Page 1

ORCA 1600 OPERATION &

MAINTENANCE MANUAL

© February 2001 GBC Films Group

Do not duplicate without written permission.

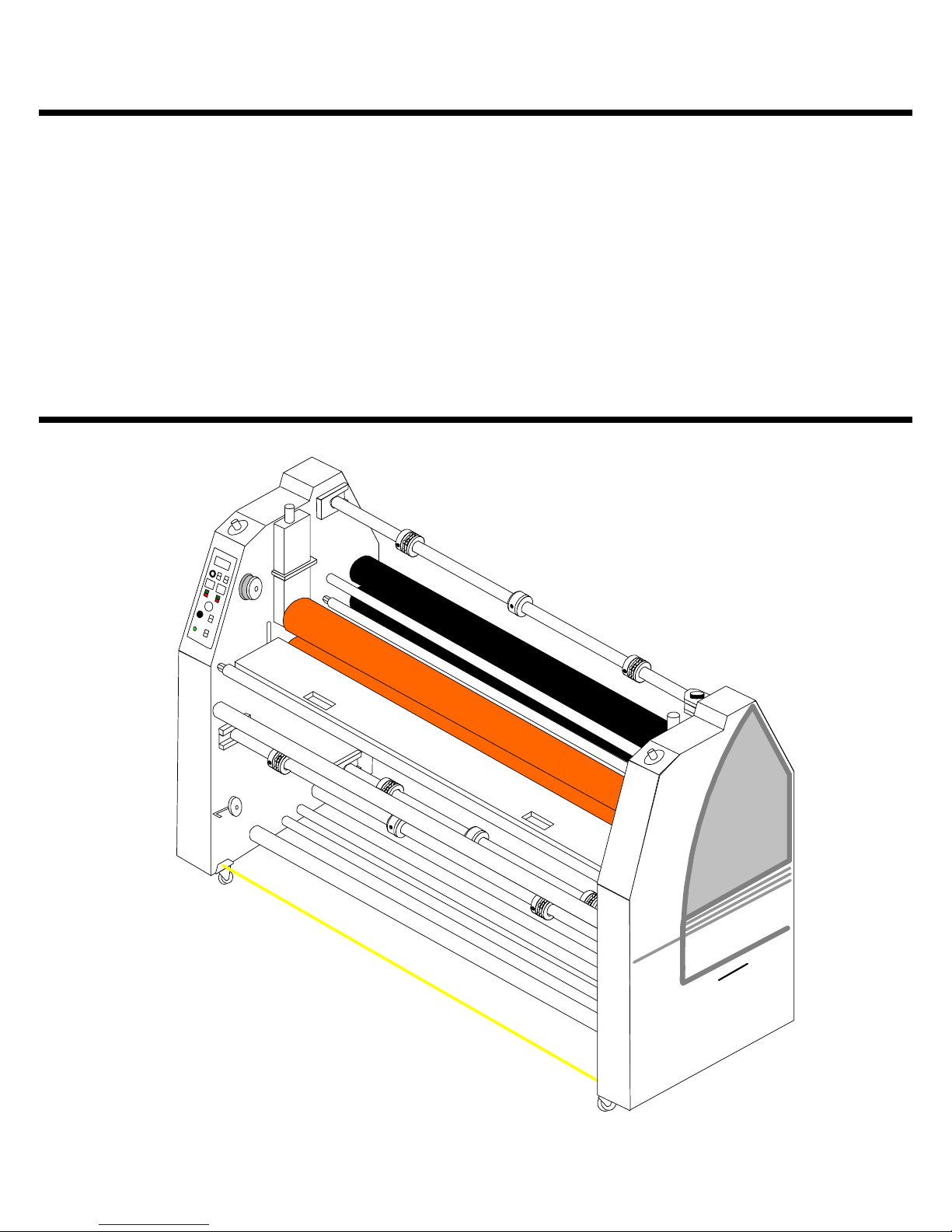

ORCA 1600

GBC

ech

- T

ro

P

GBC Pro - T ech

4151 Anderson Road

DeForest, WI 53532

Revision : A Ph: ( 608 ) 246 - 8844

Part number : 930 - 061

Fx: ( 608 ) 246 - 8645

Page 2

Read me fileOrca 1600 Operation and Maintenance Manual

Read Me File . . . . . . . . .

The information in this publication is provided for reference and is believed to be accurate and complete. GBC Films Group is not liable for errors in this publication or for incidental

or consequential damage in connection with the furnishing or use of the information in this

publication, including, but not limited to, any implied warranty of fitness or merchantability for

any particular use.

GBC Films Group reserves the right to make changes to this publication and to the

products described in it without notice. All specifications and information concerning products

are subject to change without notice.

Reference in this publication to information or products protected by copyright or patent

does not convey any license under the rights of GBC Films Group or others. GBC Films

Group assumes no liability arising from infringements of patents or any other rights of third

parties.

This publication is copyrighted © 2000 by GBC Films Group. All rights reserved. The

information contained in this publication is proprietary and may not be reproduced, stored,

transmitted, or transferred, in whole or in part, in any form without the prior and express written

permission of GBC Films Group.

The following information will explain how to move around within the electronic version

of this publication. The hand will change to a pointer finger identifying hyperlinked areas. When

moving from page to page, use

PAGE, use

from view to view, use

VIEW.

Should you find an error within this publication or would like to make a suggestion,

please utilize the fax correspondence sheet following this read me file and fax it to the number

provided. Your comments and help will ensure up to date information. Thank you.

to go back one PAGE and use to advance one PAGE. When moving

to return to a previous VIEW and use to advance to the next

to return to the first PAGE, use to advance to the last

© GBC Films Group February 2001

Page 3

Read me file Orca 1600 Operation and Maintenance Manual

This page intentionally left blank.

© GBC Films Group February 2001

Page 4

Fax Correspondence

Fax number : ( 608 ) 246 - 8645 Date :

To : Sean Flood at GBC Pro-Tech

4151 Anderson Road

DeForest, WI 53532

From :

Company :

Address :

Phone number : ( ) Fax number : ( )

Read me fileOrca 1600 Operation and Maintenance Manual

Re : Orca 1600 Operations and Maintenance Manual ( 930061 )

Section #: Page #:

Correction (s):

Additional comments:

© GBC Films Group February 2001

Page 5

Read me file Orca 1600 Operation and Maintenance Manual

This page intentionally left blank.

© GBC Films Group February 2001

Page 6

Section 1.0 Safety

1.1 Symbols ......................................................................................................1 - 1

1.2 Pneumatic safety ........................................................................................1 - 2

1.3 Safety features ............................................................................................1 - 2

1.4 Mechanical safety ......................................................................................1 - 4

T able of ContentsOrca 1600 Operation and Maintenance Manual

Table of Contents

1.5 Heating safety .............................................................................................1 - 4

1.6 Maintenance safety ....................................................................................1 - 5

1.7 Installation ..................................................................................................1 - 5

1.8 Operation ...................................................................................................1 - 8

1.9 Applications ...............................................................................................1 - 10

1.10 Troubleshooting .......................................................................................1 - 12

1.11 Maintenance ............................................................................................1 - 12

1.12 Label Explanation ....................................................................................1 - 14

Figure 1.12.1 Label Location ....................................................1 - 16

© GBC Films Group February 2001

Page I

Page 7

T able of Contents Orca 1600 Operation and Maintenance Manual

Section 2.0 Warranty

2.1 Limited warranty information ....................................................................2 - 1

2.2 Exclusions to the warranty ........................................................................2 - 1

Section 3.0 Specifications

3.1 General .......................................................................................................3 -1

3.2 Consumables................................................................................................3 - 2

3.3 Function ......................................................................................................3 - 3

3.4 Electrical ....................................................................................................3 - 4

3.5 Dimensions .................................................................................................3 - 5

Section 4.0 Installation

4.1 Pre-installation check list ..........................................................................4 - 1

Figure 4.1.1 Suggested floor layout ..............................................4 - 3

4.2 Know your machine ...................................................................................4 - 4

Page II

© GBC Films Group February 2001

Page 8

T able of ContentsOrca 1600 Operation and Maintenance Manual

4.3 Unpacking ..................................................................................................4 - 5

4.4 Shrink wrap ..............................................................................................4 - 5

4.5 Crated .........................................................................................................4 - 6

4.6 Accessory pack ..........................................................................................4 - 9

4.7 Electrical connection ..................................................................................4 - 9

4.8 Air connection ............................................................................................4 - 11

4.9 Installing levelers .......................................................................................4 - 12

4.10 Leveling ...................................................................................................4 - 13

4.11 Calibrations .............................................................................................4 - 14

Section 5.0 Operations

5.1 Power ON/ OFF .........................................................................................5 - 1

5.2 Front control panel ....................................................................................5 - 2

Figure 5.2.1 Front control panel ............................................................5 - 4

© GBC Films Group February 2001

Page III

Page 9

T able of Contents Orca 1600 Operation and Maintenance Manual

5.3 Rear control panel ......................................................................................5 - 5

Figure 5.3.1 Rear control panel ............................................................5 - 7

5.4 Setting temperature ....................................................................................5 - 8

5.5 In case of an emergency .............................................................................5 - 9

5.6 Film loading/ unloading ...........................................................................5 - 10

5.7 Main roller nip ..........................................................................................5 - 11

5.8 Pull roller nip ............................................................................................5 - 12

5.9 Shutdown procedure ..................................................................................5 - 12

Section 6.0 Applications

6.1 Temperature chart .....................................................................................6 - 1

6.2 Helpful hints ...............................................................................................6 - 2

6.3 Temp conversion chart ...............................................................................6 - 3

Figure 6.3.1 Temperature conversion chart .................................6 - 4

Page IV

© GBC Films Group February 2001

Page 10

T able of ContentsOrca 1600 Operation and Maintenance Manual

6.4 Charts and diagrams .................................................................................6 - 5

Chart - 0 ( blank chart ) ..........................................................................6 - 6

Diagram - 0 .............................................................................................6 - 7

Chart - 1 ( 1 pass mounting ) ...................................................................6 - 8

Diagram - 1 .............................................................................................6 - 9

Chart - 2 ( PSA decaling ) .....................................................................6 - 10

Diagram - 2 ............................................................................................6 - 11

Chart - 3 (Mounting a PSA decal ) ........................................................6 - 12

Diagram - 3 ............................................................................................6 - 13

Chart - 4 ( Thermal decal ) ...................................................................6 - 14

Diagram - 4 ............................................................................................6 - 15

Chart - 5 ( Mounting a thermal decal ) .................................................6 - 16

Diagram - 5 ............................................................................................6 - 17

Chart - 6 ( Thermal encapsulation ) ......................................................6 - 18

Diagram - 6 ............................................................................................6 - 19

