Page 1

Magnapunch 2.0

Heavy Duty Punch

INSTALLATION & OPERATION MANUAL

MANUAL DE INSTALACIÓN Y FUNCIONAMIENTO

MANUEL D’INSTALLATION ET D’UTILISATION

Do not duplicate without written permission from ACCO Brands.

Document Number: 80120510 Rev. A

Page 2

Magnapunch 2.0 – Installation and Operating Instructions

ACCO Brands reserves the right to make changes

to this publication and to the products described in

it without notice. All specifications and information

concerning products are subject to change without

notice. Reference in this publication to information or

products protected by copyright or patent does not

convey any license under the rights of ACCO Brands

or others. ACCO Brands assumes no liability arising

from infringements of patents or any other rights of

third parties.

This publication is copyrighted © 2011 by ACCO

Brands. All rights reserved.

Co n v e n t i o n s Us e d i n t h i s

Ma n U a l

The Magnapunch 2.0 features menu driven operation

from an LCD user interface. Menu selections and

commands appear in bold. For example:

On the Language Setup menu, press UP or DOWN

to scroll to the desired language.

ACCO Br ands Can ada

5 Precidio Cour t

Brampton, ON L6S-6B7

800.263.1063

www.gbccanada.com

Page i

ACCO Mexicana

Neptu no #43, Colo nia Nueva I ndustr ial Vallejo

Delagacion Gus tavo A. Madero, CP 07700

México, DF. (55) 1500-5578

www.gbc.com.mx

© 2011 ACCO Brands. All rights reserved. ACC O® is a regis tered trademark of

ACCO Br ands. GBC ® is a registered trad emark of General Bi nding Cor porati on.

80120510 Rev. A 11-2011

Page 3

Magnapunch 2.0 – Installation and Operating Instructions

Ta b l e o f Co n T e n T s

1. Safety 1-1

General Safeguards ................................................1-1

Die Set Cautions .................................................1-2

Electrical ..................................................................1-2

For 230 Volt Machines Only ................................1-2

GBC Technical Service .......................................... 1-3

Safety Label Locations .......................................... 1-4

2. Warranty 2-1

Limited 90-Day Warranty ........................................2-1

3. Specifications 3-1

Punching Dimensions ........................................ 3-2

FCC Class A Notice ............................................... 3-4

Canada Class A Notice - Avis Canada, Classe A .. 3-4

Modifications .......................................................... 3-4

4. Installation 4-1

GBC Technical Service .......................................... 4-1

Prior to Installation ................................................. 4-1

Installation .............................................................. 4-1

Test ing ................................................................ 4-1

Installing Die Sets .............................................. 6-6

Removing Punch Pins ........................................ 6-7

Job Setup ............................................................... 6-7

Using the LCD User Interface ............................ 6-7

Testing the Job .................................................. 6-9

Punching Operation ..............................................6-10

Punching the Job ..............................................6-10

Punch Activation ...................................................6-11

Foot Pedal .........................................................6-11

Tabletop Trigger ................................................6 -11

Punching Tips ......................................................6-12

Paper .................................................................6-12

Plastic Covers ...................................................6 -12

Chip Drawer ......................................................6-12

Hole Quality ...........................................................6-13

7. Operator Maintenance 7-1

Caring for the Magnapunch 2.0 ..............................7-1

Die Set Maintenance .........................................7-1

Cleaning the Magnapunch 2.0 ............................7-1

Troubleshooting ......................................................7-2

Notes 7-3

5. Feature guide 5-1

Power ..................................................................... 5-1

ON/OFF Switch .................................................. 5-1

Fuse ................................................................... 5-1

Power and Foot Pedal Connectors.................... 5-1

Punching Throat ..................................................... 5-1

Lift Picker ............................................................... 5-2

User Interface ......................................................... 5-2

LCD .................................................................... 5-2

Push Buttons ..................................................... 5-2

Edge Guide and Tabletop Trigger .......................... 5-2

Edge Guide ........................................................ 5-2

Tabletop Trigger ................................................. 5-3

Punching Table ....................................................... 5-3

Chip Drawer ....................................................... 5-3

Die Set ............................................................... 5-3

Foot Pedal .......................................................... 5-3

6. Operation 6-1

User Interface ......................................................... 6-2

Navigation .......................................................... 6-2

First Time Setup ................................................. 6-2

Operation ...............................................................6-3

Home Screen ..................................................... 6-3

Menu .................................................................. 6-4

Usage Instructions ............................................. 6-4

Help + Tips .........................................................6-5

Notification Screens .......................................... 6-5

Changing the Interchangeable Die Sets ................6-6

Removing Die Sets ............................................ 6-6

Page ii

Page 4

Magnapunch 2.0 – Installation and Operating Instructions

Page iii

Page 5

Magnapunch 2.0 – Installation and Operating Instructions

1. sa f e t y

Your safety, as well as the safety of others is

important. Before you install or use the Magnapunch

2.0, read and follow all the safety notices carefully

in this chapter. In this instruction manual, and on

the Magnapunch 2.0, you will find important safety

notices regarding the Magnapunch 2.0. Read all

of the instructions and save these instructions for

further use.

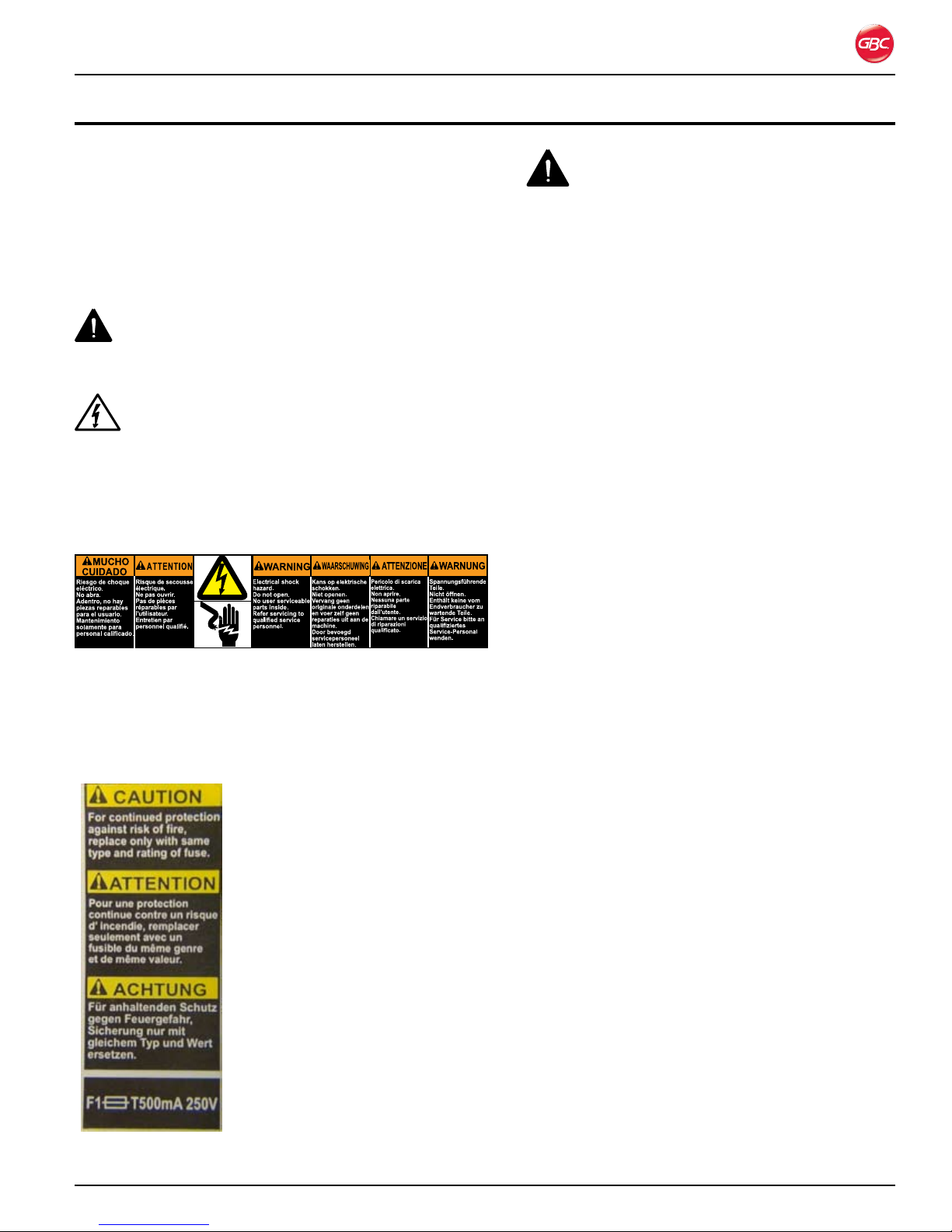

The safety alert symbol precedes each

safety notice in this manual. The symbol indicates a

potential personal safety hazard to you or others.

This safety alert symbol indicates a potential

electrical shock. It warns you not to open the

Magnapunch 2.0 and expose yourself to hazardous

voltage.

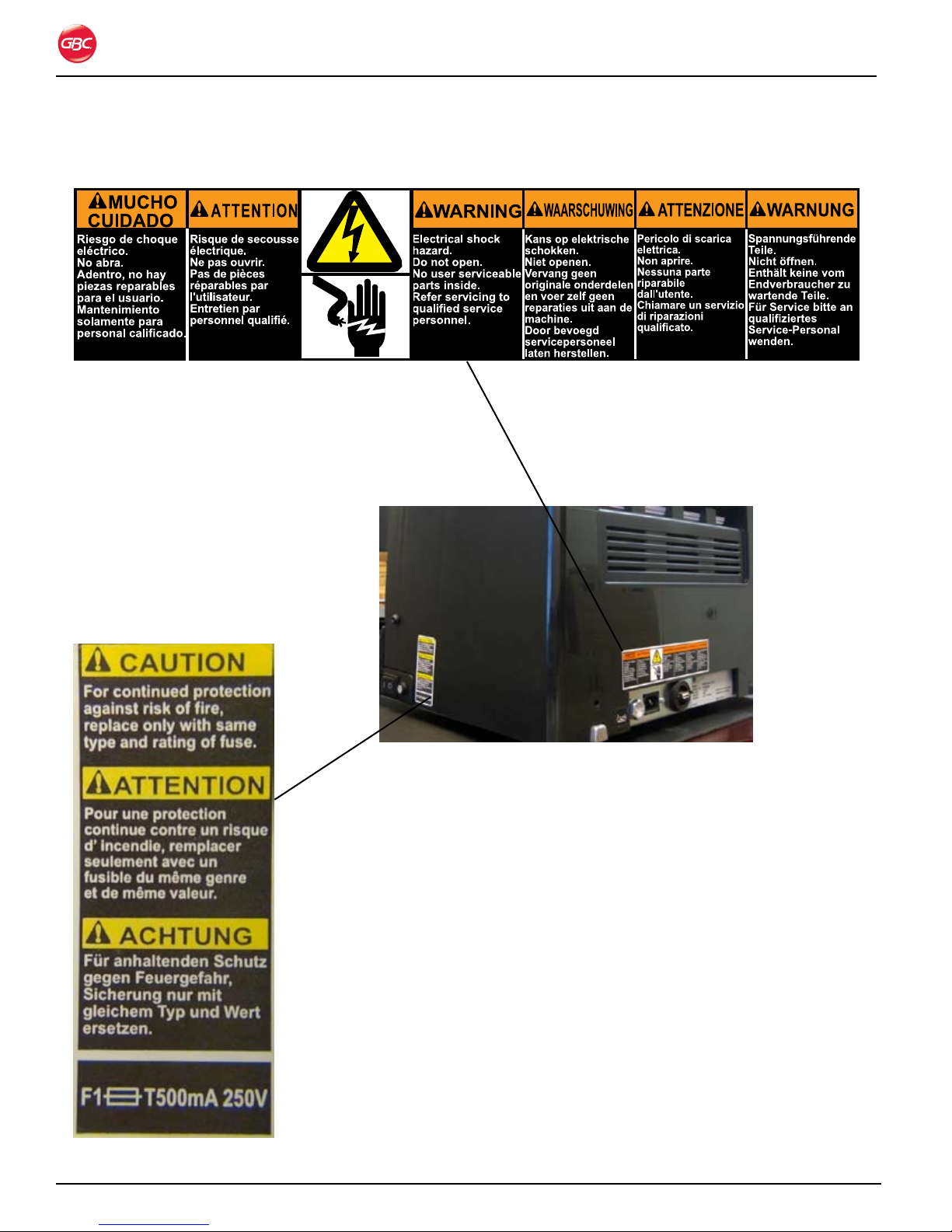

The following warnings are found on the

Magnapunch 2.0.

