Page 1

GE

Installation Guide

Lighting

GE LED Wall Washer

LED Lighting System

Product Codes

62191, 62192, 62195, 62196, 62199, 62200, 62202, 62203, 62204, 62205, 62206,

62207, 65444, 65445, 65446, 65447, 65448, 65449

BEFORE YOU BEGIN

Read these instructions completely and carefully.

WARNING/AVERTISSEMENT

RISK OF ELECTRIC SHOCK

• Turn power off before inspection, installation or removal.

• Properly ground the LED system.

RISK OF FIRE

• Follow all NEC and local codes.

Save These Instructions

This product is intended solely for the use of nonresidential architecture lighting and is not intended for

use in any other application.

RISQUES DE DÉCHARGES ÉLECTRIQUES

• Coupez l’alimentation avant l’inspection, l’installation ou le déplacement.

• Mettre à terre le système DEL de la façon appropriée.

RISQUES D’INCENDIE

• Respectez tous les codes NEC et codes locaux.

Prepare Electrical Wiring

Electrical Requirements

• Do not use in wet locations.

• The grounding and bonding of the LED system shall

be done in accordance with National Electric Code

(NEC) Article 600.

• Follow all National Electric Codes (NEC) and local codes.

imagination at work

Page 2

Components

GE LED Wall Washer Fixtures

1

1

3

4 5

2

6

Leader Cable with End Cap (62208, 62211)

2

Mounting track with bracket (65467)

3

UL approved 18-14 AWG (0.82-2.08 mm2) wire

4

connectors or In-Line Splice Connector (75545)

#10 (M5) self-tapping athead screws

5

(Optional) jumper cable (62209: 12 in. /305 mm long,

6

62210: 48 in./1219 mm long)

Standard Mounting Methods

Fixture mounting positions:

It is recommended that the LED xtures be installed into a space no smaller than 3 in. x 3 in. (76mm x 76mm) For

additional mounting practices refer to application notes on our website (www.gelightingsolutions.com)

Ceiling

Wall

CeilingCeiling Ceiling

Wall

Fixture rotation:

Light can be directed from 0 to 50 degrees in 10 degree increments in both directions with the help of 1) the rotation

angle of the xture, and 2) the mounting edge of the xture track.

40°

50°

Wall

30°

Mounting surface

20°

Wall

Mounting track can be installed

at 0 and 30 degree angles

Fixture has three positions

at 10 degree increments

10°10°

20°

30°

40°

50°

0°

Material Estimations

For material estimations, take the length of the run in feet divided by 1.05 feet to get the quantity of xtures needed.

Take the run in feet divided by 4 feet to get the quantity of mounting tracks needed.

