Gaylord RSPC-TPF-H Installation Manual

TECHNICAL MANUAL

FOR

INSTALLATION, OPERATION

Effective Date: 1-03

AND MAINTENANCE

OF

THE GAYLORD "ClearAir"TM

MODEL "TPF" SERIES

POLLUTION CONTROL UNITS

WITH FM-100 SERIES MONITOR STATION

WARNING

Improper installation, adjustment, alteration service or maintenance can cause property damage, injury or death. Read

the installation, operation and maintenance instructions thoroughly before installing or servicing this equipment. Only

trained and qualified service personnel should install or

service this equipment.

GAYLORD INDUSTRIES, INC.

10900 S.W. AVERY STREET • P .O. BOX 1149 • TUALA TIN, OR 97062-1149 USA

PHONE: 503-691-2010 • TOLL FREE: 800-547-9696 • FAX: 503-692-6048

email:info@gaylordusa.com • www.gaylordusa.com

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES, INC.

World Headquarters: P .O. Box 1149 • Tualatin, Oregon 97062-1 149 U.S.A.

T o Our Customers. . .

Congratulations on your recent purchase of a Gaylord

ClearAir Pollution Control Unit. We are proud to be able

to provide you with a quality product that exemplifies our

long-standing dedication to quality engineering.

Your unit is assembled from some of the very finest components available and is designed for years of efficient,

effective, and troublefree operation. In addition, this unit

has undergone rigorous quality control inspections and

was fully operationally tested prior to shipment.

If you have further questions, please call us toll free at

1-800-547-9696. We are more than happy to help.

Sincerely ,

Gaylord Industries, Inc.

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: gaylord@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • HEAT RECLAIM • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL • AIR HANDLING UNITS

STREET ADDRESS: 10900 S.W. Avery Street, T ualatin, Oregon 97062-8549 U.S.A.

TECHNICAL MANUAL

FOR

INSTALLATION, OPERATION

AND MAINTENANCE

OF

THE GA YLORD “ClearAir”™

MODEL “TPF” SERIES

POLLUTION CONTROL UNITS

WITH FM-100 SERIES MONITOR STATION

Published by:

GAYLORD INDUSTRIES, INC.

Tualatin, Oregon 97062-1149

U.S.A.

First Printing: January , 2003

© Copyright 2003, Gaylord Industries, Inc.

ALL RIGHT RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY

FORM BY AN ELECTRONIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR OTHERWISE WITHOUT THE WRITTEN PERMISSION

OF GAYLORD INDUSTRIES, INC. COPYRIGHT 2003.

The manufacturer reserves the right to modify the materials and specifications resulting from a continuing

program of product improvement or the availability of new materials.

Additional Copies $15.00

The Gaylord ClearAir Unit is designed and engineered by

GA YLORD INDUSTRIES, INC.

P .O. Box 1 149, T ualatin, Oregon 97062-1 149.

TABLE OF CONTENTS

INTRODUCTION .............................................................................. 1

PRINCIPLE OF OPERATION ........................................................... 2

TYPICAL TPF MODELS ................................................................... 3

GENERAL INFORMATION ............................................................... 5

TYPICAL INSTALLATION ................................................................. 7

SAMPLE ClearAir CONFIGURATIONS ............................................ 8

NAMEPLA TE DATA........................................................................... 10

RECEIVING & INSTALLATION ......................................................... 12

EQUIPMENT LIFTING PROCEDURE.............................................. 13

ODOR CONTROL SECTION

GENERAL DESCRIPTION ........................................................... 14

ODOR CONTROL MEDIA............................................................. 14

SERVICE AND MAINTENANCE .................................................. 14

REPLACING THE MEDIA ............................................................. 14

FILTERS ........................................................................................ 16

EXHAUST FAN SECTION ................................................................ 18

MAINTENANCE ................................................................................ 20

PARTS LISTS ................................................................................... 21

WIRING DIAGRAM ........................................................................... 22

TERMINAL VOL T AGES..................................................................... 23

WARRANTY .........................................................Inside back cover

INTRODUCTION

Air quality is becoming a major concern in Americas large

cities and as a result, many commercial kitchens will require

pollution control equipment in their exhaust systems to comply with the increasing demands of environmental control agencies. In addition, pollution control equipment is being used

for kitchens in high-rise buildings allowing the exhaust to

discharge out the side of the structure which saves the cost

of running the duct up many floors to the roof.

