Page 1

25&$,,,2SHUDWLRQ

0DQXDO

© 1997 GBC Pro-Tech

Do not duplicate without written permission

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

E

R

G

S

U

A

E

N

NOT

C

Y

S

E

T

C

OP

TOP

1

O

PRESSURE

40

20

ADJ

LAMINATOR ROLL CONTROLS

POWER

FAN TABLE

PRO-TECH Engineering Madison,WI 608-246-8844

9

6

12

3

15

0

18

SPEED

MOTOR CONTROLS

BOTTOM

HEAT

1

O

80

100

ROLL

N

E

G

R

U

'

FWD

AUTO

REV

STOP

30

A

R

25

R

E

T

D

20

15

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

E

R

G

S

U

A

E

N

NOT

C

Y

S

E

T

C

OP

N

E

A

R

G

R

E

R

T

U

'

D

by Pro-Tech

DANGER

GEFAHR

HAZARDOUS

VOLTAGE.

o. 5025-PT

To be serviced only

eorder N

R

by trained and

authorized personnel.

Lockout power before

servicing.

s, Inc. 800-748-0241

unication System

m

om

C

azard

1994 H

©

4151 Anderson Road

De Forest, Wisconsin 53532

Part Number 930-402 Rev. A

GBC Pro-Tech

Tel: 608-246-8844

Fax: 608-246-8645

Page 2

ORCA-III Operation Manual

The information in this publication is provided for reference and is believed to be

accurate and complete. GBC Pro-Tech is not liable for errors in this publication or for

incidental or consequential damage in connection with the furnishing or use of the

information in this publication, including, but not limited to, any implied warranty of

fitness or merchantability for any particular use.

GBC Pro-Tech reserves the right to make changes to this publication and to the

products described in it without notice. All specifications and information concerning

products are subject to change without notice.

Reference in this publication to information or products protected by copyright or

patent does not convey any license under the rights of GBC Pro-Tech or others. GBC

Pro-Tech assumes no liability arising from infringements of patents or any other rights

of third parties.

This Manual is Copyrighted © 1997 by GBC Pro-Tech. All rights reserved. The

information contained in this manual is proprietary and may not be reproduced, stored,

transmitted, or transferred, in whole or in part, in any form without the prior and

express written permission of GBC Pro-Tech .

ii

GBC Pro-Tech 1997 October

Page 3

ORCA-III Operation Manual

7DEOH RI &RQWHQWV

6HFWLRQ 6DIHW\

Caution/Warning Label Locations.......................................................................................1-5

6HFWLRQ ,QVWDOODWLRQ

Preinstallation Checklist......................................................................................................2-1

Unpacking............................................................................................................................2-4

Setup...................................................................................................................................2-5

Leveling...............................................................................................................................2-6

Startup.................................................................................................................................2-6

6HFWLRQ 2SHUDWLRQ

Safety ..................................................................................................................................3-1

Operator Controls................................................................................................................3-3

Operator Controls................................................................................................................3-3

Front Control Panel..........................................................................................................3-3

Rear Control Panel...........................................................................................................3-4

Setup................................................................................................................................3-4

Laminator Roll Pressure...................................................................................................3-4

Loading the Film..................................................................................................................3-5

Positioning the Film.............................................................................................................3-5

Heating................................................................................................................................3-6

Cooling ................................................................................................................................3-6

Paper Tips...........................................................................................................................3-6

Process Control Charts .......................................................................................................3-7

Mounting Only .....................................................................................................................3-7

Setup................................................................................................................................3-7

Procedure.........................................................................................................................3-7

Mounting/Laminating...........................................................................................................3-7

Setup................................................................................................................................3-7

Procedure.........................................................................................................................3-7

Encapsulation......................................................................................................................3-8

Setup................................................................................................................................3-8

GBC Pro-Tech 1997 October iii

Page 4

ORCA-III Operation Manual

Procedure.........................................................................................................................3-8

Encapsulation (With Envelope Feed)..................................................................................3-8

Two-Pass Mount and Laminate (Hot and Cold)...................................................................3-8

Setup................................................................................................................................3-8

Procedure, Pass 1............................................................................................................3-8

Procedure, Pass 2............................................................................................................3-8

Cold/Mount Laminate ..........................................................................................................3-9

With Hot Main Rolls: ........................................................................................................3-9

With Cold Main Rolls:.......................................................................................................3-9

Roll to Roll Transfer and Laminate (One Pass)...................................................................3-9

With Hot Main Rolls: ........................................................................................................3-9

Vinyl Transfer ......................................................................................................................3-9

Roll to Roll Transfer.............................................................................................................3-9

With Hot Main Rolls: ........................................................................................................3-9

Roll to Roll Cold Overlamination (Second Pass Main Rolls Hot) ......................................3-10

With Hot Main Rolls: ......................................................................................................3-10

PROCESS CONTROL CHART 3-1...................................................................................3-11

PROCESS CONTROL DIAGRAM 3-1B.............................................................................3-12

PROCESS CONTROL CHART 3-2...................................................................................3-13

PROCESS CONTROL DIAGRAM 3-2B.............................................................................3-14

PROCESS CONTROL CHART 3-3...................................................................................3-15

PROCESS CONTROL DIAGRAM 3-3B.............................................................................3-16

PROCESS CONTROL CHART 3-4...................................................................................3-17

PROCESS CONTROL DIAGRAM 3-4B.............................................................................3-18

PROCESS CONTROL CHART 3-5...................................................................................3-19

PROCESS CONTROL DIAGRAM 3-5B.............................................................................3-20

PROCESS CONTROL CHART 3-6...................................................................................3-21

PROCESS CONTROL DIAGRAM 3-6B.............................................................................3-22

PROCESS CONTROL CHART 3-7...................................................................................3-23

PROCESS CONTROL DIAGRAM 3-7B.............................................................................3-24

PROCESS CONTROL CHART 3-8...................................................................................3-25

PROCESS CONTROL DIAGRAM 3-8B.............................................................................3-26

PROCESS CONTROL CHART 3-9...................................................................................3-27

PROCESS CONTROL DIAGRAM 3-9B.............................................................................3-28

iv

GBC Pro-Tech 1997 October

Page 5

ORCA-III Operation Manual

PROCESS CONTROL CHART 3-10 .................................................................................3-29

PROCESS CONTROL DIAGRAM 3-10B...........................................................................3-30

PROCESS CONTROL CHART 3-11 .................................................................................3-31

PROCESS CONTROL DIAGRAM 3-11B...........................................................................3-32

PROCESS CONTROL CHART 3-12 .................................................................................3-33

PROCESS CONTROL DIAGRAM 3-12B...........................................................................3-34

PROCESS CONTROL CHART 3-13 .................................................................................3-35

PROCESS CONTROL DIAGRAM 3-13B...........................................................................3-36

Laminate Temperature Guide and Helpful Hint Sheet for GBC Pro-Tech Products.........3-37

All Pressure Sensitive Materials.....................................................................................3-37

Lamination......................................................................................................................3-37

Mounting ........................................................................................................................3-37

Vinyl Transfer.................................................................................................................3-37

6HFWLRQ 0DLQWHQDQFH DQG 7URXEOHVKRRWLQJ

Cleaning ....................................................................................................................... .......4-1

Adjusting the Main Roll Nip .................................................................................................4-3

Adjusting the Pull Roll Nip...................................................................................................4-4

Chain Tensioning and Take-Up...........................................................................................4-5

Adjusting the Air Cylinder Rate............................................................................................4-6

Lubrication...........................................................................................................................4-8

Contacting Technical Support .............................................................................................4-8

Schematic Diagram.............................................................................................................4-9

Pneumatic Diagram.............................................................................................................4-2

Output Troubleshooting Guide............................................................................................4-9

6HFWLRQ :DUUDQW\

Limited Warranty .................................................................................................................5-1

Exclusions to the Wa rranty ..............................................................................................5-1

6HFWLRQ 7HFKQLFDO ,QIRUPDWLRQ

Specifications ......................................................................................................................6-1

Illustrated Parts List.............................................................................................................6-2

6HFWLRQ ,QGH[

GBC Pro-Tech 1997 October v

Page 6

ORCA-III Operation Manual Safety

6HFWLRQ 6DIHW\

DO NOT ATTEMPT TO OPERATE YOUR

ORCA-III LAMINATOR UNTIL YOU

HAVE READ THI S S E CT I O N

CAREFULLY!

Your safety, as well as the safety of others, is

important to GBC Pr o- Tech. This section contains

important s afety information.

The following symbols are used t hroughou t this

manua l to indicate warnings and cautions .

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will res ult in death or

serious injury.

WARNING

Indicates a potentially hazardous situation

whic h, if not a voide d , c ould result i n death or

serious injury.

CAUTION

GBC Pro- Tech la minators are powerful machines

that are designed to mount, laminat e and encap sulate.

The forces required t o accomplish thes e tasks can

var y f rom negligible to very large.

The a ir-c ylinder sys tem used to provide downward

pressure on the top roll is capable of producing

forces greater than 1000 pounds (454 kg). This force

is applied to any object pres ent ed in t he op ening

(called the nip) between the two rolls.

Use care in lowering the t op main laminating roll and

know how to r eact qu ic kly in an emergency. The

laminat or roll UP-DOWN s witch is located on t he

instrument panels. This s witch controls t he u p and

down motion of the t op lamina tor roll. B efore

pressing this switch to the DOWN position, ensure

that nothing is in the nip area. If any pr oblem or

danger should occ ur, depr essing any of the

emergency but tons s tops the rolls f rom closing and

ra ises them completely.

Note

⇒

To quickly stop the machine in the event of an

emergency, press any of the emergency stop buttons

or apply force to either kick cable. This action stops

the machine completely and raises the rolls.

In addition, the laminating rolls of the ORCA-III can

reach temperatures of over 200 °F (100 °C). At these

temperatu res t here is a danger of a sever e b urn if the

rolls ar e t ouched during set- up, operation or

servicing.

Indicates a potentially hazardous situation

whic h, if not a voide d , c ould result i n minor or

moderate injury, or alerts against unsafe

practice s, o r ale r t s against ac tions which co uld

damage the product.

The ORCA-III Laminator has been designed with

saf ety as a primary considerat ion. However , you

must b ecome thoroughly familiar with the controls,

proper oper at ion, proper s ervi ce proced ures, a n d

saf ety featur es of the laminator before using or

servicing the unit.

GBC Pro-Tech 1997 October

An important feature of the laminator is the

photoelectric eye sys tem th at st ops the machine wh en

objects move into the nip area.

In “run” mode (forward or revers e arrow is lit

const antly) forward or r everse butt on must b e pushed

for progress to resume.

In “footswit c h” mode (forward or reverse ar row is

flas hing) rolls stop if photoelect ric eye is b loc ked b ut

resu me a utomatica lly when ob struction is removed

from the p hotoelectric eye pa th.

1-1

Page 7

Safety ORCA-III Operation Manual

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

R

E

S

G

U

A

E

N

NOT

C

Y

E

S

T

C

OP

N

3

0

E

A

R

25

G

R

E

T

R

U

'

D

20

PRO-TECH Engineering Madison,WI 608-246-8844

15

9

WARNING

Do not ever attempt to override the

photoelectric eye system. You could be

crushed or severely burned.

