MODEL “PG-BDL”

SERIES FILTER HOOD

GENERAL SPECIFICATIONS

Furnish Gaylord Exhaust Hood Model “PG-_____-BDL-________” as

shown on plans and in accordance with the following specifications:

GENERAL: Each exhaust hood shall be designed specifically for the

cooking equipment being covered.

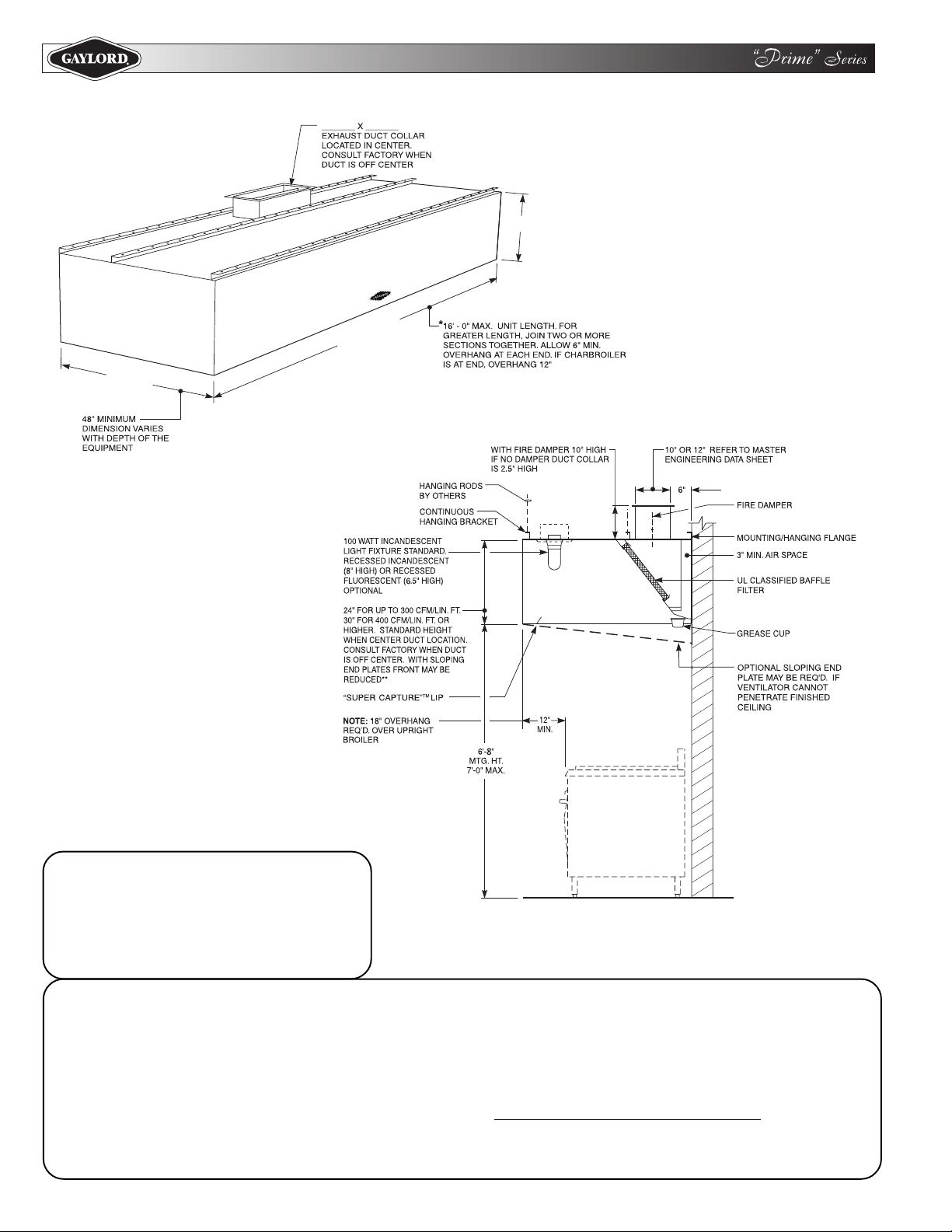

The exhaust hood shall include a stationary grease collecting gutter at the

bottom of the grease extraction device, sloped to a drain at one end to a

removable stainless steel grease cup. The sloped gutter shall be concealed by an apron which extends the full length of the hood. Each exhaust

hood shall contain one or more stainless steel baffle filters. Filters shall be

self draining, UL classified and mounted no less than a 45° angle from

horizontal.

The hood shall also include a built in 3" air space at the rear for compliance

to NFPA-96 when mounting against a limited combustible wall. Continuous

front and rear brackets shall be provided to facilitate mounting to the wall

and hanging from the overhead building structure.

o Fuse Link Activated Fire Damper (Series Prefix PG) The exhaust

hood shall include a fire damper located at the exhaust duct collar. The

damper shall be activated by fuse link(s), and upon activation, the damper

shall close, and act as a fire barrier to prevent flame from entering the duct

system. The damper shall be manually reset without the use of tools and

without opening or removing access panels. The exhaust hood shall be

UL listed under the category “Exhaust Hood with Exhaust Damper.”

o Exhaust Hood without Fire Damper (Optional - Series Prefix PGND) The exhaust hood shall be UL listed under the category “Exhaust

Hood without Exhaust Damper.”