Pollution control in kitchen exhaust systems has typically

been accomplished by any one of the following methods gas fired incinerators, scrubbers, filtration units or electrostatic precipitators. Incinerators and afterburners literally burn

the pollutants and, while effective, can be very costly and

hazardous to operate. Scrubbers consist of a water bath

and extraction baffles to remove the pollutants and though

quite effective on grease removal, they typically require the

addition of high efficiency filters to abate smoke below control agencies standards. Filtration units use a series of impingement filters to remove the pollutants and if done properly can be quite effective on both smoke and grease.

The Gaylord pollution control unit, trademarked ClearAirTM,

can be manufactured with either electrostatic precipitation

(ESP) or Filtration (TPF). Gaylord Industries, Inc. has been

manufacturing ESPs specifically designed for commercial

kitchen exhaust systems since the early 1970s, longer than

any other manufacturer. However, when initial cost is a greater

concern the TPF unit is a sound alternative.

The ClearAir TPF unit is available in several configurations,

as illustrated on the following pages, ranging in capacity from

1000 to 24,000 CFM (472 to 11,328 L/s). Most models can

include an exhaust fan and odor abatement equipment as an

option.

Basic Facts About Smoke

Smoke particles are extremely small and not visible to the

human eye unless thousands of them are grouped together

to form what we see as smoke. Individual particles are measured in units called microns and one micron equals 1/25,400

of an inch (1/64,516 of a cm).

Smoke generated by commercial cooking equipment has a

particulate size of between 0.3 and 0.8 microns and it is

these very small particles that smoke abatement equipment

must remove from the airstream. The amount of smoke being discharged from a kitchen exhaust duct is measured in

terms of its density, referred to as opacity - the degree to

which emissions block light. A 100% opacity level would be

solid black and 0% would be perfectly clear. Control agencies that have adopted smoke pollution ordinances are requiring an opacity level of no more than 20%, which is a very

light blue smoke.

Typically, heavy smoke producing cooking such as charbroiling, creates an opacity level of 60% to 70%. Opacity readings are taken by the human eye by viewing the smoke being discharged and then assigning a percentage of opacity

to what is seen. Though this method is quite subjective, it

is the method practiced by control agency inspectors who

are trained and certified in determining opacity percentages.

Other more technical methods of determining opacity or particulate density are achieved through the use of opacity meters

and cascade impactors. This level of analysis is usually

referred to as source testing. Control agencies occasionally

require this type of analysis and if so, the testing is conducted by state certified contractors which can be quite

costly and time-consuming. The efficiency of an TPF is based

on how well it reduces the opacity level of a given airstream. The Gaylord ClearAir unit will reduce the opacity

level below 20%, thereby meeting the requirements of environmental control agencies.

Basic Facts About Odor

Cooking odors (molecules) generated by the combustion of

animal and vegetable matter result in an extremely complex

mixture of reactive organic gases (ROGs). A small percentage of these odors may be absorbed by the grease particles

but the vast majority exist separately in the airstream. The

ROG molecules are much too small to be removed by any

type of filter and therefore, other methods must be used.

There are several methods with which to manage the odor.

One method is to use a media bed. The two most popular

types of media bed are activated charcoal, which absorbs

and retains the odor molecules, and the use of an odor-oxidant (potassium permanganate) which oxidizes the molecules

to solids and then retains them. The other method involves

the use of a liquid delivered with a finely atomized spray.

This spray performs a similar function to potassium permanganate in that is adsorbs or chemically neutralizes odors.

This process has the benefit of the end user being able to

adjust the amount of spray and thus the effectiveness and

cost of the odor control.

The life of the media bed type of odor control is dependent

upon several factors such as how much media is used, type

of odor, amount of odor molecules, grease loading and air

temperature. Typically, any of the above mentioned types of

media can remove 85% - 90% of the molecules. Determining the efficiency of odor control can be very subjective, as

testing is usually conducted by the human nose. More scientific testing is available through ROG analysis, but this

involves considerable costs.

Grease Removal - The Important First Step

Grease particles are also measured in terms of microns and

grease generated by commercial cooking equipment has a

particulate size of 10 microns and up. Pollution control equipment is not limited to removing smoke particles, but will

also remove a majority of the grease particles remaining in

the airstream. Therefore, the grease extraction efficiency of

the exhaust hood plays an important role in the operation

and performance of pollution control equipment.