© GBC Films Group February 2001

Page V

Page 11

T able of Contents Orca 1600 Operation and Maintenance Manual

Section 7.0 Troubleshooting

7.1 Wave problems ..........................................................................................7 - 1

7.2 Film problems .............................................................................................7 - 3

7.3 Machine problems .....................................................................................7 - 4

7.4 Glossary ......................................................................................................7 - 5

Section 8.0 Maintenance

8.1 Maintenance schedule ...............................................................................8 - 1

8.2 Cleaning the rollers ..................................................................................8 - 2

8.3 Dust - Pre-coated boards ............................................................................8 - 3

8.4 Dirt and PSA adhesive - Alcohol and cloth ...............................................8 - 3

8.5 Thermal adhesive .......................................................................................8 - 4

8.6 Clean the laminator ....................................................................................8 - 5

8.7 Clean the control panels .............................................................................8 - 6

Page VI

© GBC Films Group February 2001

Page 12

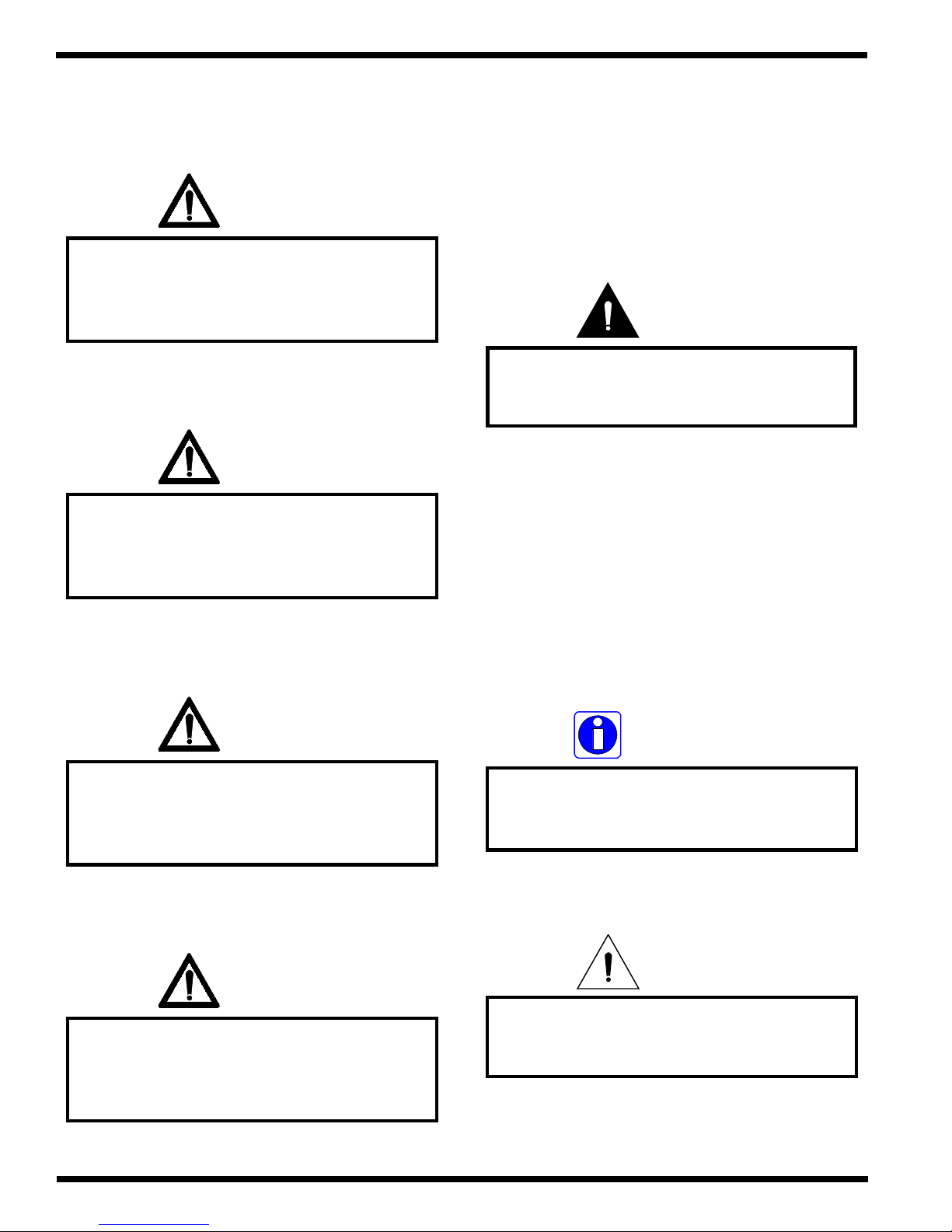

1.0 Safety

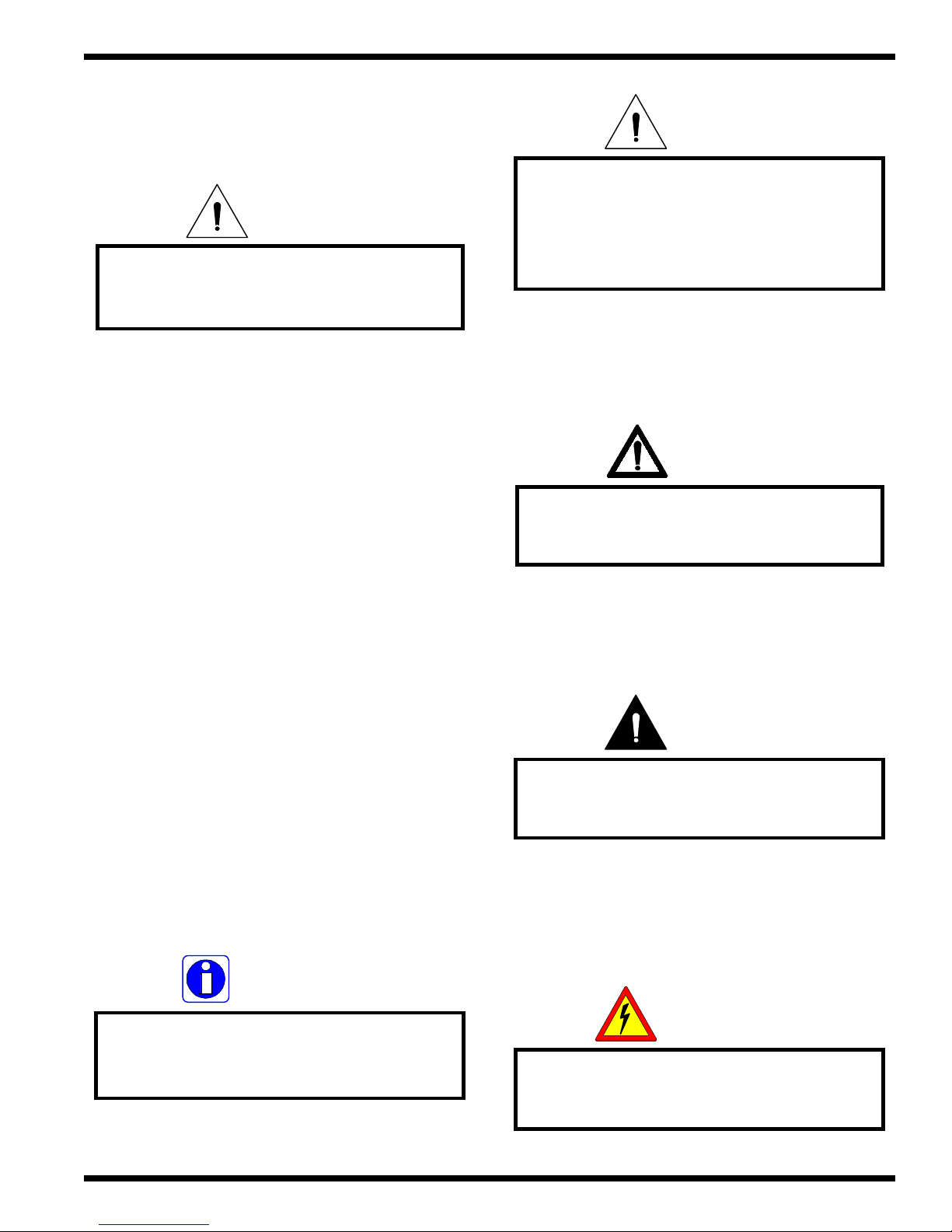

CAUTION

Do not attempt to operate your O RC A 1600

laminator until you have read this

section carefully!

SafetyOrca 1600 Operation and Maintenance Manual

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, could result in minor

or moderate injury, or alerts against unsafe

practices or alerts against actions which

could damage the product.

Your safety, as well as the safety of others, is

important to GBC Films Group. This section contains

important safety information.

The following symbols are used throughout

this manual to indicate Information, Caution,

Warning, Danger and Electrical Shock conditions.

1.1 Symbols

WARNING

Indicates a po tentially hazardou s situation

which, if not avoided, could result

in se rio u s in ju ry .

DANGER

Indicates an imminently hazardous situation

which, if not avoided, could result in death

or serious injury.

INFORMATION

Indicates helpful information that should be

considered before, during, or after an

action, step or procedure is given.

© GBC Films Group February 2001

ELECTRICAL

SHOCK

Indicates an electrical shock situation which,

if not avoided, could result in serious

paralyzation of the body or death.

Page 1 - 1

Page 13

Safety Orca 1600 Operation and Maintenance Manual

1.2 Pneumatic safety

The Orca 1600 laminator has been designed

with safety as a primary consideration; however, you

must become thoroughly familiar with the controls,

proper operation, proper service procedures and safety

features of the laminator before using or servicing the

unit.

The pneumatic system used to provide downward pressure on the top main roller and the top pull

roller is capable of producing great amount of forces.

This force is applied to any object presented in the

opening (called the nip) between the two rollers.

CAUTIO N

1.3 Safety features

Important safety features of the Orca 1600

laminator are the emergency stop push buttons ( E-

STOP ), the emergency stop cables ( E-CABLE ) and

the photo electric sensors ( PHOTO-EYE ). It is

recommended that you become thoroughly familiar

with each of these safety features purpose and how to

use them in the event of an emergency.

