TECHNICAL MANUAL

FOR

INSTALLATION, OPERATION

Effective Date: 4-11

AND MAINTENANCE

OF

TM

THE GAYLORD "ClearAir"

MODEL "RSPC-TPF" SERIES

POLLUTION CONTROL UNITS (PCU)

WITH COMMAND CENTER MODEL FM-1000-A

WARNING

Improper installation, adjustment, alteration service or maintenance can cause property damage, injury or death. Read

the installation, operation and maintenance instructions

thoroughly before installing or servicing this equipment.

Only trained and qualied service personnel should install

or service this equipment.

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • TUALATIN, OR 97062 USA

PHONE: 503-691-2010 • TOLL FREE: 800-547-9696 • FAX: 503-692-6048

email:info@gaylordusa.com • www.gaylordusa.com

GAYLORD INDUSTRIES

GAYLORD INDUSTRIES

GAYLORD INDUSTRIESGAYLORD INDUSTRIES

Direct: 503.691.2010

Fax: 503.692.6048

Toll Free: 800.547.9696

Email: info@gaylordusa.com

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord ClearAirTM Pollution Control

Unit. We are proud to be able to provide you with a quality product that exemplifies

our long-standing dedication to quality engineering.

Your unit is assembled from some of the very finest components available and is

designed for years of efficient, effective, and trouble free operation. In addition, this

unit has undergone rigorous quality control inspections and was fully operationally

tested prior to shipment.

If you have further questions, please contact us toll free at 1-800-547-9696, or

info@gaylordusa.com. We are more than happy to help.

Sincerely,

Gaylord Industries

GAYLORD INDUSTRIES

10900 SW Avery Street • Tualatin, OR 97062 U.S.A

www.gaylordusa.com • 800.547.9696

2

TECHNICAL MANUAL

FOR

INSTALLATION, OPERATION

AND MAINTENANCE

OF

THE GAYLORD "ClearAir"

MODEL “RSPC-TPF” SERIES

POLLUTION CONTROL UNITS (PCU)

WITH COMMAND CENTER MODEL FM-1000-A

Published by:

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET

TUALATIN, OREGON 97062 U.S.A

Phone: 503-691-2010

1-800-547-9696

Fax: 503-692-6048

email: info@gaylordusa.com

TM

© Copyright 2011, Gaylord Industries

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED,

STORED IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY

AN ELECTRONIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS

OR OTHERWISE WITHOUT THE WRITTEN PERMISSION OF GAYLORD

INDUSTRIES. COPYRIGHT 2010.

The manufacturer reserves the right to modify the materials and specifications resulting from a continuing

program of product improvement or the availability of new materials.

Additional Copies $15.00

The Gaylord ClearAirTM Unit is designed, engineered and manufactured by

GAYLORD INDUSTRIES

10900 SW Avery St., Tualatin, Oregon 97062

3

TABLE OF CONTENTS

INTRODUCTION …………………………………………………………………………..................... 5

SPECIFICATIONS …………………………………………………………………………………........ 6

MODEL NUMBER EXPLANATION ………………………………………………………….............. 8

TYPICAL INSTALLATION …………………………………………………………………………..…. 9

SAMPLE ClearAir CONFIGURATIONS ……………………………………………………………... 10

COMMAND CENTER CONTROL FUNCTIONS …………………………………………..………… 12

DAILY OPERATION – STARTING THE EXHAUST FAN …………………………………....……… 13

DAILY OPERATION – STOPPING THE EXHAUST FAN ……………………………….………….. 14

DAILY OPERATION – AUTOSTART ……………………………………………….........…………… 15

DAILY OPERATION – FILTER MONITORING ………………………………………….…………… 17

FIRE IN THE POLLUTION CONTROL UNIT …………………………………………….......……… 21

EXTERNAL FIRE CONDITION ……………………………………………………………….....….… 22

REMOTE START …………………………………………………………………………….…….....… 24

DAILY OPERATION – SPRAY ODOR CONTROL ……………………………...………………...... 25

SMOKE CONTROL SECTION …………………………………………………….…………..……… 26

ODOR CONTROL SECTION – MEDIA BED TYPE………………………………...……………..… 27

ODOR CONTROL SECTION – CHEMICAL SPRAY TYPE ………………………...……………… 29

EXHAUST FAN SECTION ………………………………………………………………...…………… 30

GENERAL MAINTENANCE ………………………………………………………………....………… 32

SYSTEM WIRING INTERNAL ..…………………………………………………………………..…… 33

SYSTEM WIRING EXTERNAL ..………………………………………………………………….…… 35

PCU PRESSURE SWITCH SETTINGS …….........................................…………………....…..… 37

PCU PRESSURE SWITCH TUBING DIAGRAM …………………............................……....…..… 38

NAMEPLATE SAMPLE ………………………………………………………………………………… 39

PARTS – COMMAND CENTER ………………………………………………………………….....… 40

PARTS – PCU ……………………………………………………………………………………….….. 41

PARTS – SPRAY ODOR CONTROL ……………………………………………………………….... 43

APPENDIX ....................................................................................................................... 44

RECEIVING AND INSTALLATION ……………………………….…………………………......…… A-1

START UP INSTRUCTIONS ………………………………………………………………….....……. B-1

LIMITED WARRANTY ………………………………………………………...… INSIDE BACK COVER

4

INTRODUCTION

ir quality is becoming a major concern in America’s large

A

cities and as a result, many commercial kitchens will

require pollution control equipment in their exhaust systems to

comply with the increasing demands of environmental control

agencies. In addition, pollution control equipment is being

used for kitchens in high-rise buildings allowing the exhaust

to discharge out the side of the structure which saves the cost

of running the duct up many oors to the roof.

Pollution control in kitchen exhaust systems has typically been

accomplished by any one of the following methods - gas red

incinerators, scrubbers, ltration units or electrostatic precipitators. Incinerators and afterburners literally burn the pollutants and, while effective, can be very costly and hazardous

to operate. Scrubbers consist of a water bath and extraction

bafes to remove the pollutants and though quite effective

on grease removal, they typically require the addition of high

efciency lters to abate smoke below control agencies’

standards. Filtration units use a series of impingement lters

to remove the pollutants and if done properly can be quite

effective on both smoke and grease.

The Gaylord pollution control unit, trademarked “ClearAir”TM,

can be manufactured with either electrostatic precipitation

(ESP) or Filtration (TPF). Gaylord Industries has been

manufacturing ESP’s specically designed for commercial

kitchen exhaust systems since the early 1970’s, longer

than any other manufacturer. However, when initial cost

is a greater concern the TPF unit is a sound alternative.

The ClearAirTM TPF unit is available in several congurations, as illustrated on the following pages, ranging in capacity from 1000 to 32,000 CFM (472 to 15,102 L/s). Most

models can include an exhaust fan and odor abatement

equipment as an option.

Basic Facts About Smoke

Smoke particles are extremely small and not visible to the

human eye unless thousands of them are grouped together

to form what we see as smoke. Individual particles are

measured in units called microns and one micron equals

1/25,400 of an inch (1/64,516 of a cm).

Smoke generated by commercial cooking equipment

has a particulate size of 0.15 microns and it is these very

small particles that smoke abatement equipment must

remove from the airstream. The amount of smoke being

discharged from a kitchen exhaust duct is measured in

terms of its density, referred to as opacity - the degree to

which emissions block light. A 100% opacity level would

be solid black and 0% would be perfectly clear. Control

agencies that have adopted smoke pollution ordinances

are requiring an opacity level of no more than 20%, which

is a very light blue smoke.

Typically, heavy smoke producing cooking such as charbroiling, creates an opacity level of 60% to 70%. Opacity readings are taken by the human eye by viewing the

smoke being discharged and then assigning a percentage

of opacity to what is seen. Though this method is quite

subjective, it is the method practiced by control agency

inspectors who are trained and certied in determining

opacity percentages. Other more technical methods of

determining opacity or particulate density are achieved

through the use of opacity meters and cascade impactors. This level of analysis is usually referred to as source

testing. Control agencies occasionally require this type

of analysis and if so, the testing is conducted by state

certied contractors which can be quite costly and timeconsuming. The efciency of an TPF is based on how

well it reduces the opacity level of a given airstream.The

Gaylord ClearAirTM unit will reduce the opacity level below

20%, thereby meeting the requirements of environmental

control agencies.

Basic Facts About Odor

Cooking odors (molecules) generated by the combustion

of animal and vegetable matter result in an extremely

complex mixture of reactive organic gases (ROG’s). A small

percentage of these odors may be absorbed by the grease

particles but the vast majority exist separately in the airstream.

The ROG molecules are much too small to be removed by

any type of lter and therefore, other methods must be used.

There are several methods with which to manage the odor.

One method is to use a media bed. The three most popular

types of media bed are activated charcoal, which absorbs and

retains the odor molecules, the use of an odor-oxidant media

(potassium permanganate) which oxidizes the molecules

to solids and then retains them, and a blend of the two.

Another method involves the use of a liquid delivered with

a nely atomized spray. This spray performs a similar

function to potassium permanganate in that it adsorbs or

chemically neutralizes odors. This process has the benet

of the end user being able to adjust the amount of spray

and thus the effectiveness and cost of the odor control.

The life of the media bed type of odor control is dependent upon several factors such as how much media is

used, type of odor, amount of odor molecules, grease

loading and air temperature. Typically, any of the above

mentioned types of media can remove 85% - 90% of the

molecules. Determining the efciency of odor control can

be very subjective, as testing is usually conducted by the

human nose. More scientic testing is available through

ROG analysis, but this involves considerable costs.

Grease Removal - The Important First Step

Grease particles are also measured in terms of microns

and grease generated by commercial cooking equipment

has a particulate size of 0.1 microns and up. Pollution control equipment is not limited to removing smoke particles,

but will also remove a majority of the grease particles

remaining in the airstream. Therefore, the grease extraction efciency of the exhaust hood plays an important

role in the operation and performance of pollution control

equipment.

Removal of grease particles before they reach smoke

and odor control equipment will signicantly increase

the smoke abatement efciency and the life of the odor

abatement media.

5

SPECIFICATIONS

General

Furnish one (1) Gaylord ClearAir Pollution Control Unit

model RSPC-TPF series as manufactured by Gaylord

Industries of Tualatin, Oregon in accordance with the following:

The pollution control unit (PCU) shall consist of a smoke

control section, odor control section (optional) and an

exhaust fan section (optional) all built on a common base

as an integral unit. Smoke control shall be accomplished

by a three stage high efciency lter section (TPF). The

unit shall be ETL listed and labeled.

Smoke Control Section

The smoke control section shall have three phases of

lters The lters shall consist of replaceable 30% prelter, 95% bag lter and a replaceable .95 DOP nal lter.

Replaceable lters shall be mounted in lter slide tracks to

prevent air bypass around the ends of the installed lter

bank. Filters shall be accessed through removable side

access panels with lift and turn latches.

Phase one lters shall have an average efciency of 25

to 30% and an average arrestance of 90 to 92% in accordance with ASHRAE test standard 52.1-1992. Media

support grid shall be on 1" centers with an open area 96%.

Filter enclosing frame shall be a rigid, high wet strength

beverage board, with diagonal support members 4" deep.

Phase two lters shall have an average efciency of

90 to 95% in accordance with ASHRAE test standard

52.1-1992. Sealing surface and pocket retainers shall be

congured to provide 84% open area. Seams in bag lters

shall be sealed with foamseal adhesive to completely

eliminate air leakage through stitch holes.