Removal of grease particles before they reach smoke and

odor control equipment will significantly increase the smoke

abatement efficiency and the life of the odor abatement media. It is highly recommended that a Gaylord CG3 Series

Ventilator be used with the ClearAir unit as it has a grease

extraction efficiency of 95%. Other high efficiency exhaust hoods and standard filter type hoods may be used

with the ClearAir unit. Contact Gaylord Industries for details.

1

PRINCIPLE OF OPERATION

ClearAir Unit - Principle Of Operation

Smoke Control Section

The smoke control section has three phases of filters

located prior to the odor control section. These filters

consist of replaceable 30% pre-filter, 95% bag filter and a

replaceable 99% final filter. Replaceable filters are mounted

in filter slide tracks to prevent air bypass around the ends

of the installed filter bank. Filters are accessed through

removable side access panels with lift and turn latches.

Phase one filters have an average efficiency of 25 to 30%

and an average arrestance of 90 to 92% in accordance

with ASHRAE test standard 52.1-1992. Media support

grid is on 1" centers with an open area 96%. Filter enclosing frame is a rigid, high wet strength beverage board,

with diagonal support members 4" deep.

Phase two filters have an average efficiency of 90 to 95%

in accordance with ASHRAE test standard 52.1-1992.

Sealing surface and pocket retainers are configured to provide 84% open area. Seams in bag filters are sealed with

foamseal adhesive to completely eliminate air leakage

through stitch holes.

Phase three filters are 95% efficient on .03 micron particles (DOP smoke test), 97% efficient on nebulized staphylococcus aerosols, 99+% efficient on atmospheric test

dust (ASHRAE standard 52.1-92). The casing is 16 gauge

steel with corrugated aluminum separators to insure media stability. Media is fine-fiber, high strength

microfiberglass paper. Media end cuts are encapsulated

in urethane potting adhesive.

All Gaylord ClearAir units include, as standard equipment,

a fan start stop switch and filter monitor panel. If a Gaylord

water-wash ventilator is used, a common control panel

which would wash the ventilator and provide the monitor

station for the Clear Air Unit is provided.

The ClearAir the unit includes a UL listed fire damper, with

a 280 degree fusible link, located down stream of the filters to prevent passage of fire to the duct downstream of

the unit. A fire-stat, set at 250 degrees, is located in the

filter section to shut down the exhaust fan in the event of a

fire.

Model Application

The Gaylord ClearAir unit is available in various configurations, as shown on the following The simplest configuration is the Filtration unit alone with out a fan or odor control. A second configuration includes the exhaust fan but

no odor control. This is used when smoke abatement is

the only concern. The third, and most common unit, is the

Model TPF-H- Series. This model would also be located

either in a mechanical room or on the roof and includes

odor control and the exhaust fan.

The size of each of the configurations varies with the air

volume, type of cooking equipment and options chosen.

Contact Gaylord Industries for complete details.

Construction

The housing is constructed of a minimum of 16 gauge

g-90 heat treated galvanized steel. The perimeter base is

12 gauge formed channel with lifting lugs at each corner

and along the length as required. The internal housing is

externally welded liquid tight for compliance to the International Mechanical Code grease duct construction requirements. The smoke control and odor control sections

all include a drain at the side bottom of the housings for

interconnection to a common drain to facilitate removal of

water from steam cleaning or pressure washing. The exhaust fan includes a scroll drain with a grease receptacle.

Monitor Panel

A monitor panel, for remote location, is supplied for the

operation and monitoring of the unit. The panel is be constructed of 18 gauge stainless steel, number 4 finish, and

is suitable for surface or recessed mounting. The panel

face has a gasketed hinged door with a lift and turn flush

latch. The panel includes an air proving time delay, relays

and indicator lights to continuously monitor the unit. Indicator lights are Fan On, Normal Air, Low Air, Replace

Pre-Filters, Replace Bag Filters, Replace Final Filter,

Missing Filter, and Fire In Unit. An audible alarm, with

an alarm cancel button, is included and will activate whenever the unit status is low air, replace filters, missing filters

or fire in the unit. Status other than Fire In The Unit will

not shut down the exhaust fan.

Specifier Note: If the ClearAir unit is used in conjunction

with a water wash ventilator, the monitor panel is built into

the main water wash control cabinet model GPC-6000

series.