6

FWD

12

3

AUTO

15

0

18

SPEED

REV

MOTOR CONTROLS

STOP

TOP

1

BOTTOM

HEAT

1

O

PRESSURE

O

4

0

2

0

8

0

ADJ

1

00

ROLL

LAMINATOR ROLL CONTROLS

POWER

FAN TABLE

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

E

R

S

G

U

A

E

N

NOT

C

Y

E

S

T

C

OP

N

E

A

R

G

R

E

T

R

U

'

D

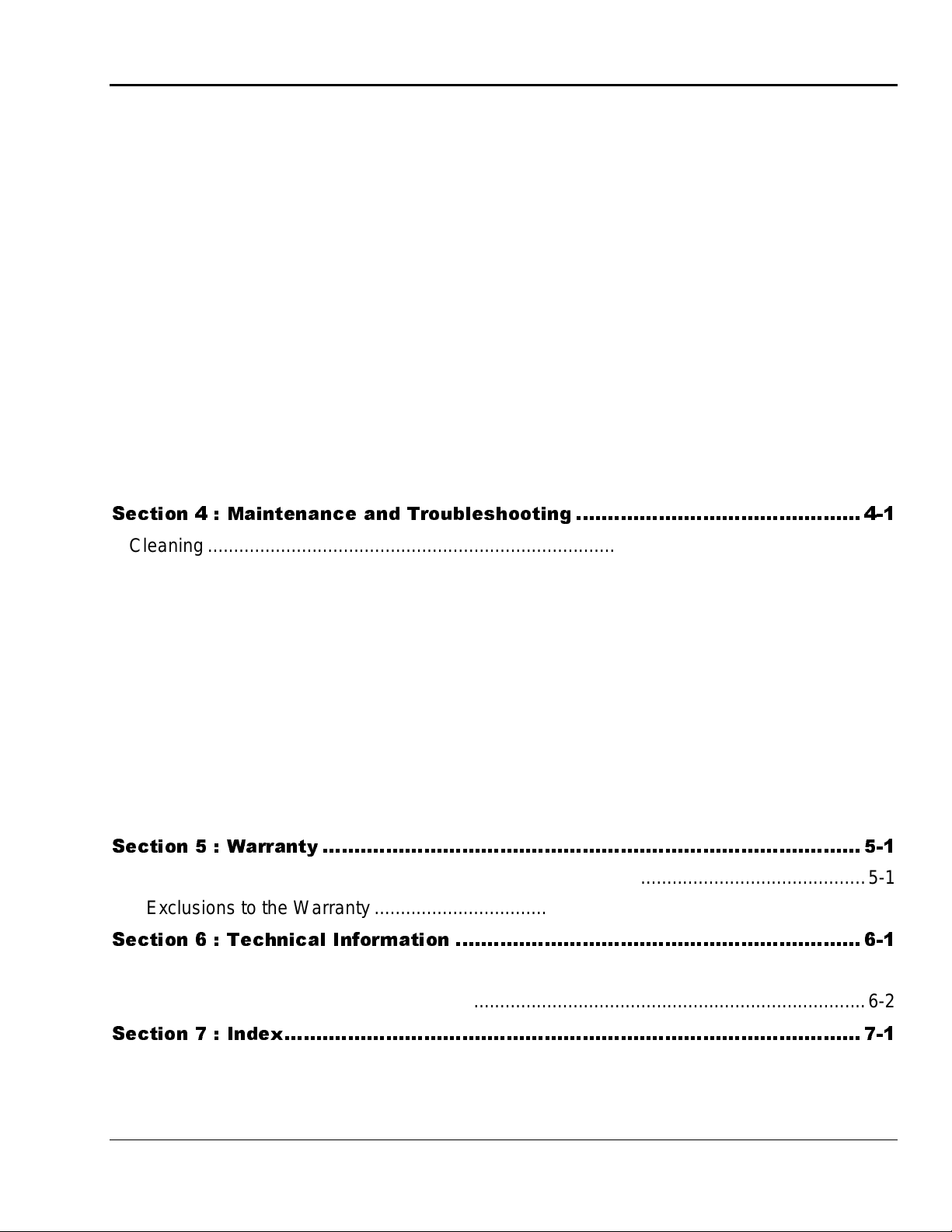

The ORCA-III Laminator has a steel cabinet that is

bolted closed to isolate the electric al and d rive system

components for the sa f ety of the op erator. Only a

qualif ied s ervice technician shou ld open these

cabinets.

The la mina tor is equipped with two emergency stop

kick cables located on the b ottom front and rear of

the lamina tor and four emergency stop b utt ons

locat ed on the top of either si de of the laminator. Any

of these, if engaged, stop s the la minator. To continue

operation all four emergency stop butt ons must be in

the up position.

Push any button

to stop the

laminator

A

U

S

NOT

E

C

N

E

G

R

U

'

D

T

E

R

T

OP

R

A

E

M

E

R

G

E

N

C

Y

S

Twist each button

to resume

operation - the

button pops up

A

U

S

NOT

1

/

4

E

C

N

E

G

R

U

'

D

T

E

R

R

E

M

n

r

u

t

Y

S

T

OP

A

E

R

G

E

N

C

by Pro-Tech

DANGER

S

U

GEFAHR

O

D

.

R

E

Emergency

Stop Kick

Cable

A

G

Z

A

A

T

H

L

O

T

V

-P

5

2

0

5

.

o

N

r

e

To be serviced only

rd

o

e

R

by trained and

authorized personnel.

Lockout power before

servicing.

1

4

2

0

8

4

-7

0

0

. 8

c

In

,

s

m

te

s

y

S

n

io

t

a

ic

n

u

m

m

o

C

rd

a

z

a

H

4

9

9

1

©

Emergency

Stop Kick

Cable

Figure 1-2: Using the Emergency Stop Kick

Cables

Despite the safety features built into the ORCA-III

La mi nator , ex tr eme cauti o n must be used when

operating or servic ing the unit. READ THE

FOLLOWING WARNINGS AND CAUT IO NS

BEFORE ATTEMPTING TO OPERATE OR

SERVICE THE O RCA-III L AMINATO R.

WARNING

Never place fingers or arms between the rolls

when they are turning or when the rolls are in

the closed position. You can be crushed or

burned.

Figure 1-1: Using the Emergency Stop Buttons

1-2

WARNING

Do not wear ties, loose fi tting cl othi ng o r

dangling jewelry w hile o pe rat ing o r servicing

the laminator. These items can get caught in

the nip and choke you or you can be crushed

or burned.

WARNING

Always use care in lowering the top laminating

roll. You can be crushed or burned.

GBC Pro-Tech 1997 October

Page 8

ORCA-III Operation Manual Safety

WARNING

Do not operate the laminator near water. You

can be severely shocked, electrocuted or cause

a fire.

DANGER

Remove power from the laminator before

servicing. You can be severely shocked,

electrocuted or cause a fire.

WARNING

Do not use liquid or aerosol cleaners on the

laminator. Do not s pill liquid of any kind on

the laminator. You can be severely shocked,

electrocuted or cause a fire. Use only a damp

cloth for cleaning.

CAUTION

Raise the upper main roll when the laminator

is not in operation. Prolonged contact can

damage the rolls.

CAUTION

Excess pressure can damage the laminating

rolls. Always select the minimum roll pressure

necessary to complete the task.

CAUTION

If silicone adhesiv e c o ntact s the upper or

lower roll, remove it IMMEDIATELY using

80% (o r s tro nger) isopropy l alcohol. It can

harden within an hour and ruin the roll.

WARNING

Exercise care when cleaning the rolls with

80% (o r s tro nger) isopropy l alcohol:

•

Use only in a well ventilated area.

•

Wear rubber gloves.

•

Use only on cool rolls.

Cle aning heated r olls ca n igni te t he fumes .

CAUTION

Use only 80% (o r s tro nger) isopropy l alcohol

or a rubber cement eraser to clean the

laminating rolls. Harsh chemicals like toluene,

acetone or M EK des t r o y the silicone covering

of the rolls.

WARNING

The operating environment must be free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors. Vapor

build up or stored flammable liquids can cause

a fire. Excessive dust can damage the

laminator.

CAUTION

Do not use a kni fe or other sharp ins trument

during installation or while se r v ic ing t he

laminator. You can cause irreparable damage

to the rolls.

GBC Pro-Tech 1997 October

1-3

Page 9

Safety ORCA-III Operation Manual

WARNING

Do not attempt to move the laminator across

anything other t han a flat, level surface

without trained and qualified riggers. You can

be crushed or seriously injured.

The ORCA-III Laminator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED RI GG E RS ONLY to

move the machine. The laminator is not

designed to be tipped up or sideways in any

way. Such action disturbs the exact alignment

of the rolling parts of the machine and

requires extensive realignment. GBC Pro-

Tech’s warranty does not cover malfunction of

the equipment due to mishandling and/or

tipping.

GBC Pro - Tech bears no responsibility for

personal injury or damage due to moving the

laminator improperly.

WARNING

Do not allow anything to rest on the power

cord. Do not locate the cord where people can

walk on it. You or others can be severely

shocked, electrocuted or cause a fire.

WARNING

Never insert objects of any kind through any

of the slots on the laminator. You can touch

dangerous voltage points or short out parts.

You can be severely shocked, electrocuted or

cause a fire.

ALWAYS USE GOOD SAFETY PRACT IC ES

WHEN OPERATING OR SER VICING THE

LAMINATOR AND KNOW HOW TO REACT

QUICKLY IN AN EMERGENCY.

WARNING

Only a qualified electrician should connect

power to the laminator. You can be severely

shocked, electrocuted or cause a fire if power

is improperly applied.

WARNING

Do not operate the laminator if the power

cord is damaged or frayed. You can be

severely shocked, electrocuted or cause a fire.

Contact a qualified electrician to replace the

cord.