Phase three lters shall be 95% efcient on .03 micron

particles (DOP smoke test), 97% efcient on nebulized

staphylococcus aerosols, 99+% efcient on atmospheric

test dust (ASHRAE standard 52.1-92). The casing shall

be 16 gauge steel with corrugated aluminum separators

to insure media stability. Media shall be ne-ber, high

strength microberglass paper. Media end cuts shall be

encapsulated in urethane potting adhesive.

Fire Detection

A thermostat, set at 250o F, shall also be located in the lter

section to shut down the exhaust fan in the event of a re.

Optional Fire Damper Required in Canada

The unit shall include a UL listed re damper, with a 280o

F fusible link, located downstream of the lters to prevent

passage of re to the duct downstream of the unit

Control Panel

A Gaylord Kitchen Exhaust System Command Center

control panel, Model FM-1000-A, designed for remote

location, shall be supplied for the operation of the exhaust

fan and monitoring of the PCU. The control panel shall be

constructed of 18 gauge stainless steel, number 4 nish,

and shall be suitable for surface or recessed mounting.

The panel face shall be a hinged door and with a lift and

turn ush latch.

The control panel shall include a Programmable Logic

Controller (PLC) and a LED display panel to operate

and monitor all conditions of the PCU. The panel shall

display text showing each PCU condition as it occurs.

The control panel shall include push buttons for Starting and Stopping the exhaust fan, and control, monitor

and notify of the following conditions; Fan On, Fan Off,

Autostart (start the exhaust fan if the hood is provided

with an Autostart system), Pre-Filter(s) dirty, Bag Filter(s)

dirty, Final Filter(s) dirty, Missing Filter(s), Fire in the PCU,

External Fire (chemical system in the hood or PCU discharged), and a Remote Start of the PCU. If the PCU is

equipped with a Spray Odor Control system the Control

Panel shall include a Low Spray Odor Chemical light.

An audible alarm, with an alarm cancel button, shall be

included and shall activate whenever the system detects

a dirty Pre-Filter, Bag Filter, Final Filter, Missing Filter, Fire

in the PCU or External Fire condition.

The Control Panel shall include terminals to allow interfacing with the make-up air system, a building management

system (remote start and stop or the exhaust fan system),

and a re alarm system.

(optional) Provide Remote Monitoring terminals to al-

low interfacing with the building management system to

monitor all functions of the control panel.

(optional) Provide Hood Light Switch on the face of

the Control Panel.

Odor Control Options

Media bed of 50/50 Blend Potassium Permanganate and

Carbon Blend

The unit shall be provided with odor control utilizing a

media bed of 50% potassium permanganate 50% carbon

blend. There are two design methods of housing the

media used in the ClearAir unit. One is called the Loose

Fill type and the other is called the Media Panel type.

Loose Fill type – The odor control media shall be housed

in steel reusable Media Modules that can be replenished

with Loose Fill media. There shall be a 30% pleated

media After Filter located immediately downstream of the

Media Models. The Modules and After Filters shall be

mounted into slide tracks to prevent air bypass around

the ends. The Modules and After Filters shall be removable through side access doors with lift and turn latches.

Media Panel type – The odor control media shall be

compressed into Media Panels that slide into Media Modules. The Modules shall be mounted into slide tracks to

prevent air bypass around the ends. The Modules and

shall be removable through side access doors with lift

and turn latches.

(optional) The unit shall be equipped with a 30% pleated media After Filter located immediately downstream of

the Media Models.

The unit shall be equipped with a Single Pass Media

Bed

6

SPECIFICATIONS

The unit shall be equipped with a Double Pass Media

Bed

The unit shall be equipped with a Triple Pass Media Bed

Spray Odor Control

The unit shall be provided with a spray odor control system utilizing an odor neutralizer chemical. The odor spray

control cabinet shall be mounted on the side of the unit and

shall contain a liquid spray compressor piped to the spray

nozzle in the fan plenum, adjustable delay timers with fuse

protected circuitry factory wired to the unit electrical panel.

The cabinet shall include one 5 gallon container of Gaylord

Formula GS-710 Odor Neutralizer. The cabinet shall contain a heater to prevent freezing of the odor neutralizer, if

mounted outdoors.

Exhaust Fan Options

Exhaust Fan (Standard Centrifugal Fan)

The unit shall include a centrifugal exhaust fan, Listed

to U.L. 762. The exhaust fan shall be an SWSI upblast

arrangement #9 or #10 with a non-overloading BI or AF

wheel. The motor, drives, bearings and fan mounting base

shall be located out of the exhaust air stream as required

by the IMC (International Mechanical Code) and NFPA-96.

The fan shall be AMCA certied and bear the AMCA seal

for performance. The fan housing shall be constructed of

heavy gauge steel. The fan bearings shall be heavy duty

self-aligning pillow block type rigidly mounted on heavy

structural steel supports. The motor shall be ODP three

phase mounted on a common base with the fan and shall

be pre-wired to the electrical cabinet located on the unit.

The electrical cabinet shall include a disconnect switch, motor starter, overloads and fuses. The factory provided drive

assembly shall be adjustable pitch on 5 HP and smaller,

xed pitch on 7.5 HP and larger. It shall also be sized for

a minimum 1.5 service factor. After nal system balancing,

xed pitch sheaves shall be provided and installed by the

air balancing contractor to provide proper ow at actual

installed conditions.

Exhaust Fan (Optional Tubular Fan)

The unit shall include a tubular centrifugal exhaust fan,

Listed to U.L. 762. The exhaust fan shall be an arrangement

#10 with a non-overloading BI, AF wheel. The motor, drives,

bearings and fan mounting base shall be located out of the

exhaust air stream as required by the IMC (International

Mechanical Code) and NFPA-96. The fan shall be AMCA

certied and bear the AMCA seal for performance. The

fan housing shall be constructed of heavy gauge steel.

The fan bearings shall be heavy duty rigidly mounted on

heavy structural steel supports. The motor shall be ODP

three phase mounted on a common base with the fan

and shall be pre-wired to the electrical cabinet located on

the unit. The electrical cabinet shall include a disconnect

switch, motor starter, overloads and fuses. The factory

provided drive assembly shall be adjustable pitch on 5 HP

and smaller and xed pitch on 7.5 HP and larger. It shall

also be sized for a minimum 1.5 service factor. After nal

system balancing, xed pitch sheaves shall be provided

and installed by the air balancing contractor to provide

proper ow at actual installed conditions.

Exhaust Fan Housing

The exhaust fan section of the unit shall be enclosed with

the same material as the smoke control section. There shall

be a removable panel for access to the fan.

Unit Construction

The unit housing shall be constructed of a minimum of 16

gauge G90 bright galvanized steel. The perimeter base

shall be 12 gauge formed channel with lifting lugs at each

corner and along the length as required. The internal housing shall be externally welded liquid tight for compliance to

the International Mechanical Code and NFPA-96 grease

duct construction requirements.

Fire Extinguishing System Options

Specier Note: NFPA-96 requires a re extinguishing

system for protection of the smoke and odor control sections and protection of the duct down stream of any lters

or dampers. Not all authorities having jurisdiction require

protection. Check with your AHJ. If required, specify one

of the following systems.

Wet chemical system

Provide a complete factory mounted Ansul wet chemical

re extinguishing system, including nozzles piping and

detection runs. Pipe penetrating the unit cabinet shall use

a UL listed tting. System shall be installed in accordance

with the manufacturer's recommendations, the systems

listing and NFPA-96. The Ansul Automan cabinet shall be

mounted on the side of the unit for easy access, certication and service. If mounted outdoors, a heater shall be

provided.

Water spray sprinkler re system

Specier Note: Units that are located indoors may be factory

pre-piped for a wet pipe building sprinkler system.

Provide a pre-piped water spray re system installed in

accordance with NFPA-96. The unit shall be piped with

one pendent type sprinkler nozzle located in the smoke

control section, one in the odor control section, if equipped

with 50/50 media bed, and one in the exhaust fan section

for interconnection to the building sprinkler system by the

appropriate trades. Pipe penetrating the unit cabinet shall

use a UL listed tting. Nozzles shall be the bulb type rated

at 325o F.

Check Out and Demonstration

Upon completion of installation, the entire pollution control system, including the kitchen exhaust hoods, shall be

commissioned by factory certied personnel. Start-up shall

include checking all lters, lter monitoring station, odor

control and exhaust fan. The appropriate maintenance

personnel shall be given a technical manual and a complete demonstration of the system, including operation

and maintenance procedures. Upon completion of the

commissioning, a detailed start-up report shall be made

available to the architect and owner certifying proper system

operation. Changes required in fan drive components shall

be performed by the air balancing contractor under the direction of the factory certied person(s) performing the start-up.

7

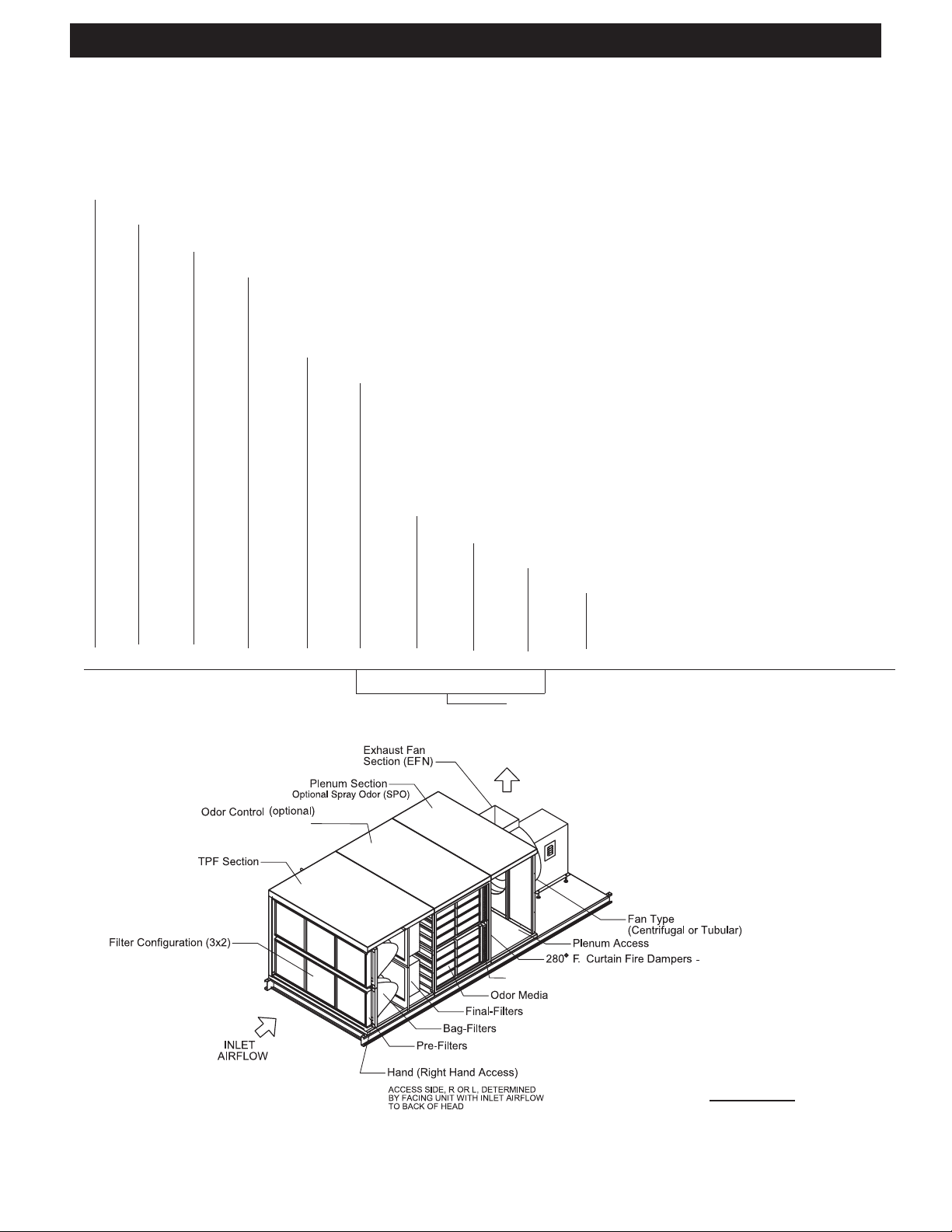

MODEL NUMBER EXPLANATION

(Required in Canada)

After-Filter (Optional) - Required if Loose Fill Type Media is Used)

Section (SO, DO, TO)

(DO shown)

The assigned model number of a ClearAirTM RSPC-TPF unit will indicate the number of Filter Banks and if it has spray

odor control, single or double pass odor control, if it has an exhaust fan plus other data. The following example shows

the make-up of a model number.

