TECHNICAL MANUAL

FOR

INSTALLATION, OPERATION

Effective Date: 4-05

AND MAINTENANCE

OF

THE GA YLORD "ClearAir

TM

MODEL "RSPC-ESP" SERIES

POLLUTION CONTROL UNITS

WITH C-6000-ESP-S COMMAND CENTER

WARNING

Improper installation, adjustment, alteration service or maintenance can cause property damage, injury or death. Read

the installation, operation and maintenance instructions thoroughly before installing or servicing this equipment. Only

trained and qualified service personnel should install or service this equipment.

"

GAYLORD INDUSTRIES

10900 S.W. A VERY STREET • TUALATIN, OR 97062-1 149 USA

PHONE: 503-691-2010 • TOLL FREE: 800-547-9696 • FAX: 503-692-6048

email:info@gaylordusa.com • www.gaylordusa.com

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES, INC.

World Headquarters: P.O. Bo x 1149 • Tualatin, Oregon 97062-1149 U.S.A.

T o Our Customers . . .

Congratulations on your recent purchase of a Gaylord

ClearAirTM Pollution Control Unit. W e are proud to be ab le

to provide you with a quality product that exemplifies our

long-standing dedication to quality engineering.

Your unit is assembled from some of the very finest com-

ponents available and is designed for years of efficient,

effective, and troublefree operation. In addition, this unit

has undergone rigorous quality control inspections and

was fully operationally tested prior to shipment.

If you hav e further questions, please contact us toll free at

1-800-547-9696, or info@gaylordusa.com. We are more

than happy to help .

Sincerely,

Gaylord Industries

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: ga ylord@ga ylordusa.com • www.ga ylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • HEAT RECLAIM • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL • AIR HANDLING UNITS

STREET ADDRESS: 10900 S.W. Avery Street, T ualatin, Oregon 97062-8549 U .S.A.

TECHNICAL MANUAL

FOR

INSTALLATION, OPERATION

AND MAINTENANCE

OF

THE GA YLORD “ClearAirTM”

MODEL “RSPC-ESP” SERIES

POLLUTION CONTROL UNITS

WITH C-6000-EPS-S COMMAND CENTER

Published by:

GA YLORD INDUSTRIES

Tualatin, Oregon 97062-1 149

U.S.A.

First Printing: September , 2003

© Copyright 2005, Gaylord Industries

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY

FORM BY AN ELECTRONIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR OTHERWISE WITHOUT THE WRITTEN PERMISSION

OF GAYLORD INDUSTRIES, INC. COPYRIGHT 2003.

The manufacturer reserves the right to modify the materials and specifications resulting from a continuing

program of product improvement or the availability of new materials.

Additional Copies $15.00

The Gaylord ClearAirTM Unit is designed and engineered by

GAYLORD INDUSTRIES, INC.

10900 S.W. A very Street, Tualatin, Oregon 97062-1 149.

TABLE OF CONTENTS

INTRODUCTION.....................................................................................................5

SPECIFICATIONS ............................................................................................... 6-7

MODEL NUMBER EXPLANA TION ..........................................................................8

TYPICAL INST ALLATION.........................................................................................9

SAMPLE ClearAir

RECEIVING & INST ALLA TION ..............................................................................12

EQUIPMENT LIFTING PROCEDURE...................................................................13

ASSEMBLING RSPC HOUSING ON UNITS SPLIT FOR SHIPMENT............. 14-15

SMOKE CONTROL .............................................................................................. 16

RSPC-ESP FIRE MODE ................................................................................ 17-18

DAIL Y OPERA TION......................................................................................... 19-20

COMMAND CENTER INSTRUCTIONS .......................................................... 21-24

TIME CLOCK OPERA TION ..................................................................................25

DETERGENT PUMP OPERA TION................................................................. 26-27

PREVENTIVE MAINTENANCE........................................................................ 28-29

CELL CONFIGURA TION.......................................................................................30

TM

CONFIGURA TIONS.........................................................10-11

SPARE CELLS......................................................................................................31

TROUBLE-SHOOTING – ESP SECTION....................................................... 32-33

ODOR CONTROL .......................................................................................... 34-37

EXHAUST F AN SECTION ............................................................................... 38-39

RP DEVICE INITIAL ST ART UP ............................................................................40

TROUBLE-SHOOTING – GENERAL.............................................................. 41-44

DETERGENT PUMP P AR TS................................................................................45

CONTROL CABINET ............................................................................................46

SUB P ANEL ..........................................................................................................47

NAMEPLA TE DAT A ......................................................................................... 48-49

TERMINAL VOL T AGES ................................................................................... 50-51

WIRING DIAGRAM ................................................................................................52

OPTIONAL CONNECTION INSTRUCTIONS......................................................... 53

PLC ST A TUS LIGHTS ............................................................................................ 54

DRAIN .................................................................................................................... 55

SPRA Y ODOR WIRING......................................................................................... 56

SPRA Y ODOR TERMINAL VOL T AGES ................................................................. 57

C-6000-ESP-S SERIES CONTROL................................................................. 58,60

C-6000-ESP-S COMPONENT SCHEDULE ..................................................... 59,61

POWER PACK PARTS ..........................................................................................62

CELL PARTS ......................................................................................................... 63

MISCELLANEOUS P ARTS .................................................................................... 64

ST ARTUP INSTRUCTIONS ................................................................................... 65

INSPECTION REPORT ......................................................................................... 66

WARRANTY ..................................................................................Inside back cover

4

INTRODUCTION

ir quality is becoming a major concern in America’s large

A

cities and as a result, many commercial kitchens will require pollution control equipment in their exhaust systems to

comply with the increasing demands of environmental control

agencies. In addition, pollution control equipment is being used

for kitchens in high-rise buildings allowing the exhaust to discharge out the side of the structure which saves the cost of

running the duct up many floors to the roof.

Pollution control in kitchen exhaust systems has typically

been accomplished by any one of the following methods gas fired incinerators, scrubbers, filtration units or electrostatic precipitators. Incinerators and afterburners literally burn

the pollutants and, while effective, can be very costly and

hazardous to operate. Scrubbers consist of a water bath and

extraction baffles to remove the pollutants and though quite

effective on grease removal, they typically require the addi-

tion of high efficiency filters to abate smoke below control

agencies’ standards. Filtration units use a series of impinge-

ment filters to remove the pollutants and if done properly can

be quite effective on both smoke and grease.

The Gaylord pollution control unit, trademarked “ClearAirTM”,

can be manufactured with either electrostatic precipitation

(ESP) or Filtration (TPF). Gaylord Industries, Inc. has been

manufacturing ESP’s specifically designed for commercial

kitchen exhaust systems since the early 1970’s, longer than

any other manufacturer. However , when initial cost is a greater

concern the TPF unit is a sound alternative.

The ClearAirTM TM ESP unit is available in several configura-

tions, as illustrated on the following pages, ranging in capac-

ity from 1000 to 32,000 CFM (472 to 15,102 L/s). Most mod-

els can include an exhaust fan and odor abatement equip-

ment as an option.

Basic Facts About Smoke

Smoke particles are extremely small and not visible to the

human eye unless thousands of them are grouped together

to form what we see as smoke. Individual particles are mea-

sured in units called microns and one micron equals 1/25,400

of an inch (1/64,516 of a cm).

Smoke generated by commercial cooking equipment has a

particulate size of between 0.3 and 0.8 microns and it is these

very small particles that smoke abatement equipment must

remove from the airstream. The amount of smoke being dis-

charged from a kitchen exhaust duct is measured in terms of

its density , referred to as opacity - the degree to which emissions block light. A 100% opacity level would be solid black

and 0% would be perfectly clear. Control agencies that have

adopted smoke pollution ordinances are requiring an opacity

level of no more than 20%, which is a very light blue smoke.

Typically , heavy smoke producing cooking such as charbroiling, creates an opacity level of 60% to 70%. Opacity readings are taken by the human eye by viewing the smoke being

discharged and then assigning a percentage of opacity to

what is seen. Though this method is quite subjective, it is

the method practiced by control agency inspectors who are

trained and certified in determining opacity percentages. Other

more technical methods of determining opacity or particulate

density are achieved through the use of opacity meters and

cascade impactors. This level of analysis is usually referred

to as source testing. Control agencies occasionally require

this type of analysis and if so, the testing is conducted by

state certified contractors which can be quite costly and timeconsuming. The efficiency of an TPF is based on how well it

reduces the opacity level of a given airstream.The Gaylord

ClearAirTM unit will reduce the opacity level below 20%,

thereby meeting the requirements of environmental control

agencies.

Basic Facts About Odor

Cooking odors (molecules) generated by the combustion of

animal and vegetable matter result in an extremely complex

mixture of reactive organic gases (ROG’s). A small percentage

of these odors may be absorbed by the grease particles but the

vast majority exist separately in the airstream. The ROG molecules are much too small to be removed by any type of filter and

therefore, other methods must be used. There are several meth-

ods with which to manage the odor. One method is to use a

media bed. The two most popular types of media bed are acti-

vated charcoal, which absorbs and retains the odor molecules,

and the use of an odor-oxidant media (potassium permangan-

ate) which oxidizes the molecules to solids and then retains

them. The other method involves the use of a liquid delivered with

a finely atomized spray. This spray performs a similar function to

potassium permanganate in that it adsorbs or chemically neutralizes odors. This process has the benefit of the end user being

able to adjust the amount of spray and thus the effectiveness and

cost of the odor control.

The life of the media bed type of odor control is dependent

upon several factors such as how much media is used, type

of odor, amount of odor molecules, grease loading and air

temperature. Typically , any of the above mentioned types of

media can remove 85% - 90% of the molecules. Determining

the efficiency of odor control can be very subjective, as testing

is usually conducted by the human nose. More scientific testing is available through ROG analysis, but this involves considerable costs.

Grease Removal - The Important First Step

Grease particles are also measured in terms of microns and

grease generated by commercial cooking equipment has a

particulate size of 10 microns and up. Pollution control equipment is not limited to removing smoke particles, but will also

remove a majority of the grease particles remaining in the

airstream. Therefore, the grease extraction efficiency of the

exhaust hood plays an important role in the operation and

performance of pollution control equipment.

Removal of grease particles before they reach smoke and

odor control equipment will significantly increase the smoke

abatement efficiency and the life of the odor abatement media. It is highly recommended that a Gaylord CG3 Series

Ventilator be used with the ClearAirTM unit as it has a grease

extraction efficiency of 95%. Other high efficiency exhaust

hoods and standard filter type hoods may be used with the

ClearAirTM unit. Contact Gaylord Industries for details.

5

SPECIFICATIONS

General

Furnish one (1) Gaylord ClearAir Pollution Control Unit model

RSPC-ESP series as manufactured by Gaylord Industries Inc.

of Tualatin, Oregon in accordance with the following:

The pollution control unit shall consist of a smoke control section, odor control section (optional) and an exhaust fan section

(optional) all built on a common base as an integral unit.

Smoke Control Section

The smoke control section shall contain one or more electrostatic precipitator (ESP) cells to remove smoke particles

from the air stream to a level no higher than 20% opacity

when operated in accordance with the operation and main-

tenance guidelines. The ESP cells shall be of a floating plate

design to eliminate plate warpage during high heat opera-

tion. The cells shall be positioned on slide tracks so that

they may be easily removed through a hinged cell access

door(s). For ease of handling, individual cells shall weigh

less than 54 lbs. There shall be removable, cleanable debris

screens located immediately upstream of the ESP cells and

a moisture separator immediately downstream. An electri-

cal panel mounted on the unit shall contain the high voltage

power pack assembly , safety disconnect switch, main dis-

connect switch, fuses and a magnetic starter for the ex-

haust fan when fan is included. The safety disconnect switch

shall interface with the electrical panel access door such

that when opened it will shut off service to the power pack(s)

and ground them to drain the residual electrical charge from

both the power pack(s) and ESP cells. The ESP cell ac-

cess door shall interface with the electrical panel access

door so that it cannot be opened without first opening the

electrical panel access door. The high voltage power pack(s)

shall be self-limiting type and shall be self contained. The

electrical panel shall include indicating lights to monitor cell

and transformer voltage. The main disconnect switch for the

exhaust fan and control circuits shall lock the electrical panel

access door closed when in the “on” position. The unit shall

contain one or more wash manifold(s) with brass spray

nozzles to wash the ESP cells with hot detergent injected

water each time the exhaust fan is shut off.

Fire Detection

A thermostat, set at 250o F, shall also be located in the filter

section to shut down the exhaust fan in the event of a fire.

Optional Fire Damper for use in Canada

The unit shall include a UL listed fire damper, with a 280o F

fusible link, located downstream of the filters to prevent passage of fire to the duct downstream of the unit

Odor Control Options

Media bed of 50/50 Blend Potassium Permanganate

and Carbon Blend

The unit shall be provided with odor control utilizing a media

bed of 50% potassium permanganate 50% carbon blend. The

odor removal media shall be housed in slide out reusable steel

modules. There shall be a 30% pleated media after filter located immediately downstream of the odor control media. Replaceable filters shall be mounted in filter slide tracks to prevent

air bypass around the ends of the installed filter bank. The odor

control media and after filters shall be removable through side

access doors with lift and turn latches.