GAYLORD

®

TM

C

LEARAIR

POLLUTION CONTROL UNIT

CONTROL PANEL MODEL

FM-100

FAN ON

NORMAL AIR

LOW AIR

REPLACE PRE FILTERS

REPLACE BAG FILTERS

REPLACE FINAL FILTERS

MISSING FILTER

FIRE IN UNIT

THERMOSTAT ACTIVATION

AND / OR FIRE SYSTEM

FIL TER MONITORING ST A TION

FM-100

DISCHARGE

CANCEL ALARM BUTTON

The ClearAir Unit Model RSPC-TPF Series is ETL Listed under

the category Air Filtering Device, Report # 3028598-1

- CAUTION -

DO NOT OPERATE UNIT WITH MISSING

FILTERS OR WITH FILTERS THAT SHOULD

BE REPLACED AS INDICATED BY MONITORING LIGHTS. THIS IS A SMOKE POLLUTION

CONTROL DEVICE AND WILL NOT OPERATE PROPERLY WITH MISSING OR DIRTY

FILTERS.

GAYLORD INDUSTRIES, INC.

TUALATIN, OREGON 97062-1149 U.S.A.

Phone: 503-691-2010 • 800-547-9696

Fax: 503-692-6048 • email: info@gaylordusa.com

Form No. TPF FP/19038

6(1625/,*+7

U.S.