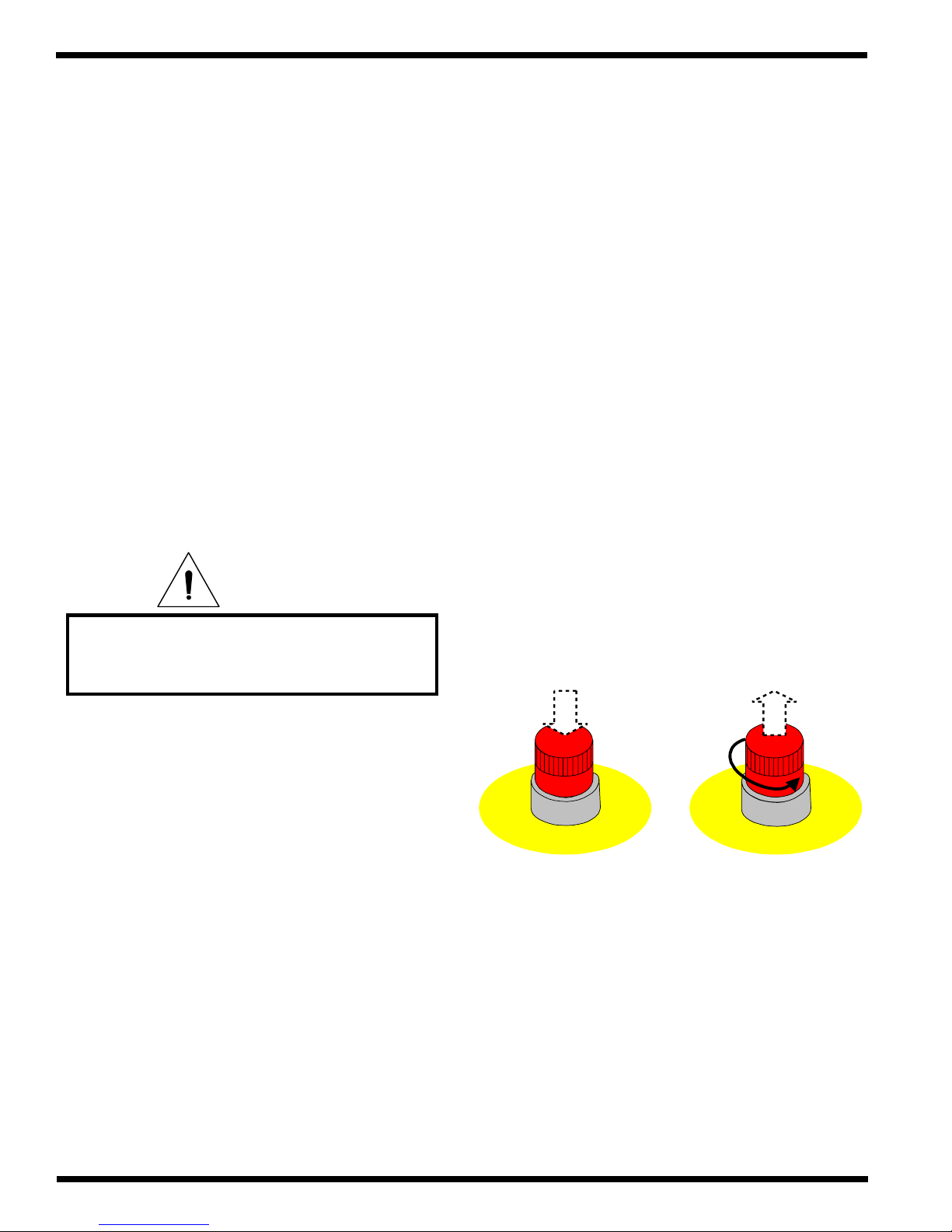

E- STOP

T o engage any one of the four E-STOPs, press

the push button down. Any one of these, when

engaged, removes power to the motor and opens the

main roller and pull roller nips.

Objects other than m edia, film or app roved

substrates, will cause irreparable damage

to the rollers if caugh t in the n ip.

Use care in lowering the top main and/ or pull

rollers. Know how to react quickly in an emergency.

The top main laminator roller UP-DOWN switch is

located on the front control panel. The top pull roller

UP-DOWN switch is located on the rear control panel.

This switch controls the up and down motion of the

top pull roller .

Before pressing either of these switches to the

DOWN position, ensure that nothing is in the nip areas. If any problem or danger should occur, depressing any of the emergency stop push buttons or engaging the emergency cables, described in Section 1.3,

stops the rollers from closing and raises them completely.

E

M

E

R

G

Engaged

Push

E

N

P

O

T

S

Y

C

E

Turn

E

M

R

G

E

C

N

Disengaged

P

O

T

S

Y

To continue operation, all E-STOPS must be

in the up position. To reset the E-STOP, twist the

button 1/4 turn counter clockwise and reset the main

roller UP-DOWN switch to UP.

Page 1 - 2

© GBC Films Group February 2001

Page 14

SafetyOrca 1600 Operation and Maintenance Manual

E- CABLE

To engage the front or rear E-CABLE, push

in on the cable using your foot. Either cable, when

engaged, removes power to the motor and opens the

main roller and pull roller nips. The E-CABLE are

provided in the event you are unable to reach one of

the four E-STOPs.

PHOTO-EYE

The Orca 1600 is equipped with three sets of

PHOTO-EYEs, one at the main roller nip, one behind

the pull roller nip and one in front of the pull roller

nip. The PHOTO-EYEs, when blocked by an object,

stop the rollers from turning and will resume turning

when the sensor is no longer blocked.

This safety feature not only protects the

operator but also protects objects from entering the

rollers nip causing damage. The PHOTO-EYEs are

calibrated at time of installation.

With the FWD/ REV switch in the FWD

position, the PHOTO-EYE at the front of the main

roller nip (1) and the rear of the pull roller nip (3) are

engaged.

0

0

6

1

A

C

R

Press in or down

O

GBC

h

c

e

T

-

o

r

P

To continue operation, reset the main roller

UP-DOWN switch to UP and continue on with

operation. The E-CABLE automatically resets itself

when the cable springs back to it’s original position.

All E-STOPs must be in the unlatched position as

well.

The E-CABLE may be adjusted if you feel

the cable is too sensitive or too loose. Contact your

local service representative for this adjustment.

( 2 ) Fr o n t p u ll r o lle r

photo-eye

( 3 ) Re a r p u ll roller ph o to -e ye

( 1 ) Main ro ll e r

photo-eye

With the FWD/ REV switch in the REV

position, the PHOTO-EYE at the front of the pull

roller nip (2) is engaged only .

© GBC Films Group February 2001

Page 1 - 3

Page 15

Safety Orca 1600 Operation and Maintenance Manual

1.4 Mechanical safety

WARNING

Never remove or open any guarding or

covers from th e m a chin e. Th ese a re

placed for you protection as well as

the protection o f the m a ch ine.

WARNING

Never place hands, fingers or objects

through any opening of the side fram e. Your

hand or fingers may be pinched or crushed

or you m ay cau se d am g e to the machine.

1.5 Heating safety

The heating components of the Orca 1600 can

reach temperatures of over 200 oF ( 100 oC ).

DANGER

At these temperatures there is a danger of

severe burn if the rolls are touched during

setup, operation or servicing.

In the event of a run away heat failure, the

machine is equipped with a thermal cut off switch.

This switch will remove power to the heating system

before any damage can be caused by the run away

heat failure.

WARNING

W hen sw inging out or in an unw ind,

keep hands and fingers away from

the pivot end. Your hand or

fingers may be pinched.

WARNING

Keep hands and fingers away from the

ends of the removable idlers when

rem oving o r installin g th em at

various loca tions on th e m ach ine.

IN FORMATION

If run aw a y h ea t failure occu rs, call

your loca l service represen tative

before using the m achine again.

CAUTIO N

Neve r leave th e roller in the do w n p osition

w ith o u t r ollin g wh e n th e ro ller s a r e h e a ted .

This w ill ca u s e d a mage to th e r o ller s.

Page 1 - 4

© GBC Films Group February 2001

Page 16

SafetyOrca 1600 Operation and Maintenance Manual

1.6 Maintenance safety

Any maintenance requiring the cabinets to be

opened with electrical power connected should be only

performed by a qualified service technician.

INFORMATION

Only a qualified service technician should

perform any procedure requiring the

cabinet doors to be opened.

1.7 Installation

The following symbols are positioned at

various points in Section 4 Installation.

CAUTION

Failure to follow the pre-installation check

list can result in damage to the laminator.

The word qualified is defined as;

Qualified ;

• Any engineer that has experience with

electrical and mechanical design of lamination

equipment. The engineers should be fully aware of

all aspects of safety with regards to lamination

equipment.

• Any commissioning or service engineer must

be of competent nature, trained and qualified to GBC

Films Group standards to fulfill that job. This person

will have completed and passed the full service

training course from GBC Films Group.

WARNING

The operating environment must be free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors.

WARNING

Vapor build up or stored flammable liquids

can cause a fire. Excessive dust can damage

the laminator.

• Any GBC T echnician, GBC Specialist, and /

or GBC Films Group T echnician that has been through

the GBC Pro-Tech service training course.

© GBC Films Group February 2001

CAUTION

Do not locate the laminator where air is

blowing directly on the machine. The air

flow can cool the rolls unevenly and result

in poor output quality.

Page 1 - 5

Page 17

Safety Orca 1600 Operation and Maintenance Manual

WARNING

The Orca 1600 Laminator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED R IGGERS ONLY to

move the lam inator. The lam inator is not

de sig n e d to b e tip ped u p or sidew a y s in a n y

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requ ires extensive realignm en t. You can

be crushed or seriously injured.

INFORMATION

ALL SHIPMENTS ARE EX-WORKS.

At our

dock, title passes to the buyer. Please review

your insurance coverage prior to shipment,

as you are responsible for all subsequent

freight charges and risks.

INFORMATION

Depending on the destination and customer

preference, your machine may be shipped in

various ways. The laminator may arrive

shrink wrapped or in a plywood crate on a

skid. Please follow the unpacking procedure

that pertains to your method of shipment.

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

INFORMATION

Before signing the Bill of Lading, you

Do not attempt to move the laminator across

without trained and qualified riggers. You

should be sure to inspect the crate

and / or pallet for signs of damage or

missing items; if applicable, make

note of this on the Bill of Lading.

WARNING

The unpacking process requires at least two

people. You can be severely injured, crushed

or cause damage to the laminator.

WARNING

anything other than a flat level surface

can be crushed or seriously injured.

INFORMATION

GBC Film Group's warranty does not

cover malfunction of the equipment due to

mishandling and / or tipping. GBC Films

Group bears no responsibility for personal

injury or damage due to moving the

laminator improperly.

Page 1 - 6

© GBC Films Group February 2001

Page 18

SafetyOrca 1600 Operation and Maintenance Manual

CAUTION

Do not allow the top to fall into the crate. It

can damage the laminator.

INFORMATION

Do not put packing screws on the floor.

They can cause problems when trying to roll

the laminator into position or you can

become injured if stepped on.

INFORMATION

About recycling: The crate components can

be reused for shipping the laminator again

or can be disassembled and the wood and

screws recycled. The shrink wrap is not

recyclable, so it must be discarded.

INFORMATION

En su re sufficien t space f or op en ing of the

cabinets for maintenance and servicing.

CAUTION

A second person must support the side

labeled 5 in Figure 4.5.1 It can fall and

damage the laminator or cause harm to you

and others.

WARNING

Do not attempt to use the ramps if they are

not secured to the pallet. Ensure the pallet is

on a flat even surface before attempting to

roll the machine off.

ELECTRICAL

SHOCK

Only a qualified electrician should connect

power to the laminator. You can be severely

shocked, electrocuted or cause a fire if

power is improperly applied.

ELECTRICAL

SHOCK

On ly a qu alified electrician sho u ld verify

the voltage. Yo u can b e severely sh ock ed ,

electrocuted or ca use a f ire.

© GBC Films Group February 2001

Page 1 - 7

Page 19

Safety Orca 1600 Operation and Maintenance Manual

1.8 Operation

WARNING

Do n o t opera te the m a ch ine w ith th e

control side or drive side cabinet

in th e o p en p o s itio n .

various points in Section 5 Operation.

The following symbols are positioned at

WARNING

ELECTRICAL

SHOCK

Do not op er a te th e la m inator if th e p ower

cord is damaged or frayed. You can be

severely shock ed , electrocuted o r cau se a

fire. Contact a qu alified electrician to

replace the cor d.

IN F OR MATIO N

Th e u pp er m a in roller an d the u p per p u ll

rolle r s h o u ld b e in th e ra is ed p o s itio n .

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

WARNING

W h en the lam in ator rollers are in

motion, keep hands and fingers

away from the nip of the rollers.

You may be CRUSHED or BURNED!

ELECTRICAL

SHOCK

Th ese calibration s req uire th e lam ina tor

to be po w ered u p w h ile the cabin ets

are open ed .

Page 1 - 8

IN FO RMAT ION

Th e la minato r will only turn o n if

all E-ST OPs are un latched .