The model number of your ClearAirTM unit along with other data can be found on the nameplate which is attached to the

electrical control panel on the ClearAirTM unit. Refer to page 38.

Standard Prex Series of ClearAirTM System (Remote Smoke Pollution Control)

Triple Pass Filter

Filter Conguration (W x H) - 1x1, 2x1, 3x1, 2x2, 3x2, 4x2, 3x3, 4x3, 3x4, 4x4

Odor Control Option:

SO = Single Pass Odor Control

DO = Double Pass Odor Control

TO = Triple Pass Odor Control

SPO = Spray Odor

Total CFM (1000 - 32,000)

Exhaust Fan Option:

EFS = Exhaust Fan, unhoused, spring isolated

EFN = Exhaust Fan, unhoused, not spring isolated

EFHS = Exhaust Fan, housed, spring isolated

EFHN = Exhaust Fan, housed, not spring isolated

(BLANK) = No Exhaust Fan

Fan Type = C (Centrifugal), T (Tubular)

Fan Size (ie. 100 - 490)

Fan Motor H.P. (ie. 1 - 75)

Hand - R = Right Hand

L = Left Hand

RSPC - TPF - 3x2 - DO - CFM - EFN - C - 300 - 15 - R

BLOCK 1 2 3 4 5 6 7 8 9

All Blank, if no exhaust fan

FIGURE 8-1

8

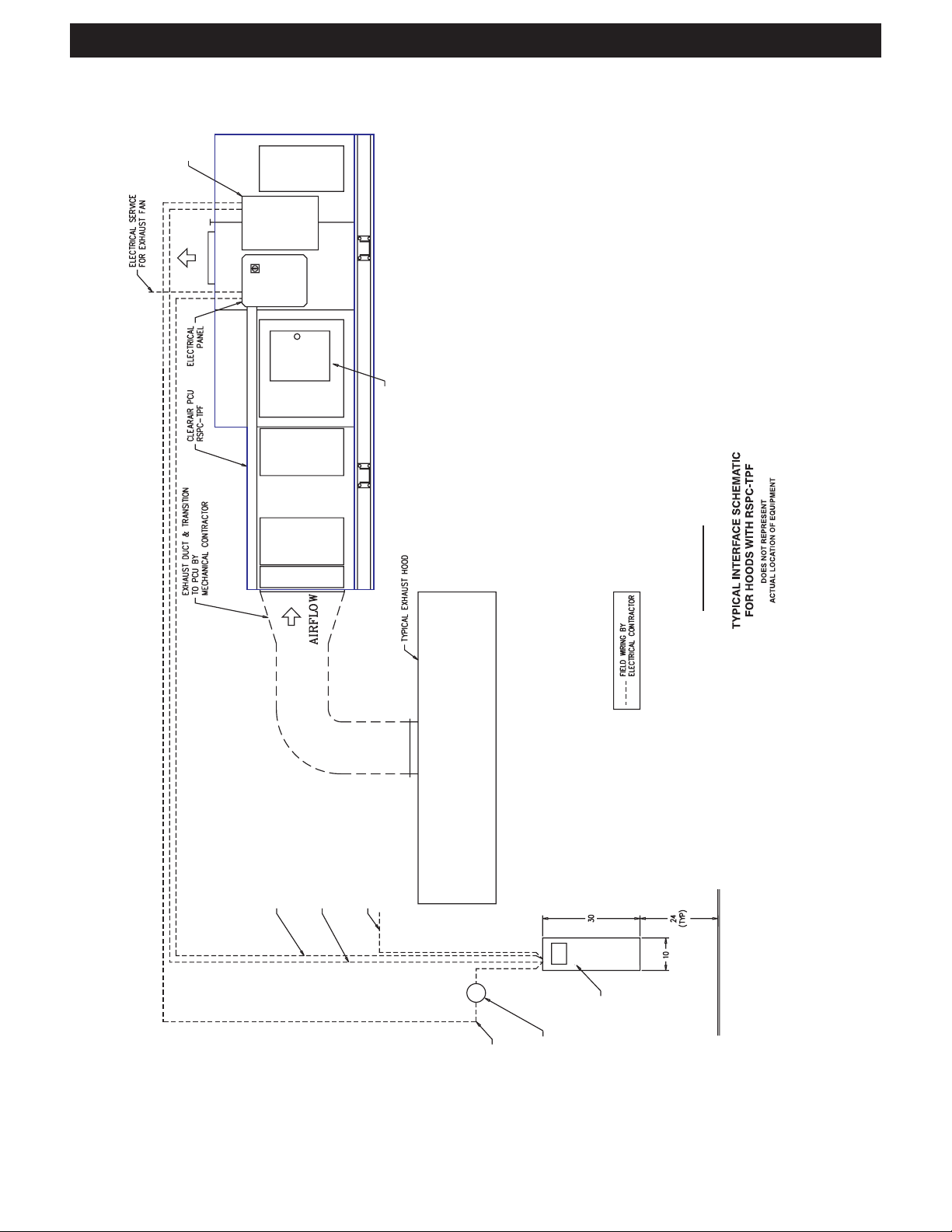

TYPICAL INSTALLATION

OPTIONAL SPRAY ODOR

CONTROL CABINET

OPTIONAL

FIRE EXTINGUISHING

SYSTEM CABINET

WIRES & GROUND FROM

COMMAND CENTER TO

CLEARAIR POLLUTION CONTROL UNIT

WIRES & GROUND FROM

COMMAND CENTER TO

FIRE EXTINGUISHING SYSTEM

120/60/1 PHASE 15AMP SERVICE

FOR COMMAND CENTER

IRES & GROUND FROM FIRE

GAYLORD COMMAND CENTER

SUPPLY FAN STARTER

BY OTHERS

FIGURE 9-1

9

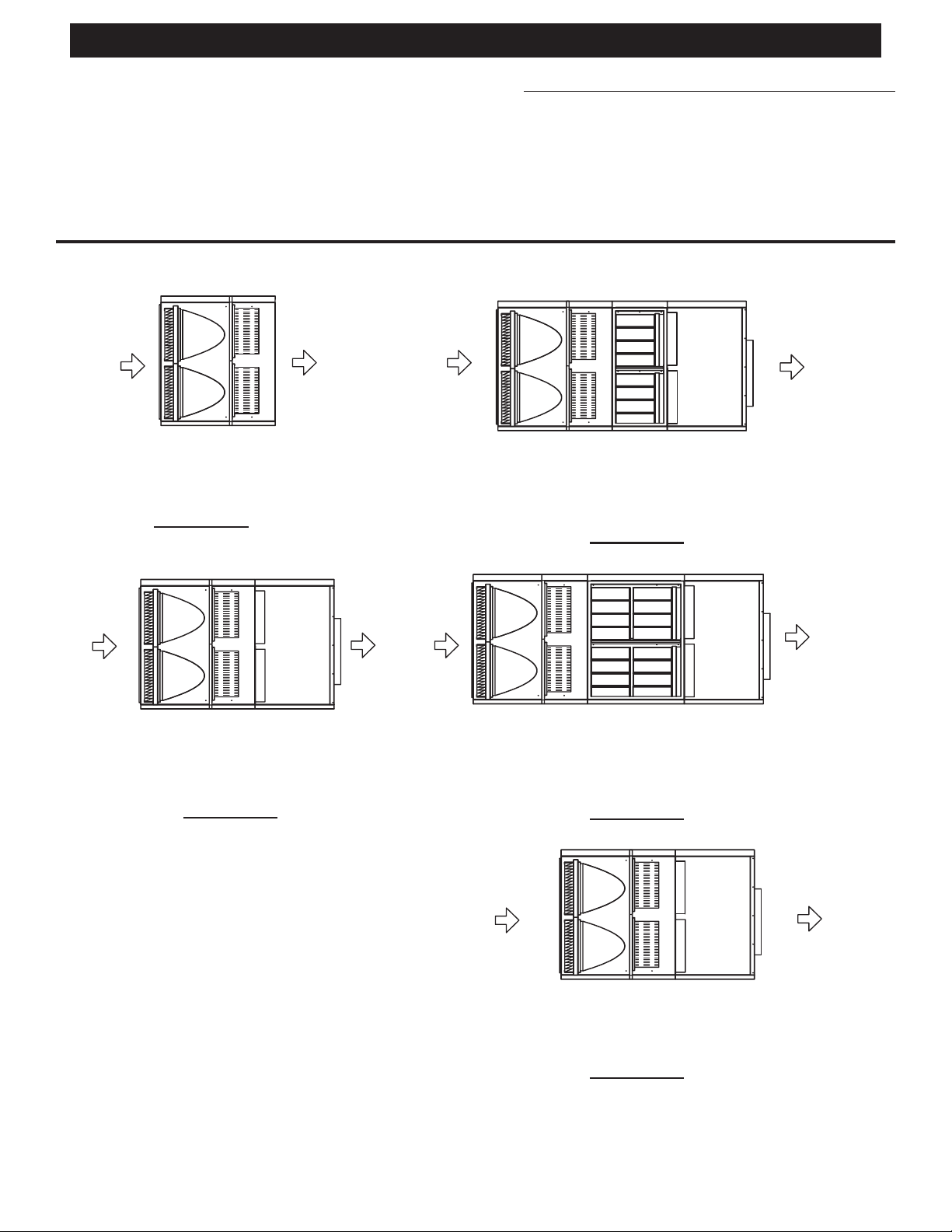

SAMPLE ClearAirTM CONFIGURATIONS

The ClearAir unit is available in sizes ranging in capacity

from 1000 to 32,000 CFM (472 to 15,102 L/s). Each unit is

equipped with Three Phase Filters for smoke control, and

may include an exhaust fan, odor abatement equipment and

fire extinguishing system as an option. The following illustrations are examples of the most common configurations.

