EFFECTIVE DATE 5-14-03

THE

GAYLORD VENTILATOR

TECHNICAL MANUAL

FOR THE GRAND “GX2-FDD” SERIES

NON WATER-WASH VENTILATORS

GAYLORD INDUSTRIES

10900 S.W. AVERY STREET • P.O. BOX 1149 • TUALATIN, OREGON 97062-1149 U.S.A.

800-547-9696 • 503-691-2010 • FAX: 503-692-6048 • email: info@gaylordusa.com

“Undisputed World Leader in

Engineered Systems for

Commercial Kitchens”

tm

GAYLORD INDUSTRIES

World Headquarters: P.O . Bo x 1149 • T ualatin, Oregon 97062-1149 U .S .A.

To Our Customers. . .

Congratulations on your recent purchase of a Gaylord

kitchen exhaust hood system. W e are proud to be ab le

to provide you with a quality product that incorporates

the latest engineering concepts and is a result of over

50 years of experience in the foodservice kitchen

exhaust industry.

If you have other Gaylord equipment such as a Gaylord

Utility Distribution System, Quencher Fire Protection Sys-

tem, or Roof Top Air Handling Equipment, etc., please

refer to the corresponding supplementary equipment

manuals.

If you have further questions, please call us toll free at

1-800-547-9696 or email:info@gaylordusa.com. We are

more than happy to help.

Sincerely,

Gaylord Industries

PHONE: 503-691-2010 • 800-547-9696 • FAX: 503-692-6048 • email: gaylord@gaylordusa.com • www.gaylordusa.com

COMMERCIAL KITCHEN EXHAUST SYSTEMS • FIRE PROTECTION • UTILITY DISTRIBUTION • ROOF TOP UNITS • POLLUTION CONTROL

STREET ADDRESS: 10900 S.W. Avery Street, Tualatin, Oregon 97062-8549 U.S.A.

TABLE OF CONTENTS

“GX2-FDD” SERIES PRINCIPLE OF OPERATION ............................................... 3

STANDARD MODELS ............................................................................................ 6

MAINTENANCE AND CLEANING INSTRUCTIONS.............................................. 7

TROUBLESHOOTING ........................................................................................... 8

MEASURING INLET SLOT VELOCITY ................................................................. 10

WIRING DIAGRAM ................................................................................................ 13

PARTS LIST ........................................................................................................... 14

START-UP INSPECTION REPORT ....................................................................... 15

WARRANTY................................................................................. Inside back cover

PATENT NUMBERS

U.S.A.: 4,266,529

4,281,635

4,356,870

CANADA: 1,139,151

1,155,366

GERMANY: 8,034,240

ALL RIGHTS RESERVED. NO PART OF THIS BOOK MAY BE REPRODUCED, STORED

IN A RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM BY AN ELECTRIC, MECHANICAL, PHOTOCOPYING, RECORDING MEANS OR O THERWISE WITHOUT PRIOR

WRITTEN PERMISSION OF GAYLORD INDUSTRIES, INC. COPYRIGHT 2003.

© Copyright 2003, Gaylord Industries

The manufacturer reserves the right to modify the materials and

specifications resulting from a continuing program of product improvement or the availability of new materials.