IN FO RMAT ION

Th e cen ter pos ition is to preven t jam ming

of the m otor when ch an gin g d irections

© GBC Films Group February 2001

Page 20

SafetyOrca 1600 Operation and Maintenance Manual

IN FO RMAT ION

Top tem p eratu re con trol un it on/ o ff

switch must b e o n to t u r n t h e lo wer

temp erature co n trol unit to on .

IN FO RMAT ION

W h en d ecreasin g p ressu re, allow the

pressure g u age to dro p b elow the desired

value, then in crease p ressu re to th e set

pressure d esired . Th is allow s fo r a more

accura te pressu re read ing .

IN FORMATION

When requiring top and bottom heat, it is

recom m en d ed to set both tem p eratu res to

the s a me set point.

INFORMATION

Th e m a xim u m set p oint tem p eratu re

is 270

o

F ( 132 oC ).

IN FO RMAT ION

W hen an emergency stop feature is activated

an d th e main r o ll is in the up p o si tio n , th e

pu ll r o ll will on ly s ta y in the u p positio n

until the em ergen cy stop fea ture is

deactivated.

IN FORMATION

INFORMATION

Th e minim u m set p o in t te m p e ra tu r e

o

is 32

F ( 0 oC ).

IN FO RMAT ION

W hen a safety feature is engaged, the

upper rollers raise and power to

the drive m o tor is rem ov ed.

Th e m o tor m u st be en ga ged fo r the co oling

fans to t u r n o n. If th e fa n sw it ch is in th e

"o n " p o s ition, the fa n s will au to matica lly

turn on wh en the motor is engaged.

© GBC Films Group February 2001

IN FO RMAT ION

Th e u pp er m a in ro ller UP / DOW N switch

resets the ma in ro ller to the correct po sition.

Page 1 - 9

Page 21

Safety Orca 1600 Operation and Maintenance Manual

1.9 Applications

CAUTIO N

Do n o t use an o pen b lade to cu t

the w eb nea r th e rollers.

You ca n p u t cuts into th e rollers!

INFORMATION

The nip can only be changed with the

upper roller in the up position.

IN FO RMAT ION

This w ill p re v ent the p u ll r o llers f ro m

contacting if the a ir shou ld be removed.

The following symbols are positioned at

various points in Section 6 Applications.

WARNING

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

IN FO RMAT ION

For o p timal tempera tu r e s ettin g s o f

various laminates, contact your

supp lier or sales rep resen tative.

Page 1 - 10

IN FO RMAT ION

Gen eral ru le: Sm aller prin ts requ ire m ore

speed or less tem pera ture. L arg er p rints

require less sp eed o r m o re tem per ature.

IN FO RMAT ION

Use film brake tension to control the

separa tion po int of the r elease liner.

© GBC Films Group February 2001

Page 22

SafetyOrca 1600 Operation and Maintenance Manual

INFORMATION

Sp e ed s a n d temper a tu re s will affe c t th e

bond strength of thermal adhesives.

IN F OR MA T ION

Not all papers and inks are compatible with

ther mal film s . T e st th e co mbin a tio n s f irst.

IN F OR MATIO N

CAUTIO N

Excess pressure can damage the laminating

rollers. Alway s u se the m in imu m roll

pressure n ecessa ry to co m p lete the task.

IN FO RMAT ION

Never stop the lam inator when an image is

within the n ip of either set of ro llers.

Th e m o un t ad h esive m u st no t exceed 1 in.

the w idth of the substrate. If it does, you

w ill e xp e rie n ce c omplications with th is

application.

INFORMATION

Ex c es siv e pressu r e will cause the

substrate to bow or flatten.

IN FORMATION

IN FO RMAT ION

Lam inates and papers should always be

stored in a co n trolled en virom en t.

Excessive brake tension may cause the

imag e to curl. A lw ays u se the minimum

amoun t of brake for the job.

© GBC Films Group February 2001

Page 1 - 11

Page 23

Safety Orca 1600 Operation and Maintenance Manual

1.10 Troubleshooting

The following symbols are positioned at

various points in Section 7 Troubleshooting.

WARNING

Do not wear ties, loose fitting clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

1.11 Maintenance

The following symbols are positioned at

various points in Section 8 Maintenance.

WARNING

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

INFORMATION

For optimal temperature settings of

various laminates, contact your

supplier or sales representative.

WARNING

Do not wear ties, loose fitting clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

INFORMATION

Improper maintenance, can

result in poor output quality.

ELECTRICAL

SHOCK

Remove power from the laminator before

servicing. You can be severely shocked,

electrocuted or cause a fire.

INFORMATION

Below is a recommended maintenance

schedule. Before performing any of the steps

listed, read through the procedures first.

Please follow the instructions pertaining to

the step you are performing.

Page 1 - 12

© GBC Films Group February 2001

Page 24

SafetyOrca 1600 Operation and Maintenance Manual

CAUTIO N

Use o nly isop rop yl alcoh ol or ru b b er cem en t

eraser to clean th e rollers. Ha rsh chemicals

like toluene, aceton e, or MEK can d estroy

the silicone covering of th e rolls.

CAUTIO N

Exer cise care w h en cleanin g the la m inating

rolle rs with 80 % is op r o p y l a lco h o l:

Us e o nly in a well ve n tila ted area

W ear rubber gloves

Use o nly on co ol rolls

CAUTIO N

CLEANING HEATED ROLLERS CAN

IGNITE THE FUMES!

CAUTIO N

Do NO T pick or pull heat activated adhesive

off the rolls w h en th ey a re cold. Y o u ca n

cause irrepa rab le da m ag e to the

lam inating r ol ls.

CAUTIO N

Ex c es siv e pressu r e c an des tro y th e silico n e

layer by pressing to hard or scrubbing

too long in one spot.

IN FO RMAT ION

Keep the terry cloth tow el k ind of d am p to

mak e th e rub b ing of the roller sm ooth .

ELECTRICAL

SHOCK

Do not use liquid or aerosol cleaners on the

laminator. Do not spill liquid of any kind on

the laminator. You can be severely shocked,

electrocuted or cause a fire. Use only a damp

cloth for cleaning unless other wise

specified.