OUTLET TO FAN

BF FF

PF

RSPC-TPF

SMOKE CONTROL ONLY

SMOKE CONTROL ONLY

(REMOTE FAN)

(REMOTE FAN)

FIGURE 10-1

KEY

AF = After Filter - optional

Required if Loose Fill Type

Odor Control Media is Used

BF = 95% Bag Filter

DO = Double Pass Odor

EF = Exhaust Fan–un-housed

EFH = Exhaust Fan–housed

PF

BF

SMOKE CONTROL

WITH SINGLE PASS ODOR CONTROL

WITH SINGLE PASS MEDIA BED ODOR CONTROL

(REMOTE FAN)

FF

SMOKE CONTROL

SO

RSPC-TPF-SO

(REMOTE FAN)

FD = Optional Curtain Fire

Damper Required in Canada

FF = 95% DOP Final Filter

PF = 30% Pre-Filter

SO = Single Pass Odor

SPO = Spray Odor Cabinet

TO = Triple Pass Odor

(not illustrated)

OUTLET TO FAN

AF

FD

FIGURE 10-2

BF

PF

FF

FD

RSPC-TPF

SMOKE CONTROL WITH PLENUM

SMOKE CONTROL WITH PLENUM

(REMOTE FAN)

(REMOTE FAN)

FIGURE 10-3

OUTLET TO FAN

OUTLET TO FAN

BF

PF

FF

DO

FD

AF

RSPC-TPF-DO

SMOKE CONTROL

WITH DOUBLE PASS MEDIA BED ODOR CONTROL

WITH DOUBLE PASS ODOR CONTROL

(REMOTE FAN)

SMOKE CONTROL

(REMOTE FAN)

FIGURE 10-4

OUTLET TO FAN

BF FF

PF

SMOKE CONTROL

SMOKE CONTROL

WITH SPRAY ODOR CONTROL

WITH SPRAY ODOR CONTROL

(REMOTE FAN)

(REMOTE FAN)

FD

SP

SPO

FIGURE 10-5

10

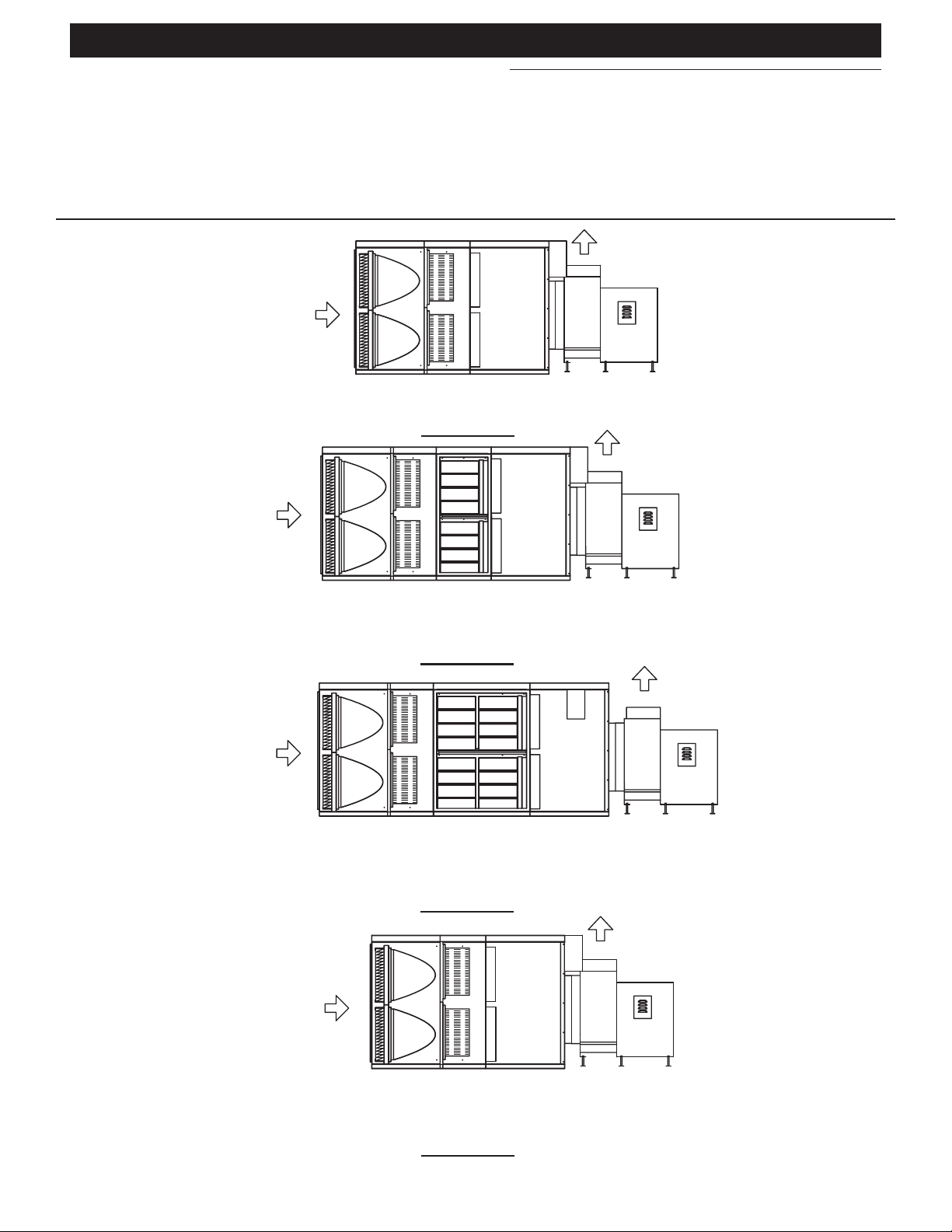

PF

BF

FF

FAN DISCHARGE

SMOKE CONTROL

WITH SINGLE PASS ODOR CONTROL

AND EXHAUST FAN

EF

SO

FD

PF

BF

FF

FD

EF

SMOKE CONTROL

WITH EXHAUST FAN

EF

PF

BF

FAN DISCHARGE

FD

FF

EF

SP

DO

AF

FD

FFBF

PF

FAN DISCHARGE

SMOKE CONTROL

WITH DOUBLE PASS ODOR CONTROL

AND EXHAUST FAN

SMOKE CONTROL

WITH SPRAY ODOR CONTROL

AND EXHAUST FAN

FAN DISCHARGE

RSPC-TPF-EF

SAMPLE ClearAirTM CONFIGURATIONS

KEY

AF = After Filter - optional

Required if Loose Fill Type

Odor Control Media is Used

BF = 95% Bag Filter

DO = Double Pass Odor

EF = Exhaust Fan–un-housed

EFH = Exhaust Fan–housed

FD = Optional Curtain Fire

Damper Required in Canada

FF = 95% DOP Final Filter

PF = 30% Pre-Filter

SO = Single Pass Odor

SPO = Spray Odor Cabinet

TO = Triple Pass Odor

(not illustrated)

RSPC-TPF-SO-EF

RSPC-TPF-DO-EFH

WITH EXHAUST FAN AND OPTIONAL FIRE DAMPER

SMOKE CONTROL

FIGURE 11-1

AF

SMOKE CONTROL

WITH SINGLE PASS MEDIA BED, ODOR CONTROL,

EXHAUST FAN AND OPTIONAL FIRE DAMPER

FIGURE 11-2

WITH DOUBLE PASS ODOR CONTROL

RSPC-TPF-SPO-EF

SMOKE CONTROL

AND EXHAUST FAN

FIGURE 11-3

SPO

SMOKE CONTROL

WITH SPRAY ODOR CONTROL

AND EXHAUST FAN

FIGURE 11-4

11

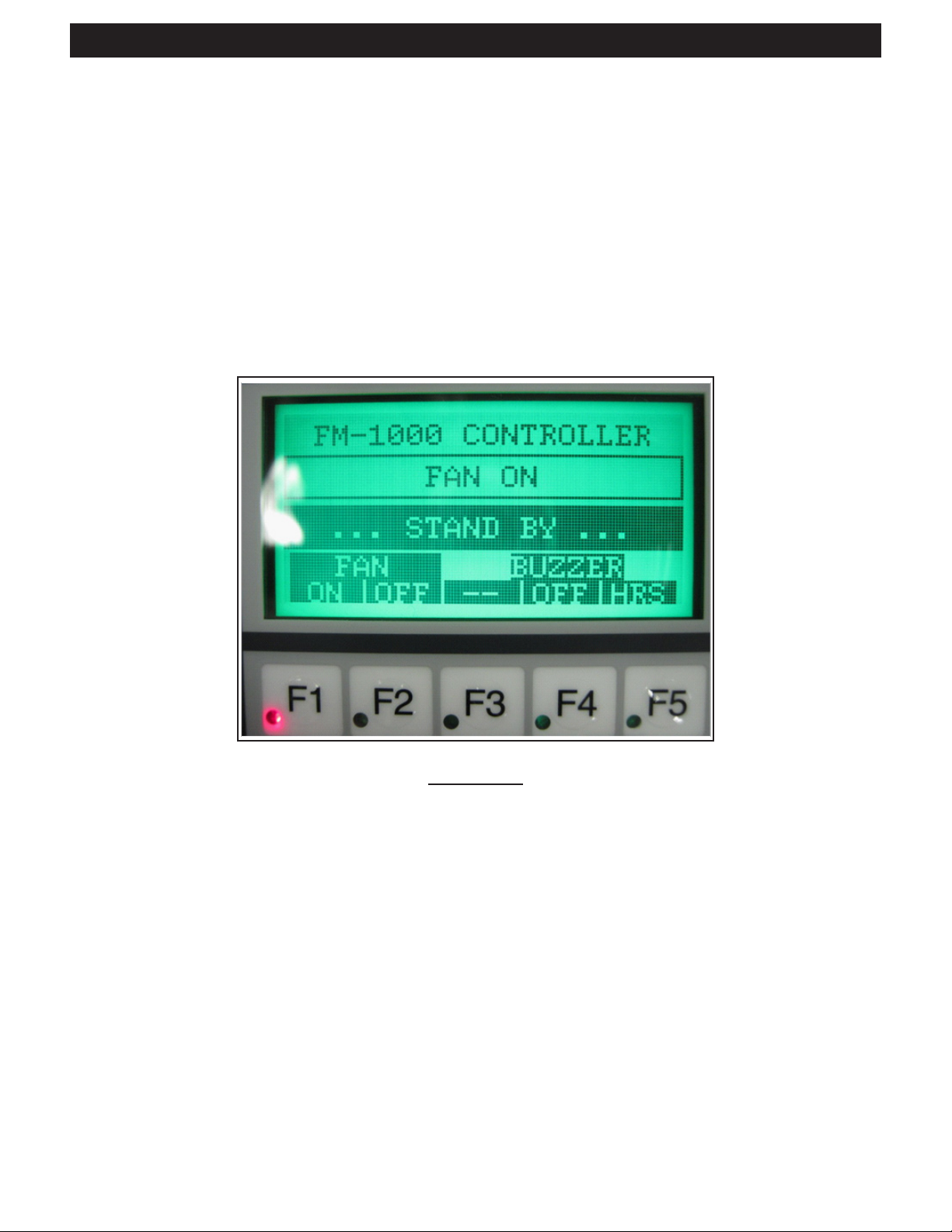

COMMAND CENTER CONTROL FUNCTIONS

The Kitchen Exhaust System Command Center, Model

FM-1000-A, controls and monitors all functions of the

Gaylord ClearAir pollution control unit (PCU). All functions

are indicated on the LED display on the face of the Command Center. The Command Center is typically located

in the kitchen area, near the ventilator and performs the

following:

• Manually Starting and Stopping the exhaust fan.

• Automatically starts the make-up air system if the

system is interfaced with the Command Center.

• Allows Autostart of exhaust fan if the ventilator includes

optional Autostart feature.

• Notication that the exhaust is on via Autostart, if

ventilator includes this option.

• Visual and audible notication that a Pre-lter(s) is

dirty.

• Visual and audible notication that a Bag Filter(s) is

dirty.

• Visual and audible notication that a Final Filter(s) is

dirty.

• Visual and audible notication that a lter(s) is missing.

• Visual and audible notication that there is a re in the

ClearAir pollution control unit.

• Terminals to interface with a building management

system to allow Remote Starting and Stopping of the

exhaust fan.

• Optional terminals to interface with a building manage

ment system to monitor all functions of the control.