Spray Odor Control

The unit shall be provided with a spray odor control system

utilizing an odor neutralizer chemical. The odor spray control

cabinet shall be mounted on the side of the unit and shall

contain a liquid spray compressor piped to the spray nozzle

in the fan plenum, adjustable delay timers with fuse protected circuitry factory wired to the unit electrical panel. The

cabinet shall include one 5 gallon container of Gaylord Formula GS-710 Odor Neutralizer. The cabinet shall contain a

heater to prevent freezing of the odor neutralizer.

Exhaust Fan Options

Exhaust Fan (Standard Centrifugal Fan)

The unit shall include a centrifugal exhaust fan. The exhaust

fan shall be an SWSI upblast arrangement #9 or #10 with a

non-overloading BI or AF wheel. The motor, drives, bearings

and fan mounting base shall be located out of the exhaust air

stream as required by the IMC (International Mechanical Code)

and NFP A-96. The fan shall be AMCA certified and bear the

AMCA seal for performance. The fan housing shall be con-

structed of heavy gauge steel. The fan bearings shall be heavy

duty self-aligning pillow block type rigidly mounted on heavy

structural steel supports. The motor shall be ODP three phase

mounted on a common base with the fan and shall be prewired to the electrical cabinet located on the unit. The electrical cabinet shall include a disconnect switch, motor starter,

overloads and fuses. The factory provided drive assembly shall

be adjustable pitch on 5 HP and smaller, fixed pitch on 7.5 HP

and larger. It shall also be sized for a minimum 1.5 service

factor. After final system balancing, fixed pitch sheaves shall

be provided and installed by the air balancing contractor to

provide proper flow at actual installed conditions.

Exhaust Fan (Optional Tubular Fan)

The unit shall include a tubular centrifugal exhaust fan. The

exhaust fan shall be an arrangement #10 with a non-overloading BI, AF wheel. The motor, drives, bearings and fan mounting

base shall be located out of the exhaust air stream as required

by the IMC (International Mechanical Code) and NFP A-96. The

fan shall be AMCA certified and bear the AMCA seal for performance. The fan housing shall be constructed of heavy gauge

steel. The fan bearings shall be heavy duty rigidly mounted on

heavy structural steel supports. The motor shall be ODP three

phase mounted on a common base with the fan and shall be

pre-wired to the electrical cabinet located on the unit. The electrical cabinet shall include a disconnect switch, motor starter,

overloads and fuses. The factory provided drive assembly shall

be adjustable pitch on 5 HP and smaller and fixed pitch on 7.5

HP and larger. It shall also be sized for a minimum 1.5 service

factor. After final system balancing, fixed pitch sheaves shall be

provided and installed by the air balancing contractor to provide

proper flow at actual installed conditions.

Exhaust Fan Housing

The exhaust fan section of the unit shall be enclosed with

the same material as the smoke control section. There shall

be a removable panel for access to the fan.

6

SPECIFICATIONS

Unit Construction

The unit housing shall be constructed of a minimum of 16

gauge G90 bright galvanized steel. The perimeter base shall

be 12 gauge formed channel with lifting lugs at each corner

and along the length as required. The internal housing shall

be externally welded liquid tight for compliance to the International Mechanical Code and NFP A-96 grease duct construction requirements.

Fire Extinguishing System Options

Specifier Note: NFP A-96 requires a fire extinguishing system for protection of the smoke and odor control sections

and protection of the duct down stream of any filters or damp-

ers. Not all authorities having jurisdiction require protection.

Check with your AHJ. If required, specify one of the follow-

ing systems.

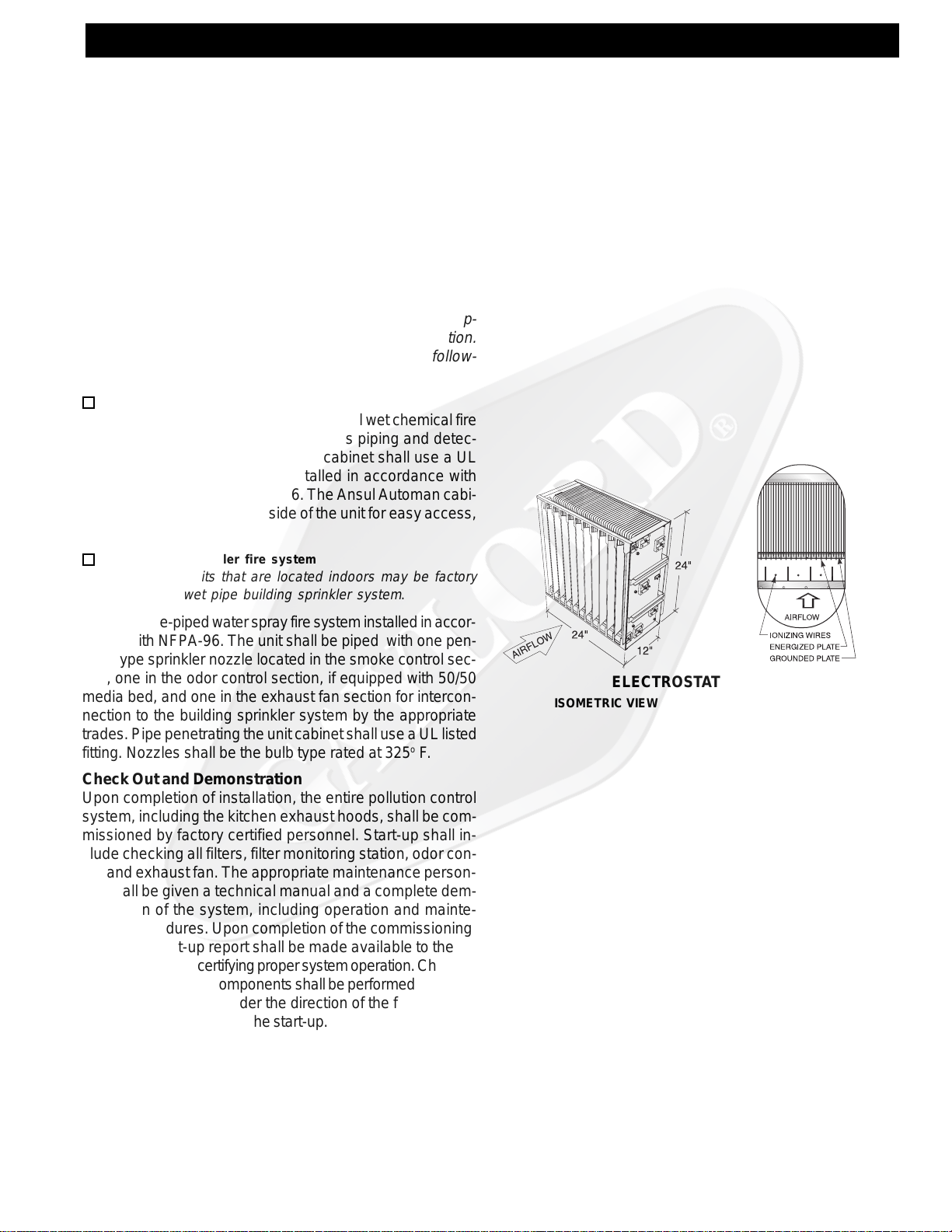

Wet chemical system

Provide a complete factory mounted Ansul wet chemical fire

extinguishing system, including nozzles piping and detec-

tion runs. Pipe penetrating the unit cabinet shall use a UL

listed fitting. System shall be installed in accordance with

the systems listing and NFP A-96. The Ansul Automan cabi-

net shall be mounted on the side of the unit for easy access,

certification and service.

Water spray sprinkler fire system

Specifier Note: Units that are located indoors may be factory

pre-piped for a wet pipe building sprinkler system

.

Provide a pre-piped water spray fire system installed in accor-

dance with NFP A-96. The unit shall be piped with one pen-

dent type sprinkler nozzle located in the smoke control sec-

tion, one in the odor control section, if equipped with 50/50

media bed, and one in the exhaust fan section for intercon-

nection to the building sprinkler system by the appropriate

trades. Pipe penetrating the unit cabinet shall use a UL listed

fitting. Nozzles shall be the bulb type rated at 325o F.

Check Out and Demonstration

Upon completion of installation, the entire pollution control

system, including the kitchen exhaust hoods, shall be com-

missioned by factory certified personnel. Start-up shall in-

clude checking all filters, filter monitoring station, odor con-

trol and exhaust fan. The appropriate maintenance person-

nel shall be given a technical manual and a complete dem-

onstration of the system, including operation and mainte-

nance procedures. Upon completion of the commissioning,

a detailed start-up report shall be made available to the architect and owner certifying proper system operation. Changes

required in fan drive components shall be performed by the air

balancing contractor under the direction of the factory certified person(s) performing the start-up.