This safety notice means that you could be seriously

hurt or killed if you open the Magnapunch 2.0 and

expose yourself to hazardous voltage. Do not open

the Magnapunch 2.0. There are no user serviceable

parts inside. Refer service to qualified service

personnel.

This safety notice means that a

fire or risk of electrical shock

could result from using an

improper fuse. For continued

protection against fire or risk of

electrical shock, replace only

with the same type and rating

fuse.

WaRninGs

Do not attempt to service or repair the •

Magnapunch 2.0.

Do not open the Magnapunch 2.0. There are •

no serviceable parts inside. Refer service to

qualified service personnel.

Do not connect the Magnapunch 2.0 to an •

electrical supply or attempt to operate the

Magnapunch 2.0 until you have completely

read these instructions. Maintain these

instructions in a convenient location for future

reference.

To guard against injury, the general safety •

precautions must be observed when installing

and using the Magnapunch 2.0.

Ensure the Power switch is in the OFF position •

when the Magnapunch 2.0 is not in use.

Consider the work area. A cluttered work area •

can lead to accidents. The Magnapunch 2.0

must be placed on a sturdy level table surface.

Allow sufficient access to the front, back, and

sides of the Magnapunch 2.0. Keep the work

area well lit.

Failure to observe these warnings could result in

severe bodily damage or death.

Ge n e R a l sa f e G U a R d s

Do not use the Magnapunch 2.0 for other than •

its intended purposes.

Do not defeat or remove electrical and •

mechanical safety equipment such as

interlocks, shields, and guards.

Do not insert objects unsuitable for punching •

or expose the equipment to liquids.

Use only GBC Magnapunch 2.0 •

interchangeable Die Sets with the

Magnapunch 2.0.

Before you operate this Magnapunch 2.0, it is •

important that you read and understand the

entire contents of these instructions.

Page 1-1

Page 6

Magnapunch 2.0 – Installation and Operating Instructions

die se t Ca U t i o n s

CAUTIONS:

Possible pinch point hazard. When installing Die •

Sets into your Magnapunch 2.0, always keep

fingers and body parts out of the Magnapunch

2.0’s Die Set slot and away from all areas of the

Die Set except for the finger groove in the Die

Set’s handle. Failure to observe these precautions

may result in injury.

Possible Die Set damage. Make certain that all •

punch pins are fully and properly seated in the Die

Set before inserting the Die Set. Failure to ensure

that all punch pins are fully seated could result in

damage to the Die Set and Magnapunch 2.0.

el e C t R i C a l

The Magnapunch 2.0 should be connected only to

a source of power as indicated in these instructions

and on the nomenclature plate located on the rear of

the Magnapunch 2.0. Contact an electrician should

the attachment plug provided with the Magnapunch

2.0 not match the receptacles at your location.

Disconnect the plug from the receptacle and contact

your dealer or distributor, or GBC Technical Service

when one or more of the following has occurred.

The power supply cord or attachment plug is •

damaged.

Liquid has been spilled into the Magnapunch •

2.0.

The Magnapunch 2.0 is malfunctioning.•

The Magnapunch 2.0 does not operate as •

described in these instructions.

CAUTION: The receptacle must be located

near the Magnapunch 2.0 and must be easily

accessible.

Disconnect the attachment plug from the receptacle

to which it is connected and keep the power

supply cord in your possession while moving the

Magnapunch 2.0.

fo R 230 vo l t Ma C h i n e s on l y

CAUTION: When choosing a detachable

line cord for use with your Magnapunch 2.0, always

observe the following.

WARNING: Do not attempt to service or repair

the Magnapunch 2.0. Failure to observe this warning

could result severe personal injury or death.

Make sure the power switch is in the Off position

when the Magnapunch 2.0 is not in use.

The cordset consists of three parts; •

attachment plug, cordage, and appliance

inlet. Each of these components must have

European regulatory approvals for safety.

The following minimum electrical ratings •

for the specific cordset are published for

safety purposes. Do not use cordsets that

do not meet the following minimum electrical

requirements.

Plug: 10 amperes, 250 volts, 50/60 Hz,

European safety approved.

Cordage: Type HO5VV-F3G0.75, harmonized

( HAR ). The symbols indicate cordage

approved to appropriate European standard.

Note, HAR may be substituted by the approval

mark of the European Safety agency which

approved the cordage. An example would be

VDE .

Appliance Connector: 10 amperes, 250 volts,

50/60 Hz, European safety approved, Type IEC

320.

The cordset shall not exceed 3 meters in

length. A cordset with component electrical

ratings greater than the minimum specified

electrical ratings may be substituted.

Page 1-2

Page 7

Magnapunch 2.0 – Installation and Operating Instructions

GBC te C h n i C a l se R v i C e

To order replacement accessories, service, parts,

or an Equipment Maintenance Agreement, please

contact GBC Technical Service and Support at:

United States

GBC Technical Service and Support – 3rd Floor

ACCO Brands

300 Tower Parkway

Lincolnshire, IL 60069

www.gbcconnect.com

1-800-723-4000

Canada

ACCO Brands Canada

5 Precidio Court

Brampton, ON L6S-6B7

www.gbccanada.com

Callcentre@GBCCanada.com

1-800-463-2545

Mexico

ACCO Mexicana

Neptuno #43, Colonia Nueva Industrial Vallejo

Delagacion Gustavo A. Madero, CP 07700

México, DF. (55) 1500-5578

www.accomexico.mx/index.php

(5525) 1500-5741

Other Sources

For service facilities in other regions, please visit:

www.gbcconnect.com/contact_us.aspx

Also use your mobile phone to scan the QR code

on the side of the Magnapunch 2.0 for a list of

authorized service providers.

Page 1-3

Page 8

sa f e t y la B e l lo C a t i o n s

Magnapunch 2.0 – Installation and Operating Instructions

Page 1-4

Magnapunch 2.0 Safety Label Locations.Figure 1.

Page 9

Magnapunch 2.0 – Installation and Operating Instructions

2. Wa R R a n t y

li M i t e d 90-da y Wa R R a n t y

ACCO Brands USA LLC, 300 Tower Parkway,

Lincolnshire, IL 60069 (in Canada, ACCO Brands

Canada Inc., 5 Precidio Court, Brampton, ON

L6S-6B7; and in Mexico, ACCO Mexicana, S.A. de

C.V. Av., Circuito Industrial Norte #6 Parque Industrial

Lerma 52000, Lerma Edo. De México) (each,

respectively, “ACCO Brands”) warrants to the original

purchaser that this Magnapunch 2.0 ACCO Brands

product is free from defects in workmanship and

material under normal use and service for a period of

90 days after purchase.

ACCO Brands’ obligation under this warranty is

limited to replacement or repair, at ACCO Brands’

option, of any warranted part found defective by

ACCO Brands without charge for material or labor.

Any replacement, at ACCO Brands’ option, may be

the same product or a substantially similar product

that may contain remanufactured or refurbished

parts. This warranty shall be void in the following

circumstances:

(i) if the product has been misused,

(ii) if the product has been damaged by negligence

or accident, or

(iii) if the product has been altered by anyone other

than ACCO Brands or ACCO Brands’ authorized

agents.

For warranty execution, please contact ACCO

Brands at:

1-800-541-0094 or www.gbcconnect.com in the

USA

800-263-1063 or www.gbccanada.com in Canada

TO THE EXTENT ALLOWED BY APPLICABLE

LAW, THIS WARRANTY IS IN LIEU OF ALL OTHER

EXPRESSED WARRANTIES. REPRESENTATIONS

OR PROMISES INCONSISTENT WITH OR

IN ADDITION TO THIS WARRANTY ARE

UNAUTHORIZED AND SHALL NOT BE BINDING ON

ACCO BRANDS. TO THE EXTENT PERMITTED BY

APPLICABLE LAWS, ANY IMPLIED WARRANTIES

(IF APPLICABLE) ARE LIMITED IN DURATION

TO THE DURATION OF THIS WARRANTY.

SOME STATES AND JURISDICTIONS DO NOT

ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. TO THE

EXTENT PERMITTED BY APPLICABLE LAW, IN

NO EVENT SHALL ACCO BRANDS BE LIABLE

FOR ANY SPECIAL, INCIDENTAL, PUNITIVE,

EXEMPLARY, CONSEQUENTIAL OR SIMILAR

DAMAGES, WHETHER OR NOT FORESEEABLE.

SOME STATES AND JURISDICTIONS DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF

SPECIAL, INCIDENTAL, PUNITIVE, EXEMPLARY,

CONSEQUENTIAL, OR SIMILAR DAMAGES, SO

THE ABOVE EXCLUSION OR LIMITATION MAY NOT

APPLY TO YOU.

FOR CONSUMERS WHO HAVE THE BENEFIT

OF CONSUMER PROTECTION LAWS OR

REGULATIONS IN THEIR JURISDICTION OF

PURCHASE OR, IF DIFFERENT, IN THEIR

JURISDICTION OF RESIDENCE, THE BENEFITS

CONFERRED BY THIS WARRANTY ARE IN

ADDITION TO ALL RIGHTS AND REMEDIES

CONVEYED BY SUCH CONSUMER PROTECTION

LAWS AND REGULATIONS.

To the extent permitted by law, this warranty is

not transferable and will automatically terminate if

the original product purchaser sells or otherwise

disposes of the product.

(55) 1500-5578 or www.gbc.com.mx in Mexico

This warranty gives you specific legal rights. Other

rights, which vary from jurisdiction to jurisdiction,

may exist. In addition some jurisdictions do not allow

(i) the exclusion of certain warranties, (ii) limitations

on how long an implied warranty lasts and/or (iii) the

exclusion or limitation of certain types of costs and/

or damages, so the above limitations may not apply.