ADDITIONAL COPIES $10.00

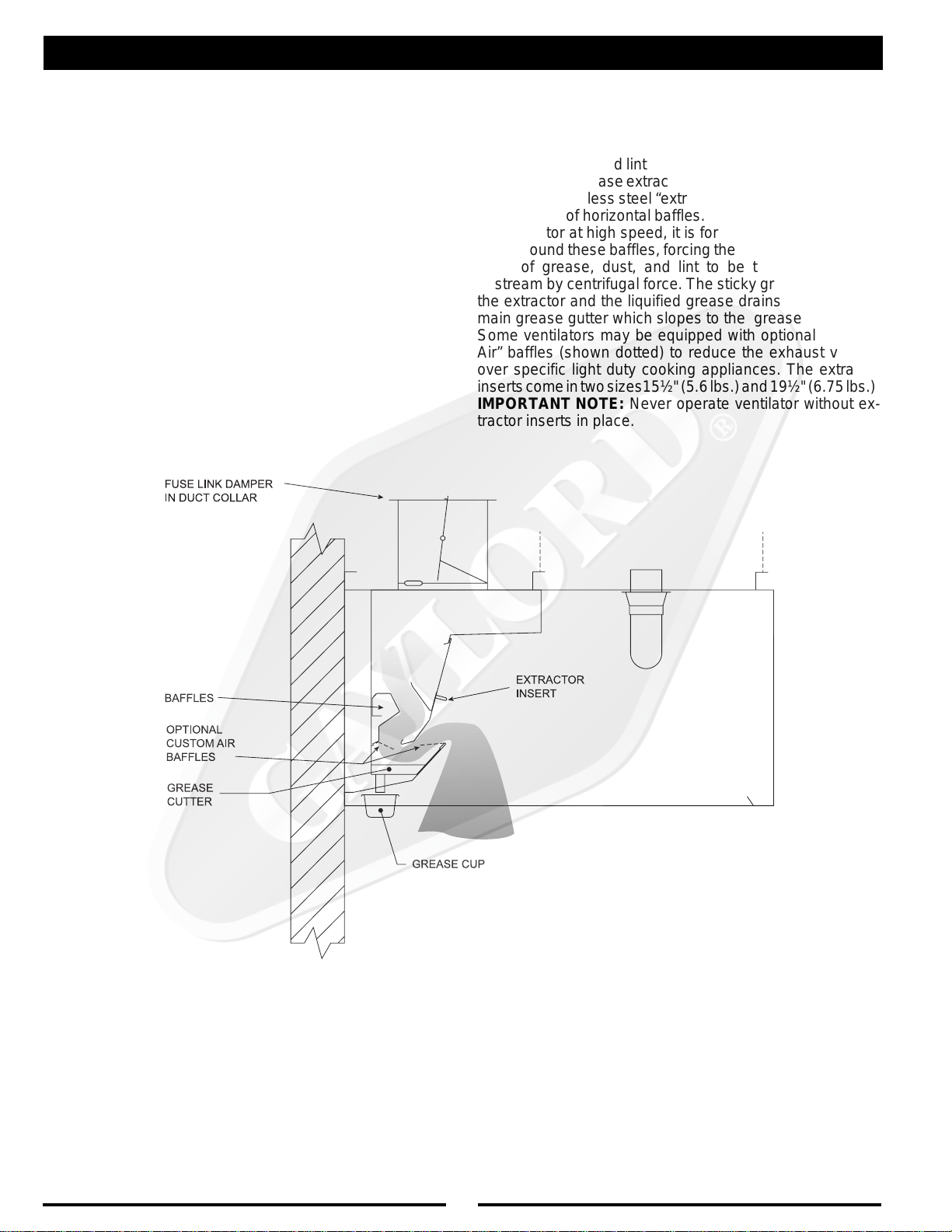

“GX2-FDD” SERIES PRINCIPLE OF OPERATION

The Gaylord “GX2-FDD” Series Non Water-Wash Ventilator

offers simplicity, economy and performance that no other

ventilator can offer. The unique “extractor insert” gives a

grease extraction efficiency far superior to that of a typical

baffle filter. The Gaylord “GX2-FDD” Series Ventilators are

UL Listed and meet all the requirements of NFPA #96 and the

International Mechanical Code.

EXHAUST FAN OPERATION

The exhaust fan is controlled by the Gaylord C-150 “Exhaust

Fan Start/Stop Switch”, an optional switch, or a standard wall

switch. The switch is usually located on a wall near the

ventilator. When the switch is flipped up to the on position,

the exhaust fan will come on.

GREASE EXTRACTION

The Gaylord “GX2-FDD” Series Ventilator extracts 90% of

the grease, dust, and lint particles from the airstream passing through it. Grease extraction is accomplished by unique,

removable stainless steel “extractor inserts” which incorporate a series of horizontal baffles. As the air moves through

the extractor at high speed, it is forced to make a series of

turns around these baffles, forcing the heavier-than-air particles of grease, dust, and lint to be thrown out of the

airstream by centrifugal force. The sticky grease collects in

the extractor and the liquified grease drains down into the

main grease gutter which slopes to the grease cup. Note:

Some ventilators may be equipped with optional “Custom

Air” baffles (shown dotted) to reduce the exhaust volume

over specific light duty cooking appliances. The extractor

inserts come in two sizes15½" (5.6 lbs.) and 19½" (6.75 lbs.).

IMPORTANT NOTE: Never operate ventilator without ex-

tractor inserts in place.

