Mode. Pump out water as necessary using

Service Mode. If an intermittent failure is

suspected, activate water valve 5 times using

Service Mode. Water valve should stay on for

50 to 71 seconds per activation and should

not turn on and off during the 50 to 71 second

activation time.

If the water valve is not operating properly or

water level is low, check the following:

17

Page 18

Water valve, flood switch, flood switch float

and stem, transorb, and then main control.

The flood switch should open when the water

level is approximately ¼ in. above the base

(bottom) of the float dome.

Resistance through the water valve solenoid –

900 to 1200

Clogged screen in water valve.

Control Module

The door panel must be removed to access

the control module (see Door Panel). The main

control is considered a “smart” control,

capable of learning the water temperature

and turbidity characteristics of the home.

It is normal if the cycle times vary over a

period of time from the factory default

settings due to temperature and water

quality.

The control module is held in place by two

screws that secures the module to the right

side of the inner door panel.

P2-1 Rinse Aid Sensor (on some models),

P2-2 – Thermostat,

P2-3- Inlet Valve,

P2-4- Dispenser,

P2-6 – Door Interlock Switch (Double Black

Wires),

P3 – Drain Motor,

P5 & P9 – Washing Motor,

P6 – Heater Element,

P7 – Door Interlock Switch (Double White

Wires),

P8 – door Interlock Switch (single Black Wire),

P10 Wax Motor connector,

CN1 + CN6 – Door Panel,

CN2 – Display Board.

Detergent/ Rinse Module

At the second activation (3), the lever lifts the

connecting rod by the notch. This action lifts

the door. The door panel must be removed to

access the rinse dispenser plunger and

release the rinse detergent/rinse module (see

Door Panel) agent. When deactivated, the

lever returns to its original starting position.

The detergent rinse module is held in place by

6 Phillips head screws and 2 brackets.

Detergent/ Rinse Module

The detergent/rinse module automatically

dispenses both the detergent and the rinse

agent at the appropriate times. The module is

activated 2 times during a wash cycle.

Detergent is dispensed at the beginning of the

main wash cycle and rinse agent at the

beginning of the final rinse. The

detergent/rinse module can be activated

using Service Mode.

18

Page 19

Active Vent

If the door is unlatched while running a wash

cycle, the cycle countdown will pause and the

vent will open.

The active vent consists of the wax motor and

housing. The active vent helps to reduce the

noise level and heat loss when in the closed

position. The control module supplies 120

VAC to the wax motor. The control module

reverses polarity to drive the motor in a

clockwise or counter clockwise (open or

closed) direction.

The vent closes about 2 minutes after the

main pump is switched on during the first fill

cycle and opens during the drying cycle

(heated and non-heated). The vent is open

during cool-down periods or when the unit is

not in use.

If the vent is closed and the door is opened

during the wash cycle, the vent will open.

When the door is closed again, the vent will

remain open for 2 minutes, and then close

again to finish the cycle.

It is normal for water vapour to come through

the active vent during the dry cycle. The

active vent can be opened and closed using

the Service Mode.

19

Page 20

Schematic

Vent Wax motor

20

Page 21

CONSUMER WARRANTY

Your appliance is warranted to be free of defects in material and workmanship.

English

How Long

What is covered

All parts

Warranted

(From Date of Sale)

One (1) year

Terms and Conditions:

This warranty applies only for single family

domestic use in Canada when the appliance has

been properly installed according to the

instructions supplied by Mabe and is connected

to an adequate and proper utility service.

Damage due to abuse, accident, commercial

use, and alteration or defacing of the serial plate

cancels all obligations of this warranty.

Service during this warranty must be performed

by an Authorized Mabe Service Agent.

Neither Mabe nor the Dealer is liable for any

claims or damages resulting from any failure of

the dishwasher or from service delays beyond

their reasonable control.

To obtain warranty service, purchaser must

present the original bill of sale. Components

repaired or replaced are warranted through the

remainder of the original warranty period only.

This warranty is extended to the original

purchaser and any succeeding owner for

products purchased for home use within

Canada. In home warranty service will be

provided in areas where it is available and

deemed reasonable by Mabe to provide.

Parts

Repair or Replace

at Supplier’s Option

One (1) year

Labour

One (1) year

What Is Not Covered

• Service trips to your home to teach you how to

use the product.

• Damage to finish after delivery.

• Improper installation – proper installation

includes adequate electrical, plumbing and

other connecting facilities.

• Replacement of house fuses or resetting of

circuit breakers.

•

Replacement of light bulbs.

•

Damage to product caused by accident, fire,

floods or acts of God.

•

Proper use and care of product as listed in the

owner’s manual, proper setting of controls.

•

WARRANTOR IS NOT RESPONSIBLE FOR

CONSEQUENTIAL DAMAGES.

EXCLUSION OF IMPLIED WARRANTIES – Your sole and exclusive remedy is product repair as

provided in this Limited Warranty. Any implied warranties, including the implied warranties of

merchantability or fitness for a particular purpose, are limited to one year or the shortest

period allowed by law.

IMPORTANT

Keep this warranty and your bill of sale as proof of original purchase and purchase date.

Mabe Service is available coast to coast.

To schedule service, call 1.800.561.3344

If further help is needed concerning this warranty, contact:

Manager, Consumer Relations, Mabe Canada, Inc.,

Suite 310, 1 Factory Lane, Moncton, N.B. E1C 9M3

Staple your receipt here.

Proof of the original purchase date is

needed to obtain service under the

warranty.

30

Loading...

Loading...