Range Hoods

Hottes de cuisinière

www.GEAppliances.ca www.electromenagersge.ca

Owner’s Manual and

Installation Instructions

PVUS930 PVUS936

Safety Instructions ....................1, 2

Operating Instructions ................. 3, 4

Carbon Filter .............................3, 4

Grease Filter .............................3, 4

Care and Cleaning. . . . . . . . . . . . . . . . . . . . .5, 6

Charcoal Filter .............................5

Grease Filter ...............................5

Hood Lights ................................6

Stainless Steel Surfaces. . . . . . . . . . . . . . . . . . . . .6

Installation Instructions ............. 7–16

Troubleshooting Tips ...................17

Consumer Support

Consumer Support ........................21

Product Registration .......................18

Warranty .................................20

Write the model and serial numbers here:

Model # _______________________________

Serial # _______________________________

Manuel de l’utilisateur et

instructions d’installation

PVUS930 PVUS936

Sécurité ...........................22, 23

Utilisation .........................24, 25

Filtre à charbon .......................24, 25

Filtre à graisses .......................24, 25

Entretien et nettoyage ..............26, 27

Filtre à charbon ..........................26

Filtre à graisses ..........................26

Lampes de la hotte .......................27

Surfaces en acier inoxydable .............27

Installation .......................28 à 37

Dépannage ........................... 38

Service à la clientèle

Enregistrement du produit ................18

Garantie .................................40

Service à la clientèle ......................41

Inscrivez ici les numéros de modèle et de série :

Nº de modèle _____________________________

Nº de série _______________________________

<ou can ¿nd them on a label on the bacN Zall

of the hood, behind the removable mesh ¿lters.

Ces numéros se trouvent sur une étiquette située

j l·arriqre de la hotte, derriqre les ¿ltres j treillis

amovibles.

350A4502P737 04-13 ATS

IMPORTANT SAFETY INSTRUCTIONS.

FOR RESIDENTIAL USE ONLY.

READ AND SAVE THESE INSTRUCTIONS.

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

IMPORTANT: Save these Instructions for the Local Electrical Inspectors use.

INSTALLER: Please leave these Instructions Zith this unit for the oZner.

OWNER: Please retain these instructions for future reference.

Safety InstructionsCare and Cleaning

7aNe care Zhen using cleaning agents or detergents.

Suitable for use in household cooNing area.

WARNIN G 7o reduce the risN of ¿re or electric shocN, do not use this fan Zith

any Solid-State Speed Control Device.

CAUTION - 7o reduce risN of ¿re and to properly exhaust air, be sure to duct

Operating

Consumer Support Troubleshooting Tips

air outside ² Do not vent exhaust air into spaces Zithin Zalls or ceilings or into

attics, craZl spaces, or garages.

Instructions

CAUTION - For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

CAUTION - To avoid motor bearing damage and noisy and/or unbalanced

impellers, Neep dryZall spray, construction dust, etc. off poZer unit.

CAUTION - Please read speci¿cation label on product for further information and

requirements.

WARNIN G – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer.

B. Before servicing or cleaning unit, sZitch poZer off at service panel and locN

the service disconnecting means to prevent poZer from being sZitched on

accidentally. When the service disconnecting means cannot be locNed, securely

fasten a prominent Zarning device, such as a tag, to the service panel.

WARNING - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause smoNing

and greasy spillovers that may ignite. Heat oils sloZly on loZ or medium

settings.

B. $lZays turn hood ON Zhen cooNing at high heat or Zhen Àambeing foods i.e.

Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambè).

C. Clean ventilating fans frequently. Grease should not be alloZed to accumulate

on fan or ¿lter.

D. Use proper pan size. $lZays use cooNZare appropriate for the size of the surface

element.

E. Keep fan, ¿lters and grease laden surface clean.

F. Use high range setting on range only Zhen necessary.Heat oil sloZly on loZ to

medium setting.

G. Don·t leave range unattended Zhen cooNing.

H. $lZays use cooNZare and utensils appropriate for the type and amount off food

being prepared.

1

WARNING – TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWINGa:

A. S0OTHER FLA0ES Zith a close-¿tting lid, cooNie sheet, or metal tray, then turn

off the burner. BE CAREFUL TO PREVENT BURNS. If the Àames do not go out

immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

B. NEVER PICK UP A FLAMING PAN – You may be burned.

C. DO NOT USE WATER, including Zet dishcloths or toZels – a violent steam

explosion Zill result.

D. Use an extinguisher ONLY if:

1. You NnoZ you have a Class ABC extinguisher, and you already NnoZ hoZ to

operate it.

2. The ¿re is small and contained in the area Zhere it started.

3. The ¿re department is being called.

4. You can ¿ght the ¿re Zith your bacN to an exit.

a

Based on ´Nitchen ¿resafety tipsµ published by NFPA.

Proper maintenance of the Range Hood will assure proper performance of the unit.

WARNIN G - UNDER CERTAIN CIRCUMSTANCES DOMESTIC APPLIANCES MAY BE

DANGEROUS.

A. Do not checN ¿lters Zith hood ZorNing.

B. Do not touch the lamps after a prolonged use of the appliance.

C. No food must be cooNed Àambè underneath the hood.

D. The use of an unprotected Àame is dangerous for the ¿lters and could cause ¿res.

E. Watch constantly the fried food in order to avoid the cooNing oil Àares up.

F. Before performing any mainteinance operation, disconnect the hood from the

electrical service.

The manufacturers Zill not to accept any responsability for eventual damages,

because of failure to observe the above instructions.

Safety Instructions Care and Cleaning

Instructions

Operating

Troubleshooting Tips

Consumer Support

2

OPERATING INSTRUCTIONS

,IWKHDSSDUDWXVLVHTXLSSHGZLWKWKHIROORZLQJFRQWUROV)LJ

Push-button A = On/off lights sZitch.

Push-button B = On/off cooNer hood sZitch. The appliance sZitches on at speed

level 1, If the cooNer hood is on depress the push-button for 2 sec. to sZitch off the

cooNer hood. If the cooNer hood is at speed level 1 it Zill not be necessary to depress

the push-button to sZitch the cooNer hood off. Decreases the motor speed.

Display C = Indicates the motor speed level selected and activates the timer.

Safety InstructionsCare and Cleaning

Push-button D = SZitches on the cooNer hood. Increases the motor speed. Touching

the Ney at 3rd speed, the intensive function runs for 10 minutes, then the appliance

go bacN to ZorN at the original speed. During this function the display blinNs.

Key E = The Timer times the functions on activation for 15 minutes, after Zhich

they are sZitched off. The Timer is deactivated by re-pressing Key E. When the

Timer is activated the decimal point must Àash on the display. The Timer cannot be

activated if the intensive speed is functioning.

- The “clean airµ function is activated by pressing Ney E for 2 seconds Zhen the

Operating

Instructions

appliance is sZitched off. This sZitches the motor on for 10 minutes every hour at

the ¿rst speed.

During functioning a rotary movement of the peripheral segments must be

visualised on the display. When this time has passed the motor sZitches off and

the ¿xed letter “Cµ must be visualised on the display until the motor re-starts after

50 minutes for another 10 minutes and so on. Press any Ney apart from the light

Neys to return to normal functioning. Press Ney E to deactivate the function.

$FWLYHFDUERQJUHDVH¿OWHUVDWXUDWLRQ

- When display item C Àashes, at a speed Zhere it alternates Zith the letter F e.g. 1

and F), the grease ¿lters must be Zashed.

- When display item C Àashes, at a speed Zhere it alternates Zith the letter A e.g. 1

and A), the carbon ¿lters must be replaced.

After the clean ¿lter has been positioned correctly, the electronic memory must

be reset by pressing button A for approximately 5 seconds, until the indication F

or A shoZn on the display C stops Àashing.

Consumer Support Troubleshooting Tips

3

MAINTENANCE

We recommend that the range hood is sZitched on before any food is cooNed. We

also recommend that the appliance is left running for 15 minutes after the food is

cooNed, in order to thoroughly eliminate all contaminated air.

The effective performance of the range hood depends on constant maintenance;

the anti-grease ¿lter and the active carbon ¿lter both require special attention.

7KHDQWLJUHDVH¿OWHU is used to trap any grease particles suspended in the

air, therefore is subMect to saturation the time it taNes for the ¿lter to become

saturated depends on the Zay in Zhich the appliance is used).

- To prevent potential ¿re hazards, the anti-grease ¿lters should be Zashed a

minimum of every 2 months it is possible to use the dishZasher for this tasN).

- After a feZ Zashes, the colour of the ¿lters may change. This does not mean they

have to be replaced.

If the replacement and Zashing instructions are not folloZed, the anti-grease

¿lters may present a ¿re hazard.

7KHDFWLYHFDUERQ¿OWHUV (on some models) are used to purify the air Zhich is

released bacN into the room. The ¿lters are not Zashable or re-usable and must be

replaced at least once every four months. The active carbon ¿lter saturation level

depends on the frequency Zith Zhich the appliance is used, the type of cooNing

performed and the regularity Zith Zhich the anti-grease ¿lters are cleaned.

Clean the range hood frequently, both inside and outside, using a cloth Zhich has

been dampened Zith denatured alcohol or neutral, non-abrasive liquid detergents.

The light on the range hood is designed for use during cooN

room illumination. Extended use of the light reduces the average duration of the

bulb.

ing and not for general

Safety Instructions Care and Cleaning

Instructions

Operating

Troubleshooting Tips

Consumer Support

4

CARE AND CLEANING

Be sure electrical power is off and all surfaces are cool before cleaning or

servicing any part of the vent hood.

Reusable Metal Grease Filters

The hood has 3 metal reusable grease filters.

The metal filters trap grease released by foods on the cooNtop. They also help

Safety InstructionsCare and Cleaning

prevent flaming foods on the cooNtop from damaging the inside of the hood.

For this reason, the filters must ALWAYS be in place Zhen the hood is used. The

grease filters should be cleaned once a month, or as needed.

To remove, press the filter locNs bacN and pull the filters doZn and out.

To replace, insert the rear filter tabs in the frame slots at the bacN of the opening.

Push the filters up and locN them into place.

To clean the grease filters, soaN them and then sZish them around in hot Zater

Operating

and detergent. Don·t use ammonia or ammonia products because they Zill darNen

Instructions

the metal. Do not use abrasives or oven cleaners. Light brushing can be used to

remove embedded dirt. Rinse, shaNe and let them dry before replacing. They may

also be cleaned in an automatic dishwasher.

NOTE: Before cleaning, make sure the charcoal filters, if present, are unclipped and

removed. See the Charcoal Filters section.

Charcoal Filters (on some models)

The charcoal filters cannot be cleaned. They must be replaced.

For converting vent hood to recirculation mode not vented to the outside),

order The folloZing Nits:

KIT0320 for model PVUS930

KIT0321 for model PVUS936

These Nits contain charcoal filters.