GREASE EXTRACTION

FIG. 1

3

“GX2-FDD” SERIES PRINCIPLE OF OPERATION

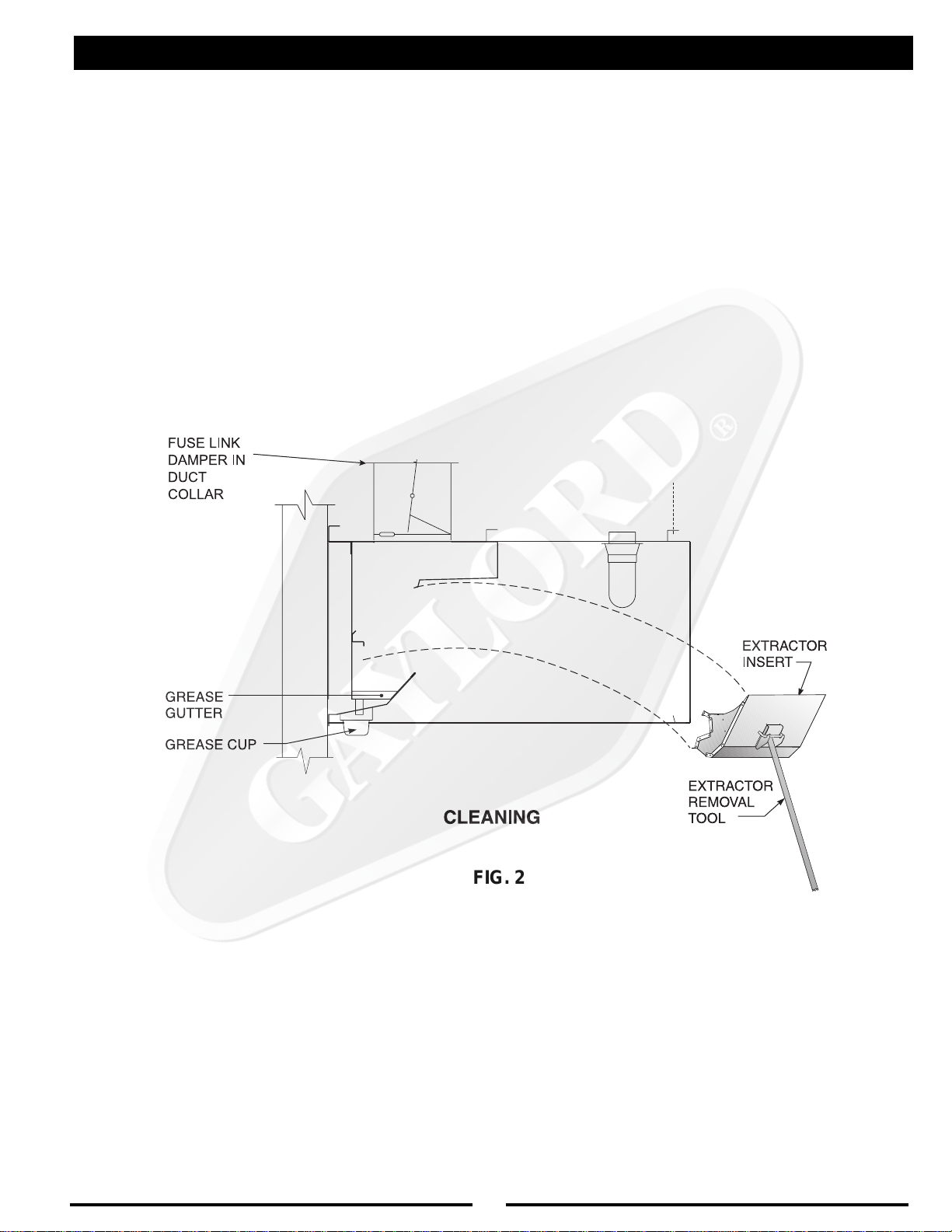

CLEANING

At the end of the cooking day the exhaust fan is turned off by

the “Exhaust Fan Start/ Stop Switch.” After the fan has been

turned off, the extractor inserts are removed and can be

washed either in a dishwasher or soaked and rinsed off. The

grease cup is also removed and emptied at this time. To ease

in the removal of the extractor inserts, an “Extractor Removal

Tool” is available which eliminates the need for kitchen

personnel to climb up on the cooking equipment, or up a

ladder.

FIG. 2

4

“GX2-FDD” SERIES PRINCIPLE OF OPERATION

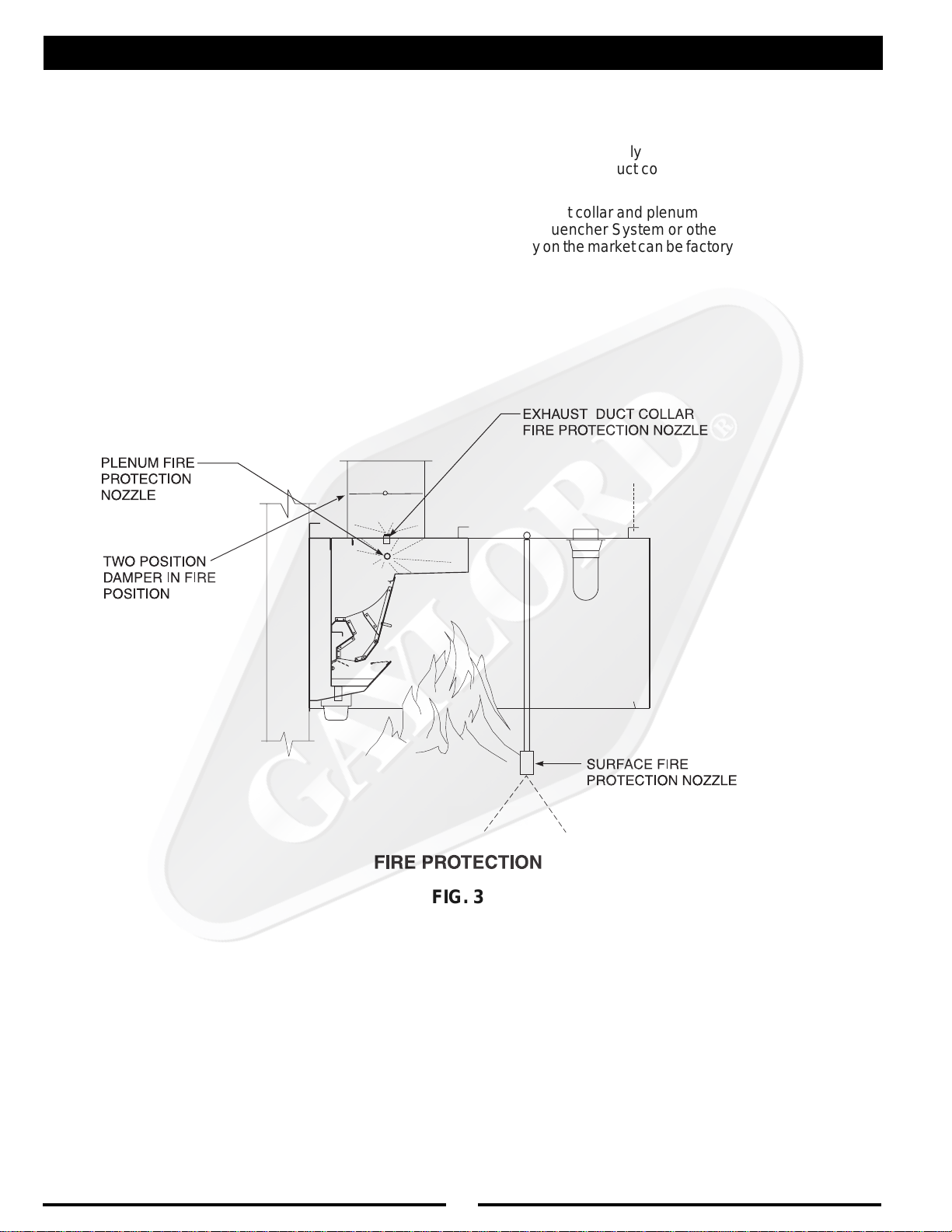

FIRE PROTECTION

NFPA #96 requires the use of surface, duct and plenum

protection on all hoods. It is these systems that are the first

line of defense against equipment fires.

The “GX2-FDD” Series ventilator incorporates a fuse link

damper at the duct collar. In the event of a fire, should the

fuse link at the duct collar reach 280°F, the fuse link melts

allowing the damper to close. (See Fig. 3) This prevents the

flames from entering the ductwork and spreading to other

parts of the building. The fire is contained in the kitchen area

where it can be properly fought. After the fire is extinguished

the fuse link in the duct collar needs to be replaced and the

damper reset.