1-4

GBC Pro-Tech 1997 October

Page 10

ORCA-III Operation Manual Safety

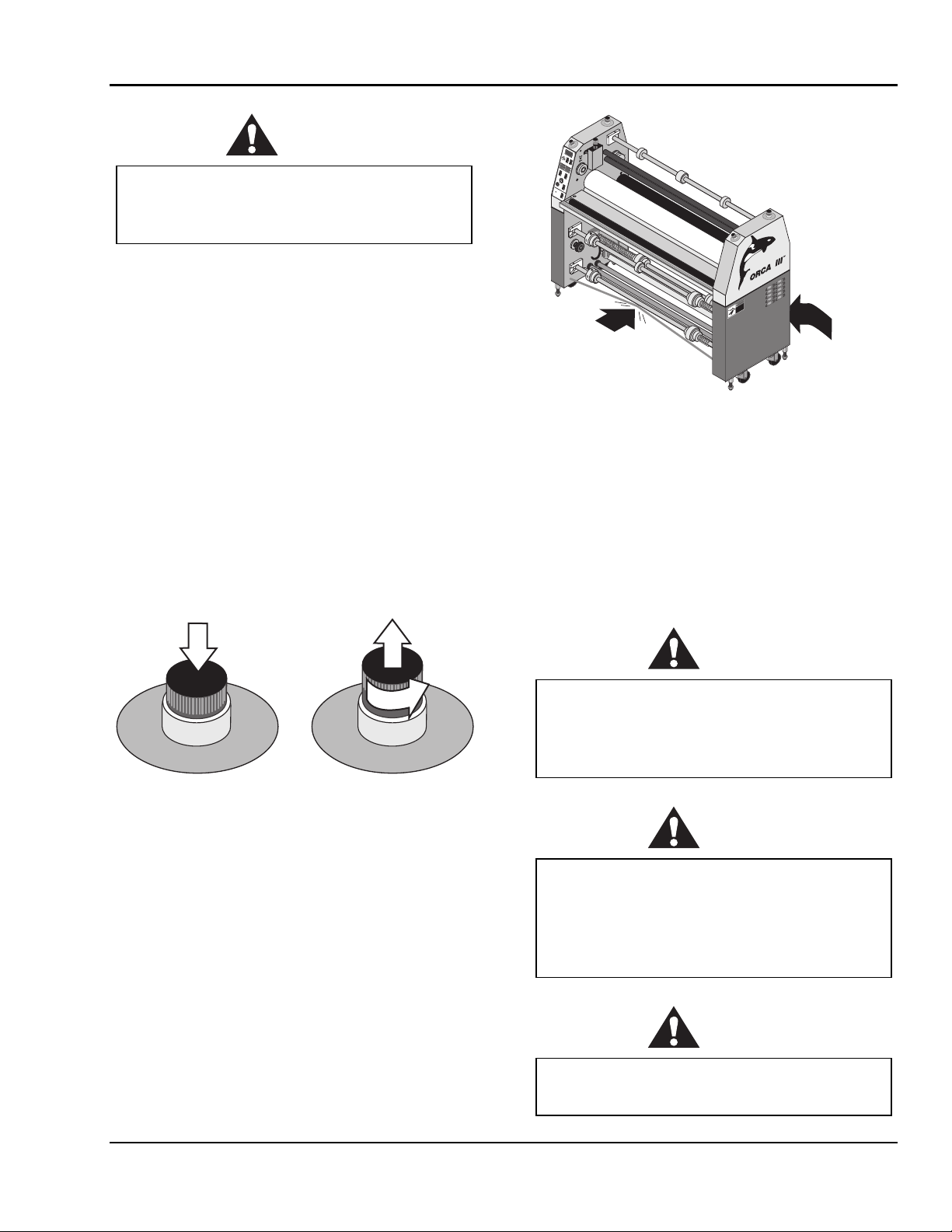

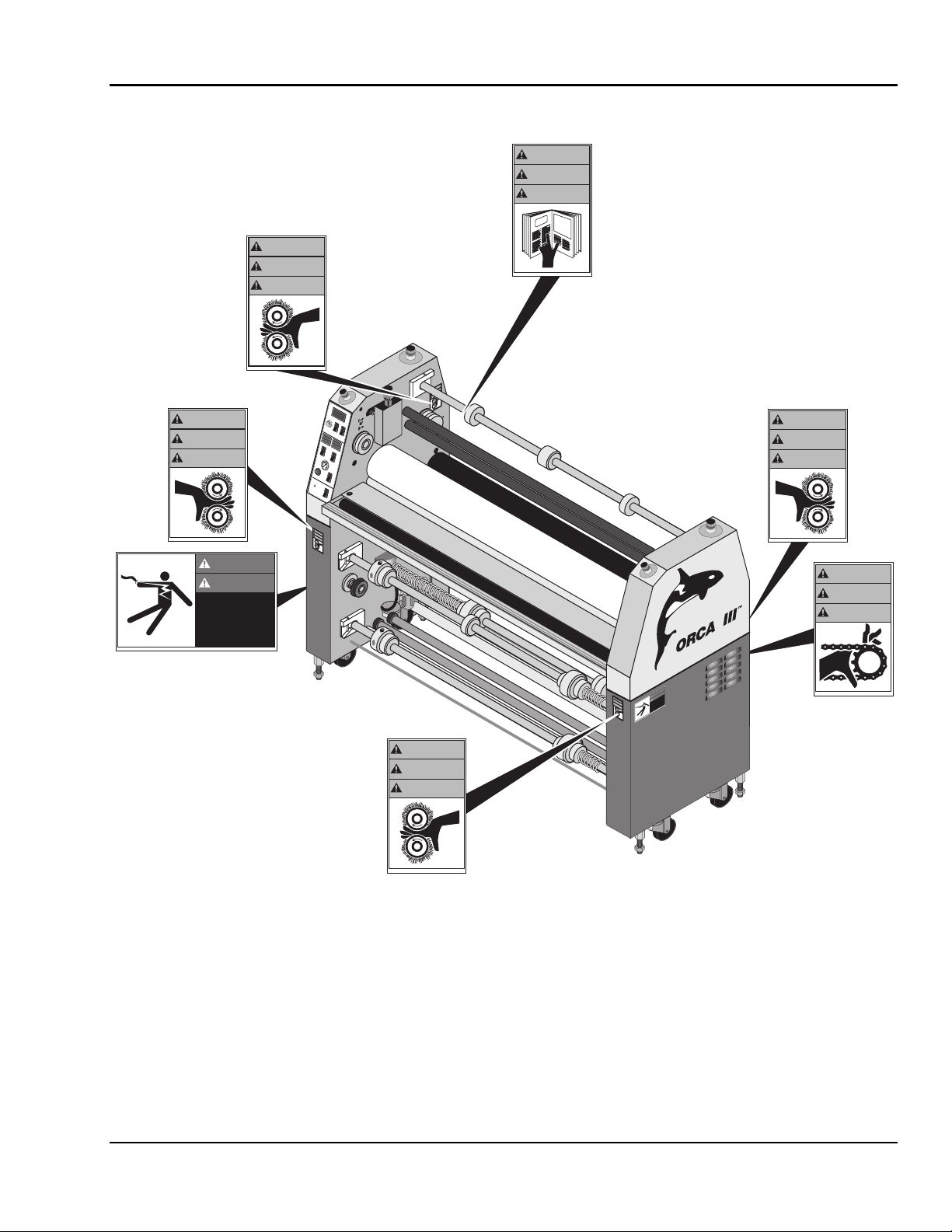

&DXWLRQ:DUQLQJ /DEHO /RFDWLRQV

Posted at various locations on your ORCA-III

Laminator are important safety labels. PAY

CAREFUL ATTENTION TO THESE LABELS AT

ALL TIMES! F i gure 1 - 3 shows the location of ea c h

of t h ese label s.

GBC Pro-Tech 1997 October

1-5

Page 11

Safety ORCA-III Operation Manual

WARNING

ACHTUNG

MISE EN GARDE

WARNING

©1994 HCS, Inc. 800-748-0241 Reorder No.1033R-PT

WARNING

ACHTUNG

MISE EN GARDE

©1994 HCS, Inc. 800-748-0241 Reorder No.1033-PT

DANGER

DANGER

GEFAHR

GEFAHR

HAZARDOUS

HAZARDOUS

VOLTAGE .

VOLTAGE .

To be serviced only

To be serviced only

by trained and

by trained and

authorized personnel.

authorized personnel.

Lockout power before

Lockout power before

servicing.

©1994 Hazard Communication Systems, Inc. 800-748-0241 Reorder No. 5025-PT

©1994 Hazard Communication Systems, Inc. 800-748-0241 Reorder No. 5025-PT

servicing.

(Inside cabinet)

ACHTUNG

MISE EN GARDE

1

O

ADJ

LAMINATOR ROLL CONTROLS

POWER

W

ARNING

ACHTUNG

MISE EN GARDE

©1994 HCS, Inc. 800-748-0241

Reorder No.1033R-PT

TOP

PRESSURE

40

20

FAN TABLE

6

3

0

SPEED

MOTOR CONTROLS

HEAT

80

100

PRO-TECH Engineering Madison,WI 608-246-8844

9

FWD

12

15

18

REV

STOP

BOTTOM

1

O

ROLL

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

E

R

G

S

U

A

E

N

NOT

C

Y

S

E

T

C

OP

N

30

E

A

R

25

G

R

E

R

T

U

'

D

20

15

AUTO

WARNING

ACHTUNG

MISE EN GARDE

T

P

R

3

3

0

1

.

o

N

r

e

d

r

o

e

R

1

4

2

0

-

8

4

7

-

0

0

8

.

c

n

I

,

S

C

H

4

9

9

1

©

©1994 HCS, Inc. 800-748-0241 Reorder No.6001-PT

WARNING

ACHTUNG

MISE EN GARDE

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

E

R

G

S

U

A

E

N

NOT

C

Y

S

E

T

C

OP

N

E

A

R

G

R

E

R

T

U

'

D

©1994 HCS, Inc. 800-748-0241 Reorder No.1033-PT

WARNING

ACHTUNG

MISE EN GARDE

by Pro-Tech

DANGER

WARNING

GEFAHR

ACHTUNG

HAZARDOUS

MISE EN GARDE

VOLTAGE.

To be serviced only

by trained and

authorized personnel.

Lockout power before

servicing.

©

1

9

9

4

H

C

S

, In

c

. 8

0

0

-7

4

8

-0

2

4

1

R

e

o

r

d

e

r N

o

.1

0

3

3

R

-P

T

©1994 Hazard Communication Systems, Inc. 800-748-0241 Reorder No. 5025-PT

©1994 HCS, Inc. 800-748-0241 Reorder No. 1012-PT

1-6

WARNING

ACHTUNG

MISE EN GARDE

©1994 HCS, Inc. 800-748-0241 Reorder No.1033R-PT

Figure 1-3: Locations of Safety Labels

GBC Pro-Tech 1997 October

Page 12

ORCA-III Operation Manual Installation

6HFWLRQ ,QVWDOODWLRQ

GBC Pro- Tech is c ommitted to a program of ongoing

product improvement. As a result, we are providing

these instructions so that you c an insu re that you r

new ORCA-III Laminator is properly and securely

unpacked, moved and insta lled.

Before an ORCA-III Laminator can be installed there

are a few r equirements t hat mus t be met. Ma k e

certain that each of the requirements listed in the

following pr eins tallation c hecklis t are met befor e

beginning installation.

CAUTION

Do not locate the laminator where air is

blowing directly on the machine. The air flow

can cool the rolls unevenly and result in poor

❒ Have you c ontac ted a certified electricia n to bot h

wire the laminator and ensure that an adequate

power supply, having the appropriate capacity,

overcurr ent pr otection, and saf ety lockout s is

available?

The laminator requires 220 to 240 VAC, 50/60

Hz, 55 A. Or, in Europe only, 3-N phase, 32 A

per phase.

CAUTION

quality output.

Failure to follow the preinstallation checklist

can result in damage to the laminator.

3UHLQVWDOODWLRQ &KHFNOLVW

❒ Are door ways and hallways wide enough f or t he

laminator to be moved to the installation site?

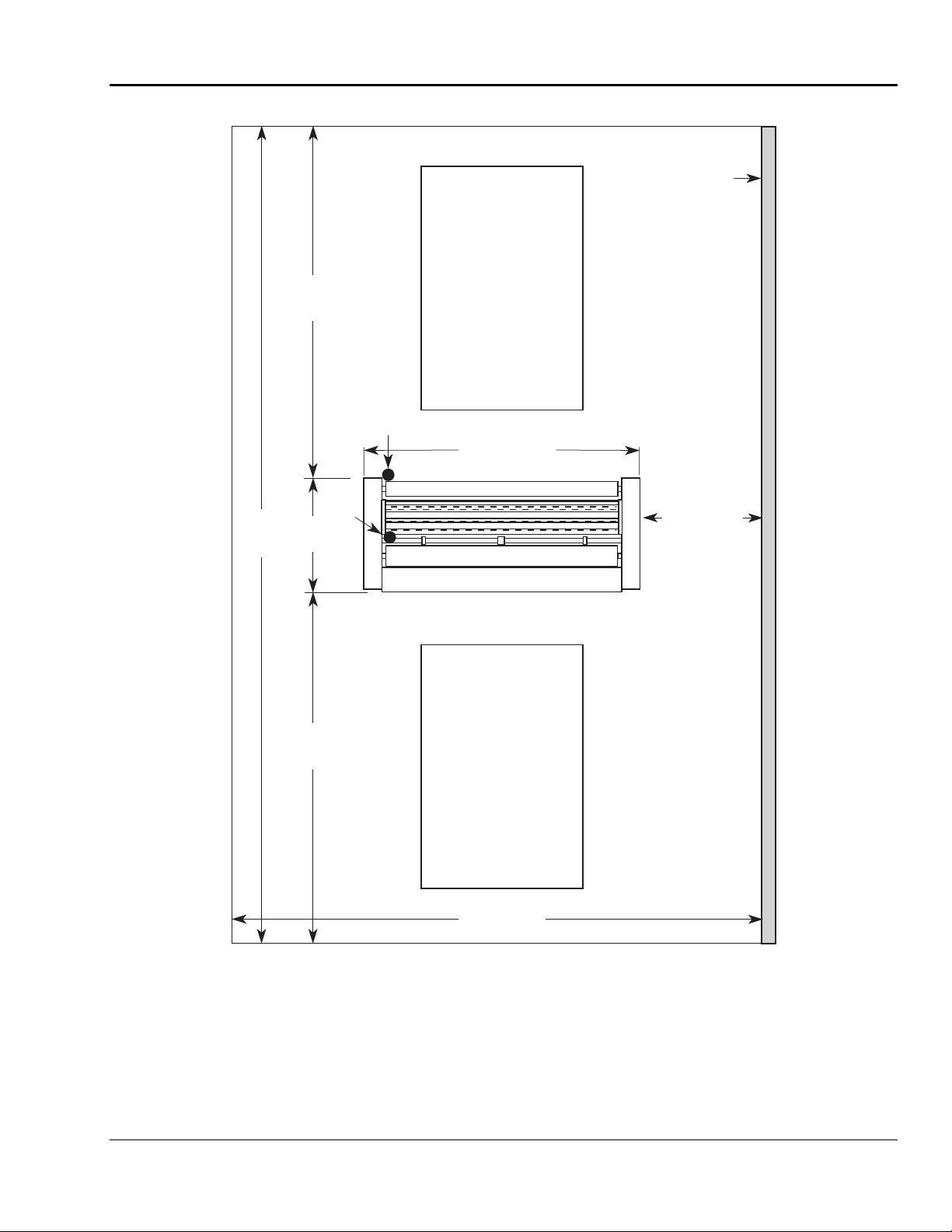

❒ Is there a mple room for the laminator?