FIGURE 12-1

COMMAND CENTER

MODEL FM-1000-A

12

DAILY OPERATION - STARTING THE EXHAUST FAN

Starting the Exhaust Fan

To start the exhaust fan press the F1 button.

Pressing the F1 button will result in:

1. There is a one minute delay, STAND BY, before the exhaust fan will come on.

2. The display panel will read as shown.

FIGURE 13-1

DISPLAY PANEL

FAN ON

STAND BY CONDITION

13

DAILY OPERATION - STARTING THE EXHAUST FAN

Starting the Exhaust Fan (continued)

At the end of one minute delay the following will occur:

1. The exhaust fan will come on.

2. The make-up air system will come on if interfaced with the control.

3. The display panel will read as shown.

FIGURE 14-1

DISPLAY PANEL

FAN ON CONDITION

14

DAILY OPERATION - STOPPING THE EXHAUST FAN

Stopping the Exhaust Fan

To stop the exhaust fan press the F2 button.

Pressing the F2 button will result in:

1. The exhaust fan will shut off.

2. The make-up air will shut off if the make-up air system is interfaced with the control.

3. The display panel will read as shown.

Note:

If the ventilator(s) is equipped with optional Autostart controls the exhaust fan may continue to run after F2 is pushed.

Refer to Page 16 for details.

FIGURE 15-1

DISPLAY PANEL

FAN OFF CONDITION

15

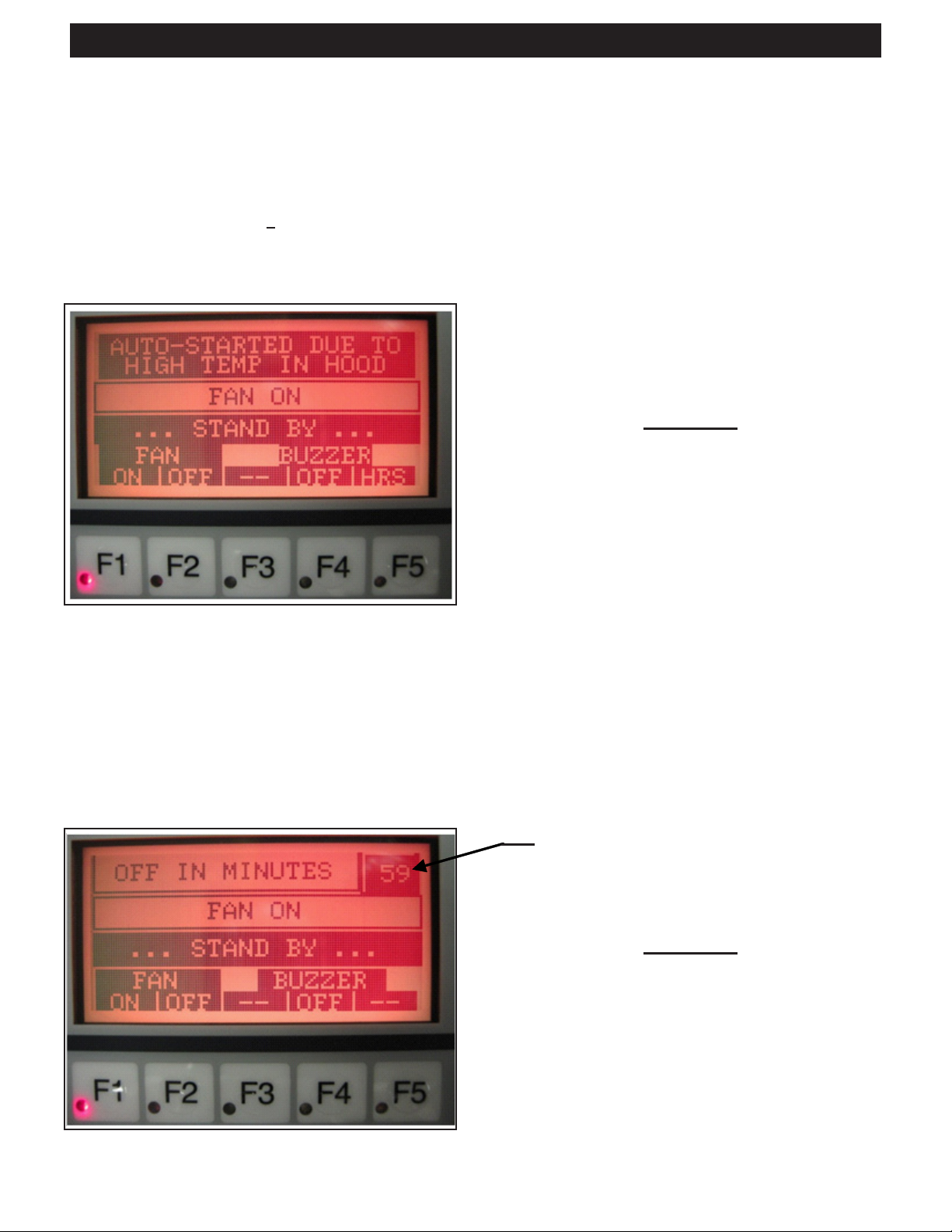

DAILY OPERATION - AUTOSTART

Countdown Clock

in Minutes

Code Requirements

Some municipalities require the exhaust fan to start automatically whenever cooking operations occur to comply with

International Mechanical Code (IMC) paragraph 507.2.1.1. This can be accomplished by the use of Gaylord Autostart

Model TST.

Description of Autostart Control

There is one or more Autostart Thermostats mounted in the canopy of the ventilator(s). The thermostat is factory set at

approximately 90 degrees F +10. If the temperature of the thermostat reaches the set point, and the exhaust fan is off,

the exhaust fan will automatically start. The display panel will read as shown in Figure 16-1.

FIGURE 16-1

DISPLAY PANEL

FAN ON

STAND BY CONDITION

After the temperature of the thermostat drops below the set point, the Command Center starts a 60 minute shut off

countdown, shown in the upper right hand corner of the display panel (refer to Figure 16-2). At the conclusion of the

countdown the exhaust fan will automatically shut off.

Note: Once a countdown has started, the exhaust fan may be manually shut off by pushing F2.

FIGURE 16-2

DISPLAY PANEL

FAN OFF

COUNTDOWN CONDITION

16

DAILY OPERATION - FILTER MONITORING

Pre-Filters

If one or more Pre-Filters are dirty an audible alarm will come on and the display panel will read PRE-FILTER DIRTY –

LOW AIR as shown in Figure 17-1. The audio alarm may be silenced by pushing F4, however if the dirty Pre-Filters are

not replaced the audible alarm will come back on the next time the exhaust fan is started.

Note: Dirty Pre-Filters will cause low air in the ventilator typically causing smoke loss into the kitchen. Replace the

lters as described on page 26.

FIGURE 17-1

DISPLAY PANEL

DIRTY PRE-FILTER CONDITION

17

DAILY OPERATION - FILTER MONITORING

Bag-Filters

If one or more Bag Filters are dirty an audible alarm will come on and the display panel will read BAG FILTER DIRTY,

LOW AIR as shown in Figure 18-1. The audible alarm may be silenced by pushing F4, however if the dirty Bag Filters

are not replaced the audible alarm will come back on the next time the exhaust fan is started.

Note: Dirty Bag Filters will cause low air in the ventilator typically causing smoke loss into the kitchen. Replace the

lters as described on page 26.

FIGURE 18-1

DISPLAY PANEL

DIRTY BAG FILTER CONDITION

18

DAILY OPERATION - FILTER MONITORING

Final Filters

If one or more Final Filters are dirty an audible alarm will come on and the display panel will read FINAL FILTER DIRTY,

LOW AIR as shown in Figure 19-1. The audible alarm may be silenced by pushing F4, however if the dirty Final Filters

are not replaced the audible alarm will come back on the next time the exhaust fan is started.

Note: Dirty Final Filters will cause low air in the ventilator typically causing smoke loss into the kitchen. Replace the

lters as described on page 26.

FIGURE 19-1

DISPLAY PANEL

FINAL FILTER CONDITION

19

DAILY OPERATION - FILTER MONITORING

Missing Filters

If one or more lters are missing an audible alarm will come on and the display panel will read MISSING FILTER, HIGH

AIR as shown in Figure 20-1. The audible alarm may be silenced by pushing F4, however if the missing lters are not

replaced the audible alarm will come back on the next time the exhaust fan is started.

Note: Missing lters in the ClearAir Unit will cause inefcient operation and smoke loss into the atmosphere. It will also

cause high exhaust air in the ventilators resulting in reduced grease extraction efciency, and unbalanced air in the

kitchen. Install required lters as described on pages 26.

FIGURE 20-1

DISPLAY PANEL

MISSING FILTER CONDITION

20

FIRE IN THE POLLUTION CONTROL UNIT (PCU)

Fire Condition

A re thermostat, factory set at approximately 250 degrees F., is located in the lter section of the PCU. Upon

activation, the following will occur:

1. The exhaust fan will shut off.

2. An audible alarm will come on.

3. The make-up air system (supply fan) will shut off if the system is interfaced with the Command Center.

4. A Fire signal is sent to the building re alarm or building management system if interfaced with the control.

5. The display panel will read as shown in Figure 21-1.

Note: The audible alarm may be canceled by pushing F4.

Once the thermostat drops below the set point the following will occur:

1. The audible alarm shuts off.

2. The system goes to a FAN OFF condition, as shown in Figure 15-1, and the exhaust fan may be restarted.

FIGURE 21-1

DISPLAY PANEL

FIRE IN THE PCU CONDITION

21

EXTERNAL FIRE CONDITION

External Fire Condition

An External Fire Condition is when a chemical re extinguishing system, such as an Ansul or Amerex system, discharges either in the PCU or in the ventilator. An External Fire Condition may occur if the building management

system or other building re system noties the Command Center of a re. When an External Fire Condition is

initiated the following occurs:

1. The exhaust fan stays on.

2. An audible alarm will come on.

3. The make-up air system (supply fan) will shut off if the system is interfaced with the Command Center.

4. A Fire signal is sent to the building re alarm or building management system if interfaced with the Command

Center.

5. The display panel will read as shown in Figure 22-1.

Note: The audible alarm may be canceled by pushing F4.

FIGURE 22-1

DISPLAY PANEL

EXTERNAL FIRE CONDITION

22

EXTERNAL FIRE CONDITION - CONTINUED

External Fire Condition

After a discharge of a chemical re extinguishing system, the system must be recharged before the exhaust fan can be

restarted. Contact your re extinguishing system company to recharge and recertify the re system. The display panel

will read as shown in Figure 23-1 until the system is recharged. It may be necessary to reset the re protection system

to start the Make Up Air and stop the exhaust fan.

FIGURE 23-1

DISPLAY PANEL

EXTERNAL FIRE CONDITION

RESET SYSTEM

23

REMOTE START

Remote Starting and Stopping the PCU

The Command Center, Model FM-1000-A, has terminals for interfacing to a remote start and stop control, such as a

building management system, to allow starting and stopping the exhaust fan remotely and automatically. This method

of control causes identical actions as pushing F1 (FAN ON) and F2 (FAN OFF). When started or stopped remotely the

display panel will read REMOTE START as shown on Figure 24-1, or REMOTE STOP (not shown).

FIGURE 24-1

DISPLAY PANEL

REMOTE START CONDITION

24

LOW ODOR CONTROL CHEMICAL

Low Odor Control

Chemical Light

Spray Odor Control Option

The PCU may be equipped with a Spray Odor Control

option instead of a media bed odor control system. The

Spray Odor Control system is mounted in a panel mounted on the PCU (refer to Figure 9-1 on page 9). The Command Center monitors the presence of the Spray Odor

Chemical in the chemical container. If the Spray Odor

Chemical is low the red Low Spray Odor Chemical light

on the face of the Command Center will illuminate and

continue to illuminate until the container is lled (refer to

Figure 25-1). Refer to Page 29 for instructions and where

to purchase the Spray Odor Chemical.