ITEM NO. _______________

APPLICATION

Wall mounted canopy for use over all types of equipment; ovens,

broilers, griddles, fryers, ranges, steam equipment, etc.

FEATURES

• UL, CUL and NSF Listed

• “Super Capture”TM Lip - Enhances Capture

and Reduces Exhaust Volume

• Complies With The IMC, UMC, BOCA and

SBCCI Mechanical Codes

• Complies With All Requirements of NFPA-96

CONSTRUCTION: The ventilator shall be of all stainless steel construc-

tion, not less than 18 gauge, type 300 series. All exposed surfaces shall

be a number 4 finish. The use of aluminized steel, galvanized steel, or 430

stainless steel is not acceptable.

LIGHT FIXTURES: The exhaust hood shall be equipped with o 100 watt

surface mounted incandescent, o 150 watt recessed incandescent, o

recessed fluorescent, light fixtures. Light fixtures shall be factory prewired to a single connection point. Exhaust hoods built in multiple sections

shall be furnished with coiled flex conduit for interconnecting sections, in

the field by others.

ACCEPTANCE & APPROVALS: The exhaust hood shall be UL, CUL and

NSF listed. The exhaust hood shall comply with all requirements of NFPA96, IMC, UMC, BOCA, and SBCCI model codes.

OPTIONAL ACCESSORIES

• Decorative Facings and Trim

• Built-in Light & Fan Switch

• Built-in Fire Extinguishing Systems

DESCRIPTION

The Gaylord “PG” series exhaust hood is an economy hood that

maintains the “standards” in materials, construction and quality found

in all Gaylord Water-Wash and Non Water-Wash high efficiency

extractor ventilators. The “PG” series hood uses stainless steel baffle

filters as a standard. A fuse link activated fire damper is standard, or

the hood may be provided without a fire damper.

The “PG” series has been tested to UL standard 710 and is listed either

under the category “Exhaust Hood with Exhaust Damper” or “Exhaust

Hood without Exhaust Damper.”

OPTIONAL EQUIPMENT

1. Exhaust Fans, Supply Fans, & Roof Top Units

2. Fire Extinguishing Systems

3. Utility Distribution Systems

4. Pollution Control Systems

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • TUALATIN, OREGON 97062 U.S.A.

PHONE: 800-547-9696 • FAX: 503-692-6048 • email: info@gaylordusa.com

www.gaylordusa.com

MODEL “PG - ___ -BDL - ___ - ____”

ND LOW

PROFILE

(LP)

DEPTH

OF

HOOD

For exact model designation add appropriate suffixes.

Example: “PG-BDL-54”

If low profile add suffix “LP” after BDL.

**

LOW PROFILE MINIMUM HEIGHT AT FRONT:

Light & Medium Duty Equipment (400°F) 12" Min.

Heavy Duty Equipment (600°F) 18" Min.

Extra Heavy Duty Equipment (700°F) "LP" Not Available

ITEM NO. ______________________ EST. WT. _________________________

LENGTH _____________ WIDTH ______________ HEIGHT ______________

EXHAUST - CFM ________________ DUCT SIZE ____________ S.P. ______

LIGHTS VOLTAGE

qq

100W SURFACE INCANDESCENT

q

qq

qq

150W RECESSED INCANDESCENT

q

qq

q q

RECESSED FLUORESCENT

q

q q

q q

120 VOLTS

q

q q

q q

220/240 VOLTS

q

q q

The manufacturer reserves the right to

modify the materials and specifications resulting from a continuing program of product improvement or the

availability of new materials

TYPICAL SECTION VIEW

ENGINEERING DATA

Mechanical Requirements

The amount of exhaust volume required is dependent upon the type of

cooking equipment and the type and volume of cooking. Refer to the Master

Engineering Data Sheet in the Engineering Data section of the Gaylord

catalog for the charts on determining exhaust volume, duct sizes, and static

pressure.

Electrical

A Gaylord stop/start switch, Model C-150, may be provided as an option for

each exhaust fan. Lights to be on separate circuit, 120 volt standard, 220/

240 volt optional.

Form No. PG-BDL 0307 / 30716 © Copyright 2007, Gaylord Industries Litho USA

Ventilator Lengths

Maximum unit length 16'-0". For greater lengths, join two or more sections

together. Check to ensure that there is adequate access into building and

kitchen area.

Note: Ventilators manufactured outside North America; maximum unit length

*

10'-0".

Hanging Weight

Ventilator Width 48" 54" 60"

Wt. / Lineal ft. Lbs. 65 70 75

Loading...

Loading...