Surface, duct collar and plenum fire protection utilizing The

Gaylord Quencher System or other fire protection systems

currently on the market can be factory installed as an option.

FIG. 3

5

STANDARD VENTILATOR MODELS

Model GX2-FDD-BDL

Application - Wall mounted canopy

style for all types of equipment.

Model GX2-FDD-BDL-DS

Application - For island style

cooking arrangements where one side

of the cooking line is light duty equipment

and the other side medium duty equipment.

ST ANDARD MAKE-UP AIR OPTIONS

The make-up air options shown below are available on all BDL Series Ventilators

except the MAI Series is not available on the GX2-FDD-BDL-CL.

Model GX2-FDD-BDL-CL

Application - For single island

arrangements

Model GX2-FDD-BDL-BB

Application - For island style

cooking arrangements over all duties

of equipment.

MODEL “MAW” SERIES

FRONT FACE DISCHARGE

This method of introducing make-up air into the

kitchen is flexible and has many advantages.

Make-up air is discharged through stainless steel

perforated panels as illustrated (MAW Series) or

optional registers (MAR Series). Typical supply

volume is 80% of the exhaust or more, depending on air balance desired. Supply air temperatures should range from 60 to 65°F (16 to 18°C),

but may be as low as 50°F (10°C) depending on

air volume, distribution, and internal heat load.

MODEL “MAI” SERIES

INTERNAL DISCHARGE

This method of introducing air into the hood is

typically referred to as the “short circuit” method.

This design has very limited applications and the

amount of supply air able to be introduced varies

considerably with the type of cooking equipment.

This air may be untempered air in most areas

depending upon climatic conditions and the type

of cooking equipment. The difference between

the quantity of air being introduced and the

amount of air being exhausted must be supplied

through a traditional make-up air system.

6

MAINTENANCE AND CLEANING INSTRUCTIONS

CLEANING

At the end of each cooking day, the exposed interior

surfaces of the ventilator should be wiped down and the

grease cup emptied. During the course of operation, grease

particles are gradually collecting inside the extractor inserts.

Daily , or at periodic intervals, depending on the type of cooking, the extractor inserts must be removed and cleaned.

To clean, proceed as follows:

1.Remove extractor inserts by hand or by using the

extractor removal tool. CAUTION: Care should be

taken when removing extractors, especially over fryers. It is recommended that the cooking equipment be

cooled down and the fryers be covered prior to removing

extractors. To remove, lift up slightly on e xtractor insert

and pull straight out.

2.Extractor inserts may be cleaned either by using a dish-

washer or by washing in a sink using hot water and a

degreasing detergent. Formula G-510 is highly

recommended for this application. For information

contact:

20/10 Products Inc.

P.O. Box 7609

Salem, OR 97303

Phone: 800-286-2010

Fax: 503-363-4296

E-mail: twentyten@juno.com

3.With the extractor inserts removed, wipe and clean the

back wall and the grease gutter with hot detergent wa-

ter. NOTE: If a steam or hot w ater pressure washer is

used for periodic cleaning of the interior, connect a hose

to the gutter drain and lead it to a floor sink or large

buck et to drain off the water.

4.T o replace the extractor inserts, care must be taken to

insure that point “A” rests in the rear clip as illustrated

in Fig. 4.

5.If the ventilator(s) has a fuse link operated supply duct

fire damper NFPA-96 requires inspection of the fuse

link every 6 months and replacement annually.

INSPECTION AND CLEANING REQUIREMENTS

The 2001 edition of NFP A-96 (Standard for V entilation Control and Fire Protection of Commercial Cooking Operations)

require that hoods, ducts and exhaust fans be inspected

by a properly trained, qualified and certified company or

person(s) in accordance with the following table.

Upon inspection, if found to be contaminated with deposits

from grease- laden vapors, the entire exhaust system shall

be cleaned by a properly trained, qualified, and certified

company or person(s) acceptable to the authority having

jurisdiction.

When a vent cleaning service is used, a certificate showing date of inspection or cleaning shall be maintained on

the premises. After cleaning is completed, the vent

cleaning contractor shall place or display within the kitchen

area a label indicating the date cleaned and the name of

the servicing company. It shall also indicate areas not

cleaned. Factory trained service agencies are certified by

Gaylord Industries, Inc. to perform these inspections. For

the name and phone number of your nearest agent call

800-547-9696 or www.ga ylordusa.com and go to service.

ELUDEHCSNOITCEPSNIMETSYSTSUAHXE

gnikooCfoemuloVroepyTycneuqerF

snoitarepognikoocleufdilosgnivressmetsySylhtnoM

snoitarepognikoocemulov-hgihgnivressmetsyS

gnikoockowrogniliorbrahc,gnikoocruoh-42sahcus

gnikoocemulov-etaredomgnivressmetsyS

snoitarepo

hcus,snoitarepognikoocemulov-wolgnivressmetsyS

ro,sessenisublanosaes,spmacyad,sehcruhcsa

sretnecroines

CAUTION: Care should be taken when removing extractors,

especially over fryers. It is recommended that the cooking

equipment be cooled down and the fryers be covered prior to

removing extractors.