FIGURE 25-1

COMMAND CENTER

LOW SPRAY ODOR CHEMICAL CONDITION

25

Air Flow

TRIPLE PASS FILTERS SMOKE CONTROL SECTION

Air Flow

Air Flow

General Description

Smoke particles are removed from the airstream by the

smoke laden exhaust air passing through a series of three

high efciency lters. The rst set of lters are called PreFilters (PF), the second set are called Bag Filters (BF)

and the third are called Final Filters (FF). The lters are

installed in Racks and the number of lters in a Rack is determined by the amount of exhaust air (CFM) the PCU is

designed to handle. The model number of the PCU incorporates numbers to identify the quantity of lters in each

rack. Refer to Model Number Explanation on page 8.

The life of each of the three types of lters vary considerably depending upon the type of cooking equipment, the

type of food being cooked, the amount of smoke being

generated and the number of hours and days of operation.

Generally the greater amount of grease and smoke generated the fewer days of life the lters have. Table T-26-1

below shows an approximate number of lter changes per

year, for each type of lter, based on the duty of cooking.

This Table is a starting point and is not to be considered as

accurate for cost purposes. Your results will vary.

Table T-26-1

Filter Replacement

To replace any of the three types of lters, Pre-Filter, Bag

Filter, or Final Filter, proceed as follows:

1. Turn off exhaust fan.

2. Open Filter Access Door.

3. Remove the wing nuts and the Filter Clamp Panel.

4. Slide Filters out of the Racks.

5. Slide in the new lters making sure the arrow on the

end of the Pre-Filter or Bag Filter is facing in the direc tion of air ow.

Important Note: The Final Filter is installed with the

arrow on the lter facing towards the direction of air

ow.

6. Replace the Filter Clamp Panel and wing nuts.

7. Replace the Filter Access Door.

8. The exhaust fan can now be turned on.

Approximate Number of Filter Changes Per Year

Total

Pre-

Bag

Final

Type of Cooking Equipment

Light Duty

Ovens, steamers and kettles

Medium Duty

Braising pans, tilting skillets, fryers, griddles,

grooved griddles, open burner ranges, hot top

ranges, and conveyor ovens

Heavy Duty

Gas and electric char broilers, upright broilers,

woks and conveyor broilers

Extra Heavy Duty

Solid fuel broilers

Filter

Filter

17 2 1.5 20.5

26 3 2 31

52 6 4 62

122 8 6 136

Filter

Filters

Changed

per Year

Operation

To achieve maximum smoke removal it is necessary to

have clean lters. The lters are monitored by a series of

pressure switches mounted near each of the three lter

Racks. As the lters build up with grease and smoke particles the pressure switches react to the increased pressure and send a signal to the Command Center. If the

lters are clean within design parameters the display will

read NORMAL AIR FLOW. If any of the three types of

lters are dirty, the display will read either PRE-FILTERS

DIRTY – LOW AIR, BAG FILTERS DIRTY – LOW AIR,

OR FINAL FILTERS DIRTY – LOW AIR. If the lters are

not changed when the display indicates, the result will be

reduced grease extraction efciency and smoke loss at

the ventilator. If a lter is missing, the pressure switch(s)

will feel a low pressure and send a signal to the Command

Center, and the display will read MISSING FILTER.

FIGURE 26-1

PRE-FILTER

FIGURE 26-2

BAG FILTER

FIGURE 26-3

FINAL FILTER

26

ODOR CONTROL SECTION - MEDIA BED TYPE

Table T-27-2

General Description

ClearAir units that include media bed odor control have a

sufx in the model number of “SO” for single pass, “DO”

sufx for double pass and “TO” for triple pass odor control. Refer to the Nameplate on the unit. (see page 39 for

a sample Nameplate).

ODOR CONTROL MODULES

RACKS

FIGURE 27-1

The odor control media utilizes a blend of 50% potassium

permanganate and 50% activated carbon. The media

is housed in Odor Control Modules as shown in Figure

27-1. As the air is drawn through the Modules the potassium permanganate oxidizes the lighter odor molecules

and chemically changes them into harmless solids which

remain in the media, and the carbon absorbs the heavier

odor molecules. The Odor Control Modules are mounted

into slide tracks for easy removal and replacement and to

prevent air bypass around the ends.

The life of the odor control media is dependent upon

several factors such as the type of odor, amount of odor

molecules, grease loading and the exhaust air temperature. The media has a at efciency curve, meaning

that the efciency, or effectiveness, stays constant until

the media has expended and then the efciency drops

off rapidly. The carbon portion of the media’s efciency

drops continually during its life. Thus a regular schedule

of change out of odor control media needs to be established and followed.

There are two types of Odor Control Media Modules used

in the ClearAir unit. One is called the Media Panel Type

and the other is called the Loose Fill type.

With the Media Panel type the odor control media is compressed into 18” x 24” x 1.25” Media Panels which slide

into a Module (see Figure 28-1). The Module(s) then

slide into the Racks in the PCU (refer to Figure 27-1). As

an option the unit may be equipped with a 30% pleated

media After Filter located immediately downstream of the

Media Models.

With the Loose Fill type the odor control media is housed

in steel reusable Media Modules that can be replenished

with Loose Fill media (refer to Figure 29-1). With Loose

Fill media a 30% pleated media After Filter located immediately downstream of the Media Models is required.

Service and Maintenance

Generally the life of the Odor Control Media is the number

of days shown in Table T-27-1. However every cooking

condition varies and therefore it is important to establish

Odor Control Media Bed Inspection

Frequency Chart

Type of Cooking Equipment

Light Duty

Ovens, steamers and kettles

Medium Duty

Braising pans, tilting skillets, fryers,

griddles, grooved griddles, open burner

ranges, hot top ranges, and conveyor

ovens

Heavy Duty

Gas and electric char broilers, upright

broilers, woks and conveyor broilers

Extra Heavy Duty

Solid fuel broilers

Frequency In

Days

120

90

60

30

TABLE T-27-1

ODOR CONTROL

MEDIA MONITORING

TUBE

(USE GREASE PENCIL)

LAST REFILL

DATE INITIAL

LAST INSPECTION

FIGURE 27-2

ODOR CONTROL MEDIA

MONITORING TUBE

DATE INITIAL

FORM NO. OCMM 797

FIGURE 27-3

the frequency of inspection and replacement of the media.

If the unit has Double or Triple Pass Odor Control the life

expectancy between the rst, second and third pass will

vary. To assist in determining if the media has expended

an Odor Control Media Monitoring Tube is provided (see

Figure 27-2). This tube is mounted in the odor control plenum of the PCU so that it is exposed to the odor molecules

in the exhaust air, the same as the Media Modules. The

tube is identied by the label shown in Figure 27-3. The

label includes an area where the date of the last inspection and Media Panel installation can be lled in with a

grease pencil.

To inspect the Media Monitoring Tube, using an open end

wrench, turn the tube nut counter clockwise and remove

the Monitoring Tube assembly. The Media starts off a

dark purple so if the media in the Monitoring Tube is Dark

Purple it is still good. If the Media is dark brown, break a

granule open and if the inside is light tan there is very little

life left and the Media should be replaced. If the outside of

the granules are light tan the Media is completely expended and the Media must be replaced. If you are unable to

determine the status of the Media send a small sample,

one teaspoon, to Green Ladder Technologies if the unit

uses the Media Panel type or Cameron Great Lakes if the

unit has the Loose Fill type. Note the date of installation

on the sample. They will conduct a life test and advise the

results by e-mail, fax or phone. Refer to pages 28 and 29

for contact information.

Once the media in the Monitoring Tube has expended,

and you wish to continue checking with the Media Monitoring Tube it must be replaced with a new one. To order

new Media Monitor Tube contact Gaylord Industries.

27

ODOR CONTROL SECTION - MEDIA PANEL TYPE REPLACEMENT

Media Panel

Locking Clip

Module

Ordering New Media Panels

The Media Panels slide into Modules, and there are two Media Panels per Module (see Figure 28-1). To order new Medial Panels contact Green Ladder Technologies.

Green Ladder Technologies, LLC

1502 Louis Bork Drive

Batavia, IL 60510

E-mail: info@greenladdertech.com

Phone: 630-457-1872

Fax: 630-482-2760

Replacing Media Panels

Caution: Each Module weighs approximately 28 lbs. and may be awkward to handle, particularly from the upper racks.

It is highly recommend that a heavy duty steel wheeled ladder be used when removing the upper modules.

Caution: Exhaust Fan must be off before opening the Odor Control Media Access Door

To replace the Media Panels proceed as follows:

1. Turn off the exhaust fan.

2. Open the Odor Media Access Door on the PCU.

3. Carefully slide out the Modules.

4. Place the module on edge with the open side up, “V” side down (refer to Figure 28-1).

5. Flip the Locking Clip up (refer to Figure 28-1).

6. Pull out both Media Panels (refer to Figure 28-2)

7. Slide in the new Media Panels make sure the label stating “Inlet Side” is facing out. The two stiffening rods on the back

of the panel should be facing the inside of the “V”.

8. Flip the Locking Clip down.

9. Carefully slide the Modules, with the label facing you, back into the Racks making sure the “V” of the Module is facing

the airow as shown in Figure 28-1.

10. Replace the Odor Media Access Door.

11. Dispose the used Media Panels. The used panels are not recyclable.

FIGURE 28-1

BOTH MEDIA PANELS

IN PLACE

FIGURE 28-2

LIFTING OUT ONE

MEDIA PANEL

28

FIGURE 28-3

ONE MEDIA PANEL

REMOVED

ODOR CONTROL SECTION – MEDIA BED LOOSE FILL TYPE

Replacing Loose Fill Media

There are two methods of replacing the media, the “Advancing Program” or Site Rell.

Advancing Program - This is a program offered by Cameron/Great Lakes, Inc. where they will ship recycled prelled Modules in exchange for used Modules. The pre-lled

Modules are shipped two to a box, box size 25" x 25" x 13",

which weigh approximately 90 lbs. The boxes are palletized, 36 to a pallet, and are shrink wrapped. Three primary

advantages of the “Advancing Program” are: 1) virtually no

requirement for storage except for the short period of time

needed to switch the new modules for the expended ones

2) minimizes unit down time and 3) avoids lling on site.

Cameron Great Lakes

2335 NW 29th

Portland, OR 97210

800-777-4044

630-377-0711

To participate in the “Advancing Program” proceed as follows:

1. Contact the local Cameron/Great Lakes distributor and

order the number of Modules required.

2. Upon receipt, remove the depleted Modules and replace

with the new Modules.

3. Empty the media from the depleted Modules into contain

ers for disposal.

4. Pack the empty used Modules into the boxes the new

ones came in and ship back to the distributor.

Site Rell - Site rell involves the purchase and storage of

new media, emptying and relling the modules and disposing of the spent media. New media may be purchased

from your local Cameron Great Lakes distributor. For the

name and phone number of the local distributor call Cameron/Great Lakes.

New media comes in standard ve gallon buckets which weigh

40 lbs each. One bucket will rell approximately 1.33 modules.

It is recommended that new media is purchased no more than

2 weeks in advance of its use. The buckets should be protected against physical damage as KOR48/carbon will begin

to oxidize any odor molecule when exposed to atmosphere.

The buckets should be stored in a cool dry area.

