Gaylord GX2-UV-BDL-DS-CL Specifications

Ultima VentTM with UV Technology

MODEL “GX2-UV-BDL-DS-CL”

CARTRIDGE EXTRACTOR VENTILATOR WITH UV

GENERAL SPECIFICATIONS

Furnish Gaylord Ventilator Model “GX2-UV-___-BDL-DS-CL____________”

as shown on plans and in accordance with the following specifications:

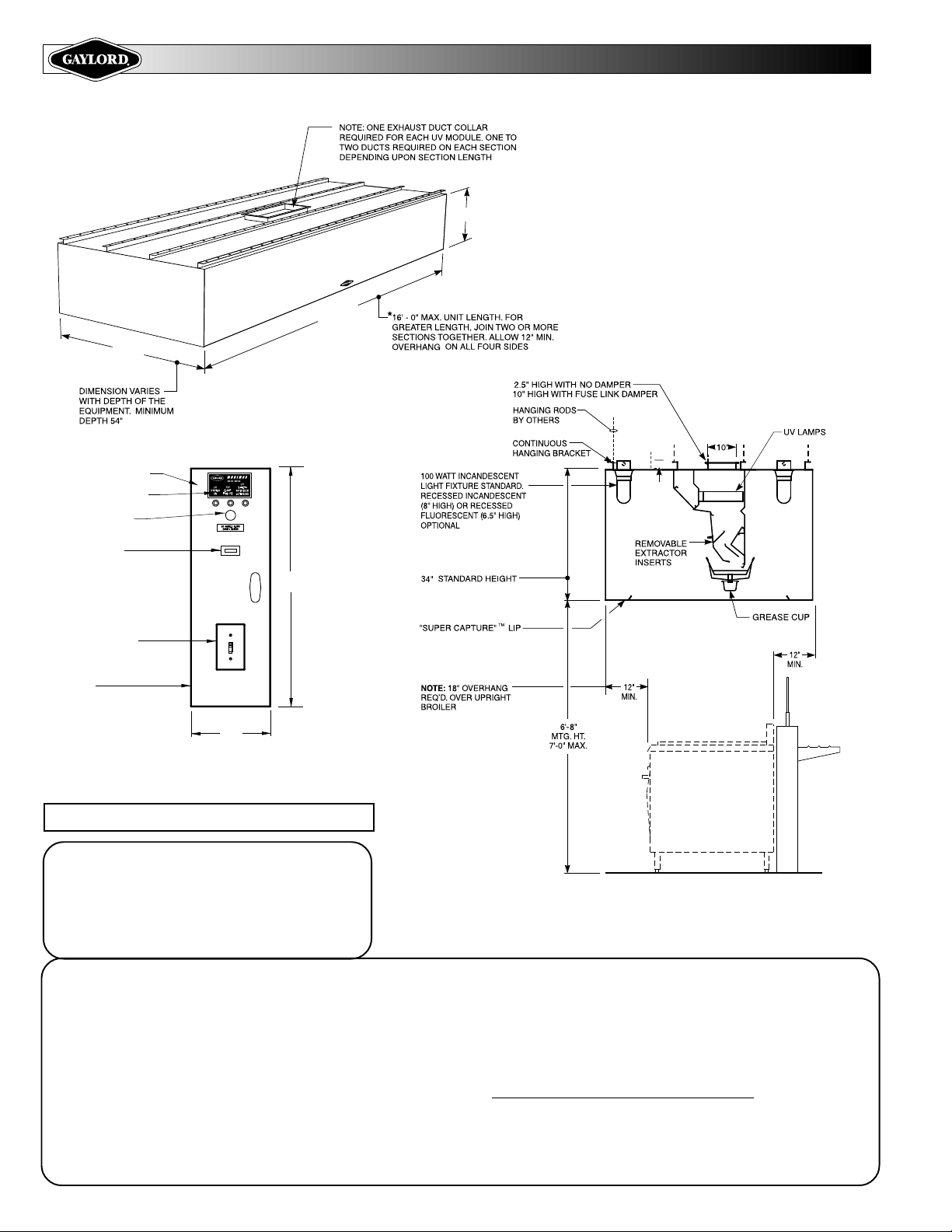

GENERAL: Each ventilator shall have one high-velocity centrifugal

grease extractor with two air inlet slots, one on each side of the extractor.

One slot shall have an adjustable baffle to regulate the ration of exhaust

volume between the two slots. The extraction chamber shall contain one

or more removable “extractor inserts” with a grease extraction efficiency

of 90% of the mechanically extractable grease particulate. The extractor

insert shall include a built-in particulate separator creating one integral

extractor unit to remove for cleaning. Each extractor includes a Gaylord

Extractor Monitor ("GEM") to ensure that all cartridges are in place before

the UV lamps can operate. It shall also include ultraviolet lamps to remove

a majority of the remaining particulate for a total grease extraction

efficiency of up to 99% when operated and maintained in accordance with

the Gaylord Technical Manual and design specificiations. Extractor

inserts shall be constructed of stainless steel and contain full-length, selfdraining baffles. Extractors shall be easily removable, for periodic cleaning, from the floor area immediately in front of the equipment by utilizing an

extractor removal tool. The grease collecting gutter at the bottom of the

extractor housing shall slope to a drain at one end of the ventilator to a

removable stainless steel grease cup. The sloped gutter shall be

concealed by an apron which extends the full length of the hood. The

Ventilator shall include a "Super Capture"TM lip on the front panel for

enhancement of smoke and grease capture. Continuous brackets shall

be provided to facilitate hanging from the overhead building structure.

❏ (Optional) The ventilator shall include “Custom Air” baffles to reduce the

exhaust volume over specific cooking equipment as indicated on the plans

(add suffix “CA” to model number). The ventilator shall operate at air

quantities and static pressure as indicated on plans.