A work area mus t be est ablis hed t hat allows for

operation in b oth the front and the r ear of the

machine and p rovides s pac e for effic ient mater ial

flow. Figure 2-1 shows a typical machine area

layout.

❒ Is t he envir onment app ropria te for the laminator?

The la mina tor requires a c lean, du st and vapor

free environment to oper ate properly. I t must not

be located where there is a ir blowing directly on

the machi n e.

WARNING

USA - For singl e pha se 3 wire, tie L 1, L2, an d

L3 t ogether.

Europe - For 3-N phase, L1, L2, and L3 are each

separate phases.

WARNING

Do not operate the laminator if the power

cord is damaged or frayed. You can be

severely shocked, electrocuted or cause a fire.

Contact a qualified electrician to replace the

cord.

WARNING

Do not allow anything to rest on the power

cord. Do not locate the cord where people can

walk on it. You or others can be severely

shocked, electrocuted or cause a fire.

The operating environment must be free of

dust, flammable liquids and vapors. You can

be injured by inhaling chemical vapors. Vapor

build up or stored flammable liquids can cause

a fire. Excessive dust can damage the

laminator.

GBC Pro-Tech 1997 October

2-1

Page 13

Installation ORCA-III Operation Manual

❒ Is there an appropriate filtered air supply

available?

The lamin ator requires filtered air at 2 cubic feet

per minute (cfm), 50 liters/minute at a pressure

of 100 pounds per square inch (psi) (700 kPa).

The air supply must be clean (free of dirt) and

dry. Moisture caus es c orrosion and particles

block pneu ma tic cont rols. Eit her pr oblem can

cause the laminator to malfunction.

It is the cus tomer's responsibilit y to pr ovide

appropriate filters and water traps for the air

hose before the a i r is r o ut ed to the laminato r.

Pro-Tech suggests that the best approach to the

air requirement is to p rovide a dedicated sma ll

compressor for the laminator. A standard lightduty ½ to ¾ horse power (1 kW) electric air

compressor with 1.5 to 2.5 cfm output with a 5

gallon (2 0 liter ) storage tank is appropriate.

CAUTION

The air supply to the laminator must be clean

and dry or the machine will be damaged.

2-2

GBC Pro-Tech 1997 October

Page 14

ORCA-III Operation Manual Installation

20'

(609 cm)

8'8"

(264 cm)

Supply

2'8"

(81 cm)

Electrical

Supply

Air

4' x 6'

(122 cm x 182 cm)

Work Table

on Wheels

Table Height

35-3/4"

(90.5-91.5 cm)

82" (208 cm)

Rear

Front

Wall

3' (91 cm)

8'8"

(264 cm)

4' x 6'

(122 cm x 182 cm)

Work Table

on Wheels

Table Height

35-3/4"

(90.5-91.5 cm)

13' (396 cm)

Figure 2-1: Laminator Space Requirements

GBC Pro-Tech 1997 October 2-3

Page 15

Installation ORCA-III Operation Manual

8QSDFNLQJ

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

E

M

E

R

S

G

U

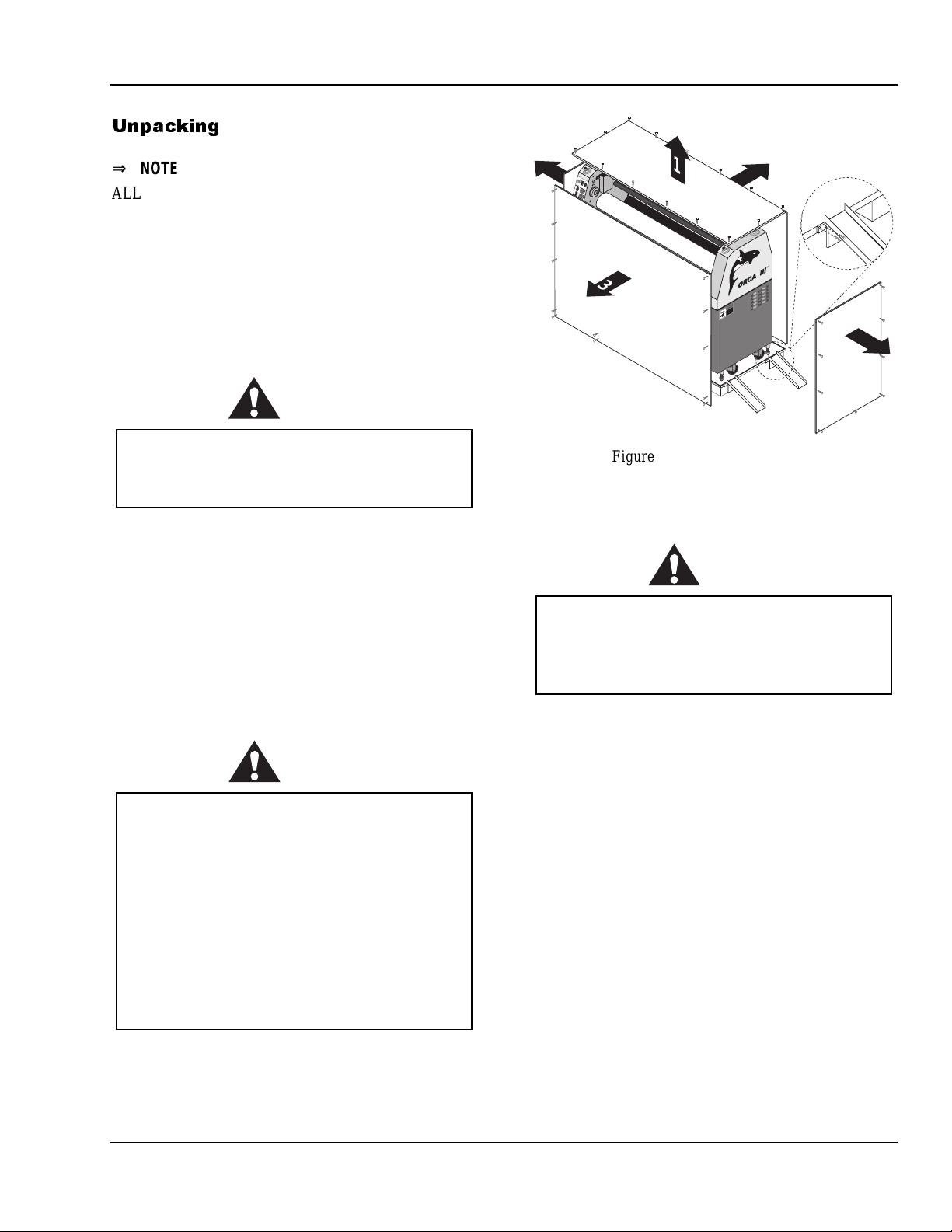

⇒ NOTE

ALL SHIPMENTS ARE EX- WORKS. At our dock

title passes to the buyer. Please review your

insurance coverage prior to shipment, as you are

responsible for all subsequent freight charges and

risks. Before signing the Bill of Lading you should

be sure to inspect the crate and/or pallet for signs of

damage or missing items; if applicable, make a note

of this on the Bill of Lading.

WARNING

A

E

N

NOT

C

Y

S

E

T

C

OP

N

3

0

E

A

R

25

G

R

E

R

T

'

U

D

20

15

P

R

O

-TE

C

4

H

E

n

gineering M

adiso

9

6

n,W

I 608-246

FWD

12

3

-8844

AUTO

15

0

18

SPEED

REV

MOTOR CONTROLS

1

STOP

T

O

O

P

HEAT

1

B

O

T

O

T

O

M

PRESSURE

4

0

2

0

ADJ

8

0

1

0

0

ROLL

LAMINATOR ROLL CONTROLS

POWER

FAN

3

1

5

Install

Screws

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

E

M

E

R

S

G

U

A

E

N

NOT

C

Y

S

E

T

C

OP

N

E

A

R

G

R

E

R

T

'

U

D

by Pro-Tech

DANGER

GEFAHR

HAZARDOUS

T

VOLTAGE.

-P

5

2

. 50

o

N

er

rd

To be serviced only

o

e

R

by trained and

authorized personnel.

Lockout power before

servicing.

1

4

02

8

4

-7

0

0

. 8

c

In

s,

m

te

s

y

S

n

tio

a

ic

n

u

m

m

o

C

d

ar

z

a

H

4

9

9

1

©

2

The unpacking process requires at least two

people. You can be severely injured or

crushed.

Tools required:

• Phillips head screwdriver

7

/8" open end wrench or adju stable wrench

•

To uncrate the laminator:

1. Remove the top of the crate and then the sides in

the order shown in Figure 2-2 .

CAUTION

Do not allow the top to fall into the crate. It

can damage the laminator.

Do not put packing screws on the floor. They

can cause problems when trying to roll the

machine into position.

A second person must support the side labeled

5 in Figure 3-4. It can fall and damage the

laminator.

Figure 2-2: Removing the Crate

2. Carefully unwrap the shrink wrap f rom around

the laminator.

CAUTION

Do not use a kni fe or other sharp ins trument

during installation or while se r v ic ing t he

laminator. You can cause irreparable damage

to the rolls.

3. Ca refully remove any a c c es sories pac ked wit h

the laminator. The accessory pack should

contain:

1 Set, hex wrenches

5

/16" T-handle wrench

1

1 Slitting knife

1 Manual

1 Set, spare fuses

1 Air line qu ic k- c ouple connector, f emale

100% white cotton terry rags

4. Have t he laminator r olled off the skid and plac ed

on the floor by licensed r iggers. The ramps

included with the laminator can be secured to the

edge of the crate b ottom us ing the screws left

over from the crate dis assembly (see Figure 2 - 2).

2-4

GBC Pro-Tech 1997 October

Page 16

ORCA-III Operation Manual Installation

Before machines leave our loading dock, they are

WARNING

Do not attempt to move the laminator across

anything other t han a flat, level surface

without trained and qualified riggers. You can

be crushed or seriously injured.

pre-treated with a VCI protective film to provide

total corrosion protection. This protective film is

wrapped around the machine and completely sealed.

In addition, moisture absorbing silicone desiccite

packs are packed inside the crate and machine

cabinets.

The ORCA-III Laminator is a large and

heavy piece of equipment. It is necessary to

employ LICENSED RI GG E RS ONLY to

move the machine. The laminator is not

designed to be tipped up or sideways in any

way. Such action disturbs the exact alignment

of the rolling parts of the machine and

requires extensive realignment. GBC Pro-

Tech’s warranty does not cover malfunction of

the equipment due to mishandling and/or

tipping.

GBC Pro - Tech bears no responsibility for

personal injury or damage due to moving the

laminator improperly.

5. Remove any pl astic strapping and packing paper

taped to the

roll

s.

CAUTION

Do not use a kni fe or other sharp ins trument

during installation or while se r v ic ing t he

laminator. You can cause irreparable damage

to the rolls.

6. Remove all packing mat erials to a saf e dis tance

from the laminator.

⇒

A NOTE ABOUT RECYCLING

The crate components can be reused for shipping

the machine again, or can be disassembled and the

wood and screws recycled. The shrink wrap is not

recyclable, h o wever, s o i t mu s t be d i s ca r ded .

Prior to start up of the machine, you must remove

the desiccite packs from each cabinet and discard.

DO NOT operate the machine with the desiccite

packs inside the cabinets

7. Level the lamina tor u sing the procedure lat er in

this s ection.

6HWXS

Once the ORCA-III Laminator has been unpacked

and moved into final pos ition check ea c h of the

following items.

Tools required:

1

•

/8" hex wrench

•

Adjust able wrench

Setup Procedure

1. Insp ect the la minator for any obviou s shipping

damage.