Page 2-1

Page 10

Magnapunch 2.0 – Installation and Operating Instructions

Page 2-2

Page 11

Magnapunch 2.0 – Installation and Operating Instructions

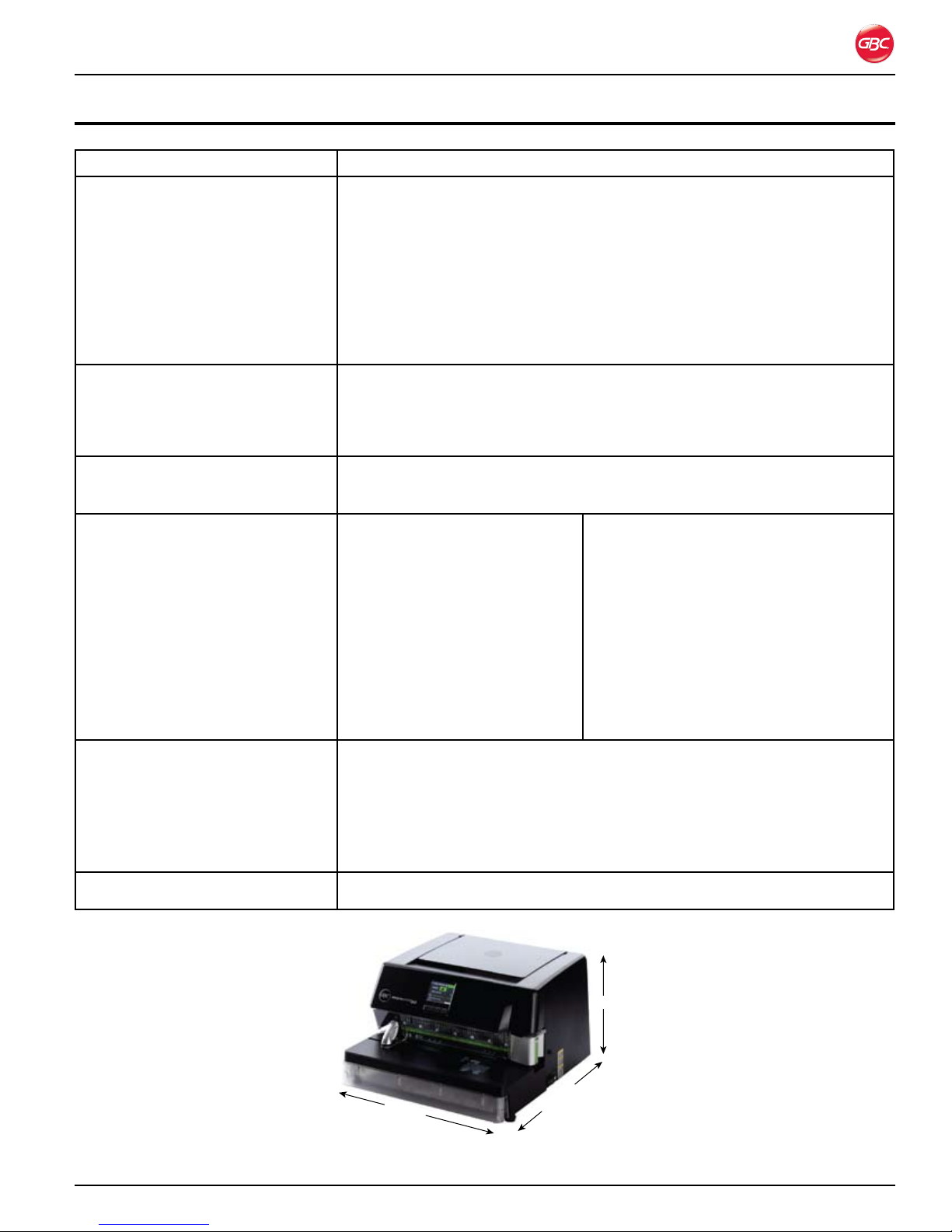

Width

Depth

Height

3. speCifiCations

Item Specification

Punch Pattern

Plastic Binding•

Plastic Color Coil, GBC and •

Industry standard 4:1 (C4)

Plastic Color Coil, 5:1 (C5)•

Twin Loop Wire, 2:1 (W2)•

Twin Loop Wire, 3:1 (W3)•

VeloBind•

SureBind•

3 or 4 Hole Binding•

Maximum number of sheet punch capacity for 20 lb. (75 g/m2) bond.

39

29

29

29

34 (round) 29 (square)

34 (round) 29 (square)

49

49

34

Dimensions

Width•

Height•

Depth•

18.5 in. (47.0 cm)

12.0 in. (30.5 cm)

20.0 in. (50.8 cm)

Weight

Machine•

Shipping•

Electrical Requirements

Fuse (F1 T1A 250V)•

Voltage•

Current•

Power•

U.S. Receptacle•

94 lbs. (42.4 kg)

116 lbs. (52.6 kg)

US Model

20A, 250V

115 VAC

5.6 Amperes maximum, 50/60

Hz

644 W

NEMA 5-15R

Refer to the nomenclature

plate located on the rear of the

Magnapunch 2.0 for the specific

Europe Model

20A, 250V

230 VAC

3.5 Amperes maximum, 50/60 Hz

805 W

YP-24 R

Refer to the nomenclature plate located

on the rear of the Magnapunch 2.0 for the

specific electrical rating applicable to the

unit.

electrical rating applicable to the

unit.

Noise Level 94dB when punching maximum pages of media.

Under 2003/10/EC on the minimum health and safety requirements regarding

the exposure of workers to the risks arising from physical agents (noise), the

following sound pressure levels require the following action by employers:

80dB employers must make hearing protection available to workers. •

85dB a hearing protection warning sign must be displayed. •

87dB individual hearing protection shall be used by workers.•

Motor 1/4 HP

Width

Height

Depth

Dimension Reference.Figure 2.

Page 3-1

Page 12

Magnapunch 2.0 – Installation and Operating Instructions

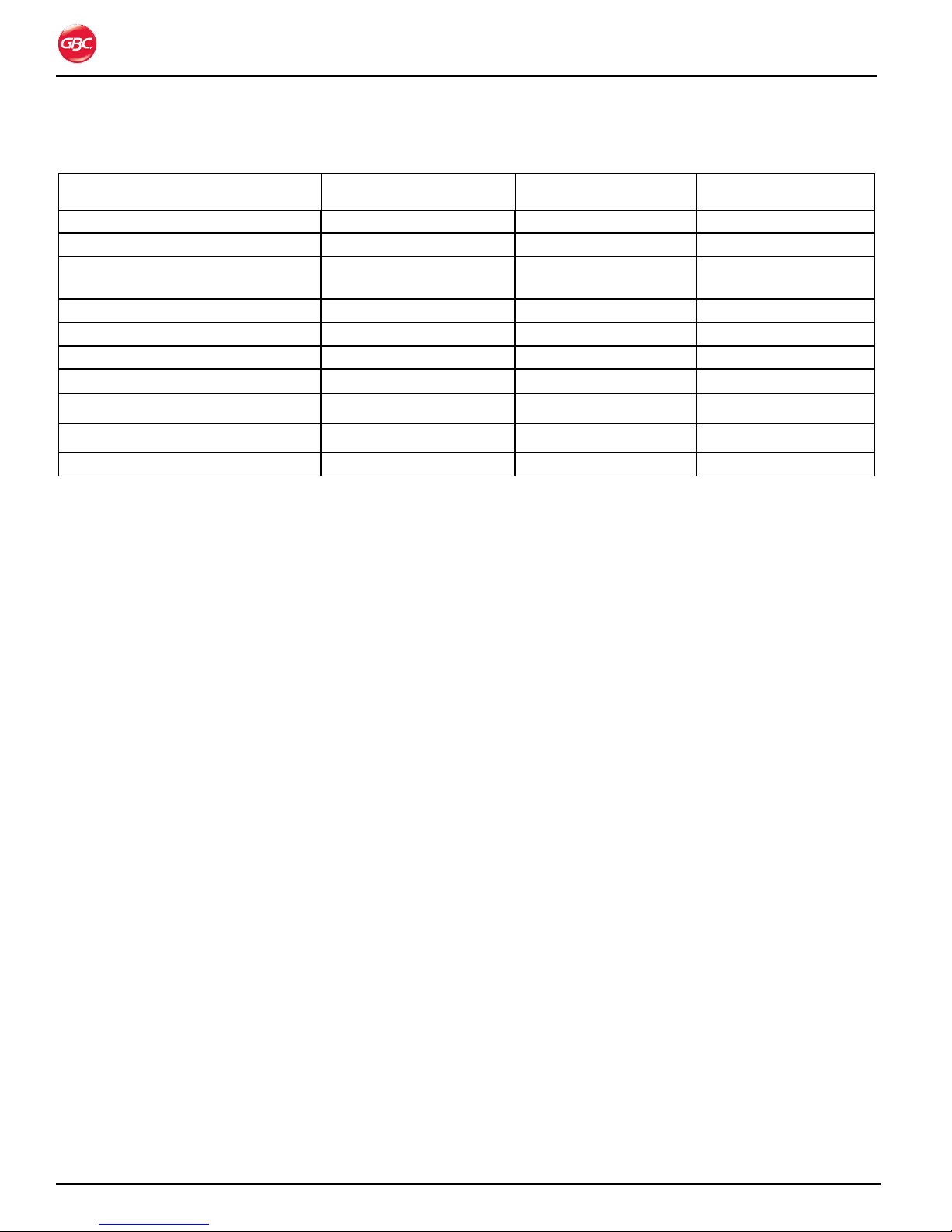

pU n C h i n G di M e n s i o n s

Punch Pattern Maximum Punch Length Number of Punch Pins Center to Center Hole

Spacing

Plastic binding 14 in. (356 mm) 25 0.5625 in. (14.29 mm)

Plastic Color Coil, GBC 4:1 (C4) 14 in. (356 mm) 55 0.2475 in. (6.29 mm)

Plastic Color Coil, industry

standard 4:1 (C4)

Plastic Color Coil, 5:1 (C5) 14 in. (356 mm) 69 0.20 in. (12.70 mm)

Twin loop wire 2:1 (W2) 14 in. (356 mm) 27 0.50 in. (12.70 mm)

Twin loop wire 3:1 (W3) 14 in. (356 mm) 41 0.3333 in. (8.47 mm)

ProClick 3:1 square 12 in. (305 mm) 34 0.3333 in. (8.47 mm)

VeloBind

SureBind

3 or 4 hole binding Varies Up to 7 or 4 Varies

®

®

14 in. (356 mm) 55 0.25 in. (6.35 mm)

15 in. (381 mm) 14 1.0 in. (25.40 mm)

14 in. (356 mm) 12 Varies

Page 3-2

Page 13

Magnapunch 2.0 – Installation and Operating Instructions

Page 3-3

Page 14

Magnapunch 2.0 – Installation and Operating Instructions

fCC Cl a s s a no t i C e

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

This device may not cause harmful •

interference.

This device must accept any interference •

received, including interference that may

cause undesired operation.

Note: This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against

harmful interference when the equipment is operated

in a commercial environment. This equipment

generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance

with the instruction manual, may cause harmful

interference to radio communications. Operation

of this equipment in a residential area is likely to

cause harmful interference in which case the user

will be required to correct the interference at his own

expense.