ylretrauQ

yllaunnaimeS

yllaunnA

FIG. 4

7

.1tonsirotalitneV-ssoLekomS

TROUBLE-SHOOTING

MOTPMYSMELBORPELBISSOPNOITCAEVITCERROC

SSOLEKOMS

.ylreporpgnitsuahxe

.A

.gniwollofehtkcehcwolsiyticolev

yticolevriaegarevA-yticolevriawoL

.1

niebdluohstolsyrtneriaehthguorht

notrahCyticoleVriAehthtiwecnadrocca

.2

gnirusaemfodohtemreporproF.01egap

ehtfI.11egapotrefer,yticolevriaeht

.3

.naftsuahxeehtnotlebgnippilsronekorB

.leehwnaftsuahxeehtfonoitatorreporP

reviledtsumnaf(naftsuahxefoezisreporP

.)gnitaretalpeman

.4

.5

.B

.C

.D

.riapu-ekametauqedanI

nwostievahtsumrotalitneVdrolyaGehT

.1

hcus,tsuahxerehtoondnametsystsuahxe

.tiotnideitebdluohs,sdoohrehsawhsidsa

.sresuffidriapu-ekamdecalpylreporpmI

.1

.2

.3

.1

epytoneraIIfI.nideitsmetsysrotalitnev

.devomerebtsumyehtos

.rotalitnev

.aeranehctik

.ssolekomsnignitluser

.smetsystsuahxenehctik

.nepotfellenapnoitcepsnikrowtcuD

.noitisopreporpnironepotonrepmaD

erehttahtyfirevdnametsystcudtcepsnI

lliwrotalitnevehttadetceridriapu-ekaM

riaehtgnitpursidstfardssorcetaercylekil

srevuolehttsujdA.rotalitnevehtotniwolf

ehtmorfyawariapu-ekamehttceridot

hguorhtdereviledebdluohsriapu-ekaM

sretsigerrosresuffiddetarofrephtgnellluf

ehttuohguorhtdetubirtsidthgiehgniliecta

ehtraendetacolsretsigerriapu-ekaM

otdetsujdaebdluohssrevuoleht,rotalitnev

.rotalitnevehtmorfyawariaehttcerid

ehttariapu-ekamgnicrofrognitceriD

stfardssorcsetaercyllacipytrotalitnev

rofdeilppusebtsumriapu-ekaM

llahguorhtdetsuahxeriafotnemecalper

.E

NOITCARTXEESAERG

.1.noitcartxEesaerGrooP.ArotalitneVseireS"DDF-2XG"drolyaGehT

.2

.saeratnecajdamorf

.egrahcsidnaftsuahxE

.wolsiemulov

.1

.devomer

.2

.dednemmocer

.1debircsedsayticolevtolstelniehtkcehC

dnatsud,esaergehtfo%09otpustcartxe

gnissapmaertsriaehtmorfselcitraptnil

deniatniamdnadetareponehw,tihguorht

.snoitacificepsngisedhtiwecnadroccani

tonsirotalitnevehttahtsraeppatifI

tsuahxeehtyllacipyt,ylreporpgnitcartxe

ot%57tahtsi"bmuhtfoelur"larenegA

,hserfebdluohsriatnemecalperehtfo%08

thguorbria)deloocrodetaeh(,denoitidnoc

gniniamerehthtiw,aeranehctikehtotni

nehctikehtotniwolfotdewolla%52ot%02

ehtrevoneercsonebdluohserehT

ebdluohsti,dnuofsienofI.egrahcsid

ebtondluohsegrahcsidfonoitceridehT

drawnwodronsdniwgniliaverpehtotni

ylhgihsiegrahcsidlacitrevA.foorehtotno

siyticolevehtfI.21hguorht01segapno

roesaercni,egnarderiuqerehtnihtiwton

.deriuqersadeepsnafehtecuder

8

.1ehtnodenrutsihctiwsnafehtnehwfI

TROUBLE-SHOOTING

MOTPMYSMELBORPELBISSOPNOITCAEVITCERROC

NAFTSUAHXE

.noemoctonseodnaftsuahxe

.A

.B

.deppirt

Iepyt)citamotuA/nOsdnaH(AOHnaf

noitisopcitamotuaehtmorf

retratscitengamnorotcetorpdaolrevO

.1

.retnecdnammoc

.1

eht,desusihctiwsretratscitengam

devomneebevahyamhctiwsrotceles

.noitisopcitamotuaeht

ehtnonottub"teseR"ehthsuP

hsupehtdnaretratscitengam

ehtnonottub"naFtratS"eht

otrotcelesnrutdnahctiwskcehC

.C

.D

.deppirtrekaerbtiucricnaftsuahxE

.1

nahtiwdeppiuqesimetsysehtfI

.1

,naftsuahxeehtrofhctiwstcennocsid

.tuonwolbevahyamsesufroesufa

rekaerbtiucrictes-eR

dnasesuffoytiunitnockcehC

.yrassecenfiecalper

9

MEASURING INLET SLOT VELOCITY

MEASURING INLET SLOT VELOCITY

Smoke capture and grease extraction efficiency are de-

pendent upon the proper air velocity at the inlet slot of the

ventilator.The required average slot velocities are shown

on the “Air Velocity Chart” below. If the slot velocity is

below the required average, the exhaust fan must be

adjusted accordingly.

NOTE: The height of the inlet slot can vary depending

upon the design of the ventilator. It is, therefore, important

to first measure the inlet slot and compare it to the chart

below to determine the required average inlet slot velocity. The designed CFM per lineal foot is related to the

velocity as shown on the chart below. The total CFM for

the ventilator can be found on the ventilator nameplate.

(See Figure 6).