For replacement charcoal filters, order Part no. ACK00059.

These Nits can be ordered from your GE supplier.

NOTE:&KDUFRDO¿OWHUVDUHnot included with the hood. They must be ordered from

your GE supplier.

If the model is not vented to the outside, the air Zill be recirculated through

disposable charcoal ¿lters that help remove smoNe and odors.

The charcoal ¿lters should be replaced Zhen they are noticeably dirty or discolored

usually after 6–12 months, depending on hood usage).

NOTE:'2127ULQVHRUSXWFKDUFRDO¿OWHUVLQDQDXWRPDWLFGLVKZDVKHU

Consumer Support Troubleshooting Tips

5

Stainless Steel Surfaces (on some models)

Do not use a steel-wool pad; it will scratch the surface.

1. ShaNe bottle Zell.

2. Place a small amount of CERAMA BRYTE

Conditioner on a dry cloth or dry paper toZel.

3. Clean a small area approximately 8µ x 8µ/20.3 cm x 20.3 cm), rubbing Zith the

grain of the stainless steel if applicable.

4. Dry and buff Zith a clean, dry paper toZel or soft cloth.

5. Repeat as necessary.

To order:

To order CERAMA BRYTE

our toll-free number:

National Parts Center 1.800.661.1616

www.GEAppliances.ca

CERAMA BRYTE

Stainless Steel Cleaning

Polish and Conditioner # PM10X313

®

®

Stainless Steel Cleaning Polish and Conditioner, please call

®

Stainless Steel Cleaning Polish and

Hood Lights

This hood requires tZo bulbs QRWLQFOXGHG, maximum 50 Zatts.

Purchase and install WB27M02956, 50 W Maximum halogen bulbs.

When replacing a bulb, let it cool ¿rst. MaNe sure that poZer to the light has been

turned off. Never alloZ a hot bulb to come into contact Zith Zater.

Safety Instructions Care and Cleaning

Instructions

Operating

WARNING: To reduce the risN of electric shocN, do not connect electrical poZer

to the hood Zithout both bulbs in place.

To change the light bulbs:

See page 4 and Fig.9.

CAUTION: Do not touch the hood light bulbs Zhen they are on. They may be

hot enough to cause injury.

The light bulbs operate at extremely high temperatures. If they

shatter, the hot glass could cause personal injury.

6

Troubleshooting Tips

Consumer Support

Installation Range Hood

Instructions

Questions? Call 800.561.3344

or visit our Website at:

BEFORE YOU BEGIN

Read these instructions completely and carefully.

:

IMPORTANT –

local inspector’s use.

:

IMPORTANT –

codes and ordinances.

:

Note to Installer –

instructions with the Consumer.

:

Note to Consumer –

for future reference.

: Skill level – Installation of this appliance requires

basic mechanical and electrical skills.

: Completion time – 30 minutes–3 hours

: Proper installation is the responsibility of the installer.

: Product failure due to improper installation is not

covered under the Warranty.

Save these instructions for

Observe all governing

Be sure to leave these

Keep these instructions

FOR YOUR SAFETY:

WARNING –

installation, switch power off at service panel and

lock the service disconnecting means to prevent power

from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the

service panel.

Before beginning the

GEAppliances.ca

DUCTWORK REQUIREMENTS

NOTE: Read the ductwork sections only if you do not

have existing ductwork. If you have existing ductwork,

skip to the “Damage” section and proceed.

WARNING –

TO PROPERLY EXHAUST AIR, BE SURE TO DUCT AIR OUTSIDE—

DO NOT VENT EXHAUST AIR INTO SPACES WITHIN WALLS OR

CEILINGS OR INTO ATTICS, CRAWL SPACES OR GARAGES.

The venting system must exhaust to the outside.

This hood can be vented vertically through upper cabinets

or horizontally through an outside wall. Ductwork is not

included.

Exhaust connection:

The hood exhaust has been designed to mate with

standard 6” diameter round ducting.

If a 7” round duct is required, a transition adaptor must be

used*. Do not use less than a 6” diameter duct.

Maximum duct length:

For satisfactory air movement, the total duct length

1

of a 3

⁄4” x 10” rectangular, 6” or 7” diameter round

duct should not exceed 65 equivalent feet. See the

WORKSHEET–CALCULATE TOTAL EQUIVALENT

DUCTWORK LENGTH section.

NOTE: It is important that ducting be installed using

the most direct route and with as few elbows as possible.

This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dampers swing freely and

nothing is blocking the ducts.

Elbows, transitions, wall and roofcaps, etc.,

present additional resistance to airflow and are equivalent

to a section of straight duct longer than their actual

physical size. When calculating the total duct length, add

the equivalent lengths of all transitions and adaptors plus

the length of all straight duct sections. The charts on the

following pages show you how to calculate total equivalent

ductwork length using the approximate feet of equivalent

length of some typical ducts.

TO REDUCE THE RISK OF FIRE AND

* IMPORTANT: If a rectangular-to-round

transition adaptor is used, the bottom

corners of the damper will have to be

cut to fit, using the tin snips, in order

to allow free movement of the damper.

Equivalent lengths of duct pieces

are based on actual tests and reflect

requirements for good venting

performance with any hood.

1 ft = 0.3 m; 1 in. = 2.5 cm

7

Installation Instructions

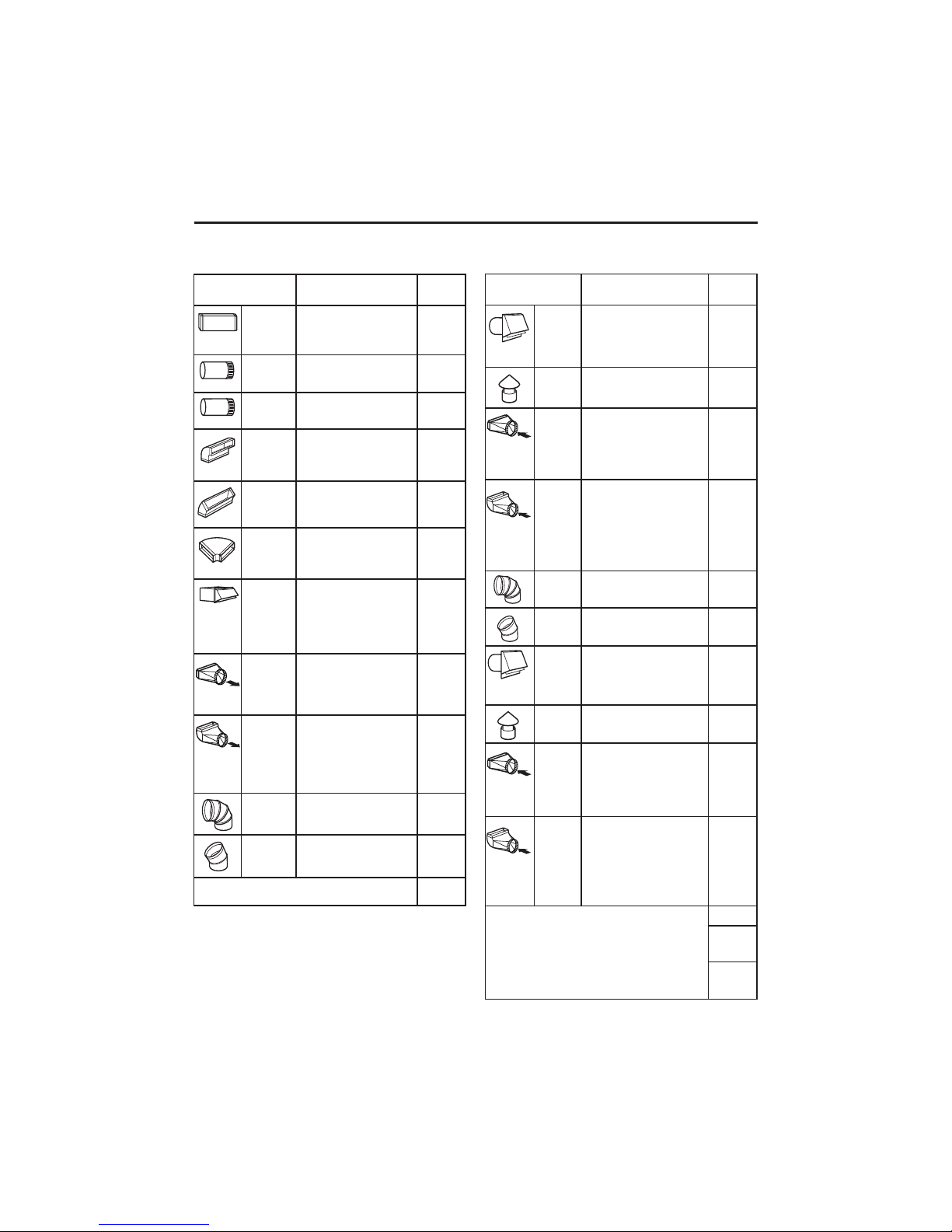

WORKSHEET—CALCULATE TOTAL EQUIVALENT DUCTWORK LENGTH

DUCT EQUIVALENT NUMBER

PIECES LENGTH x USED = TOTAL

31⁄4” x 10” 1 Ft. x ( ) = Ft.

Rect.,

straight

7” Round, 1 Ft. x ( ) = Ft.

straight

6” Round, 1 Ft. x ( ) = Ft.

straight

1

3

⁄4” x 10” 14 Ft. x ( ) = Ft.

Rect. 90°

elbow

1

⁄4” x 10” 8 Ft. x ( ) = Ft.

3

Rect. 45°

elbow

1

⁄4” x 10” 33 Ft. x ( ) = Ft.

3

Rect. 90°

flat elbow

1

3

⁄4” x 10” 24 Ft. x ( ) = Ft.

Rect.

wall cap

(18 ft. w/o

damper)

x ( ) = Ft.

with

damper

1

3

⁄4” x 10” 2 Ft. x ( ) = Ft.

Rect. to

6” round

transition

1

3

⁄4” x 10” 4 Ft. x ( ) = Ft.

Rect. to

6” round

transition

90° elbow

6” Round, 25 Ft. x ( ) = Ft.

90° elbow

6” Round, 16 Ft. x ( ) = Ft.

45° elbow

Subtotal column 1 = Ft.

MAXIMUM DUCT LENGTH: For satisfactory air movement,

the total duct length of a 3

1

⁄4” x 10” rectangular, 7” diameter

round duct should not exceed 65 equivalent feet.

DUCT EQUIVALENT NUMBER

PIECES LENGTH x USED = TOTAL

6” Round 53 Ft. x ( ) = Ft.

wall cap

with

(39 ft. w/o

damper)

damper

6” Round 72 Ft. x ( ) = Ft.

roof cap

6” Round 3 Ft. x ( ) = Ft.

to

1

3

⁄4” x 10”

rect.

transition

6” Round 9 Ft. x ( ) = Ft.

to

1

3

⁄4” x 10”

rect.

transition

90° elbow

7” Round, 14 Ft . x ( ) = Ft.

