Gaylord PG Installation Manual

EFFECTIVE DA TE 3-2001

PROOF

THE GAYLORD INSTALLATION,

OPERATION & MAINTENANCE MANUAL

for

“PG”, “PG-ND”, “PGX” and “PGX-ND”

5.5.97

#

1

SERIES HOODS

GAYLORD INDUSTRIES, INC.

10900 S.W. AVERY STREET • P.O. BOX 1149 • TUALATIN, OREGON 97062-1149 U.S.A.

1-800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

An Illinois Tool Works Company

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES, INC.

World Headquarters: P .O. Box 1149 • Tualatin, Oregon 97062-1149 U.S.A.

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. We are proud to be able

to provide you with a quality product that incorporates

the latest engineering concepts and is a result of over

50 years of experience in the foodservice kitchen exhaust

industry .

If you have other Gaylord equipment such as a Gaylord

Utility Distribution System, Quencher Fire Protection System, or Roof Top Air Handling Equipment, etc., please

refer to the corresponding supplementary equipment

manuals.

If you have further questions, please call us toll free at

1-800-547-9696. We are more than happy to help.

Sincerely,

Gaylord Industries, Inc.

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: gaylord@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062-8549 U.S.A.

TABLE OF CONTENTS

OPERATION .......................................................................................................... 1

STANDARD MODELS............................................................................................ 2

MAINTENANCE AND CLEANING INSTRUCTIONS.............................................. 3

TROUBLESHOOTING ........................................................................................... 4

MEASURING BAFFLE FILTER VELOCITY ........................................................... 6

MEASURING CARTRIDGE EXTRACTOR VELOCITY.......................................... 7

PARTS LIST........................................................................................................... 8

INSTALLATION REQUIREMENTS ........................................................................ 9

HOOD START-UP INSPECTION REPORT ........................................................... 10

WARRANTY

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, ST ORED

IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR OTHERWISE WITHOUT PRIOR

WRITTEN PERMISSION OF GAYLORD INDUSTRIES, INC. COPYRIGHT 2001.

© Copyright 2001, Gaylord Industries, Inc.

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product improvement or the availability of new materials.