TRAHCYTICOLEVRIA

SEIRES"SD"TPECXESEIRES"2XG"LLAROF

motsuCtuohtiW

lanimoN

thgieH

fo

tolStelnI

dengiseD

repMFC

.tFlaeniL

selffaBriA

.niM mumitpO .xaM

telnIegarevA

)MPF(yticoleVtolS

dengiseD

repMFC

.tFlaeniL

motsuChtiW

selffaBriA

.niM mumitpO .xaM

telnIegarevA

)MPF(yticoleVtolS

"3

"4

052

072

582

003

004

0031

0631

5241

5641

0961

0541

051

0831

0051

5341

5751

0051

5261

5451

0781

0871

067

061

097

071

018

081

548

052

0401

088

008

078

038

009

558

539

088

0511

5901

*SROTALITNEVSEIRES"SD"ROF

rePMFCdengiseD

.tFlaeniL

latoT

tnorF

htoB

tolS

stolS

003

051

004

052

raeR

tolS

051

051

.niM mumitpO .xaM

067

5731

tolStnorF

088

008

0251

0541

telnIegarevAderiuqeR

)MPF(yticoleVtolS

tolSraeR

.niM mumitpO .xaM

595

526

595

526

556

556

Air velocity readings less than what is specified on the “Air

Velocity Chart” may allow smoke and grease to escape

the confines of the ventilator and/or reduce grease extraction efficiency. This can result in grease deposits which

lead to sanitation problems or fire hazards if left uncorrected. If air velocity readings are higher than those

specified, it will require more energy to operate the

exhaust fan and excessive noise levels will result. Higher

or lower velocities than the required average will normally

put the entire heating and ventilating system out of balance. When measuring the air velocity it is very important

to take an average reading across the inlet slot plane as

described on Page 11. Positioning the sensing head

incorrectly will give velocity readings that cannot be compared to the “Air Velocity Chart”.

10

FIG. 5A

FIG. 5B

MEASURING INLET SLOT VELOCITY

The standard instrument used for measuring the inlet velocities on a Gaylord

Ventilator is a Pacer, Model DA40 or DA4000 Digital Anemometer. This

instrument is the easiest, most accurate and the best suited for measuring

ventilator inlet slot velocities. To take accurate air velocity readings, follow

the instructions below.

Instructions

1. It is first necessary to determine if the ventilator includes Custom Air baffles

as shown in Fig. 5B. If shop drawings are available, and if equipped, the

custom baffles and their location will be noted on the front elevation. If not

available, to determine if Custom Air baffles are provided run your hand along

the bottom inlet slot and feel for the Custom Air baffle as illustrated in Fig. 5B.

2. If the ventilator includes Custom Air baffles, it will be necessary to take two

sets of readings - one for the section of ventilator that includes Custom Air baffles

and one where it does not.

3. Attached the sensing head guide bracket, Gaylord Part Number 18408, to

the sensing head.

4. Attach the cable from the sensing head to the meter and the handle

sections to the sensing head.

5. Place the sensing head guide bracket against the lower lip of the inlet slot

as illustrated.

6. Using the 16 second averaging feature on the meter, slide the sensing head along

the slot, back and forth, for a 3'-0" to 4'-0" distance, and record the velocity at the end

of the 16 second mark. Continue this process for the full length of the ventilator.

Important Note: If the ventilator includes custom air baffles as illustrated in Fig.

5B, always take separate readings on the section of the ventilator that includes

custom air from the section that does not have the baffles. Non custom air and

custom air readings must be recorded separately. Do not average them together.

Important Note: On the rear slot of a Model BDL-DS Series, do not use the

guide bracket. Refer to Figure 5C.

7. Record the velocity (fpm) on the start up inspection report form. A sample

report form, which can be photocopied, is provided on page 16.

8. The designed, or optimum velocity, is noted on the shop drawings and

the Air Velocity Chart on page 10. Two velocities will be noted if the ventilator

includes custom air baffles.

9. Compare the recorded air velocity to the designed air velocity shown on the

shop drawings or the Air Velocity Chart on page 10. The recorded velocity may

be slightly lower or higher providing that it is within the minimum and maximum

range as shown on the Air Velocity Chart .

If the air velocity is outside the minimum/maximum range, the performance of

the ventilator will be affected and therefore the exhaust fan must be adjusted.

FIG. 5C

CROSS SECTION OF TYPICAL

VENTILATOR INLET SLOTS

11

LISTED

370Y

EXHAUST HOOD WITH

EXHAUST DAMPER

THIS EXHAUST HOOD HAS BEEN TESTED

TO STANDARD UL 710 "EXHAUST HOODS

FOR COMMERCIAL COOKING

EQUIPMENT"

THIS EXHAUST HOOD IS LISTED UNDER UL

FILE NUMBER 11403

THIS EXHAUST HOOD MEETS ALL REQUIRE-

MENTS OF THE LATEST EDITION OF NFPA-

96 AND THE IMC (INTERNATIONAL MECHANI-

CAL CODE)

o

SUPPLIED WITH FACTORY INSTALLED UL LISTED

GRINNELL CORP. EA-1, 1/4" ORIFICE, 65 DEGREE

DEFLECTOR SPRINKLER(S) FOR THE PROTEC-

TION OF UNLIMITED LENGTH OF GREASE DUCT

HAVING A MAXIMUM DUCT PERIMETER OF 50

INCHES PER SPRINKLER. CONNECT TO NFPA 13

SPRINKLER SYSTEM WATER SUPPLY ONLY.