90° elbow

7” Round, 9 Ft . x ( ) = Ft.

45° elbow

7” Round 28 Ft. x ( ) = Ft.

wall cap (

with

21 ft. w/o

damper)

damper

7” Round 39 Ft. x ( ) = Ft.

roof cap

7” Round 1 Ft. x ( ) = Ft.

to

1

3

⁄4” x 10”

rect.

transition

7” Round 5 Ft . x ( ) = Ft.

to

1

3

⁄4” x 10”

rect.

transition,

90° elbow

x ( ) = Ft.

x ( ) = Ft.

Subtotal column 2 = Ft.

Subtotal column 1 = Ft.

Total ductwork = Ft.

1 ft = 0.3 m; 1 in. = 2.5 cm

8

Installation Instructions

DAMAGE – SHIPMENT/INSTALLATION

2If the unit is damaged in shipment, return the unit to the

store in which it was bought for repair or replacement.

Call 800.531.3344.

2If the unit is damaged by the customer, repair or

replacement is the responsibility of the customer.

2If the unit is damaged by the installer (if other than

the customer), repair or replacement must be made

by arrangement between customer and installer.

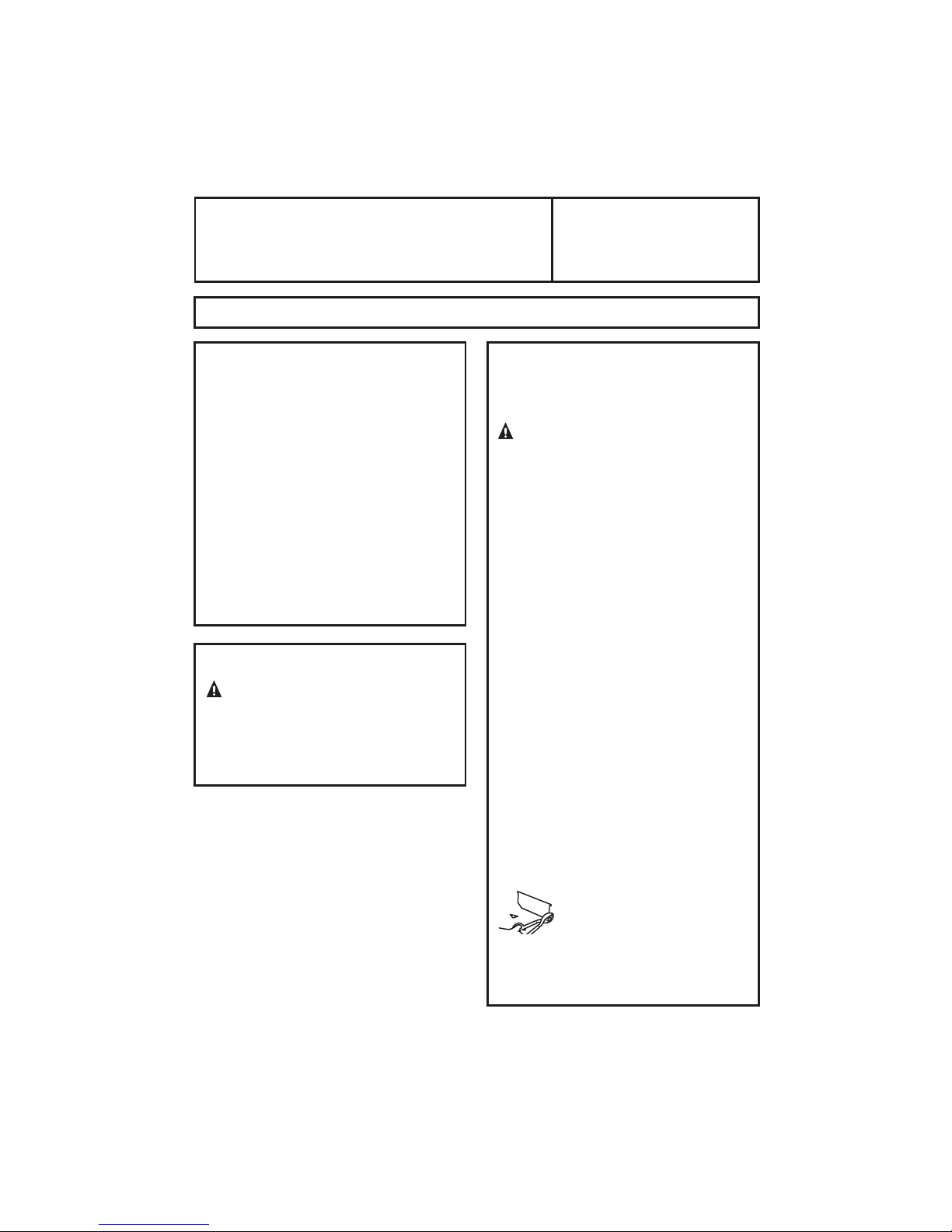

MOUNTING SPACE

24”, 30” or 36” to

match cooktop width

66” or

more from

the floor to

the top of

the hood

Bottom edge of

cabinet needs

to be 30” or

more from

the cooking

surface

30”

min.

TOOLS YOU WILL NEED

Flat-blade and Phillips

screwdrivers

Saw (saber or

keyhole)

1/4” pivoting

hex socket

Flashlight

Pliers

Caulking

Pencil

Electric drill

Tape measure

Level

PARTS YOU WILL NEED

6” round straight ducting

6” round 90° elbow ducting

6”-7” hose clamp (2)

Duct tape

Metal snips

(in some

applications)

Wire stripper

1/4” Nutdriver

NOTES:

2Hood width may be greater than the width of the range

or cooktop, but it may not be smaller.

2Ensure the range or cooktop is installed per

manufacturer’s installation instructions.

2If you are going to vent your range hood to the outside,

see the “Ducting Requirements” section for exhaust duct

preparation.

1 ft = 0.3 m; 1 in. = 2.5 cm

9

READ AND SAVE THESE INSTRUCTIONS.

GENERAL

Carefully read the folloZing important information regarding installation safety and

maintenance. Keep this information booNlet accessible for further consultations. The appliance

has been designed for use in the DUCTING version air exhaust to the outside Fig.1A - Fig.1B) or

FILTERING Optional KIT0320 for 30µ 7.2 cm) model and KIT0321 for 36µ 91.4 cm) model.

INSTALLATION INSTRUCTIONS

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A. Installation ZorN and electrical Ziring must be done by quali¿ed persons) in accordance

Zith all applicable codes and standards, including ¿re-rated construction.

B. Suf¿cient air is needed for proper combustion and exhausting of gases through the Àue

chimney) of fuel burning equipment to prevent bacN drafting. FolloZ the heating equipment

manufacturer’s guideline and safety standards such as those published by the National Fire

Protection Association NFPA), and the American Society for Heating, Refrigeration and Air

Conditioning Engineers ASHRAE), and the local code authorities.

C. When cutting or drilling into Zall or ceiling, do not damage electrical Ziring and other hidden

utilities.

D. Ducted fans must alZays be vented to the outdoors.

E. This unit must be grounded.

WARNIN G - TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

Attention!

- Before carrying out assembly operations, open the pacNaging, taNe the hood and place it

on a comfortable surface.

- Remove the anti-grease ¿lter/s Fig.1C).

A. If hood installation is used Zith the air outlet Fig.1B or Fig.4B, the Zires set-up in the

relevant Ziring harness must be released by pulling the lever outZards, as indicated in

¿gure 2, phase 1-2.

B. Disconnect the 6-Zay quicN coupling of the motor located inside of the hood, as shoZ in

¿gure 2. - phase 3.

C. The Zires positioned inside of the hood are fasted Zith a cable tie. Cut the cable tie as

shoZn in ¿gure 2 - phase 4.

Once transformation operations have been completed, reassemble the components folloZing

the steps in reverse Fig.2).

In this Zay it Zill be easier to manoeuvre the unit.

- If the appliance is to be mounted in DUCTING version, prepare the air evacuation hole.

- It is recommended to use an air evacuation pipe Zith the same diameter as the air outlet

Àange. The use of a reduction could decrease product performance and increase noise.

Attention! This product utilizes the air evacuation hole available in 2 different positions,

Zhich can be used according to your requirements;

1 – In the upper part of the hood Fig.1A.

2 – In the rear part of the hood Fig.1B.

- The air evacuation Àange is supplied Zith the rectangular shape X and circular shape Y

Fig.1).

10

Version with air evacuation hole in the upper partRI WKHKRRG )LJ

This product is supplied Zith the air outlet in the upper part and the electric connection box

positioned in the rear part of the hood, as indicated in ¿gure 5 see paragraph: connection

to the electric power supply).

- If a rectangular air outlet pipe is used E, the hood is already set-up Fig.3.1).

- If, hoZever, a circular air outlet pipe is to be used F, the 7 screZs H must be removed along

Zith the bracNet ; Fig.3.2).

Version with air evacuation hole in the rear partRIWKHKRRG)LJ

- If your requirements are the use of the air outlet in the rear part of the hood carry out all

phases shoZn in ¿gure 2), remove the screZs I Fig. 4.1) that ¿x the motor bracNet Y and turn

the entire motor unit and position it as indicated in Fig.4.2. Put the motor bracNet Y bacN in its

seat and ¿x it Zith the previously removed screZs I.

Attention! Whenever a circular air outlet pipe is to be used F, the operation indicated in

Fig.3.2 must alZays be repeated.

3RZHU6XSSO\&RQQHFWLRQ

For connection to the poZer supply refer to the folloZing Fig.5:

1. BreaN and remove the small circular metal sheet positioned in the rear part of the hood, Zith

the aid of a flat screZ driver Fig.5.1.

2. Remove the poZer supply lid by loosening the 2 screZs A Fig.5.2.

3. Connect the Zires of the hood to those of the poZer supply as described Fig.5.3:

BLACK = L line

WHITE = N neutral

*5((1<(//2: G ground

- A double-pole sZitch properly rated must be installed to provide the range hood poZer

supply disconnection.

- Connect the electrical conduit to the Field Wiring Compartment using listed conduit ¿ttings.

- Carry out the poZer supplly connection in accordance Zith the national electric code,

ANSI/NFPA 70-1999.

- Insert the Zires into the box, then close the box cover, securing it using the screZs that

Zere previously removed.

OPTIONAL: the electric poZer supply box can be removed and ¿xed in the position indicated in Fig.6.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING Before connecting the appliance to the power supply network,

the electric plant box must be positioned in the seat.

To move the electric power supply box, refer to that indicated in Fig.6:

1. Loosen the tZo screZs C Fig.6.1.

2. BreaN and remove the small circular metal sheet positioned in the upper part of the hood,

Zith the aid of a Àat screZdriver Fig.6.2.