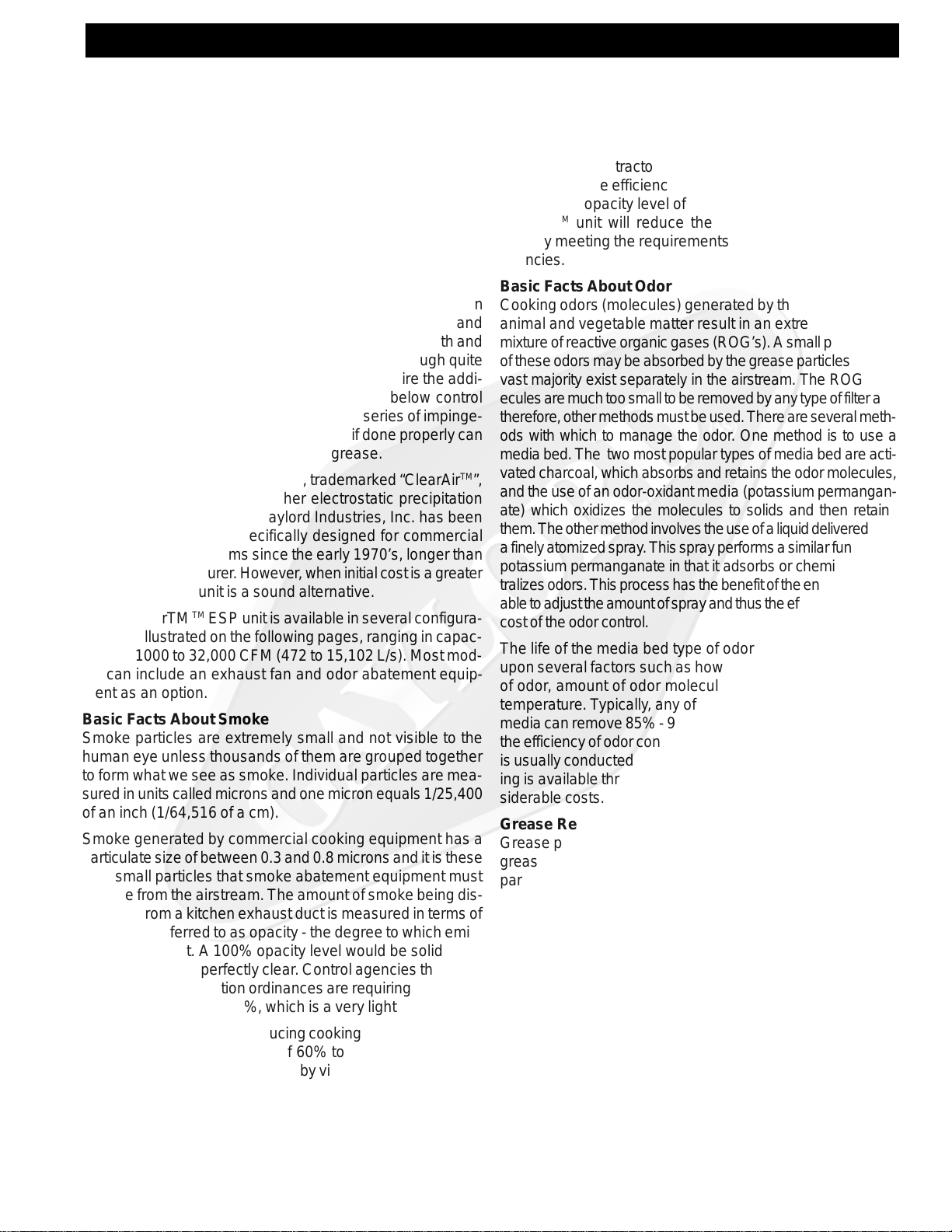

ELECTROSTA TIC CELL

ISOMETRIC VIEW SIDE VIEW

7

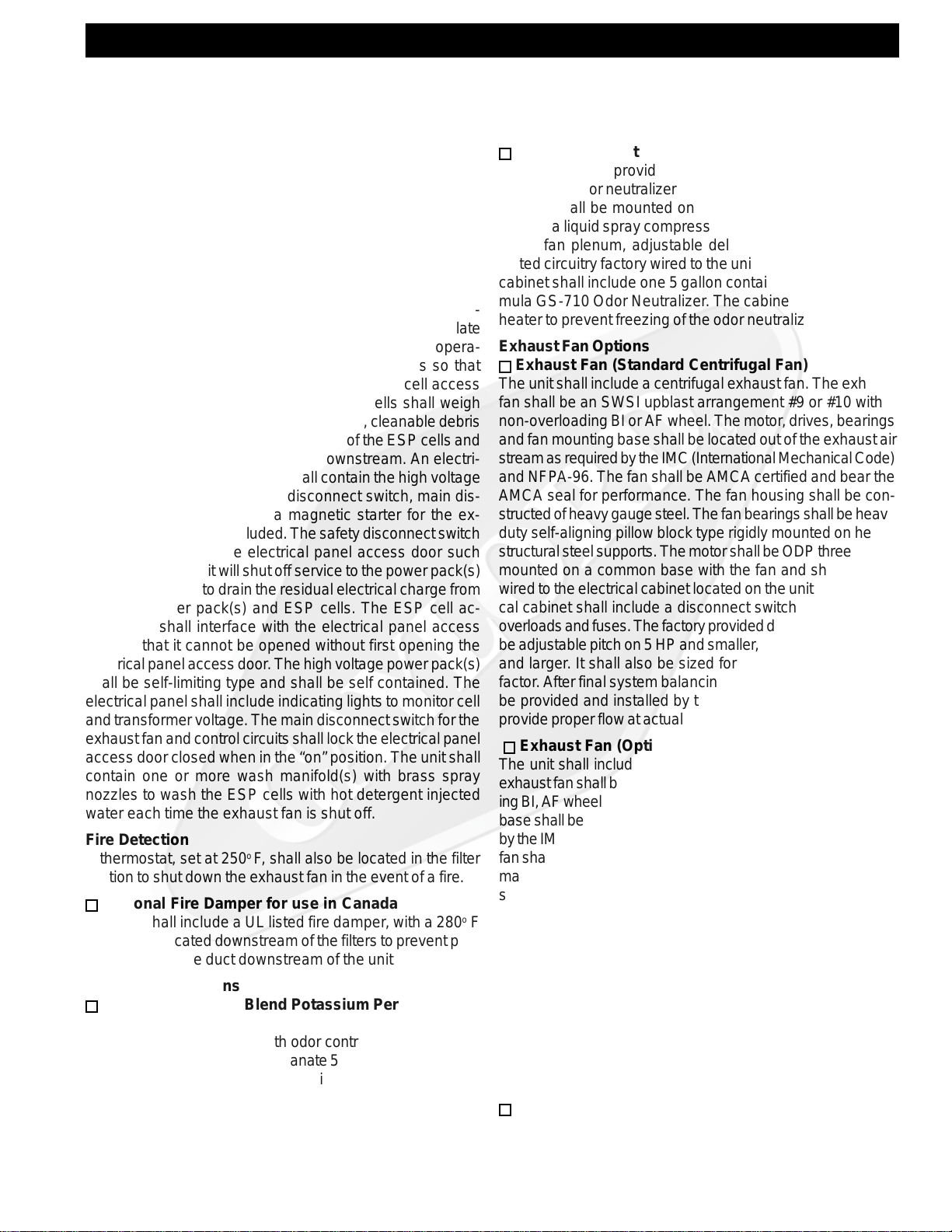

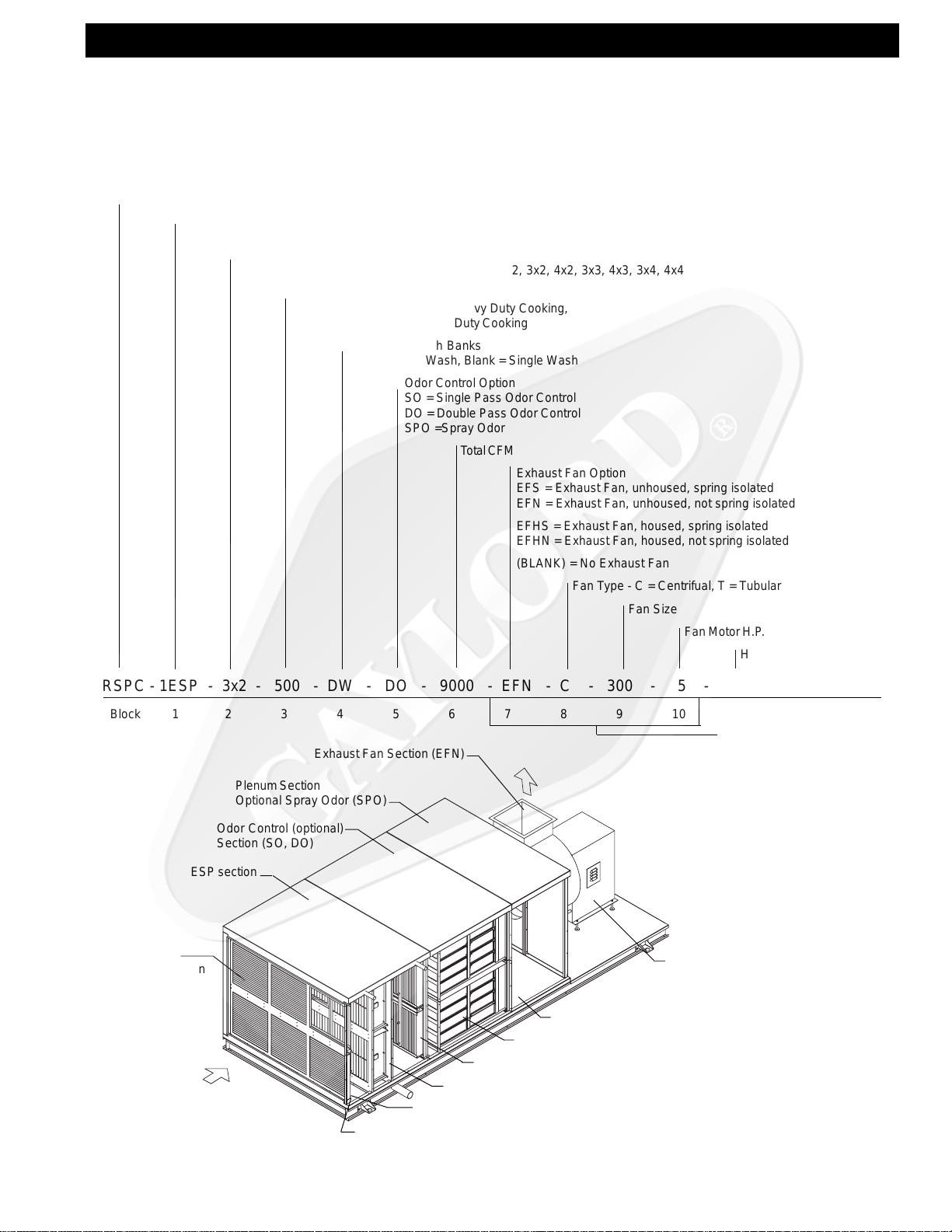

MODEL NUMBER EXPLANATION

The assigned model number of a ClearAirTM RSPC-ESP unit will indicate the number of Cell Banks and if it has spray odor

control, single o r double pass odor control, if it has an exhaust fan plus other data. The following example shows the make-up of

a model number .

The model number of your ClearAirTM unit along with other data can be found on the nameplate which is attached to the

electrical control panel on the ClearAirTM unit. Refer to page 49.

Standard Prefix Series of ClearAir System (Remote Smoke Pollution Control)

1 ESP = Single Pass Electrostatic Cells

2 ESP = Double Pass Electrostatic Cells

ESP Cell Configuration (WxH) - 1x1, 2x1, 3x1, 2x2, 3x2, 4x2, 3x3, 4x3, 3x4, 4x4

Nominal FPM ESP Cell Velocity

250 FPM = Heavy and Extra Heavy Duty Cooking,

500 FPM = Light and Medium Duty Cooking

Number of Wash Banks

DW = Double Wash, Blank = Single Wash

Odor Control Option

SO = Single Pass Odor Control

DO = Double Pass Odor Control

SPO =Spray Odor

T otal CFM

Exhaust Fan Option

EFS = Exhaust Fan, unhoused, spring isolated

EFN = Exhaust Fan, unhoused, not spring isolated

EFHS = Exhaust Fan, housed, spring isolated

EFHN = Exhaust Fan, housed, not spring isolated

(BLANK) = No Exhaust Fan

Fan Type - C = Centrifual, T = T ubular

Fan Size

Fan Motor H.P .

Hand - R = Right Hand

L = Left Hand

RSPC - 1ESP - 3x2 - 500 - DW - DO - 9000 - EFN - C - 300 - 5 - R

Block 1 2 3 4 5 6 7 8 9 10 11

All Blank, if no exhaust fan

Exhaust Fan Section (EFN)

Plenum Section

Optional Spray Odor (SPO)

Odor Control (optional)

Section (SO, DO)

ESP section

ESP Cell

Configuration

(3 x 2)

Inlet Airflow

Plenum Access

Odor Media (DO shown)

Moisture Separator

ESP Cells Single Pass (1ESP)

Debris Screen

Hand (Right Hand Access)

Access Side, R or L, Determined by Facing

Unit with Inlet Airflow to back of head

Fan Type (Centrifual

or Tubular)

8

TYPICAL INSTALLATION

9

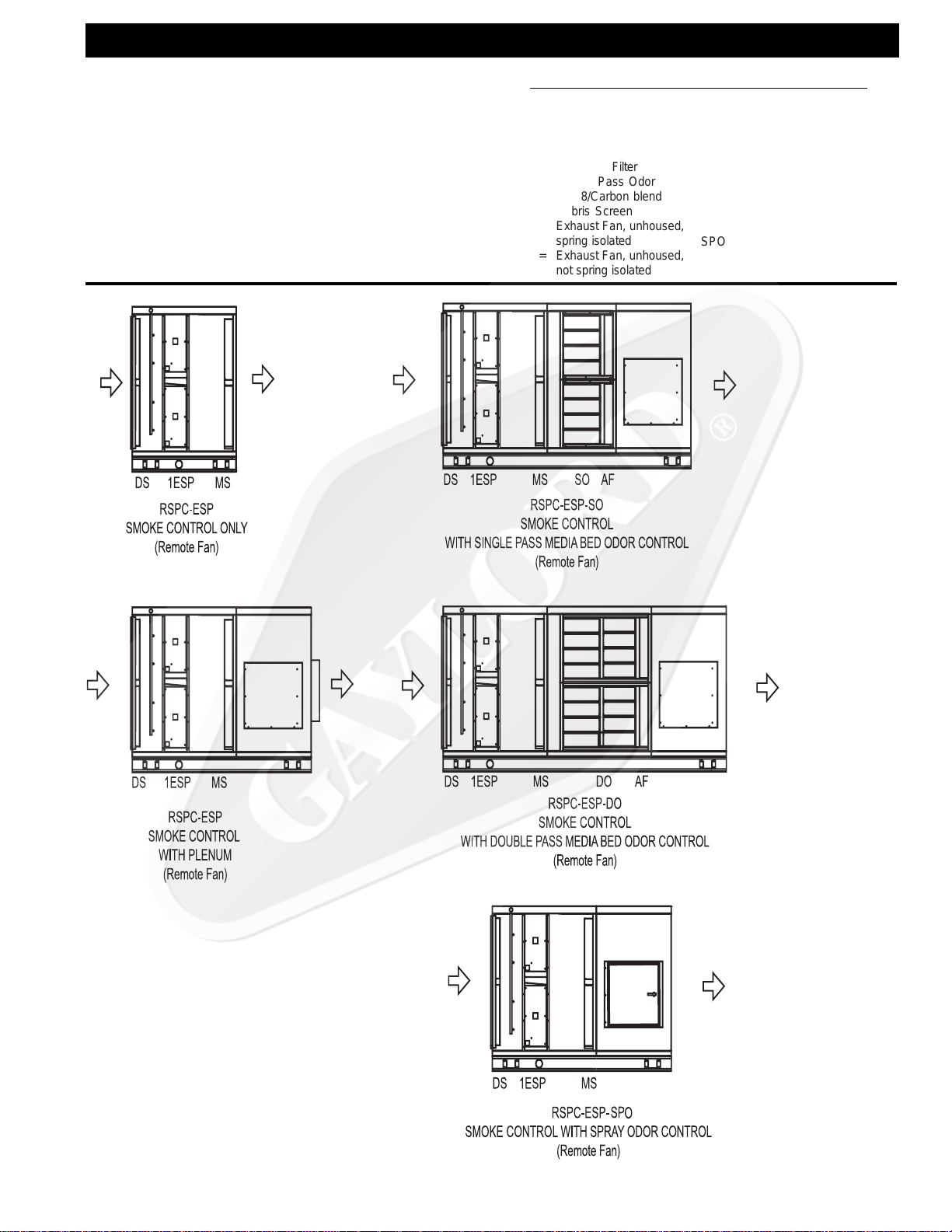

SAMPLE ClearAirTM RSPC-ESP CONFIGURATIONS

The ClearAirTM unit is available in sizes ranging in capacity from 1000 to 32,000 CFM (472 to 15,102 L/s). Each unit

is equipped with Three Phase Filters f or smoke control, and

may include an exhaust fan, odor abatement equipment and

Quencher System, or Ansul System as an option. The following illustrations are examples of the most common configurations.