PATENT PENDING

MEASURING INLET SLOT VELOCITY

ENGINEERING DATA

1. MINIMUM TOTAL EXHAUST

VOLUME FOR THIS HOOD SECTION

2. MAXIMUM TOTAL SUPPLY

VOLUME FOR THIS HOOD SECTION

3. EXHAUST STATIC PRESSURE AT

DUCT COLLAR

4. SUPPLY STATIC PRESSURE AT

DUCT COLLAR

5. THIS HOOD SECTION SUITABLE FOR APPLIANCES WITH MAXIMUM COOKING

SURFACE TEMPERATURE OF:

˚F FOR LINEAL FT. OF HOOD

˚F FOR LINEAL FT. OF HOOD

6. REFER TO GAYLORD VENTILATOR TECHNICAL MANUAL FOR INLET

VELOCITY REQUIREMENTS AND METHOD OF CHECKING VELOCITY

7. ELECTRICAL RATING OF LIGHT FIXTURES: 120 VOLT, 60 HZ. OR 220 VOLT,

50 HZ. OVERALL RATING - 12 AMPS OR LESS

8. ON "GX2" and "PG" SERIES VENTILATORS EQUIPPED WITH FUSE LINK

OPERATED EXHAUST FIRE DAMPER USE ONLY 280˚ F , RATED 30 LBS. MIN. UL

LISTED FUSIBLE LINK FOR REPLACEMENT

9

. IF HOOD IS EQUIPPED WITH INTEGRAL MAKE-UP AIR WITH FUSE LINK OPER-

ATED FIRE DAMPER USE ONLY 165˚ F, RATED 30 LBS. MIN. UL LISTED FUSIBLE

LINKS FOR REPLACEMENT

10.DUCTWORK AND EXHAUST FAN

A. STATIC PRESSURE OF DUCT SYSTEM MUST BE ADDED TO VENTILATOR

STATIC FOR TOTAL SYSTEM STATIC

B. ALL DUCTWORK MUST BE WELDED LIQUIDTIGHT

HOOD MOUNTING REQUIREMENTS

MINIMUM DISTANCE FROM COOKING SURFACE TO FRONT

LOWER EDGE OF HOOD

MAXIMUM DISTANCE FROM COOKING SURFACE TO FRONT

LOWER EDGE OF HOOD

MINIMUM OVERHANG FROM FRONT OF HOOD CAVITY TO

FRONT OF COOKING SURFACE

MAXIMUM SETBACK FROM FRONT OF HOOD CAVITY TO

FRONT OF COOKING SURFACE

MINIMUM OVERHANG FROM SIDE OF HOOD TO EDGE OF

COOKING SURFACE

SERIAL NO:

MODEL NO:

C.F.M.

C.F.M.

W.G.

W.G.

TOTAL EXHAUST CFM HERE

TOTAL SUPPLY CFM HERE

FIGURE 6

The total required exhaust volume can be

found stamped on the UL nameplate located

on each hood section.

WORLD HEADQUARTERS

GAYLORD INDUSTRIES, INC.

10900 S.W. AVERY STREET

TUALATIN, OR 97062-8549 USA

PHONE: 1-503-691-2010

FAX: 1-503-692-6048

EMAIL: info@gaylordusa.com

UL-GX2/PG 1000

MAINTENANCE INSTRUCTIONS

1. REMOVE, INSPECT AND CLEAN FILTERS OR GAYLORD EXTRACTOR

CARTRIDGES AS REQUIRED

2. REMOVE AND EMPTY GREASE CUP AS REQUIRED

3. CAUTION - DO NOT OPERATE VENTILATOR WITHOUT FILTERS OR EXTRACTOR

CARTRIDGES IN PLACE

4. REPLACE FILTERS IN "PG" SERIES ONLY WITH UL CLASSIFIED GREASE FILTERS.

IN "PGX" AND "GX2" SERIES REPLACE WITH GAYLORD INDUSTRIES

EXTRACTOR CARTRIDGES.

5. IF THE VENTILATOR(S) HAS A FUSE LINK OPERATED EXHAUST OR SUPPLY

DUCT FIRE DAMPER THE NATIONAL FIRE PROTECTION ASSOCIATION'S

PAMPHLET NFPA-96 REQUIRES INSPECTION OF THE FUSE LINK EVERY 6

MONTHS AND REPLACED ANNUALLY. REFER TO THE GAYLORD VENTILATOR

TECHNICAL MANUAL FOR DETAILS.

12

WIRING DIAGRAM

13

PARTS LIST

DROLYAG

.ONTRAP

08381

58381

54781

64781

12301

32301

00481

91101raelC-ebolGthgiL

NOITPIRCSEDNOITARTSULLI

tresnIrotcartxE"2/1-51

tresnIrotcartxE"2/1-91

)srotcartxE.tF.niL/MFC052(

tresnIrotcartxE"2/1-51

tresnIrotcartxE"2/1-91

)srotcartxE.tF.niL/MFC004(

stcuDylppuSrofkniLesuFF°561

stcuDtsuahxErofkniLesuFF°082

looTlavomeRrotcartxE

)srotcartxE.tF.niL/MFC004+052roF(

11231

01231

11101

21101

57031"4x"6x"4/1-3puCesaerG

41381lortnoChctiwSpotS/tratS051-C

emarF&sneLthgiLtnecsednacnI

reniateR&sneLthgiLdesseceR"21x"21

emarF&sneLthgiLtnecseroulF

reniateR&sneLthgiLdesseceR.tF2

reniateR&sneLthgiLdesseceR.tF3

reniateR&sneLthgiLdesseceR.tF4

14

VENTILATOR START-UP INSPECTION REPORT

For Model “GX2-FDD” Series Ventilators

Job Name ______________________________________________________________________________ Gaylord Representative___________________________________________________________

Address ________________________________________________________________________________ Representative Company Name ____________________________________________________

______________________________________________________________________________________ File Number_____________________________________ Date__________________________

City/State Zip

MAKE-UP AIR

1. Kitchen make-up air supply is turned on______Yes______No

2. Type of make-up air

¨ Ceiling Registers ¨ Built into Hood

¨ Ceiling Linear Diffusers ¨ Other

3. If ceiling register or linear diffusers approximate distance from face of hood

_____________________________________________________________

FIRE DAMPER INFORMATION

¨ V entilator has electric fire damper (GX2 Series)

¨ V entilator has fuse link fire damper (GX2-FDD Series)

¨ V entilator does not ha v e a fire damper (GX2-ND Series)

AIR VOLUME READINGS

Push “Start Fan” and take velocities. Record as follows: Exhaust record in the “EX” row, Exhaust at Custom

Air baffles (if applicable) record in the “CA” row, and Make-up Air record in the “MA” ro w.