3. TaNe the electric connection box and ¿x it using the 2 screZs C, previously removed, in the

position indicated in Fig.6.3.

4. For the electric power supply connection refer to Fig.5.2-3.

The appliance must be installed at a minimum height of 26 inches 66 cm) from an electric

cooNer stove, or 30 inches 76,2 cm) from gas or combined cooNer stoves. If a connection

ductZorN composed of tZo parts is used, the upper part must be placed outside the loZer

part. Do not connect the range hood exhaust duct air to the same duct air used to exhaust hot

air or fumes from other appliances other than electrical. Before proceeding Zith the assembly

operations, remove the anti-grease ¿lters Fig. 1C) so that the unit is easier to handle.

11

This product can be installed in 2 different Zays.

- Mounting the hood in the lower part of the cabinet.

B type installation Fig.9.

- Mounting the hood on the wall:

A type installation Fig.9.

0RXQWLQJWKHKRRGLQWKHORZHUSDUWRIWKHFDELQHW)LJ%

- ChecN that the screZs used that are not supplied Zith the product are suitable for the type of

object.

- Position the ¿xing template on the loZer part of the shelf Fig.8B), considering the minimum

distance from the cooNer top).

- MaNe 6 holes in the shelf respecting the measurements indicated Fig.7).

- Fix the 4 screZs A Zithout tightening them completely.

- Position the hood under the pensile, push toZards the Zall up to end run, tighten/fasten the 4

screZs A and ¿x it de¿nitively using the 2 safety screZs B.

0RXQWLQJWKHKRRGRQWKHZDOO)LJ$

Position the ¿xing template on the Zall Fig.8A), considering the minimum distance from the

cooNer top).

- MaNe 4 holes respecting the measurement indicated in the ¿gures Fig.7).

- Fix the 2 upper screZs A Zithout tightening them completely along Zith the plugs.

- Hang the hood on the Zall, aligning it in a horizontal position and tighten/fasten the 2 screZs

A

. When it has been regulated, ¿x it de¿nitively using the 2 safety screZs B.

For the various installations use screZs and screZ anchors suited to the type of Zall e.g.

reinforced concrete, plasterboard, etc.). If the screZs and screZ anchors are provided Zith the

product, checN that they are suitable for the type of Zall on Zhich the hood is to be ¿xed.

Limited to installation on plasterboard Zalls: maNe sure that the screZs are ¿xed to the Zall

support elements. If this is not the case, install a support structure made up from 2 by 4 inch

5.08 by 10.16 cm) cross members in correspondence Zith the screZ anchorage points.

12

A

X

B

Y

D

D

Fig.1 Fig.1C

1

1

2

1

2

3-4

3

Fig.2

4

A

E

E

Fig.3

H

F

X

2

1

13

H

F

B

Fig.4

I

2

Y

4

1

3

I

Fig.5

1

2

A

A

3

C

C

2

3

C

Fig.6

1

14

Fig.7

Fig.8

B

A

B

A

15

B

A

B

4

A

A

1

Fig.9

B

ABCDE

Fig.10

16

BEFORE YOU CALL FOR SERVICE…

Troubleshooting Tips

6DYHWLPHDQGPRQH\5HYLHZWKHIROORZLQJFKDUW¿UVWDQG\RXPD\QRW

need to call for service.

Problem Possible Causes What To Do

Fan does not

Safety InstructionsCare and Cleaning

operate when the

switch is on

Fan fails to

circulate air or

moves air more

slowly than

Operating

normal

Instructions

Fan continually

cycles off and on

A fuse may be blown

or a circuit breaker

may be tripped.

Excessively soiled

¿OWHU

The motor is

probably overheating

and turning itself off.

This can be harmful

to the motor. Filter

may be excessively

soiled.

Replace fuse or reset circuit

breaNer.

Wash and replace the ¿lters. See

the Reusable Metal Grease Filters

section.

Replace the ¿lter if it is too soiled

to clean. If it is not soiled, or if

replacing the ¿lter does not solve

the problem, call for service.

Replace the ¿lter if it is soiled. If

it is not soiled, or if replacing the

¿lter does not solve the problem,

call for service.

Consumer Support Troubleshooting Tips

17

OWNERSHIP REGISTRATION

P.O. BOX 1780

MISSISSAUGA, ONTARIO

L4Y 4G1

Please place in envelope and mail to:

Veuillez mettre dans une enveloppe et envoyez à :

18

(FOR CANADIAN CONSUMERS ONLY -

POUR RÉSIDENTS CANADIENS SEULEMENT)

P.O. BOX 1780, MISSISSAUGA

POSTEZ À :

MAIL TO:

Veuillez enregistrer votre produit afin de nous permettre de

communiquer avec vous si jamais un avis de sécurité concernant

ce produit était émis et de communiquer facilement avec vous en

vertu de votre garantie, si le besoin s’en fait sentir.

www.electromenagersge.ca

www.geappliances.ca

ONTARIO, L4Y 4G1

LAST NAME / NOM

FIRST NAME / PRÉNOM

D/J

APT.NO/APP./RR#

POSTAL CODE/CODE POSTAL

PROVINCE

: EXPIRATION

Y/A M

IF YES/SI OUI

MODEL / MODÈLE

YES/OUI

NO/NON

SERIAL / SÉRIE

ENGLISH

FRANÇAIS

CORRESPONDENCE

CORRESPONDANCE

.

CITY / VILLE

TELEPHONE/TÉLÉPHONE E-MAIL/COURRIEL

IND. RÉG.

AREA CODE/

AVEZ-VOUS ACHETÉ UN CONTRAT DE SERVICE POUR CET APPAREIL ?

DID YOU PURCHASE A SERVICE CONTRACT FOR THIS APPLIANCE?

I do not wish to receive any promotional offers regarding this product.

Y/A M D/J

Je ne désire pas recevoir d’offres promotionnelles concernant ce produit

NAME OF SELLING DEALER / NOM DU MARCHAND

INSTALLATION DATE / DATE D’INSTALLATION

MS.

MRS. / MME

RUE STREET NAME / RUE

O

OWNERSHIP REGISTRATION CERTIFICATE – FICHE D’INSCRIPTION DU PROPRIÉTAIRE

Please register your product to enable us to contact you in

the remote event a safety notice is issued for this product

and to allow for efficient communication under the terms of

our warranty, should the need arise.

MR. / M.

MISS/MLLE

REGISTER ON-LINE:

ENREGISTREMENT SUR INTERNET À :

STREET NO / N

DÉCOUPEZ ICI ET ENVOYEZ LA FICHE – MERCI

CUT ALONG THIS LINE AND RETURN CARD – THANKS

For Canadian

Customers

Pour les

consommateurs

canadiens

19

Mabe Range Hood Warranty.

All warranty service provided by our Factory Service Centers, or

an authorized Customer Care

visit us on-line at GEAppliances.ca, or call 800.561.3344.

Please have serial number and model number available when

calling for service.

®

technician. To schedule service,

For The Period Of: Mabe Will Replace:

One Year Any part of the range hood which fails due to a defect in materials or workmanship.

From the date of the During this limited one-year warranty, Mabe will also provide, free of charge, all labor and

original purchase in-home service to replace the defective part.

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

Safety Instructions Care and Cleaning

What Mabe Will Not Cover:

Service trips to your home to teach you how to use

the product.

Improper installation, delivery or maintenance.

Failure of the product if it is abused, misused, or

used for other than the intended purpose or used

commercially.

Replacement of house fuses or resetting of circuit

breakers.

EXCLUSION OF IMPLIED WARRANTIES―Your sole and exclusive remedy is product repair as provided

in this Limited Warranty. Any implied warranties, including the implied warranties of merchantability

or fitness for a particular purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for

home use within Canada. If the product is located in an area where service by a Mabe Authorized Servicer is not

available, you may be responsible for a trip charge or you may be required to bring the product to an Authorized

Mabe Service Location for service.

Some provinces do not allow the exclusion or limitation of incidental or consequential damages. This

warranty gives you specific legal rights, and you may also have other rights which vary from province to

province. To know what your legal rights are, consult your local or provincial consumer affairs office or your

province’s Attorney General.

Warrantor: Mabe Canada Inc. Burlington, Ontario

Damage to the product caused by accident, f ire, floods

or acts of God.

Incidental or consequential damage caused by possible

defects with this appliance.

Damage caused after delivery.

Product not accessible to provide required service.

Instructions

Operating

Troubleshooting Tips

Consumer Support

20

Consumer Support.

GE Appliances Website

Have a question or need assistance with your appliance? Try the GE Appliances Website 24 hours a day,

any day of the year! For greater convenience and faster service, you can now download Owner’s Manuals,

order parts or even schedule service on-line.

Schedule Service

Expert Mabe repair service is only one step away from your door. Get on-line and schedule your service at

your convenience any day of the year! Or call 800.561.3344 during normal business hours.

Parts and Accessories

Individuals qualified to service their own appliances can have parts or accessories sent directly to their homes

(VISA and MasterCard are accepted). Order by phone at 800.661.1616 during normal business hours.

Instructions contained in this manual cover procedures to be performed by any user. Other servicing

generally should be referred to qualified service personnel. Caution must be exercised, since improper

servicing may cause unsafe operation.

Contact Us

If you are not satisfied with the service you receive from GE, contact us on our Website with all the details

including your phone number, or write to: General Manager, Customer Relations

Mabe Canada Inc.

Suite 310, 1 Factory Lane

Moncton, N.B. E1C 9M3

GEAppliances.ca

GEAppliances.ca

GEAppliances.ca

GEAppliances.ca

Register Your Appliance

Register your new appliance on-line—at your convenience! Timely product registration will allow for

enhanced communication and prompt service under the terms of your warranty, should the need arise.

You may also mail in the pre-printed registration card included in the packing material.

GEAppliances.ca

Printed in China

21

IMPORTANTES CONSIGNES DE SÉCURITÉ.

RÉSERVÉ À UN USAGE RÉSIDENTIEL SEULEMENT

LISEZ ET CONSERVEZ CES INSTRUCTIONS

VEUILLEZ LIRE TOUTES LES INSTRUCTIONS AVANT DE

CONTINUER.

IMPORTANT : Conservez ces instructions pour l'inspecteur en électricité local.

À L'ATTENTION DE L'INSTALLATEUR : Veuillez laisser ces instructions avec

l'appareil pour que l'acheteur puisse s'y reporter.

À L'ATTENTION DE L'ACHETEUR : Veuillez conserver ces instructions pour vous y

reporter ultérieurement.

Faites preuve de prudence lorsque vous utilisez des agents de nettoyage ou des

détergents.

Cet appareil est conçu pour être utilisé dans une cuisine résidentielle.

AVERTISSEMENT - Pour réduire les risques d'incendie ou de choc électrique,

n'utilisez pas cet appareil avec un dispositif de contrôle de la vitesse à semiconducteurs.