KEY

1ESP = Single Pass Electro-

static Cells

2ESP = Double Pass Electro-

static Cells

AF = 30% After Filter

D O = Double Pass Odor

Kor48/Carbon blend

DS = Debris Screen

EFS = Exhaust Fan, unhoused,

spring isolated

EFN = Exhaust Fan, unhoused,

not spring isolated

EFHS = Exhaust Fan, housed,

spring isolated

EFHN = Exhaust Fan, housed, not

spring isolated

FD = Optional Curtain Fire

Damper

MS = Moisture Separator

S O = Single Pass Odor

Kor48/Carbon blend

SPO = Spray Odor Cabinet

10

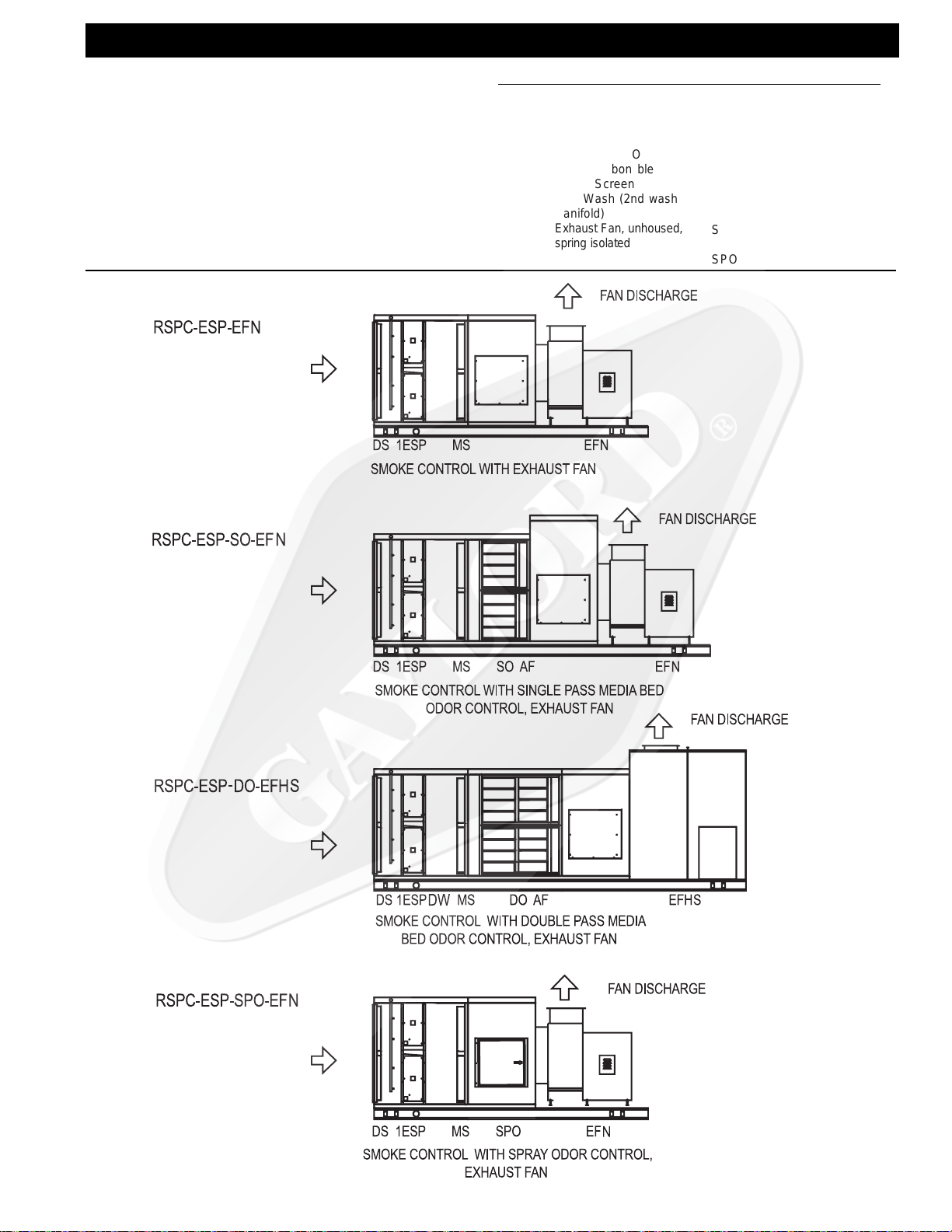

SAMPLE ClearAirTM RSPC-ESP CONFIGURATIONS

KEY

1ESP = Single Pass Electro-

static Cells

2ESP = Double Pass Electro-

static Cells

D O = Double Pass Odor

Kor48/Carbon blend

DS = Debris Screen

DW = Dual Wash (2nd wash

manifold)

EFS = Exhaust Fan, unhoused,

spring isolated

EFN = Exhaust Fan, unhoused,

EFHS = Exhaust Fan, housed,

EFHN = Exhaust Fan, housed,

FD = Optional Curtain Fire

MS = Moisture Separator

SO = Single Pass Odor

SPO = Spray Odor Cabinet

not spring isolated

spring isolated

not spring isolated

Damper

Kor48/Carbon blend

11

RECEIVING & INSTALLATION

RECEIVING

Most ClearAirTM units are shipped in one piece. However,

some units, because of size or special jobsite conditions,

may be shipped in multiple sections. Follow the instructions provided with the unit to join sections back together. If the unit includes media bed odor control, the KOR48/

carbon odor control media is packaged separately. Verify

against the shipping documents that you have received all

items and note any shipping damage, obvious or hidden, to

your carrier and on your Bill of Lading. If damage is found,

immediately file a claim with the transport company . All units

are thoroughly inspected and fully operation tested at the

factory prior to shipment.

Verify that the electrical and air flow ratings on the unit name-

plate agrees with jobsite requirements. If a contradiction arises

notify the factory prior to proceeding with installation.

SAFETY CONSIDERA TIONS

Installing and servicing the ClearAirTM unit can be hazardous

due to the presence of electrical components. Only trained

and qualified service personnel should install or service this

equipment.

Untrained personnel can perform basic maintenance, such

as cleaning and replacing filters. All other operations should

be performed by trained service personnel. When installing

or servicing, observe precautions in literature and on tags

and labels attached to unit.

Follow all safety codes. Wear safety glasses and work gloves.

Use quenching cloth for brazing operations. Have fire extin-

guisher available. Read these instructions thoroughly .

WARNING

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch. Electrical shock can cause personal injury or death.

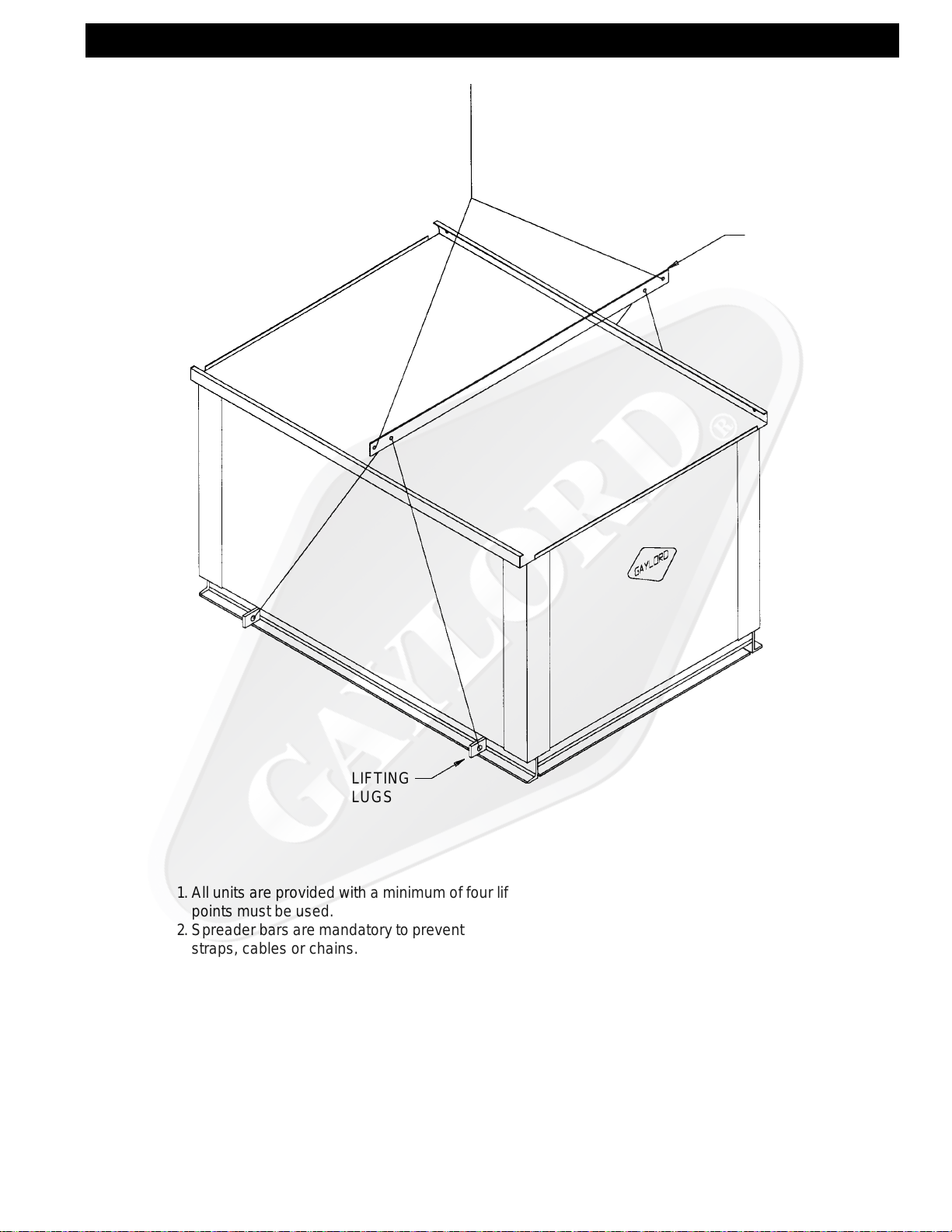

RIGGING

All units are provided with a minimum of four (4) lifting points

for rigging attachment. WARNING: Use all lifting points pro-

vided. (Refer to Page 13) Spreader bars are mandatory to

prevent contact and damage to the unit by lifting hooks, straps,

cables, or chains. Consult the mechanical or structural engi-

neer before moving the unit across the roof deck.

INSTALLA TION CODES

This unit requires external plumbing and electrical connections

to be made in the field. It is recommended that the Authority

Having Jurisdiction (AHJ) be consulted regarding local codes

and installation procedures. Gaylord Industries is not responsible for obtaining necessary approvals and permits which may

be required for installation, nor is it responsible for verifying that

the unit has been installed in accordance with national, state,

and local codes. In the absence of locally adopted codes use

the current editions of the N ational Electrical Code and the

Uniform Mechanical Code. Connections of the exhaust duct to

the inlet and outlet of the ClearAirTM unit must be fully welded to

comply with NFPA-96.

INST ALLATION PRECAUTIONS

1. The services of qualified contractors are essential for safe

and proper installation of this equipment.

2. The air volumes and external static pressures that are

listed on the unit are for the middle of the operating range of

the filters. The initial air volume should be at least 10% higher

than the listed CFM. As the filters load up the air volume will

drop. This is inherent to this type of unit. If the unit is set up

at or below the design CFM, as the filters load up, the kitchen

hood may experience smoke loss problems. Please consult the factory if you have questions.

3. The unit is designed for installation on a level surface.

4. When installed in an enclosed space a fire rated enclosure may be required for the unit and associated duct work.

Consult the Authority Having Jurisdiction.

5. Consult the Authority Having Jurisdiction regarding requirements covering the point of termination of the exhaust

outlet of this unit. Minimum distances must usually be

maintained between the exhaust outlet and any outside air

intakes and/or adjacent structures or property lines.

6. Do not apply power to the unit until all electrical connec-

tions have been made and a pre-start-up preliminary inspection has been completed.

7. Allow a minimum of 36 inches clearance in front of the

filter access door and electrical compartment door for service and routine maintenance per NEC.

SHORT TERM STORAGE

Units that include media bed odor control are provided with

KOR48/carbon media which is shipped separate from the

unit. KOR48/carbon media must be stored in a dry place

with less than 95% relative humidity .

EXHAUST F AN RECEIVING AND STORAGE

If the unit is equipped with an exhaust fan it must be relubricated as soon as it arrives. T o prevent corrosion all bearings should receive grease and be rotated the first of every

month. Rotate the wheel several revolutions every three to

five days to keep a coating of grease on all internal bearing

parts. Turn the wheel by hand while greasing bearings. A

clean 1/16" bead of grease must appear on each side of each

bearing. Refer to specific bearing lubricating instructions on

the fan. Also, refer to bearing lubricating instructions found in

the exhaust fan section of this manual.

Bearings which are to be stored or idle for an extended period of time should be wrapped in a neutral grease-proof paper, foil, or plastic film. Compounds can be recommended

by the bearing manufacturer to provide protection for several

months to several years.

After long-term storage, grease should be purged from the

bearings and fresh grease injected prior to start-up.

12

EQUIPMENT LIFTING PROCEDURE

SPREADER

BAR

LIFTING

LUGS

1 .All units are provided with a minimum of four lifting points for rigging attachment. All lifting

points must be used.