© GBC Films Group February 2001

Page 1 - 13

Page 25

Safety Orca 1600 Operation and Maintenance Manual

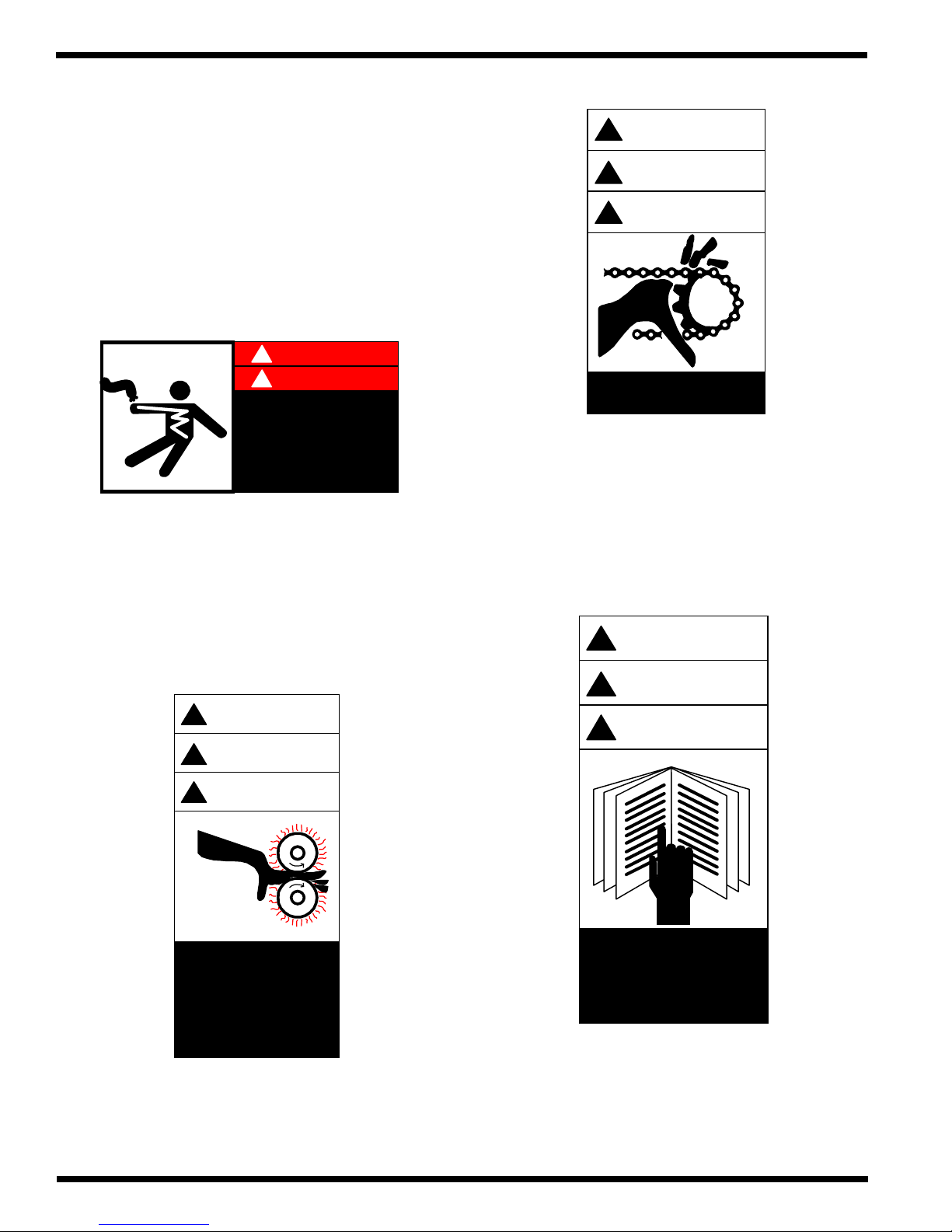

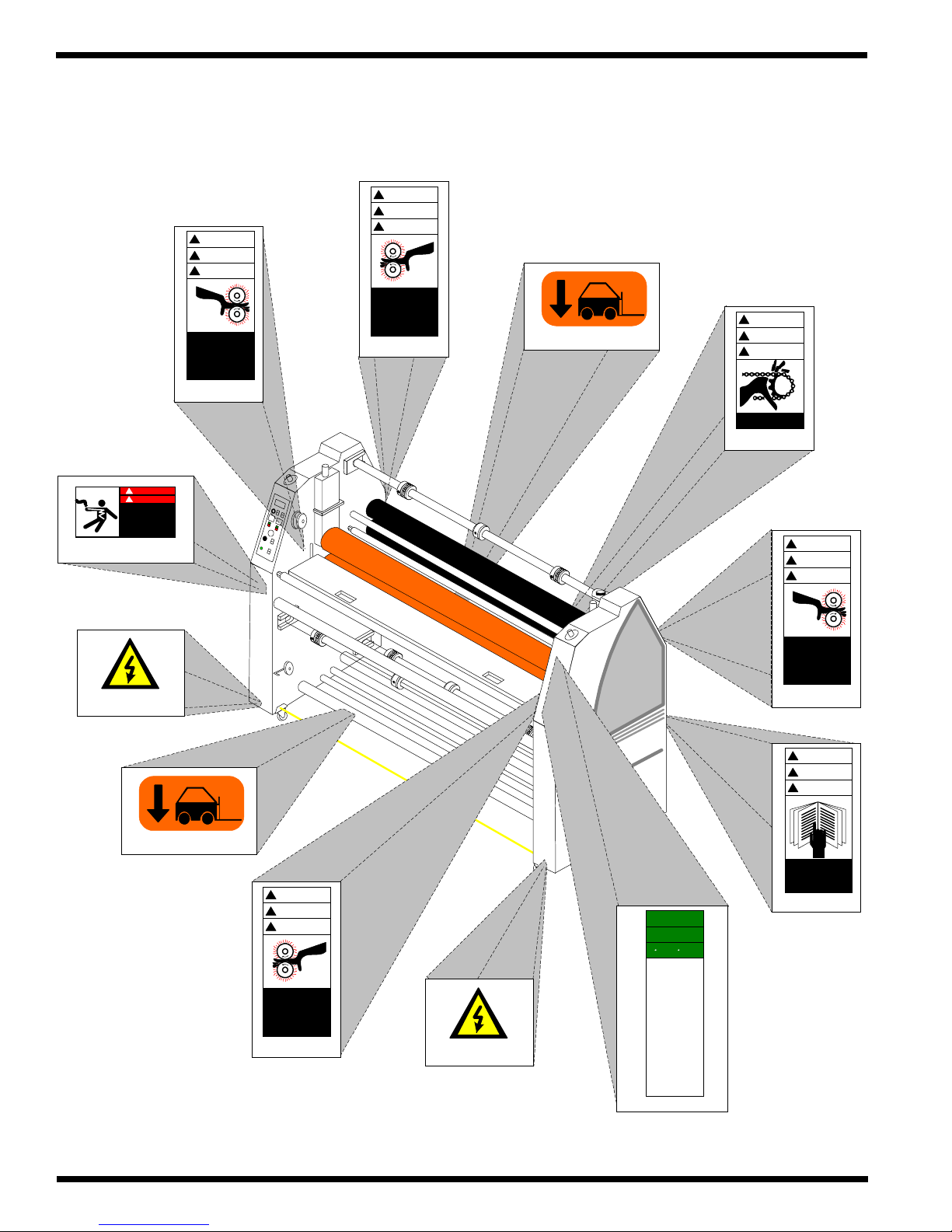

1.12 Label locations

WARNING

!

ACHTUNG

Posted at various locations on the Orca 1600

Laminator are important safety labels. Pay careful

attention to these labels at all times! Figure 1.12.1

illustrates the location of each of these labels.

!

DANGER

!

GEFAHR

HAZARDOUS

VOLTAGE

To be serviced only

by trained and

authorized personnel.

Lockout power b efore

servicing

Moving Parts: Keep hands and fingers away . You

may be crushed and/ or cut.

!

M ISE EN GARDE

!

Moving parts can

crush and cut.

Hazardous Voltage: Do not open these cabinets.

This machine is to be serviced only by trained and

authorized personnel.

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Crush and burn

haza rd. S tay clear

of moving rollers.

Stop m achine and

raise roll befo re

cleaning.

WARNING

!

ACHTUNG

!

M ISE EN GARDE

!

Carefully read Operator's

Manual before handling

this machine. Observe

instructions and safety

rules when operating.

Roller Pinch Point: Keep hands and fingers away .

You may be crushed and/ or burned.

Page 1 - 14

Read Manual: Read and understand the Operations

Manual before attempting to run this machine.

© GBC Films Group February 2001

Page 26

SAFETY

INSTRUCTIONS

SICHERHEITSRICHTLINIEN

CONSIGNES DE

SECURITE

1. Read and un derstan d the O peration

M a n ualand a ll s a fety lab e ls before

ope r a ting thi s m achin e .

2. Only a trained person is to be

per m itted to o p erate th is mac h ine.

Tr a in in g sho u ld includ e in struct io n

in operation under normal conditions

and emergency situations.

3. This machine is to be serv iced on ly

by trained and authorized personnel.

Follo w lock o u t proc e d ures b e f o r e

servicing.

4. Never reach into the m ach ine for any

reason unless the m a ch ine is at a

CO M PLE TE S T OP.

5. Never leave the m ach ine stop ped in

such a m ann er that an other w o rker can

start the machine while you are working

on o r within th e m achin e .

6. Never change or defeat the function of

elec tr ic al interlo c k s or oth e r m achin e

" sh utdow n " switc h es.

7. Before starting this machine, check that:

- All persons are clear of the machine.

- No m ainten a nce wo rk is be in g perfo r m ed

on t h e mac h i n e .

-All g u ards ar e in place .

-All parent rolls are well chucked in the

unwind stands.

- The ma ch ine is free of paper scra ps ,

wra p s and ja ms.

8. There is potential hazard of entaglemen t

in th is m achin e caus e d by item s such as

long hair, loo se clot h i n g , and jew elry.

Make sure your clothing and hair fit

clos e ly to yo u r body and th a t a ll je w elry,

rings and watches are removed.

SafetyOrca 1600 Operation and Maintenance Manual

Lift Here: This point may be used as a lifting point.

If ignored, damage will occur to the laminator.

Refer to Figure 1.12.1 illustrates the

location of each of these labels.

Safety Instructions: Read this label first before all

else!

Electrical Shock: Live voltage present. Exercise

extreme caution. You may be electrocuted!

© GBC Films Group February 2001

Page 1 - 15

Page 27

Safety Orca 1600 Operation and Maintenance Manual

y

p

p

g

p

g

y

p

g

y

pp

y

g

g

g

p

g p

g

p

p

y

g

y

y

g

g

y

Figure 1.12.1 Label placement

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Crush and burn

hazard. Stay clear

of mo ving rolle r s.

Stop machine and

raise roll before

cleaning.

( Back of cabinet )

( x 2 in re ar )

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Moving parts can

crush and cu t.

( Left side frame )

!

!

!

WARNING

ACHTUNG

MISE EN GARDE

!

DANGER

!

GEFAHR

HAZARDOUS

VOLTAGE

To be serviced only

by trained and

authorized personnel.

Lockout power before

servicing

( Front of cabinet

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Crush and burn

hazard. Stay clear

of mo ving rolle r s.

Stop machine and

raise roll before

cleaning.

( Right sid e frame )

( Front of cabinet )

( x 2 in front )

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Crush and burn

hazard. Stay clear

of mo ving rolle r s.

Stop machine and

raise roll before

cleaning.

( Left side frame )

( Front of cabinet )

Crush and burn

hazard. Stay clear

of mo ving rolle r s.

Stop machine and

raise roll before

cleaning.

( Ba c k o f c abinet )

00

6

1

A

C

R

O

Pro - Tech

C

B

G

SAFETY

INSTRUCTIONS

SICHERHEITSRICHTLINIEN

CONSIGNES DE

SECURITE

1. Read and understand the Operation

Manualan d a ll safe t

labels before

o

erating this machine.

2. Only a trained person is to be

ermitte d to operate this machine .

Trainin

should include instruction

in o

eration under normal conditions

and emer

ency situations.

3. This machine is to be servic e d o nl

by trained and authorized personnel.

rocedures before

Follow lockout

servicin

.

4. Never reach into the machine for an

reason unless the machine is at a

COMPLETE STO P .

5. Never leave the machine sto

ed in

such a manner that another worker can

ou are workin

start the machine w hile

on or within the m achine.

e or defeat the function of

6. Never chan

electrical interlock s or othe r m a chin e

" shutdown " switches.

this machine, check that:

7. Before startin

- All

ersons are clear of the machine.

erformed

- No maintena nce w ork is bein

on the ma chine .

-All

uards are in place.

arent rolls are w e ll ch ucke d in the

-All

unwind stands.

- The machin e is free of paper scraps,

wra

s and jams.

8. There is potential hazard of entaglement

in this machine ca used b

item s such as

hair, loose clothing, and jewelry.

lon

Make sure

our clothing and hair fit

to your body and that all jewelry,

closel

s and watches are removed.

rin

WARNING

!

ACHTUNG

!

MISE EN GARDE

!

Carefully read Operator's

Manual before handlin

this machine. Observe

instructions and safet

rules when operating.

( Ba c k o f c abinet )

Front of cabinet

Page 1 - 16

© GBC Films Group February 2001

Page 28

2.0 Warranty

GBC Films Group warrants the equipment sold

is free from defects in material and workmanship for a

period of one ( 1 ) year parts and 90 days labor from

the date of installation. This warranty is the only warranty

made by GBC Films Group and con not be modified or

amended.

GBC Films Group’s sole and exclusive

liability and the customer’s sole and exclusive

remedy under this warranty shall be, at GBC Films

Group’s option, to repair or replace any such

defective part or product. These remedies are only

available if GBC Films Group’s examination of the

product discloses to GBC Films Group’ s satisfaction

that such defects actually exist and were not caused

by misuse, neglect, attempt to repair , unauthorized

alteration or modification, incorrect line voltage, fire,

accident, flood, or other hazard.

WarrantyOrca 1600 Operation and Maintenance Manual

CAUTION

Unauthorized customer alterations will

void this warranty.

THE WARRANTY MADE HEREIN IS IN

LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING

ANY WARRANTY OR

MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. GBC

PRO-TECH WILL NOT BE LIABLE

FOR PROPERTY DAMAGE OR

PERSONAL INJURY ( UNLESS

PRIMARILY CAUSED BY ITS

NEGLIGENCE ), LOSS OF PROFIT OR

OTHER INCIDENTAL OR

CONSEQUENTIAL DAMAGES

ARISING OUT OF THE USE OR

INABILITY TO USE THE EQUIPMENT.

2.1 Limited Warranty

This warranty specifically does not cover damage

to the laminating rollers caused by knives, razor blades,

other sharp objects, failure caused by adhesives or

improper use of the machine. Warranty repair or

replacement does not extend the warranty beyond the

initial one year period from the date of delivery .

© GBC Films Group February 2001

2.2 Exclusions to the

Warranty

This warranty specifically does not

cover;

1. Damage to the laminating rollers caused by knives,

razor blades, other sharp objects or failure caused

by adhesives.

Page 2 - 1

Page 29

Warranty Orca 1600 Operation and Maintenance Manual

2. Damage to the machine caused by lifting, tilting and/

or any attempt to position the machine other than

rolling on the installed castors on even surfaces.

3. Improper use of the machine.

4. Damage due from unqualified person(s) servicing the

machine.

Qualified

• Any engineer that has experience with electrical

and mechanical design of lamination equipment.The

engineers should be fully aware of all aspects of safety

with regards to lamination equipment.

• Any commissioning or service engineer must be

of competent nature, trained and qualified to GBC ProT ech standards to fulfill that job. This person will have

completed and passed the full service training course from

GBC Pro-T ech.

• Any GBC T echnician, GBC Specialist, and / or

GBC Pro-T ech Technician that has been through the GBC

Pro-T ech service training course.

Page 2 - 2

© GBC Films Group February 2001

Page 30

3.0 Specifications

Specifications provide all of the technical data for

the Orca 1600 Laminator .

3.1 General

SpecificationsOrca 1600 Operation and Maintenance Manual

Description:

Features:

• Mid level, wide format color finisher for the sheet fed

ink jet market. The Orca 1600 is a self standing,

bi-directional laminator ..