2. Open t he left and r ight side cabinet c overs wit h

3. Insp ect all the bolts and tighten a ny that were

4. Have a cert if ied electricia n wire the lamina tor

5. Set th e n i p. (See Maintenance for t h e pr o cedure.)

6. Verify that the infra red sensors ar e not blocked.

5

/32" hex wrench by removing the four scr ews

the

holding each cover in plac e.

loosened duri ng shipping.

directly to a power source.

⇒

NOTE

A word about international shipments: As these are

heavy pieces of equipment, GBC Pro-Tech takes

every precaution to ensure that our laminators are

properly crated to the highest standards.

GBC Pro-Tech 1997 October

WARNING

NEVER BLOCK T H E I NFRARED

SENSO RS! The rolls can overheat and cause

a fire or seriously damage the laminator.

2-5

Page 17

Installation ORCA-III Operation Manual

7. Adjust the air cylinder rate. (See Section 4:

Maintenance and Troubleshooting for the

procedure.)

8. Replace both cabinet covers.

/HYHOLQJ

Tools required:

• Adjustable wrench

• Carpenter's level

To lev e l t he laminator:

1. Ra ise each end, remove the cas tors and ins tall a

leveling pad a nd stu d onto each of the foot

brackets at the four bottom corners of the

laminator. T hread t hird nut on st ud ab ove f oot

bracket.

WARNING

Do not lift the wheels more than 3/4" (2 cm.)

above the floor. The leveling pads can become

unstable. You can be crushed.

2. Thread s tud int o 4 leveling pads loc k down with

nut. T hread second nut onto stud.

3. Place a carpenter's level front to rear across the

two lower tie ba rs at one end of the machine .

4. Level this end of the machine fr ont to r ear,

ra ising or lowering the leveling pads by a djusting

the middle nuts on the foot b olts.

5. Move the level to t he other end of t he machine

and level front to rear.

6WDUWXS

The first time the laminator is started and every time

it is s erviced you should use the following checklist to

confirm t hat the unit is op erating properly and that all

saf ety mechanisms ar e functioning.

Startup Checklist

Star t the la minator and go t hrough the following

checklist.

❒ Are the emergency stop but tons working?

Push down on one of the emergency s top b utt ons.

The laminator should stop. Pull up on the but ton

and push t he reset but ton on the lower back of

the lamina tor. The laminator shou ld resu me

operation. Always c hec k all four bu ttons.

WARNING

Never operate the laminator unless both of the

emergency stop buttons are functioning

properly. You can be crushed or burned.

❒ Is t he p hotoelectr i c eye system working?

With t he la minator ru nning and the r olls in the

“up” position, place an object approximately the

size of you r hand just in f ront of the nip on b oth

the fr ont and back of the lamina tor to confirm

that the photoelectric eye system is func tioning.

The

the nip. The lamina tor should r es ume operation if

the machine is in “footswitch” mode. I f the

machine is in “ run” mode, it shou ld be necessa ry

to push the FORWARD or REVE RSE button

to resume roll motion.

s shou ld stop . Move t he ob ject away fr om

roll

6. Place the level direct ly on one of the tie ba rs and

level the machine side to si de.

7. Recheck t he front to rear level condition to ins ure

that it has not c hanged. I f it has, repeat the

leveling procedure.

8. When all the measurements indicate that the

machine is level, tighten down the top nuts on t he

foot b rac kets t o loc k the pads in their current

position.

2-6

WARNING

Never operate the laminator unless the

photoelectric eye system is functioning

properly. You can be crushed or burned.

GBC Pro-Tech 1997 October

Page 18

ORCA-III Operation Manual Installation

❒ Are the emergency stop kic k c ables working?

With t he laminator r unning, s tep on or kic k the

front emergency stop kick cable. All power

should b e removed from the machine. The rolls

should s top t urning and rise. P ush t he reset

but ton. Restar t the heaters , fa ns, and roll mot ion.

Lower the rolls then repeat the test for the back

emergency stop kick cable.

WARNING

Never operate the laminator unless both of the

emergency stop kick cables are functioning

properly. You can be crushed or burned.

❒ Is t he motor func tioning?

Test the motor at variou s speeds ra nging f rom

0-15. At 0 the

Run the motor in both forwa rd and reverse.

s shou ld stop turning.

roll

❒ Are the hea ters working ?

Verify that the top heater controller heats the top

roll a nd the bottom heater c ontroller heat s the

bottom roll.

Once you ha ve c omplet ed the startup c hecklist you

can safely run a test sample.

GBC Pro-Tech 1997 October

2-7

Page 19

Installation ORCA-III Operation Manual

Blank Page.

2-8

GBC Pro-Tech 1997 October

Page 20

ORCA-III Operation Manual Operation

6HFWLRQ 2SHUDWLRQ

6DIHW\

The ORCA-III Laminator has been designed with

saf ety as a primary considerat ion. However , you

must b ecome thoroughly familiar with the controls,

proper oper at ion, proper s ervi ce proced ures, a n d

saf ety featur es of the laminator before using or

servicing the unit.

GBC Pro- Tech la minators a re power ful mac hines

that are designed to mount, laminat e and encap sulate.

The forces required t o accomplish thes e tasks can

var y f rom negligible to very large.

The a ir-c ylinder sys tem used to provide downward

pressure on the top roll is capable of producing

forces greater than 1000 pounds (454 kg). This force

is applied to any object pres ent ed in t he op ening

(called the nip) between the two rolls.

Use care in lowering the top laminat ing roll a nd know

how to r eact qu ic kly in an emergency. The lamina tor

roll UP-DOWN swit c h is located on the inst rument

panels . This switc h c ontrols the up and down motion

of the top laminator roll. Before turning this switch to

the DOWN position, ens ure t hat nothing is in t he nip

area.

In addition, the laminating rolls of the ORCA-III can

reach temperatures of over 200 °F (100 °C). At these

temperatu res t here is a danger of a sever e b urn if the

rolls ar e t ouched during set- up, operation or

servicing.

The ORCA-III Laminator has a steel cabinet that is

bolted closed to isolate the electric al and d rive system

components for the sa f ety of the op erator. Only a

qualif ied s ervice technician shou ld open these

cabinets.

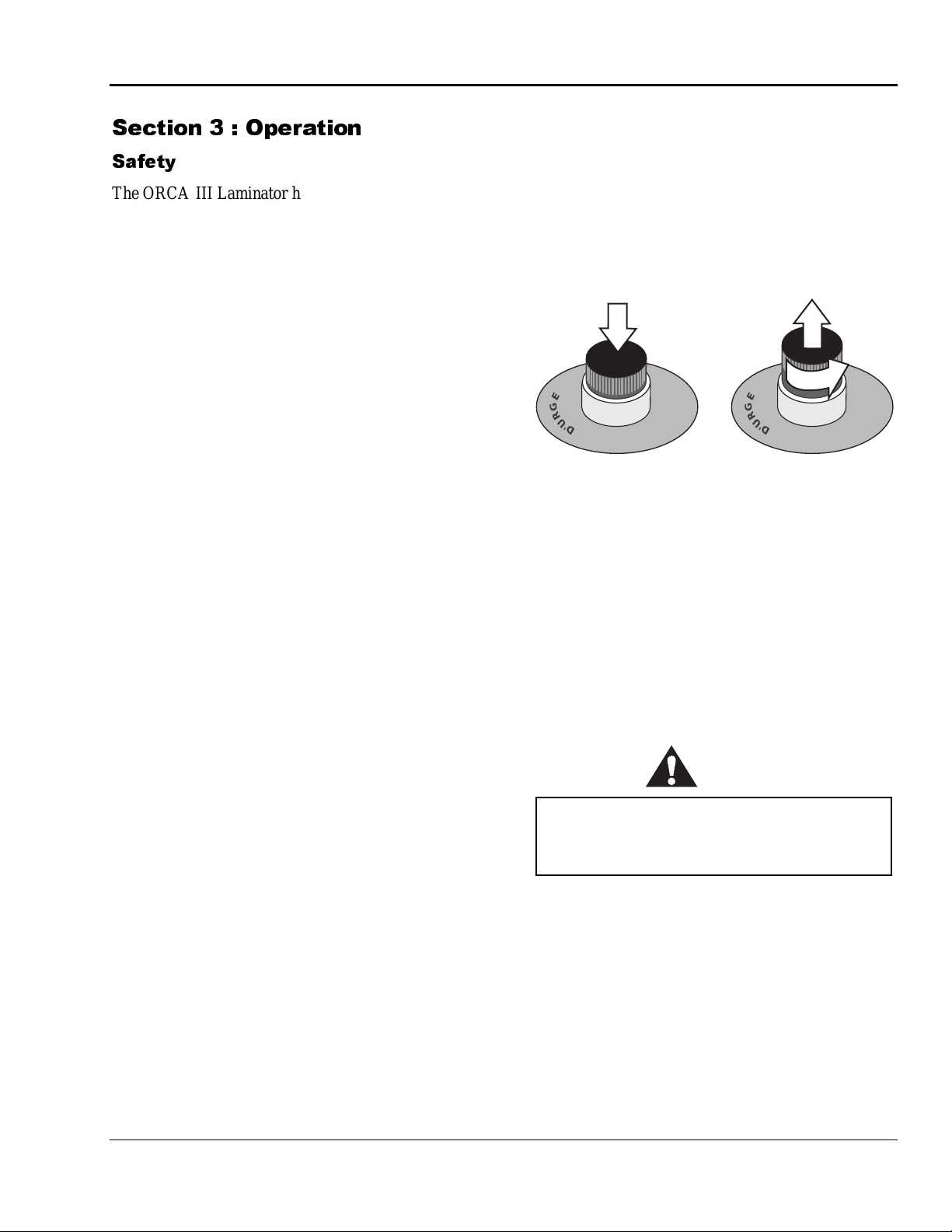

The la mina tor is equipped with fou r emergency stop

buttons located on the top of either side of the

laminator. Any of t hes e, if engaged, stop s the

laminator. To c ontinue oper ation all four emergency

stop buttons must be in the up position.

Push any button

to stop the

laminator

A

U

S

NOT

E

C

N

E

G

R

U

'

D

T

E

R

E

M

E

R

G

E

N

C

Y

S

T

OP

R

A

Figure 3-1: Using the Emergency Stop Buttons

Twist each button

to resume

operation - the

button pops up

A

U

S

NOT

1

/

4

E

C

N

E

G

R

U

'

D

T

E

R

R

E

M

n

r

u

t

Y

S

T

OP

A

E

R

G

E

N

C

The ORCA-III is equipped with a photoelectric eye

system that stops the machine when objects move into

the ni p a rea.

In “run” mode (forward or revers e arrow is lit

const antly) forward or r everse butt on must b e pushed

for progress to resume.

In “footswit c h” mode (forward or reverse ar row is

flas hing) rolls stop if photoelect ric eye is b loc ked b ut

resu me a utomatica lly when ob struction is removed

from the p hotoelectric eye pa th.

WARNING

Do not ever attempt to override the

photoelectric eye system. You could be

crushed or severely burned.

In addition to the safety features built into the

ORCA-III Laminator, extreme caution must be used

when opera ting or servicing the unit.