2 .Spreader bars are mandatory to prevent contact and damage to the unit by lifting hooks,

straps, cables or chains.

13

HOUSING ASSEMBLY INSTRUCTIONS

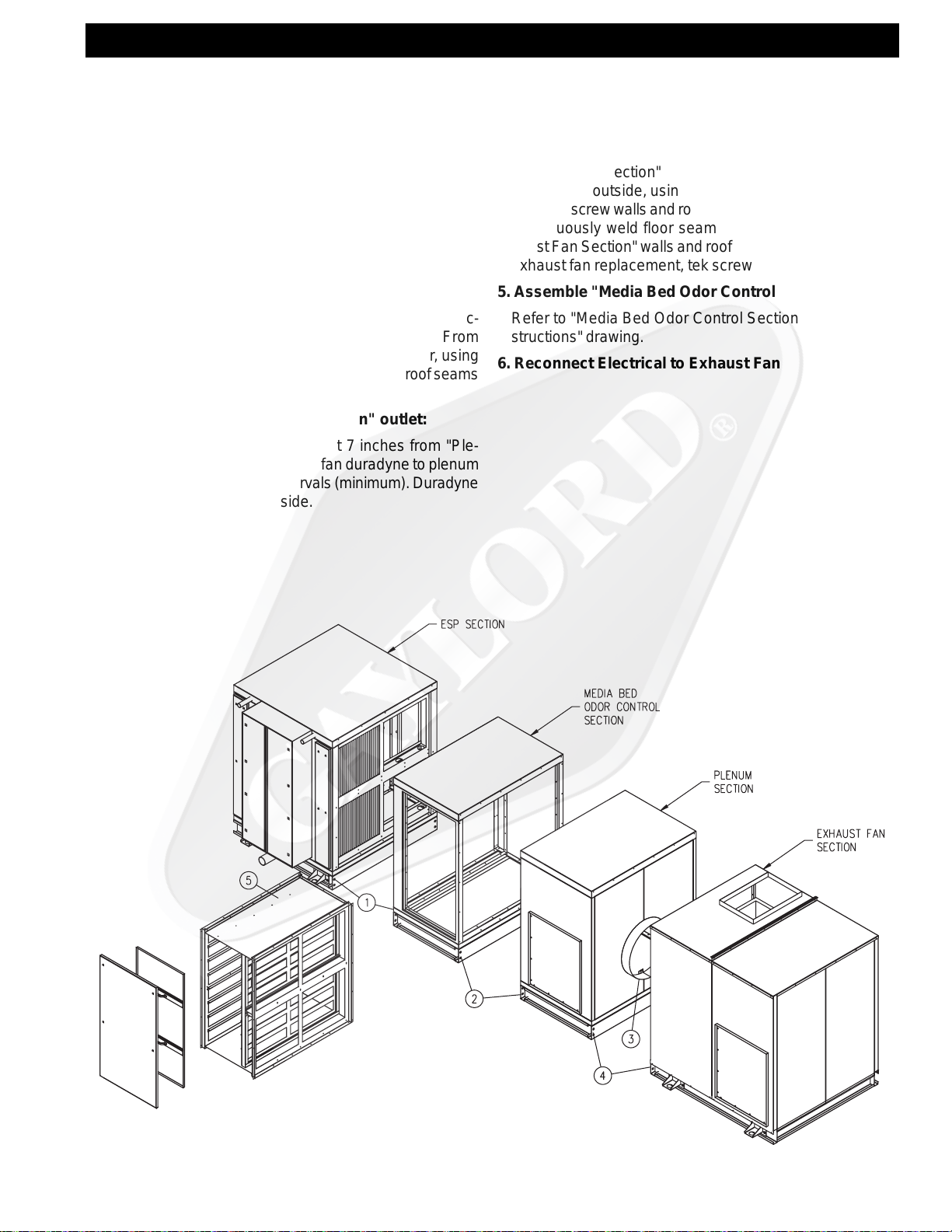

Typically, RSPC units are shipped as one piece. Sometimes for building accessibilty reasons a RSPC unit may be

shipped in multiple pieces. If this is the case, refer to the instruction below and on page 15.

1. Attach "ESP Section" to "Media Bed Odor Control

Section":

Bolt "Media Bed Odor Control Section" and "ESP Section"

bases together on outside of unit, using 3/4" holes. Tek

screw walls and roofs together, using 3/16" holes. Continuously weld: floor, wall, and roof seams from inside of unit.

2. Attach "Media Bed Odor Control Section" to "Plenum Section":

Bolt "Media Bed Odor Control Section" and "Plenum Sec-

tion" bases together on outside, using 3/4" holes. From

inside plenum, tek screw walls and roofs together, using

3/16" holes. Continuously weld: floor, wall, and roof seams

from inside of unit.

3. Attach Fan Inlet to "Plenum Section" outlet:

Push "Exhaust Fan Section" about 7 inches from "Ple-

num Section". T ek screw & caulk fan duradyne to plenum

interconnect ring, at 5 inch intervals (minimum). Duradyne

is pre-attached to fan inlet side.

4. Attach "Plenum Section" to "Exhaust Fan Section":

Bolt "Plenum Section" and "Exhaust Fan Section" bases

together on outside, using 3/4" holes. From inside of plenum, tek screw walls and roofs together, using 3/16" holes.

Continuously weld floor seam from inside plenum. "Exhaust Fan Section" walls and roof to remain removable for

exhaust fan replacement, tek screw and bolt only .

5. Assemble "Media Bed Odor Control Section":

Refer to "Media Bed Odor Control Section Assembly Instructions" drawing.

6. Reconnect Electrical to Exhaust Fan

14

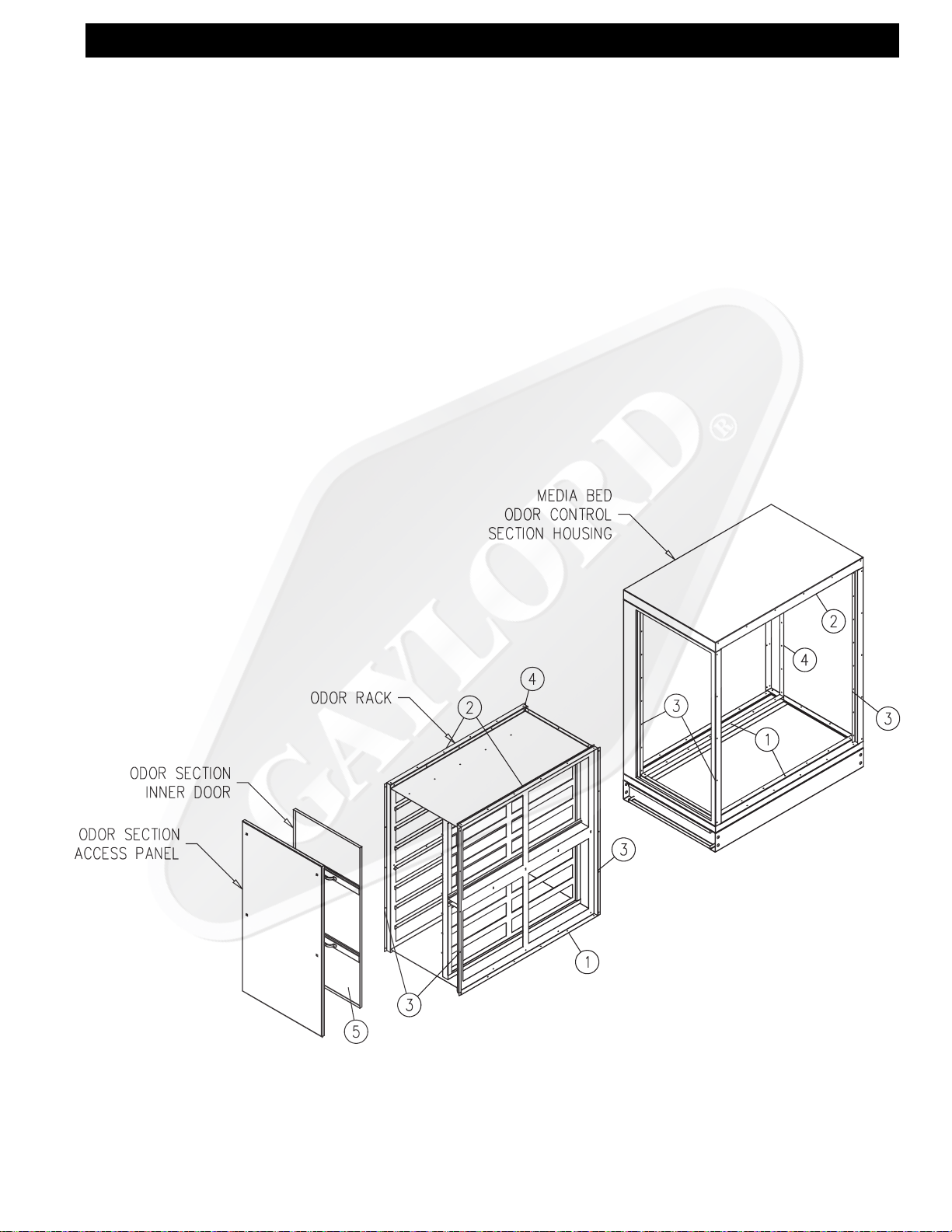

MEDIA BED ODOR CONTROL SECTION ASSEMBLY INSTRUCTIONS

NOTE: Assemble this section, only after the rest of

the unit has been assembled.

1.Slide odor rack into unit through door opening. T ek screw

rack to floor rails, using 3/16" holes.

2.T ek screw upper rack to both sides of roof rails.

3.Tek screw first 3 sides to mouning rails from outside of

the unit.

4.Attach fourth side by entering odor rack to reach screw

holes.

5.Attach odor section inner door, flip latches to secure.

15

SMOKE CONTROL

Principle of Operation

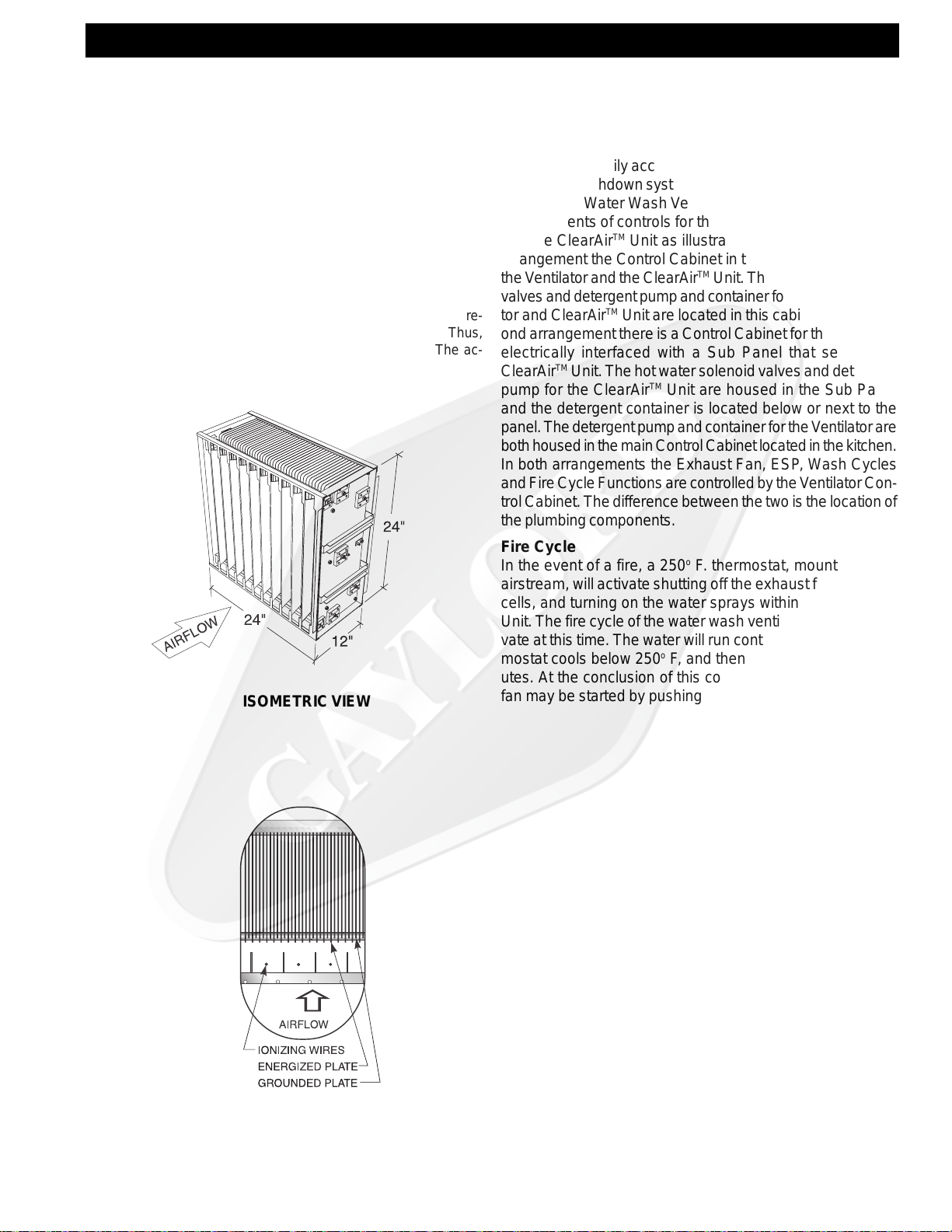

The ClearAirTM TM Pollution Control Unit removes smoke particles

by electrostatic precipitation. The principle of operation of electrostatic precipitation is actually quite basic. The electrostatic cell

is made up of a series of aluminum plates spaced approximately

1

/4” (6.35mm) apart and the number of cells used is determined

by the air volume and the type of cooking equipment involved.