ADDITIONAL COPIES $7.00

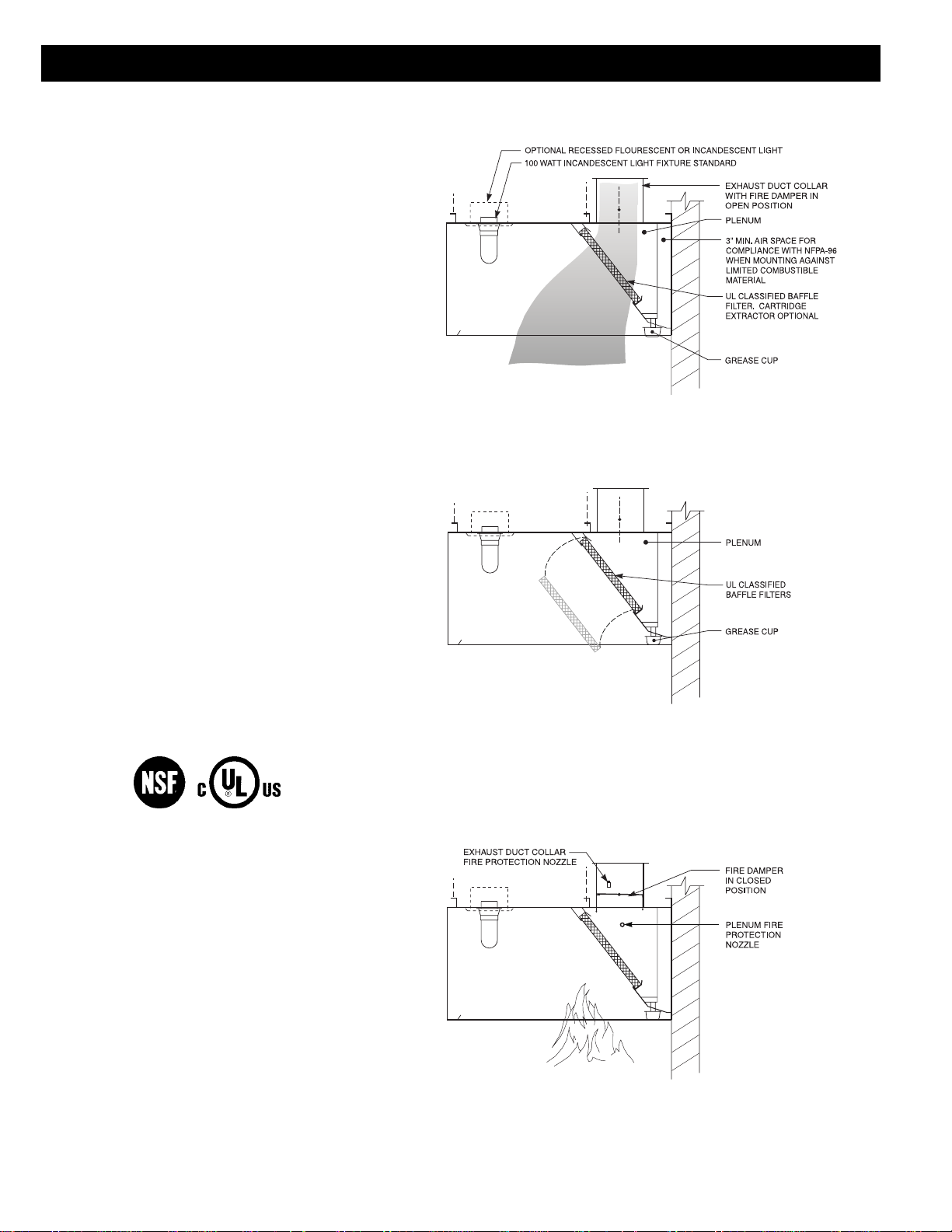

FAN OPERATION

To operate the exhaust fan turn on the fan switch that is typically mounted on a wall near the hood. The “PG” hood may

be equipped with a fan and/or light switch mounted on the

face of the hood.

GREASE EXTRACTION

The Gaylord “PG” Series Hood, as a standard, utilizes UL Classified filters to extract the grease from the airstream. The filter

is a self-balancing baffle type and is constructed of aluminum

or stainless steel. Typical grease extraction rate varies between 40% and 65%.

The hood may be equipped with optional extractor cartridges,

as shown in figure 6 page 3, that have a grease extraction

efficiency of up to 90%. When equipped with cartridges, the

model number prefix is “PGX”. Refer to the nameplate on the

hood for exact model number. (See Figure 7, page 5.)

CLEANING

At the end of the cooking day, or at periodic intervals, the filters

or cartridges are removed and washed either in a dishwasher

or soaked in a deep well sink, scrubbed and rinsed.

FIRE PROTECTION

NFPA #96 requires the use of surface, duct and plenum

protection on all hoods.

These systems are designed to detect and extinguish fires on

the cooking surface, within the plenum and at the duct collar.

Refer to the fire extinguishing system owner’s manual for

operation and maintenance instructions of these systems.

The “PG” hood is equipped with an exhaust duct fire damper.

In the event of a fire, should the fuse link reach its activation

point of 212 °F, the damper would close preventing the flames

from entering the ductwork and spreading to other parts of the

building. The fire is contained in the kitchen area where it can

be properly fought.

The hood may be supplied without a fire damper which is

designated by the suffix “ND” in the model number. Example:

“PG-ND”. Refer to the nameplate on the hood for the exact

model number. (See Figure 7, page 5).