Removing and Relling the Modules

Caution - each Module weighs approximately 30 lbs. and

may be awkward to handle particularly in the upper racks.

It is highly recommended that a heavy duty steel wheeled

ladder be used when removing the upper Modules.

Caution - Exhaust fan must be off before opening the odor

control media access door.

Relling the Modules is a relatively simple task not requiring

any special tools. Follow steps 1-13:

1. Turn off exhaust fan.

2. Open Media Access Door

MEDIA

MODULE

FIGURE 29-1

3. Carefully slide out the Modules

4. Set the Module on end so the securing screw is on top.

5. Remove the securing screw and slide the cover plate

off.

6. Place the lling jig over opening.

7. Pour the media into the Module.

8. To eliminate voids, shake or vibrate the Module to en-

sure that the media settles.

9. Continue adding media until Module is full.

Caution: Do not overll as it may cause the

sides to bulge.

10. Replace cover plate and install securing screw.

11.

Optional - some dusting may

occur on initial start up of the

unit. To minimize this, vacuum

or blow out the Modules.

MEDIA MODULE

FIGURE 29-2

Slide the Modules back into the rack being cautious

12.

that the airow label is matching the airow of the unit.

FIGURE 29-3

MEDIA MODULE - SECTION VIEW

13. Replace the Odor Media Access Door.

29

ODOR CONTROL SECTION - CHEMICAL SPRAY TYPE

CYCLE

TIMER

SECONDS

SECONDS

TIMER

SPRAY

1

20

40

60

80

100

120

140

160 1

20

40

60

80

100

120

140

160

OVERVIEW

The Spray Odor Control system is housed in a cabinet

mounted on the PCU (refer to Figure 9-1 on page 9). The

major components are a spray nozzle, air compressor,

timers and a 5 gallon tank to hold the Spray Odor solution (refer to Figure 43-1 on page 43). The compressor

pulls the solution up through the pick-up tube in the tank

by creating a vacuum, and then pushes it out through an

atomizing nozzle into the plenum after the Final Filters. The

spray is not on constant, but is timed on and off, the length

of time on dependent upon the amount of odor created by

the cooking process.

SETTING THE TIMERS

The Spray Odor Unit operates on spray-on and spray-off

timed cycles while the PCU unit is in the “Fan On” mode.

The Spray Odor Control includes two (2) timers, one (1) for

the “Cycle Timer” (this is the spray ”OFF” timer) and one

(1) for the “Spray Timer” (this is the spray “ON” timer). Both

timers are calibrated and can be set between 5 and 600

seconds. The factory/setting is always 15 seconds “ON”

and 15 seconds “OFF”.

CAUTION: Always de-energize the PCU before opening

the Electrical and Timer Control Panel inside the Odor

Spray Cabinet.

pressor unit to the compression tting and threaded

into the air inlet side of the nozzle, for any leakage.

2. Check the liquid suction line, which is connected to

the liquid inlet side of the nozzle, and ensure that it is

immersed in the odor control solution.

3. If it appears that the nozzle is only blowing air and does

not lift up the odor control solution out of the container,

do the following:

Remove the cleanout plug from the nozzle body and, using

a very thin pin or wire, clean the hole in the uid cap (orice)

and replace the cleanout plug. Remove the foot valve from

the liquid container and inspect screen for clogging. Brush

clean if clogged.

SPRAY ODOR CHEMICAL

In order for the spray odor system to work correctly the system must be supplied with a chemical solution. This solution

in conjunction with the delivery nozzle system that nely

atomizes the spray is what makes the system work. We

recommend the use of FORMULA GS-710. This material

has been effective at removing between 80% and 90% of

the odors from the kitchen exhaust in many applications.

For the contact information of the nearest distributor of

FORMULA GS-710:

ADJUSTING THE TIMERS

To adjust the spray odor cycle and timers, open the Spray

Odor Cabinet, and remove the screwed-in-place timer

control cover plate. Adjust as necessary for satisfactory

odor control.

Cycle Timer

To set the “Off” period, turn the dial to the desired off time

interval.

Spray Timer

To set the “On” period, turn the dial to the desired on time

interval.

COMPRESSOR

The air pressure is factory set at 20 psi. If the solution is

not being pulled up through the pick-up tube adjust the

pressure slightly up or down until the climbs up the tube.

SPRAY ODOR CONTROL SPRAY NOZZLE ASSEMBLY

NOZZLE MAINTENANCE

To obtain the best performance from your nozzle, it may

become necessary to clean it periodically.

The nozzle may become clogged and cease spraying due

to factors such as dust, foreign particles accumulated in

the orice, and/or leakage in the air or liquid section of the

nozzle.

The following procedure should be done to maintain the

nozzle’s performance:

Gaylord Industries

10900 SW Avery Street

Tualatin, OR 97062

Phone: (800) 547-9696

Fax: (503) 692-6048

Website www.gaylordusa.com

FIGURE 30-1

CYCLE AND SPRAY TIMER

1. Check the air line, which is connected from the com-

30

EXHAUST FAN SECTION

GENERAL

The exhaust fan in the ClearAirTM Unit is a heavy duty type.

The size of the fan, motor, and drives have been chosen for

the most efcient operation.

FAN PREVENTIVE MAINTENANCE

Every six months conduct the following maintenance:

1. Check for condition and tension of belts. Replace

cracked, glazed or frayed belts. Re-check tension

after 48 hours and re-tension if necessary. Do not

over-tighten belts or bearing damage may result. Belt

should depress its width when pressed rmly inward at

midway point between the pulleys and belt should be

tight enough to prevent slippage. When replacing worn

belt, replace motor pulley if “shoulder” has a worn-in

groove.

2. Check fan and motor bearings for possible binding,

noise or overheating. Lubricate fan in accordance with

instructions on fan housing.

3. Motors generally used are of the sleeve bearing type

and require periodic oiling. A good grade of ASE No.

10 lubricating oil should be inserted into the oiler connections on each end of the motor about every two

months. Not more than a teaspoonful should be used;

over-oiling will result in oil drip.

TROUBLESHOOTING

1. Reduced Airow:

a. Blower impellers operating in wrong direction.

b. Belt slippage or belts broken.

c. Overload, starter cutout.

2. Noise in Blower:

a. Bad bearings.

b. Loose tie rods or blades.

c. Blower wheels loose on shaft, wheels rubbing on

housing.

d. Drive pulley loose on shaft.

e. Foreign object located in blower wheel or blower

housing.

Necessary Action - Correct situation found immediately,

as continued operation can shorten life of component

parts and result in poor airow and eventual general

shut-down of system until needed repair is made.

31

GENERAL MAINTENANCE

Daily Maintenance

The Command Center should be looked at once a day to

check if notication of dirty lters is displayed. If the display reads DIRTY FILTERS, they should be replaced. A

scheduled should be developed, based on the operation of

this kitchen, to replace the lters on a regular basis. Refer

to page 26 for details.

Six Months

Remove the lters and inspect the interior of the unit for

grease build up. If needed the unit should be cleaned to

the same standards as the grease duct as described in

NFPA 96.

Annually

The exhaust fan belts should be checked for wear and tension. If the belt is cracked, frayed, or other wise displaying

signs of damage it should be replaced.

Fire Damper

The ClearAir unit may be equipped with a re damper on

the outlet side of the nal lter. There are fusible links on the

dampers that will sense a re. NFPA-96 requires these fuse

links be replaced annually. Replace with a 280°F (138°C)

link of the same type.

Fuse Link Replacement

1. Open the plenum access door.

2. Remove the defective link.

3. Replace with a new link by wrapping the link support

across the blades and securing at the clip on the other

side of the frame.

4. Replace the plenum access doors

5. Start the fan.

32

SYSTEM WIRING - INTERNAL

Socket

F2

Fuse - Spray Odor

LT1

Low Chemical Light - Red

Table T-33-1

FM-1000-A Componant Schedule

Tag Description Size

PLC Programable Logic Controller

HMI Human Machine Interface

CBL HMI Cable

AL1 Sonalert

CR6 Control Relay

Socket

CR7 Control Relay

Socket

CR8 Control Relay

Socket

CR9 Control Relay

F1 Fuse - Main

F3 Fuse - PLC Power

F4 Fuse - PLC Outputs

F5 Fuse - Remote Outputs

F6 Fuse - TX Primary

F7 Fuse - TX Secondary

120VAC 19319

120VAC 19318

Gaylord

Part No.

20110

20111

6.56 Ft. 20107

DPDT 30828

SPDT 30837

SPDT 30827

SPDT 30836

SPDT 30827

SPDT 30836

SPDT 30827

SPDT 30836

6.3A 17061

6.3A 17601

0.5A 18153

4A 16822

4A 16822

7A 16508

3.5A 16504

"ON" & "OFF" applies to the LED light status for each PLC channel, Input and Output

Input Side Ouput Side

X = Input Channel Number Y = Output Channel Number

Signal Source - Description

Autostart Thermostat(s) Activates

Pre-Filter Dirty

Bag Filter Dirty

Final Filter Dirty

Missing Filter

PCU Thermostat Activates (Internal Fire)

Fire System Discharges (External Fire)

PCU Started From Remote Source

Table T-33-2

PLC Input /Output TABLE

Exhaust Fan

Y0 Y1 Y2 Y3 Y4 Y5

X0

X1

X2

X3

X4

X5

X6

X7

ON ON OFF ON NA

ON ON ON OFF ON NA

ON ON ON OFF ON NA

ON ON ON OFF ON NA

ON ON ON OFF ON NA

OFF ON ON OFF OFF NA

OFF ON ON OFF OFF NA

ON OFF ON OFF ON NA

Audible Alarm

OFF

System

Make-Up Air

External)

Fire Mode

(Internal or

Control

Spray Odor

Spare

33

SYSTEM WIRING - INTERNAL

34

SYSTEM WIRING - EXTERNAL

35

SYSTEM WIRING - EXTERNAL

CUV-1000 Terminal Voltages

N.O. Dry Contacts for Interface to Building

Table T-36-1

FM-1000-A Terminal Voltages

Terminal Description Fan Off Fan On Int. Fire Ext. Fire

L1 Main Power Connection : Hot 120 VAC 120 VAC 120 VAC 120 VAC

L2 Main Power Connection : Neutral

31 Output - Supply Fan Motor Starter 0 VAC 120 VAC 0 VAC 0 VAC

33 Input - Thermostat Return (N.C. Stats) 120 VAC 120 VAC 0 VAC 120 VAC

34 Fused Supply to Fire Switch, etc. 120 VAC 120 VAC 120 VAC 120 VAC

35 120vac Neutral Leg

36 Output - Spray Odor Power (optional) 0 VAC 120 VAC 0 VAC 0 VAC

38 Output - Exhaust Fan Motor Starter 0 VAC 120 VAC 0 VAC 120 VAC

P1 Input - Pressure Switch #1 0 VAC 0 VAC

P2 Input - Pressure Switch #2 0 VAC 0 VAC

P3 Input - Pressure Switch #3 0 VAC 0 VAC

P4 Input - Pressure Switch #4 0 VAC

SF3

SF4

EF3

EF4

A11

A12

Q11

Q12

FS Input From External Fire Sw. 0 VAC 0 VAC 0 VAC 120 VAC

AS Input - Autostart Thermostat in Hood

RF1 120 VAC 120 VAC 120 VAC 120 VAC

RF2

N.O. Dry Contacts for Supply Fan Remote

Control

N.O. Dry Contacts for Exhaust Fan

Remote Control

Fire Alarm / Monitor System

N.C. Dry Contacts for Interface to Building

Fire Alarm / Monitor System

Remote On/Off Switch Terminals

Wired to N.O. Switch

Open

Open Closed Open Closed

Open Open Closed Closed

Closed Closed Open Open

120 VAC when Autostart Thermostat(s) rise

above temperature setpoint

120 VAC when Remote N.O. On/Off Switch

is closed ("ON")