ATTENTION - Pour réduire les risques d’incendie et assurer l’évacuation adéquate de

l’air, assurez-vous d’acheminer les conduits vers l’extérieur. N’évacuez pas l’air dans

des espaces intra-muraux, dans le plafond ou dans le grenier, dans un vide sanitaire

ou le garage.

ATTENTION - Pour évacuation de type général uniquement. N'utilisez pas cet

appareil pour évacuer des substances ou des vapeurs nocives ou explosives.

ATTENTION - Pour éviter d'endommager les paliers du moteur et de rendre les

roues à ailettes bruyantes et/ou déséquilibrées, empêcher les produits pulvérisés

sur les cloisons sèches, la poussière produite lors des travaux de construction, etc.

de venir en contact avec le moteur de la hotte.

ATTENTION - Pour plus de détails sur l'appareil et ses exigences, veuillez lire

l'étiquette des spéci¿cations située sur la hotte.

AVERTISSEMENT - POUR DIMINUER LES RISQUES D'INCENDIE, DE CHOC

ÉLECTRIQUE OU DE BLESSURES, VEUILLEZ SUIVRE LES INSTRUCTIONS SUIVANTES :

A. Cet appareil ne doit uniquement être utilisé qu'aux ¿ns prévues par son fabricant.

Si vous avez des questions, contactez le fabricant.

B. Avant de réparer ou d'entretenir l'appareil, coupez l'alimentation au tableau

de distribution et bloquez le disjoncteur pour éviter que le courant ne soit

accidentellement rétabli. Quand il n'est pas possible de bloquer le disjoncteur,

posez un moyen d'avertissement bien visible, comme une étiquette, sur le tableau

de distribution.

AVERTISSEMENT - POUR RÉDUIRE LE RISQUE DES FEUX DE GRAISSE SUR LA

CUISINIÈRE :

A. Ne laissez jamais sans surveillance les éléments de surface à des réglages élevés.

Les débordements peuvent produire de la fumée et des projections de graisse qui

pourraient s’enÀammer. Faites chauffer l'huile doucement à un réglage bas ou moyen.

B. Mettez toujours la hotte en MARCHE lorsque vous cuisinez à feu fort ou que vous

faites Àamber des aliments p. ex. : des crêpes Suzette, des cerises jubilé ou du

steaN au poivre Àambé).

UtilisationSécurité

Entretien et

nettoyage

Dépannage

Service à la

clientèle

22

C. Nettoyez régulièrement les ventilateurs. Ne laissez pas la graisse s’accumuler sur

le ventilateur ou sur le ¿ltre.

D. Utilisez des casseroles de dimensions appropriées. Utilisez toujours des casseroles

dont la taille correspond à celle de l’élément de cuisson.

E. Gardez le ventilateur, les ¿ltres et les autres surfaces pouvant accumuler de la

graisse propres en tout temps.

F. N’utilisez un réglage de chaleur élevé que lorsque nécessaire. Faites chauffer

l’huile lentement, à un réglage de la chaleur de bas à moyen.

G. Ne laissez pas la cuisinière sans surveillance lorsque vous cuisinez.

H. Utilisez toujours des plats et des ustensiles de cuisson appropriés selon le type et

la quantité d’aliments à préparer.

AVERTISSEMENT - POUR RÉDUIRE LES RISQUES DE BLESSURES S’IL SURVIENT UN

FEU DE GRAISSE SUR LA CUISINIÈRE, SUIVEZ LES CONSIGNES SUIVANTESa :

A. ÉTOUFFEZ LES FLAMMES en recouvrant l’ustensile d’un couvercle, d’une

plaque à biscuits ou d’un plateau en métal, puis éteignez l’élément chauffant.

PRENEZ GARDE DE NE PAS VOUS BRÓLER. Si les Àammes ne s’éteignent pas

immédiatement, ÉVACUEZ LES LIEU; ET APPELEZ LES POMPIERS.

B. N'ESSAYEZ JAMAIS DE SAISIR UN USTENSILE EN FEU; vous pourriez vous brûler.

C. N'UTILISEZ PAS D'EAU, de torchons ni de serviettes; une violente explosion de

vapeur en résulterait.

D. Utilisez un extincteur SEULEMENT si :

1. Vous avez en votre possession un extincteur de classe ABC et vous savez vous en

servir.

2. Le feu est petit et circonscrit à l'endroit où il s'est déclaré.

3. Vous avez appelé les pompiers.

4. Vous pouvez combattre le feu en faisant dos à une sortie.

a

Tiré du document © Kitchen Firesafety Tips ª Conseils de sécurité-incendie pour

nettoyage

Entretien et

Dépannage Utilisation Sécurité

la cuisine) publié par la NFPA.

/HQWUHWLHQDGpTXDWGHFHWWHKRWWHGHFXLVLQLqUHDVVXUHUDVRQERQIRQFWLRQQHPHQW

AVERTISSEMENT - DANS CERTAINES CIRCONSTANCES, LES APPAREILS

ÉLECTROMÉNAGERS PEUVENT ÇTRE DANGEREU;.

A. Ne véri¿ez pas l’état des ¿ltres lorsque la hotte fonctionne.

B. Ne touchez pas aux lampes après une utilisation prolongée de l’appareil.

C. Aucune nourriture ne doit être Àambée sous la hotte.

D. L’utilisation d’une Àamme nue peut endommager les ¿ltres et causer un incendie.

E. En tout temps, surveillez les aliments en train de frire pour éviter que l’huile de

cuisson ne s’enÀamme.

F. Débranchez la hotte de sa source d’alimentation électrique avant de l’entretenir

ou de la réparer.

Les fabricants ne peuvent être tenus responsables des dommages éventuels que

le non-respect de ces consignes pourrait entraîner.

clientèle

Service à la

23

UTILISATION

6LODKRWWHHVWPXQLHGHVFRPPDQGHVVXLYDQWHV¿J

Touche A = Interrupteur de mise en marche/arrêt de la lampe.

Touche B = Interrupteur de mise en marche/arrêt de la hotte. En appuyant sur

cette touche, la hotte se met en marche au niveau de vitesse 1. Lorsque la hotte

fonctionne, appuyer sur la touche pendant 2 secondes permet de l'arrêter. Si la hotte

fonctionne au niveau de vitesse 1, il n'est pas nécessaire d'appuyer sur cette touche

pour l'arrêter. Réduisez la vitesse du moteur.

$I¿FKHXU& Af¿che la vitesse du moteur et indique que la minuterie fonctionne.

Touche D = Permet de mettre la hotte en marche. Permet également d'augmenter sa

vitesse. Appuyer sur la touche lorsque la hotte est au niveau de vitesse 3 fait en sorte

que l'appareil fonctionnera au niveau maximal pendant 10 minutes, puis reviendra à

la vitesse d'origine. L'af¿cheur clignote lorsque cette fonction est activée.

Touche E = La minuterie compte la durée des fonctions activées pendant 15 minutes,

puis les éteint. La minuterie peut être désactivée en appuyant de nouveau sur la

touche E. Lorsque la minuterie est activée, le point décimal clignote sur l'af¿cheur.

La minuterie ne peut pas être activée si la hotte fonctionne à sa vitesse maximale.

- La fonction « clean air ª air propre) peut être activée en appuyant sur la touche E

pendant 2 secondes lorsque la hotte est éteinte. Cette fonction permet de démarrer

la hotte et de la faire fonctionner à la première vitesse pendant 10 minutes toutes

les heures. Lorsque cette fonction est activée et que la hotte fonctionne, le cercle

extérieur de l'icône tournera sur lui-même sur l'af¿cheur. Après les 10 minutes de

fonctionnement, le moteur s'éteindra et la lettre « C ª apparaîtra sur l'af¿cheur

jusqu'au redémarrage de la hotte 50 minutes plus tard pour un autre cycle de

fonctionnement de 10 minutes. Pour retourner au mode de fonctionnement normal,

appuyez sur n'importe quelle touche à l'exception de la touche de la lampe).

Appuyez sur la touche E pour désactiver cette fonction.

6DWXUDWLRQGX¿OWUHDQWLJUDLVVHjFKDUERQDFWLI

- Lorsqu'un chiffre indiquant l'une des vitesses de la hotte C se met à clignoter sur

l'af¿cheur en alternance avec la lettre F ex. : 1 et F), vous devrez nettoyer les ¿ltres

antigraisse.

- Lorsqu'un chiffre indiquant l'une des vitesses de la hotte C se met à clignoter sur

l'af¿cheur en alternance avec la lettre A ex. : 1 et A), les ¿ltres au charbon doivent

être remplacés.

Une fois qu'un ¿ltre propre a été installé correctement, la mémoire de l'appareil

doit être réinitialisée en appuyant sur la touche A pendant environ 5 secondes,

jusqu'à ce que la lettre F ou A qui clignote sur l'af¿cheur C arrête de clignoter.

UtilisationSécurité

Entretien et

nettoyage

Dépannage

24

Service à la

clientèle

ENTRETIEN

Nous conseillons de démarrer la hotte avant de commencer la cuisson d'aliments.

Nous recommandons également de la laisser fonctionner pendant 15 minutes

après la cuisson des aliments a¿n d'éliminer complètement les odeurs de cuisson.

Le rendement de la hotte sera supérieur si vous l'entretenez régulièrement; les ¿ltres

antigraisse et au charbon actif doivent faire l'objet d'une attention particulière.

/H¿OWUHDQWLJUDLVVH sert à capturer les particules de graisse en suspension dans

l'air et est donc sujet à se saturer le temps qu'il prend à se remplir dépend de la

façon dont vous utilisez la hotte).

- Pour éviter les risques d'incendie, les ¿ltres antigraisse doivent être lavés au

minimum tous les 2 mois vous pouvez les laver au lave-vaisselle).

- Après quelques nettoyages, la couleur des ¿ltres peut changer. Ce changement de

couleur ne signi¿e pas qu'ils doivent être remplacés.

Si les instructions relatives au remplacement et au nettoyage des ¿ltres ne sont

pas suivies, les ¿ltres antigraisse peuvent présenter des risques d'incendie.

/HV¿OWUHVDXFKDUERQDFWLI (certains modèles) sont utilisés pour puri¿er l'air qui est

retourné dans la cuisine. Ces ¿ltres ne sont pas lavables ni réutilisables et doivent

être remplacés au moins une fois tous les quatre mois. Le niveau de saturation des

¿ltres au charbon dépend de la fréquence à laquelle la hotte est utilisée, le type de

cuisson et la fréquence avec laquelle les ¿ltres antigraisse sont nettoyés.

Nettoyez l'intérieur et l'extérieur de la hotte régulièrement à l'aide d'un chiffon

imbibé d'alcool dénaturé ou d'un détergent liquide neutre et non abrasif.