• T wo swing out film unwinds ( 1 upper, 1 lower )

• One swing out print unwind

• T wo rewinds ( 1 upper front, 1 lower rear center )

• Infeed and oufeed tables

• Pressure plate

• Footswitch

• Bi-directional operations

• Four emergency stop push buttons ( E-STOPs )

• Front and rear emergency cables ( E-CABLEs )

• Photo-electric nip sensors

• Independent top and bottom heater units

• T wo fixed web tension idlers ( 1 lower, 1 upper )

• Three repositionable web idlers

• No slip core grip chucks ( 2 per unwind )

• Speed ranges from 0 to 15 ft/min ( 0 - 4.6 m/min )

• Pneumatic air cylinders for roller nip control

• T wo removable cooling ducts ( 1 upper, 1 lower )

• Multiple thermal protection circuitry

Applications:

© GBC Films Group February 2001

• Single sided lamination

• Encapsulation

• Mounting

• Decaling

Page 3 - 1

Page 31

Specifications Orca 1600 Operation and Maintenance Manual

3.2 Consumables

Film types:

Film diameters:

Core size:

Film widths:

• Pressure sensitive laminates

• Pressure sensitive adhesives

• Low melt laminates

• Thermal laminates

• Thermal adhesives

• Up to a 10 in. roll diameter ( 25.4 cm )

• 3 in. core standard ( 7.62 cm )

• 64 in. maximum pressure sensitive ( 163 cm )

• 62 in. maximum thermal ( 158 cm )

Paper widths:

Mounting thickness:

Safety:

Rewind tubes:

• 63 in. maximum paper width ( 160 cm )

• Up to 1 in. thick ( 2.54 cm ) either direction

• Designed to UL / CSA / CE safety standards

• 3 in. diameter x 66-3/8 in. length (7.62 x 168.59 cm)

Page 3 - 2

© GBC Films Group February 2001

Page 32

Section 3.3 Function

SpecificationsOrca 1600 Operation and Maintenance Manual

Speed:

Motor:

Heating capabilities:

Controls:

Heater controls:

• 0 - 15 ft / min ( 0 - 4.6 m / min )

• 2-1/4 horse power drive motor

• Bi-directional D.C. motor

• 68oF - 270oF ( 20oC - 132oC )

• Front control panel

• Rear control panel

• Footswitch

• Independent Cal 3200 control units

Rollers:

Roll design:

• Heat capable upper and lower main rollers

• Driven lower main roller

• Free spinning upper main roller

• Pneumatic controled lower pull roller

• Free spinning upper pull roller

• High release silicone rollers

© GBC Films Group February 2001

Page 3 - 3

Page 33

Specifications Orca 1600 Operation and Maintenance Manual

Section 3.4 Electrical

United States and Canada:

Europe:

B.T .U. output:

Heater wattages:

Amperage draw:

• 230 - 240 V AC, 50/60 Hz, single phase, 55 amps.

• 230 - 240 VAC, Wye 3 phase, 25 amps/ phase

• 34,120 B.T .U. / hour

• 5000 watts per heater

• No heat, motor only : 1 - 3 amps

• T op heat and motor : 20 - 23 amps

• Both heat and motor : 40 - 43 amps

D/C voltage used:

A/C voltage used:

AIR

Compressor requirements:

• 24 vdc

• 230 vac ( minimum )

• Filtered air at 2 cubic feet per minute ( cfm ), 50 liters/

minute at a pressure of 70 pounds per square inch ( psi )

( 500 kPa ).

Page 3 - 4

© GBC Films Group February 2001

Page 34

Section 3.5 Dimensions

Weight:

SpecificationsOrca 1600 Operation and Maintenance Manual

Crated:

Uncrated:

Dimensions

Crated:

Uncrated

• 2800 lbs. ( 1270 kg. )

• 2300 lbs. ( 1043 kg. )

• 75 in. (H) x 43 in. (W) x 102 in. (L)

( 191 cm (H) x 109 cm (W) x 259 cm (L) )

• 60 in. (H) x 33 in. (W) x 82 in. (L)

( 152 cm (H) x 84 cm (W) x 208 cm (L) )

Refer to Figure 3.5.1

Nip Height:

• 35 1/5 in. ( 90 cm )

© GBC Films Group February 2001

Page 3 - 5

Page 35

Specifications Orca 1600 Operation and Maintenance Manual

Figure 3.5.1 Dimensions

33 in.

( 84 c m )

82 in.

( 208 cm )

0

60 in.

0

6

1

A

C

R

O

h

c

e

- T

o

r

P

GBC

( 152 cm )

Page 3 - 6

© GBC Films Group February 2001

Page 36

InstallationOrca 1600 Operation and Maintenance Manual

4.0 Installation

GBC Films Group is committed to a program of

ongoing product improvement. As a result, we are

providing these instructions so you can insure that your

new Orca 1600 Laminator is properly and securely

unpacked, moved, and installed.

Before an Orca 1600 Laminator can be installed,

there are a few requirements that must be met. Make

certain that each of the requirements listed in the following

pre-installation checklist are met before beginning

installation.

CAUTION

Is the environment appropriate for the laminator?

The laminator requires a clean, dust and vapor

free environment to operate properly . It must not

be located where there is air blowing directly on

the machine

Have you contacted a certified electrician to both

wire the laminator and ensure that adequate power

is being supplied, having the appropriate capacity ,

over current protection and safety lockouts are

available?

WARNING

The operating environment must be free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors.

Failure to follow the pre-installation check

list can result in damage to the laminator.

4.1 Pre-installation

Are doorways and hallways wide enough for the

laminator to be moved to the installation site?

Is there ample room for the laminator?

A work area must be established that allows for

operation in both the front and rear of the

laminator and provides space for efficient material

flow . Figure 4.1.1 illustrates a typical machine

area layout.

WARNING

Vapor build up or stored flammable

liquids can cause a fire. Excessive

dust can damage the laminator.

CAUTION

Do not locate the laminator where air is

blowing directly on the machine. The air

flow can cool the rolls unevenly and result

in poor output quality.

© GBC Films Group February 2001

Page 4 - 1

Page 37

Installation Orca 1600 Operation and Maintenance Manual

The laminator requires 230 to 240 vac, 50/ 60

Hz, 55 amps. Or, in Europe only, 3-N phase,

240 vac, 32 amps/ phase.

WARNING

The Orca 1600 Laminator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED R IGGERS ONLY to

move the lam inator. The lam inator is not

de sig n e d to b e tip ped u p or sidew a y s in a n y

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requ ires extensive realignm en t. You can

be crushed or seriously injured.

For instructions on how to connect power,

proceed to 4.7 Electrical connection in this section.

Page 4 - 2

© GBC Films Group February 2001

Page 38

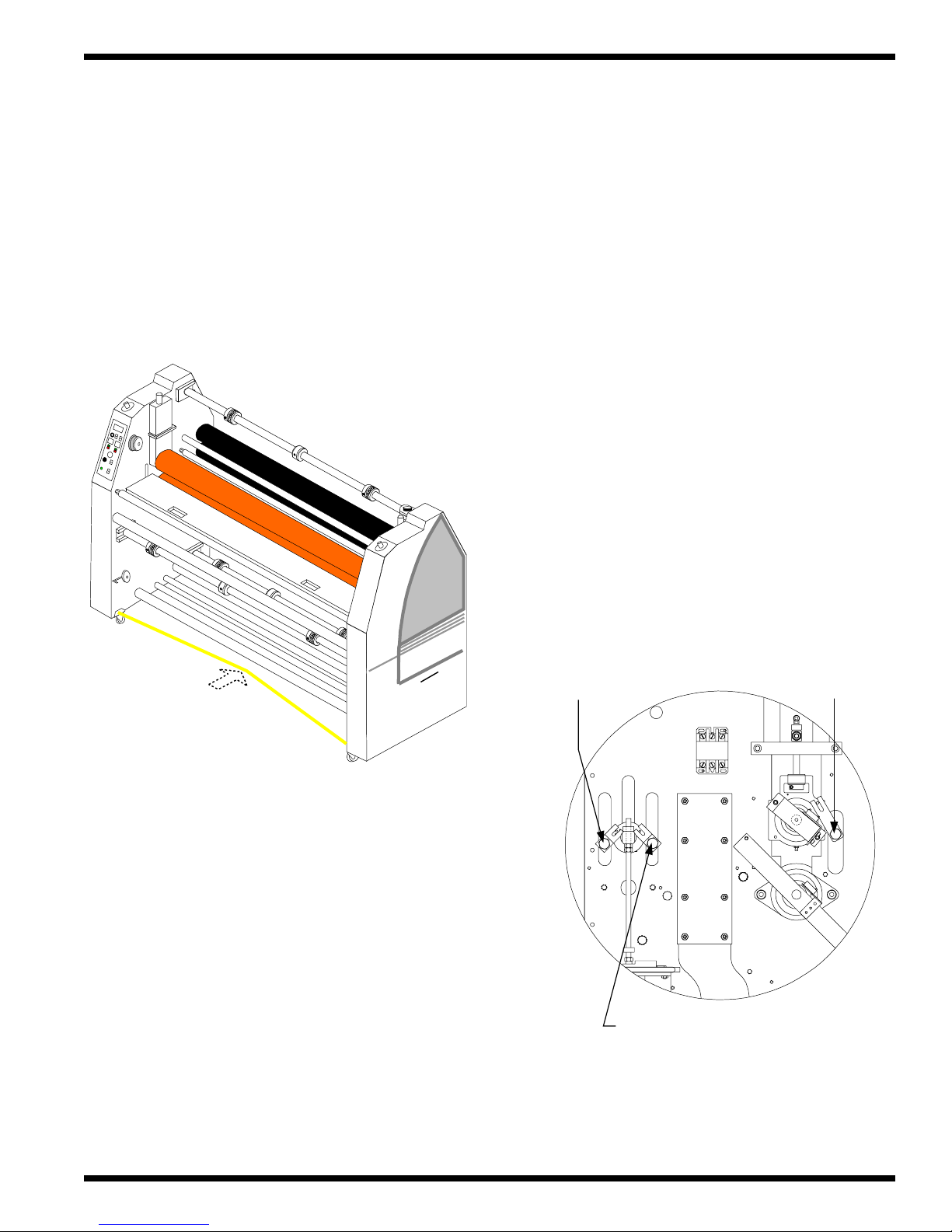

Figure 4.1.1 Suggested Floor Layout

InstallationOrca 1600 Operation and Maintenance Manual

4 ft. x 6 ft.

20 ft.

( 508 ) cm

Air compressor

or air line drop

Electrical cord

drop

8 ft 8 in

( 220 cm )

(101.6 x 152 cm)

W ork table on wheels

Back

3 ft

( 91 c m )

Front

© GBC Films Group February 2001

8 ft 8 in

( 220 cm )

4 ft. x 6 ft.