Page 3

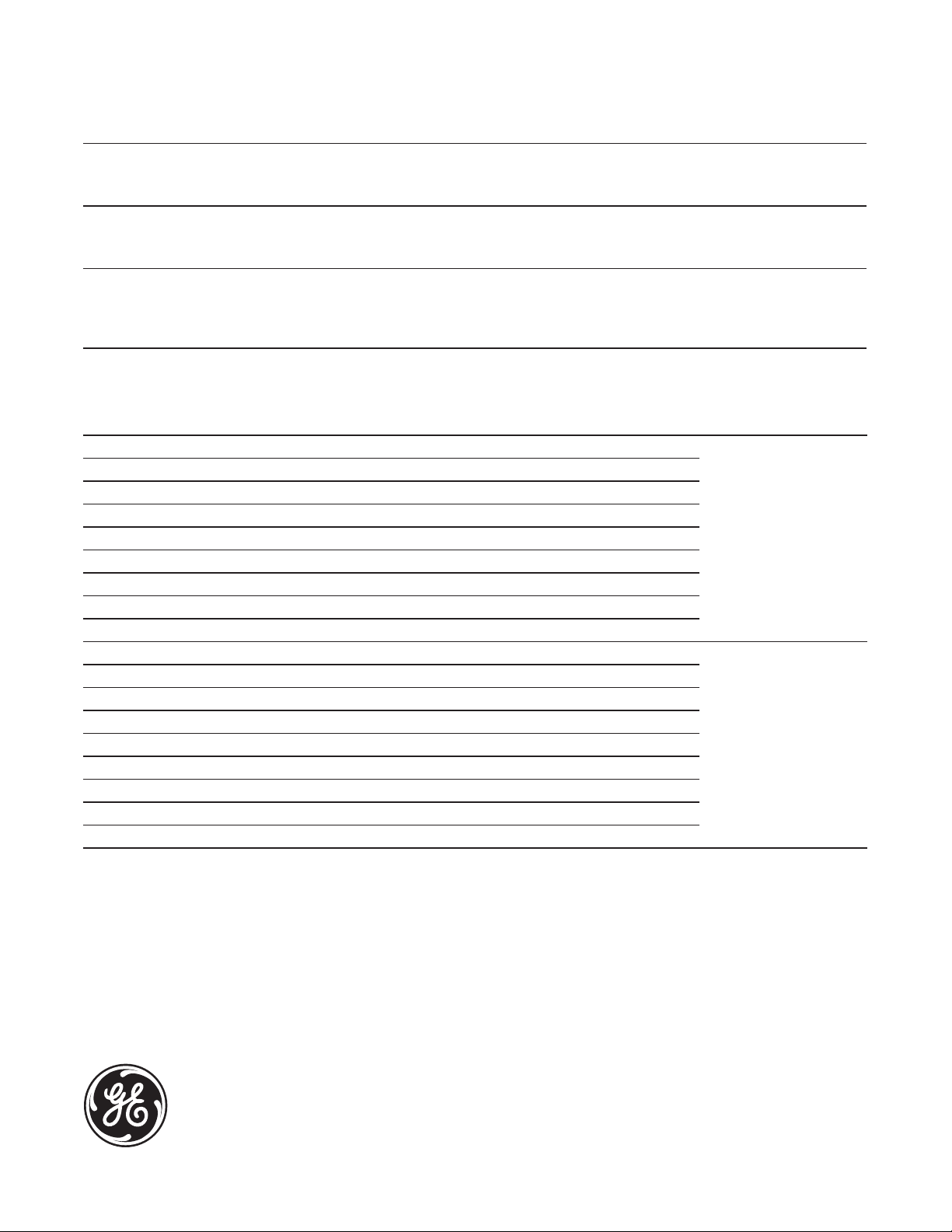

Leader cable to LED xture

Gray (-0-10V)

Blue (+0-10V)

Black (+)

White (-)

Green (ground)

120-277V

AC Line

Dimmer

Leader cable to LED xture

Gray (-0-10V)

Black (+0-10V)

Brown (+)

Blue (-)

Green/yellow

(ground)