La lampe de la hotte est conçue pour être utilisée durant la cuisson des aliments

et ne doit pas servir à éclairer la cuisine. Une utilisation prolongée de la lampe

diminuera la durée de vie de l'ampoule.

nettoyage

Entretien et

Dépannage Utilisation Sécurité

clientèle

Service à la

25

ENTRETIEN ET NETTOYAGE

Assurez-vous que l’alimentation électrique est coupée et que toutes les

surfaces sont froides avant de nettoyer ou de réparer une partie de la hotte.

Filtres à graisses métalliques réutilisables

La hotte est équipée de 3 filtres à graisses réutilisables en métal.

Les filtres métalliques retiennent la graisse émise par les aliments lors de l’utilisation

de la surface de cuisson. Ces filtres empêchent également les flammes provenant

des aliments cuits sur la surface de cuisson d’endommager l’intérieur de la hotte.

Pour cette raison, il faut TOUJOURS que les filtres soient en place lors de l’utilisation

de la hotte. Les filtres à graisses doivent être nettoyés tous les mois ou lorsque cela

s’avère nécessaire.

Pour enlever les filtres, appuyez sur le verrou, tirez vers le bas et dégagez-les.

Pour réinstaller les filtres, faites glisser les languettes arrière dans les fentes du

châssis, à l’arrière de l’ouverture.

Poussez les filtres vers le haut et enclenchez-les en place.

Pour nettoyer les filtres à graisses, faites-les tremper, puis agitez-les dans une

solution d’eau chaude et de détergent. N’utilisez pas de produits contenant de

l’ammoniaque, car ils noirciraient le métal. N’utilisez pas de produits de nettoyage

pour four ou abrasifs. Vous pouvez effectuer un brossage léger pour éliminer les

saletés incrustées. Rincez, secouez et laissez sécher les filtres avant de les réinstaller.

Il est également possible de les laver au lave-vaisselle.

REMARQUE : Avant de procéder au nettoyage, assurez-vous que les filtres à charbon

ont été enlevés, si la hotte en est munie. Reportez-vous à la section sur les filtres à

charbon.

UtilisationSécurité

Entretien et

nettoyage

Filtres à charbon (certains modèles)

Les filtres à charbon ne peuvent pas être nettoyés. Ils doivent être remplacés.

Pour convertir la hotte en mode recyclage de l’air l’air n’est pas envoyé à l’extérieur),

commandez les ensembles suivants :

Ensemble n° KIT0320 pour le modèle PVUS930

Ensemble n° KIT0321 pour le modèle PVUS936

Ces ensembles contiennent deux filtres à charbon.

Pour remplacer les filtres à charbon, commandez la pièce n° ACK00059.

Ces nécessaires peuvent être commandés auprès de votre fournisseur GE.

REMARQUE :/HV¿OWUHVjFKDUERQQHVRQWSDVFRPSULVDYHFODKRWWH&HX[FLSHXYHQW

être commandés auprès de votre fournisseur GE.

Si la hotte n’est pas ventilée vers l’extérieur, l’air est recyclé à travers des ¿ltres à

charbon jetables qui retiennent la fumée et les odeurs.

Les ¿ltres à charbon doivent être remplacés lorsqu’ils sont très encrassés ou lorsqu’ils

ont changé de couleur généralement après une période de 6 à 12 mois, selon la

fréquence d’utilisation de la hotte).

REMARQUE :1(ULQFH]3$6OHV¿OWUHVjFKDUERQHW1(OHVQHWWR\H]3$6DXODYHYDLVVHOOH

26

Dépannage

Service à la

clientèle

Surfaces en acier inoxydable (certains modèles)

N’utilisez pas de tampon en laine d’acier, il égratignerait la surface.

1. Secouez bien la bouteille.

2. Placez une petite quantité de CERAMA BRYTE

essuie-tout sec.

3. Nettoyez une petite zone environ 8 po x 8 po/20,3 cm x 20,3 cm), en frottant

dans le sens du grain de l’acier inoxydable, le cas échéant.

4. Séchez et polissez avec un essuie-tout ou un linge doux, sec et propre.

5. Répétez au besoin.

Pour commander :

Pour commander du CERAMA BRYTE

inoxydable, veuillez composer notre numéro sans frais :

Centre national des pièces 1-800-661-1616

www.electromenagersge.ca

CERAMA BRYTE

produit pour nettoyer,

polir et préserver

l’acier inoxydable N° PM10X313

Lampes de la hotte

Cette hotte nécessite l’utilisation de deux ampoules QRQFRPSULVHV, d’un maximum

de 50 W.

Achetez et installez des ampoules halogènes WB27M02956, d’un maximum de 50 W.

Lorsque vous remplacez une ampoule, laissez-la d’abord refroidir. Assurez-vous

nettoyage

Entretien et

que l’alimentation en électricité de la lampe a été coupée. Ne laissez jamais une

ampoule chaude entrer en contact avec de l’eau.

®

®

, produit pour nettoyer, polir et préserver l’acier

®

sur un chiffon sec ou sur un

AVERTISSEMENT : Pour réduire le risque de choc électrique, ne branchez pas la

hotte à sa source d’alimentation sans que les ampoules ne

soient en place..

Pour changer les ampoules :

Reportez-vous à la page 23 et à la ¿gure 9.

ATTENTION : Ne touchez pas les ampoules de la hotte lorsqu’elles sont

Dépannage Utilisation Sécurité

Les ampoules fonctionnent à des températures

clientèle

ervice à la

allumées. Elles peuvent être assez chaudes pour causer

des blessures.

extrêmement élevées. Si les ampoules se cassent, le verre

peut causer des blessures.

27

Instructions Hotte de

d’installation

Des questions? Appelez le 1-800-561-3344

AVANT DE COMMENCER

Lisez attentivement toutes ces instructions.

7

IMPORTANT –

l’inspecteur local.

7

IMPORTANT –

règlements en vigueur.

Remarque destinée à l’installateur –

7

laisser ces instructions au consommateur.

Remarque destinée au consommateur –

7

Conservez ces instructions pour vous y reporter

ultérieurement.

7 Aptitude – L’installation de cet appareil exige des

compétences de base en mécanique et en électricité.

7 Durée de l’installation – 30 minutes à 3 heures.

7 L’installateur est responsable de la qualité de l’installation.

7 Une panne du produit due à une mauvaise installation n’est

pas couverte par la garantie.

Conservez ces instructions pour

Observez tous les codes et

POUR VOTRE SÉCURITÉ :

AVERTISSEMENT –

l’installation, coupez le courant au tableau de distribution et

bloquez le disjoncteur pour éviter que le courant ne soit

accidentellement rétabli. Quand il n’est pas possible de

bloquer le disjoncteur, posez un moyen d’avertissement bien

visible, comme une étiquette, sur le tableau de distribution.

EXIGENCES CONCERNANT LES CONDUITS

REMARQUE : Lisez les sections concernant les conduits

seulement si vous n’avez pas de conduits existants. Si vous

avez des conduits existants, passez directement à la section

« Dommages ».

Avant de commencer

ou visitez notre site Web au

Veillez à

cuisinière

www.electromenagersge.ca

AVERTISSEMENT –

RISQUES D’INCENDIE ET ASSURER L’ÉVACUATION ADÉQUATE DE

L’AIR, ASSUREZ-VOUS D’ACHEMINER LES CONDUITS VERS

L’EXTÉRIEUR. N’ÉVACUEZ PAS L’AIR DANS DES ESPACES INTRAMURAUX, DANS LE PLAFOND OU DANS LE GRENIER, DANS UN

VIDE SANITAIRE OU LE GARAGE.

L’évacuation du système de ventilation doit se faire vers

l’extérieur.

L’évacuation de l’air de cette hotte peut se faire verticalement

à travers les armoires supérieures ou horizontalement à travers

un mur donnant sur l’extérieur. Les conduits ne sont pas inclus.

Raccordement au conduit :

Le conduit d'évacuation de la hotte a été conçu pour s'adapter

au conduit rond standard de 6 po de diamètre.

S'il vous faut utiliser un conduit rond de 7 po, vous

devrez installer un adaptateur de transition rectangulaire

à rond*. N’utilisez pas un conduit dont le diamètre est

inférieur à 6 po.

Longueur maximale du conduit :

Pour une circulation d’air satisfaisante, la longueur totale du

conduit rectangulaire de 3¼ x 10 po ou du conduit rond de 6 ou

7 po de diamètre ne doit pas excéder une longueur équivalente

à 65 pi. Consultez la section FICHE TECHNIQUE - CALCUL DE LA

LONGUEUR ÉQUIVALENTE TOTALE DES CONDUITS.

REMARQUE : Il est important que les conduits soient installés en

utilisant le chemin le plus direct et avec le moins de coudes

possible. Cela permet de garantir une bonne évacuation et de

prévenir les blocages. Assurez-vous également que les registres

bougent librement et que rien ne bloque les conduits.

Les coudes, adaptateurs de transition, évents muraux

ou de toiture, etc.

la circulation de l’air et sont équivalents à une section de

conduit droit plus longue que leur dimension réelle. Lorsque

vous calculez la longueur totale du conduit, ajoutez les

longueurs équivalentes de tous les adaptateurs de transition et

des coudes, ainsi que la longueur de toutes les sections de

conduit droit. Vous trouverez dans les tableaux des pages

suivantes comment calculer la longueur équivalente totale à

l’aide de la

mètres de certains types de conduits les plus utilisés.

offrent une résistance supplémentaire à

longueur équivalente approximative en pieds et en

* IMPORTANT : Si vous utilisez un adaptateur de

transition rectangulaire à rond, il faudra

couper les coins inférieurs du registre aux

dimensions de l’adaptateur à l’aide de cisailles

pour que le registre puisse bouger librement.

Les longueurs équivalentes des pièces de

conduits sont basées sur des essais réels et

représentent les longueurs nécessaires à une

bonne ventilation pour n’importe quelle hotte.