(101.6 x 152 cm)

W ork table on wheels

13 ft

( 330 cm )

Page 4 - 3

Page 39

Installation Orca 1600 Operation and Maintenance Manual

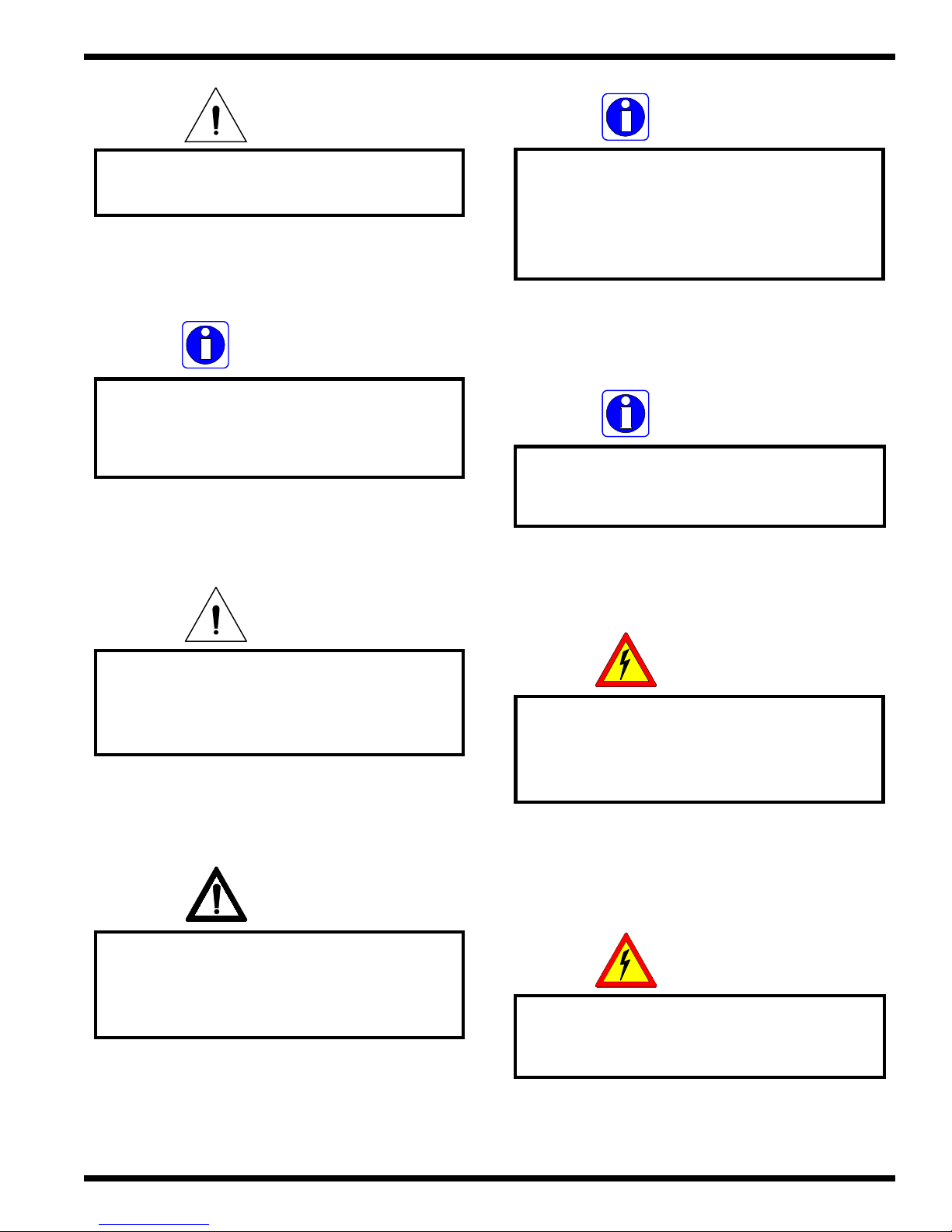

4.2 Know your machine

Before performing any procedure within this

manual, it is recommended that you take time to know

the parts of your new machine.

Figure 4.2.1 The laminator

Control side

Rear

Figure 4.2.3 Front view

Front

control

panel

Lower unwind

Rewind brake

Cardboard

rewind tube

Middle unwind

Motor

E-STOP

E-CABLE

Leveling

pad

Front

Figure 4.2.2 Top view

Rear table

Pu ll ro lle r s

Upper unwind

ORCA 1600

Pro - Tech

C

B

G

Drive side

Upper unwind brake

Rear table

bracket

Figure 4.2.4 Rear view

E-STOP

Core chuck

Core support

Permanent Id ler

Rear

control

panel

Circuit

breaker

Ma in ro llers

Fro n t ta b le

Table idler

Pressure plate

Page 4 - 4

Ma in ro lle r

shim dial

Castor

Tie bar

Pu ll ro lle r

shim dials

Unwind saddle

© GBC Films Group February 2001

Page 40

InstallationOrca 1600 Operation and Maintenance Manual

4.3 Unpacking

INFORMATION

ALL SHIPMENTS ARE EX-WORKS.

dock, title passes to the buyer. Please review

your insurance coverage prior to shipment,

as you are responsible for all subsequent

freight charges and risks.

INFORMATION

Before signing the Bill of Lading, you

should be sure to inspect the crate

and / or pallet for signs of damage or

missing items; if applicable, make

note of this on the Bill of Lading.

At our

With regards to your shipping method, use one of

the following procedures described to safely and properly

unwrap / uncrate your laminator .

4.4 Shrink Wrapped

a) Inspect the machine for any obvious shipping

damages upon receipt.

b) Carefully unwrap the shrink wrap from around

the laminator .

CAUTION

INFORMATION

Depending on the destination and customer

preference, your machine may be shipped in

various ways. The laminator may arrive

shrink wrapped or in a plywood crate on a

skid. Please follow the unpacking procedure

that pertains to your method of shipment.

WARNING

Do not attempt to move the laminator across

The unpacking process requires at least two

people. You can be severely injured, crushed

or cause damage to the laminator.

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

c) With another person, carefully wheel your

Orca 1600 Laminator to the installation site.

WARNING

anything other than a flat level surface

without trained and qualified riggers. You

can be crushed or seriously injured.

© GBC Films Group February 2001

Page 4 - 5

Page 41

Installation Orca 1600 Operation and Maintenance Manual

4.5 Crated

WARNING

The Orca 1600 Laminator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED R IGGERS ONLY to

move the lam inator. The lam inator is not

de sig n e d to b e tip ped u p or sidew a y s in a n y

way. Such action disturbs the exact

alignment of the rolling parts of the machine

and requ ires extensive realignm en t. You can

be crushed or seriously injured.

4.5.1 Uncrate the laminator

a) Remove the top of the crate and then the sides

in the order shown in Figure 4.5.1

CAUTION

Do not allow the top to fall into the crate. It

can damage the laminator.

INFORMATION

GBC Film Group's warranty does not

cover malfunction of the equipment due to

mishandling and / or tipping. GBC Films

Group bears no responsibility for personal

injury or damage due to moving the

laminator improperly.

Tools required

• # 2 Phillips head screwdriver

• 7/8” open end wrench or adjustable wrench

• Crow bar

• A second person

INFORMATION

Do not put packing screws on the floor.

They can cause problems when trying to roll

the laminator into position or you can

become injured if stepped on.

CAUTION

A second person must support the side

labeled 5 in Figure 4.5.1 It can fall and

damage the laminator or cause harm to you

and others.

Page 4 - 6

© GBC Films Group February 2001

Page 42

InstallationOrca 1600 Operation and Maintenance Manual

Figure 4.5.1 Disassembling of the crate

3

Remove This Side

4

1

5

ORCA 160 0

Pro - Tech

GBC

4.5.3 Moving the laminator

a) Have the laminator removed off of the skid one of

two methods:

1) Rolled off the skid and placed on the floor by

licensed riggers using the included ramps. The

ramps must be secured utilizing screws

removed from the disassembled crate.

2

4.5.2 The shrink wrap

a) Gently unwrap the shrink wrap from around the

laminator.

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

WARNING

Do not attempt to use the ramps if they are

not secured to the pallet. Ensure the pallet is

on a flat even surface before attempting to

roll the machine off.

2) Lifted off of the skid with a forklift by positioning

the forks where indicated by fork lift decals

located on the tie bars on the machine.

b) Move all packing materials to a safe distance.

© GBC Films Group February 2001

Page 4 - 7

Page 43

Installation Orca 1600 Operation and Maintenance Manual

b) Remove any plastic strapping and/or packing

paper taped to the rollers.

CAUTION

Do not use a knife or other sharp object to

remove the shrink wrap from around the

laminator. You can cause irreparable

damage to the rollers.

c) Remove all packing materials to a safe distance

from the laminator and dispose of properly .

e) Consider the following when determining where

to locate your machine;

WARNING

Th e op erating en viron m en t m ust b e free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors.

WARNING

Vapor build up or stored flammable liquids

can cause a fire. Excessive dust can damage

the la mina tor .

INFORMATION

About recycling: The crate components can

be reused for shipping the laminator again

or can be disassembled and the wood and

screws recycled. The shrink wrap is not

recyclable, so it must be discarded.

d) Use two people to carefully roll the laminator to

the desired location.

WARNING

Do not attempt to m o v e th e la minato r a c ro ss

anything other than a flat level surface

without trained and qualified riggers. You

can b e cru shed o r seriou sly injured .

CAUTIO N

Do n o t locate the lam ina tor w h ere air is

blow ing directly on the machine. Th e a ir

flow can cool th e rolls un even ly an d resu lt in

poor quality output.

INFORMATION

En su re sufficien t space f or op en ing of the

cabinets for maintenance and servicing.

Page 4 - 8

© GBC Films Group February 2001

Page 44

InstallationOrca 1600 Operation and Maintenance Manual

4.6 Accessory pack

Once the Orca 1600 Laminator has been

unpacked and moved into final position, open the accessory

pack and verify the contents.

Accessory Pack contents

• One T-handle allen wrench ( 475-200 )

• One Zippy knife ( 475-620 )

• One T erry clothe towel ( 475-950 )

• One Operators manual ( 930-061 )

• One roll masking tape ( 475-000 )

• T wo Polyurethane O-rings ( 480-005 )

• One strain relief for main power ( 175-201 )

• One rubber cement pad ( 930320 )

• Four fuses, 3.0A ( 186-200 )

• Four leveling pads ( 475-100 )

4.7 Electrical Connection

The Orca 1600 laminator requires 220 ~ 240

VAC electrical power for proper operation. The power

supply may be either single phase or three phase ( five

wire or four wire ). For single-phase power, a 55 amp

service is required and for three-phase power, 25 amps

per phase is required.

The Orca 1600 requires the electrical power cord

to be wired directly to the line terminal block located within

the control side cabinet.

Before the machine is installed, a qualified

electrician must route the proper wiring to the location

where the machine will be stationed. The machine then

can be connected to the power supply by a qualified

electrician following one of the three instructions listed

below .

If you are missing any of the items listed above,

contact your local service technician or sales

representative.

Contacts:

GBC Parts ( 800 ) 790 - 7787

GBC Europe parts 33 - 45 - 535 - 7676

© GBC Films Group February 2001

ELECTRICAL

SHOCK

Only a qualified electrician should connect

power to the laminator. You can be severely

shocked, electrocuted or cause a fire if

power is improperly applied.

4.7.1 Preparation

a) Ensure the power at the junction box is in the

OFF position. Use a voltage meter to verify.

Page 4 - 9

Page 45

Installation Orca 1600 Operation and Maintenance Manual

g

g

g

b) Open the control side cabinet by removing the

four hex button head screws with a 5/32 in. allen

wrench.