GBC Pro-Tech 1997 October

3-1

Page 21

Operation ORCA-III Operation Manual

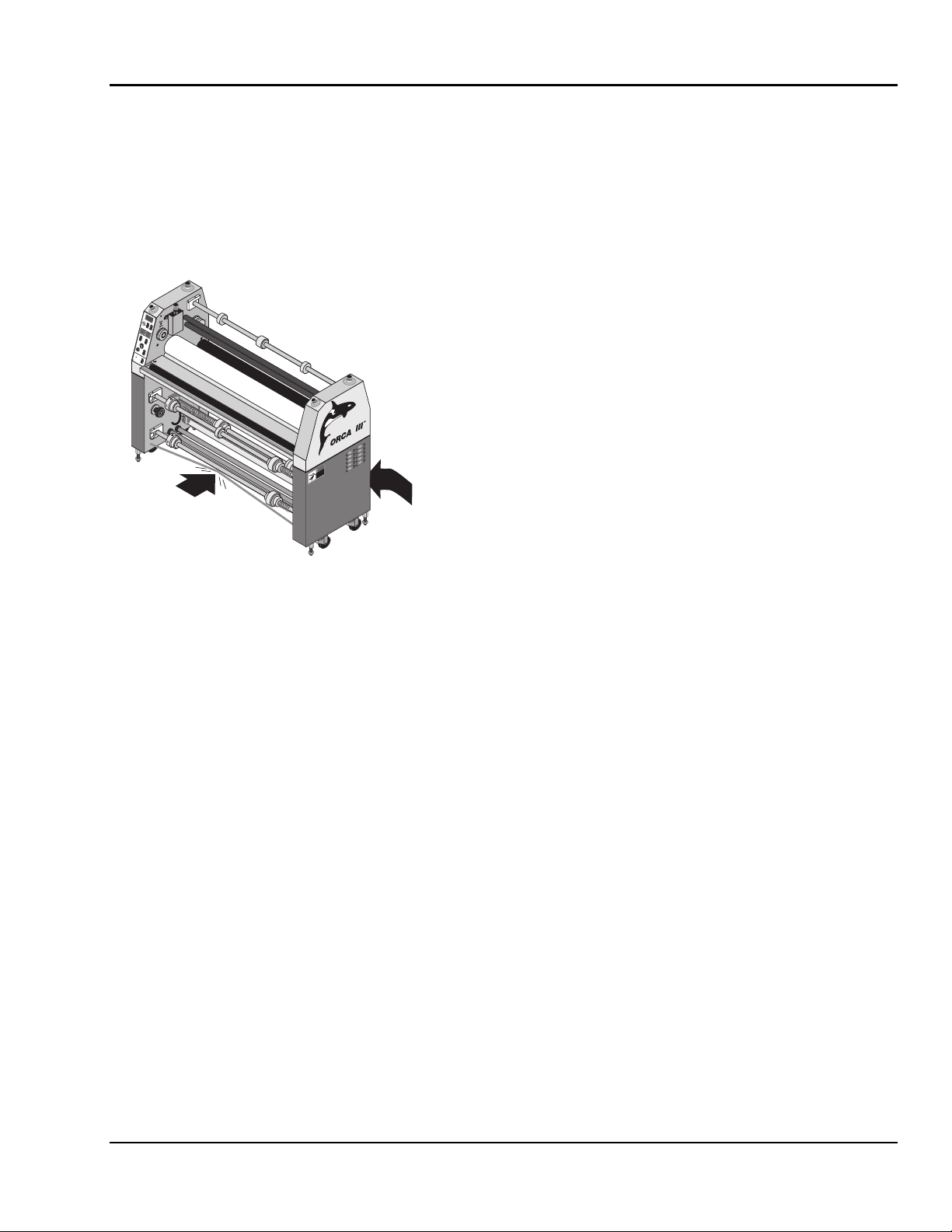

In addition, the ORCA-III is equipped with two

Emergency S top Ki c k Cables located at t he lower

front and b ack of the laminator. Either of these, if

stepped on or kicked, st ops the laminat or. To r es tart,

pus h the res et button and reacti vate t he heater s, f ans,

roll motion, and r oll positi on c ontrols .

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

R

E

S

G

U

A

E

N

NOT

C

Y

E

S

T

C

OP

N

3

0

E

A

R

25

G

R

E

T

R

U

'

D

20

PRO-TECH Engineering Madison,WI 608-246-8844

15

9

6

FWD

12

3

AUTO

15

0

18

SPEED

REV

MOTOR CONTROLS

STOP

TOP

1

BOTTOM

HEAT

1

O

PRESSURE

O

4

0

2

0

80

ADJ

1

00

ROLL

LAMINATOR ROLL CONTROLS

POWER

FAN TABLE

A

U

S

NOT

E

M

E

E

C

R

N

G

E

E

G

N

R

C

U

'

Y

D

S

T

T

E

OP

R

R

A

M

E

E

R

S

G

U

A

E

N

NOT

C

Y

E

S

T

C

OP

N

E

A

R

G

R

E

T

R

U

'

D

by Pro-Tech

DANGER

S

U

GEFAHR

O

D

.

R

E

Emergency

Stop Kick

Cable

A

G

Z

A

A

T

H

L

O

T

V

-P

5

2

0

. 5

o

N

r

e

d

To be serviced only

r

o

e

R

by trained and

authorized personnel.

Lockout power before

servicing.

1

4

2

-0

8

4

-7

0

0

. 8

c

, In

s

m

te

s

y

S

n

tio

a

ic

n

u

m

m

o

C

d

r

a

z

a

H

4

9

9

1

©

Emergency

Stop Kick

Cable

Figure 3-4: Emergency Stop Kick Cables

3-2

GBC Pro-Tech 1997 October

Page 22

ORCA-III Operation Manual Operation

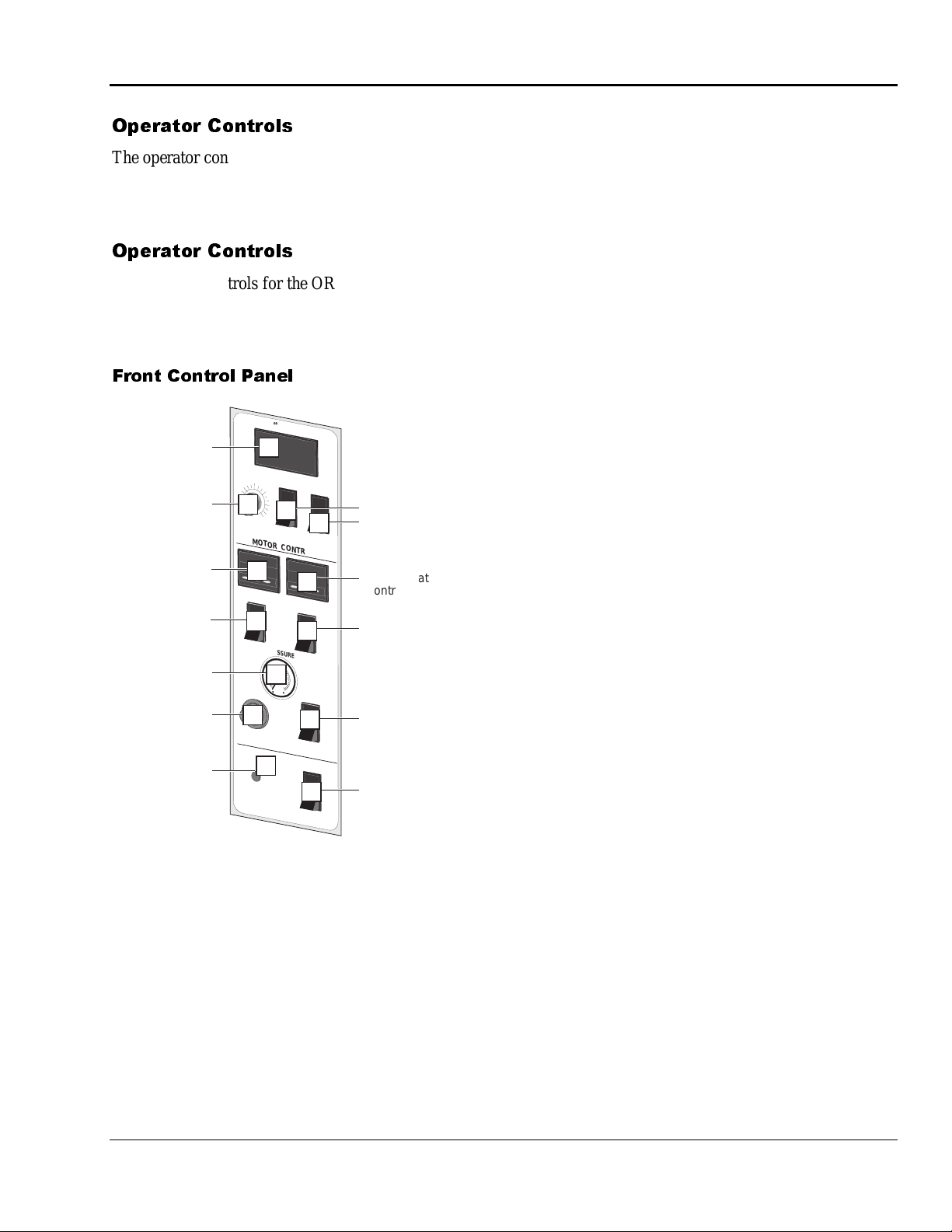

2SHUDWRU &RQWUROV

The operator controls for the ORCA-III Laminator

ar e loc ated on t he front and r ear of the unit, to t he

right of the operator posit i on. T he names and

functions of these controls are as follows:

2SHUDWRU &RQWUROV

The operator controls for the ORCA-III Laminator

ar e loc ated on t he front and r ear of the unit, to t he

right of the operator posit i on. T he names and

functions of these controls are as follows:

)URQW &RQWURO 3DQHO

PRO-TECH Engineering Madison,WI 608-246-8844

Speed Display

Speed Adjust

Upper Heater

Controller

Upper

Heater

ON/OFF

Main Roll Air

Pressure Gauge

Main Roll Air

Pressure

Adjustment

Power

Light

1

9

FWD

6

3

2

0

18

SPEED

MOTOR CONTROLS

3

TOP

1

4

O

ADJ

6

LAMINATOR ROLL CONTROLS

POWER

7

12

15

13

REV

HEAT

PRESSURE

40

20

5

80

100

11

BOTTOM

1

10

O

FAN TABLE

AUTO

12

STOP

ROLL

9

8

Motor REV/REW

Motor Control

Switch

Lower Heater

Controller

Lower

Heater

ON/OFF

Main Roll Up/Down

Switch

Fan/Vacuum

Table ON/OFF

4. UPPER ROLL HEAT O N/O FF - Turns the

heater c ontroller for the top laminati ng roll on or

off.

5. MAIN ROLL AIR PRES S URE G AUG E -

Displays the air pr es sur e p ushing t he main

laminating roll down.

6. MAIN ROLL AIR PRES S URE CO NT RO L -

Varies the air pressure fed to the cylinders that

drive the t op lamina ting r oll down.

7. POWER LIGHT - Indicates when the main

power is b eing applied t o the machine.

8. FAN/VACUUM TABLE ON/OFF - Turns t he

vacu um ta ble on or off.

9. MAIN ROLL UP/DOW N - Sets the main roll

to the u p (loa d) or down ( operate) p osition.

10. LOWER HEAT ON/OFF - Turns th e h eater

contr oller in the bottom lamina ting roll on or off.

11. LOWER HEATER CONTROLLER -

Pr ovides a readou t of t he t emperature of the

bottom laminating roll and the set-point for the

desired temperature. The upper heater must be on

for the lower hea ter t o function.

12. FOOTS W IT CH / CO NT I NUO US RUN -

Changes control of t he mac hine drive from t he

foots witch to continuou s ru n.

13. MOT IO N CO NT RO L FORWARD/STOP

REVERSE - Controls t he direction of the drive

system - forward, stop, or revers e.

Figure 3-1: Front Control Panel

1. SPEED DISPLAY - Provides digit al readout of

the machi n e speed and tot al throug h put in ei ther

metric or st andard unit s.

2. SPEED ADJUSTMENT - Adjusts the speed of

th e machin e from z e ro to maximum a s the c ontr ol

is tu rned clockwis e.

3. UPPER HEATER CONTROLLER - Provides

a readout of the temperature of the upper

laminating roll and the set-point for the desired

temperature.