Common

Common

120 VAC

if filter is

dirty

120 VAC

if filter is

missing

Closed Open Open

0 VAC

120 VAC

if filter is

dirty

120 VAC

if filter is

missing

RS Remote Start Active

FM External Fire Mode Active 0 0 0 BMS

AA Autostart Mode Active

MF Missing Filter

FF Final Filter Dirty

BF Bag Filter Dirty

PF Pre-Filter Dirty

F1 Output - Exhaust Fan Motor Starter 0 BMS 0 BMS

COM Common

Optional "RM" Terminals (Remote Monitoring)

BMS when Remote N.O. On/Off Switch is

closed ("ON")

BMS when Autostart thermostats

above temperature setpoint

BMS Voltage (0-220VAC)

36

PCU PRESSURE SWITCH SETTINGS

PRESSURE SWITCHES

There are four Pressure Switches as show on Figure 37-1,

Figures 38-1, and 38-2. The Pressures Switches are used

to detect a dirty or missing lter and send a signal to the

Command Center. Pressure Switches PS1, PS2 and PS3

are factory set to a static pressure as shown on the Table

T-38-1. Pressure Switch PS4 is used to detect a missing

lter and must be set after the PCU is installed. To set PS4

proceed as follows:

SETTING THE MISSING FILTER PRESSURE SWITCH

To set the Missing Filter Pressure Switch, PS4, proceed

as follows:

1. Open each of the three Filter Access Doors on the PCU

and check to make sure all lters are in place. If a lter

is missing you cannot proceed with the adjustment until

the missing lter(s) is installed.

2. Close and latch all Filter Access Doors and push F1 on the

Command Center. After the one minute STAND BY delay

the exhaust fan will start.

3. Look at the Command Center display panel. If the display

panel reads FAN ON, NORMAL AIR, proceed to step num

ber 4. If the display reads FAN ON, MISSING FILTER HIGH AIR, adjust Pressure Switch PS4 as follows: (NOTE:

during a MISSING FILTER condition the Command Center

audible alarm is on. To silence the alarm push F4)

4. Look at the Command Center display panel. If the display

reads FAN ON, NORMAL AIR, proceed as follows:

a) Open the Pre-Filter Access Door, remove one lter,

and replace and latch the access door.

b) Loosen the Cover Plate Hold Down Screw and

remove the Cover Plate (refer to Figure 37-1).

c) Turn the Pressure Switch Adjusting Screw (refer to

Figure 37-2) counter clockwise until the display

panel reads FAN ON, MISSING FILTER - HIGH,

and then turn the screw another 1/2 turn counter

clock wise.

(NOTE: the Command Center audible alarm will come

on during a MISSING FILTER condition. To silence

the alarm, push F4)

d) Replace the missing lter.

e) Double check the display panel to make sure it reads

FAN ON, NORMAL AIR.

f) Adjustment of PS4 is now complete. Replace the

Cover Plate and tighten the hold down screw.

g) Using a crescent wrench, turn the Safety Disconnect

door shaft counter clockwise to de-energize the

Electrical Panel.

h) Close the Electrical Panel Door and turn the Safety

Disconnect Switch clockwise to energize the panel.

The adjustment is complete.

CAUTION: Do not touch live electrical terminals. Contact

with live power will result in immediate injury or death to

personnel.

a) The Pressure Switches are located inside the

Electrical Panel (refer to Figure 38-2). Turn the Safety

Disconnect Switch and open the panel door.

b) Using a crescent wrench, turn the Safety Disconnect

door shaft clockwise to energize the Electrical

Panel.

c) Push F1 on the Command Center to start the

exhaust fan.

d) On Pressure Switch PS4 loosen the Cover Plate

Hold Down Screw and remove the Cover Plate (refer

to Figure 37-1).

e) Wait for the one minute STAND BY delay until

the exhaust fans starts.

f) Turn the Pressure Switch Adjusting Screw (refer

to Figure 37-2) clockwise until the display panel

reads FAN ON, NORMAL AIR, and then turn the

screw another 1/2 turn clockwise.Proceed to step 4.

COVER PLATE HOLD

DOWN SCREW

FIGURE 37-1

PRESSURE SWITCH

COVER ON

PRESSURE SWITCH

ADJUSTING SCREW

37

FIGURE 37-2

PRESSURE SWITCH

COVER OFF

PCU PRESSURE SWITCH TUBING DIAGRAM

Table T-38-1

Pressure Switch Settings

Pressure

Factory Pressure

Sensing Pressure For

Sw. No.

Setting

PS1 Pre-Filter .50" W.G. (.124 KPA)

PS2 Bag Filter 1.25 W.G. (.310 KPA)

PS3 Final Filter 2.00" W.G (.497 KPA)

PS4 Missing Filter (not set)

FIGURE 38-1

TUBING DIAGRAM

FIGURE 38-2

SENSOR LOCATION

38

NAMEPLATE SAMPLE

The ClearAirTM nameplate is located on the electrical compartment access door of the unit. If inquiring on service or

ordering parts, please have model number and serial number available.

ENGINEERING DATA

FILTER SECTION

CFM

SMOKE POLLUTION CONTROL UNIT

MODEL NUMBER

RSPC -TPF -

SERIAL NUMBER

INT. STATIC PRESSURE "W.G.

VOLTS PHASE HERTZ AMPS WATTS

1

MAX. FUSE SIZE AMPS

MAX. BREAKER SIZE AMPS

SUITABLE FOR USE WITH CONTROL

MODEL NO.

FOR EITHER INDOOR OR

OUTDOOR INSTALLATION

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET

TUALATIN, OREGON 97062

FOR NAME OF THE NEAREST SERVICE AGENCY CALL:

800-547-9696

The ClearAirTM unit Model RSPC-TPF Series

is ETL Listed under the category Air Filtering

Device, Report #3028598-1

FORM NO. CATPFNP 902/19039

Or Visit www.gaylordusa.com

C

OPTIONAL FAN SECTION

CFM

TOTAL STATIC PRESSURE "W.G.

EXHAUST FAN POWER CIRCUIT:

VOLTS PHASE HERTZ AMPS

MIN. CIRCUIT AMPACITY

MAX. FUSE SIZE AMPS

MAX. BREAKER SIZE AMPS

THE FILTER INDICATOR LIGHTS SHOULD BE INSPECTED FREQUENTLY TO ENSURE THAT COLLECTED GREASE IS BEING

US

42106

FIGURE 39-1

ClearAirTM NAMEPLATE

REMOVED BY THE FILTER. REFER TO THE TECHNICAL MANUAL

FOR SPECIFIC INSTRUCTIONS.

FLA

-CAUTION-

39

6

7

10

11

4

5

8

9

12

13

Figure 39-1

Command Center

6

7 3

10 11

4 5

8 9 12

13

PARTS - COMMAND CENTER

FIGURE 40-1

COMMAND CENTER

MODEL FM-1000-A

Table T-40-1

Pc

No.

1 Human Machine Interface (HMI) Shown from back 20111

2 Low Odor Control Chemical Light Shown from back 19318

3 Lift and Turn Latch Shown from back 11118

4 Fuse – 6.3A For F1 & F2 17061

5 Fuse – 0.5A For F3 18153

6 Fuse – 4.0A For F4 16822

7 Control Relay DPDT 30828

8 Control Relay (three required) SPDT 30827

9 Fuse – 4.0A For F5 16822

10 PLC (Programmable Logic Control 20108

11 PLC Remote Monitoring Module Optional 20113

12 Sonalert Alarm 19319

13 Spare Fuses NA

Description Comments

Gaylord Part

Number

40

PARTS - PCU

PCNo.

1 30%Pre‐Filter 30074

2 90%BagFilter 30515

Description GaylordPartNo. Illustration

TableT‐41‐1

PCUParts

3 95% DOPFinalFilter 30514

4

5

OdorControlMedia

MonitoringTube

SafetyInterlockPressure

SW

Pre‐Filter,SP=0.50WG

BagFilter,SP=1.25WG 19664

FinalFilter,SP=2.00WG 19666

MissingFilter,SPNotSet

30913

19663

41

FireThermostat(15"long,

6

7

250deg.F.N.O.

Latch‐ForPre‐FilterAccess

Door

PARTS - PCU

TableT‐41‐1(continued)

PCUParts

18782

19821

8

9

Latch‐ForBagFilterand

FinalFilterAccessDoor

Latch‐ForFanHousing

AccessDoor

19771

19547

42

PARTS - SPRAY ODOR CONTROL

6

5

4

3

7

8

2

1

9

10

SPRAY ODOR CONTROL CABINET

11

12

FIGURE 43-1

13

Table T-43-1

Spray Odor Component Schedule

Pc. No. Description

1

2 1/4" I.D. Flexible Suction Tube 10272

3 Spray Nozzle Assembly 19065

4 3/8" Copper Tubing 11000

5 Electrical Box N/A

6 Cycle and Spray Timer Relay (Behind Panel) 19073

7 Pressure Gauge 10276

8 Needle Valve 19070

9 Air Compressor 19072

10 Heater 19075

11 5 Gallon (18.9 Liter) Container of GS-710 19097

12 Level Sensor for Spray Odor Chemical (In Tank) 19071

13 1/4" Foot Valve (In Tank) 10269

Spray Odor Cabinet Assembly (25"x25")

Gaylord

Part No.

19119

43

APPENDIX A: RECEIVING AND INSTALLATION

APPENDIX B: START UP INSTRUCTIONS

44

RECEIVING & INSTALLATION

RECEIVING

Most ClearAirTM units are shipped in one piece. However,

some units, because of size or special jobsite conditions,

may be shipped in multiple sections. Follow the instructions provided with the unit to join sections back together.

If the unit includes media bed odor control, the odor control

media is packaged separately. Verify against the shipping

documents that you have received all items and note any

shipping damage, obvious or hidden, to your carrier and

on your Bill of Lading. If damage is found, immediately le

a claim with the transport company. All units are thoroughly

inspected and fully operation tested at the factory prior to

shipment.

Verify that the electrical and air ow ratings on the unit name

plate agrees with jobsite requirements. If a contradiction

arises notify the factory prior to proceeding with installation.

SAFETY CONSIDERATIONS

Installing and servicing the ClearAirTM unit can be hazardous due to the presence of electrical components. Only

trained and qualied service personnel should install or

service this equipment.

Untrained personnel can perform basic maintenance, such

as cleaning and replacing lters. All other operations should

be performed by trained service personnel. When installing

or servicing, observe precautions in literature and on tags

and labels attached to unit.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have re

extinguisher available. Read these instructions thoroughly.

WARNING

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch. Electrical shock can cause personal injury or death.

RIGGING

All units are provided with a minimum of four (4) lifting points

for rigging attachment. WARNING: Use all lifting points

provided. (Refer to Page B-2.) Spreader bars are mandatory to prevent contact and damage to the unit by lifting

hooks, straps, cables, or chains. Consult the mechanical

or structural engineer before moving the unit across the

roof deck.

INSTALLATION CODES

This unit requires external plumbing and electrical connections

to be made in the eld. It is recommended that the Authority

Having Jurisdiction (AHJ) be consulted regarding local

codes and installation procedures. Gaylord Industries is not

responsible for obtaining necessary approvals and permits

which may be required for installation, nor is it responsible

for verifying that the unit has been installed in accordance

with national, state, and local codes. In the absence of locally adopted codes use the latest editions of the National