42106

2

CLEARAIR TPF TYPICAL MODELS

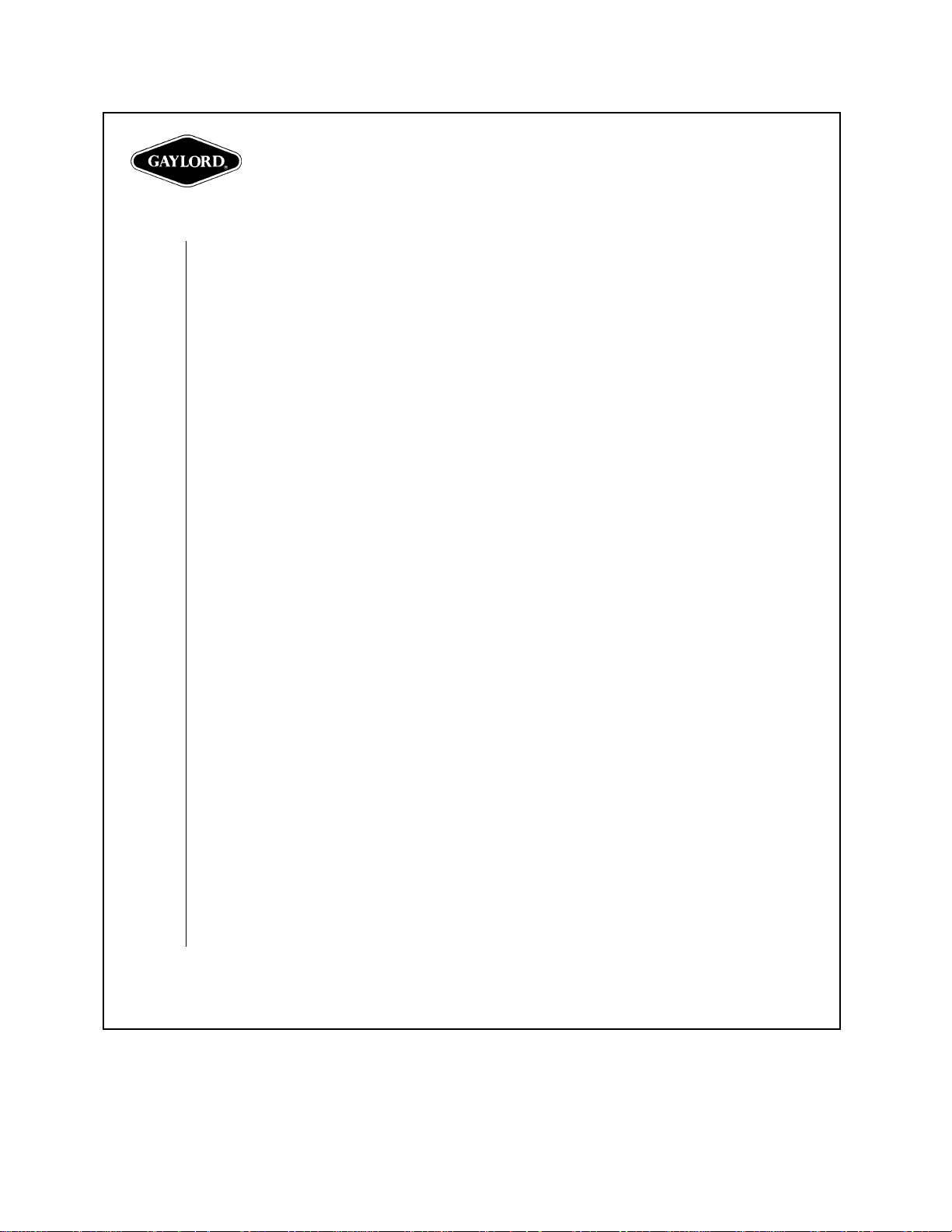

MODEL TPF-H

Horizontal Style

The model TPF-H is a Filtration smoke abatement unit designed for use with a remote exhaust

fan and odor control unit(if required) which can

be supplied by Gaylord Industries as an option.

Model TPF-H-EF

Horizontal Style with Exhaust Fan

The Model TPF-H-EF is an Filtration smoke abatement unit that includes a built-in exhaust fan. The

primary feature of this unit is that the interconnecting ductwork, transitions and fan are factory

installed in a single roof top package. The unit

comes pre-wired for single point electrical connection and includes a magnetic starter, fuses,

and a disconnect switch. This model is available

for both indoor and outdoor installations in sizes

from 1000 to 24,000 CFM (472 to 11,328 L/s).

PF

BF FF FDQM

PF

OUTLET TO FAN

BF FFQM

FAN DISCHARGE

EF

Model TPF-H-SO

Horizontal Style with Odor Control

The Model TPF-H-SO is an Filtration smoke

abatement unit that includes built-in odor control and is designed for use with a remote exhaust fan which can be supplied by Gaylord Industries as an option. The odor control section

includes a 30% pre-filter, and a single pass odor

control media. This model is available for both

indoor and outdoor installations in sizes from

1000 to 24,000 CFM (472 to 11,328 L/s).

Model TPF-H-SO-EF

Horizontal Style with Odor

Control and Exhaust Fan

The Model TPF-H-SO-EF is an Filtration smoke

abatement unit that includes built-in odor control and exhaust fan. The primary feature of this

unit is that the interconnecting ductwork, transitions and fan are factory installed in a single roof

top package. The unit comes pre-wired for single

point electrical connection and includes a magnetic starter, fuses and a disconnect switch. The

odor control section includes a 30% pre-filter,

and a single pass of odor control media. This

model is available for both indoor and outdoor

installations in sizes from 1000 to 24,000 CFM

(472 to 11,328 L/s).