Mo d i f i C a t i o n s

Any modifications made to this device that are not

approved by ACCO Brands Corporation may void the

authority granted to the user by the FCC and/or by

Industry Canada to operate this equipment.

Toutes modifications apportées à ce dispositif et

non approuvées par ACCO Brands Corporation

annuleront le droit accordé à l’utilisateur par le FCC

et/ou par Industrie Canada de faire fonctionner cet

équipement.

Ca n a d a Cl a s s a no t i C e - av i s

Ca n a d a , Cl a s s e a

This Class A digital apparatus complies with

Canadian ICES-003.

Cet appareil numérique de la classe B est conforme

à la norme NMB-003 du Canada.

Page 3-4

Page 15

Magnapunch 2.0 – Installation and Operating Instructions

4. in s t a l l a t i o n

WARNING: Do not attempt to service or repair

the Magnapunch 2.0. Failure to observe this warning

could result in severe personal injury or death.

Disconnect the plug from the receptacle and contact

GBC Technical Service when one or more of the

following has occurred.

The power supply cord or attachment plug is •

damaged.

Liquid has been spilled into the Magnapunch •

2.0.

The Magnapunch 2.0 is malfunctioning.•

The Magnapunch 2.0 does not operate as •

described in these instructions.

GBC te C h n i C a l se R v i C e

United States

1-800-723-4000

Canada

1-800-463-2545

Mexico

(5525) 1500-5741

Other Sources

For service facilities in other regions, please visit:

www.gbcconnect.com/contact_us.aspx

Also use your mobile phone to scan the QR code

on the side of the Magnapunch 2.0 for a list of

authorized service providers.

To set up the Magnapunch 2.0 for the first time:

Place the Magnapunch 2.0 on a stable flat 1.

surface capable of supporting the weight of the

Magnapunch 2.0. An additional work surface

near the Magnapunch 2.0 is recommended for

items to be punched.

The Magnapunch 2.0 should be located near the 2.

electrical power with sufficient space behind and

above it to allow for ventilation. Adequate space

above the punch is required to open the top lid

and for staging the paper to be punched.

Connect the attachment plug provided with the 3.

Magnapunch 2.0 to a suitably grounded outlet

only. Avoid connecting other equipment to the

same branch circuit to which the Magnapunch

2.0 is connected, as this may result in nuisance

tripping of circuit breakers or blowing fuses.

Connect the Foot Pedal to the rear of the 4.

Magnapunch 2.0 and place the Foot Pedal on the

floor within easy reach of your foot.

te s t i n G

After the Magnapunch 2.0 has been properly

installed, it must be tested to ensure proper

operation.

Notes:

The first time the Magnapunch 2.0 is •

powered-up, a setup screen appears. Select

the language and then measurement units.

pR i o R t o in s t a l l a t i o n

Inspect the packaging and Magnapunch 2.0 for

damage. Shipping damage should be brought to the

immediate attention of the delivering carrier.

The Magnapunch 2.0 weighs 94 lbs. (42.4 kg). Two

people are required to lift and move the punch.

in s t a l l a t i o n

To unpack the Magnapunch 2.0:

Cut the plastic shipping straps and the packing 1.

tape.

Remove the Magnapunch 2.0 from the shipping 2.

carton. Use the cut outs in the cardboard base

pad to indicate where to place your hands.

Language setup screen.Figure 3.

A Die Set must be installed before running the •

Magnapunch 2.0.

To test the Magnapunch 2.0:

Punch 10 sheets of 20 lb. (75 g/m1.

in one lift.

Punch five sheets of 20 lb. (75 g/m2.

to check for a clean hole punch.

If using a PB Die Set, Punch 10 sheets of 20 lb. 3.

(75 g/m2) bond paper at each back gauge setting

to ensure three distinct positions.

2

) bond paper

2

) bond paper

Page 4-1

Page 16

Magnapunch 2.0 – Installation and Operating Instructions

Page 4-2

Page 17

Magnapunch 2.0 – Installation and Operating Instructions

5. fe a t U R e G U i d e

This chapter helps you identify the main components of the Magnapunch 2.0.

User Interface

Edge Guide and

Tabletop Trigger

Punching Table

Chip Drawer

Lift picker

Die Set

Fuse

Punching Throat

Magnapunch 2.0 Identification. Figure 4.

po W e R

on/off sW i t C h

Use the ON/OFF switch to turn the Magnapunch

2.0 on and off. Press the ON/OFF switch to the I

position to turn the Magnapunch 2.0 On. Press

the ON/OFF switch to the O position to turn the

Magnapunch 2.0 Off.

fU s e

One fuse protects the Magnapunch 2.0 and its

electrical components from current that is higher

than the Magnapunch 2.0 is rated for.

CAUTION: For continued protection against

fire or risk of electrical shock, replace only with the

same type and rating fuse.

ON/OFF switch

po W e R a n d fo o t pe d a l Co n n e C t o R s

PowerFoot Pedal Service port

Connections on Back of Magnapunch 2.0.Figure 5.

The Power Cord plugs into a standard US 115 VAC

NEMA 5-15R (European 230 VAC YP-24 10 to 16

Amp) wall outlet.

pU n C h i n G th R o a t

To replace a fuse, insert a flat blade screwdriver

into the fuse cover, push, and then turn counterclockwise. Replace the fuse, insert into the fuse

holder, and turn it clockwise.

The Punching Throat is where the media’s edge to be

punched is inserted during the punching process.

NOTE: Do not force more media into the throat than

will fit easily.

Page 5-1

Page 18

Magnapunch 2.0 – Installation and Operating Instructions

li f t pi C k e R

Raise the lid of the Lift Picker to stack media that has

been punched or that is to be punched.

Magnapunch 2.0 with Media in Lift Picker.Figure 6.

Us e R in t e R f a C e

The User Interface (UI) consists of an LCD and four

buttons below the LCD. The LCD displays system

messages and provides access to operational

functions. The push buttons below the LCD are used

to navigate through the menus, select items, and

commit commands.

pU s h BU t t o n s

The Push Buttons relate to the commands at the

bottom of the LCD. The action of the button may

change depending on the menu on the LCD.

ed G e GU i d e a n d ta B l e t o p

tR i G G e R

Edge Guide

adjustment handle

Edge Guide and Tabletop Trigger.Figure 8.

ed G e GU i d e

Tabletop Trigger

Start Up Screen.Figure 7.

lCd

The LCD provides continuous status of the

Magnapunch 2.0 and includes step by step

instructions on how to use your Magnapunch 2.0.

The Edge Guide sets the position for a variety of

punching patterns and paper sizes.

Turn the Edge Guide handle 1/4 turn

counter-clockwise to unlock. Move the Edge Guide

to line up with the desired setting on the Die Set and

then turn the handle clockwise 1/4 turn to lock the

Edge Guide in place.

Edge Guide Unlocked.Figure 9.

Page 5-2

Page 19

Magnapunch 2.0 – Installation and Operating Instructions

ta B l e t o p tR i G G e R

The Tabletop Trigger is incorporated into the Edge

Guide. The Tabletop Trigger is used to automatically

punch without the use of the Foot Pedal. The

Tabletop Trigger is activated on the Home screen of

the User Interface.

Push the stack of media into the Throat and then

slide to the left against the Trigger to activate the

punch.

pU n C h i n G ta B l e

The Punching Table is where you lay the media to be

punched. Place the media on the Punching Table,

push the media into the Throat, and then slide to the

left.

Ch i p dR a W e R

The Chip Drawer collects the paper chips from

the punched media. When the Chip Drawer is full,

a message on the LCD UI alerts you to empty the

drawer.

die se t

The Magnapunch 2.0 offers thirteen different Die

Sets to match the punching requirements for your

documents. To change a Die Set, refer to “Changing

the Interchangeable Die Sets”.

fo o t pe d a l

The Foot Switch is activated on the Home Screen.

When media is inserted into the Punching Throat

and pushed against the Edge Guide, press the Foot

Pedal to activate the punch.

Foot Pedal.Figure 10.

Page 5-3

Page 20

Magnapunch 2.0 – Installation and Operating Instructions

Page 5-4

Page 21

Magnapunch 2.0 – Installation and Operating Instructions

6. op e R a t i o n

The Magnapunch 2.0 uses a variety of easily

interchangeable Die Sets for different binding styles.

By selecting the appropriate Die Set, you can use

your Magnapunch 2.0 to punch documents in any of

the binding styles indicated in the following table.

Punch StylesTable 1.

Minimum Margin

Binding Style Punch Pattern

CombBind

Color Coil

Color Coil

Color Coil 5:1 (5 holes per inch)

WireBind

WireBind

VeloBind 1 hole per inch 0.500 in. (12.7 mm)

SureBind

3, 5, or 7 Hole Binding 11 in. 3 holes across bound edge of document, 11 inch paper

2 or 4 Hole Binding A4 4 holes across bound edge of document, A4 paper

®

®

®

®

Cerlox (Plastic Comb, Plastic Binding)

4:1 GBC (4 holes per inch 0.2475” center-to-center hole spacing)

4:1 Industry Standard (4 holes per inch, 0.2500” center-to-center

hole spacing)

2:1 (2 holes per inch) Both square and round hole patterns

available.

3:1 (3 holes per inch) Both square and round hole patterns

available.

Approximately 1 hole per inch

to First Binding

Hole

0.282 in. (7.2 mm)

0.092 in. (2.6 mm)

0.040 in. (1.0 mm)

1 0.030 in.

(0.8 mm)

0.375 in. (9.5 mm)

0.261 in. (6.6 mm)

0.531 in. (13.5 mm)

Note: Each punching style listed in the table requires

a separate Die Set for the Magnapunch 2.0. Custom

Die Sets for special punching patterns (not listed

above) can also be made to your specifications. For

more information on custom Die Sets, contact your

local GBC sales representative.

IMPORTANT: A decal on the handle of each

interchangeable Die Set indicates the punching

pattern for that Die Set. When reading the Operating

Instructions, please note the special instructions for

the correct punching pattern Die Set that you have

installed in your Magnapunch 2.0.

WARNING: Do not attempt to service or repair

the Magnapunch 2.0. Failure to observe this warning

could result severe personal injury or death.

Disconnect the plug from the receptacle and contact

your dealer or distributor, or GBC Technical Service

at one of the numbers below when one or more of

the following has occurred.

The power supply cord or attachment plug is •

damaged.

Liquid has been spilled into the Magnapunch •

2.0.

The Magnapunch 2.0 is malfunctioning.•

The Magnapunch 2.0 does not operate as •

described in these instructions.

US - 800-723-4000

Canada - 800-463-2545

Mexico - (5525) 1500-5741

CAUTION:

The receptacle must be located near •

the Magnapunch 2.0 and must be easily

accessible.

Disconnect the attachment plug from the •

receptacle to which it is connected and keep

the power supply cord in your possession

while moving the Magnapunch 2.0.

Do not use the Magnapunch 2.0 for other than •

its intended purposes.

Do not defeat or remove electrical and •

mechanical safety equipment such as shields

and guards.

Do not insert objects unsuitable for punching •

or expose the equipment to liquids.

Use only GBC Magnapunch 2.0 •

interchangeable Die Sets with the

Magnapunch 2.0.