Every other plate is energized with 5000 volts of D.C. power and

the alternating plates are grounded. At the entry point of the cell

is a series of thin wires spaced approximately 4” (101.60mm)

apart. These wires, referred to as ionizing wires, are energized

with 10,000 volts D.C. and as the smoke particles enter the cell

and pass over the wires they receive a positive charge. As the

charged particles continue through the cell, the positive plate re-

pels them and the negative or grounded plate attracts them. Thus,

the smoke particles are collected on the negative plates. The ac-

tion is efficient, safe and simple.

ISOMETRIC VIEW

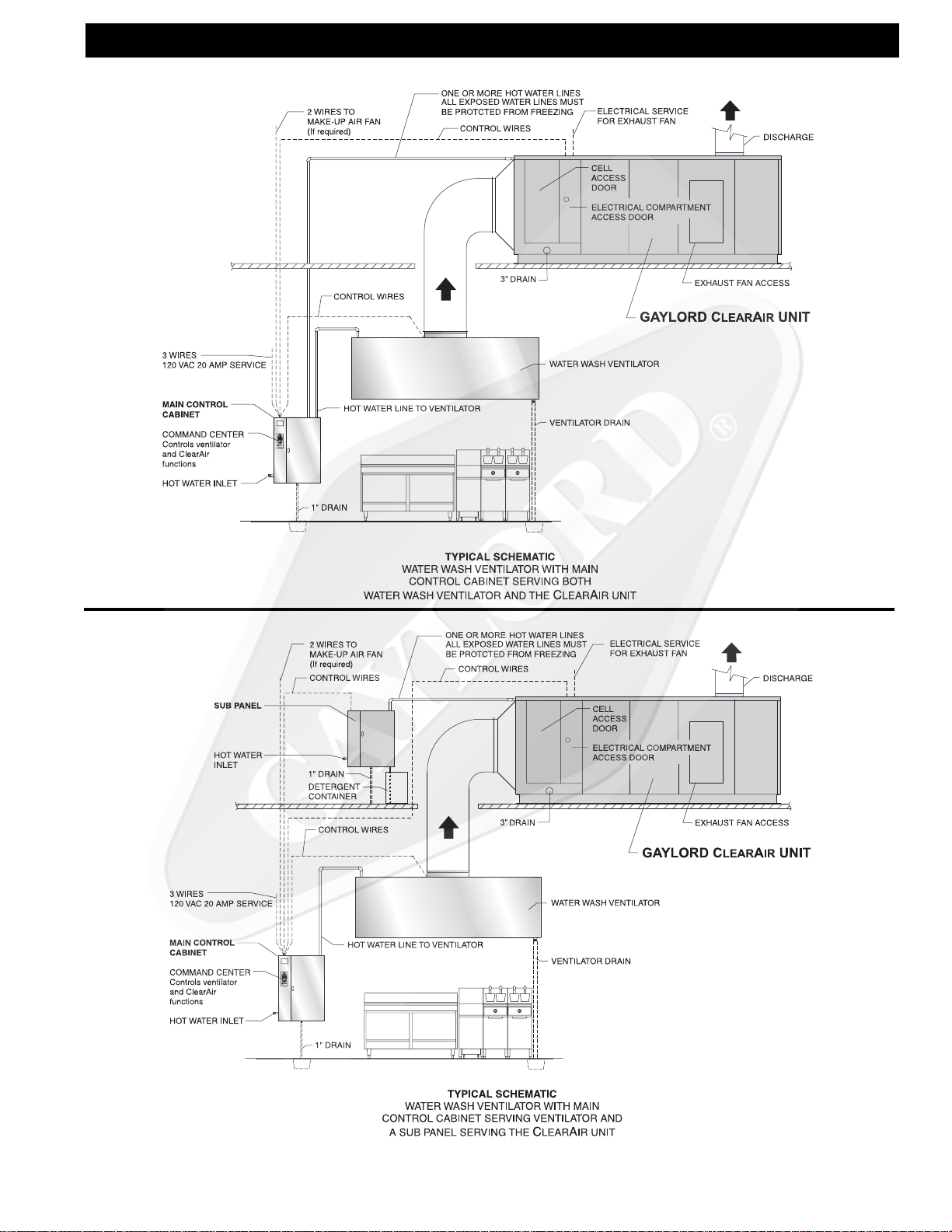

Wash Cycle

All Gaylord ClearAirTM units include, as standard equipment,

an internal washdown system and control cabinet which when

activated washes the unit with hot detergent injected water

to remove the daily accumulation of smoke and grease particles. The washdown system and contols are interfaced with

the Gaylord Water W ash V entilator. There are two possible

arrangements of controls for the operation of the Ventilator

and the ClearAirTM Unit as illustrated on page 9. In the first

arrangement the Control Cabinet in the kitchen serves both

the Ventilator and the ClearAirTM Unit. The hot water solenoid

valves and detergent pump and container for both the Ventilator and ClearAirTM Unit are located in this cabinet.In the second arrangement there is a Control Cabinet for the ventilator

electrically interfaced with a Sub Panel that serves the

ClearAirTM Unit. The hot water solenoid valves and detergent

pump for the ClearAirTM Unit are housed in the Sub Panel

and the detergent container is located below or next to the

panel. The detergent pump and container for the Ventilator are

both housed in the main Control Cabinet located in the kitchen.

In both arrangements the Exhaust Fan, ESP, Wash Cycles

and Fire Cycle Functions are controlled by the Ventilator Con-

trol Cabinet. The difference between the two is the location of

the plumbing components.

Fire Cycle

In the event of a fire, a 250o F. thermostat, mounted in the

airstream, will activate shutting off the exhaust fan and ESP

cells, and turning on the water sprays within the ClearAir

TM

Unit. The fire cycle of the water wash ventilator will also activate at this time. The water will run continually until the thermostat cools below 250o F, and then run for another 2 minutes. At the conclusion of this cool down cycle the exhaust

fan may be started by pushing "Start Fan".

SIDE VIEW

ELECTROSTATIC CELL

16

RSPC-ESP FIRE MODE

INTERNAL FIRE MODE

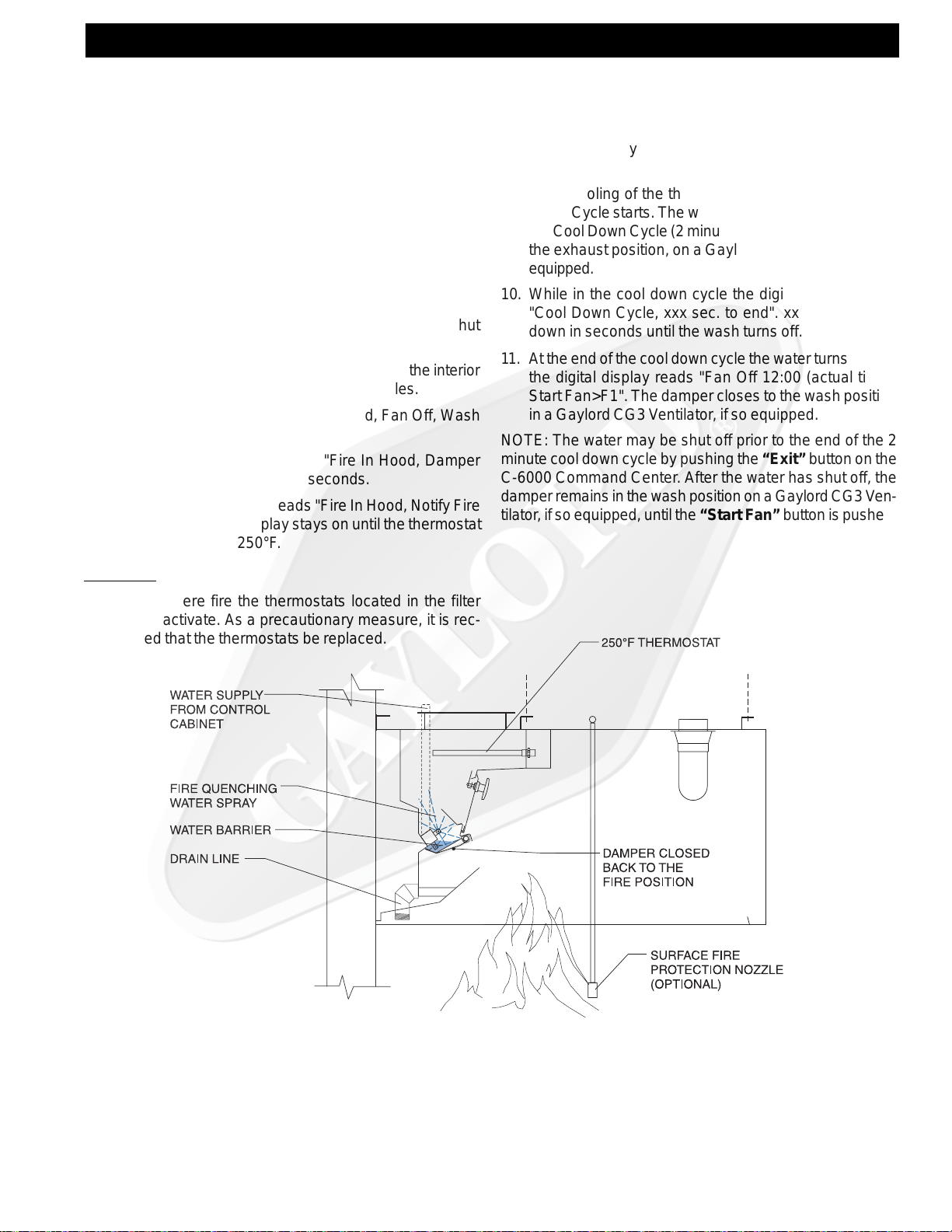

Automatic internal fire protection is accomplished by the

action of the thermostat(s), which is located in the filter section of the RSPC-ESP. When the temperature of the conveying airstream, which must pass over the thermostats,

reaches 250°F, the system is activated, and the following

occurs:

1. The damper begins closing back to the fire position, on

a Gaylord CG3 ventilator, if so equipped, position 3 as

shown in Fig.4—stopping the combustion-supporting,

natural draft through the ventilator and creating a fire

barrier to contain the fire in the kitchen.

2. The exhaust fan is shut off. The supply fan is also shut

off.

3. Fire-smothering water spray is released into the interior

of the RSPC-ESP through the spray nozzles.

4. The digital display reads "Fire In Hood, Fan Off, Wash

On" for approximately 5 seconds.

5. Then the digital display reads "Fire In Hood, Damper

Closing" for approximately 5 seconds.

6. Then the digital display reads "Fire In Hood, Notify Fire

Department". This display stays on until the thermostat

cools down below 250°F .

7. A red light on the Command Center illuminates.

8. If the Command Center is intertied with a building alarm

or monitoring system, a fire signal would be sent to that

system.

9. Upon cooling of the thermostat below 250oF, the Cool

Down Cycle starts. The water continues to spray during

the Cool Down Cycle (2 minutes). The damper moves to

the exhaust position, on a Gaylord CG3 Ventilator , if so

equipped.

10. While in the cool down cycle the digital display reads

"Cool Down Cycle, xxx sec. to end". xxx is the countdown in seconds until the wash turns off.

1 1. At the end of the cool down cycle the water turns off and

the digital display reads "Fan Off 12:00 (actual time),

Start Fan>F1". The damper closes to the wash position

in a Gaylord CG3 Ventilator , if so equipped.

NOTE: The water may be shut off prior to the end of the 2

minute cool down cycle by pushing the “Exit” button on the

C-6000 Command Center. After the water has shut of f, the

damper remains in the wash position on a Gaylord CG3 Ven-

tilator, if so equipped, until the “Start Fan” button is pushed.

CAUTION:

In case of severe fire the thermostats located in the filter

section will activate. As a precautionary measure, it is rec-

ommended that the thermostats be replaced.