POUR RÉDUIRE LES

1 pi = 0,3 m; 1 po = 2,5 cm

28

Instructions d’installation

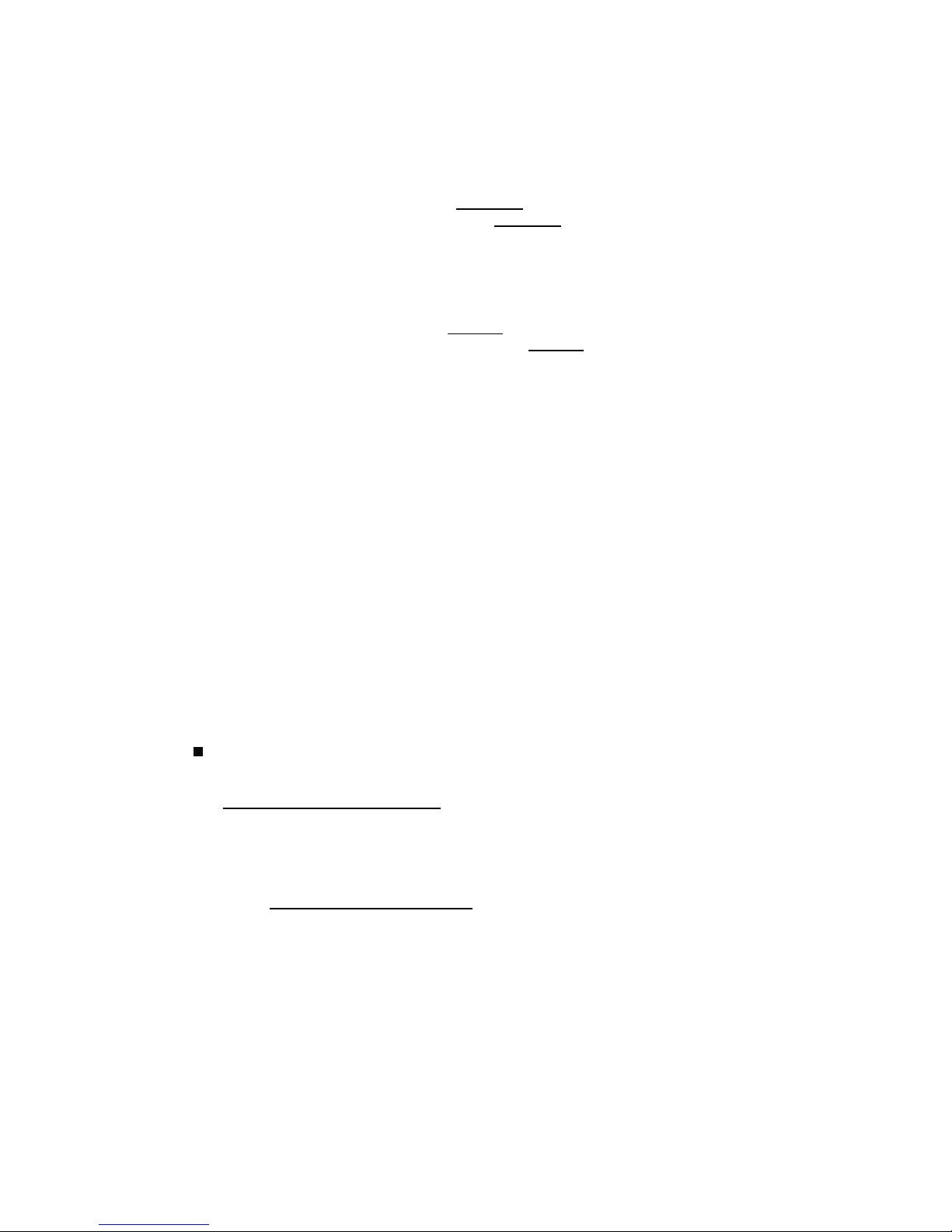

FICHE TECHNIQUE — CALCUL DE LA LONGUEUR ÉQUIVALENTE TOTALE DES CONDUITS

PIÈCE LONGUEUR NOMBRE

DE CONDUIT ÉQUIVALENTE x UTILISÉ = TOTAL

Conduit droit, 1 pi x ( ) = pi

rectangulaire

de 3¼ x 10 po

Conduit droit, 1 pi x ( ) = pi

rond de 7 po

Conduit droit, 1 pi x ( ) = pi

rond de 6 po

Coude de 90°, 14 pi x ( ) = pi

rectangulaire

de 3¼ x 10 po

Coude de 45°, 8 pi x ( ) = pi

rectangulaire

de 3¼ x 10 po

Coude plat 33 pi x ( ) = pi

de 90°, rect.

de 3¼ x 10 po

Évent mural 24 pi x ( ) = pi

rectangulaire

de 3¼ x 10 po

avec

registre

Adaptateur de 2 pi x ( ) = pi

transition, rect.

de 3¼ x 10 po

à rond de 6 po

Coude de 4 pi x ( ) = pi

transition

de 90°, rect.

de 3¼ x 10 po

à rond de 6 po

Coude de 90°, 25 pi x ( ) = pi

rond de 6 po

Coude de 45°, 16 pi x ( ) = pi

rond de 6 po

LONGUEUR MAXIMALE DU CONDUIT : Pour une circulation d’air

satisfaisante, la longueur totale du conduit rectangulaire de

3¼ x 10 po ou du conduit rond de 7 po de diamètre ne doit pas

excéder une longueur équivalente à 65 pi.

(18 pi sans

registre)

Total partiel colonne 1 = pi

x ( ) = pi

PIÈCE LONGUEUR NOMBRE

DE CONDUIT ÉQUIVALENTE x UTILISÉ = TOTAL

Évent mural 53 pi x ( ) = pi

rond de 6 po

avec

registre

Évent de 72 pi x ( ) = pi

toiture rond

de 6 po

Adaptateur 3 pi x ( ) = pi

de transition,

rond de 6 po

à rect. de

3¼ x 10 po

Coude de 9 pi x ( ) = pi

transition

de 90°, rond

de 6 po

à rect. de

3¼ x 10 po

Coude de 90°,

rond de 7 po

Coude de 45°,

rond de 7 po

Évent mural 28 pi x ( ) = pi

rond de 7 po (

avec

registre

Évent de 39 pi x ( ) = pi

toiture rond

de 7 po

Adaptateur 1 pi x ( ) = pi

de transition,

rond de 7 po

à rect. de

3¼ x 10 po

Coude de 5 pi x ( ) = pi

transition

de 90°, rond

de 7 po à

rect. de

3¼ x 10 po

(39 pi sans

registre)

14 pi x ( ) = pi

9 pi x ( ) = pi

21 pi sans

registre)

x ( ) = pi

x ( ) = pi

Total partiel colonne 2 = pi

Total partiel colonne 1 = pi

1 pi = 0,3 m; 1 po = 2,5 cm

Longueur totale

des conduits = pi

29

Instructions d’installation

DOMMAGES - EXPÉDITION/INSTALLATION

0Si l’appareil est endommagé durant le transport, retournez-

le au magasin où vous l’avez acheté pour réparation ou

remplacement. Téléphonez au 1-800-531-3344.

0Si l’appareil est endommagé par le client, la réparation ou le

remplacement reste à la charge du client.

0Si l’appareil est endommagé par l’installateur (s’il s’agit d’une

personne différente du client), la réparation ou le

remplacement doivent faire l’objet d’une entente entre le client

et l’installateur.

DÉGAGEMENTS POUR L’INSTALLATION

Le rebord inférieur

de l’armoire

doit être à

au moins

30 po de

la surface de

24

correspondre à la largeur

de la surface de cuisson.

Au moins

66 po entre

le sol et le

dessus de

la hotte

po, 30 ou 36 po pour

30 po

min.

cuisson

OUTILS NÉCESSAIRES

Tournevis plat et

tournevis Phillips

Scie

(sauteuse ou à guichet)

Douille hex.

pivotante

de 1/4 po

Lampe

torche

Pinces

Pistolet à

calfeutrer

Crayon

Perceuse électrique

Ruban à mesurer

Niveau

PIÈCES NÉCESSAIRES

Conduit rond de 6 po

Conduit coudé rond de 6 po, 90°

Colliers de serrage (2) de 6 po et 7 po

Ruban adhésif

en toile

Cisailles à métaux

(dans certains cas)

Pince à

dénuder

Tournevis à

douille de 1/4 po

REMARQUES :

0La largeur de la hotte peut être supérieure à la largeur de la

cuisinière ou la surface de cuisson, mais elle ne peut pas

être plus petite.

0Assurez-vous que la cuisinière ou la surface de cuisson a été

installée selon les instructions d’installation du fabricant.

0Si l’évacuation de l’air de votre hotte de cuisinière s’effectue

vers l’extérieur, consultez la section « Exigences concernant

les conduits » pour la préparation du conduit d’évacuation.

1 pi = 0,3 m; 1 po = 2,5 cm

30

LISEZ ET CONSERVEZ CES INSTRUCTIONS

CONSIGNES GÉNÉRALES

Lisez attentivement les renseignements suivants concernant la sécurité lors de l'installation de

la hotte et de son entretien. Conservez ce livret à portée de main pour consultation ultérieure.

La hotte a été conçue pour une utilisation en version ASPIRANTE évacuation de l'air vers

l'extérieur, ¿g. 1A - ¿g. 1B) ou FILTRANTE ensemble KIT0320 pour modèle de 30 po 76,2 cm) et

KIT0321 pour modèle de 36 po 91,4 cm).

INSTRUCTIONS D'INSTALLATION

AVERTISSEMENT - POUR DIMINUER LES RISQUES D'INCENDIE, DE CHOC ÉLECTRIQUE OU DE

BLESSURES, VEUILLEZ SUIVRE LES INSTRUCTIONS SUIVANTES :

A. L'installation et le câblage électrique doivent être effectués par une personne quali¿ée et

conformément à tous les codes et toutes les normes applicables, incluant les règlements

concernant les constructions classées résistantes au feu.

B. Une quantité d'air suf¿sante est nécessaire à une combustion et à une évacuation

appropriées des gaz par le conduit d'évacuation cheminée) de l'équipement à combustible

pour éviter tout refoulement. Suivez les instructions et normes de sécurité du fabricant

de l'appareil chauffant, comme celles publiées par la National Fire Protection Association

NFPA), l'American Society for Heating, Refrigeration and Air Conditioning Engineers ASHRAE)

et les autorités locales.

C. Lorsque vous effectuez des découpes ou que vous percez dans un mur ou un plafond,

n'endommagez pas le câblage électrique ou les installations des services publics.

D. L'air des ventilateurs qui disposent de conduits d'aération doit toujours être évacué vers l'extérieur.

E. Cet appareil doit être mis à la terre.

AVERTISSEMENT - POUR RÉDUIRE LES RISQUES D'INCENDIE, N'UTILISEZ QUE DES CONDUITS

EN MÉTAL.

Attention!

- Avant de procéder à l'assemblage, ouvrez l'emballage, puis disposez la hotte sur une

surface confortable.

- Retirez les ¿ltres antigraisse ¿g. 1C).

A. Si la hotte est installée avec une sortie d'air ¿g. 1B ou 4B), les ¿ls contenus dans le

faisceau correspondant doivent être dégagés en tirant le levier vers l'extérieur, tel

qu'illustré dans la ¿gure 2, étapes 1 et 2.

B. Débranchez le raccord à 6 directions du moteur situé à l'intérieur de la hotte, tel qu'illustré

dans la ¿gure 2, étape 3.

C. Les câbles situés dans la hotte sont ¿xés à l'aide d'un collier de serrage. Coupez le collier

tel qu'illustré dans la ¿gure 2, étape 4.

Après avoir terminé les opérations de transformation, réassemblez les composants en

effectuant les opérations dans le sens inverse Fig. 2).

De cette manière, il sera plus facile de manipuler la hotte.

- Si l’on monte l’appareil en version ASPIRANTE, il faut prévoir l’ori¿ce pour l’évacuation de l’air.