Failure to observe these warnings could result in

severe bodily damage or death.

Page 6-1

Page 22

Magnapunch 2.0 – Installation and Operating Instructions

Us e R in t e R f a C e

The LCD and the row of buttons below it make up

the user interface (UI). The LCD provides the current

status and settings of the Magnapunch 2.0, and

provides setup and operation instructions for using

your Magnapunch 2.0

nav iGation

Use the buttons on the keypad to move between

menus, scroll, and make selections. The action of the

buttons is shown on the LCD.

When the Magnapunch 2.0 is turned on, the Start up

screen briefly displays, followed by the Home screen.

LCD

fi R s t ti M e se t U p

The first time the Magnapunch 2.0 starts up, you

need to set the language and unit of measure that

will be used on the menus. After the start-up screen

displays briefly, the Language Setup screen displays.

After you perform the setup, these screens do not

display. You can access them from the Home screen

any time by selecting MENU from the Home Screen

and then selecting SETUP feature from the MENU

options..

To set the language and units:

Turn On the Magnapunch 2.0.1.

Keypad

User Interface and Home screen.Figure 11.

HOME Returns to the Home screen.

UP Scrolls up through options.

When the selection gets to the top of

the options, it returns to the bottom

of the list.

BACK Goes back one screen.

DOWN Scrolls down through options. When

the selection gets to the bottom of

the options, it returns to the top of

the list.

NEXT Goes forward one screen.

SELECT Selects or commits menu selection.

MENU Displays an instructional menu.

When the Magnapunch 2.0 has been inactive for

more than 30 minutes, the LCD goes to the Start up

screen and “sleeps.” To “wake” up the LCD, press

any key.

Language Setup Screen.Figure 12.

On the Language Setup menu, press 2. UP or

DOWN to scroll to the desired language.

Press 3. SELECT to select the language.

Unit Selection ScreenFigure 13.

On the Unit Selection screen, press 4. UP or

DOWN to select CM or INCHES.

Press 5. SELECT.

Press 6. HOME to return to the Home screen.

Page 6-2

Page 23

Magnapunch 2.0 – Installation and Operating Instructions

op e R a t i o n

After the Magnapunch 2.0 has been turned on, the

Home screen displays. It is the menu from which you

set up and operate the Magnapunch 2.0. To return to

this menu from any other screen, press HOME.

ho M e sC R e e n

The Home screen displays the current status and

operational settings of the Magnapunch 2.0.

Use • UP and DOWN to scroll to each item on

the menu.

Press • SELECT to select the item or command

the Magnapunch 2.0 to do something.

Home Screen with Edge Sensor and Foot Pedal Figure 14.

On.

Edge Sensor

The Edge Sensor virtually eliminates mis-punches by

preventing the punch to cycle when the media is not

fully inserted in the Punch Throat.

The Edge Sensor is On when the checkmarks

are highlighted in green and Off when the O is

highlighted in blue.

To turn On the Edge Sensor:

Use 1. UP and DOWN to scroll to EDGE SENSOR.

Press 2. SELECT to toggle between the settings.

Edge Sensor Screen Indicating Correct Figure 15.

Alignment.

If the punch is triggered when only the left or right

bar is displayed, the punch will not trigger and an

ALERT EDGE SENSOR Error displays. When this

occurs, allow the Magnapunch 2.0 1-2 seconds to

clear and continue punching.

Note: When punching documents less than 6.5 (16.5

cm)inches, the turn OFF the Edge Sensor.

Punch

The punch is activated by the Tabletop Trigger or the

Foot Pedal. The selected mode appears green.

On the Home screen use the up and down keys until

the PUNCH mode is selected. The mode selected

is represented by the white arrow on the left. With

Tabeltop Trigger or Foot Pedal selected, press

SELECT to toggle between the two options.

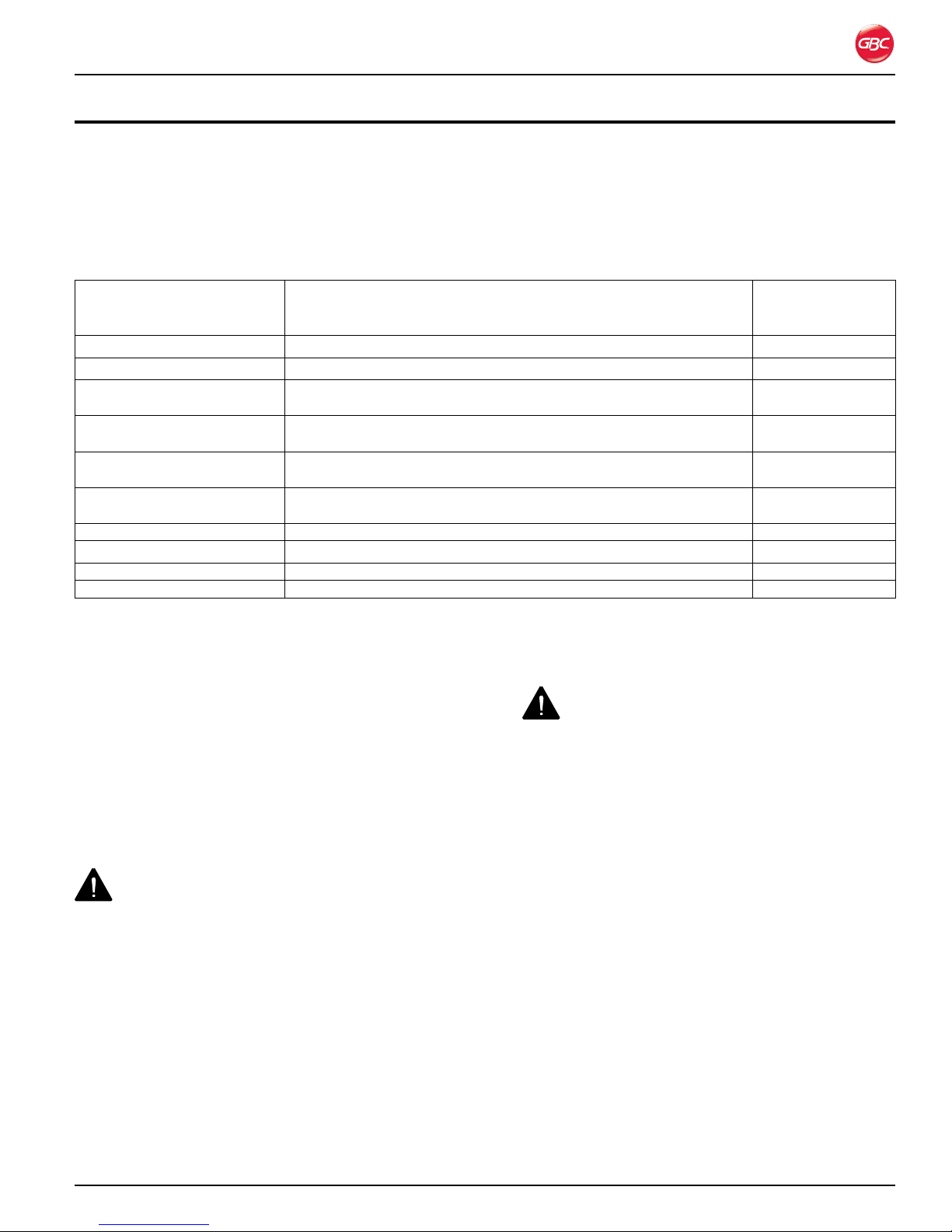

Job Cycles

Job Cycles displays the number of punch cycles

for individual jobs. You can reset the counter on the

Reset Count screen. To exit the Job Cycles screen

without resetting the count, select EXIT and then

press SELECT.

Edge Sensor Screen

When the Edge Sensor is turned On, the

Magnapunch 2.0 detects when the media is properly

inserted in the Punch Throat. Green bars are

displayed on the User Interface to represent that

both the left and right edge of the media are fully

insert. When both bars are displayed, activate the

punch.

Page 6-3

Page 24

To reset the job cycles count:

On the Home screen, scroll to1. JOB CYCLES.

Press 2. SELECT.

Job Cycles Screen.Figure 16.

Scroll to 3. RESET COUNT.

Press 4. SELECT.

Press 5. HOME to return to the Status menu.

Die Indicator

The Die Indicator displays which Die Set is currently

in the Magnapunch 2.0. The Magnapunch 2.0 will

report one of the following errors if the Die Set was

not recognized, missing, or not properly inserted.

Magnapunch 2.0 – Installation and Operating Instructions

Menu Screen.Figure 17.

Navigate to any of the options by using UP and

DOWN. When the Menu option you would like to

choose is highlighted, press SELECT.

Home

Select HOME to return to the Home screen. See

“Home Screen”.

Usage Instructions

Select USAGE INSTRUCTIONS to go to that screen.

See “Usage Instructions”.

Select Media Length

Select SELECT STANDARD LENGTH to go to that

screen. See “Usage Instructions”.

Read error, punch operable• Somehow

layout Read error, punch operable = die is not

loaded properly but the system did not read

the bar code and recognize die pattern.

No die loaded, punch inoperable• No die

loaded, punch inoperable = die missing or not

loaded completely.

Refer to “Troubleshooting” for information on how to

resolve these issues.

Chip Drawer Status

The indicator displays how full the Chip Drawer is.

An ERROR is displayed when the drawer is nearly full

and needs to be emptied.

If the Chip Drawer is missing, the indicator displays

red circles as an error code.