FIRE CYCLE

GA YLORD CG3 V entilator

17

RSPC-ESP FIRE MODE

y

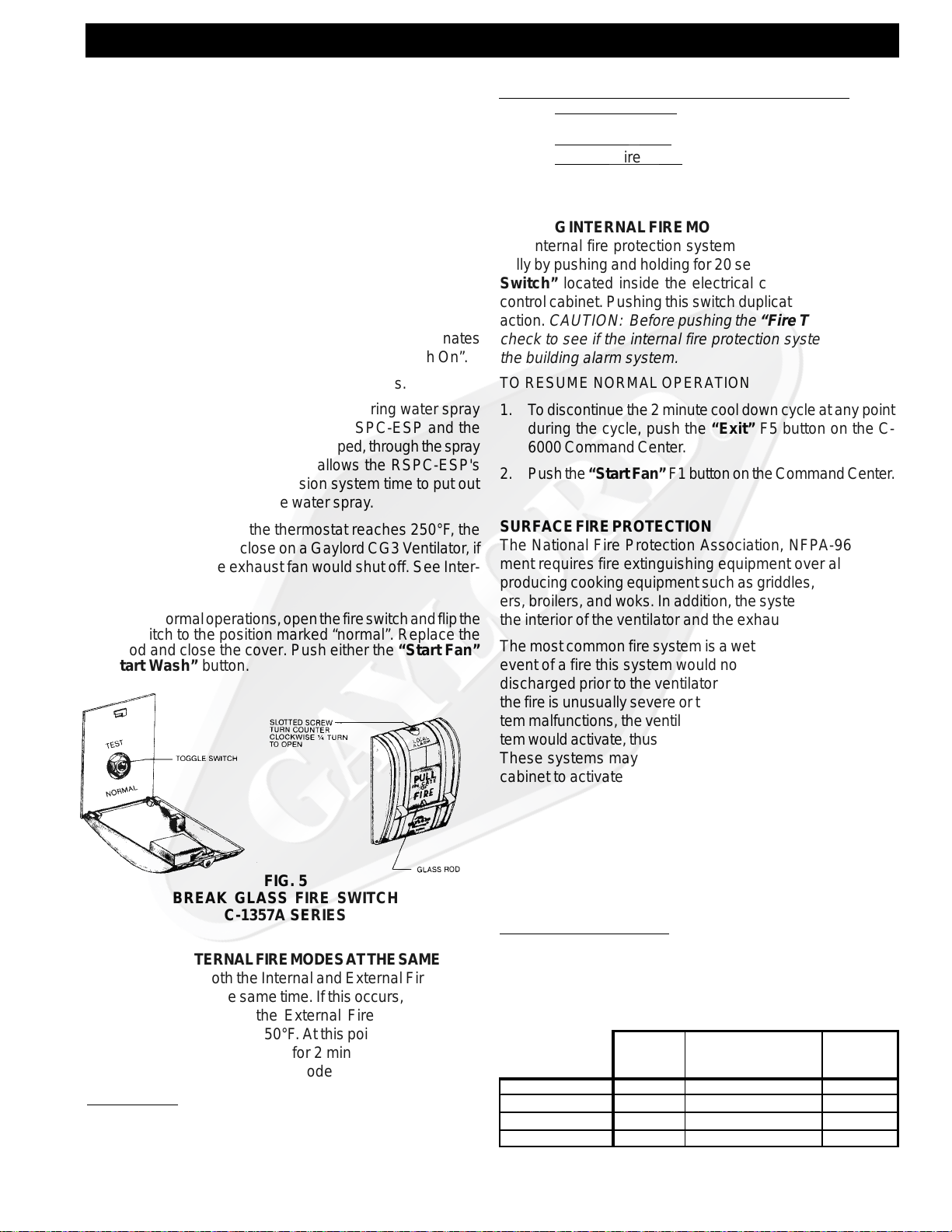

EXTERNAL FIRE MODE

An External Fire Mode is activated by the Pollution Control

Units or Ventilator’s Fire Suppression (Duct, Plenum, Surface/Appliance) system’s microswitch or contacts and/or an

optional break glass fire switch (see Figure 5). T erminals 4

& FS are used for the External Fire Mode, refer to wiring

diagram for details. The break glass fire switch, if used,

would normally be located at the exit of the kitchen. When

the External Fire Mode is activated, the following occurs:

1. The Exhaust Fan comes on immediately if it was off to

help remove smoke, heat, etc.

2. The Supply Fan shuts off immediately.

3. The digital display reads “Ext.FireActive” and alternates

between “Reset FireSwitch” and “Fan On, Wash On”.

4. A red light on the Command Center flashes.

5. After a 60-second delay, a fire smothering water spray

is released into the interior of the RSPC-ESP and the

Gaylord CG3 ventilators, if so equipped, through the spray

nozzles.The 60-second delay allows the RSPC-ESP's

and ventilator’s fire suppression system time to put out

the fire, before starting the water spray .

If the fire intensifies and the thermostat reaches 250°F, the

fire damper would then close on a Gaylord CG3 Ventilator , if

so equipped, and the exhaust fan would shut off. See Inter-

nal Fire Mode.

To resume normal operations, open the fire switch and flip the

toggle switch to the position marked “normal”. Replace the

glass rod and close the cover. Push either the “Start Fan”

or “Start Wash” button.

Summary of Both Fire Modes at the Same Time

1. Internal Fire Mode (until thermostat temperature

drops below 250°F)

2. Cool Down Cycle (for 2 minutes)

3. External Fire Mode (until the External Fire Switch is

reset)

TESTING INTERNAL FIRE MODE

The internal fire protection system may be tested periodically by pushing and holding for 20 seconds, the “Fire Test

Switch” located inside the electrical compartment of the

control cabinet. Pushing this switch duplicates thermostatic

action.

CAUTION: Before pushing the “Fire Test Switch”,

check to see if the internal fire protection system is tied to

the building alarm system.

TO RESUME NORMAL OPERATION

1. To discontinue the 2 minute cool down cycle at any point

during the cycle, push the “Exit” F5 button on the C-

6000 Command Center.

2. Push the “Start Fan” F1 button on the Command Center .

SURFACE FIRE PROTECTION

The National Fire Protection Association, NFPA-96 document requires fire extinguishing equipment over all grease

producing cooking equipment such as griddles, ranges, fryers, broilers, and woks. In addition, the system must protect

the interior of the ventilator and the exhaust duct.

The most common fire system is a wet chemical type. In the

event of a fire this system would normally be activated and

discharged prior to the ventilator’s internal fire protection. If

the fire is unusually severe or the surface fire protection system malfunctions, the ventilator’s internal fire protection system would activate, thus providing a second level of defense.

These systems may be intertied with the ventilator control

cabinet to activate the External Fire Mode.

FIG. 5

BREAK GLASS FIRE SWITCH

C-1357A SERIES

INTERNAL & EXTERNAL FIRE MODES AT THE SAME TIME

It is possible that both the Internal and External Fire modes

can be activated at the same time. If this occurs, the Internal

Fire Mode will override the External Fire mode until the

thermostat(s) cool below 250°F . At this point the Cool Down

Cycle will start counting down for 2 minutes. After the Cool

Down Cycle, the External Fire mode will start.

Special Note: If the control is in the Cool Down Cycle when

the External Fire mode is activated, the Cool Down Cycle

will finish counting down for 2 minutes, before switching to

the External Fire Mode.

FIRE MODE SUMMARY:

Note: The Damper Position applies to a Gaylord CG3 Ventilator, if so equipped.

INTERNAL

FIRE

Exhaust Fan OFF OFF ON

Supply Fan

Damper Position

Water S pray

OFF OFF OFF

FIRE EXHAUST EXHAUST

ON ON ON

COOL DOWN CYCLE

(for Internal Fire

Mode onl

!)

EXTERNAL

FIRE

18

DAILY OPERATION

DAIL Y OPERA TION

TM

All functions of the Gaylord Ventilator and ClearAir

Unit, such

as starting the exhaust fan, starting the wash cycle, etc., are

controlled by the Command Center located on the control

cabinet. Refer to Pages 21 through 25 for detailed instructions on the operation of the Command Center.

COMMAND CENTER

MODEL C-6000 SERIES

CONTROL CABINET

MODEL GPC-6000-ESP SERIES

Starting the Exhaust Fan

TM

To start the exhaust fan and ClearAir

Unit push the “Start

Fan” button on the Command Center. If the Command Center

is programmed to start the fan automatically, then the start

button does not need to be pushed. It is important to start the

exhaust fan before turning on the cooking equipment.

When the exhaust fan is activated the following occurs:

1.The damper on Gaylord's CG3 Ventilator begins opening to

the exhaust position. (if applicable)

2.A green light on the Command Center illuminates.

3.The supply fan comes on.

4.The digital display reads "Starting Fan & Damper Open-

ing" for approximately 5 seconds. Then the digital display

reads "Starting Fan, xx Seconds to Fan On". xx is the

coundown in seconds until the exhaust fan comes on.

5. After the damper fully opens (elapsed time approximately

TM

45 seconds) the ClearAir

Unit exhaust fan starts.

6.The digital display then reads "Fan On 12:00" (current

time) and "Start Wash> F2".

7. The cell status light(s) will come on indicating that the

ESP cells are operating.

Stopping the Exhaust Fan and Starting the Wash Cycle

CAUTION: The cooking equipment must be shut off prior

to shutting off the exhaust fan. Failure to do this will cause

excessive heat buildup and could cause the surface fire

protection system to discharge.

To start the wash cycle push the “Start Wash” button on the

Command Center. If the Command Center is programmed to start

the wash automatically , then the start button does not need to be

pushed. When the wash cycle is activated the following occurs:

1.The exhaust and supply fans shut off.

2. The ESP cells shut off.

3.The damper begins closing forward to the wash position.

This action takes approximately 45 seconds.

4.The digital display reads "Starting Wash, Damper Closing"

for approximately 45 seconds, then the digital display reads

"Starting Wash, Wash On in xx seconds". xx is the countdown in seconds to until the wash starts.

5.After the damper in the ventilator closes to the wash position,

the hot detergent injected water sprays come on to wash

away the grease collected during the day's operation. The wash

cycle stays on for the length of time programmed in the Command Center. The length of the wash cycle may be set between

3 and 9 minutes.Typical settings for the CG3 Ventilator are 3

minutes for light-duty equipment, 5 minutes for medium-duty

equipment and 9 minutes for heavy-duty equipment. The typical

TM

setting for the ClearAir

RSPC-ESP unit is 5 minutes. Refer

to page 20 for details on setting the length of the wash.

6. During a Ventilator wash, the digital display reads "Hood

Wash, Wash #1 xxx seconds." xxx is the countdown in

seconds until this portion of the wash is completed.

7. During an ESP wash, the digital display reads:

"ESP Wash 1, Wash #2 xxx seconds"

"Hot Water Heating, Wash #2 xxx seconds"

"ESP Wash 2, Wash #2 xxx seconds."

"Hot Water Heating, Wash #2 xxx seconds"

"ESP Rinse, Wash #2 xxx seconds"

xxx is the countdown in seconds until this portion of the

wash is completed.

8.The digital display now reads "Fan Off 12:00" (current time)

and Start Fan>F1.

After the wash cycle is completed, wipe the exposed front

surface of the damper at the air inlet slot, as well as other

exposed exterior surfaces.

In very heavy cooking operations it may be necessary to

wash the equipment more than once a day. This can be

done manually by pushing the “Start Wash” button.

NOTE: For proper operation of the wash system there must

be adequate water pressure and temperature.There is a pressure/temperature gauge inside the control cabinet.

Water Pressure 60 psi min. - 80 psi max.

Water temperature 160°F min. - 180°F max.

NOTE: Some control cabinets are equipped with a low de-

tergent switch. If so equipped, the green light will flash if the

detergent tank is empty or if the detergent pump is malfunctioning and detergent is not pumping. The digital display reads

"Low Detergent" and the text alternates from "Fill Tank" and

"Check Pump". If the detergent tank is filled with water the

detergent switch will activate as if there is no detergent.

NOTE: The wash system is designed to remove daily accumulations of grease within the equipment. If the equipment

is not washed a minimum of once during a cooking day, a

grease buildup could accumulate which the wash system

cannot remove. If this occurs, it is recommended that the

equipment be put through several wash cycles by pushing

the “Start Wash” button on the Command Center. If this

does not remove the grease, it will be necessary to remove

the grease manually by using a scraping tool, such as a

putty knife, or retain the services of a commercial hood cleaning service to steam clean or pressure wash the system.

WARNING: Some commercial hood cleaning services blow a fire

retardant chemical into hood and duct systems. Fire retardant chemicals should never be applied to any portion of The Gaylord Ventilator or ESP unit. If retardant is applied, it must be removed.

19

DAILY OPERATION

g

Ventilator wash

The length of the ventilator wash is determined primarily by

the cooking equipment involved. Set the wash length from

3 – 9 minutes for light, medium or heavy duty equipment as

shown on the Recommended Ventilator Wash Time Chart

on this page. Adequate cleaning of the Ventilator is dependent upon water pressure, water temperature, grease accumulation and hours of operation. It may be necessary to

increase the wash cycle time above recommendations depending upon these conditions.