OPERATION

GREASE EXTRACTION

CLEANING

FIRE PROTECTION

FIGURE 1

1

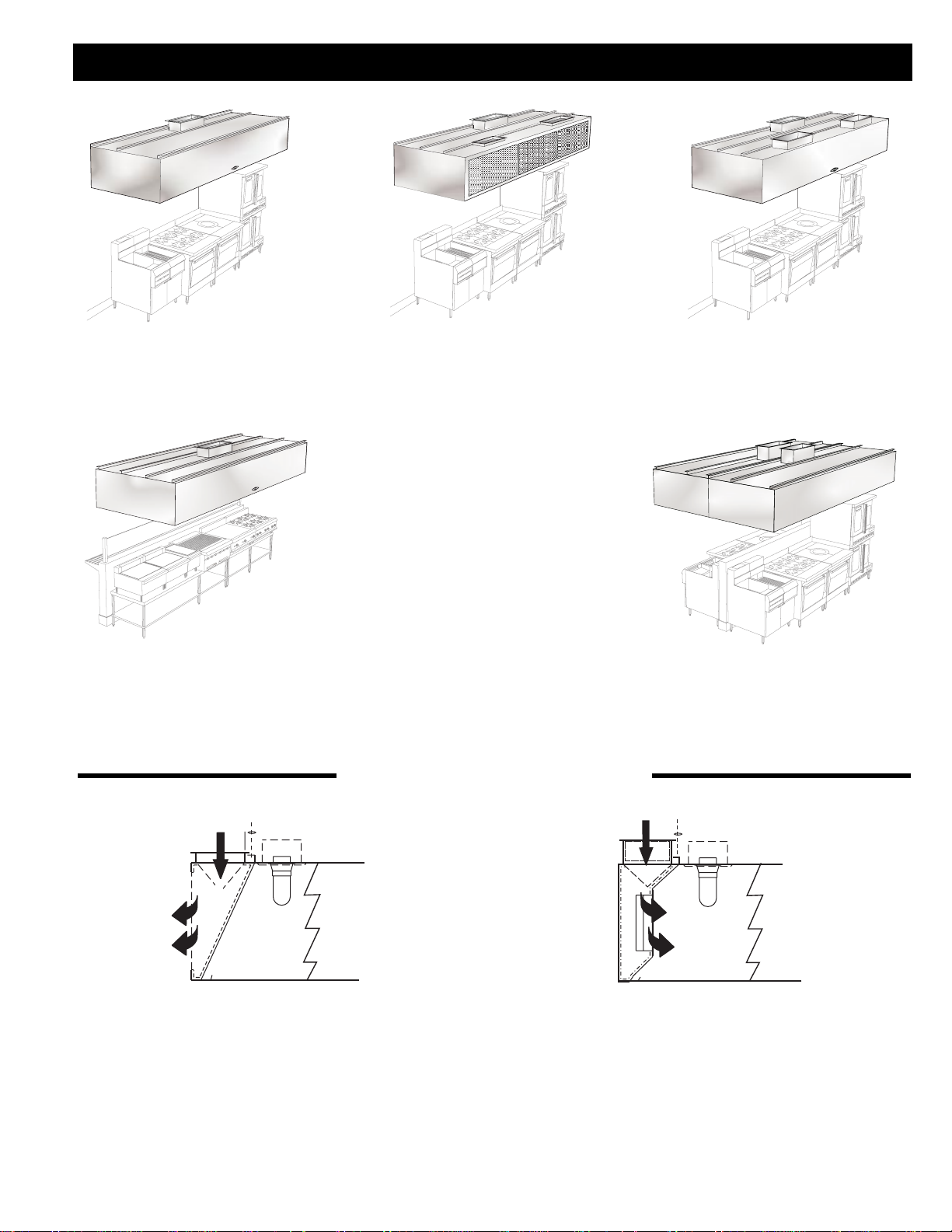

STANDARD MODELS

MODEL “PG-BDL”

APPLICATION - Wall mounted

canopy style.

MODEL “PG-BDL-BBC-CL”

APPLICATION - Used for cafeteria lines or

any other single line island arrangement.

The make-up air options shown below are available on all BDL Series V entilators.

MODEL “PG-BDL-MAW”

APPLICATION - W all mounted canopy

style with perforated panels for front face

make-up air discharge.

FIGURE 2

Standard Ventilator Models

STANDARD MAKE-UP AIR OPTIONS

MODEL “PG-BDL-MAI”

APPLICATION - W all mounted canopy

style with registers for internal

make-up air discharge.

MODEL “PG-BDL-BB”

APPLICATION - Used for typical island style

back to back cooking arrangement.

MODEL “MAW” SERIES

FRONT FACE DISCHARGE

This method of introducing make-up air into the

kitchen is flexible and has many advantages.

Make-up air is discharged through stainless steel

perforated panels as illustrated (MAW Series) or

optional registers. Typical supply volume is 80%

of the exhaust or more, depending on air balance desired. Supply air temperatures should

range from 60 to 65°F (16 to 18°C), but may be

as low as 50°F (10°C) depending on air volume,

distribution, and internal heat load.

FIGURE 3

Standard Make-up Air

Options

2

MODEL “MAI” SERIES

INTERNAL DISCHARGE

This method of introducing air into the hood is

typically referred to as the “short circuit” method.

This design has very limited applications and the

amount of supply air able to be introduced varies

considerably with the type of cooking equipment.

This air may be untempered air in most areas

depending upon climatic conditions and the type

of cooking equipment. The difference between

the quantity of air being introduced and the

amount of air being exhausted must be supplied

through a traditional make-up air system.

Loading...

Loading...