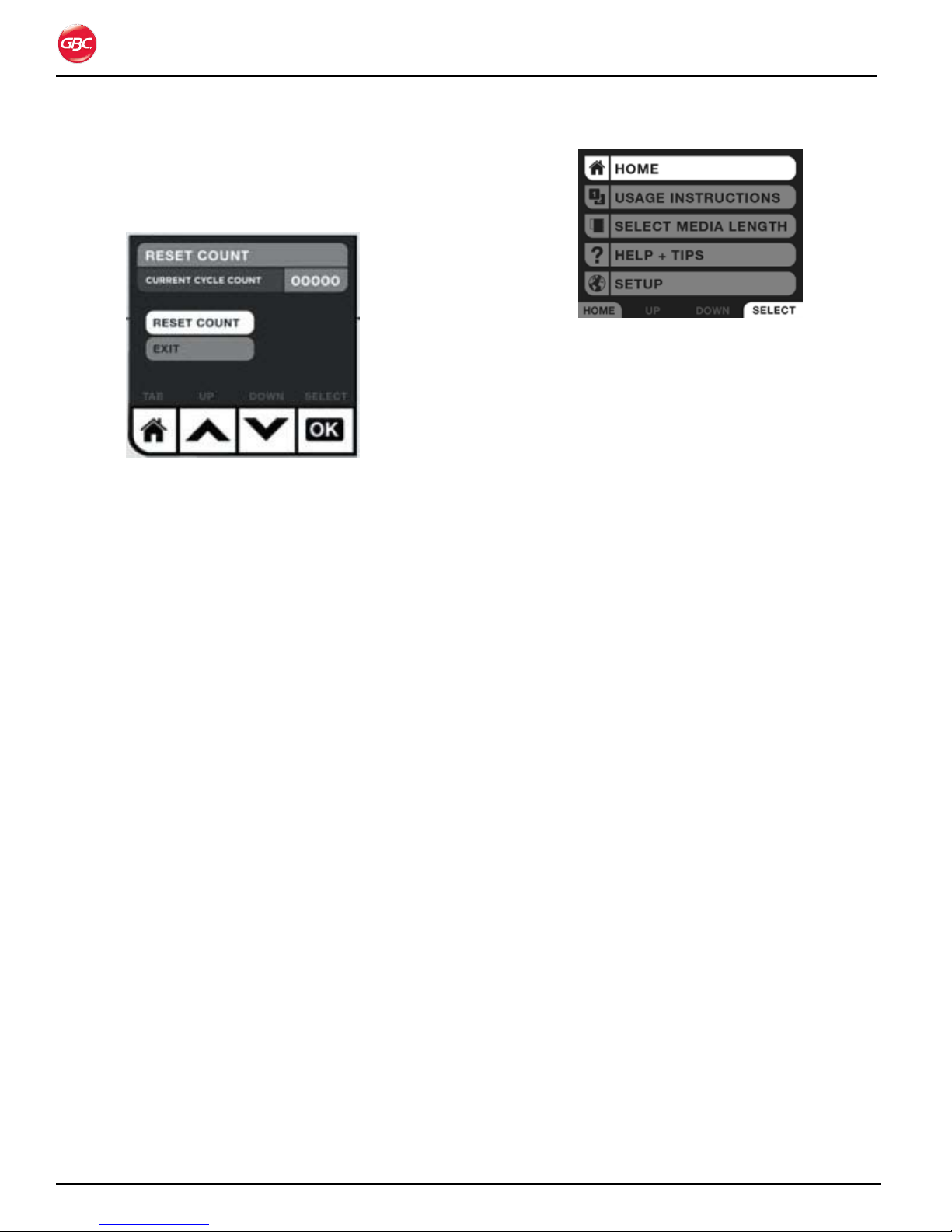

Me n U

Use the Menu screen to access other key functions

of the Magnapunch 2.0. The Menu screen is

accessed from the Home screen. While on the

HOME screen, press MENU.

Help + Tips

Select HELP + TIPS to access Help screens. See

“Help + Tips”.

Setup

Select SETUP to go to the Setup screens. See “First

Time Setup”.

Us a G e in s t R U C t i o n s

Use the Usage Instructions screen to access

instructions on the operation and set up of the

Magnapunch 2.0. Some screens are animated and

self-explanatory, which show how to set up the

Magnapunch 2.0.

To access the Usage Instructions screen, press

MENU. Scroll to an option and press SELECT.

Page 6-4

Page 25

Magnapunch 2.0 – Installation and Operating Instructions

Usage Instructions Screen.Figure 18.

Step by Step Instructions

Selecting STEP BY STEP INSTRUCTIONS takes

you to the Select Standard Length screen.

Select Standard Length

Use the SELECT STANDARD LENGTH screen to

set the length of the media that will be punched.

he l p + ti p s

Use the HELP + TIPS screens to learn how to

operate the Magnapunch 2.0. Access this menu from

the MENU screen.

Help + Tips Menu.Figure 21.

Select Standard Length Screen.Figure 19.

Use UP and DOWN to highlight the media size to be

punched and then press SELECT. To return to this

screen or to select a different option, press LIST.

Custom

Use the Custom screen to set the Magnapunch 2.0

for other sizes of media. Select the size and then

use UP and DOWN to increase or decrease the size.

Briefly press and release UP and DOWN to scroll in

small increments and press and hold for to scroll in

large increments.

Die Set Damage Screen.Figure 22.

no t i f i C a t i o n sC R e e n s

Notification screens alert you to issues that may

prevent you from using the Magnapunch 2.0

properly. Follow the information on the screen to

rectify the issue. Also see “Troubleshooting”.

Example of an Alert Screen.Figure 23.

Select Custom Length Screen.Figure 20.

Page 6-5

Page 26

Magnapunch 2.0 – Installation and Operating Instructions

Ch a n G i n G t h e in t e R C h a n G e a B l e

die se t s

Your Magnapunch 2.0 offers the convenience

of interchangeable Die Sets, allowing you to

economically punch documents for a wide variety of

binding styles.

Re M o v i n G di e se t s

To remove Die Sets from the Magnapunch 2.0:

The interchangeable Die Set slot of the Magnapunch

2.0 is located on the right front side of the

Magnapunch 2.0. If a Die Set is already installed in

your Magnapunch 2.0, you can easily remove the Die

Set.

Grab the Die Set handle by placing your palm on 1.

the front and wrapping your fingers behind the

handle (located on the right side of the Die Set).

Die Set handle.

dust, and potential damage. Contact your GBC sales

representative for information on obtaining a Die Set

Storage Holder.

in s ta l l i n G di e se t s

CAUTIONS:

Possible pinch point hazard. When installing Die •

Sets into your Magnapunch 2.0, always keep

fingers and body parts out of the Magnapunch

2.0’s Die Set slot and away from all areas of the

Die Set except for the finger groove in the Die

Set’s handle. Failure to observe these precautions

may result in injury.

Possible Die Set damage. Make certain that all •

punch pins are fully and properly seated in the Die

Set before inserting the Die Set. Failure to ensure

that all punch pins are fully seated could result in

damage to the Die Set and Magnapunch 2.0.

To install a Die Set:

Grab the Die Set handle by placing your palm on 1.

the front and wrapping your fingers behind the

handle (located on the right side of the Die Set).

Refer to “Figure 24. Die Set Partially Pulled Out.”

Carefully align the leading edges of the Die 2.

Set’s support rails with the leading edges of the

Magnapunch 2.0’s guide rails.

Using your fingers in the Die Set’s handle, firmly 3.

push the Die Set into the Magnapunch 2.0’s Die

Set slot. You will hear a click when the automatic

locking mechanism engages. This mechanism

securely holds the Die Set during punching

operations.

Note: If the Die Set is not properly inserted into the

Magnapunch 2.0 and locked into place, the LCD

displays an error.

Die Set Partially Pulled Out.Figure 24.

Securely grasp the handle and tug firmly. 2.

Continue pulling on the handle until the Die Set 3.

is fully removed. Support the Die Set with both

hands.

Properly store the removed Die Set (away from 4.

dust, dirt, falls, etc.).

Helpful Hint: The GBC Die Set Storage Holder is

an excellent way to store your interchangeable Die

Sets for the Magnapunch 2.0. This holder securely

holds several Die Sets, protecting them from dirt,

Page 6-6

Page 27

Magnapunch 2.0 – Installation and Operating Instructions

Re M o v i n G pU n C h pi n s

You can easily remove and replace punch pins

for proper punching some combinations of paper

sizes and punching patterns. The Magnapunch 2.0

helps you determine if and when punch pins need

to be removed. Refer to “Job Setup”, to set up the

Magnapunch 2.0. Each punch pin is labeled with a

number to help you identify the recommended pin to

be pulled.

NOTE: Each Die Set comes with a magnetic pin

retainer. Make sure this retainer is in place after

adjusting, removing, and inserting pins. Do not throw

this retainer away.

To remove punch pins:

Remove the magnetic Pin Retainer.1.

Firmly grasp the top of the selected Punch Pin 2.

and pull upward. The Punch Pin will slide out of

the Die Set.

Jo B se t U p

Before beginning a punching job, ensure the

Magnapunch 2.0 is setup properly. Use the LCD user

interface (UI) to guide you through the setup process.

For common paper sizes, use the marking on the Die

Set.

Us i n G t h e lCd Us e R in t e R f a C e

To set up the Magnapunch 2.0 for a job:

Insert the proper Die Set for the punch pattern 1.

required for the job. See “Punching Operation”.

Press 2. MENU on the Home screen.

Removing Punch Pins.Figure 25.

Carefully store the removed Punch Pin(s) for 3.

future use.

Replace the magnetic Pin Retainer.4.

To replace punch pins:

Remove the magnetic Pin Retainer.1.

Insert the Pins into the correct holes.2.

Replace the magnetic Pin Retainer.3.

Home Screen.Figure 26.

Scroll down and select 3. SELECT MEDIA

LENGTH.

Select one of the standard paper sizes or enter a 4.

custom paper size based on your application.

Select Standard Length ScreenFigure 27.

5.

Page 6-7

Page 28

Press 6. NEXT. The LCD screen displays an image

similar to the ruler on the Die Set and shows

where the left Edge Guide should be placed.

Magnapunch 2.0 – Installation and Operating Instructions

Pin Configuration Screen.Figure 30.

Reinsert the Die Set into the Magnapunch 2.0.9.

Set Side Screen.Figure 28.

Slide the left Edge Guide to that position and 7.

press NEXT.

NOTE: When positioning the left Edge Guide, the

right edge of the clear pointer should be placed on

the dot.

Pointer on dot.

Setting Edge Guide On the Dot.Figure 29.

Following the instructions on the LCD UI, remove 8.

the Die Set from the Magnapunch 2.0, ensure

all pins are in place and then remove the pins

identified on the LCD UI. This will eliminate

punches at the edge of your document.

NOTE: Each pin is labeled with a pin number on the

Die Set ruler.

To leverage Die Set markings for common paper

sizes:

Common media sizes are displayed on the Die Set

label and have a line with a dot at the end identifying

where to set the left Edge Guide.

Insert the proper Die Set for the punch pattern 1.

required for the job.

On the 2. HOME screen, set the PUNCH mode to

foot pedal to avoid accidently cycling the punch.

Home Screen with Foot Pedal Selected.Figure 31.

Slide the left Edge Guide to the proper position 3.

based on your media size.

NOTE: when positioning the left Edge Guide, the

right edge of the clear pointer should be placed on

the dot. See “Figure 29. Setting Edge Guide On the

Dot.”

Insert your media to be punched and place 4.

against the left Edge Guide. Look at the Die Set

pins and identify any that need to be removed to

avoid punching the edge of your document.

Remove the Die Set and take out the pins if 5.

necessary.

Reinsert the Die Set.6.

Set the Punch mode back to 7. Trigger if needed.

Page 6-8

Sheet Sizes Larger Than the Maximum

Punch Width

Page 29

Magnapunch 2.0 – Installation and Operating Instructions

Because of its open-end Punch Throat design, you

can use your Magnapunch 2.0 to punch sheet sizes

that are larger than the maximum width of paper that

can be punched in one operation.

Note: Multiple steps are required to punch these

larger sheets of paper. Some experimentation will

be required to determine the correct position for the

Edge Guide.

te s t i n G t h e Jo B

Before beginning a punching job, test your

Magnapunch 2.0’s variable settings by punching

five to ten sheets of paper that match the exact size

of the actual materials to be bound. This will allow

you to make any adjustments to the Magnapunch

2.0 without wasting the documents to be bound.

The following steps indicate how to test your

Magnapunch 2.0 for proper Edge Guide alignment.

To test hole alignment for your job:

On the 1. HOME screen, set the PUNCH mode to

Foot Pedal to avoid accidently cycling the punch.

greater on the left, move the Edge Guide

to the right. Then punch another five test

sheets and re-check the spacings. Repeat

this process as needed until the spacings

are equal.

Checking Edge Guide Alignment.Figure 33.