.ONMETI.ONLAIRESDOOH

XE

AC

AM

XE

AC

AM

XE

AC

AM

THGIROTTFELMORF)MPF(SEITICOLEVRIA

EGRAHCSIDRIAPU-EKAMROTOLSDOOH

EGAREVA

ELECTRIC DAMPER TEST (If equipped):

1. Remove one or more extractors so damper is visible. Push the “START FAN” button.

A. The damper should move to the fully opened position in approx. 1 minute 15 seconds. _____Yes ___No

B. The exhaust fan came on ___Yes ___No

2. Push “STOP FAN” button.

A. The damper should move to the fully closed position in approx. 15 seconds_____Yes_____No

B. The exhaust fan shut off ___Yes ___No

3. If the “GX2” Series ventilator(s) is interconnected with any “CG3” water wash series, perform the following

test:

A. With the exhaust fan on, open the electrical compartment on the control cabinet and push the “FIRE

TEST” button. The following should occur:

1. Exhaust fan shut off ___Yes ___No

2. Damper fully closed ___Yes ___No

B. At conclusion of the test push the “CANCEL” button. The following should occur:

1. The damper stayed closed ___Yes ___No

2. Fan stay ed off ___Yes ___No

C. Push the “START FAN” button. The following should occur:

1. Damper moves to the fully open position ___Yes ___No

2. Exhaust fan comes on ___Yes ___No

INST ALLA TIONINCLUDES THE FOLLOWING:

¨ Gaylord Rooftop Unit (GRT)

¨ Gaylord Clearair Pollution Control Unit (RSPC) ¨ The Gaylord “Quencher” Fire Protection System

¨ Gaylord Distributor (UDS) ¨ Wet Chemical Fire Protection System

Personnel provided with ventilator technical man ual________Yes________No

Inspection Witnessed By (Print Name) ______________________________________________________

Signature ________________________________________________ Date _______________________

Comments____________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

__________________________________________________________________________________________________

__________________________________________________________________________________________________

Distribution: WHITE-Gaylord Industries, Inc. YELLOW-Customer PINK-Dealer GOLDENROD-Sales Rep Litho U.S.A.

GAYLORD INDUSTRIES P.O. BOX 1149 •10900 S. W . A very Street • Tualatin, OR 97062-1149

PHONE:1-503-691-2010 • FAX: 1-503-692-6048 •

email:info@gaylordusa.com

Form No. GX2SUR200

LIMITED WARRANTY

THE GAYLORD NON WATER-WASH VENTILATOR

LIMITED WARRANTY

August 2000

The Gaylord Ventilator and component parts furnished with The Gaylord Ventilator by the

Licensed Gaylord Manufacturer are warrantied by the Licensed Gaylord Manufacturer

producing the ventilator to be free from defects of material and workmanship under normal

use when installed, operated and serviced in accordance with factory recommendations.

The Licensed Gaylord Manufacturer's obligation under this warranty and any warranties

implied by law shall be limited to repairing or replacing at its option any part of said

equipment when the Licensed Gaylord Manufacturer's examination shall disclose to its

satisfaction to be thus defective, for a period of one (1) year from the date of beneficial use,

or eighteen months from date of shipment, whichever occurs first, provided proper and

acceptable evidence of such is recorded at the f actory . THE LICENSED GA YLORD MANU-

F ACTURER SHALL NOT BE RESPONSIBLE FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGES RESULTING FROM A BREACH OF THIS WARRANTY.

In the United States the labor required to make repairs and replacements under this war-

ranty shall be furnished by Gaylord Industries Inc. or the Licensed Gaylord Manufacturer or

its authorized representative. Such labor shall only be provided Mondays through Fridays

between the hours of 8 a.m. and 4 p.m. Requests for repairs or replacement parts should

be made to GA YLORD INDUSTRIES, P.O. Bo x 1149, Tualatin, Oregon 97062-1149.

Outside the United States, all replacement parts furnished under this warranty shall be

F . O.B. Gaylord Industries, Tualatin, Oregon U.S.A. The owner shall pa y the necessary freight

delivery charges, and the necessary labor for removal and installation of parts, and any

tariffs, duties or taxes.

This warranty does not cover routine maintenance or malfunctions or improper operation

caused by fluctuating electrical power or power surges, and improper exhaust fan operation.

This is the sole warranty with respect to the aforesaid items. NEITHER THE GAYLORD

LICENSEE NOR ANY OTHER PARTY MAKES ANY OTHER WARRANTY OF ANY KIND

WHATSOEVER, EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED

THE AFORESAID OBLIGA TIONS ARE HEREBY DISCLAIMED AND EXCLUDED FR OM

THIS AGREEMENT.

WORLDWIDE SALES, MANUFACTURING AND SERVICE

FOR THE NAME AND LOCATION OF THE NEAREST

CERTIFIED SERVICE AGENCY, VISIT OUR WEB SITE:

WWW.GAYLORDUSA.COM

OR CONTACT US AT:

GAYLORD INDUSTRIES

P.O. BOX 1149 • 10900 S.W. AVERY STREET

TUALATIN, OREGON 97062-1149 U.S.A

Phone: 503-691-2010

1-800-547-9696

Fax: 503-692-6048

email: info@gaylordusa.com

LOCAL SERVICE AGENCY

FORM NO. TM-GX2-FDD-501/30649 © COPYRIGHT 2003, GAYLORD INDUSTRIES LITHO IN U.S.A.

Loading...

Loading...