PF

BF

PF

QM

FF

BF

QM

FF

SO FD

SO

AF

OUTLET TO FAN

FD

FAN DISCHARGE

EF

3

CLEARAIR TPF TYPICAL MODELS

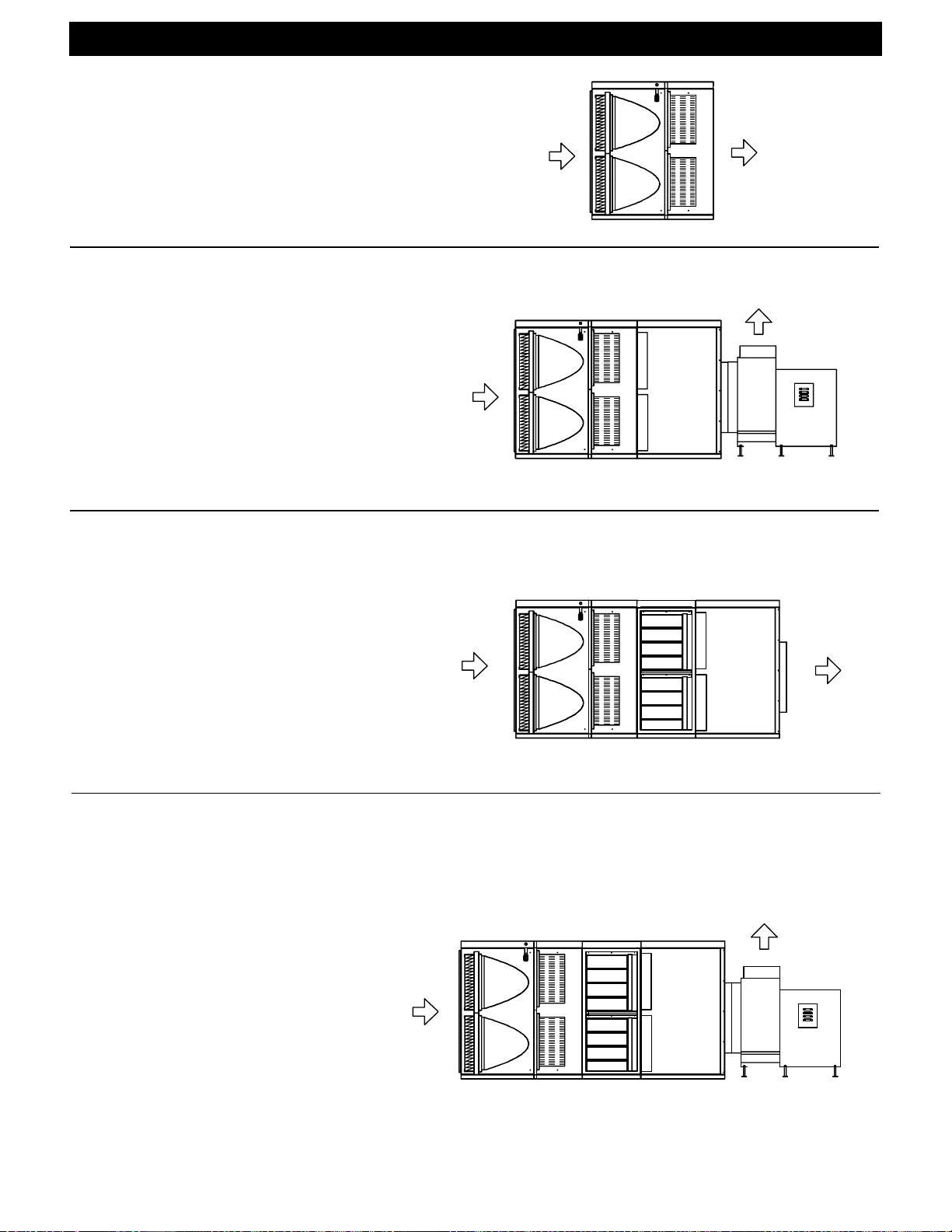

Model TPF-H-DO-EF

Horizontal Style with Double Odor

Control and Exhaust Fan

The Model TPF-H-DO-EF is an Filtration smoke

abatement unit that includes built-in odor control

and exhaust fan. The primary feature of this unit

is that the interconnecting ductwork, transitions

and fan are factory installed in a single roof top

package. The unit comes pre-wired for single

point electrical connection and includes a magnetic starter, fuses and a disconnect switch. The

odor control section includes a 30% pre-filter,

and a double pass of odor control media. This

model is available for both indoor and outdoor

installations in sizes from 1000 to 24,000 CFM

(472 to 11,328 L/s).