For SureBind: b. Remove the punched sheets

from the Punch Throat. Fold the media

in half as represented in Figure 33. Look

at the two holes closest to the center or

“V” of the fold. The holes on each side

should line up with each other if the Edge

Guide is positioned properly. If this is not

correct, slightly adjust the Edge Guide,

punch another two to three test sheets, and

re-check the spacings. Repeat this process

as needed until the spacings are correct.

Note: Before making any adjustments to the

Magnapunch 2.0’s variable settings, make sure the

PUNCH mode on the HOME screen is set to Foot

Pedal to prevent accidently cycling the punch.

Home Screen with Foot Pedal Selected.Figure 32.

Insert five pieces of paper of the same size as 1.

the document to be punched completely into the

Punching Throat.

Slide the paper to the left until it touches the 2.

Edge Guide.

Hold the test sheets in place and depress the 3.

Foot Pedal to punch the test sheets.

To check the Edge Guide alignment, do one of 4.

the following.

For all punching patterns a. except SureBind:

Remove the punched sheets from the

Punch Throat. Take one punched sheet,

fold it so that the holes overlap, and confirm

the space between the edge of the media

and the first hole is equal to the space

between the edge of the media and the last

hole. If the spaces are not equal, slightly

adjust the Edge Guide. If the margin is

Page 6-9

Page 30

Magnapunch 2.0 – Installation and Operating Instructions

pU n C h i n G op e R a t i o n

pU n C h i n G t h e Jo B

Note: Before making any adjustments to the

Magnapunch 2.0’s variable settings, make sure the

PUNCH mode on the HOME screen is set to Foot

Pedal to prevent accidently cycling the punch.

After installing the correct Die Set in your

Magnapunch 2.0, and following the setup

instructions in “Job Setup” and “Testing the Job”, you

are ready to begin punching. The following sections

indicate how to activate the Magnapunch 2.0. Read

these sections completely to become familiar with

unique Die Set features and helpful punching tips.

Note: The Punching Margin is fixed for most Die Sets

and no margin adjustments are required. Refer to the

next section to set up the CombBinding Die with the

three position adjustable back gauge.

For CombBinding Only

The CombBind Die Set is equipped with a variable

punching margin (also called depth of punch)

device. This feature allows you to choose from three

punching margins for your plastic comb bound

documents. The punching margins offered by your

Magnapunch 2.0 are listed in the following table.

To change the punching margin for plastic

binding Die Sets:

Do one of the following.1.

For Punching Margin 3, firmly grasp the •

Control Lever and fully push it in to the Die

Set. The Control Lever will click into place

when this setting is reached.

For Punching Margin Setting 2, firmly grasp •

the Control Lever and pull gently outward.

The Control Lever will click into place as this

position is reached.

For Punching Margin Setting 1, continue to •

pull gently outward. The Control Lever will

click into place when this position is reached.

Punching Margin SettingsTable 2.

Punching

Margin

Setting

1 (Small) 0.10 in. (2.5 mm) ≤ 5/16 in. (7.9 mm)

2 (Medium) 0.14 in. (3.6 mm) 3/8 to 9/16 in. (9.5

3 (Large) 0.19 in. (4.8 mm) ≥ 5/8 in. (15.9 mm)

The Control Lever for setting the punching margin is

located inside of the plastic binding Die Set’s handle.

The punching margin is controlled by pushing in or

pulling out this lever.

Punching

Margin Depth

Best Plastic

Binding Elements

Diameter:

mm to 14.3 mm)

Die Set Partially Pulled Out. Figure 34.

Page 6-10

Page 31

Magnapunch 2.0 – Installation and Operating Instructions

pU n C h aC t i v a t i o n

The Magnapunch 2.0 can be activated using either

the Foot Pedal or the Tabletop Trigger. The activation

mode is selected on the HOME screen. Using

SELECT, toggle between the modes. The mode

highlighted in green is the active punch mode.

Home Screen with Foot Pedal Selected.Figure 35.

fo o t pe d a l

Using the Foot Pedal allows you to ensure that the

sheets are lined up before the punch is activated.

To punch using the Foot Pedal:

ta B l e t o p tR i G G e R

The Tabletop Trigger allows you to quickly punch

stacks of sheets. Pressing the stack against the

Trigger, activates the punch.

To punch using the Tabletop Trigger:

Turn the Magnapunch 2.0 On and set the 1.

PUNCH mode to TABLETOP TRIGGER.

Push the stack of sheets into the Punch Throat 2.

completely.

Turn the Magnapunch 2.0 On and set the 1.

PUNCH mode to FOOT PEDAL.

Push the stack of media into the Punch Throat 2.

completely, while sliding to the left, so that the

stack presses against the Edge Guide.

Media Lined up for Punching.Figure 36.

Media Ready for Punching.Figure 37.

Slide the stack to the left into the Tabletop 3.

Trigger, activating the punch.

Depress and then release the Foot Pedal.3.

Remove the stack of media.4.

Page 6-11

Page 32

Magnapunch 2.0 – Installation and Operating Instructions

pU n C h i n G ti p s

This section provides additional information about

punching paper and proper operation of the

Magnapunch 2.0.

pa p e R

The Magnapunch 2.0 is capable of punching any

paper from onion skin bond to cardboard stock.

Because there are variations in the thicknesses and

types of materials that can be punched, it is difficult

to define the exact maximum number of sheets that

can be punched at one time.

For typical maximum punching capacities for the

Magnapunch 2.0 using 20 lb. (75 g/m2) bond sheets,

refer to “Table 3. Punching Capacity”.

Punching too many sheets at a time can damage

the Magnapunch 2.0. It also affects the quality of the

punched holes. This hole quality degradation varies

by the paper stock and personal esthetic standards.

Generally, reducing the number of sheets punched

per cycle improves the quality and appearance of the

holes.

pl a s t i C Co v e R s

You can use the Magnapunch 2.0 to punch plastic

covers. Be sure to observe the following guidelines

to prevent damage to the Magnapunch 2.0 and Die

Sets.

Punch no more than two or three covers per •

cycle.

Separate each plastic cover with a sheet of 20 •

lb. (75 g/m2) paper before punching.

Ch i p dR a W e R

The Chip drawer is located at the front of the

Magnapunch 2.0 base. The Chip Drawer should be

periodically emptied to avoid jamming and damage

to the Magnapunch 2.0 and Die Sets.

Page 6-12

Chip Drawer Opened.Figure 38.

Page 33

Magnapunch 2.0 – Installation and Operating Instructions

ho l e QU a l i t y

The following table is a guide to help you determine

how many sheets of paper you can punch in each

cycle. This is based on 20 lb. (75 g/m2) bond.

Punching CapacityTable 3.

Die Label Die

Pattern

Color Coil 4:1

(0.2475)

Color Coil 4:1 (0.25)

Color Coil 4:1

(0.2475)

Color Coil 5:1

CombBind® 19-hole

ZipBind

WireBind 3:1

WireBind 2:1

WireBind 3:1

WireBind 2:1

ProClick® 3:1

VeloBind 11- pin

SureBind 10-pin

Looseleaf 3-5-7/

combo 2-4

®

Description Draft

Ensures that punched holes do not

overrun top and bottom of page

Industry standard 29 25 20

Oversized oval holes for spines over 20

mm; required for DigiCoil

— 29 25 20

Three position adjustable back gauge 39 32 25

Square punch pattern 29 25 20

Square punch pattern 34 25 20

Round punch pattern 34 25 20

Round punch pattern 34 25 20

For use with ProClick™ Pronto binding

systems

— 49 42 35

— 49 42 35

For punching U.S. letter size, A4 and

the 8.5 in. edge of legal and medical

documents

Good

Quality

29 25 20

24 14 14

24 20 16

34 30 25

Quality

Professional

Quality

Page 6-13

Page 34

Magnapunch 2.0 – Installation and Operating Instructions

Page 6-14

Page 35

Magnapunch 2.0 – Installation and Operating Instructions

7. op e R a t o R Ma i n t e n a n C e

Ca R i n G f o R t h e Ma G n a p U n C h 2.0

The primary maintenance required by the operator

is to periodically empty the Chip Drawer and to keep

the work area clean and free of paper debris and

dust. The Edge Sensors within the Die Sets may

need to be replaced occasionally.

die se t Ma i n t e n a n C e

The Edge Sensor feature referred to in “Edge

Sensor” requires sensor flags to be installed in the

Die Sets. If the machine begins to not sense the

media being inserted in the throat, the sensor flags

may need to be changed. Please follow the steps

below to replace the sensors.

To replace Die Set Edge Detection sensor flags:

Grab the die set handle by placing your palm on 1.

the front and wrapping your fingers behind the

handle. Pull the Die Set out of the Magnapunch

2.0 and place it face down on a sturdy surface.

Using a Phillips screw driver, remove the screws 2.

holding the two sensor flags in place.

Pull out the old sensor flags and replace with 3.

new ones.

Reinsert the screws and tighten4.

Replace the Die Set in the Magnapunch 2.0.5.

Cl e a n i n G t h e Ma G n a p U n C h 2.0

Clean only the exterior of the Magnapunch

2.0. A soft, damp cloth may be used to wipe

the Magnapunch 2.0’s exterior, but do not

use detergents or solvents as damage to the

Magnapunch 2.0 may occur.

WARNINGS:

Do not attempt to service or repair the •

Magnapunch 2.0.

Do not open the Magnapunch 2.0. There are no •

user serviceable parts inside.

Refer service to qualified service personnel.•

Failure to observe these warnings could result in

severe personal injury or death.

Page 7-1

Page 36

Magnapunch 2.0 – Installation and Operating Instructions

tR o U B l e s h o o t i n G

Symptom Possible Cause Corrective Action

Read error, punch is

operable

The barcode on the Die Set was not read

successfully.

The bar code reader is malfunctioning Contact your service provider.

Remove and reinsert the Die Set.

No Die Set loaded, punch

does not operate

One or both Edge

Detection sensors remain

on.

No power. Power cord not fully inserted. Check the power cord to ensure it is

Die Set is not fully inserted. Remove and re-insert the Die Set.

Die Set is not contacting the safety

switch.

Edge detection flag on Die Set is stuck in

an outward position.

Sensor could be blocked by paper dust. Remove Die Set and blow air into the

Faulty sensor. Contact your service provider.

Contact your service provider.

Remove Die Set and push the edge

detection flag in. If problem continues,

replace the flag.

area where the Die Set goes in the

Magnapunch 2.0.

connected fully at both ends.

If this does not resolve the problem,

contact your service provider.

Page 7-2

Page 37

Magnapunch 2.0 – Installation and Operating Instructions

no t e s

Date purchased:

Serial number:

Page 7-3

Page 38

Page 39

Page 40

ACCO Br ands Can ada

5 Precidio Cour t

Brampton, ON L6S-6B7

800.263.1063

www.gbccanada.com

ACCO Mexicana

Neptu no #43, Colo nia Nueva I ndustr ial Vallejo

Delagacion Gus tavo A. Madero, CP 07700

México, DF. (55) 1500-5578

www.gbc.com.mx

© 2011 ACCO Brands. All rights reserved. ACC O® is a regis tered trademark of

ACCO Br ands. GBC ® is a registered trad emark of General Bi nding Cor porati on.