GBC Pro-Tech 1997 October

3-3

Page 23

Operation ORCA-III Operation Manual

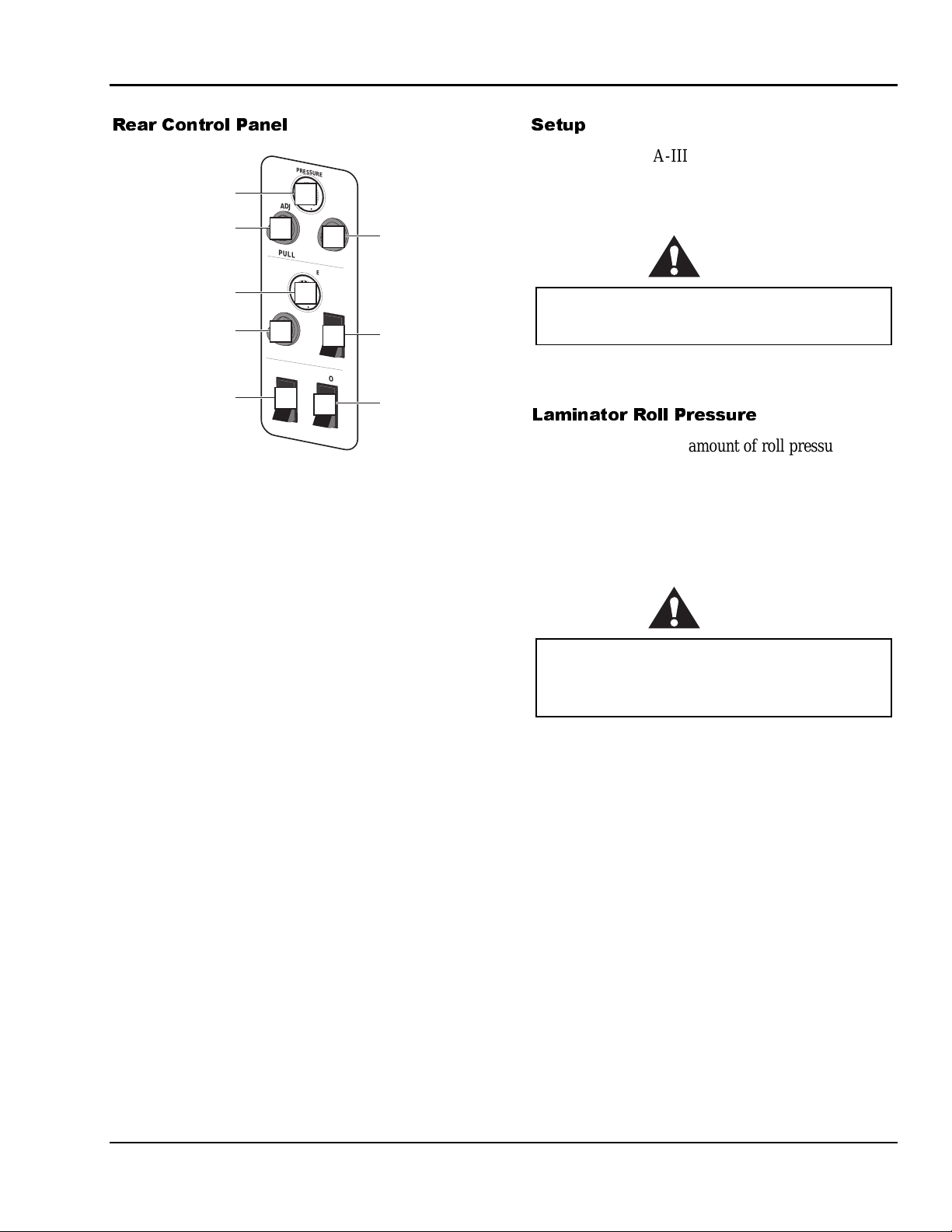

5HDU &RQWURO 3DQHO

PRESSURE

40

20

Pull Roll Clutch Air

Pressure Gauge

Pull Roll Clutch

Air Pressure

Adjustment

Pull Roll Air

Pressure Gauge

Pull Roll Air

Pressure

Adjustment

Cooling Fans

ON/OFF

80

1

100

ADJ

2

PULL ROLL CLUTCH

PRESSURE

40

20

80

3

100

ROLL

ADJ

4

PULL ROLL CONTROLS

COOLING FANS

AUTO

5

6

STOP

8

7

Pull Roll

Clutch

ON/OFF

Pull Roll

Up/Down

Switch

Motor Control

Switch

Figure 3-2: Rear Control Panel

1. PULL ROLL CLUTCH PRESSURE

GAUGE - M easures and displays t he air

pres sur e driving the pull roll clutch, which sets

web tension.

6HWXS

Setup of the ORCA-III Laminator is quick and

straightfor ward when instruct ions are followed

exactly.

CAUTION

Always use the same shim settings on the left

and right side of the laminator.

To adj ust t h e n i p pl eas e see Section 4: Maintenance

and Troubleshooting.

/DPLQDWRU 5ROO 3UHVVXUH

Use only the minimum amount of roll pressure

needed to accomplis h the task. While higher pres sur e

can ma ke t he adhesive bond f aster, exces s pr essure

can damage the rolls. Wrinkles and bubbles have

cau ses that gener ally cannot be c ured by app l ying

more pressure.

2. PULL ROLL CLUTCH AIR PRESSURE

ADJUSTMENT - Adjusts the clutch pressure

from z e ro to maximum a s the control is turned

clockwise.

3. PULL ROLL AIR PRES S URE G AUG E -

Meas ures and disp lays the air pres sur e p ushing

the pull roll down.

4. PULL ROLL AIR PRES S URE

ADJUSTMENT- Varies the air pressure fed to

the cylinders that drive t he pull roll down.

5. COOLING FANS ON/OFF- Tu rns the cooling

fans on or of f .

6. FOOTSWITCH / CO NT I NUO US RUN -

Changes control of t he mac hine drive from t he

foots witch to continuou s ru n.

7. PULL ROLL UP/DOWN - Sets the pull roll to

the up ( load) or down (operate) position.

8. PULL ROLL CLUTCH ON/OFF- Tur ns t he

pull roll clut c h on or off.

CAUTION

Excess pressure can damage the laminating

rolls. Minimum laminator roll pressure is

consistent with good results.

A typical roll pressure for soft substrates such as

Foamcore or Orca-Board is between 20 to 30 pounds

per square inch (PSI) or 140 to 205 kPa.

The r ange of typ ic al values for hard subst rates is 25

to 50 PSI or 170 to 345 kPa.

3-4

GBC Pro-Tech 1997 October

Page 24

ORCA-III Operation Manual Operation

/RDGLQJ WKH )LOP

Film is loa ded on t he appropriate unwinds. Loading

and a ligning the film ar e dis c ussed later in this

section. For ap plications s uch as encap sula tion, f ilm

is fed from both t he top a nd bott om feed unwinds .

The process of loading and aligning film is t he s ame

for both the top and the bottom unwinds. There are

two import ant p oints t o remember when loading film:

1. The a dhesive side of t he film mus t be or ient ed

away ( on the outside) fr om the laminating roll.

Otherwise it will immediately bond to the roll,

creating a major c lean-up pr oject.

Films ha ve a shiny side and a du ll side. The dull

side is t he one with the adhesi ve. The du ll side

should ALWAYS face outward from the

laminating roll.

CAUTION

Always mount the film so that the adhesive

side faces outward from the laminating roll.

This prevents hours of roll cleaning.

2. Th e film must be centered on t h e unwind for best

performance. This is vital when two films are fed

together . If the two films are not aligned, f eed

problems, wrinkles a nd other assorted trou bles

will occur .

3RVLWLRQLQJ WKH )LOP

The following procedur e is app licable t o all the feed

unwinds.

Tools required:

5

/16" T-handle wrench

•

• Tape measure

To position the film:

1. Open t he top unwind by removing the p in and

swinging the a rm out.

2. Position the film chuck with the brake on the left

side of the arm. Make sure that the brake piston

is fully retracted (pu shed in).

3. Load t he film.

4. Center the film on the u nwind arm b y measuring

the distance form the ends of the film to the sides

of the machine using a tape measure.

5. Lock down t he c huck on the right side using the

5

/16" T-handle wrench supplied with your

laminator. Mount a rubber O-ring on the left side

of the film, followed by a film chuck. Be sure

that the collar only touches , bu t does not tighten,

the O-ring.

6. Ti g h ten t h e screw on the brake chuck.

7. Recheck the cent ering of the film roll with the

tape measure. Readjust if necessary.

8. Return the arm to its locked position and reinsert

the locking pin.

CAUTION

Carefully align the two films being fed into the

nip. If not, y o u will o bt ain poo r r e s ults .

GBC Pro-Tech 1997 October

3-5

Page 25

Operation ORCA-III Operation Manual

+HDWLQJ

Use the following instructions when heating one or

both of the laminating rolls. The pr oc edure is t he

same for the top and bottom heaters.

1. Set the heater switch to ON.

2. Adjust the t emper at ur e cont roller for the desired

opera ting temperatur e usi n g the temperatu re

controller push b u ttons.

3. For the Syrlec type controller, use the up and

down arrows to adjust the set point. Hold down

the required arrow until the correct set point is

acheived.

For the CAL3200, it is necessary to press the

star button at the same time as the up or down

arrow to adjust the set point temperature.

4. When heating the rolls, keep t h e top rol l d ow n

and t urning at a modera te speed t o prevent

uneven heating.

5. It will t ake ap prox ima tely 25 minutes for the

laminating roll(s) to reac h op erating temperatu re.

When the pres et operating tempera tu re has been

reac hed, the mac hine is ready to use.

3DSHU 7LSV

1. Always c ut t he lea ding edge of a print s traight so

it ca n be fed perp endicular to t he laminating roll.

2. If you ar e laminat ing very thin p aper s, you

should consider utilizing the ORCA III's envelope

feed. This pa tented techniqu e is the best c hoic e

for the output from electrostatic printers that

have signif i c ant water cont ent or for paper s with

excessive stretch.

6. The ORCA-III can be used for cold mounting

and la mina ting while maintaining the temperat ure

of the main la minating rolls by using the ou tput

rolls as a lamina tor ( by feeding prints from the

rear) f or a quick change-over b et ween hot and

cold laminating.

&RROLQJ

The following is the fastest way to cool down the

machine.

1. Set th e h eater switches to OFF.

2. Position the two rear air tubes so that they are

tilted to direct air flow at the rolls.

3. Set the Laminator Roll Control to the DOWN

position.

4. Set the Forward/Reverse switch to the

FORWARD posit on.

5. Set the speed control to 5 fpm (150 cpm).

6. Let t he machine run until the lamina ting rolls

return to room temperature.

3-6

GBC Pro-Tech 1997 October

Page 26

ORCA-III Operation Manual Operation

3URFHVV&RQWURO&KDUWV

Process control charts allow you to record the way

you thread film through the machine's rolls and idlers

(called webbing) and the control settings for each

product and process. Process control charts are an

excellent tool for training new operators. They

provide a "road map" for correct machine setup and

operation.

This section contains a blank process control chart

and diagram for the ORCA-III as well as completed

charts for the basic operations of the laminator.

GBC Pro-Tech laminators respond in a very accurate

and repeatable manner. The charts provide a way to

set up each time, every time for repeatable

performance by assuring that all controls are set to

optimum.

The process control charts should be kept in this

manual or in a book close to the laminator. Use the

machine to encapsulate the popular charts so they can

withstand food and coffee spills and so they are

always available for ready reference.

⇒

NOTE

When trying new products and processes, remember

that GBC Pro-Tech's customer service

representatives are only a phone call away.In North

America, please call 1-800-236-8843.

The completed process control charts included in this

section are based on Orca-Film, Orca-Board and

typical prints.

0RXQWLQJ2QO\

6HWXS

1. See process charts 3-1, 3-2 and diagram 3-2b.

2. Shims: Set to the thickness of the material being

used for mounting.

3. Upper Laminator Roll Pressure: 40 P SI (275

kPa).

3URFHGXUH

1. Lay the print on the board. Using a tack iron,

tack the leading edge of the print down onto the

board so it is held in place.

2. Put a piece of con tact/release paper over the

print. Otherwise, adhesive will be applied to the

laminating roll, which can cause damage and the

ink from electrostatic prints will be deposited on

the roll.

3. Feed the print/Orca-Board package through the

nip.

0RXQWLQJ/DPLQDWLQJ

The following procedure is for one-step mounting and

heat-activated laminating using mounting board with

one adhesive side (such as Orca-Board).

6HWXS

1. See process chart 3-3 and diagram 3-3b.

2. Mount the film and web as shown in diagram

3-3b.

1

3. Shims: Set the two front shim dials to

than board thickness.

4. Laminator Roll Pressure: 40 PSI (275 kPa).

5. Speed: 3 fpm (90 cpm).

6. Upper Laminator Roll Heat: 230 °F (110 °C).

7. Cooling: Off

8. Film Tension: Minimum amount needed to have

the film lay smooth, about half way up the roll,

on the upper main roll. Generally one to two

turns on the unwind brake.