- Nous vous recommandons d’utiliser un tuyau d’évacuation d’air ayant le même diamètre

que la bride de sortie air. L’utilisation d’une réduction pourrait amoindrir les performances

du produit et augmenter le niveau de bruit.

31

Attention! Ce produit peut utiliser l’orifice d’évacuation de l’air dans 2 positions différentes,

selon vos exigences :

1 – dans la partie supérieure de la hotte Fig. 1A)

2 – dans la partie arrière de la hotte Fig. 1B).

- La bride d’évacuation d’air est fournie en format rectangulaire X et circulaire Y Fig. 1).

9HUVLRQDYHF RUL¿FH GpYDFXDWLRQGDQV OD partie supérieureGHODKRWWH)LJ

Ce produit est fourni avec la sortie d'air dans la partie supérieure de la hotte et le boîtier

pour branchement électrique sur la partie arrière de la hotte, tel qu'illustré dans la ¿gure 5

voir le paragraphe : EUDQFKHPHQWpOHFWULTXH).

- La hotte est déjà con¿gurée pour une utilisation avec un tuyau rectangulaire de sortie d’air E

Fig. 3.1).

- Toutefois, si vous utilisez le tuyau rond de sortie d’air F, les 7 vis H et l’étrier ; doivent être

retirés Fig. 3.2).

9HUVLRQDYHFRUL¿FHGpYDFXDWLRQGDQVODpartie arrièreGHODKRWWH)LJ

- Si vos exigences prévoient l’utilisation de la sortie d’air dans la partie arrière de la hotte

effectuer toutes les phases indiquées sur la ¿gure 2), retirez les vis I Fig. 4.1) ¿xant l’étrier

moteur Y, tournez tout le groupe moteur dans la position indiquée dans la Fig. 4.2. Remettez

l’étrier moteur Y dans son logement et ¿xez-le à l'aide des vis qui ont été retirées I.

Attention! Chaque fois que le tuyau rond de sortie d’air F est utilisé, répétez l'opération

illustrée dans la Fig. 3.2.

&RQQH[LRQpOHFWULTXH

Pour des instructions sur la façon de connecter la hotte à la source d'alimentation électrique,

reportez-vous à la figure 5 :

1. Cassez et enlevez la petite plaque métallique ronde située dans la partie arrière de la hotte

en tapant dessus à l’aide d’un tournevis plat Fig. 5.1).

2. Retirez le couvercle du boîtier d’alimentation en dévissant les 2 vis A Fig. 5.2).

3. Raccordez les fils de la hotte à ceux de l’alimentation électrique en suivant la procédure

illustrée dans la Fig. 5.3 :

NOIR = Ligne électrique

BLANC = Neutre

9(57-$81( Mise à la terre

- Un interrupteur bipolaire d'intensité nominale appropriée doit être installé a¿n d'empêcher

les coupures de courant de la hotte.

- Connectez le ¿l électrique au compartiment du câblage d'alimentation en utilisant des

raccords homologués.

- Installez la connexion électrique conformément au code national de l'électricité

ANSI/NFPA 70-1999.

- Insérez les ¿ls dans la boîte, puis vissez le couvercle de la boîte à l'aide des vis que vous

avez précédemment enlevées.

EN OPTION : la boîte d’alimentation électrique peut être démontée et ¿xée comme indiqué à la

¿gure 6.

ATTENTION : POUR RÉDUIRE LE RISQUE D'INCENDIE, DE CHOC ÉLECTRIQUE OU DE

BLESSURE, RESPECTEZ LES DIRECTIVES SUIVANTES Avant de connecter l’appareil au réseau

G·DOLPHQWDWLRQOHERvWLHUGHO·LQVWDOODWLRQpOHFWULTXHGRLWrWUHSRVLWLRQQpGDQVOHORJHPHQW

Pour déplacer le boîtier d'alimentation, reportez-vous à la Fig. 6 :

1. Dévissez les deux vis C Fig. 6.1).

2. Cassez et enlevez la petite plaque métallique ronde située dans la partie supérieure de la

hotte en tapant dessus à l’aide d’un tournevis plat Fig. 6.2).

32

3. Prenez le boîtier de connexion électrique et ¿xez-le dans la position indiquée sur la Fig. 6.3

à l’aide des 2 vis C qui ont été retirées.

4. Pour le EUDQFKHPHQWjO·DOLPHQWDWLRQpOHFWULTXH, reportez-vous à la Fig. 5.2-3.

Cette hotte doit être installée à une hauteur minimale de 26 po 66 cm) de la surface

de cuisson des cuisinières électriques ou à une distance minimale de 30 po 76 cm) des

cuisinières à gaz ou combinées. Si vous utilisez la connexion de conduit en deux parties,

la partie supérieure doit être placée à l’extérieur de la partie inférieure. Ne raccordez pas

le conduit d’évacuation de la cuisinière au conduit utilisé pour évacuer l’air chaud ou les

vapeurs d’autres appareils s’il ne s’agit pas d’appareils électriques. Avant de procéder au

montage, retirez les) ¿ltres) antigraisse ¿g. 1C) a¿n de faciliter la manipulation de la hotte.

Ce produit peut être installé de 2 façons différentes.

- Montage de la hotte dans la partie inférieure de l'armoire :

Type d'installation B Fig. 9).

- Montage de la hotte sur le mur :

Type d'installation A Fig. 9).

0RQWDJHGHODKRWWHGDQVODSDUWLHLQIpULHXUHGHODUPRLUH)LJ%

- Assurez-vous que les vis utilisées qui n'ont pas été fournies avec le produit sont adaptées au

type de meuble.

- Disposez le gabarit de ¿xation sur la partie inférieure de l'armoire Fig. 8B), en tenant compte

de la distance minimale requise de la surface de cuisson.

- Percez 6 trous sur l'armoire en respectant les mesures indiquées Fig. 7).

- Fixez les 4 vis A sans les visser complètement.

- Positionnez la hotte sous l'armoire, poussez-la vers le mur de manière à l’amener en ¿n de

course, puis vissez/serrez les 4 vis A et ¿xez la hotte dé¿nitivement à l’aide des 2 vis de sûreté B.

0RQWDJHGHODKRWWHVXUOHPXU)LJ$

Disposez le gabarit de ¿xation sur le mur Fig. 8A), en tenant compte de la distance minimale

requise de la surface de cuisson.

- Percez 4 trous en respectant les mesures indiquées Fig. 7).

- Fixez les 2 vis supérieures A sans les visser complètement et les chevilles à expansion.

- Suspendez la hotte au mur, en l’alignant en position horizontale et vissez/serrez les 2 vis A.

Une fois qu'elle a été placée dans la bonne position, ¿xez-la dé¿nitivement à l’aide des 2 vis

de sûreté B.

Pour les diverses conditions d'installation, utilisez les vis et les ancrages adaptés à votre type

de mur sur lequel on entend ¿xer l’appareil

ancrages de vis sont fournis avec la hotte, assurez-vous qu'ils sont adaptés au type de mur

sur lequel la hotte sera installée.

En ce qui concerne l’installation sur des murs en placoplâtre : assurez-vous que les vis sont

¿xées aux éléments portants du mur. Si ce n’est pas le cas, installez une structure de support

comprenant des poutres de 2 x 4 po 5,08 x 10,16 cm) en face des points d’ancrage des vis.

béton armé, placoplâtre, etc.). Si les vis et les

33

A

X

B

Y

D

D

Fig. 1 Fig.1C

1

1

2

1

2

3-4

3

Fig. 2

4

A

E

E

Fig. 3

H

F

X

2

1

34

H

F

B

Fig. 4

I

2

Y

4

1

3

I

Fig. 5

1

2

A

A

3

C

C

2

3

C

Fig. 6

1

35

1-13/16 po

12 po

3-1/4 po

30 po 36 po

3-1/4 po

10 po

1-3/4 po

6 po

12 po

6 po

1-13/16 po

3-1/4 po

11 po

12-3/8 po

22 po

30 po 36 po

9/16 po

6-1/16 po

2 po

29-15/16 po

6-1/16 po

9/16 po

2 po

3 po

3-1/2 po

9 po

2-1/4 po

4 po

7 po

Fig. 7

11 po

1-3/4 po

6 po

22 po

35-15/16 po

9/16 po

3 po 3 po

2 po

3 po

9/16 po

2 po

3-1/2 po

1 po = 2,54 cm

9 po

2-1/4 po

7 po 4 po

Fig. 8

B

A

B

A

36

B

A

B

4

A

A

1

Fig. 9

B

ABCDE

Fig. 10

37

AVANT DE CONTACTER LE SERVICE DE DÉPANNAGE…

Conseils de dépannage

Économisez du temps et de l’argent! Consultez le tableau ci-dessous pour

éviter tout appel de service qui ne serait pas nécessaire.

Problème Causes possibles Solutions

Le ventilateur

ne fonctionne

pas lorsque la

commande est

activée

Le ventilateur ne

fait pas circuler

l’air ou il déplace

l’air plus lentement

qu’à la normale

Le ventilateur

effectue

continuellement

des cycles d’arrêt

et de marche

Un fusible peut

rWUHJULOOpRXOH

disjoncteur s’est

déclenché.

/HV¿OWUHVVRQWWUqV

encrassés.

Le moteur surchauffe

probablement et

V·DUUrWHGHOXL

PrPH&HODSHXW

endommager le

PRWHXU/HV¿OWUHV

sont très encrassés.

Remplacez le fusible ou

réenclenchez le disjoncteur.

Nettoyez les ¿ltres et remettez-

les en place. Reportez-vous

à la section Filtres à graisses

métalliques réutilisables.

Remplacez les ¿ltres s’ils sont trop

encrassés pour être nettoyé. Si les

¿ltres ne sont pas encrassés, ou

si le fait de les remplacer ne règle

pas le problème, communiquez

avec le service d’entretien.

Remplacez les ¿ltres s’ils sont

sales. Si les ¿ltres ne sont pas

encrassés, ou si le fait de les

remplacer ne règle pas le

problème, communiquez avec le

service de réparation.

UtilisationSécurité

Entretien et

nettoyage

Dépannage

38

Service à la

clientèle

NOTES

39

Garantie Mabe

Toutes les réparations sous garantie sont effectuées par nos Centres de

réparation ou par nos réparateurs agréés Customer Care

demande d’une réparation en ligne, visitez le www.electromenagersge.ca

ou appelez au 1-800-561-3344. Veuillez avoir les numéros de série et de

modèle de votre appareil à portée de main lorsque vous appelez pour

obtenir un service.

®

. Pour faire la

Agrafez votre facture ici.

Une preuve de la date d’achat

d’origine est requise pour

bénéficier du service de réparation

sous garantie.

Période de garantie : Mabe remplacera :

Un an Toute pièce défectueuse de la hotte de cuisinière en raison d’un vice de matériau ou de fabrication.