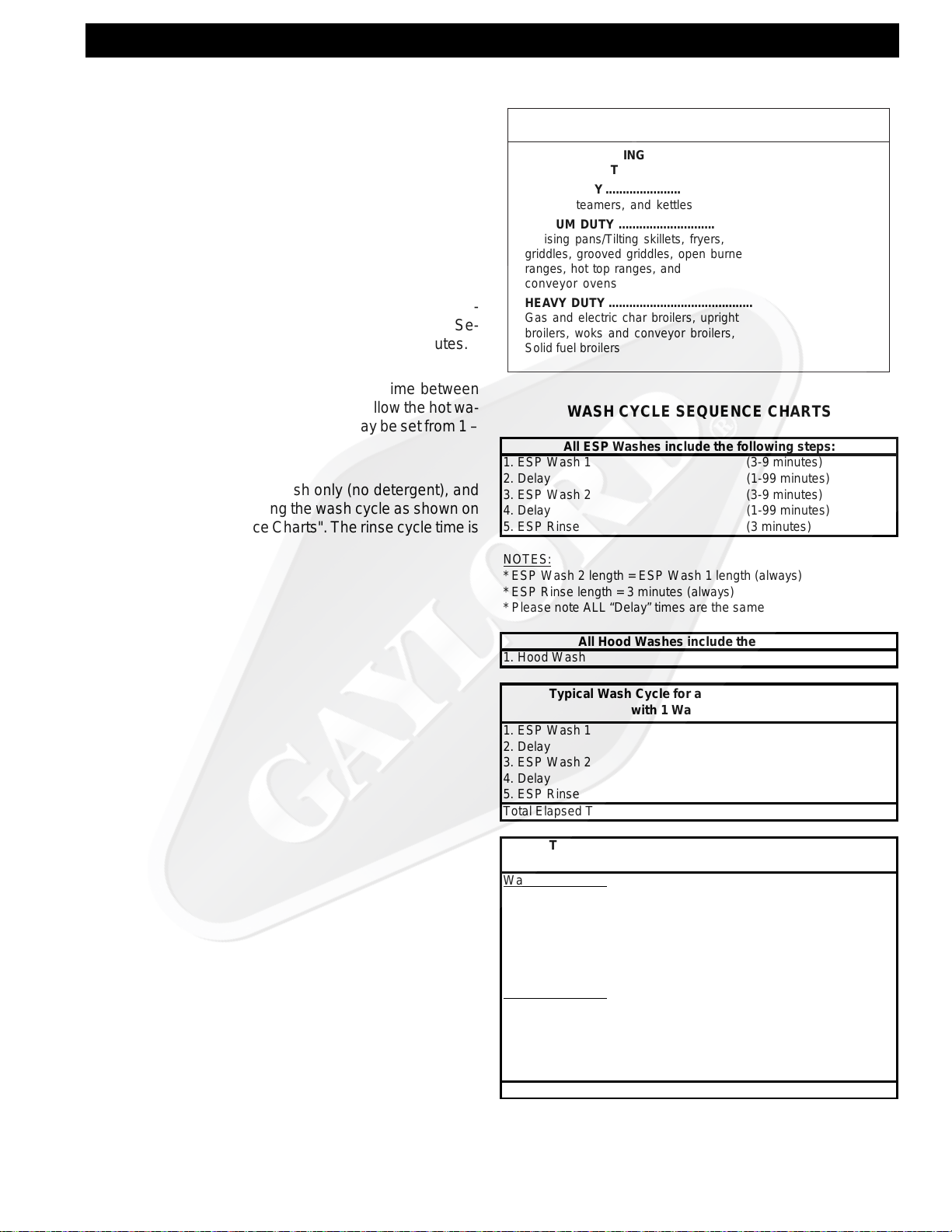

ClearAirTM wash

The length of wash cycle time for the ClearAirTM Unit is nor-

mally set for 5 minutes as shown on the "Wash Cycle Se-

quence Charts". Set length of ESP washes to 5 minutes.

Delay

The "Wash Delay" is used to set the delay time between

each wash. A delay may be necessary to allow the hot wa-

ter system to recover. The W ash Delay may be set from 1 –

99 minutes as required.

Rinse cycle

A rinse cycle is a hot water wash only (no detergent), and

occurs at various times during the wash cycle as shown on

the "Wash Cycle Sequence Charts". The rinse cycle time is

3 minutes.

TYPE OF COOKING RECOMMENDED WASH

EQUIPMENT TIMES (MINUTES)

LIGHT DUTY ........................................... 3

Ovens, steamers, and kettles

MEDIUM DUTY ....................................... 5

Braising pans/Tilting skillets, fryers,

griddles, grooved griddles, open burner

ranges, hot top ranges, and

conveyor ovens

HEAVY DUTY.......................................... 9

Gas and electric char broilers, upright

broilers, woks and conveyor broilers,

Solid fuel broilers

WASH CYCLE SEQUENCE CHARTS

All ESP Washes include the followin

1. ESP Wash 1 (3-9 minutes)

2. Delay (1-99 minutes)

3. ESP Wash 2 (3-9 minutes)

4. Delay (1-99 minutes)

5. ESP Rinse (3 minutes)

NOTES:

* ESP Wash 2 length = ESP Wash 1 length (always)

* ESP Rinse length = 3 minutes (always)

* Please note ALL “Delay” times are the same

steps:

TRAHCEMITHSAWROTALITNEVDEDNEMMOCER

All Hood Washes include the following:

1. Hood Wash (3-9 minutes)

Typical Wash Cycle for a Single Pass (1ESP) unit

with 1 Wash manifold:

1. ESP Wash 1 (5 minutes)

2. Delay (1 minute)

3. ESP Wash 2 (5 minutes)

4. Delay (1 minute)

5. ESP Rinse (3 minutes)

Total Elapsed Time: 15 minutes

Typical Wash Cycle for a Single Pass (1ESP) unit

with 2 Wash manifolds (DW):

Wash Manifold #1

1. ESP Wash 1 (5 minutes)

2. Delay (1 minute)

3. ESP Wash 2 (5 minutes)

4. Delay (1 minute)

5. ESP Rinse (3 minutes)

6. Delay (1 minute)

Wash Manifold #2

7. ESP Wash 1 (5 minutes)

8. Delay (1 minute)

9. ESP Wash 2 (5 minutes)

10. Delay (1 minute)

11. ESP Rinse (3 minutes)

Total Elapsed Time: 31 minutes

20

MODEL C-6000-ESP SERIES COMMAND CENTER - INSTRUCTIONS

General Description:

The C-6000-ESP Command Center is designed to start and

stop the exhaust fan and wash up to 5 groups of ventilators

and a ClearAirTM RSPC-ESP unit in sequence with a delay

period between each wash. A sequence wash may be necessary if the building’s hot water system is not capable of

supplying the required volume of water at one given time.

The exhaust fan and wash sequence may be started Manu-

ally by pushing the “Start Fan” or “Start Wash” buttons, or

may be programmed for Automatic operation.

Programmed operations may include:

1.Starting the exhaust fan once within a 24-hour period.

2.Stopping the exhaust fan and starting the wash cycle se-

quence once within a 24-hour period.

3.Programming the length of the wash cycles and delay

periods between the wash cycles. The maximum length

of a wash cycle is 9 minutes. The maximum length of the

delay period is 99 minutes.

4.Skipping a day so the exhaust fan and wash cycle do not

operate for holidays or specific days within a 7-day week

when the kitchen is not operating.

The C-6000-ESP Command Center provides information and

programming for various functions by accessing nine differ-

ent menu catagories. An overview of the nine menu items

are as follows:

1.Cycle T ype: T oggles each wash solenoid between a Hood

wash and an ESP wash. Preset at factory and protected

by a password.

2.Detergent: Displays Toll-Free Number to order detergent:

800-286-2010.

3.Wash Length: Sets length of each wash cycle from 3 to 9

minutes.

4.Delay Time (for sequence wash units only): Sets delay

between washes from 1 minute to 99 minutes.

5.Set Clock: Day, hour and minutes.

6.AutoMode [M or A]: Sets the C-6000-ESP to Manual or

Automatic modes. In Automatic mode, the C-6000-ESP

will start the Fan and Wash at the preset times that were

set using the Set Wash Times option.

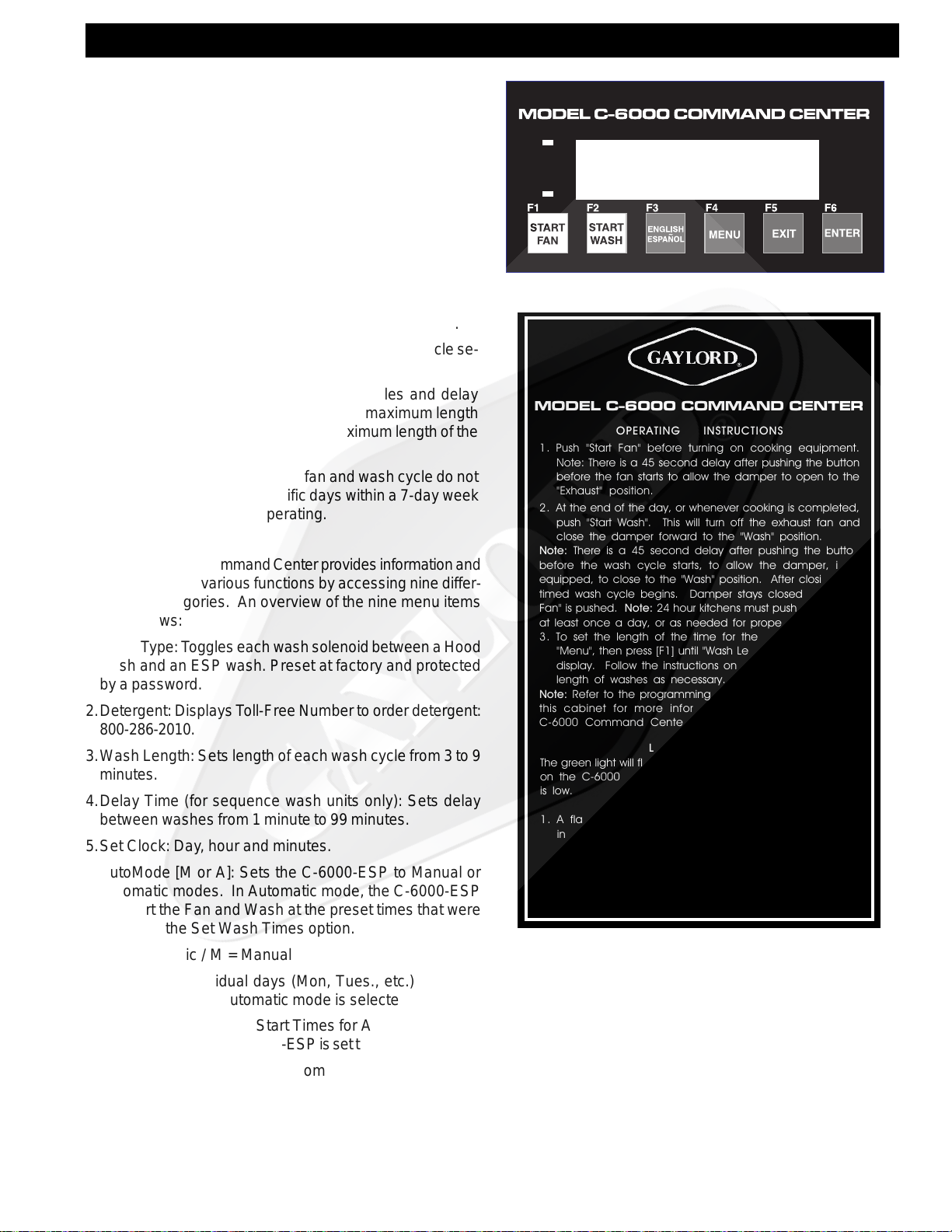

MODEL C-6000 COMMAND CENTER

OPERATING INSTRUCTIONS

1. Push "Start Fan" before turning on cooking equipment.

Note: There is a 45 second delay after pushing the button

before the fan starts to allow the damper to open to the

"Exhaust" position.

2. At the end of the day, or whenever cooking is completed,

push "Start Wash". This will turn off the exhaust fan and

close the damper forward to the "Wash" position.

Note: There is a 45 second delay after pushing the button

before the wash cycle starts, to allow the damper, if so

equipped, to close to the "Wash" position. After closing, the

timed wash cycle begins. Damper stays closed until "Start

Fan" is pushed. Note: 24 hour kitchens must push "Start Wash"

at least once a day, or as needed for proper cleaning.

3. To set the length of the time for the wash cycle, press

"Menu", then press [F1] until "Wash Length" appears on the

display. Follow the instructions on the display to edit the

length of washes as necessary.

Note: Refer to the programming instructions on the inside of

this cabinet for more information on programming the

C-6000 Command Center.

LOW DETERGENT

The green light will flash and "Low Detergent" will be displayed

on the C-6000 Command Center indicating the detergent

is low.

FIRE CONDITION

1. A flashing red light and the message "Ext. Fire Active"

indicates the control is in an External Fire Mode - exhaust

fan on, damper open, and water wash nozzles on.

2. A continuous red light and the message "Fire In Hood"

indicates the control is in an Internal Fire Mode - exhaust

fan off, damper closed, and water wash nozzles on.

A = Automatic / M = Manual

Also allows individual days (Mon, Tues., etc.) to be set

ON or OFF when Automatic mode is selected.

7.Set Wash Times: Sets Start Times for Automatic start of

Fan and wash when C-6000-ESP is set to Automatic mode.

8.Wash Test: Runs through a complete Wash Cycle with

decreased times.

Damper Closing Time = 10 sec.

Wash Times = 10 sec.

Water Heating Time = 10 sec.

Exits menu when finished.

C-6000-ESP COMMAND CENTER

9. Number of Washes: Preset at factory and protected with

a password.

Allows the number of washes to be changed from 1 to 13

(S1 to S13).

21