240 VAC

Line

Dimmer

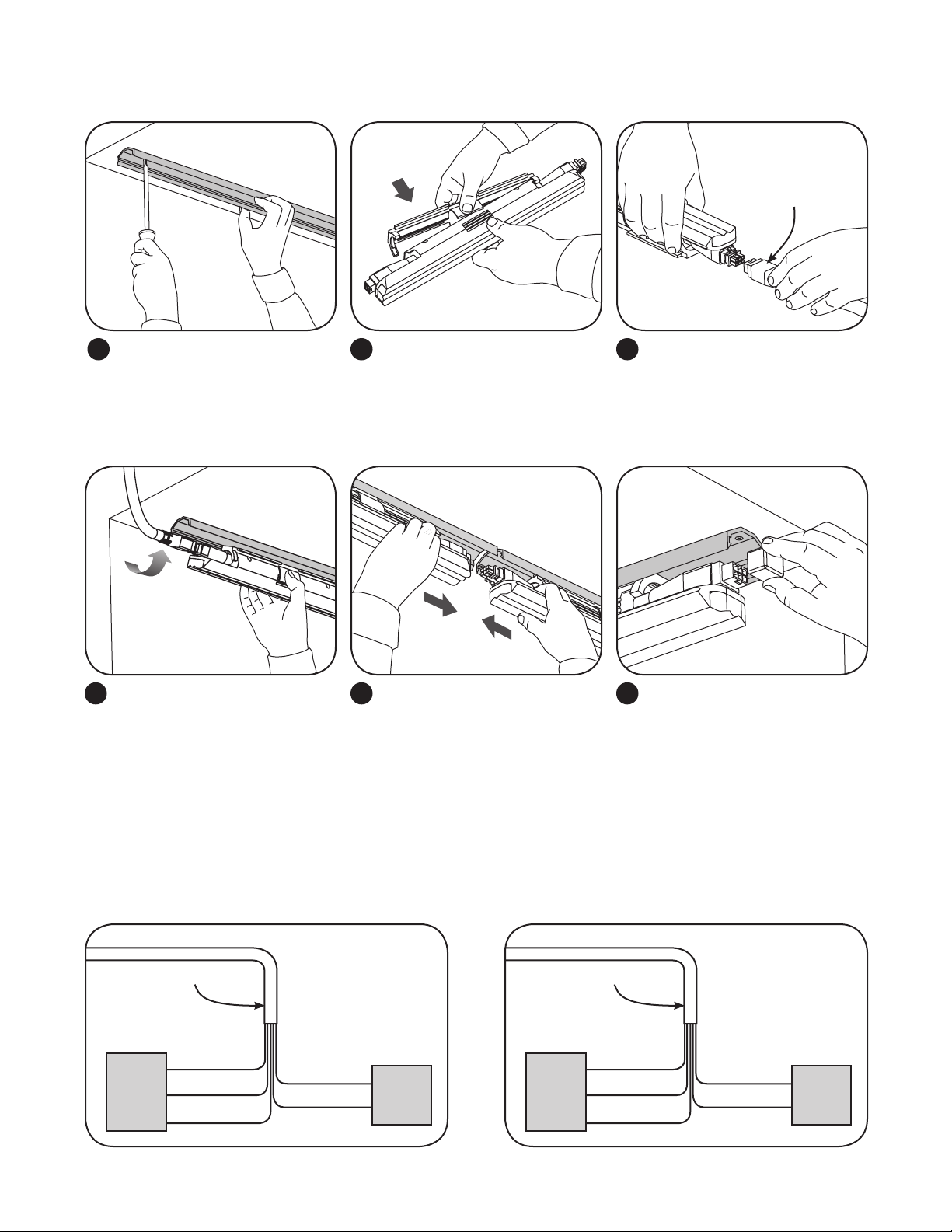

Installation

Leader cable

Install mounting track inside the

1 2

wall cavity using a minimum

of two #10 (M5) self-tapping

athead screws per section. If

required, cut mounting track to

desired length.

Snap in LED xture

Snap the rst LED xture into the

4

mounting track.

Assemble the LED xture and

the bracket by pressing them

together.

Orient plugs male to female

Continue placing xtures, being

5 6

sure to join plugs male to female.

Attach jumper cables as needed

to work around any obstacles,

corners or separations.

Connect the leader cable to the

3

male plug on the rst LED xture.

Place end cap from leader cable

on the electrical plug of the last

xture in the run.

Electrical Connections

Connect the leader cable to the power source and dimmer.

OPTIONAL: If dimming is not used, cap the purple and gray wires with UL approved wire connectors. Do not connect the

wires together.

Page 4

Troubleshooting

Symptom Solution

All LED xtures are not

illuminated

• Check leader cable connection and/or check circuit breaker.

• Check plug connectors on the LED xtures for improper connections or short circuits.

• Ensure leader cable is securely connected to the female plug connector on the rst LED xture.

Some LED xtures are

not illuminated

• Check plug connectors on the LED xtures for improper connections or short circuits.

• Ensure any jumper cables are securely connected between the male/female plug connectors of the

LED xtures.

Shadows within

application

• Re-position LED xtures along mounting surface ensuring architectural elements are not directly in

front of any LEDs.

• Adjust layout of LED xtures to ensure uniformity of illumination.

• Adjust leader cable and/or jumper cable orientation to ensure cables do not cover any LEDs.

Specications

Product Code Description Code Voltage IP Rating

62199 (LWW1-HO12-012-827) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62202 (LWW1-HO12-030-827) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62191 (LWW1-HO12-110-827) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

65444 (LWW1-HO12-012-830) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

65445 (LWW1-HO12-030-830) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62192 (LWW1-HO12-110-830) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62200 (LWW1-HO12-012-840) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62203 (LWW1-HO12-030-840) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62195 (LWW1-HO12-110-840) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62204 (LWW1-MO12-012-827) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62206 (LWW1-MO12-030-827) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62196 (LWW1-MO12-110-827) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

65446 (LWW1-MO12-012-830) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

65447 (LWW1-MO12-030-830) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

65448 (LWW1-MO12-110-830) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62205 (LWW1-MO12-012-840) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

62207 (LWW1-MO12-030-840) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

65449 (LWW1-MO12-110-840) 120 VAC-277 VAC, 50-60Hz IP51: Dry or Damp Location

Maximum Run Length

For 120 VAC: 70 Fixtures

(~73.5 feet/22.41m)

For 240 VAC: 140 Fixtures

(~147 feet/44.82m)

For 277 VAC: 165 Fixtures

(~173.3 feet/52.84m)

For 120 VAC: 140 Fixtures

(~147 feet/44.82m)

For 240 VAC: 290 Fixtures

(~304.5 feet/92.84m)

For 277 VAC: 300 Fixtures

(~315 feet/96.04m)

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. This

Class [A] RFLD complies with the Canadian standard ICES-003. Ce DEFR de la classe [ A ] est conforme á la NMB-003 du Canada.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

GE Lighting • 1-888-MY-GE-LED

GE Lighting Solutions, LLC is a subsidiary of the General Electric Company. Tetra is a trademark of GE Lighting. The GE brand and logo are trademarks of the General Electric Company.

© 2013 GE Lighting Solutions, LLC. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

(1-888-69-43-533)

• www.gelighting.com

ARCH053-100213

Loading...

Loading...