BF

FAN DISCHARGE

FF

QMPF

DO AF

FD

EF

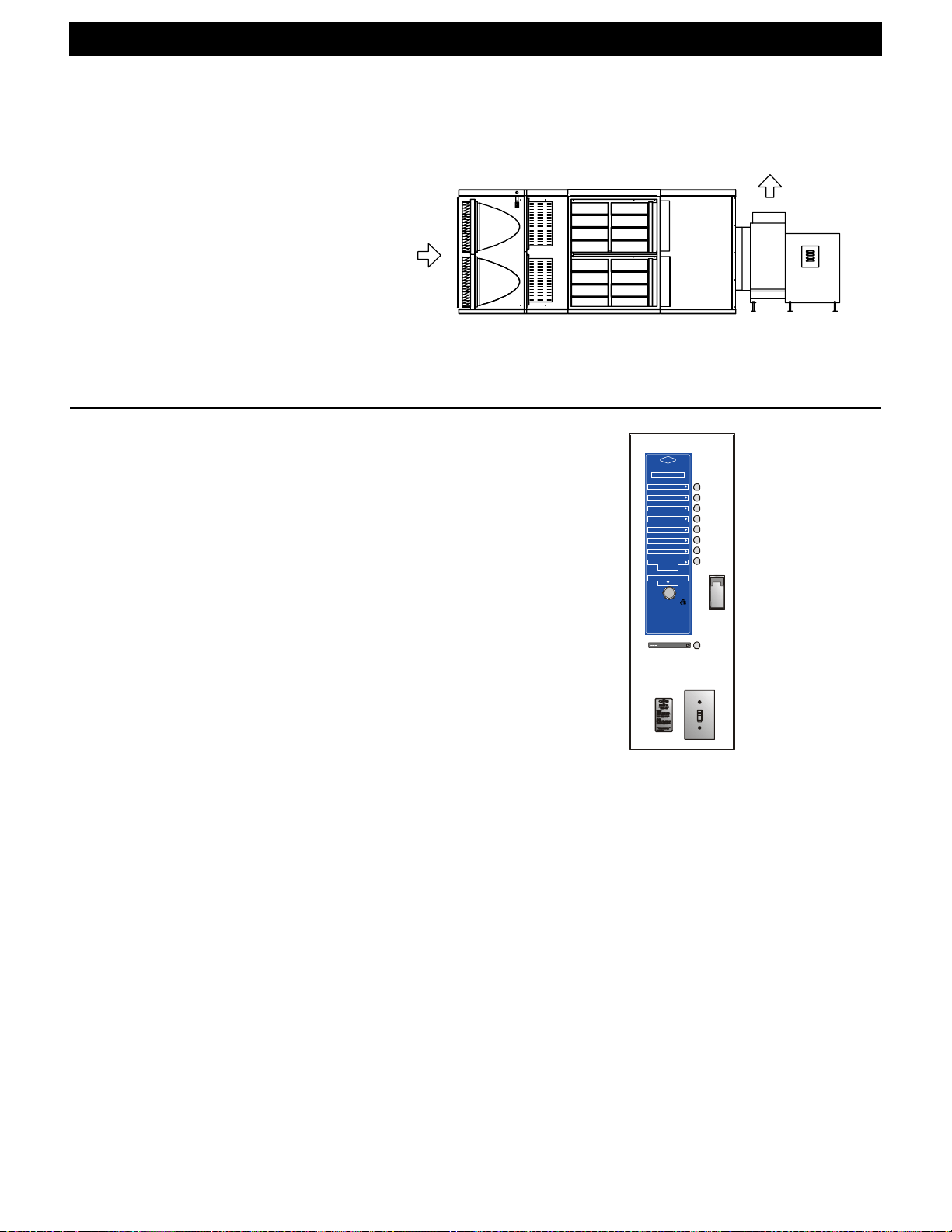

Monitor Panel

Model FM-100

Every ClearAir unit comes complete with a remote monitor station, Model FM -100 Series.

The monitor panel contains switch for controlling

the exhaust fan, indicator lights for monitoring

the filters and internal fire protection system.

This monitor panel can be combined with the

ventilators wash and fire cycle functions if a

Gaylord water-wash type ventilator was used. The

cabinet is constructed of all stainless steel and

would typically be located within the kitchen.

GAYLORD

CLEARAIR

POLLUTION CONTROL UNIT

CONTROL PANEL MODEL

FM-100

FAN ON

NORMAL AIR

LOW AIR

REPLACE PRE FILTERS

REPLACE BAG FILTERS

REPLACE FINAL FILTERS

MISSING FILTER

FIRE IN UNIT

THERMOSTAT ACTIVATION

AND / OR FIRE SYSTEM

DISCHARGE

CANCEL ALARM BUTTON

The ClearAir Unit Model RSPC-TPF Series is ETL Listed under

the category Air Filtering Device, Report # 3028598-1

- CAUTION -

DO NOT OPERATE UNIT WITH MISSING

FILTERS OR WITH FILTERS THAT SHOULD

BE REPLACED AS INDICATED BY MONITORING LIGHTS. THIS IS A SMOKE POLLUTION

CONTROL DEVICE AND WILL NOT OPERATE PROPERLY WITH MISSING OR DIRTY

FILTERS.

GAYLORD INDUSTRIES, INC.

TUALATIN, OREGON 97062-1149 U.S.A.

Phone: 503-691-2010 • 800-547-9696

Fax: 503-692-6048 • email: info@gaylordusa.com

Form No. TPF FP/19038

6(1625/,*+7

®

TM

U.S.

42106

4

General

GENERAL INFORMATION

The pollution control unit consists of a smoke control

section, odor control section and an exhaust fan all built

on a common base as an integral unit. Smoke control will

be accomplished by a three stage high efficiency filter

section and odor control by an odor oxidant media. The

unit is ETL listed and labeled. The unit should be used in

conjunction with a listed water wash or cartridge extractor

ventilator with a minimum grease extraction efficiency of

90%.