❏ Fuse Link Activated Fire Damper Option (series prefix “GX2-UVFDD”) The damper shall be activated by fuse link(s) located at the duct

collar. The ventilator shall be UL listed under the category “Exhaust Hood

with Exhaust Damper”.

❏ Ventilator without Fire Damper Option - (series prefix “GX2-UVND”) The ventilator shall be UL listed under the category “Exhaust Hood

without Exhaust Damper”.

ULTRAVIOLET LIGHT SECTION: The ventilator shall include ultraviolet

lamps mounted in modules located in the plenum section. There shall be

one or more UV modules, as dictated by the ventilator length, and each

module shall be on a slide track for easy removal. Access to the modules

shall be through keyed hinged doors, and shall include an interlock switch

to shut off the lamps in the event the doors are opened during operation.

A pressure switch shall be provided to monitor the airflow to prevent

operation of the lamps when the airflow is inadequate. A Gaylord Extractor

Monitor (“GEM”) shall be provided to shut off the lamps when a cartridge

is removed. Mounted on the face of the plenum of each ventilator section

shall be indicator lights to monitor “UV System On”, “UV Lamp Failure” and

“UV Safety Interlock Activated”. A duplicate set of these lights shall be

mounted on the ventilator control cabinet, Model CUV-100. The control

panel shall be equipped with an audible alarm indicating there is a lamp

failure or one of the safety interlock switches has been activated.

ITEM NO. _______________

APPLICATION

Used for cafeteria lines or single line island arrangement.

CONSTRUCTION: The ventilator shall be of all stainless steel

construction, not less than 18 gauge, type 300 series. All exposed

surfaces shall be a number 4 finish. The use of aluminized steel,

galvanized steel, or 430 stainless steel is not acceptable.

ELECTRICAL: The ventilator shall be factory pre-wired to single

connection points. On multiple section ventilators power for the UV

lamps must be supplied to each section. Wiring for controls and light

fixtures shall be furnished with coiled flex conduit for interconnecting

sections by applicable trades.

LIGHT FIXTURES: The ventilator shall be equipped with ❏ 100 watt

surface mounted incandescent, ❏ 150 watt recessed incandescent,

❏ recessed fluorescent, light fixtures. Light fixtures shall be factory

pre-wired to a single connection point. Ventilators built in multiple

sections shall be furnished with coiled flex conduit for interconnecting

sections.

ACCEPTANCE & APPROVALS: The ventilator shall be UL, CUL

and NSF listed. The ventilator shall comply with all requirements of

NFPA-96, IMC, UMC, BOCA and SBCCI model codes.

Patent Pending

GAYLORD INDUSTRIES

10900 SW AVERY ST. • TUALATIN, OREGON 97062 U.S.A.

PHONE: 800-547-9696 • FAX: 503-692-6048 • email: info@gaylordusa.com

www.gaylordusa.com

Ultima VentTM with UV Technology

ALL STAINLES STEEL

UV STATUS LIGHTS

AUDIBLE ALARM

CANCEL BUTTON

HOUR METER

MODEL “GX2-UV-___-BDL-DS-CL-____”

**

DAMPER OPTION

FDD = Fuse link damper at the duct collar

**

ND = No damper

DEPTH OF

VENTILATOR

For exact model designation add depth

following the letters “GX2-UV-ND-BDL-DS-CL”.

Example: “GX2-UV-ND-BDL-DS-CL-60”

34"

EXHAUST FAN/

SYSTEM ON/OFF

SWITCH

7" DEEP

8"

CUV-100

CONTROL CABINET

The manufacturer reserves the right to modify the materials and specifications resulting

from a continuing program of product improvement or the availability of new materials.

ITEM NO. _____________________ EST. WT. ________________________

LENGTH _____________ WIDTH ______________ HEIGHT ______________

LIGHTS ____________

qq

q

100W SURFACE INCANDESCENT

qq

qq

q

150W RECESSED INCANDESCENT

qq

q q

q

RECESSED FLUORESCENT

q q

ENGINEERING DATA

Mechanical Requirements

Exhaust volume depends upon the type of cooking equipment and the type and volume

of cooking. Refer to the Master Engineering Data Sheet in the Engineering Data section

of the Gaylord catalog for the charts to determine exhaust and supply volume, S.P.,

duct, hot water, and drain sizes. The standard “GX2-UV-BDL-DS-CL” ventilator

operates at 250 CFM/lin. ft. on the heavy side and 150 CFM/lin. ft. on the light side

for a total of 400 CFM/Lin. ft. If the cooking equipment requires more exhaust, as

determined by the Master Engineering Data Sheet, it may be necessary to use backto-back ventilator model “GX2-UV-BDL-BB” series (consult factory).

Electrical

o Provide 120 volt 20 amp, o 220/240 volt, 50-60 Hz., 24 hour service to

Gaylord CUV-100 Control Cabinet (refer to illustration above). To be fused

separately. Provide a separate 120 volt 20 amp service to each ventilator

section to power UV lamps. Ventilator lights to be on separate circuit, 120

volt standard, 220/240 volt optional.

TYPICAL SECTION VIEW

Ventilator Lengths

Maximum unit length 16'-0" . For greater lengths, join two or more sections

together. Check to ensure that there is adequate access into building and kitchen

area.

Note: Ventilators manufactured outside North America; maximum unit length

*

10'-0".

Hanging Weight

Ventilator Width 4'-6" 5'-0" 5'-6"

Wt. / lineal ft. lbs. 120 125 130

Form No. GX2-UV-BDL-DS-CL 706-30817 © Copyright 2006, Gaylord Industries Litho USA

Loading...

Loading...