Bolts

34

32

8

9

10

24

7

3111

11

6521

1

22

2

A1A2

12

4

3

14

34

32

8

9

10

24

7

3111

11

6521

1

F+P2P3 I1P1 L1F- L2A+A-

22

2

A1A2

4

14

3

12

34

32

9

10

7824

3111

11

6521

1

22

2

A1A2

12

4

3

14

34

8

32

9

10

24

7

3111

11

6521

1

22

2

A1A2

3

12

4

14

O

4

1

34

I

32

U

9

8

10

N

T

24

7

P

3111

P

11

U

6521

U

1

3

T

2

T

22

2

A1A2

14

3

12

4

34

32

9

10

7824

3111

11

6521

1

22

O

2

4

1

A1A2

12

4

I

14

3

U

N

T

34

32

8

P

9

P

10

24

7

U

U

3111

11

3

T

2

T

6521

1

22

2

A1A2

3

12

4

14

+ -

BA

PEB EA

AB

EAEB P

Figure 4.7.1 Single phase ( 3 wire )

Hot LegHot Leg

Blue Wires

Ground

Gound

Wire

Red W ires

L 6 L 4 L 2

L 5 L 3 L 1

Figure 4.7.2 Delta three phase ( 4 wire )

Cut here

Jumper

Bar

Line terminal block

Stra in re lie f

c) Remove the power cable strain relief ( 175-201 )

from the accessory box and install it at the lower

rear hole of the control side cabinet.

d) Connect the power cord to the line terminal

block. Refer to the correct Figure for your

connection. Jumper bars may require removing

or cutting.

Blue WiresRed W ires

L 6 L 4 L 2

L 5 L3 L 1

Gound

Wire

Terminal

connecter

Jumper Bars

Position

Hot Le

Red Wires

L 6 L 4 L 2

L 5 L 3 L 1

Hot Le

Blue Wires

Hot Le

Ground

Gound

Wire

Jumper Wire

Figure 4.7.3 Wye three phase ( 5 wire )

Blue Wires

Gound

Wire

Remove

Jumper Bars

Red W ires

L 6 L 4 L 2

L 5 L 3 L1

Jumper Bars

Page 4 - 10

Hot Leg

Hot Leg

Hot Leg

Neutral Leg

Ground

© GBC Films Group February 2001

Page 46

InstallationOrca 1600 Operation and Maintenance Manual

e) Turn the junction box power to the ON

position.

f) Verify line voltage with regards to the type of

power being supplied to the laminator at the line

terminal block.

ELECTRICAL

SHOCK

On ly a qu alified electrician sho u ld verify

the voltage. Yo u can b e severely sh ock ed ,

electrocuted or ca use a f ire.

g) Once the power has been properly connected,

continue with 4.8 Air connection before closing

the control side cabinet.

4.8 Air connection

The laminator requires filtered air at 2 cubic feet

per minute (cfm), 50 liters/minute at a pressure of 70

pounds per square inch (psi) (500 kPa). The air supply

must be clean (free of dirt) and dry . Moisture causes

corrosion and particles can block the pneumatic controls.

Either problem can cause the laminator to malfunction.

It is the customer’s responsibility to provide

appropriate filters and water traps for the air hose before

the air is routed to the laminator . GBC suggests that the

best approach to the air requirement is to provide a

dedicated small compressor for the laminator . A standard

light duty 1/2 to 3/4 horse power (1 kW) electric air

compressor with 1.5 to 2.5 cfm output with a 5 gallon

(20 liter) storage tank is appropriate.

WARNING

Do n o t opera te the m a ch ine w ith th e

control side or drive side cabinet

in th e o p en p o s itio n .

ELECTRICAL

SHOCK

Do not op er a te th e la m inator if th e p ower

cord is damaged or frayed. You can be

severely shock ed , electrocuted o r cau se a

fire. Contact a qu alified electrician to

replace the cor d.

a) Once a quick disconnect is attached to the end of

the hose from the compressor, connect the air to

the air filter located on the machine.

Air filter

Quick-

disconnect

© GBC Films Group February 2001

Page 4 - 11

Page 47

Installation Orca 1600 Operation and Maintenance Manual

b) Set the main air in pressure to 70 pounds per

square inch (psi) (500 kPa) by turning the air

regulator knob.

100

Regulator

knob

4.9 Installing levelers

Leveling of the machine is a customer option. If

you choose not to level the laminator and you encounter

output problems, please level the machine and try your

application again before calling for technical support.

Resting the laminator on the leveling pads will prevent the

machine from rolling during set up, operation or servicing.

Tools required

• ( 1 ) 1/2 in. open end wrench

• ( 1 ) 7/8 in. open end wrench

• Four leveling pads

( from the accessory pack )

IN F OR MAT ION

Th e u pp er m a in roller an d the u p per p u ll

rolle r s h o u ld b e in th e ra is ed p o s itio n .

c) Close the control side cabinet and secure with the

factory bolts.

a) Be sure that the machine is placed where you

want it to rest.

b) Secure the four leveling pads onto the four foot

bolts.

c) Use the 1/2 in. wrench on the foot bolt and the

7/8 in. wrench on the leveling pads and tighten

them together.

Page 4 - 12

1/2 Wrench

7/8 Wrench

© GBC Films Group February 2001

Page 48

InstallationOrca 1600 Operation and Maintenance Manual

4.10 Leveling

Leveling of the machine is an important step in

assuring that the equipment will run at it’s optimal speed

and capabilities with little adjustments as possible.

a) Use the foot bolt to raise/ lower the machine so

that the bubble in the leveler is centered.

Center the bubble

c) Place the leveler on the control side frame, not

the top of the cabinet, and level the machine from

front to rear.

Place level here

0

0

6

1

A

C

R

O

ro - Tech

P

C

B

G

1/2 in.

Wrench

b) Place the leveler on the lower front tie bar and

level the machine from left to right.

e) Do the same for the drive side.

Place level here

0

0

6

1

A

C

R

O

Pro - Tech

GBC

Plac e lev e l h er e

© GBC Films Group February 2001

f) Place the leveler on the lower rear tie bar and

level the machine from left to right.

0

0

6

1

A

C

R

O

ro - Tec h

P

C

B

G

g) V erify all sides to confirm that the machine is level.

Page 4 - 13

Page 49

Installation Orca 1600 Operation and Maintenance Manual

4.11 Calibrations

The following calibrations should be performed

by a qualified GBC technician before the machine is to be

operated. These calibrations may not be performed by

the operator . Improper calibrations can result in poor

lamination output.

ELECTRICAL

SHOCK

Th ese calibration s req uire th e lam ina tor

to be po w ered u p w h ile the cabin ets

are open ed .

a) The main roller nip is to be calibrated.

b) The pull roller nip is to be calibrated.

c) All three photo-eyes are to be calibrated.

d) The drive chains are to be checked and

tensioned if necessary .

e) Air rate on both set of rollers are to be checked.

f) Safety check and control panel operation checks

are to be performed.

Page 4 - 14

© GBC Films Group February 2001

Page 50

Orca 1600 Operation and Maintenance Manual

Operations

5.0 Operations

WARNING

Do not wear ties, loose fit clothing or

dangling jewelry while operating or

servicing the laminator. These items can get

caught in the nip and choke you or you can

be crushed or burned.

This section discusses power on/off, the

function of the front control panel, the function of the

rear control panel, how to set the temperature, what

to do in case of an emergency, film loading and

unloading, how to set the main roller nip, how to set

the pull roller nip and how to properly shutdown the

laminator.

5.1 Power on/ off

ELECTRICAL

SHOCK

Do n o t turn p o w er on if the p ower cord

is damaged or frayed. You can be

severely shocked, electrocuted or

cause a fire. Contact a qualified

electrician to replace the cord .

a) Ensure power from the junction box on the

wall is in the “ON” position.

b) Physically check to confirm that all four E-

STOPs are in the unlatched position.

WARNING

W h en the lam in ator rollers are in

motion, keep hands and fingers

away from the nip of the rollers.

You may be CRUSHED or BURNED!

IN FO RMAT ION

Th e la minato r will only turn o n if

all E-ST OPs are un latched .

© GBC Films Group February 2001

c) Turn the circuit breaker on the machine to

the “ON” position.

Off

On

Page 5 - 1

Page 51

Operations

Orca 1600 Operation and Maintenance Manual

5.2 Front control panel

The control panel on the Orca 1600 Laminator

is located at the front operating position of the machine

on the left ( control ) side cabinet.

The front control panel enables the operator

to control linear footage/ rate display, motor speed,

motor direction, motor auto/ stop, top temperature,

bottom temperature, main roller pressure and main

roller up/ down.

( 1 ) Speed Readout: Displays the speed of the

machine and the linear footage total. When the “ R” is

displayed, the readout is displaying the rate. When only

a numeric value is displayed, the readout is displaying

linear footage.

( 3 )Forward / Reverse Switch: determines the motor

direction. In the FWD position, the motor will turn in

a forward motion. In the REV position, the motor

will turn in a reverse direction. In the center position,

the motor will not turn at all.

IN FO RMAT ION

Th e cen ter pos ition is to preven t jam m in g

of the m otor when ch an gin g d irections

( 4 ) Auto / Stop Switch: This switch will engage the

motor circuitry and disengage the motor circuitry . This

is a momentary switch for latching purposes so that

two separate switches can serve the same function.

See Rear Control Panel for the other location of this

switch.

• The “ SEL “ button will toggle the unit between the

two choices of readouts. ( speed rate or linear

footage total )

• The “ RST “ button will reset the linear footage total

whether the display is showing rate or linear footage

total.

R 0 .0

SEL

( 2 )Speed Control Dial: Adjusts the speed of the

motor from zero to a maximum speed of 15 feet per

minute ( 4.5 meters per minute ). Turn the dial

clockwise to increase speed and counter clockwise to

reduce speed.

RST

AUTO

STOP

SPEED

FW D

REV

( 5 ) Temperature Control Unit ( Top ): This unit is

used to set the desired heating temperature of the top

main roller . The display can be programmed to show

o

F or oC.

68

CAL 3200

68

CAL 3200

Page 5 - 2

© GBC Films Group February 2001

Page 52

Orca 1600 Operation and Maintenance Manual

Operations

( 6 ) Temperature Control Unit ( Bottom ): This

unit is used to set the desired heating temperature of

the bottom main roller. The display can be programmed

to show oF or oC.

68

CAL 3200

68

CAL 3200

( 7 ) Top Heater on / off Switch: Turns the

temperature controller unit for the upper main roll to

on ( I ) or off ( O ).

( 9 ) Main Roll Pressure Adjustment: Adjusts the

air pressure supplied to the main roller air cylinders.

Pull out on the knob to turn and push in on the knob

to lock down.

IN FO RMAT ION

W h en d ecreasin g p ressu re, allow the

pressure g u age to dro p b elow the desired

value, then in crease p ressu re to th e set

pressure d esired . Th is allow s fo r a more

accura te pressu re read ing .

( 10 ) Main Roll Pressure Gauge: Displays the air

pressure supplied to the main roller air cylinders.

IN FO RMAT ION

Top tem p eratu re con trol un it on/ o ff

switch must b e o n to t u r n t h e lo wer

temp erature co n trol unit to on .

( 8 ) Bottom Heater on / off Switch: Turns the

temperature controller unit for the lower main roll to

on ( I ) or off ( O ).

TOP BOTTOM

HEAT

( 1 1 ) Main Roll up / down Switch: When pressed to

the down position, the upper main roller lowers. When

pressed to the up position, the upper main roller raises.

PRESSURE

50

40

P.S .I.

60

70

80

90

100