Smoke Control Section

The smoke control section has three phases of filters

located prior to the odor control section. These filters

consist of replaceable 30% pre-filter, 95% bag filter and a

replaceable 99% final filter. Replaceable filters are mounted

in filter slide tracks to prevent air bypass around the ends

of the installed filter bank. Filters are accessed through

removable side access panels with lift and turn latches.

Phase one filters shall have an average efficiency of 25 to

30% and an average arrestance of 90 to 92% in accordance with ASHRAE test standard 52.1-1992. Media

support grid is on 1" centers with an open area 96%. Filter

enclosing frame is a rigid, high wet strength beverage

board, with diagonal support members 4" deep.

Phase two filters have an average efficiency of 90 to 95%

in accordance with ASHRAE test standard 52.1-1992.

Sealing surface and pocket retainers are configured to

provide 84% open area. Seams in bag filters are sealed

with foamseal adhesive to completely eliminate air leakage through stitch holes.

Phase three filters are 95% efficient on .03 micron

particles (DOP smoke test), 97% efficient on nebulized

staphylococcus aerosols, 99+% efficient on atmospheric

test dust (ASHRAE standard 52.1-92). The casing is 16

gauge steel with corrugated aluminum separators to

insure media stability. Media is fine-fiber, high strength

microfiberglass paper. Media end cuts are encapsulated

in urethane potting adhesive.

The unit includes a UL listed fire damper, with a 280 degree fusible link, located down stream of the filters to

prevent passage of fire to the duct downstream of the unit.

A fire-stat, set at 250 degrees, is located in the filter

section to shut down the exhaust fan in the event of a fire.

Odor Control Section

Odor control can be provided by either:

Carbon and potassium permanganate blend, Carbon

only or Chemical Spray Odor control

If an media bed type of odor control is selected. The odor

removal media is a 50% potassium permanganate 50%

carbon blend or 100% carbon and is housed in slide out

reusable steel modules. There is a 30% pleated media

after filter located immediately downstream of the odor

control media. The odor control media and after filters are

removable through removable side access doors with lift

and turn latches.

Chemical Spray Odor Control

The odor removal is performed through the injection of an

adsorbing chemical. This is done with a compressor pushing air through an atomizing type nozzle that draws the

chemical from the resevoir. The 5 gallon resevoir is in the

cabinet on the side of the unit that houses the compressor. The spray system can be set for continuous spray or

intermittent spray with timers in the control cabinet. This

unit can be provided with an optional heater for cold climates.

Exhaust Fan Section (Standard Centrifugal Fan)

The exhaust fan is an SWSI upblast arrangement #9 or

#10 with a non-overloading BI or AF wheel. The motor,

drives, bearings and fan mounting base are located out of

the exhaust air stream. The fan is AMCA certified and

bears the AMCA seal for performance. The fan housing is

constructed of heavy gauge steel and all seams are

continuously welded. The fan bearings are heavy duty

self-aligning pillow block type rigidly mounted on heavy

structural steel supports. The motor is OPD three phase

mounted on a common base with the fan and is pre-wired

to the electrical control cabinet. The factory provided drive

assembly is adjustable pitch on 7.5 HP and smaller, fixed

pitch on 10 HP and larger. It will also be sized for a

minimum 1.5 service factor. After final system balancing,

fixed pitch sheaves are to be provided and installed by

the air balancing contractor to provide proper flow at actual installed conditions. The exhaust fan section is

equipped with removable panels for access to the fan.

Exhaust Fan Section (Optional Tubular Fan)

The exhaust fan is a tubular centrifugal or SWSI arrangement #9 or #10 with a non-overloading BI or AF wheel. The

motor, drives, bearings and fan mounting base are located

out of the exhaust air stream as required by the IMC

(International Mechanical Code) and NFPA-96. The fan is

AMCA certified and bears the AMCA seal for performance.

The fan housing is constructed of heavy gauge steel and

all seams are continuously welded. The fan bearings are

heavy duty self-aligning pillow block type rigidly mounted

on heavy structural steel supports. The motor is OPD three

phase mounted on a common base with the fan and is

pre-wired to the fan control cabinet. The fan control

cabinet includes the disconnect switch, motor starter,

overloads and fuses. The factory provided drive assembly

is adjustable pitch on 7.5 HP and smaller, fixed pitch on

10 HP and larger. It is sized for a minimum 1.5 service

factor. After final system balancing, fixed pitch sheaves

are provided and installed by the air balancing contractor

to provide proper flow at actual installed conditions.

5

Loading...

Loading...