Doc 80120510 Rev. A 11-2011

Page 41

Magnapunch 2.0

Perforadora de gran capacidad

MANUAL DE INSTALACIÓN Y

FUNCIONAMIENTO

Está prohibido realizar copias sin el permiso por escrito de ACCO Brands.

Documento número: 80120510 Rev. A

Page 42

Magnapunch 2.0: Instrucciones de instalación y funcionamiento

ACCO Brands se reserva el derecho de realizar

modificaciones a esta publicación y a los productos

que aquí se describen sin previo aviso. Todas las

especificaciones y la información sobre los productos

están sujetas a cambio sin previo aviso. Las referencias

a información o productos protegidos por patentes o

derechos de autor que se realizan en esta publicación no

representan una licencia de acuerdo con los derechos

de ACCO Brands o de terceros. ACCO Brands no se

responsabiliza por las violaciones de patentes ni de

cualquier otro derecho de terceros.

Esta publicación está protegida por leyes de derechos

de autor © 2011 por ACCO Brands. Todos los derechos

reservados.

Co n v e n C i o n e s u t i l i z a d a s e n e s t e

m a n u a l

La perforadora Magnapunch 2.0 se maneja por medio de

un menú a través de una interfaz de usuario en LCD. Las

opciones del menú y los comandos aparecen en negrita.

Por ejemplo:

En el menú Language Setup (Configuración de idioma),

presione UP (Arriba) o DOWN (Abajo) para ir al idioma

deseado.

ACCO Br ands Can ada

5 Precidio Cour t

Brampton, ON L6S-6B7

800.263.1063

www.gbccanada.com

Página i

ACCO Mexicana

Neptu no #43, Colo nia Nueva I ndustr ial Vallejo

Delagacion Gus tavo A. Madero, CP 07700

México, DF. (55) 1500-5578

www.gbc.com.mx

© 2011 ACCO Brands. Todos los derechos reservad os. ACCO® e s una marca comercial regist rada

de ACCO Bra nds. GBC® e s una marca comercial regist rada de General Binding Corp oration.

80120510 Rev. A 11-2011

Page 43

Magnapunch 2.0: Instrucciones de instalación y funcionamiento

Ta b l a d e c o n T e n i d o s

1. Seguridad 1-1

Medidas de seguridad generales ...........................1-1

Precauciones para los juegos de matrices ........1-2

Energía eléctrica ......................................................1-2

Solo para máquinas que funcionan a

230 voltios .........................................................1-2

Servicio técnico de GBC ........................................ 1-3

Ubicaciones de la etiqueta de seguridad .............. 1-4

2. Garantía 2-1

Garantía limitada de 90 días ...................................2-1

3. Especificaciones 3-1

Dimensiones de las perforaciones .................... 3-2

Aviso de FCC clase A ............................................. 3-3

Aviso de Clase A para Canadá:

Avis Canada, Classe A ......................................... 3-3

Modificaciones ....................................................... 3-3

4. Instalación 4-1

Servicio técnico de GBC ........................................ 4-1

Antes de realizar la instalación .............................. 4-1

Instalación .............................................................. 4-1

Prueba ................................................................ 4-2

5. Guía de funciones 5-1

Energía eléctrica ..................................................... 5-1

Interruptor ON/OFF (Encendido/Apagado) ........ 5-1

Fusible ................................................................ 5-1

Conectores de la energía eléctrica y

del pedal. ......................................................... 5-1

Boca de perforación .............................................. 5-1

Bandeja para almacenar hojas .............................. 5-2

Interfaz de usuario ................................................. 5-2

LCD .................................................................... 5-2

Botones .............................................................. 5-2

Guía de papel y Activador de tablero .................... 5-2

Guía de papel ..................................................... 5-2

Activador de tablero .......................................... 5-3

Tablero de perforación ........................................... 5-3

Cajón de residuos .............................................. 5-3

Juego de matrices ............................................. 5-3

Pedal .................................................................. 5-3

Pantallas de notificación .................................... 6-6

Cómo cambiar los juegos de matrices

intercambiables ......................................................6-6

Cómo extraer los juegos de matrices................ 6-6

Cómo colocar los juegos de matrices ............... 6-6

Cómo extraer los punzones ............................... 6-7

Configuración de la tarea ....................................... 6-7

Cómo utilizar la interfaz de usuario de la

pantalla LCD .................................................... 6-7

Cómo probar la tarea ......................................... 6-9

Proceso de perforación ........................................6-10

Tarea de perforación .........................................6-10

Activación de la perforadora .................................6-11

Pedal .................................................................6-11

Activador de tablero .........................................6-11

Consejos para la perforación ...............................6-12

Papel .................................................................6-12

Cubiertas de plástico ........................................6 -12

Cajón de residuos .............................................6-12

Calidad de los orificios ..........................................6-13

7. Mantenimiento del operador 7-1

Cómo mantener la perforadora Magnapunch 2.0 ..7-1

Mantenimiento del juego de matrices ..............7-1

Cómo limpiar Magnapunch 2.0 ..........................7-1

Solución de problemas ...........................................7-2

Notas 7-3

6. Funcionamiento 6-1

Interfaz de usuario ................................................. 6-2

Navegación ........................................................ 6-2

Configuración inicial .......................................... 6-2

Funcionamiento ...................................................... 6-3

Pantalla Home (Principal) ................................... 6-3

Menú .................................................................. 6-4

Instrucciones de uso ......................................... 6-5

Ayuda y Consejos .............................................. 6-5

Página ii

Page 44

Magnapunch 2.0: Instrucciones de instalación y funcionamiento

Página iii

Page 45

Magnapunch 2.0: Instrucciones de instalación y funcionamiento

1. se g u R i d a d

Su seguridad y la de otras personas es muy importante.

Antes de instalar o utilizar Magnapunch 2.0, debe leer

detenidamente y respetar todos los avisos de seguridad de

este capítulo. Encontrará avisos de seguridad importantes

sobre Magnapunch 2.0 en este manual de instrucciones y

en el dispositivo. Lea todas las instrucciones y consérvelas

para consultarlas en el futuro.

Antes de los avisos de seguridad de este manual,

encontrará el símbolo de alerta de seguridad. Este símbolo

indica que puede existir un riesgo para su seguridad física

o la de otras personas.

Este símbolo de alerta de seguridad indica

que existe el riesgo de que se produzca una descarga

eléctrica. Le advierte que no debe abrir Magnapunch 2.0

ni exponerse a voltajes peligrosos.

Se pueden encontrar las siguientes advertencias en la

perforadora Magnapunch 2.0.

Este aviso de seguridad significa que puede resultar

gravemente herido o morir si abre Magnapunch 2.0 y se

expone al voltaje peligroso. No abra Magnapunch 2.0.

No contiene piezas que puedan ser reparadas por el

usuario. Las reparaciones las debe realizar el personal de

mantenimiento calificado.

Este aviso de seguridad significa

que la utilización de un fusible

inapropiado puede causar un

incendio o riesgo de descarga

eléctrica. Para mantener la

protección contra incendios o

riesgos de descarga eléctrica,

reemplace los fusibles con otros

del mismo tipo y valor nominal.

Si no respeta las advertencias, se pueden producir

lesiones físicas graves e incluso la muerte.

me d i d a s d e s e g u R i d a d g e n e R a l e s

adveRtenCias

No intente reparar ni realizar el mantenimiento de •

la perforadora Magnapunch 2.0.

No abra Magnapunch 2.0. No contiene piezas que •

puedan ser reparadas. Las reparaciones las debe

realizar el personal de mantenimiento calificado.

No conecte Magnapunch 2.0 a una fuente de •

alimentación de energía eléctrica para utilizarla

hasta que haya leído todas estas instrucciones.

Conserve estas instrucciones en una ubicación

conveniente para consultarlas en el futuro.

Para protegerse contra lesiones, siga las •

precauciones generales de seguridad cuando

instale y utilice la perforadora Magnapunch 2.0.

Asegúrese de que el interruptor de encendido se •

encuentre en la posición OFF (Apagado) cuando

Magnapunch 2.0 no esté en uso.

Revise que el área de trabajo no esté desordenada; •

de lo contrario, pueden producirse accidentes.

La perforadora Magnapunch 2.0 se debe colocar

sobre una superficie nivelada, firme y estable.

Deje suficiente espacio libre en la parte frontal y

posterior y a los costados de Magnapunch 2.0.

Mantenga el área de trabajo bien iluminada.

No utilice la perforadora Magnapunch 2.0 para •

otros fines que no sean para los que fue diseñada.

No fuerce ni retire los equipos de seguridad •

mecánicos y eléctricos como el mecanismo

de bloqueo, el revestimiento o la cubierta de

protección.

No introduzca objetos que no sean apropiados •

para perforar. No exponga el equipo a líquidos.

Utilice solo juegos de matrices intercambiables de •

GBC para Magnapunch 2.0 con esta perforadora.

Antes de utilizar Magnapunch 2.0, debe leer •

y comprender todo el contenido de estas

instrucciones.

Página 1-1

Page 46

Magnapunch 2.0: Instrucciones de instalación y funcionamiento

PR e C a u C i o n e s P a R a l o s j u e g o s d e

m a t R i C e s

PRECAUCIÓN:

Posible riesgo de punto de contacto. Cuando coloque •

los juegos de matrices en la perforadora, siempre

mantenga los dedos y otras partes del cuerpo fuera de

la ranura para los juegos de matrices de Magnapunch

2.0 y lejos de todas las áreas del juego de matrices

excepto por el asa del mango. Si no respeta estas

precauciones, se pueden producir lesiones.

Posibles daños del juego de matrices. Asegúrese de •

que todos los punzones se encuentren correctamente

colocados en el juego de matrices antes de colocarlo.

De lo contrario, se puede dañar el juego de matrices y

la perforadora Magnapunch 2.0.

en e R g í a e l é C t R i C a

La perforadora Magnapunch 2.0 solo debe conectarse

a una fuente de alimentación según se indica en estas

instrucciones y en la placa de nomenclatura ubicada en

la parte posterior de la máquina. Comuníquese con un

electricista en caso de que el enchufe proporcionado

con Magnapunch 2.0 no sea compatible con los

tomacorrientes del lugar.

ADVERTENCIA: No intente reparar ni realizar el

mantenimiento de Magnapunch 2.0. Si no respeta esta

advertencia, se pueden producir lesiones físicas graves e

incluso la muerte.

Asegúrese de que el interruptor de encendido se

encuentra en la posición Off (Apagado) cuando

Magnapunch 2.0 no esté en uso.

En caso de que le suceda lo siguiente, desconecte el

enchufe del tomacorriente y comuníquese con su proveedor o distribuidor, o con el Servicio técnico de GBC.

Si el cable de alimentación o el enchufe están •

dañados.

Si se volcó líquido sobre la perforadora •

Magnapunch 2.0.

Si Magnapunch 2.0 no funciona correctamente.•

Si la perforadora Magnapunch 2.0 no funciona •

como se describe en estas instrucciones.

PRECAUCIÓN: El tomacorriente debe estar

ubicado cerca de Magnapunch 2.0 y debe poder

acceder a él fácilmente.

Desconecte el enchufe del tomacorriente al que está

conectado y sostenga el cable de alimentación mientras

mueve Magnapunch 2.0.