3URFHGXUH

Feed the Orca-Board dull (adhesive) side up with the

print positioned as desired. A tack iron can be used to

hold the leading edge of the print in place.

/32" less

4. Speed: 3 fpm (90 cpm).

5. Upper Laminator Roll Heat: 230°F (110 °C).

GBC Pro-Tech 1997 October

3-7

Page 27

Operation ORCA-III Operation Manual

(QFDSVXODWLRQ

6HWXS

1. See process chart 3-4 and diagram 3-4b.

2. Shims: None.

3. Front Laminat ing Roll Pressure: 80 PSI

(550 kPa).

4. Back P ull Roll Clu tch Pressure: On, 8 0 PS I

(550 kPa).

5. Pull Roll: Down, Pressu re - 80 PSI ( 550 kPa).

6. Speed: 5-7 fpm (150-210 cpm).

7. Upper Laminator Roll Heat: 220-230 °F

(104-110 °C).

8. Lower Laminator Roll Heat: 220-230 °F

(104-110 °C).

9. Cooling: Optional

10. Use of the r ear wind-up roll for the fi n i shed

mater ial is op tional. It is a good p rocedure for

long runs.

6HWXS

1. See process charts 3-5, 3-6, 3-7, and 3-8 and

diagrams 3-5b, 3-6b, 3-7b, and 3-8b for film

mounting instructions and ma c hine adjustments.

2. Ensure that the mounting film from the bottom

side has the sticky (adhesive) side riding up

ar ound the outside of t he b ottom la mina ting r oll.

3URFHGXUH 3DVV

1. Run the print t hrough to apply adhesive and

laminate.

2. Trim to slightly larger t han the desired finished

size.

3URFHGXUH 3DVV

1. Prepare to p ut t he p rint through a s econd time to

mount the print to the substrate - anything from

wood, t o Masinote, to Gator foam. Start by

setting the shims to the appropriate spacing for

the material used.

2. Trim the board to the size of the print.

3URFHGXUH

Feed the work into the nip with the leading edge tight

and entering the nip evenly from side to s ide. For thin

pap er fr om electrost atic print ers in roll form it is best

to fold over the leading edge approx imately 6 inches

to cr eate a squa re leading edge.

(QFDSVXODWLRQ :LWK (QYHORSH

)HHG

The us e of th e en v el o pe feed featu re greatly

simplifies the input of lar ge ha nd- fed prints. The

proc edure is identical to that f or regu lar

encapsulation ( see above), h ow ev er, the mach i n e

setup is diff erent as shown in proc es s chart 2-5 and

diagram 2-5B

7ZR3DVV 0RXQW DQG /DPLQDWH +RW

DQG &ROG

There ar e severa l ap proa ches to the moun t/ l aminat e

task. I t ca n be accomplished with either hot or cold

laminate film on the top. Also, the second pass f or

mounting can be done by f eeding from either the fr ont

or back of the laminator.

3. Align the wor k to the boar d and ensu re an ex act

fit. Place weights on the center of t he p rint to

make sure tha t it does not move relat i ve t o the

board during t he next st eps.

4. Ra ise one end of the print and peel ba c k

approx i mat ely two inches of the li n er t o expo se

the adhesive that was applied to the print in the

first pass . Fold it under .

5. Lay t h e pr i n t b ack d ow n even ly a nd ext remely

flat. From t he c ent er outward, tac k the expos ed

adhesive to the substrate.

6. Position the pi ece so that the end with the liner

peeled ba ck is fa cing the nip. Insert the first one

inch of the board into the nip. Very carefully

wrap the print back and over the top laminating

rol l . Be sure t h ere ar e no wrink l es in the nip a rea.

Car eful l y peel of f th e l i n er as the b o ard

progress es through the la minator .

7. Trim the p i ece to the f i n i shed size.

3-8

GBC Pro-Tech 1997 October

Page 28

ORCA-III Operation Manual Operation

&ROG0RXQW /DPLQDWH

:LWK +RW 0DLQ 5ROOV

1. See process chart 3-8 and diagram 3-8b for film

mounting instructions and machine adjustments.

2. Move the feed table to the rear of the laminator.

3. Ra ise the main roll ( hot).

The blades on both the infeed and outfeed

slitters are razor sharp. You can cut yourself

9LQ\O 7UDQVIHU

WARNING

severely.

4. Reverse the motor.

5. Web a c c ording to drawing.

6. Set the nip height and tack the lea ding edge for

the second pass . Run thr ough as the liner is being

pulled off.

:LWK &ROG 0DLQ 5ROOV

1. See process chart 3-9 and diagram 3-9b for film

mounting instructions and machine adjustments.

2. Use the machine as a cold laminator with the

main rolls not heat ed.

5ROO WR 5ROO 7UDQVIHU DQG /DPLQDWH

2QH 3DVV

:LWK +RW 0DLQ 5ROOV

1. See process chart 3-10 and diagram 3-10b for

film mounting inst ructions and machine

adjustments.

2. Web the vinyl over the bottom roll and hold with

the pull r olls.

3. It is useful to have a leader on the paper so it can

be webbed t hrough and taped t o the rewind

befor e s tarti ng.

4. Lower the main roll, start the motor, and begin

the tr ansfer proc ess . Ta pe th e finished pro d uct to

the rewind and add t he laminat ion by raising the

pull roll. Web the laminate around the upper pull

roll. Be sure it is smooth on the roll, t hen lower

the roll.

5. Add infeed a n d o ut feed sl itter s a s needed.

1. See process chart 3-11 and diagram 3-11b for

film mounting inst ructions and machine

adjustments.

2. Web the vinyl u p ar ound the bot tom main roll

and over to the pu ll roll. Make s ure the material

is webbed straight and lower t he pull roll to hold

the vinyl.

3. Place both table idlers in the slots on the table

bracket s. Web the paper through a s shown in

diagram 2-11b.

4. Oft en, when paper is not on a c ore, hand tension

must b e applied t o the paper in order t o ma intain

transf er qua lity unt il the end of the trans f erred

image.

5ROO WR 5ROO 7UDQVIHU

:LWK +RW 0DLQ 5ROOV

1. See process chart 3-12 and diagram 3-12b for

film mounting inst ructions and machine

adjustments.

2. Web the vinyl u p ar ound the bot tom main roll

and over to the pull roll. Lower the pull roll t o

hold the vinyl.

3. Web the paper up to the main roll. Lower the

main roll to start the transfer process.

4. Tape t he vinyl ont o the lower rewind and p eel off

the paper. Wind it on the upper rewind.

5. La mina tion can be done in a s econd pass, if

required. See cha rt 2- 13.

GBC Pro-Tech 1997 October

3-9

Page 29

Operation ORCA-III Operation Manual

5ROO WR 5ROO &ROG 2YHUODPLQDWLRQ

6HFRQG 3DVV 0DLQ 5ROOV +RW

:LWK +RW 0DLQ 5ROOV

1. See process chart 3-12 and diagram 3-13b for

film mounting inst ructions and machine

adjustments.

2. Install the brake adapter on the rear rewind.

3. Bring the vinyl up over the bot tom lamination

roll a nd throu gh the main rolls.

4. Tape the overlaminate release liner to the upper

rewind.

5. Web the overlaminate material around the upper

pull roll and lower it to begin over l amination.

3-10

GBC Pro-Tech 1997 October

Page 30

ORCA-III Operation Manual Operation

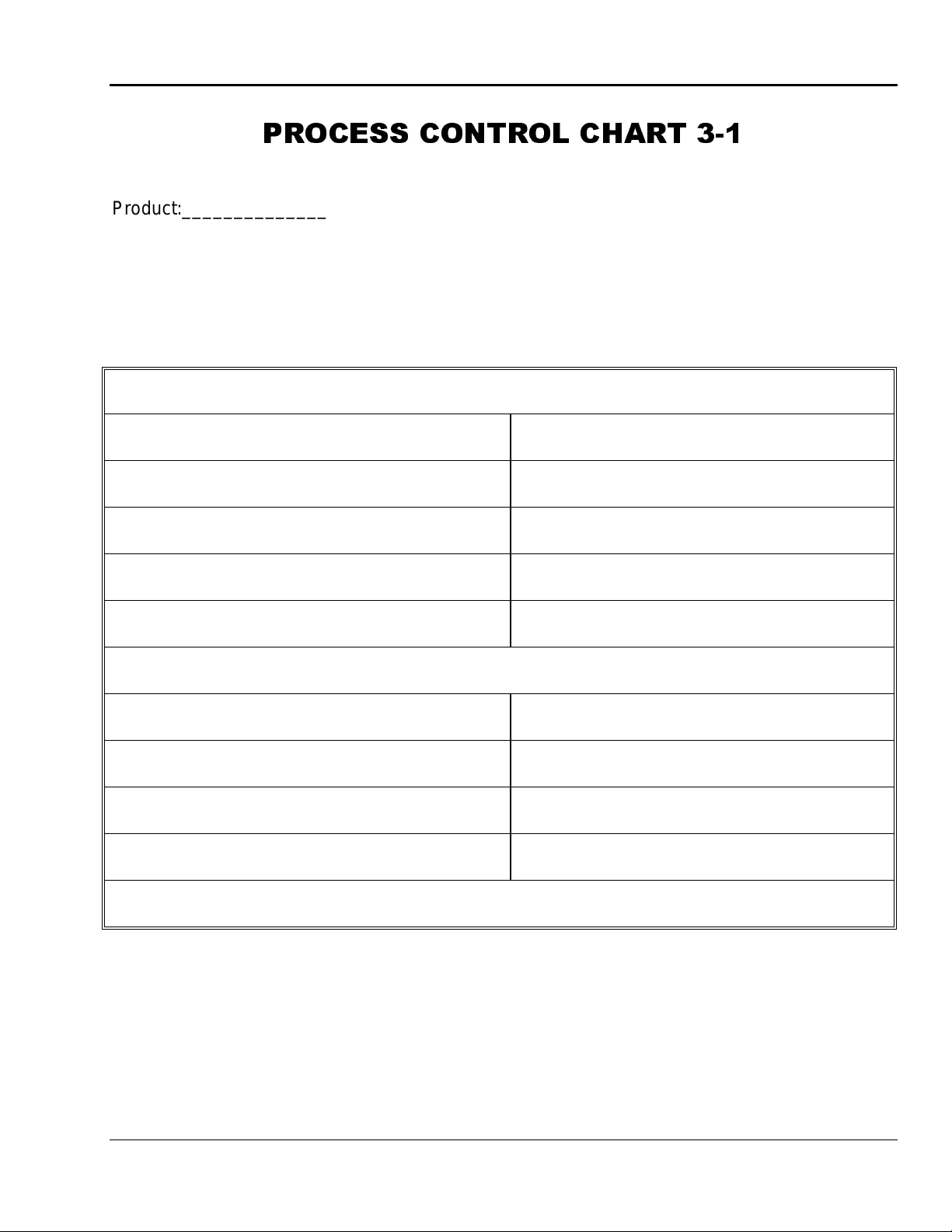

352&(66 &21752/ &+$57

Product:__________________Process:_________________________Date: _____________

Material Top:___________________________Material Bottom:________________________

Other Material: ______________________________________________________________

FRONT CONTROL SETTINGS

Speed (Ft/min): Reverse/Forward:

Roll Up/Down: Shim Dial:

Roll Pressure: Top Temp. Set:

Top Heater On /Off: Bottom Temp. Set:

Bottom Heater On/Off:

REAR CONTROL SETTINGS

Pull Clutch On/Off: Pull Roll Up/Down:

Pull Clut ch Pressur e: Pull Roll Pressure:

Shim Dial: Cooling:

See Chart 3-1B for Webbing Outline

Special Instructions: __________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

GBC Pro-Tech 1997 October

3-11

Page 31

Operation ORCA-III Operation Manual

352&(66 &21752/ ',$*5$0 %

IDENTIFICATION DI AGRAM

(I) Removable Idler

(F) Fixed Idler

(U) Unwind Shaft

(R) Rewind

(M) Main Roll

(P) Pull Roll

(C) Cooling Tube

(S) Slitter Idler

Small Table

Infeed Slitter

S

R